Research into Plastic Deformation of Double Reduced Sheets

Abstract

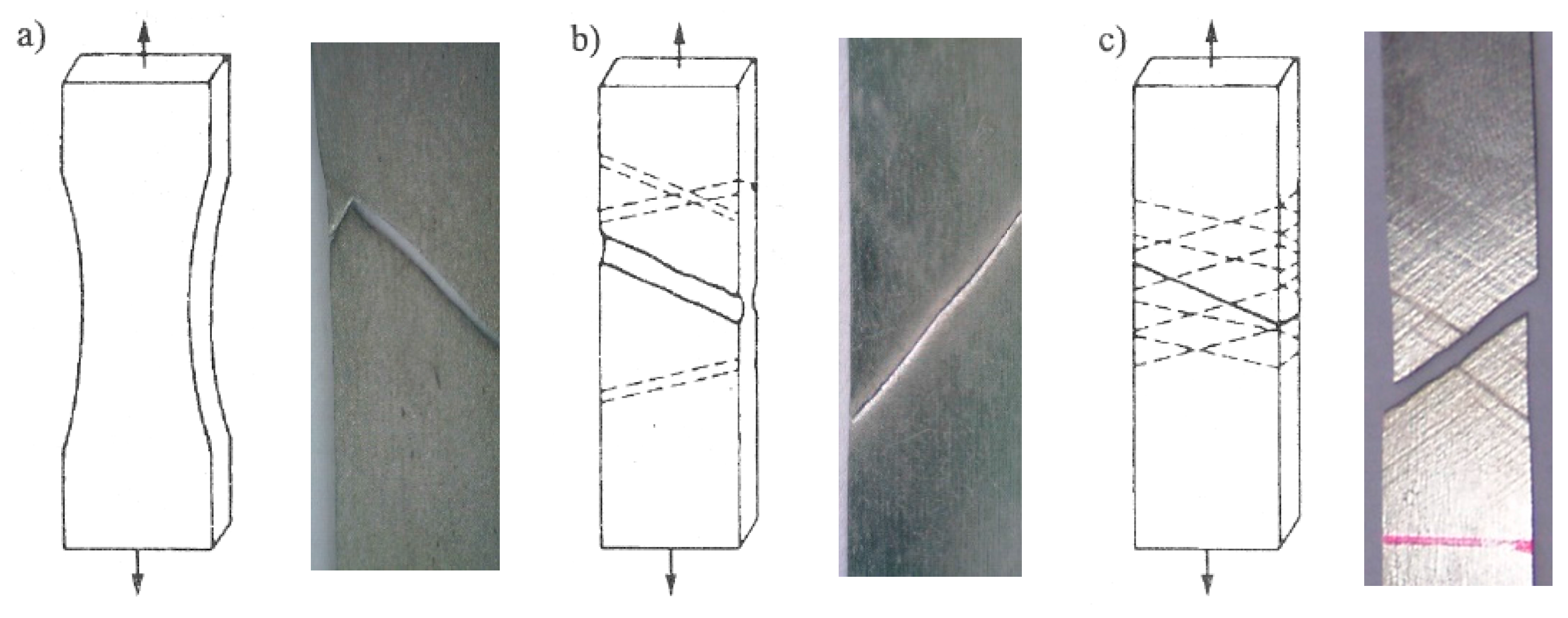

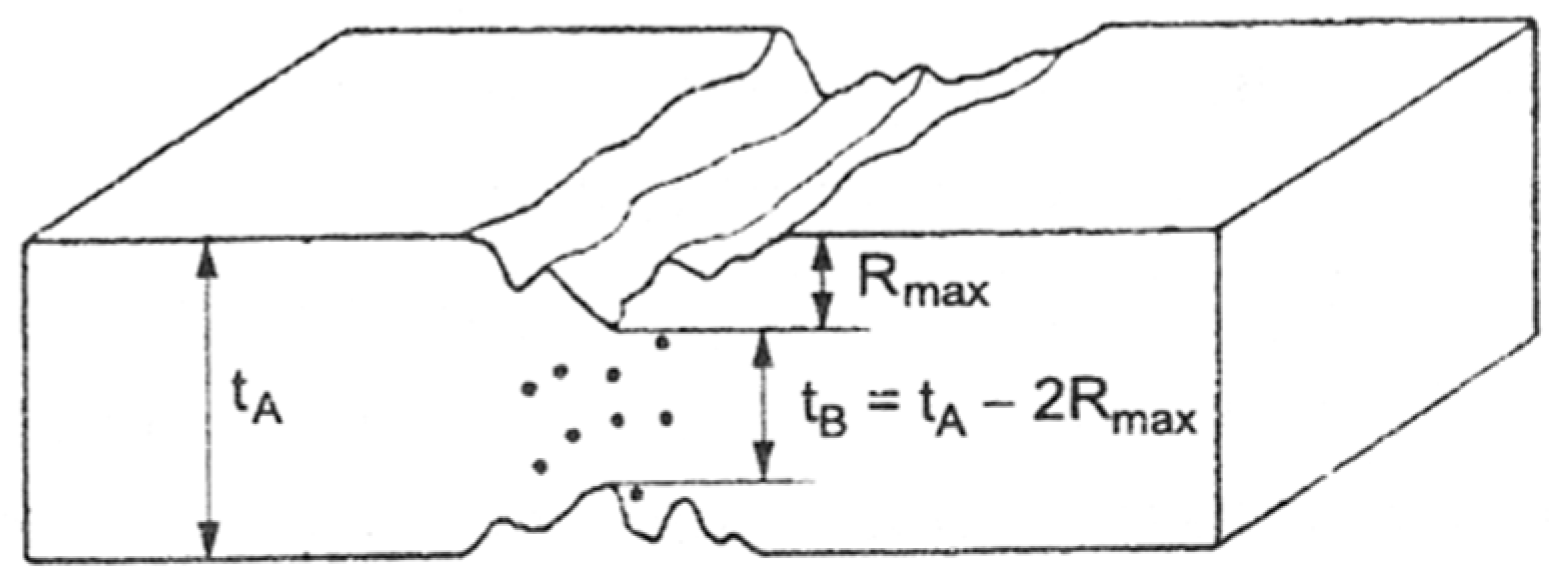

:1. Introduction

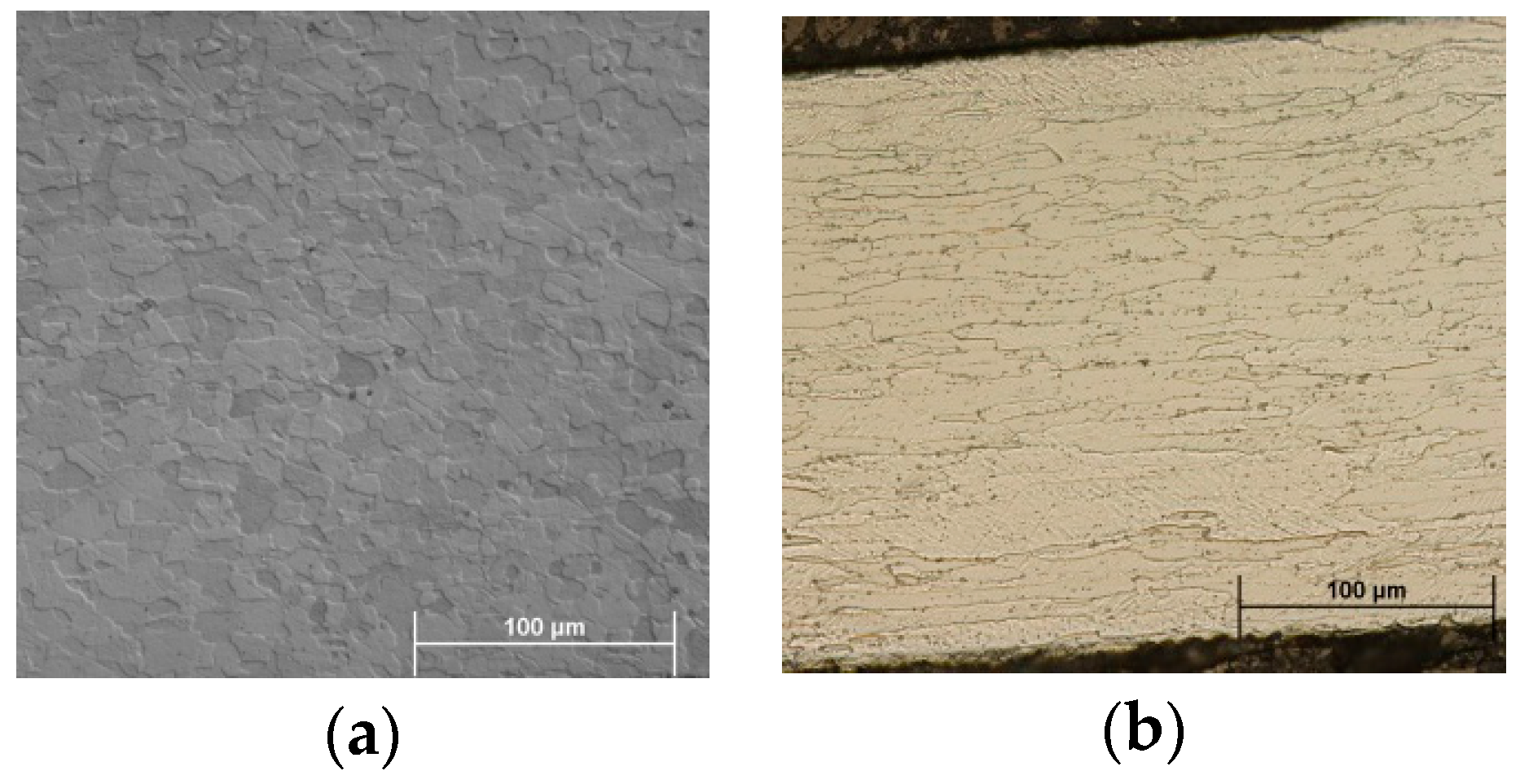

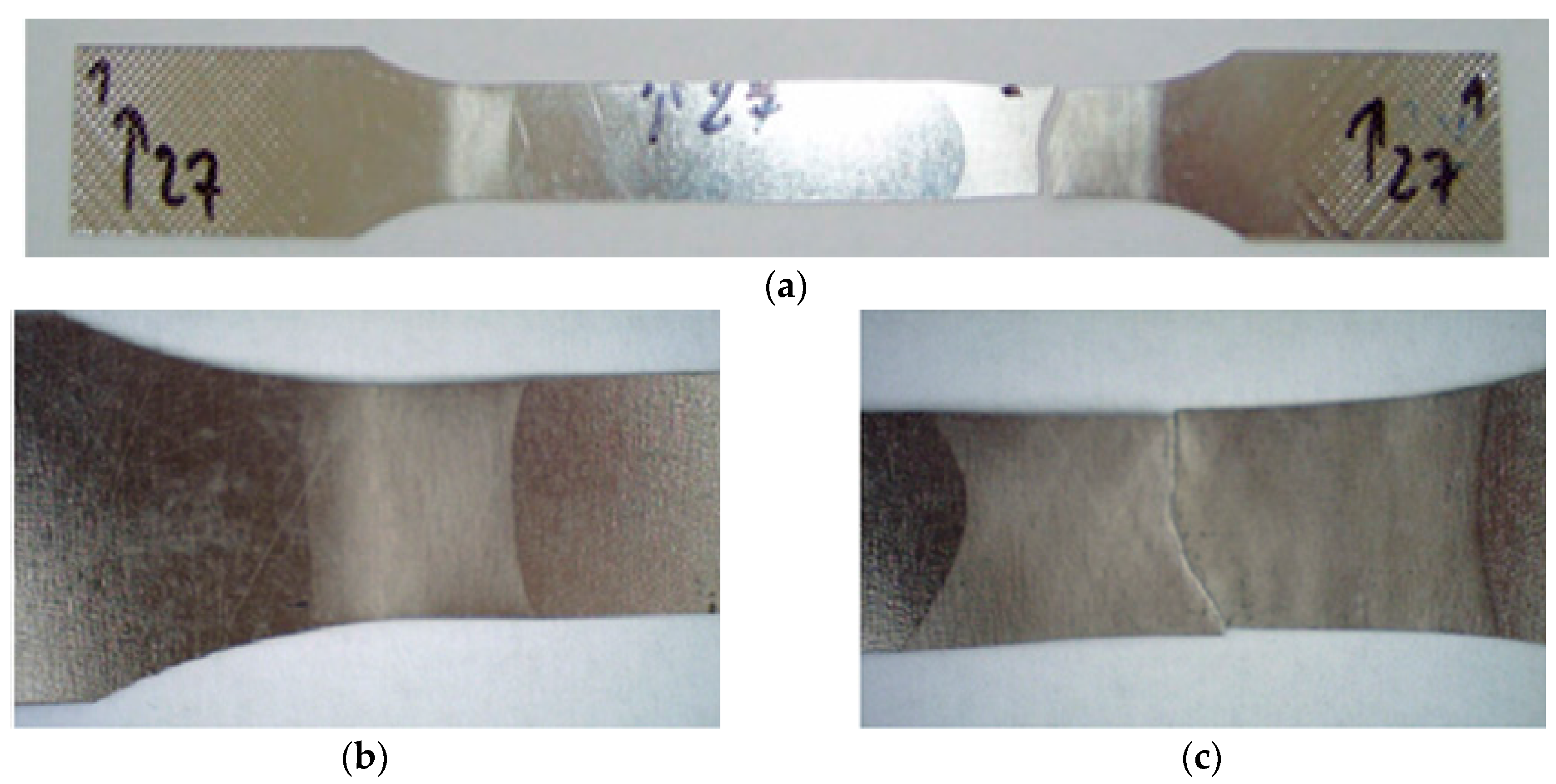

2. Materials and Methods for Experimental Research

3. Experimental Results and Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hill, R. On discontinuous plastic states with special reference to localized necking in thin sheets. J. Mech. Phys. 1952, 1, 19–30. [Google Scholar] [CrossRef]

- Makarov, P.V.; Schmauder, S.; Cherapanov, I.O.; Smolin, Y.I.; Romanova, A.V.; Balokhonov, R.R.; Saraev, D.Y.; Soppa, E.; Kizler, P.; Fischer, G.; et al. Simulation of elastic-plastic deformation and fracture of materials at micro, meso- and macrolevels. Theor. Appl. Fract. Mech. 2001, 37, 183–244. [Google Scholar] [CrossRef]

- Stachowicz, F.; Spišák, E. Sposoby Oceny Zdolnosci Blach Cienkich do Ksztaltowania Plastycznego na Zimno; Oficyna Wydawnicza Politechniki Rzeszowskiej: Rzeszów, Poland, 1998. [Google Scholar]

- Marciniak, Z. Mechanics of Sheet Metal Forming; Plenum Press: New York, NY, USA, 1978. [Google Scholar]

- Machová, A. Dynamic microcrack initiation in α-iron. Mater. Sci. Eng. 1996, 206, 279–289. [Google Scholar] [CrossRef]

- Slota, J.; Spišák, E.; Jurčišin, M. Local strain hardening and non-uniformity of plastic strain of tinplate. Key Eng. Mater. 2014, 606, 23–26. [Google Scholar] [CrossRef]

- Spišák, E.; Slota, J.; Majerníková, J. The analysis of plastic strain of single and double reduced tinplates. Chem. Lett. 2011, 105, 485–487. [Google Scholar]

- Gburík, R.; Černík, M.; Legatt, R.; Vranec, P. Crystallographic texture of light tinplate coatings made in various electrolytes. Mat. Sci. Eng. IOP Conf. Ser. 2015, 82, 012062. [Google Scholar] [CrossRef]

- Spišák, E.; Majerníková, J. The loss of plastic properties stability of thin tinplates and its influence on change of corrosive resistance. Appl. Mech. Mater. 2014, 693, 340–345. [Google Scholar] [CrossRef]

- Spišák, E.; Majerníková, J. The loss of plasticity stability. Appl. Mech. Mater. 2014, 693, 346–351. [Google Scholar] [CrossRef]

- Kvačkaj, T.; Bidulská, J. From micro to nano scale structure by plastic deformations. Mater. Sci. Forum 2014, 783–786, 842–847. [Google Scholar] [CrossRef]

- Spišák, E.; Džupon, M.; Majerníková, J.; Spišáková Duľová, E. Failure of coatings of tinplates. Acta Metall. Slov. 2015, 21, 213–219. [Google Scholar] [CrossRef]

- Swift, H.W. Plastic instability under plane stress. J. Mech. Phys. 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, Y. A study of inhomogeneous plastic deformation of 1045 steel. J. Eng. Mater. Technol. 2004, 126, 164–172. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, Y.A. Lüders bands propagation of 1045 steel under multiaxial stress state. Int. J. Plast. 2005, 21, 651–670. [Google Scholar] [CrossRef]

- Yu, H.; Burgess, I.W.; Davison, J.B.; Plank, R.J. Numerical simulation of bolted steel connections in fire using explicit dynamic analysis. J. Constr. Steel Res. 2008, 64, 515–525. [Google Scholar] [CrossRef]

- Nadai, A. Theory of Flow and Fracture of Solids, 2nd ed.; McGraw-Hill: New York, NY, USA, 1950. [Google Scholar]

- Mihaliková, M.; Ambriško, L.; Pešek, L. Videoextensometric measuring of deformation processes in automotive steel sheets at two strain rate levels. Kov. Mater. 2011, 49, 137–141. [Google Scholar] [CrossRef]

- Sarfarazi, M.; Ghosh, S.K. Microfracture in polycrystalline solids. Eng. Fract. Mech. 1987, 27, 257–267. [Google Scholar] [CrossRef]

- Ziegenbein, A.; Plessing, J.; Neuhaeuser, H. Mesoscopic studies on Lüders band deformation in concentrated Cu-based alloy single crystals. Phys. Mesomech. 1998, 1, 5–18. [Google Scholar]

- Panin, V.E. Physical Mesomechanics of Heterogeneous Media and Computer Aided Design of Materials; Cambridge International Science Publishing: Cambridge, UK, 1998. [Google Scholar]

- European Standard EN. Cold Reduced Tin Mill Products-Electrolytic Tinplate and Electrolytic Chromium/Cr Oxide Coated Steel; European Standard EN 10202:2001; The European Standard Publications: Brussels, Belgium, 2001. [Google Scholar]

- Beygelzimer, Y.; Estrinand, Y.; Kulagin, R. Synthesis of hybrid materials by severe plastic deformation: A new paradigm of SPD processing. Adv. Eng. Mater. 2015, 17, 1853–1861. [Google Scholar] [CrossRef]

- Kawasaki, M.; Ahn, B.; Kumar, P.; Jang, J.; Langdon, T.G. Nano- and micro-mechanical properties of ultrafine-grained materials processed by severe plastic deformation techniques. Adv. Eng. Mater. 2017, 19, 1600578. [Google Scholar] [CrossRef]

- Pineau, A.; Benzerga, A.A.; Pardoen, T. Failure of metals I: Brittle and ductile fracture. Acta Mater. 2016, 107, 424–483. [Google Scholar] [CrossRef]

- Hosford, W.F.; Caddell, R.M. Metal Forming: Mechanics and Metallurgy; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

| Fe | C | Si | Mn | P | S | Cu | Al |

| 99.52 | 0.075 | 0.022 | 0.130 | 0.014 | <0.002 | 0.030 | 0.065 |

| Cr | Mo | Ni | V | Ti | Nb | Co | W |

| 0.009 | 0.013 | 0.005 | 0.009 | <0.002 | 0.018 | 0.036 | 0.048 |

| Sample Number | Rp0.2 (MPa) | Rm (MPa) | A50 (%) |

|---|---|---|---|

| 27 (0°)1 | 464 | 458 | 20.38 |

| 27 (0°)2 | 465 | 452 | 22.25 |

| 27 (0°)3 | 423 | 419 | 22.21 |

| 27 (0°) | 450.7 | 443 | 21.61 |

| 27 (90°)1 | 492 | 489 | 3.28 |

| 27 (90°)2 | 518 | 511 | 0.10 |

| 27 (90°)3 | 502 | 499 | 2.27 |

| 27 (90°) | 504 | 499.7 | 1.89 |

| Sample Number | Rp0.2 (MPa) | Rm (MPa) | A50 (%) |

|---|---|---|---|

| 18 (0°)1 | 560 | 576 | 2.09 |

| 18 (0°)2 | 545 | 556 | 2.20 |

| 18 (0°)3 | 578 | 598 | 1.95 |

| 18 (0°) | 561 | 576.7 | 2.08 |

| 18 (90°)1 | 683 | 712 | 1.42 |

| 18 (90°)2 | 637 | 672 | 0.94 |

| 18 (90°)3 | 658 | 691 | 1.22 |

| 18 (90°) | 659.3 | 691.7 | 1.19 |

| Sample Number | Rp0.2 (MPa) | Rm (MPa) | Elongation (%) | hdome (mm) |

|---|---|---|---|---|

| 271 | 368 | 509 | 12.72 | 17.8 |

| 272 | 375 | 509 | 13.28 | 18,2 |

| 273 | 367 | 504 | 11.77 | 17.1 |

| 27 | 370 | 507.3 | 12.59 | 17.7 |

| Sample Number | Rp0.2 (MPa) | Rm (MPa) | Elongation (%) | hdome (mm) |

|---|---|---|---|---|

| 181 | 565 | 590 | 3.95 | 9.8 |

| 182 | 538 | 575 | 5.42 | 11.5 |

| 183 | 551 | 582 | 4.79 | 10.8 |

| 18 | 551.3 | 582.3 | 4.72 | 10.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spišák, E.; Majerníková, J.; Duľová Spišáková, E.; Kaščák, Ľ. Research into Plastic Deformation of Double Reduced Sheets. Metals 2018, 8, 99. https://doi.org/10.3390/met8020099

Spišák E, Majerníková J, Duľová Spišáková E, Kaščák Ľ. Research into Plastic Deformation of Double Reduced Sheets. Metals. 2018; 8(2):99. https://doi.org/10.3390/met8020099

Chicago/Turabian StyleSpišák, Emil, Janka Majerníková, Emília Duľová Spišáková, and Ľuboš Kaščák. 2018. "Research into Plastic Deformation of Double Reduced Sheets" Metals 8, no. 2: 99. https://doi.org/10.3390/met8020099