Electroactive Shape Memory Property of a Cu-decorated CNT Dispersed PLA/ESO Nanocomposite

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Instrumentations

2.1.1. Decoration of CNTs with Cu

2.1.2. Preparation of Cu-CNT Dispersed PLA/ESO Nanocomposite

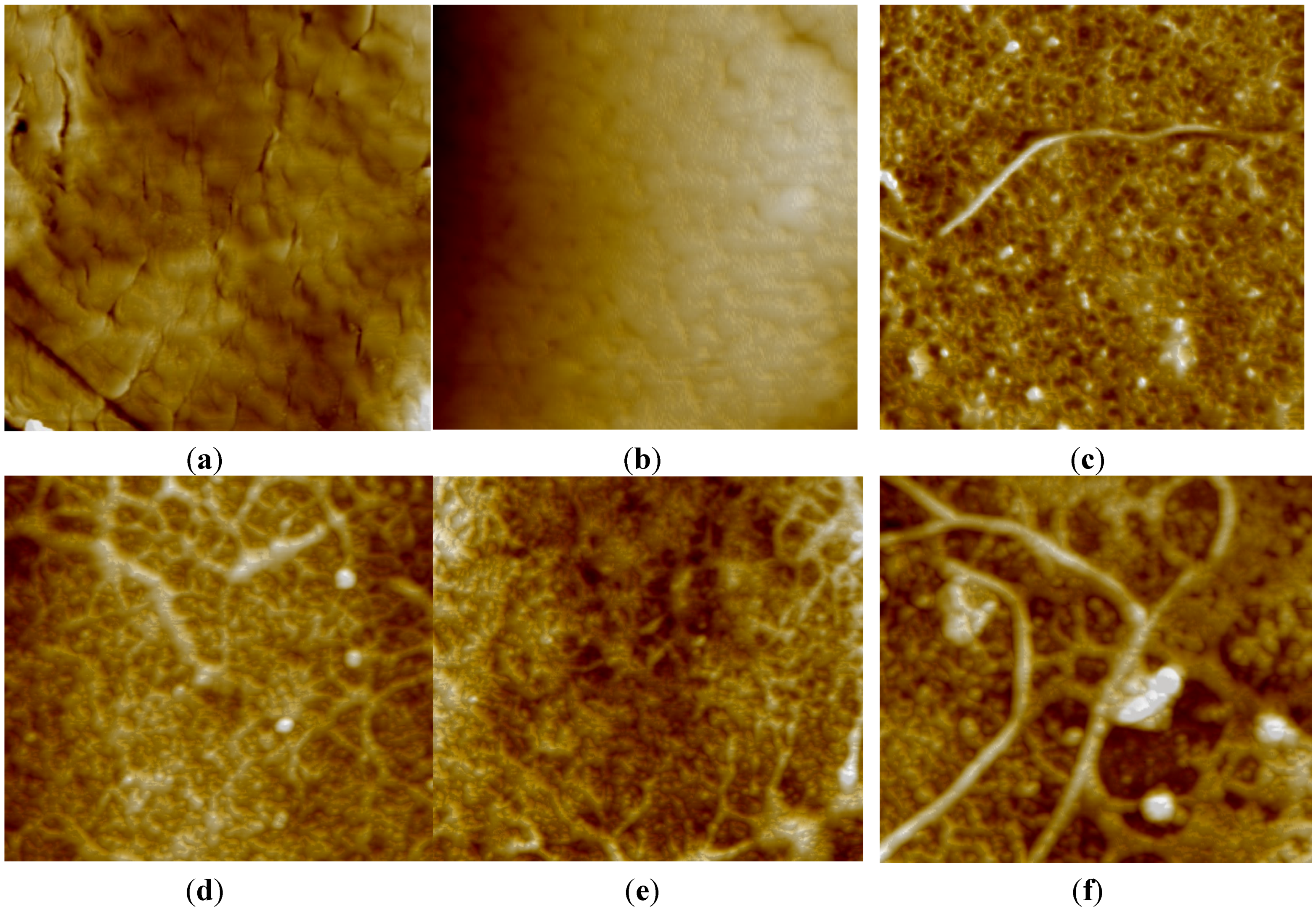

2.1.3. Atomic Force Microscopy

2.1.4. Mechanical Analysis

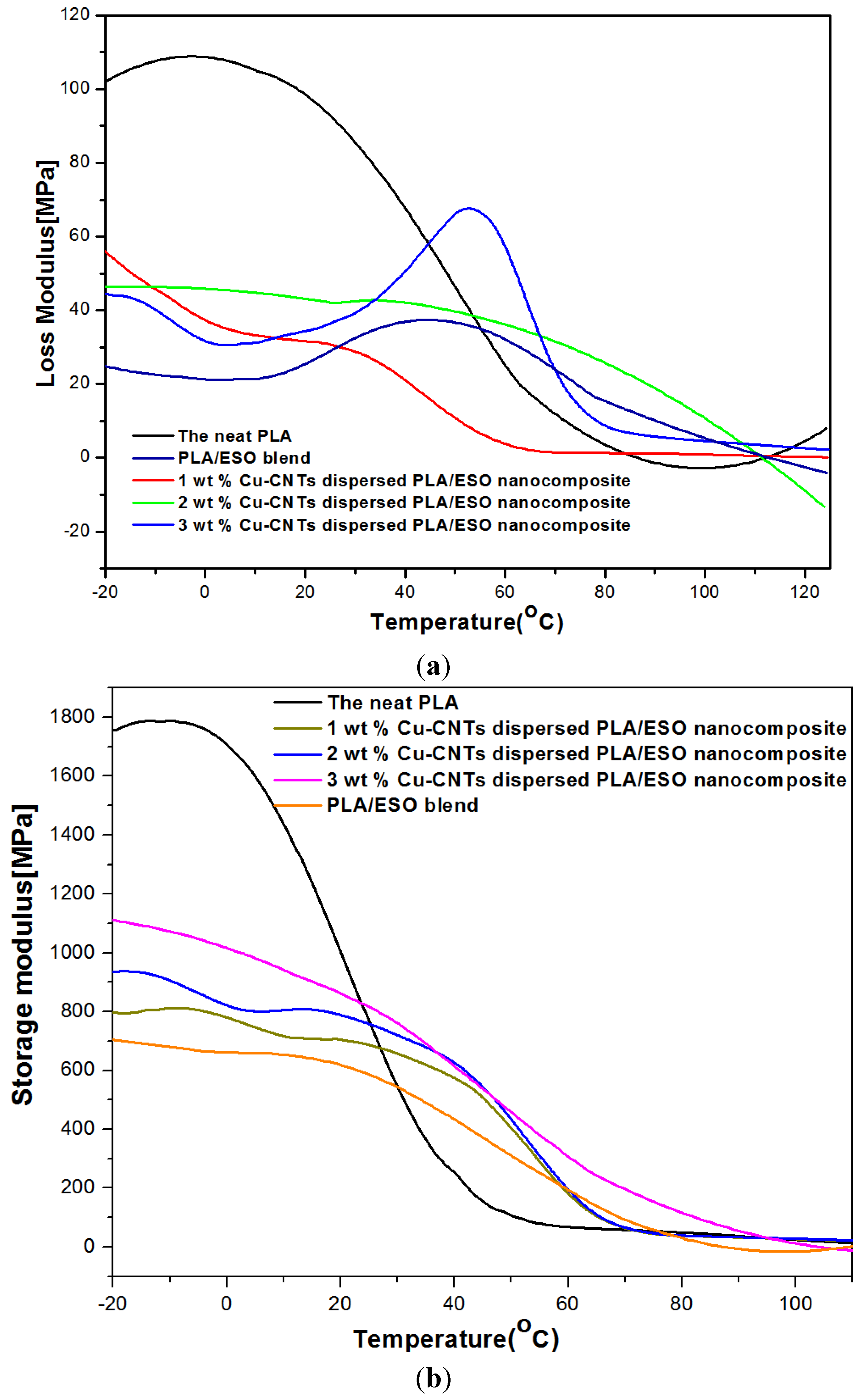

2.1.5. Dynamic Mechanical Analysis

2.1.6. Electro active Shape Memory Study

3. Results and Discussion

| Samples | Stress at break (MPa) | Elongation at break % | Electrical resistivity (Ohm.cm) | Shape recovery time (s) | Shape recovery (%) |

|---|---|---|---|---|---|

| Neat PLA | 0.63 ± 0.1 | 7 | 1.67 × 109 | No response | No response |

| PLA/ESO blend | 0.47 ± 0.1 | 135 | 7.5 × 109 | No response | No response |

| 1 wt % Cu-CNT dispersed nanocomposite | 0.90 ± 0.1 | 45 | 1.1 × 104 | 75 | 47 |

| 2 wt % Cu-CNT dispersed nanocomposite | 0.97 ± 0.1 | 39.5 | 1.9 × 102 | 35 | 98 |

| 3 wt % Cu-CNT dispersed nanocomposite | 0.85 ± 0.1 | 11.3 | 3.5 × 103 | 63 | 53 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Leng, J.S.; Lan, X.; liu, Y.J.; Du, S.Y. Shape-memory polymers and their composites: Stimulus methods and applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Leng, J.S.; Lu, H.B.; liu, Y.J.; Huang, W.M.; Du, S.Y. Shape-memory polymers: A class of novel smart material. MRS Bull. 2009, 34, 848–855. [Google Scholar] [CrossRef]

- Behl, M.; Razzaq, M.Y.; Lendlein, A. Multifunctional shape-memory polymers. Adv. Mater. 2010, 22, 3388–3410. [Google Scholar] [CrossRef] [PubMed]

- Wischke, C.; Lendlein, A. Shape-memory polymers as drug carriers—A multifunctional system. Pharm. Res. 2010, 27, 527–529. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Zhao, H.; Zhang, S.; Jiao, L.; Lu, J.; Wang, H.; Guo, J. Polyester-hydrophilic PEO networks as multifunctional biomaterials. Macromol. Symp. 2011, 306, 18–26. [Google Scholar] [CrossRef]

- Razzaq, M.Y.; Behl, M.; Kratz, K.; Lendlein, A. Multifunctional hybrid nanocomposites with magnetically controlled reversible shape-memory effect. Adv. Mater. 2013, 25, 5730–5733. [Google Scholar] [CrossRef] [PubMed]

- Ecker, M.; Pretsch, T. Multifunctional poly (ester urethane) laminates with encoded information. RSC Adv. 2014, 4, 286–292. [Google Scholar] [CrossRef]

- Ecker, M.; Pretsch, T. Novel design approaches for multifunctional information carriers. RSC Adv. 2014, 4, 46680–46688. [Google Scholar] [CrossRef]

- Landlein, A.; Langer, R. Biodegradable, elastic shape-memory polymers for potential biomedical applications. Science 2002, 296, 1673–1676. [Google Scholar] [CrossRef] [PubMed]

- Vaia, R. Nanocomposites-remote-controlled actuators. Nat. Mater. 2005, 4, 429–430. [Google Scholar]

- Meng, Q.H.; Hu, J.L. A review of shape memory polymer composites and blends. Composites Part A Appl. Sci. Manufact. 2009, 40, 1661–1672. [Google Scholar] [CrossRef]

- Mather, P.T.; Luo, X.F.; Rousseau, I.A. Shape memory polymer research. Ann. Rev. Mater. Res. 2009, 39, 445–471. [Google Scholar] [CrossRef]

- Sofla, A.Y.N.; Meguid, S.A.; Tan, K.T.; Yeo, W.K. Shape morphing of aircraft wing: Status and Challenges. Mater. Des. 2010, 31, 1284–1292. [Google Scholar] [CrossRef]

- Li, Y.C.; Li, J.C.; Li, W.H.; Du, H.P. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 2014, 23, 023001. [Google Scholar] [CrossRef]

- Sun, L.; Huang, W.M.; Wang, C.C.; Ding, Z.; Zhao, Y.; Tang, C.; Gao, X.Y. Polymeric shape memory materials and actuators. Liq. Cryst. 2014, 41, 277–289. [Google Scholar] [CrossRef]

- Alexandre, K.; James, A.E.; Stoyan, K.S. Electro-mechanical actuator with muscle memory. J. Mater. Chem. C 2014, 2, 8029–8034. [Google Scholar]

- Bothe, M.; Pretsch, T. Bidirectional actuation of a thermoplastic polyurethane Elastomer. J. Mater. Chem. C 2013, 1, 14491–14497. [Google Scholar] [CrossRef]

- Bothe, M.; Pretsch, T. Two-way shape changes of a shape-memory poly (ester urethane). Macromol. Chem. Phys. 2012, 213, 2378–2385. [Google Scholar]

- Serrano, M.C.; Ameer, G.A. Recent insights into the biomedical applications of shape-memory polymers. Macromol. Biosci. 2012, 12, 1156–1171. [Google Scholar] [CrossRef] [PubMed]

- Small, W.; Singhal, P.; Wilson, T.S.; Maitland, D.J. Biomedical applications of thermally activated shape memory polymers. J. Mater. Chem. 2010, 20, 3356–3366. [Google Scholar] [CrossRef] [PubMed]

- Ratna, D.; Karger, K.J. Recent advances in shape memory polymers and composites: A review. J. Mater. Sci. 2008, 43, 254–269. [Google Scholar] [CrossRef]

- Rousseau, I.A. Challenges of shape memory polymers: A review of the progress toward overcoming SMP’s limitations. Polym. Eng. Sci. 2008, 48, 2075–2089. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Review of progress in shape-memory polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- Alam, J.; Alam, M.; Arockiasamy, D.L.; Shanmugharaj, A.M.; Raja, M. Development of plasticized PLA/NH2-CNTs nanocomposite: Potential of NH2-CNTs to improve electroactive shape memory properties. Polym. Compos. 2014, 35, 2129–2136. [Google Scholar] [CrossRef]

- Luo, X.F.; Mather, P.T. Conductive shape memory nanocomposites for high speed electrical actuation. Soft Mat. 2010, 6, 2146–2149. [Google Scholar] [CrossRef]

- Luo, H.S.; Li, Z.W.; Yi, G.B.; Zu, X.H.; Wang, H.; Wang, Y.J.; Huang, H.L.; Hu, J.W.; Liang, Z.F.; Zhong, B.B. Electro-responsive silver nanowire-shape memory polymer composites. Mater. Lett. 2014, 134, 172–175. [Google Scholar] [CrossRef]

- Kim, J.T.; Jeong, H.J.; Park, H.C.; Jeong, H.M.; Bae, S.Y.; Kim, B.K. Electroactive shape memory performance of polyurethane/graphene nanocomposites. React. Funct. Polym. 2015, 88, 1–7. [Google Scholar] [CrossRef]

- Mohan, R.; Shanmugharaj, A.M.; Sung, H.R.; Subha, J. Influence of metal nanoparticle decorated CNTs on polyurethane based electro active shape memory nanocomposite actuators. Mater. Chem. Phys. 2011, 129, 925–931. [Google Scholar]

- Lu, H.B.; Liu, Y.J.; Gou, J.H.; Leng, J.S.; Du, S.Y. Electroactive shape-memory polymer nanocomposites incorporating carbon nanofiber paper. Int. J. Smart. Nano. Mat. 2010, 1, 2–12. [Google Scholar] [CrossRef]

- Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar]

- Vasilios, G.; Dimitrios, G.; Vasilios, T.; Luci, P.; Dirk, M.G.; Maurizio, P. Decorating carbon nanotubes with metal or semiconductor nanoparticles. J. Mater. Chem. 2007, 17, 2679–2694. [Google Scholar]

- Li, K.J.; Wang, W.C.; Cao, D.P. Metal (Pd, Pt)-decorated carbon nanotubes for CO and NO sensing. Sens. Actuators B Chem. 2011, 159, 171–177. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alam, J.; Khan, A.; Alam, M.; Mohan, R. Electroactive Shape Memory Property of a Cu-decorated CNT Dispersed PLA/ESO Nanocomposite. Materials 2015, 8, 6391-6400. https://doi.org/10.3390/ma8095313

Alam J, Khan A, Alam M, Mohan R. Electroactive Shape Memory Property of a Cu-decorated CNT Dispersed PLA/ESO Nanocomposite. Materials. 2015; 8(9):6391-6400. https://doi.org/10.3390/ma8095313

Chicago/Turabian StyleAlam, Javed, Aslam Khan, Manawwer Alam, and Raja Mohan. 2015. "Electroactive Shape Memory Property of a Cu-decorated CNT Dispersed PLA/ESO Nanocomposite" Materials 8, no. 9: 6391-6400. https://doi.org/10.3390/ma8095313