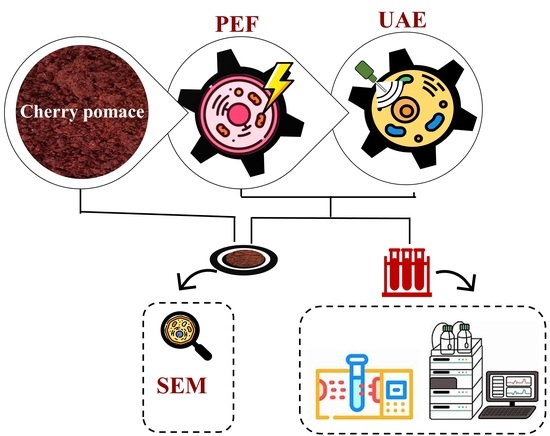

Sustainable Valorization of Industrial Cherry Pomace: A Novel Cascade Approach Using Pulsed Electric Fields and Ultrasound Assisted-Extraction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Chemicals

2.2. PEF and US Equipment

2.3. Cascade of Pulsed Electric Fields (PEF)- and Ultrasound (US)-Assisted Extraction Experiments

2.4. Chemical Characterization of the Sweet Cherry Pomace Extracts

2.4.1. Determination of Total Phenolic Content (TPC)

2.4.2. Determination of Flavonoid Content (FC)

2.4.3. Determination of Total Anthocyanin Content (TAC)

- MW = molecular weights of cyanidin-3-O-glucoside;

- DF= dilution factor;

- ε = molar extinction coefficient;

- DW = dry weight of cherry pomace;

- 103 = conversion factor from g to mg; and

- L/S = liquid-to-solid ratio.

2.4.4. Determination of Ferric-Reducing Antioxidant Power (FRAP)

2.4.5. HPLC-DAD Analyses of the Extracts

2.5. Scanning Electron Microscopy (SEM) Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. PEF-Assisted Extraction Process of Phenolic Compounds from Industrial Cherry Pomace

3.2. Cascade PEF-UAE Extraction Process of Phenolic Compounds from Cherry Pomace

3.3. Quantification of the Main Phenolic Compounds via HPLC-DAD Analysis

3.4. Impacts of PEF and US Pre-Treatment on the Microstructure of Cherry Pomace Tissue

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vavoura, M.; Badeka, A.; Kontakos, S.; Kontominas, M. Characterization of Four Popular Sweet Cherry Cultivars Grown in Greece by Volatile Compound and Physicochemical Data Analysis and Sensory Evaluation. Molecules 2015, 20, 1922–1940. [Google Scholar] [CrossRef] [PubMed]

- Milea, A.S.; Vasile, A.M.; Cîrciumaru, A.; Dumitrascu, L.; Barbu, V.; Râpeanu, G.; Bahrim, G.E.; Stanciuc, N. Valorizations of Sweet Cherries Skins Phytochemicals by Extraction, Microencapsulation and Development of Value-Added Food Products. Foods 2019, 8, 188. [Google Scholar] [CrossRef] [PubMed]

- De Pilli, T.; Lopriore, G.; Montemitro, M.; Alessandrino, O. Effects of Two Sweet Cherry Cultivars (Prunus avium L., Cvv. ‘Ferrovia’ and ‘Lapins’) on the Shelf Life of an Innovative Bakery Product. J. Food Sci. Technol. 2019, 56, 310–320. [Google Scholar] [CrossRef] [PubMed]

- McCune, L.M.; Kubota, C.; Stendell-Hollis, N.R.; Thomson, C.A. Cherries and Health: A Review. Crit. Rev. Food Sci. Nutr. 2011, 51, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Howatson, G.; Bell, P.G.; Tallent, J.; Middleton, B.; McHugh, M.P.; Ellis, J. Effect of Tart Cherry Juice (Prunus cerasus) on Melatonin Levels and Enhanced Sleep Quality. Eur. J. Nutr. 2012, 51, 909–916. [Google Scholar] [CrossRef]

- Basu, A.; Betts, N.M.; Ortiz, J.; Simmons, B.; Wu, M.; Lyons, T.J. Low-Energy Cranberry Juice Decreases Lipid Oxidation and Increases Plasma Antioxidant Capacity in Women with Metabolic Syndrome. Nutr. Res. 2011, 31, 190–196. [Google Scholar] [CrossRef] [PubMed]

- Schumacher, H.R.; Pullman-Mooar, S.; Gupta, S.R.; Dinnella, J.E.; Kim, R.; McHugh, M.P. Randomized Double-Blind Crossover Study of the Efficacy of a Tart Cherry Juice Blend in Treatment of Osteoarthritis (OA) of the Knee. Osteoarthr. Cartil. 2013, 21, 1035–1041. [Google Scholar] [CrossRef]

- Moosavian, S.P.; Maharat, M.; Chambari, M.; Moradi, F.; Rahimlou, M. Effects of Tart Cherry Juice Consumption on Cardio-Metabolic Risk Factors: A Systematic Review and Meta-Analysis of Randomized-Controlled Trials. Complement Ther. Med. 2022, 71, 102883. [Google Scholar] [CrossRef]

- Kelley, D.S.; Rasooly, R.; Jacob, R.A.; Kader, A.A.; Mackey, B.E. Consumption of Bing Sweet Cherries Lowers Circulating Concentrations of Inflammation Markers in Healthy Men and Women. J. Nutr. 2006, 136, 981–986. [Google Scholar] [CrossRef]

- Teslić, N.; Kojić, J.; Đermanović, B.; Šarić, L.; Maravić, N.; Pestorić, M.; Šarić, B. Sour Cherry Pomace Valorization as a Bakery Fruit Filling: Chemical Composition, Bioactivity, Quality and Sensory Properties. Antioxidants 2023, 12, 1234. [Google Scholar] [CrossRef]

- Gençdağ, E.; Görgüç, A.; Yılmaz, F.M. Valorization of Sweet Cherry (Prunus avium) Wastes as a Source of Advanced Bioactive Compounds. In Mediterranean Fruits Bio-wastes: Chemistry, Functionality and Technological Applications; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; pp. 559–579. ISBN 9783030844363. [Google Scholar]

- Rrucaj, E.; Carpentieri, S.; Siano, F.; Ferrari, G.; Pataro, G. Optimizing the Solvent Extraction Process for High-Value Compounds from Sweet Cherry Press Cake Treated with Pulsed Electric Fields Using Response Surface Methodology. Front. Food Sci. Technol. 2023, 3. [Google Scholar] [CrossRef]

- Acero, N.; Gradillas, A.; Beltran, M.; García, A.; Muñoz Mingarro, D. Comparison of Phenolic Compounds Profile and Antioxidant Properties of Different Sweet Cherry (Prunus avium L.) Varieties. Food Chem. 2019, 279, 260–271. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, A.C.; Bento, C.; Jesus, F.; Alves, G.; Silva, L.R. Sweet Cherry Phenolic Compounds: Identification, Characterization, and Health Benefits. In Studies in Natural Products Chemistry; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 59, pp. 31–78. [Google Scholar]

- Blando, F.; Oomah, B.D. Sweet and Sour Cherries: Origin, Distribution, Nutritional Composition and Health Benefits. Trends Food Sci. Technol. 2019, 86, 517–529. [Google Scholar] [CrossRef]

- Domínguez-Rodríguez, G.; García, M.C.; Marina, M.L.; Plaza, M. Pressurized Liquid Extraction Combined with Enzymatic-Assisted Extraction to Obtain Bioactive Non-Extractable Polyphenols from Sweet Cherry (Prunus avium L.) Pomace. Nutrients 2021, 13, 3242. [Google Scholar] [CrossRef] [PubMed]

- Paini, J.; Benedetti, V.; Ail, S.S.; Castaldi, M.J.; Baratieri, M.; Patuzzi, F. Valorization of Wastes from the Food Production Industry: A Review Towards an Integrated Agri-Food Processing Biorefinery. Waste Biomass Valorization 2022, 13, 31–50. [Google Scholar] [CrossRef]

- Jiménez-Moreno, N.; Esparza, I.; Bimbela, F.; Gandía, L.M.; Ancín-Azpilicueta, C. Valorization of Selected Fruit and Vegetable Wastes as Bioactive Compounds: Opportunities and Challenges. Crit. Rev. Environ. Sci. Technol. 2020, 50, 2061–2108. [Google Scholar] [CrossRef]

- Ganessingh, V.; Sahibdeen, R.; Maharaj, R. An Evaluation of the Impact of Novel Processing Technologies on the Phytochemical Composition of Fruits and Vegetables. In Phytochemicals—Source of Antioxidants and Role in Disease Prevention; InTech: London, UK, 2018. [Google Scholar]

- Arshad, R.N.; Abdul-Malek, Z.; Ahmad, M.H.; Buntat, Z.; Nawawi, Z.; Pavan Kumara, C.L.G.; Abdulameer, A.Z.; Sidik, M.A.B. Coaxial Treatment Chamber for Liquid Food Treatment through Pulsed Electric Field. Indones. J. Electr. Eng. Comput. Sci. 2020, 19, 1169–1176. [Google Scholar] [CrossRef]

- Kashyap, P.; Riar, C.S.; Jindal, N. Polyphenol Bio-Accessibility and Antioxidant Activity of in Vitro Digested Ultrasound-Assisted Meghalayan Cherry (Prunus nepalensis) Pomace Extract. Biomass Convers Biorefin 2022, 14, 14071–14085. [Google Scholar] [CrossRef]

- Carpentieri, S.; Mazza, L.; Nutrizio, M.; Jambrak, A.R.; Ferrari, G.; Pataro, G. Pulsed Electric Fields- and Ultrasound-Assisted Green Extraction of Valuable Compounds from Origanum vulgare L. and Thymus serpyllum L. Int. J. Food Sci. Technol. 2021, 56, 4834–4842. [Google Scholar] [CrossRef]

- Raso, J.; Frey, W.; Ferrari, G.; Pataro, G.; Knorr, D.; Teissie, J.; Miklavčič, D. Recommendations Guidelines on the Key Information to Be Reported in Studies of Application of PEF Technology in Food and Biotechnological Processes. Innov. Food Sci. Emerg. Technol. 2016, 37, 312–321. [Google Scholar] [CrossRef]

- Carullo, D.; Abera, B.D.; Casazza, A.A.; Donsì, F.; Perego, P.; Ferrari, G.; Pataro, G. Effect of Pulsed Electric Fields and High Pressure Homogenization on the Aqueous Extraction of Intracellular Compounds from the Microalgae Chlorella Vulgaris. Algal Res. 2018, 31, 60–69. [Google Scholar] [CrossRef]

- Juliano, P.; Bainczyk, F.; Swiergon, P.; Supriyatna, M.I.M.; Guillaume, C.; Ravetti, L.; Canamasas, P.; Cravotto, G.; Xu, X.-Q. Extraction of Olive Oil Assisted by High-Frequency Ultrasound Standing Waves. Ultrason. Sonochem. 2017, 38, 104–114. [Google Scholar] [CrossRef] [PubMed]

- Chemat, F.; Rombaut, N.; Sicaire, A.-G.; Meullemiestre, A.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Ultrasound Assisted Extraction of Food and Natural Products. Mechanisms, Techniques, Combinations, Protocols and Applications. A Review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef]

- Kumar, K.; Srivastav, S.; Sharanagat, V.S. Ultrasound Assisted Extraction (UAE) of Bioactive Compounds from Fruit and Vegetable Processing by-Products: A Review. Ultrason. Sonochem. 2021, 70, 105325. [Google Scholar] [CrossRef] [PubMed]

- Kashyap, P.; Riar, C.S.; Jindal, N. Optimization of Ultrasound Assisted Extraction of Polyphenols from Meghalayan Cherry Fruit (Prunus nepalensis) Using Response Surface Methodology (RSM) and Artificial Neural Network (ANN) Approach. J. Food Meas. Charact. 2021, 15, 119–133. [Google Scholar] [CrossRef]

- Kumari, B.; Tiwari, B.K.; Hossain, M.B.; Brunton, N.P.; Rai, D.K. Recent Advances on Application of Ultrasound and Pulsed Electric Field Technologies in the Extraction of Bioactives from Agro-Industrial By-Products. Food Bioproc. Technol. 2018, 11, 223–241. [Google Scholar] [CrossRef]

- Carpentieri, S.; Ferrari, G.; Pataro, G. Pulsed Electric Fields-Assisted Extraction of Valuable Compounds from Red Grape Pomace: Process Optimization Using Response Surface Methodology. Front. Nutr. 2023, 10, 1–20. [Google Scholar] [CrossRef]

- Barbosa-Pereira, L.; Guglielmetti, A.; Zeppa, G. Pulsed Electric Field Assisted Extraction of Bioactive Compounds from Cocoa Bean Shell and Coffee Silverskin. Food Bioproc. Technol. 2018, 11, 818–835. [Google Scholar] [CrossRef]

- Carpentieri, S.; Ferrari, G.; Pataro, G. Optimization of Pulsed Electric Fields-Assisted Extraction of Phenolic Compounds From White Grape Pomace Using Response Surface Methodology. Front. Sustain. Food Syst. 2022, 6, 1–17. [Google Scholar] [CrossRef]

- Pataro, G.; Carullo, D.; Bobinaite, R.; Donsì, G.; Ferrari, G. Improving the Extraction Yield of Juice and Bioactive Compounds from Sweet Cherries and Their By-Products by Pulsed Electric Fields. Chem. Eng. Trans. 2017, 57, 1717–1722. [Google Scholar] [CrossRef]

- Bobinaitė, R.; Pataro, G.; Visockis, M.; Bobinas, Č.; Ferrari, G.; Viškelis, P. Potential Application of Pulsed Electric Fields to Improve the Recovery of Bioactive Compounds from Sour Cherries and Their By-Products; FOODBALT: Jelgava, Latvia, 2017; pp. 70–74. [Google Scholar]

- Sotelo, K.A.G.; Hamid, N.; Oey, I.; Pook, C.; Gutierrez-Maddox, N.; Ma, Q.; Ying Leong, S.; Lu, J. Red Cherries (Prunus Avium Var. Stella) Processed by Pulsed Electric Field—Physical, Chemical and Microbiological Analyses. Food Chem. 2018, 240, 926–934. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Jung, J.; Tomasino, E.; Zhao, Y. Optimization of Solvent and Ultrasound-Assisted Extraction for Different Anthocyanin Rich Fruit and Their Effects on Anthocyanin Compositions. LWT 2016, 72, 229–238. [Google Scholar] [CrossRef]

- Martín-García, B.; Tylewicz, U.; Verardo, V.; Pasini, F.; Gómez-Caravaca, A.M.; Caboni, M.F.; Dalla Rosa, M. Pulsed Electric Field (PEF) as Pre-Treatment to Improve the Phenolic Compounds Recovery from Brewers’ Spent Grains. Innov. Food Sci. Emerg. Technol. 2020, 64, 102402. [Google Scholar] [CrossRef]

- Manzoor, M.F.; Zeng, X.A.; Rahaman, A.; Siddeeg, A.; Aadil, R.M.; Ahmed, Z.; Li, J.; Niu, D. Combined Impact of Pulsed Electric Field and Ultrasound on Bioactive Compounds and FT-IR Analysis of Almond Extract. J. Food Sci. Technol. 2019, 56, 2355–2364. [Google Scholar] [CrossRef] [PubMed]

- Aadil, R.M.; Zeng, X.A.; Han, Z.; Sahar, A.; Khalil, A.A.; Rahman, U.U.; Khan, M.; Mehmood, T. Combined Effects of Pulsed Electric Field and Ultrasound on Bioactive Compounds and Microbial Quality of Grapefruit Juice. J. Food Process. Preserv. 2018, 42, e13507. [Google Scholar] [CrossRef]

- Donsì, F.; Ferrari, G.; Pataro, G. Applications of Pulsed Electric Field Treatments for the Enhancement of Mass Transfer from Vegetable Tissue. Food Eng. Rev. 2010, 2, 109–130. [Google Scholar] [CrossRef]

- Magri, A.; Malorni, L.; Cozzolino, R.; Adiletta, G.; Siano, F.; Picariello, G.; Cice, D.; Capriolo, G.; Nunziata, A.; Di Matteo, M.; et al. Agronomic, Physicochemical, Aromatic and Sensory Characterization of Four Sweet Cherry Accessions of the Campania Region. Plants 2023, 12, 610. [Google Scholar] [CrossRef] [PubMed]

- Pirozzi, A.; Ferrari, G.; Donsì, F. Cellulose Isolation from Tomato Pomace Pretreated by High-Pressure Homogenization. Foods 2022, 11, 266. [Google Scholar] [CrossRef]

- Patra, M.; Salonen, E.; Terama, E.; Vattulainen, I.; Faller, R.; Lee, B.W.; Holopainen, J.; Karttunen, M. Under the Influence of Alcohol: The Effect of Ethanol and Methanol on Lipid Bilayers. Biophys J. 2006, 90, 1121–1135. [Google Scholar] [CrossRef]

- Rajha, H.N.; Darra, N.E.; Vorobiev, E.; Louka, N.; Maroun, R.G. An Environment Friendly, Low-Cost Extraction Process of Phenolic Compounds from Grape Byproducts. Optimization by Multi-Response Surface Methodology. Food Nutr. Sci. 2013, 04, 650–659. [Google Scholar] [CrossRef]

- Barba, F.J.; Grimi, N.; Vorobiev, E. New Approaches for the Use of Non-Conventional Cell Disruption Technologies to Extract Potential Food Additives and Nutraceuticals from Microalgae. Food Eng. Rev. 2015, 7, 45–62. [Google Scholar] [CrossRef]

- Bocker, R.; Silva, E.K. Pulsed Electric Field Assisted Extraction of Natural Food Pigments and Colorings from Plant Matrices. Food Chem. X 2022, 15, 100398. [Google Scholar] [CrossRef] [PubMed]

- Pataro, G.; Bobinaitė, R.; Bobinas, Č.; Šatkauskas, S.; Raudonis, R.; Visockis, M.; Ferrari, G.; Viškelis, P. Improving the Extraction of Juice and Anthocyanins from Blueberry Fruits and Their By-Products by Application of Pulsed Electric Fields. Food Bioproc. Technol. 2017, 10, 1595–1605. [Google Scholar] [CrossRef]

- Lamanauskas, N.; Pataro, G.; Bobinas, Č.; Šatkauskas, S.; Viškelis, P.; Bobinaitė, R.; Ferrari, G. Impulsinio Elektrinio Lauko Įtaka Sulčių Ir Bioaktyvių Medžiagų Išgavimui Iš Aviečių Ir Jų Produktų. Zemdirbyste 2016, 103, 83–90. [Google Scholar] [CrossRef]

- Chaovanalikit, A.; Wrolstad, R.E. Total Anthocyanins and Total Phenolics of Fresh and Processed Cherries and Their Antioxidant Properties; Institute of Food Technologists: Chicago, IL, USA, 2004; Volume 69. [Google Scholar]

- Postma, P.R.; Pataro, G.; Capitoli, M.; Barbosa, M.J.; Wijffels, R.H.; Eppink, M.H.M.; Olivieri, G.; Ferrari, G. Selective Extraction of Intracellular Components from the Microalga Chlorella Vulgaris by Combined Pulsed Electric Field–Temperature Treatment. Bioresour. Technol. 2016, 203, 80–88. [Google Scholar] [CrossRef]

- Medina-Meza, I.G.; Barbosa-Cánovas, G.V. Assisted Extraction of Bioactive Compounds from Plum and Grape Peels by Ultrasonics and Pulsed Electric Fields. J. Food Eng. 2015, 166, 268–275. [Google Scholar] [CrossRef]

- Rajha, H.N.; Abi-Khattar, A.-M.; El Kantar, S.; Boussetta, N.; Lebovka, N.; Maroun, R.G.; Louka, N.; Vorobiev, E. Comparison of Aqueous Extraction Efficiency and Biological Activities of Polyphenols from Pomegranate Peels Assisted by Infrared, Ultrasound, Pulsed Electric Fields and High-Voltage Electrical Discharges. Innov. Food Sci. Emerg. Technol. 2019, 58, 102212. [Google Scholar] [CrossRef]

- Tzima, K.; Brunton, N.P.; Lyng, J.G.; Frontuto, D.; Rai, D.K. The Effect of Pulsed Electric Field as a Pre-Treatment Step in Ultrasound Assisted Extraction of Phenolic Compounds from Fresh Rosemary and Thyme by-Products. Innov. Food Sci. Emerg. Technol. 2021, 69, 102644. [Google Scholar] [CrossRef]

- Tomás-Barberán, F.A.; Ruiz, D.; Valero, D.; Rivera, D.; Obón, C.; Sánchez-Roca, C.; Gil, M.I. 7 Health Benefits from Pomegranates and Stone Fruit, Including Plums, Peaches, Apricots and Cherries; John Wiley & Sons, Ltd.: London, UK, 2013. [Google Scholar]

- Serradilla, M.J.; Hernández, A.; López-Corrales, M.; Ruiz-Moyano, S.; de Guía Córdoba, M.; Martín, A. Composition of the Cherry (Prunus avium L. and Prunus cerasus L.; Rosaceae). In Nutritional Composition of Fruit Cultivars; Elsevier: Amsterdam, The Netherlands, 2015; pp. 127–147. ISBN 9780124081178. [Google Scholar]

- Corrales, M.; Toepfl, S.; Butz, P.; Knorr, D.; Tauscher, B. Extraction of Anthocyanins from Grape By-Products Assisted by Ultrasonics, High Hydrostatic Pressure or Pulsed Electric Fields: A Comparison. Innov. Food Sci. Emerg. Technol. 2008, 9, 85–91. [Google Scholar] [CrossRef]

- Brianceau, S.; Turk, M.; Vitrac, X.; Vorobiev, E. Combined Densification and Pulsed Electric Field Treatment for Selective Polyphenols Recovery from Fermented Grape Pomace. Innov. Food Sci. Emerg. Technol. 2015, 29, 2–8. [Google Scholar] [CrossRef]

- Barba, F.J.; Brianceau, S.; Turk, M.; Boussetta, N.; Vorobiev, E. Effect of Alternative Physical Treatments (Ultrasounds, Pulsed Electric Fields, and High-Voltage Electrical Discharges) on Selective Recovery of Bio-Compounds from Fermented Grape Pomace. Food Bioproc. Technol. 2015, 8, 1139–1148. [Google Scholar] [CrossRef]

- Kaur, N.; Aggarwal, P.; Kumar, V.; Kaur, S. Ultrasound-Assisted Extraction of Phytochemicals from Java Plum (Syzygium cumini L.) Pomace: Process Optimization, Phytochemical Characterization Using HPLC, FTIR, SEM and Mineral Profiling. Waste Biomass Valorization 2023, 14, 949–961. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Wang, R.; Rahaman, A.; Zeng, X.A.; Brennan, C.S. Combined Effects of Pulsed Electric Field and Ultrasound Pretreatments on Mass Transfer and Quality of Mushrooms. LWT 2021, 150, 112008. [Google Scholar] [CrossRef]

- Seremet (Ceclu), L.; Botez, E.; Nistor, O.-V.; Andronoiu, D.G.; Mocanu, G.-D. Effect of Different Drying Methods on Moisture Ratio and Rehydration of Pumpkin Slices. Food Chem. 2016, 195, 104–109. [Google Scholar] [CrossRef] [PubMed]

- Maran, J.P.; Priya, B. Ultrasound-assisted extraction of polysaccharide from Nephelium lappaceum L. Fruit peel. Int. J. Biol. Macromol. 2014, 70, 530–536. [Google Scholar] [CrossRef]

- González-Centeno, M.R.; Knoerzer, K.; Sabarez, H.; Simal, S.; Rosselló, C.; Femenia, A. Effect of acoustic frequency and power density on the aqueous ultrasonic-assisted extraction of grape pomace (Vitis vinifera L.)—A response surface approach. Ultrason. Sonochem. 2014, 21, 2176–2184. [Google Scholar] [CrossRef]

| Extraction Step | Extraction Method | Neochlorogenic Acid (mg/gDW) | Chlorogenic Acid (mg/gDW) | 4-p-coumaroylquinic Acid (mg/gDW) | Cyanidin-3-O-glucoside (mg/gDW) | Cyanidin-3-O-rutinoside (mg/gDW) | 3,5-Dicaffeoylquinic Acid (mg/gDW) | Rutin (mg/gDW) |

|---|---|---|---|---|---|---|---|---|

| I | SLE(I) | 14.60 ± 0.61 | 1.44 ± 0.17 | 2.52 ± 0.22 | 0.80 ± 0.03 | 7.84 ± 0.41 | 1.96 ± 0.03 | 2.72 ± 0.21 |

| PEF | 22.00 ± 1.12 | 3.8 ± 0.22 | 4.80 ± 0.27 | 2.08 ± 0.12 | 14.16 ± 0.54 | 6.00 ± 0.51 | 10.12 ± 0.65 | |

| II | SLE(II) | 2.04 ± 0.23 | 0.20 ± 0.6 | 0.20 ± 0.04 | 0.16 ± 0.02 | 1.92 ± 0.27 | 0.32 ± 0.02 | 0.68 ± 0.12 |

| UAE | 3.56 ± 0.35 | 0.68 ± 0.03 | 0.64 ± 0.08 | 0.44 ± 0.04 | 3.48 ± 0.90 | 0.56 ± 0.06 | 1.16 ± 0.04 | |

| Total | PEF+SLE(II) | 24.04 ± 0.98 | 4.00 ± 0.14 | 5.00 ± 0.41 | 2.24 ± 0.09 | 16.08 ± 1.13 | 6.32 ± 0.83 | 10.8 ± 0.66 |

| PEF+UAE | 25.56 ± 1.21 | 4.48 ± 0.09 | 5.44 ± 32 | 2.52 ± 0.11 | 17.64 ± 0.98 | 6.56 ± 0.74 | 11.28 ± 0.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rrucaj, E.; Carpentieri, S.; Scognamiglio, M.; Siano, F.; Ferrari, G.; Pataro, G. Sustainable Valorization of Industrial Cherry Pomace: A Novel Cascade Approach Using Pulsed Electric Fields and Ultrasound Assisted-Extraction. Foods 2024, 13, 1043. https://doi.org/10.3390/foods13071043

Rrucaj E, Carpentieri S, Scognamiglio M, Siano F, Ferrari G, Pataro G. Sustainable Valorization of Industrial Cherry Pomace: A Novel Cascade Approach Using Pulsed Electric Fields and Ultrasound Assisted-Extraction. Foods. 2024; 13(7):1043. https://doi.org/10.3390/foods13071043

Chicago/Turabian StyleRrucaj, Ervehe, Serena Carpentieri, Mariarosa Scognamiglio, Francesco Siano, Giovanna Ferrari, and Gianpiero Pataro. 2024. "Sustainable Valorization of Industrial Cherry Pomace: A Novel Cascade Approach Using Pulsed Electric Fields and Ultrasound Assisted-Extraction" Foods 13, no. 7: 1043. https://doi.org/10.3390/foods13071043