1

School of Materials Science and Engineering, Lanzhou University of Technology, Lanzhou 730050, China

2

State Key Laboratory of Advanced Processing and Recycling of Non-ferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China

Metals 2017, 7(9), 338; https://doi.org/10.3390/met7090338 - 1 Sep 2017

Cited by 20 | Viewed by 6449

Abstract

▼

Show Figures

The corrosion behavior of keyhole-free friction stir spot welded joints of dissimilar 6082 aluminum alloy and DP600 galvanized steel in 3.5% NaCl solution has been investigated by the immersion test and electrochemical analysis. The surface of the aluminum alloy produced exfoliation and pitting

[...] Read more.

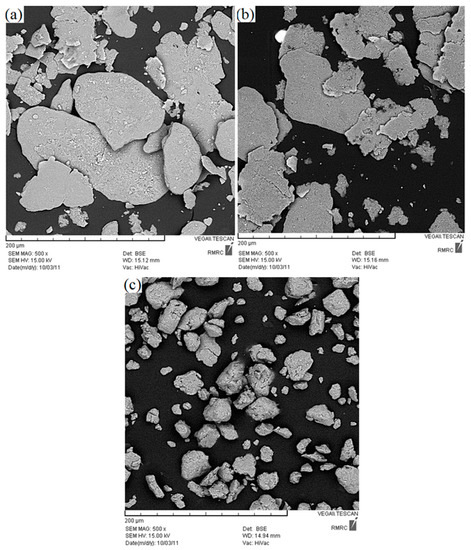

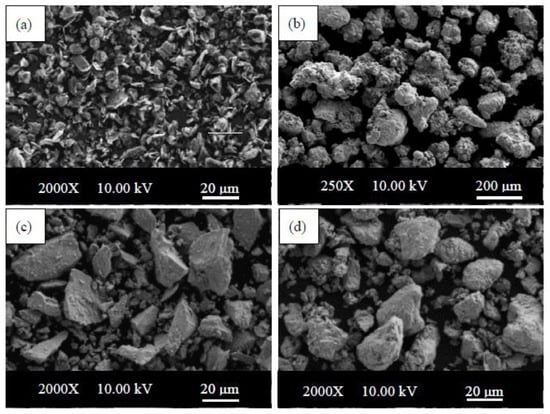

The corrosion behavior of keyhole-free friction stir spot welded joints of dissimilar 6082 aluminum alloy and DP600 galvanized steel in 3.5% NaCl solution has been investigated by the immersion test and electrochemical analysis. The surface of the aluminum alloy produced exfoliation and pitting corrosion. The pitting occurred seriously on the interface of the 6082 aluminum alloy, but the steel had no corrosion. The corrosion galvanic couples were formed between elements of Si and Fe with a high electrode potential, and Mg and Al with a low electrode potential, around them. Mg and Al elements of Mg2Si and Si-containing solid-solution phase α (Al) preferentially became an anodic dissolution and formed exfoliation corrosion around the Si elements. Fe-rich phase θ (Al3Fe) as the cathode caused corrosion of Mg and formed pitting around Mg-rich phase β (Al3Mg2) as the anode. The sequence of the corrosion resistance of different areas of the joints (with decreasing corrosion resistance) was WNZ (Weld Nugget Zone) > TMAZ (Thermo-mechanically Affected Zone) > BM (Base Metal) > HAZ (Heat-affected Zone). The joints of keyhole-free FSSW (Fiction Stir Spot Welding) of dissimilar 6082 aluminum alloy and DP600 galvanized steel have better corrosion resistance than base metal in 3.5% NaCl solution.

Full article