- Article

Integrated Sustainability Assessment of a Rice Mill Biorefinery: From Waste Valorization to Circular Economy Pathways

- Natalia Salgado-Aristizabal,

- Juan D. Galvis-Nieto and

- Carlos E. Orrego-Alzate

- + 2 authors

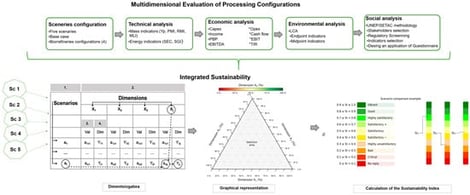

Rice processing generates substantial residual biomass globally—about 170 million tons of husk, 62–71 million tons of bran and 23–39 million tons of broken rice annually—which remains largely underutilized and creates environmental burdens and lost economic opportunities. This study was conducted to address the necessity for integrated sustainability assessments of rice mill biorefineries. The focus of this study is on transitioning from a global context of residual biomass generation to a local-scale application in small and medium mills (100–300 tons/day). We apply a resource-centric framework, combining process simulation, techno-economic analysis, and Life Cycle Assessment (LCA—selected for its capacity to quantify trade-offs and avoid burden-shifting across multiple impact categories) with Social-LCA. Five valorization scenarios are assessed. Results demonstrate that biorefinery pathways fundamentally alter supply provision: husk cogeneration boosts energy self-sufficiency (SGI = 12.54), displacing fossil fuels, while silica and nutrient recovery create new, local material flows, substituting for virgin resources. However, chemically intensive routes increase human toxicity impacts (up to 4.0 × 10−1 kg 1,4-DB eq/kg) despite product diversification. Social analysis reveals a tension between worker preferences for advanced technology and community priorities for low-chemical, employment-generating options. Probabilistic sensitivity analysis identifies a diversified configuration (oil, flour, feed, cogeneration) as most robust, optimizing overall resource productivity and circularity. This work transitions the conceptual model of a rice mill from a linear processor to a multi-output bio-resource hub, offering actionable pathways to enhance regional energy, mineral, and nutrient security through circular economy implementation.

9 February 2026

![(A)—Primary energy pathways in the two scenarios [10]. (B)—Change in CO2 emissions from fuel combustion and avoided emissions from deployment of selected clean technologies [11].](https://mdpi-res.com/cdn-cgi/image/w=281,h=192/https://mdpi-res.com/resources/resources-15-00025/article_deploy/html/images/resources-15-00025-g001-550.jpg)