- Article

Corrosion Behavior of AISI 904L Austenitic Stainless Steel in High-Temperature and High-Pressure Water Environment

- Kewei Fang,

- Yan Liu and

- Erwei Liu

- + 3 authors

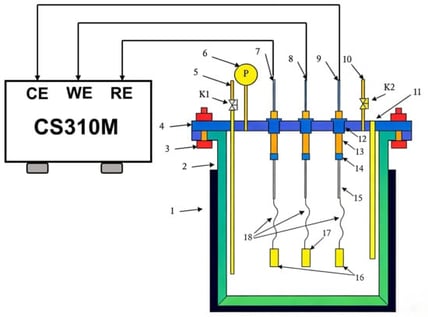

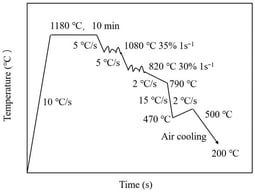

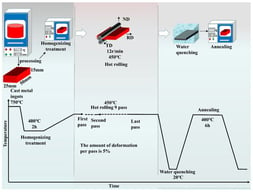

AISI 904L stainless steel (904L SS) is a promising material for nuclear power plant primary circuits due to its superior corrosion resistance, but its corrosion behavior under simulated high-temperature and high-pressure water environments with different microstructures remains poorly understood. In order to systematically investigate and clarify the electrochemical behavior and corrosion behavior under stress of 904L SS with three different microstructures (as-received, sensitized, and solution-treated) in a simulated primary circuit water environment of a nuclear power plant, experiments are conducted using dynamic polarization, electrochemical impedance spectroscopy (EIS), and U-bend immersion methods. The results show that temperature has a significant effect on corrosion resistance. As the temperature increases, the impedance of all microstructures decreases significantly, the passivation zone narrows, and the corrosion current density increases. Under high-temperature and high-pressure conditions, the corrosion resistance of the sensitized samples is the worst, while the samples treated with solution have the best overall performance. That is, microstructural optimization through solution treatment can effectively enhance the high-temperature and high-stress corrosion resistance of 904LSS in the primary circuit water environment.

14 February 2026