Abstract

Sustainability as a concept is present in most aspects of our everyday life, and industry is no exception. Likewise, there is no doubt that the necessity to produce goods in a sustainable way and to ensure that products are sustainable is gaining more and more attention from producers, customers, governments, and various organizations. Understandably, there are several ways to increase the sustainable development of industrial production. One effective tool is simulation, which can have a significant impact on improving environmental, economic, and social sustainability. This paper explores the role of simulation as a powerful scientific and engineering solution in advancing sustainability within industrial ecosystems. Its main scope is to map the existing literature on the usage of simulation as a supportive tool for achieving this goal. For this purpose, a bibliometric analysis was conducted, allowing for tailored insights into the use of simulation in sustainable production.

1. Introduction

Sustainable development as a way to understand the interaction of economic, social, and environmental systems, is widely recognized to have its origins in the UN Conference on the Human Environment in Stockholm in 1972. In terms of modern-day problems, sustainability is one of the main domains of interest worldwide. Therefore, even the industrial sector has come to the conclusion that it is necessary to take a stand on this particular issue [1,2,3]. The question of creating sustainable industry has been raised with the purpose of clarifying the many challenges and problems that businesses are confronted with in the application of this concept. The first time these issues were brought up in an industrial context was in the Brundtland report of 1987 by the World Commission on Environment and Development. This report, concerning industrial matters, focuses on changing how resources and environmental considerations are viewed in industrial planning and decision making [4]. Further elaboration and details are found in the concepts of Industry 4.0, and more recently, in the concept of Industry 5.0. In both concepts, sustainability is divided into three categories: economic, environmental, and social [5,6]. In terms of industrial practice, sustainability is segmented into three categories: corporate sustainability, industrial sustainability, and manufacturing sustainability (MS) [7,8,9,10]. This leads us to the conclusion that the concept of sustainability is contemplated in all areas and structural levels of enterprise. It is logical that sustainability cannot be the main goal of a manufacturing company; therefore, there has to be some impetus to participate in this industrial trend.

Some of the main reasons to incorporate sustainability into production, other than sustainable conviction, are as follows [1]:

- Customer demand for sustainable products. Nowadays, the marketing for many companies and products is based on their sustainable characteristics, in terms of how they were produced and how sustainable their usage is in terms of, for example, energy usage, maintenance, and recycling processes. Then, there is the question of what materials were used in production, where these materials were obtained, and last but not least, who made them and under what conditions.

- Government pressure/support in sustainable production. Individual states can help companies or put pressure on them by implementing laws in the form of bans or, on the other hand, providing financial help if the company innovates in terms of sustainability. The United Nations has set the goal to accomplish seventeen sustainable goals as part of the 2030 Agenda for Sustainable Development [11]. Some of these are aimed directly at the industrial sector.

- Energy and material prices. These commodities are crucial for the functioning of manufacturing companies. According to the latest data from 2021 from Eurostat, the industrial sector consumed 25.6% of all final energy in the EU, making it one of the largest energy consumers. Of the total amount of energy, only 9.7% was made up of renewable sources and biofuels [12]. The prices of these commodities are constantly increasing, and that is why companies should, for their own good, want to reduce their usage.

In addition, it is also necessary to view environmental sustainability through the prism of the reduction of manufacturing waste linked to material inputs. To better understand waste process flows in manufacturing enterprises, a holistic approach is recommended by Ball et al. [13]. The authors developed the input/output flow model of materials, energy, and waste to show how they can interact, using simulation. Their paper also demonstrates how this tool can be used to select appropriate technologies to reduce material and energy consumption as well as the carbon footprint. Moreover, they showed how results of the simulation can be used to redesign manufacturing processes to achieve the above-mentioned effects. In this context, the concept of design for the environment has been introduced to describe design and redesign practices through which products and manufacturing processes are optimized [14]. Therefore, the analysis of the relationships among of materials, energy, and waste is one of the first important steps companies need to take to decrease the consumption of resources and energy and to reduce the emissions of pollutants in line with the Corporate Social Responsibility concept [15,16,17].

It is crucial for management to think about sustainable production for their company but also a sustainable future for everyone. In connection with sustainable industry, the terms circular and sharing economy are commonly used [18,19]. The main goal of a circular economy is focused on embracing practices that emphasize resource efficiency and waste prevention by promoting close-loop systems in contrast to linear principles [20,21,22]. Therefore, decision making in terms of sustainability is important but also difficult. A small mistake could lead to a big financial loss. On that note, there are supportive methods and tools that can help management in decision making not just in matters of sustainability but also in the optimalization of various types of processes.

One of these is simulation. Simulation can be described in a simplified form as an imitation of a system [23,24,25]. From a dynamic point of view, it can be divided into two categories: static simulation and dynamic simulation. All simulations have advantages and disadvantages in terms of their usage [26]. Simulation, as a tool, is used daily in almost all aspects of everyday life. Probably the most well-known everyday simulations include weather forecasting, flight and car simulators, and job position training [27]. It is important to note that simulation is a supportive tool and not a solution for problems. Simulation can help provide a better understanding of the problem or create more possibilities for management or others responsible for decisions. Simulation is not omnipotent; it is only as good as the data that the creator puts into it [28]. In terms of data for simulation, the amount and quality have improved with the implementation of digitalization based on Industry 4.0. The implementation of smart sensors, RFID technologies, the Internet of Things, and cloud technologies brings potential for the usage of simulations with data in real time. In other words, simulation can be used for monitoring and analyzing processes and events in almost real time, which can help with smooth and quick decision making [29,30,31,32,33].

The main research questions (RQs) that this paper addresses can be formulated as follows:

- RQ1: What are possibilities for the utilization of simulation methods for addressing sustainable issues?

- RQ2: What types of simulation methods are most often used for addressing sustainable issues in selected industrial fields?

2. Materials and Methods

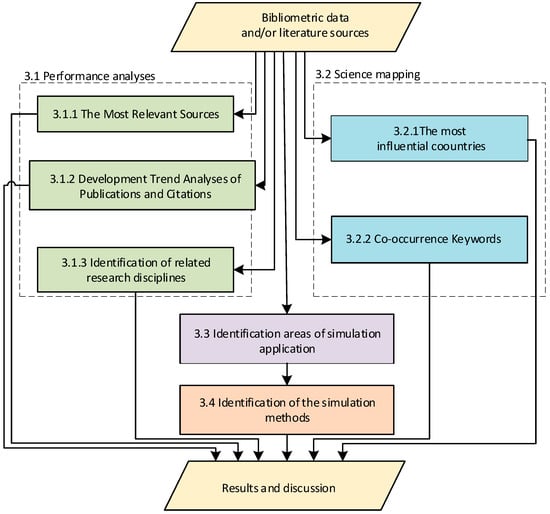

To analyze the existing literature on the particular research problem as well as to reach conclusions regarding the stated research questions, the following two approaches were employed. The first one is based on a bibliometric analysis performed with a specialized software that is described below. Two types of bibliometric analyses were applied, namely (1) performance analyses, and (2) science mapping to obtain relevant scientific insights from several angles for the given problem. After the initial step, selected papers were reviewed for deeper analysis. The overall structure of the paper’s methodology with some details is depicted in Figure 1.

Figure 1.

Methodological framework of the study.

3. Bibliometric Analysis and Literature Review

This section describes the results of the bibliometric analysis and the review of selected papers regarding the usage of simulation for ensuring sustainability in industry according to the triple bottom-line construct [34]. To this end, the Web of Science (WoS) database was used to search for specified terms and conditions. The section is divided into two main parts: bibliometric analysis and the review of selected papers. Performance analysis includes categorization of total publications by document type, publication growth, research area, contribution by country, publication title, frequently cited publications, and citation metrics. Country co-authorship, keyword co-occurrence, and the most used keywords are a part of the science mapping analysis, which is performed using VOSviewer 1.6.20 [35,36,37].

3.1. Performance Analysis Based on Bibliometric Indicators

The search terms for the purpose of the performance analysis were as follows: simulation (Topic) AND sustainability (Topic) AND industry (Topic) entered on the following day: 25 March 2024. The conditions were also specified by the years, ranging from 2013 to 2023. Together, 1275 documents were identified. Only articles, proceeding papers, review articles, early access documents, and book chapters were analyzed in this study. After removing unrelated documents, a total of 1272 publications were further analyzed. These publications were divided based on their types; see Table 1.

Table 1.

Publications based on document types.

From the previous table, it can be seen that more than 89% of the publications were articles (74.1%) and proceeding papers (15%). Review articles made up 8.1% of the total documents, while early access documents and book chapters contributed 1.8% and 1%, respectively.

3.1.1. The Most Relevant Sources

This subsection is devoted to the evaluation of the publication sources of the papers. There were more than 210 publication sources for this topic, from which the top 10 ones were identified. They are listed in terms of importance in Table 2.

Table 2.

The list of the most relevant sources.

From Table 2, it can be seen that, not surprisingly, the most frequently occurring publication source is Sustainability, with 125 documents. The Journal of Cleaner Production, with 73 publications, took second place. Other documents are distributed across various journals with a similar scope. It is useful to mention some journals not listed in the table above: Buildings, Energy, Polymers, Agricultural Systems, Green Chemistry, and Foods.

3.1.2. Development Trend Analyses of Publications and Citations

The annual publication growth of all the publications in the field, including the number of citations per year and the total number of citations per publications, is shown in Table 3.

Table 3.

The number of citations per year and the number of citations per publication.

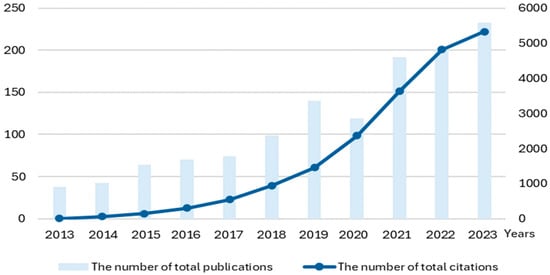

The highest number of total citations was recorded in 2023, with 5328 citations from a total of 19,628 citations. The highest number of citations per paper occurred in 2022. The total annual publications saw an increasing trend from 2013 to 2019. A slight drop occurred in the total annual publications in 2020 due to the COVID-19 pandemic situation. However, the total annual publication number continued to increase until it peaked in 2023, with 233 publications from a total of 1272 publications, as can be seen in Figure 2.

Figure 2.

Trend analysis of annual publications and citation growth in a given field.

3.1.3. Identification of Related Research Disciplines

The 1272 publications were subsequently divided into more than 60 research areas. The top 15 research areas are listed in Table 4.

Table 4.

The top 15 research areas in the field.

The highest number of the documents (585) were categorized under the Engineering domain; 333 publications were assigned to the Environmental sciences ecology research area, and 318 publications were from the field of Science technology. The remaining 321 documents were covered by twelve other research areas listed in the lower part of the table. To point out the most important publications on the research topic, Table 5 provides the list of the top 10 cited papers.

Table 5.

Selected attributes of the top ten cited publications.

It is also evident from Table 5 that there is a great interest in this topic in the scientific field, which is supported by the number of citations, a wide range of countries involved in this research, and the number of reputable international journals.

The most cited paper [38], with 951 citations, provides insights into the microscopic mechanisms governing the resultant separation performance, suggesting a plausible correlation between the inherent structural features/topology of metal–organic frameworks and the associated gas/vapor separation performance. The Monte Carlo simulation is used in this publication. The diversity of publication titles and countries within papers is intriguing. Among the ten publications presented in Table 5, three are categorized as review papers and seven as articles.

3.2. Science Mapping Using Bibliometric Networks

Bibliometric mapping or science mapping is used to investigate the interrelations between selected research aspects using a spatial representation of how system elements such as individual documents or authors are related to one another. Such mapping helps to better understand the structure and dynamism of the given research area and to identify research frontiers, leading collaborations, the most relevant sources, and so on. This method was applied in order to identify the most influential countries in this area and the most important sub-domains that can help to uncover connections between different themes within the field of study.

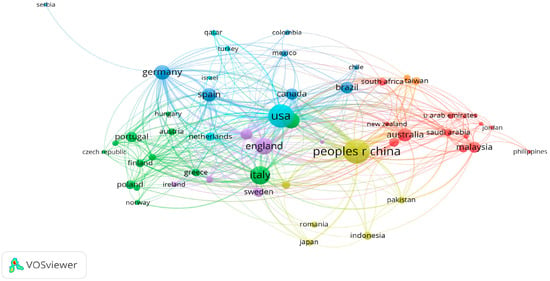

3.2.1. The Most Influential Countries in the Research Field

As was mentioned above, this sub-subsection aims to identify the most important countries and collaboration networks in the research area. This is important because scholars from across the world are collaborating to expand and develop their research interests, which ultimately advances the development of knowledge in a particular domain. This trend can be viewed using VOSviewer software, which allows the creation of a country co-authorship network map. To this end, the input data for VOSviewer was imported from WoS database; the keywords mentioned in Section 3.1 were used and subsequently transferred into the bibliometric map shown in Figure 3.

Figure 3.

The country co-authorship map in VOSviewer.

The results obtained from VOSviewer showed that country co-authorship analysis identified the USA as having the largest international collaboration, with 151 total link strength, followed by China, England, Germany, and Italy, with 130, 101, 79, and 78 total link strength, respectively. The strongest international collaboration occurs between the USA and China, with 24 link strength. This is followed by cooperation between China and Australia, with 10 total strong links between them. In the third position from this point of view is the cooperation between China–England and China–Canada, with 9 total strong connections.

The publications in the specified fields involve scholars from more than 90 countries. The top 15 countries with the most contributions in the specified field are depicted in Table 6.

Table 6.

The top 15 countries with the most contributions in the specified field.

As can be seen from this table, Chinese scholars have the highest number of citations, and French scholars have the greatest number of citations per paper.

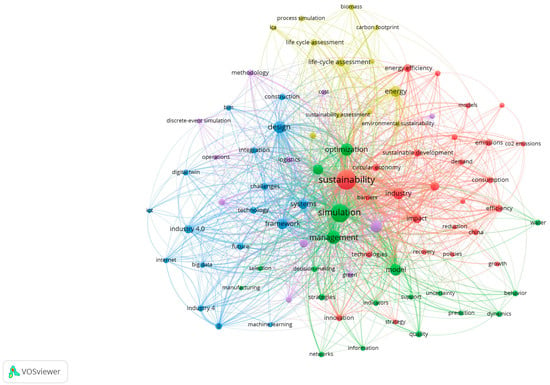

3.2.2. Mapping of the Most Important Sub-Domains of the Research Topic

To identify the most important sub-domains of the research topic, the co-occurrence keywords search was used to access scientific manuscripts that were sourced from the WoS database using the same input data as in the previous Section 3.2.1. The keyword co-occurrence map was generated by VOSviewer, and the minimum number of occurrences of a keyword was set to 15. A total of 85 keywords met the threshold, for which the network shown in Figure 4 was created. The keywords are grouped into five clusters, which are illustrated in different colors. The size of the circle for each keyword emphasizes frequency of the usage of the particular keyword. The bigger the circle, the more frequently the word is used.

Figure 4.

The keyword co-occurrence map.

The most frequent keyword was ‘sustainability’, which occurred 410 times, with a total link strength of 1378. The second most used keyword was ‘simulation’, appearing 347 times and having a total link strength of 1284. The third most important was ‘management’, which occurred 169 times and had a 711 total link strength. From the same figure, it is possible to determine four clusters; the red cluster contains keywords such as sustainability, industry, simulation, impact, circular economy, system dynamics, sustainable development, innovation, etc. This cluster is mostly focused on sustainability topics and its application through the company. The second cluster—the green one—involves the keywords simulation, optimization, management, model, system, strategies, support, indicators, energy, decision making, information, prediction, uncertainty, etc. The listed keywords can help managers direct their activities to correspond with these categories. The third blue cluster includes keywords like design, framework, technology, challenges, future, Industry 4.0, big data, internet, Internet of Things, digital twin, machine learning, etc. The blue cluster highlights the digital transformation of a company using Industry 4.0 tools. The last cluster, purple in color, features the following keywords: performance, supply chain management, waste, implementation, operations, logistics, implementation, etc. This cluster highlights approaches to improve supply chain management and influence the industry towards sustainability by building a responsible supply chain.

Following the results from the previous map, the top ten keywords and their allocation to the clusters are listed in Table 7.

Table 7.

The top 10 keywords and their allocation to the clusters.

The primary results from bibliometric analysis indicate a significant interest in the topic of simulation usage in sustainable industry. This conclusion is based on the number of publications and the presence of more than 60 research areas under which publications were submitted. These areas encompass a wide range of disciplines, including engineering, chemistry, agriculture, and telecommunications, among others, suggesting that simulation has broad applications across various fields in connection with sustainable industry. Furthermore, interest in this topic is evident across numerous countries, as indicated by the number of publications originating from different regions. As was already mentioned, it is not surprising that the majority of publications are found in reputable journals that focus on sustainability, such as Sustainability and the Journal of Clean Production. Additionally, strong connections in collaborations between scholars suggest a collective effort to address sustainable industry issues and explore how simulation can contribute to solving this global problem. In terms of the most frequently occurring keywords, sustainability and simulation are closely linked to concepts such as management, optimization, design, performance, and industry as a whole. One could argue that achieving sustainable industry, supported by simulation, can be applied throughout the entire product life cycle.

In the next paragraph, a deeper analysis of selected publications will be conducted to gain a better understanding of where and in what contexts simulation is used in terms of sustainable industry.

3.3. Identification of Areas of Simulation Application

The final step in investigation of the published articles is to look at some of them more closely in terms of the areas in which simulations are used for sustainability purpose. For this particular analysis, publications from WoS were used, and papers with 50 and more citations, based on the WOS dataset, were selected for in-depth analysis. This analysis was carried by analyzing the selected publications as distributed over four categories. It is reasonable to assert that almost every paper can by placed in more than one category; thus, the categorization was carried out based on the main field of study.

In the following part, each category is briefly described based on the publications were assigned to it. The two most prominent categories with the most assigned papers are the energy/source category and building/construction category. Manufacturing as a discipline is third in this context.

3.3.1. Energy and Energy Sources

Based on the selected publications, the main topics of this category are how to prevent extensive usage of energy and what can be used for alternative sources of energy. In the publication by Cossu [47], the authors focus on the photovoltaic energy used in the greenhouse industry and focus on identification of strategies to design such greenhouses with a specific agricultural purposes. The authors of [48] used numerical simulation to calculate the light distribution and availability for the main types of photovoltaic greenhouses in the EU. The other publications focused on the usage of photovoltaics include an article by Yang, which emphasizes the usage of simulation in monitoring energy performance [49]. Even if solar energy has great potential, there are many problems with its application as the main source of energy in industry. One of these obstacles is the lack of thermal conversion devices, which have specific parameters for industrial application. In a study by Fernabdez-Garcia, numerical simulation was used for designing such devices [50].

The publication by Jokar is focused on studying the cement industry and its impact on CO2 pollution, focusing on how more effective methods in processing can help ensure the cement industry is more sustainable in terms of alternative material usage and reduction of pollution. Simulation carried out by the authors was used to indicate how CO2 emissions and economical aspects are affected by sustainable decisions [51]. Another publication [52], focused on the usage of alternative sources of energy, namely jet fuel production, was published by Shen. The study in [53] focused on feedstock lignin and cellulosic ethanol. Simulation in this particular publication was conducted via the Aspen Plus simulation tool. In terms of alternative fuels, the publication by Li presents another feedstock opportunity for producing sustainable fuel. In their study, Monte Carlo simulation is used [54]. The review on biomass as a renewable source of energy focused on the biomass supply chain [55]. Another industry affected by sustainable goals is the shipping industry; in the publication by Trivyza, simulation is used for ship energy systems [56]. Another alternative source of energy, namely natural gas hydrate, was more or less successfully tested. One study focused on the exploitation of natural gas hydrate; the investigated methods were thermal simulation and numerical simulation [57]. In another example, natural gas from shale was tested by simulation [58].

3.3.2. Building/Construction

Sustainability has gained much attention in the building and construction sectors. Concerning the building and construction industry, two of the methods that were adopted in various publications were Building Information Modeling [40,42,59,60,61,62], with its model-based methods for studying construction through the whole life cycle, and Building Energy Modeling [63,64,65], bringing opportunities to study construction energy consumption. These models present opportunities to study and analyze construction and the processes that take place [66,67,68]. In terms of sustainability, it is necessary to look at ways to make the building industry greener in terms of the analysis of existing buildings and possibilities to make them more energy efficient but also regarding new ways to build and which materials are more fitting for sustainability demands [69,70].

3.3.3. Manufacturing and Supply Chain

One of the greatest impacts on the sustainability aspect is undoubtedly manufacturing and the processes connected with it. Therefore, there is a significant demand for solutions to tackle these challenges. Even manufacturing industries themselves are interested in making their systems more sustainable, at least from an economic standpoint. This trend can be noticed in government strategies such as Industry 4.0, Industry 5.0, and Made In China 2025, which focus on processes related to industry, with sustainability being a key topic in these concepts [71,72,73,74,75,76,77].

For sustainable manufacturing, it is crucial to examine all levels and processes connected to manufacturing systems. A new perspective on manufacturing sustainability has introduced strategies such as trade-in programs [78], where old products are exchanged for new ones. In this situation, determining the value of the new product is difficult due to the varying condition of the returned product. Simulation proves to be a helpful tool in achieving economic sustainability in such scenarios.

Based on concrete literature, simulations could bring great advantages in designing sustainable manufacturing systems [79]. In many aspects of manufacturing, such as people management, supply chain, and employee management, studies have shown that simulation can be beneficial [80]. For instance, a study by Rehman [81] focuses on the implementation of green manufacturing for organizational performance, for which artificial neural network simulation is utilized. Several publications are based on the implementation of simulation in terms of energy modeling and resource utilization [82,83,84,85] In terms of sustainability for workers, 3D modeling and simulation are used; for example, one publication used simulation to set parameters in Delmia Robotics [86] to optimize energy consumption.

A critical component of manufacturing is the supply chain. Numerous studies are dedicated to examining the supply chain through simulation methods across various branches of manufacturing. There is a significant focus on supply chain studies within the food industry [87]. For example, Kamble’s [88] paper utilizes a digital twin for studying the supply chain, which is a simulation-based model of the physical world. Similar studies support the use of simulation in optimizing supply chains, which can help minimize waste, energy consumption, and carbon emissions, as well as evaluate supply chain strategies for more sustainable decision making.

3.3.4. Livestock, Agriculture, and Food Industry

In this section, utilization of simulation is presented in the livestock, agriculture, and food industry. In the context of beef cattle production [89,90], simulation was used to quantify greenhouse gas emissions, fossil energy use, water consumption, and nitrogen loss. Similarly, in the production of aged red wine, a Monte Carlo simulation was employed to address parameter uncertainty, providing confidence intervals for environmental impacts [91]. Additionally, simulation techniques were utilized to analyze land use [92] and food security scenarios [93], using the GlobAgri-AgT model. Studies explored supply chain configurations [44,46,94] and food packaging solutions using mathematical simulation and modeling approaches [41].

3.4. Identification of the Simulation Methods

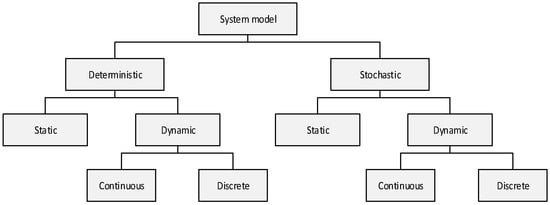

Simulation methods are modeling approaches that are commonly used for analyzing and optimizing complex systems in operations research. Simulation modeling is frequently defined as the process of creating and experimenting with a computerized mathematical model of physical systems [95]. Simulation methods can be categorized using the taxonomy system model shown in Figure 5.

Figure 5.

Taxonomy system model (adapted from [96]).

This categorization corresponds to mathematical models that are broadly divided into deterministic and mathematical approaches. Further, in line with RQ2, it is possible to identify actual simulation methods from the above-mentioned literature sources [97]. The simulation methods that are mostly used for solving sustainable issues in the selected industrial field are presented in Table 8.

Table 8.

The simulation tools used in sustainability.

According to Kelton and Law [96], the most commonly used type of simulation models is the stochastic-dynamic one. The results obtained showed that this type of simulation model is included in 22 publications of the 34 literature sources. Moreover, this table also provides examples of simulation tools used in the articles. Among them, the most frequently used is Building Information Modeling software. This simulation tool is mostly used in building and construction areas to represent the physical and functional aspects of a facility in a digital format. One of the most interesting software programs, which deals specifically with sustainability and the circular economy, is Aspen Plus.

4. Results and Discussion

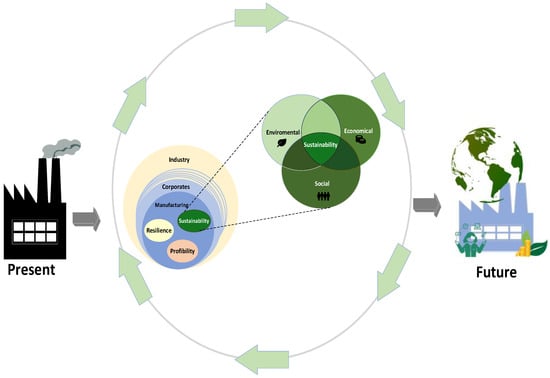

The presented literature review shows the possibility of utilizing simulation in industrial practice. Simulation, as one of the optimization tools, can bring great opportunities for studying and decision making in terms of the sustainability issues that managers face. The results of the presented bibliometric analysis show that interest in this topic is increasing. This can be seen, for example, in the number of nationalities of the scholars involved in this research. Furthermore, there are efforts to address this issue globally. This demonstrates collaborations on various publications involving authors from countries like China, England, Canada, and others. The study then presents a more in-depth analysis of selected papers. From the mentioned analysis, it is valid to declare that simulation has found utilization in creating a more sustainable environment in the industry. By this statement, the first research question is answered; the utilization of simulation in various industries is presented in Section 3.3. As for the second research question, the classification of system models is provided in Section 3.4. Along with this classification, the most-used simulation methods for solving sustainability issues were identified. Moreover, the frequently used system models applied in the simulations were selected according to the taxonomy from Figure 5. From the viewpoint of uncertainty, stochastic models are more often used than deterministic ones, dynamic models prevail over static ones, and discrete models are more common than continuous ones. In addition, the typical simulation software brands for the given purpose were determined from the pertinent publications; these are Building Information Modeling (BIM) and AspenPlus. These simulation tools are in most cases used as a supporting tool in decision making by creating various scenarios and possibilities to achieve the best results. To make the industry sectors sustainable, it is important to achieve accomplishment in three aspects: environmental, economic, and social sustainability. To achieve this kind of implementation in terms of sustainable industry and a sustainable world, the circular economy is viewed as a promising notion. Conceptualization of this approach in relation to sustainable industrial development is outlined in graphic form in Figure 6.

Figure 6.

Circular economy as a crucial element of sustainable industrial development.

The concept of circular economy is frequently linked with sustainable manufacturing; both of these concepts highlight the importance of implementing green thinking into industrial sectors in a global perspective. As mentioned in previous sections, the survival of a company can be built solely on sustainable principles. Based on the literature review, it can be stated that simulation can be considered as a valuable tool for sustainable industrial development.

5. Conclusions

It is an indisputable fact that sustainability is a prominent topic not just in the industrial sector but also in every aspect of life. Technological progress brings many opportunities to solve problems in more sophisticated and accurate way. Simulation clearly contributes to the current methods of achieving this effect. It is necessary to say that sustainable production is a key element to achieving competitiveness in the long run. This movement is supported by concepts like Industry 4.0, Industry 5.0, and Made in China 2025, where sustainability is one of the main pillars. Based on research in the literature, the potential of utilization of simulation for sustainability questions is considerable, but there is also great room for improvement in designing new and improving existing simulation methods and tools. With regards to future work and possible improvements in the utilization of simulations for a more sustainable industry, it is necessary to implement sustainability modules into simulation tools for easier implementation of simulations for sustainable industrial development. Also, there appears to be a need for more simulation tools regarding social and employee sustainability.

Author Contributions

Conceptualization, J.N. and V.M.; methodology, J.N. and V.M.; software, J.N.; validation, J.N. and V.M.; formal analysis, J.N. and V.M.; investigation, J.N. and V.M.; writing—original draft preparation, J.N.; writing—review and editing, J.N. and V.M.; visualization, J.N. and V.M.; supervision, V.M.; funding acquisition, V.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the KEGA project No. 044TUKE-4/2023 granted by the Ministry of Education of the Slovak Republic and by the project SME 5.0 with funding received from the European Union’s research and innovation program under the Marie Skłodowska-Curie grant agreement No. 101086487.

Data Availability Statement

All data are contained within the paper.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Herrmann, C.; Schmidt, C.; Kurle, D.; Blume, S.; Thiede, S. Sustainability in manufacturing and factories of the future. Int. J. Precis. Eng. Manuf.-Green Technol. 2014, 1, 283–292. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H.D. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and smart manufacturing: An integrated approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef]

- Mondini, G. Sustainability assessment: From Brundtland report to sustainable development goals. Valori Evalutazioni 2019, 23, 129–137. [Google Scholar]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Neri, A.; Cagno, E.; Di Sebastiano, G.; Trianni, A. Industrial sustainability: Modelling drivers and mechanisms with barriers. J. Clean. Prod. 2018, 194, 452–472. [Google Scholar] [CrossRef]

- Zhivkova, S. Sustainability and the reasons for its adoption in the companies. Proc. CBU Econ. Bus. 2022, 3, 75–80. [Google Scholar] [CrossRef]

- Duić, N.; Urbaniec, K.; Huisingh, D. Components and structures of the pillars of sustainability. J. Clean. Prod. 2015, 88, 1–12. [Google Scholar] [CrossRef]

- Modrak, V.; Soltysova, Z.; Modrak, J.; Behunova, A. Reducing impact of negative complexity on sustainability of mass customization. Sustainability 2017, 9, 2014. [Google Scholar] [CrossRef]

- United Nations. General Assembly Resolution A/RES/70/1. Transforming Our World, the 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/2030agenda (accessed on 8 April 2024).

- Eurostat. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Final_energy_consumption_in_industry_-_detailed_statistics (accessed on 8 April 2024).

- Ball, P.D.; Evans, S.; Levers, A.; Ellison, D. Zero carbon manufacturing facility—Towards integrating material, energy, and waste process flows. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 1085–1096. [Google Scholar] [CrossRef]

- Billatos, S. Green Technology and Design for the Environment; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Shabbir, M.S.; Wisdom, O. The relationship between corporate social responsibility, environmental investments and financial performance: Evidence from manufacturing companies. Environ. Sci. Pollut. Res. 2020, 27, 39946–39957. [Google Scholar] [CrossRef] [PubMed]

- Kitsios, F.; Kamariotou, M.; Talias, M.A. Corporate sustainability strategies and decision support methods: A bibliometric analysis. Sustainability 2020, 12, 521. [Google Scholar] [CrossRef]

- Modrak, V.; Dima, I.C.; Man, M. Methodical approach to corporate sustainability planning. Pol. J. Manag. Stud. 2011, 3, 156–166. [Google Scholar]

- Reuter, M.A.; van Schaik, A.; Gutzmer, J.; Bartie, N.; Abadías-Llamas, A. Challenges of the circular economy: A material, metallurgical, and product design perspective. Annu. Rev. Mater. Res. 2019, 49, 253–274. [Google Scholar] [CrossRef]

- Soltysova, Z.; Modrak, V. Challenges of the sharing economy for SMEs: A literature review. Sustainability 2020, 12, 6504. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ghaithan, A.M.; Alshammakhi, Y.; Mohammed, A.; Mazher, K.M. Integrated impact of circular economy, industry 4.0, and lean manufacturing on sustainability performance of manufacturing firms. Int. J. Environ. Res. Public Health 2023, 20, 5119. [Google Scholar] [CrossRef]

- Salibi, J.G.D.O.R.; Rodrigues, A.L.D.S.M.; Lima, P.A.B.; de Souza, F.B. Lean and the circular economy: A systematic literature review. J. Lean Syst. 2022, 7, 23–46. [Google Scholar]

- Banks, J. Discrete Event System Simulation; Pearson Education India: Bangalore, India, 2005. [Google Scholar]

- Ingalls, R.G. Introduction to simulation. In Proceedings of the 2011 Winter Simulation Conference, Phoenix, AZ, USA, 11–14 December 2011; pp. 1374–1388. [Google Scholar]

- Banks, J. Introduction to simulation. In Proceedings of the 2000 Winter Simulation Conference Proceedings, Orlando, FL, USA, 10–13 December 2000; Volume 1, pp. 9–16. [Google Scholar]

- Carson, J.S. Introduction to modeling and simulation. In Proceedings of the Winter Simulation Conference, Orlando, FL, USA, 4 December 2005; p. 8. [Google Scholar]

- Robinson, S. Simulation: The Practice of Model Development and Use; Bloomsbury Publishing: London, UK, 2014. [Google Scholar]

- Maria, A. Introduction to modeling and simulation. In Proceedings of the 29th Conference on Winter Simulation, Atlanta, GA,, USA, 1–7 December 1997; pp. 7–13. [Google Scholar]

- De Paula Ferreira, W.; Armellini, F.; De Santa-Eulalia, L.A. Simulation in industry 4.0: A state-of-the-art review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Khan, A.A.; Abonyi, J. Simulation of sustainable manufacturing solutions: Tools for enabling circular economy. Sustainability 2022, 14, 9796. [Google Scholar] [CrossRef]

- Gunal, M.M. Simulation for Industry 4.0. Past, Present, and Future, 1st ed.; Springer Nature: Cham, Switzerland, 2019; pp. 19–36. [Google Scholar]

- Parv, A.L.; Deaky, B.A.; Stasiak-Betlejewska, R. Sustainable manufacturing systems–a simulation model. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Brasov, Romania, 7–10 October 2021; Volume 1009, p. 012045. [Google Scholar]

- Rocholl, J.; Mönch, L. Simulation-based performance assessment of sustainable manufacturing decisions. In Proceedings of the 2021 Winter Simulation Conference, Phoenix, AZ, USA, 12–15 December 2021; pp. 1–12. [Google Scholar]

- Elkington, J.; Rowlands, I.H. Cannibals with forks: The triple bottom line of 21st century business. Altern. J. 1999, 25, 42. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Moral-Muñoz, J.A.; Herrera-Viedma, E.; Santisteban-Espejo, A.; Cobo, M.J. Software tools for conducting bibliometric analysis in science: An up-to-date review. Prof. Inf. Inf. Prof. 2020, 29. [Google Scholar] [CrossRef]

- Chen, C. Science mapping: A systematic review of the literature. J. Data Inf. Sci. 2017, 2, 1–40. [Google Scholar] [CrossRef]

- Adil, K.; Belmabkhout, Y.; Pillai, R.S.; Cadiau, A.; Bhatt, P.M.; Assen, A.H.; Eddaoudi, M. Gas/vapour separation using ultra-microporous metal–organic frameworks: Insights into the structure/separation relationship. Chem. Soc. Rev. 2017, 46, 3402–3430. [Google Scholar] [CrossRef] [PubMed]

- Nunes, S.P.; Culfaz-Emecen, P.Z.; Ramon, G.Z.; Visser, T.; Koops, G.H.; Jin, W.; Ulbricht, M. Thinking the future of membranes: Perspectives for advanced and new membrane materials and manufacturing processes. J. Membr. Sci. 2020, 598, 117761. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, Z.; Chang, R.; Li, Y. Building Information Modeling (BIM) for green buildings: A critical review and future directions. Autom. Constr. 2017, 83, 134–148. [Google Scholar] [CrossRef]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The next generation of sustainable food packaging to preserve our environment in a circular economy context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef] [PubMed]

- Abanda, F.H.; BYERS, L. An investigation of the impact of building orientation on energy consumption in a domestic building using emerging BIM (Building Information Modelling). Energy 2016, 97, 517–527. [Google Scholar] [CrossRef]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Impacts of Industry 4.0 technologies on Lean principles. Int. J. Prod. Res. 2020, 58, 1644–1661. [Google Scholar] [CrossRef]

- Chowdhury, M.T.; Sarkar, A.; Paul, S.K.; Moktadir, M.A. A case study on strategies to deal with the impacts of COVID-19 pandemic in the food and beverage industry. Oper. Manag. Res. 2022, 15, 166–178. [Google Scholar] [CrossRef]

- Goodarzian, F.; Taleizadeh, A.A.; Ghasemi, P.; Abraham, A. An integrated sustainable medical supply chain network during COVID-19. Eng. Appl. Artif. Intell. 2021, 100, 104188. [Google Scholar] [CrossRef] [PubMed]

- Jouzdani, J.; Govindan, K. On the sustainable perishable food supply chain network design: A dairy products case to achieve sustainable development goals. J. Clean. Prod. 2021, 278, 123060. [Google Scholar] [CrossRef]

- Cossu, M.; Cossu, A.; Deligios, P.A.; Ledda, L.; Li, Z.; Fatnassi, H.; Poncet, C.; Yano, A. Assessment and comparison of the solar radiation distribution inside the main commercial photovoltaic greenhouse types in Europe. Renew. Sustain. Energy Rev. 2018, 94, 822–834. [Google Scholar] [CrossRef]

- Lv, D.; Shi, R.; Chen, Y.; Wu, Y.; Wu, H.; Xi, H.; Xia, Q.; Li, Z. Selective adsorption of ethane over ethylene in PCN-245: Impacts of interpenetrated adsorbent. ACS Appl. Mater. Interfaces 2018, 10, 8366–8373. [Google Scholar] [CrossRef]

- YANG, R.J. Overcoming technical barriers and risks in the application of building integrated photovoltaics (BIPV): Hardware and software strategies. Autom. Constr. 2015, 51, 92–102. [Google Scholar] [CrossRef]

- Fernández-García, A.; Rojas, E.; Pérez, M.; Silva, R.; Hernández-Escobedo, Q.; Manzano-Agugliaro, F. A parabolic-trough collector for cleaner industrial process heat. J. Clean. Prod. 2015, 89, 272–285. [Google Scholar] [CrossRef]

- Jokar, Z.; Mokhtar, A. Policy making in the cement industry for CO2 mitigation on the pathway of sustainable development-A system dynamics approach. J. Clean. Prod. 2018, 201, 142–155. [Google Scholar] [CrossRef]

- Shen, R.; Tao, L.; Yang, B. Techno-economic analysis of jet-fuel production from biorefinery waste lignin. Biofuels Bioprod. Biorefining 2019, 13, 486–501. [Google Scholar] [CrossRef]

- Morales, M.; Arvesen, A.; Cherubini, F. Integrated process simulation for bioethanol production: Effects of varying lignocellulosic feedstocks on technical performance. Bioresour. Technol. 2021, 328, 124833. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Bhagwat, S.S.; Cortés-Peña, Y.R.; Ki, D.; Rao, C.V.; Jin, Y.-S.; Guest, J.S. Sustainable lactic acid production from lignocellulosic biomass. ACS Sustain. Chem. Eng. 2021, 9, 1341–1351. [Google Scholar] [CrossRef]

- Zahraee, S.M.; Shiwakoti, N.; Stasinopoulos, P. Biomass supply chain environmental and socio-economic analysis: 40-Years comprehensive review of methods, decision issues, sustainability challenges, and the way forward. Biomass Bioenergy 2020, 142, 105777. [Google Scholar] [CrossRef]

- Trivyza, N.L.; Rentizelas, A.; Theotokatos, G. A novel multi-objective decision support method for ship energy systems synthesis to enhance sustainability. Energy Convers. Manag. 2018, 168, 128–149. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Y.; Zhang, H.; Xiao, B.; Guo, X.; Wei, R.; Xu, L.; Sun, L.; Yu, B.; Leng, S.; et al. The status of exploitation techniques of natural gas hydrate. Chin. J. Chem. Eng. 2019, 27, 2133–2147. [Google Scholar] [CrossRef]

- Ehlinger, V.M.; Gabriel, K.J.; Noureldin, M.M.B.; El-Halwagi, M.M. Process design and integration of shale gas to methanol. ACS Sustain. Chem. Eng. 2014, 2, 30–37. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Vandenbergh, T.; Pyl, L. BIM-based life cycle assessment and life cycle costing of an office building in Western Europe. Build. Environ. 2020, 169, 106568. [Google Scholar] [CrossRef]

- Muller, M.F.; Esmanioto, F.; Huber, N.; Loures, E.R.; Canciglieri, O. A systematic literature review of interoperability in the green Building Information Modeling lifecycle. J. Clean. Prod. 2019, 223, 397–412. [Google Scholar] [CrossRef]

- Yin, S.; Li, B.; Xing, Z. The governance mechanism of the building material industry (BMI) in transformation to green BMI: The perspective of green building. Sci. Total Environ. 2019, 677, 19–33. [Google Scholar] [CrossRef]

- Jalaei, F.; Jalaei, F.; Mohammadi, S. An integrated BIM-LEED application to automate sustainable design assessment framework at the conceptual stage of building projects. Sustain. Cities Soc. 2020, 53, 101979. [Google Scholar] [CrossRef]

- Jin, R.; Zhong, B.; Ma, L.; Hashemi, A.; Ding, L. Integrating BIM with building performance analysis in project life-cycle. Autom. Constr. 2019, 106, 102861. [Google Scholar] [CrossRef]

- Pezeshki, Z.; Soleimani, A.; Darabi, A. Application of BEM and using BIM database for BEM: A review. J. Build. Eng. 2019, 23, 1–17. [Google Scholar] [CrossRef]

- Chen, Y.; Tong, Z.; Malkawi, A. Investigating natural ventilation potentials across the globe: Regional and climatic variations. Build. Environ. 2017, 122, 386–396. [Google Scholar] [CrossRef]

- Aste, N.; Manfren, M.; Marenzi, G. Building Automation and Control Systems and performance optimization: A framework for analysis. Renew. Sustain. Energy Rev. 2017, 75, 313–330. [Google Scholar] [CrossRef]

- Dong, L.; Liang, H.; Zhang, L.; Liu, Z.; Hu, M. Highlighting regional eco-industrial development: Life cycle benefits of an urban industrial symbiosis and implications in China. Ecol. Model. 2017, 361, 164–176. [Google Scholar] [CrossRef]

- Gan, V.J.; Lo, I.M.; Ma, J.; Tse, K.T.; Cheng, J.C.; Chan, C.M. Simulation optimization towards energy efficient green buildings: Current status and future trends. J. Clean. Prod. 2020, 254, 120012. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Xu, N. Digital twin for sustainability evaluation of railway station buildings. Front. Built Environ. 2018, 4, 77. [Google Scholar] [CrossRef]

- Riley, B. The state of the art of living walls: Lessons learned. Build. Environ. 2017, 114, 219–232. [Google Scholar] [CrossRef]

- Marsono, A.K.B.; Balasbaneh, A.T. Combinations of building construction material for residential building for the global warming mitigation for Malaysia. Constr. Build. Mater. 2015, 85, 100–108. [Google Scholar] [CrossRef]

- Giret, A.; Trentesaux, D.; Prabhu, V. Sustainability in manufacturing operations scheduling: A state of the art review. J. Manuf. Syst. 2015, 37, 126–140. [Google Scholar] [CrossRef]

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. Chang. 2018, 135, 66–74. [Google Scholar] [CrossRef]

- Takakuwa, S.; Veza, I.; Celar, S. “Industry 4.0” in Europe and East Asia. Ann. DAAAM Proc. 2019, 29, 61–69. [Google Scholar]

- Maddikunta, P.K.R.; Pham, Q.V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2020, 26, 100257. [Google Scholar] [CrossRef]

- Wu, Y.A.; Ng, A.W.; Yu, Z.; Huang, J.; Meng, K.; Dong, Z. A review of evolutionary policy incentives for sustainable development of electric vehicles in China: Strategic implications. Energy Policy 2021, 148, 111983. [Google Scholar] [CrossRef]

- Modrak, V.; Soltysova, Z.; Onofrejova, D. Complexity assessment of assembly supply chains from the sustainability viewpoint. Sustainability 2019, 11, 7156. [Google Scholar] [CrossRef]

- Tozanli, Ö.; Kongar, E.; Gupta, S.M. Trade-in-to-upgrade as a marketing strategy in disassembly-to-order systems at the edge of blockchain technology. Int. J. Prod. Res. 2020, 58, 7183–7200. [Google Scholar] [CrossRef]

- Sathish, T. Modeling of Support Vector Mechanism for Green Manufacturability Quantification of Production. In Proceedings of the Advances in Manufacturing Technology: Select Proceedings of ICAMT 2018; Springer: Singapore, 2019; pp. 391–397. [Google Scholar]

- Lugert, A.; Batz, A.; Winkler, H. Empirical assessment of the future adequacy of value stream mapping in manufacturing industries. J. Manuf. Technol. Manag. 2018, 29, 886–906. [Google Scholar] [CrossRef]

- Rehman, M.A.; Seth, D.; Shrivastava, R.L. Impact of green manufacturing practices on organisational performance in Indian context: An empirical study. J. Clean. Prod. 2016, 137, 427–448. [Google Scholar] [CrossRef]

- Garwood, T.L.; Hughes, B.R.; Oates, M.R.; O’Connor, D.; Hughes, R. A review of energy simulation tools for the manufacturing sector. Renew. Sustain. Energy Rev. 2018, 81, 895–911. [Google Scholar] [CrossRef]

- May, G.; Stahl, B.; Taisch, M. Energy management in manufacturing: Toward eco-factories of the future–A focus group study. Appl. Energy 2016, 164, 628–638. [Google Scholar] [CrossRef]

- Giampieri, A.; Ling-Chin, J.; Ma, Z.; Smallbone, A.; Roskilly, A.P. A review of the current automotive manufacturing practice from an energy perspective. Appl. Energy 2020, 261, 114074. [Google Scholar] [CrossRef]

- Meike, D.; Pellicciari, M.; Berselli, G. Energy efficient use of multirobot production lines in the automotive industry: Detailed system modeling and optimization. IEEE Trans. Autom. Sci. Eng. 2013, 11, 798–809. [Google Scholar] [CrossRef]

- Gadaleta, M.; Pellicciari, M.; Berselli, G. Optimization of the energy consumption of industrial robots for automatic code generation. Robot. Comput.-Integr. Manuf. 2019, 57, 452–464. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ekinci, E.; Mangla, S.K.; Sezer, M.D.; Kayikci, Y. Performance evaluation of reverse logistics in food supply chains in a circular economy using system dynamics. Bus. Strategy Environ. 2021, 30, 71–91. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital twin for sustainable manufacturing supply chains: Current trends, future perspectives, and an implementation framework. Technol. Forecast. Soc. Change 2022, 176, 121448. [Google Scholar] [CrossRef]

- Rotz, C.A.; Asem-Hiablie, S.; Place, S.; Thoma, G. Environmental footprints of beef cattle production in the United States. Agric. Syst. 2019, 169, 1–13. [Google Scholar] [CrossRef]

- Asem-Hiablie, S.; Battagliese, T.; Stackhouse-Lawson, K.R.; Rotz, C.A. A life cycle assessment of the environmental impacts of a beef system in the USA. Int. J. Life Cycle Assess. 2019, 24, 441–455. [Google Scholar] [CrossRef]

- Meneses, M.; Torres, C.M.; Castells, F. Sensitivity analysis in a life cycle assessment of an aged red wine production from Catalonia, Spain. Sci. Total Environ. 2016, 562, 571–579. [Google Scholar] [CrossRef]

- Niswonger, R.G.; Morway, E.D.; Triana, E.; Huntington, J.L. Managed aquifer recharge through off-season irrigation in agricultural regions. Water Resour. Res. 2017, 53, 6970–6992. [Google Scholar] [CrossRef]

- Mora, O.; Le Mouël, C.; de Lattre-Gasquet, M.; Donnars, C.; Dumas, P.; Réchauchère, O.; Brunelle, T.; Manceron, S.; Marajo-Petitzon, E.; Moreau, C.; et al. Exploring the future of land use and food security: A new set of global scenarios. PLoS ONE 2020, 15, e0235597. [Google Scholar] [CrossRef]

- Jonkman, J.; Barbosa-Póvoa, A.P.; Bloemhof, J.M. Integrating harvesting decisions in the design of agro-food supply chains. Eur. J. Oper. Res. 2019, 276, 247–258. [Google Scholar] [CrossRef]

- Chung, C.A. Simulation Modeling Handbook: A Practical Approach; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Kelton, W.D.; Law, A.M. Simulation Modeling and Analysis; McGraw Hill: Boston, MA, USA, 2000. [Google Scholar]

- Soleymani Shishvan, M.; Benndorf, J. Operational decision support for material management in continuous mining systems: From simulation concept to practical full-scale implementations. Minerals 2017, 7, 116. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).