1. Introduction

Due to the overwhelming growth of international trade in recent years, international freight transportation develops rapidly. Compared to unimodal freight transportation (e.g., railway, road, and maritime transportation), intermodal freight transportation is more competitive and advantageous with respect to security, flexibility, and productivity [

1]. A significant amount of containers being transshipped are empty. As a result, intermodal freight transportation has been playing a more and more important role in global freight transportation [

2]. Owing to different economic needs in different regions, the volumes of import and export trade in many regions are also quite different, which leads to the imbalance of global trade. For instance, the container flow from Eastern Asia to North America reaches a volume of 17.9 million TEUs, while the volume of the opposite direction (i.e., from North to Eastern Asia) was only 8.2 million TEUs, in 2017 [

3]. Consequently, intermodal freight industries have to reposition empty containers, from the regions with empty container accumulation to the regions with empty container shortage. However, in practice, the surplus empty containers sometimes are not sufficient to fulfil the customer’s demand. Thus, additional empty containers need to be leased from leasing companies, which is a more responsive way compared with repositioning. As a result, intermodal freight industries should make a highly efficient operation plan with minimal expenditure, which allocates surplus empty containers from supply regions to demand regions, and determines the number of leased empty containers in demand regions.

In addition to minimising the operational cost, traffic pollution should be considered [

4]. Recently, transportation growth has become one of main factors contributing to the increase of CO

2 emissions [

5]. Take maritime transportation for example, in 2012, total shipping CO

2 emissions were estimated at 938 million tons accounting for 2.6% of global CO

2 emissions. Among this, international shipping emission was approximately 796 million tons CO

2 [

6]. Therefore, both operation cost and CO

2 emissions should be considered simultaneously in the process of repositioning empty containers.

This paper focuses on the empty container repositioning problem (ECRP), with the consideration of leasing decisions and CO2 emissions in an intermodal sea–rail network. The ECRP is defined as to determine how many empty containers should be repositioned, which route should be used to transport empty containers, as well as where and how many empty containers should be leased in order to satisfy the demands.

As an intrinsic issue of container management and intermodal transportation, ECRP has received more attention in recent years (e.g., [

7,

8,

9]). As a consequence, there is substantial literature on ECRP. Some of the studies provide concise and precise updates on the latest progress made in the area of ECRP research from different perspectives (e.g., [

10,

11]). Specifically, Braekers et al. [

10] conducted a comprehensive overview of ECRP at a regional level from three different planning levels, i.e., strategic level, tactical level, and operational level. Song and Dong [

11] provided a detailed literature review focusing on the ECRP models for different transportation networks, and sorted them into two categories: network flow models and inventory control-based models.

Table 1 lists the key references on ECRP, in terms of transportation model, stochasticity, and CO

2 emissions.

Generally, the literature could be classified into two categories: deterministic ECRP and stochastic ECRP. For deterministic ECRP, in the pioneer study of Florez [

12], a model based on a dynamic transshipment network was established for optimising ECRP, which considered repositioning and leasing empty containers simultaneously. Crainic and Delorme [

13] described ECRP as a multicommodity location–allocation problem with balance requirements, and employed a dual-ascent solution approach to solve it. Song and Carter [

15] considered ECRP from the perspective of ocean carriers, identified critical factors affecting ECRP, and investigated the influence of route coordination and container sharing. Moon et al. [

16] developed a mixed integer programming model for ECRP, incorporating the policies of leasing and purchasing containers to minimise total cost. A hybrid genetic algorithm was employed to solve the proposed model.

Different from the literature above, some papers allow for ECRP with other decision-making problems, e.g., cargo routing problem, service network design problem, and ship deployment problem. For instance, Brouer et al. [

17] addressed the cargo routing problem and ECRP simultaneously, and formulated it as a multi-commodity flow problem with interbalancing constraints, which was solved by the delayed column generation algorithm. The problem was further studied by Song and Dong [

19] on a maritime transportation network with multiple service routes, deployed vessels, and regular voyages. Regarding service network design problem, Shintani et al. [

14] studied the ECRP combined with a container liner service network design, which was formulated as a two-stage problem solved by a heuristic based on genetic algorithm. This problem was later investigated by Meng and Wang [

18], who proposed a mixed integer linear programming model to formulate this problem. In their study, the concept of segment was firstly introduced to facilitate the problem formulation. A realistic case of Asia–Europe–Oceania shipping was carried out to demonstrate the proposed model, and concluded that the total operation cost could be reduced significantly by considering empty container repositioning. The ECRP raised by these two papers is limited to global ocean shipping. By contrast, An et al. [

21] presented the service network design for inland water liner transportation with ECRP. By incorporating the specific features of inland water transportation, a nonlinear mixed integer programming model was constructed, and subsequently solved by a hybrid algorithm integrating genetic algorithm and integer programming method. Furthermore, Song and Dong [

20] proposed a three-stage solution methodology, where the first, second, and third stage were used to deal with the service network design problem, ECRP, and ship deployment problem, respectively.

Compared with the literature about unimodal ECRP, some studies are concerned with the ECRP in an intermodal transportation system. Specifically, Choong et al. [

35] analysed the effect of planning horizon length on mode selection of ECRP for intermodal transportation network, and indicated that the slower and cheaper transportation modes are more encouraged under the condition that the planning horizon is long enough. Meng et al. [

36] developed a linear mixed integer programming model for intermodal liner service network design, which accounted for laden container routing, ECRP, and ship route selection. A combination of intermodal service network design problem and ECRP was studied by Braekers et al. [

37] in a barge hinterland system, and discussed from different perspectives, i.e., the perspective of barge operators and the perspective of shipping lines. In addition to quantitative analysis on ECRP, Kolar et al. [

38] described a research agenda of ECRP based on a qualitative analysis by conducting interviews with representatives of ocean carriers, and indicated some insightful findings.

All the literature mentioned above is studied under deterministic circumstances. However, generally, empty container repositioning is subjected to various stochastic factors in practice. For instance, the number of empty containers available cannot be forecasted precisely, because of stochastic demand and supply. For empty container demand, it is difficult to obtain exact future volume, due to a high dynamic environment and low precision forecast [

2]. Similarly, the accurate future volume of empty container supply is also hard to estimate, due to the uncertain returning time of containers from customers [

22]. Hence, both demand and supply should be described as uncertain parameters when addressing ECRP. To incorporate the stochastic nature of empty container repositioning, many efforts have been made to explore stochastic ECRP models (e.g., [

17,

18,

19,

28,

31,

32,

33,

34]). Crainic et al. [

23] focused on the ECRP that involved stochastic demand and supply modelled as random variables in the context of the land transportation of international maritime shipping. Moreover, Li et al. [

24] addressed the ECRP in one port, where the amounts of import and export containers were treated as independent and identically distributed variables. They extended the results to the long-run average case and the infinite-horizon problem with a discounted factor. This problem was further generalized by Li et al. [

25] to take multi-ports into consideration. The allocation plan of empty containers was derived by using a heuristic algorithm with ε-optimal policies. Lam et al. [

27] presented a dynamic programming model for stochastic ECRP, and introduced an approximate approach based on temporal difference learning. Song and Zhang [

30] constructed a fluid flow model for ECRP concerning stochastic demand, which is simulated as a two-state Markov chain. In order to examine the impact of different stochastic demand patterns on ECRP, Song and Dong [

31] analysed the performances under three types of different demand distributions (i.e., normal distribution, uniform distribution, and exponential distribution). Lee et al. [

32] focused on the joint container fleet sizing problem, and ECRP with the consideration of stochastic demand based on the feedback mechanism of inventory information, while Dong et al. [

33] compared the results of different empty container repositioning policies under uncertain demand.

In addition to stochastic demand and supply, there are some papers concentrating on stochastic capacity. For example, Long et al. [

2] set up a two-stage stochastic programming model involving uncertain demand, supply, ship weight capacity, and ship space capacity. Stage one determined the operation plan for repositioning empty containers with deterministic parameters, while stage two adjusted the decisions derived from stage one based on the probability distribution of random variables. Sample average approximation and progressive hedging strategy were applied to solve this model. A two-stage stochastic network model for dynamic ECRP was established by Cheung and Chen [

22] in an ocean transportation network, to minimise the expected total cost by taking into account stochastic demand, supply, and capacity. Francesco et al. [

29] addressed the ECRP in a maritime transportation system concerning stochastic demand, supply, residual transportation capacity of vessels, and loading and unloading capacity.

Additionally, for unimodal ECRP, Song [

26] examined the ECRP from the perspective of the optimal stationary policy in two-terminal shuttle service system with uncertain demand. By exploring the structural characteristics of objective function, a Markov decision process method was used to obtain the results. Song and Dong [

28] extended this model to the ECRP in a cyclic route under stochastic and dynamic conditions, which analysed the impact of demand patterns, fleet sizes and, in particular, degrees of uncertainty. For stochastic intermodal ECRP, Dong and Song [

39] dealt with the container fleet sizing problem, combined with ECRP involving stochastic demand and inland transportation time, and revealed the relationship between the optimal container fleet size and the inland transportation time. Xie et al. [

40] emphasised the coordination and sharing issue of empty container management with uncertain demand and supply between a liner company and a rail company. The optimal delivery policy, and its change with initial inventory state, were investigated under the centralised model, whereas a bilateral buy-back contract was designed in the decentralised model.

Although the literature on ECRP is substantial and extensive, most literature mainly focuses on the operation cost of repositioning empty containers, rather than environmental performance, e.g., CO

2 emissions. So far, the research on ECRP with CO

2 emissions is still scarce, both practically and theoretically. To the best of our knowledge, only Song and Xu [

41], and Bernat et al. [

34] studied CO

2 emissions whilst repositioning empty containers. Song and Xu [

41] provided an operational activity-based method to calculate CO

2 emissions in relation to ECRP, and revealed the relationship among CO

2 emissions, empty container repositioning policies, and handling capacity. More recently, Bernat et al. [

34] presented new periodic review policies integrating CO

2 emissions, repair option, street-turns, as well as stochastic parameters. A simulation model with metaheuristic approach was then developed to assess the optimality of these policies.

Empty container repositioning is an extremely important issue in the container shipping industry [

11]. A highly efficient repositioning plan can effectively reduce the amount of repositioned and leased empty containers, and shorten the total repositioning distance from the nodes with surplus empty containers to the nodes with deficit empty containers, which leads to a reduction of total repositioning cost for container carriers. However, uncertainty in container shipping may have a negative effect on empty container movements [

15], which causes the inefficiency, and even infeasibility, of the current repositioning plan. Thus, a reliable and robust repositioning plan is required to tackle these unpredictable factors in the container transportation system. At the same time, a well-organised repositioning plan can also reduce fuel consumption, traffic congestion, and emissions, due to the decrease of empty container movements. Accordingly, empty container repositioning not only has an economic impact on container carriers, but also an environmental influence on the sustainable development of containerised transportation.

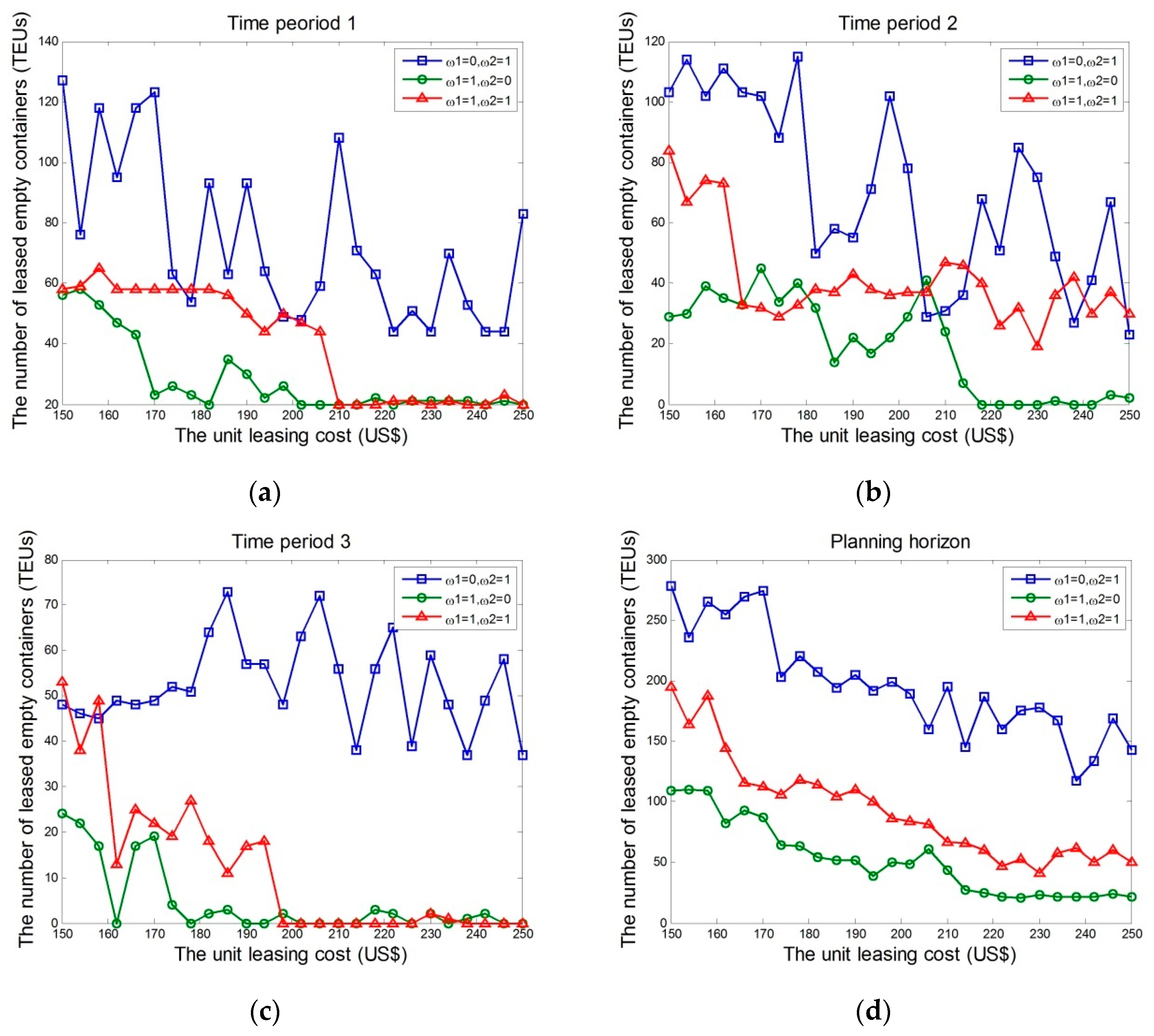

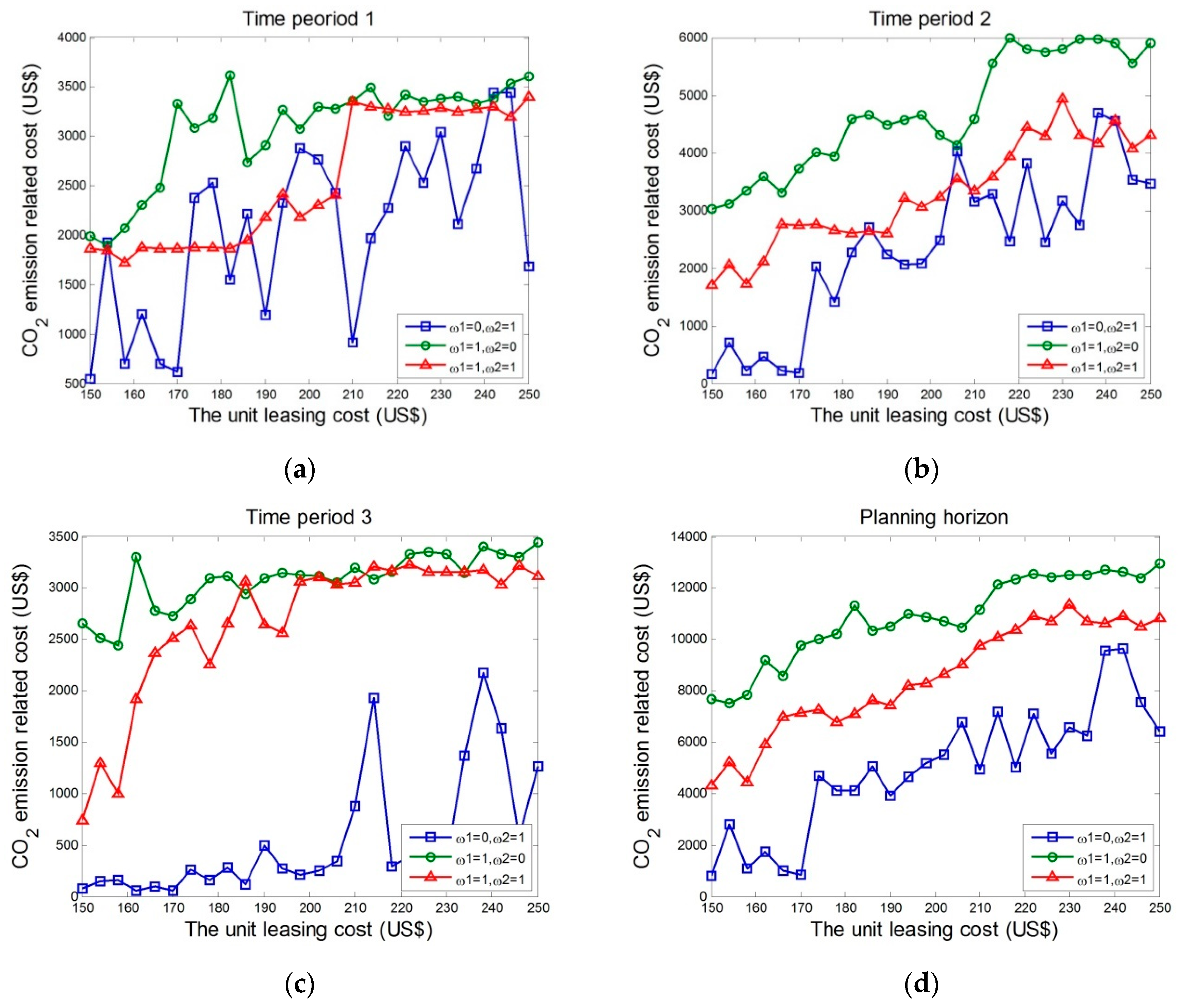

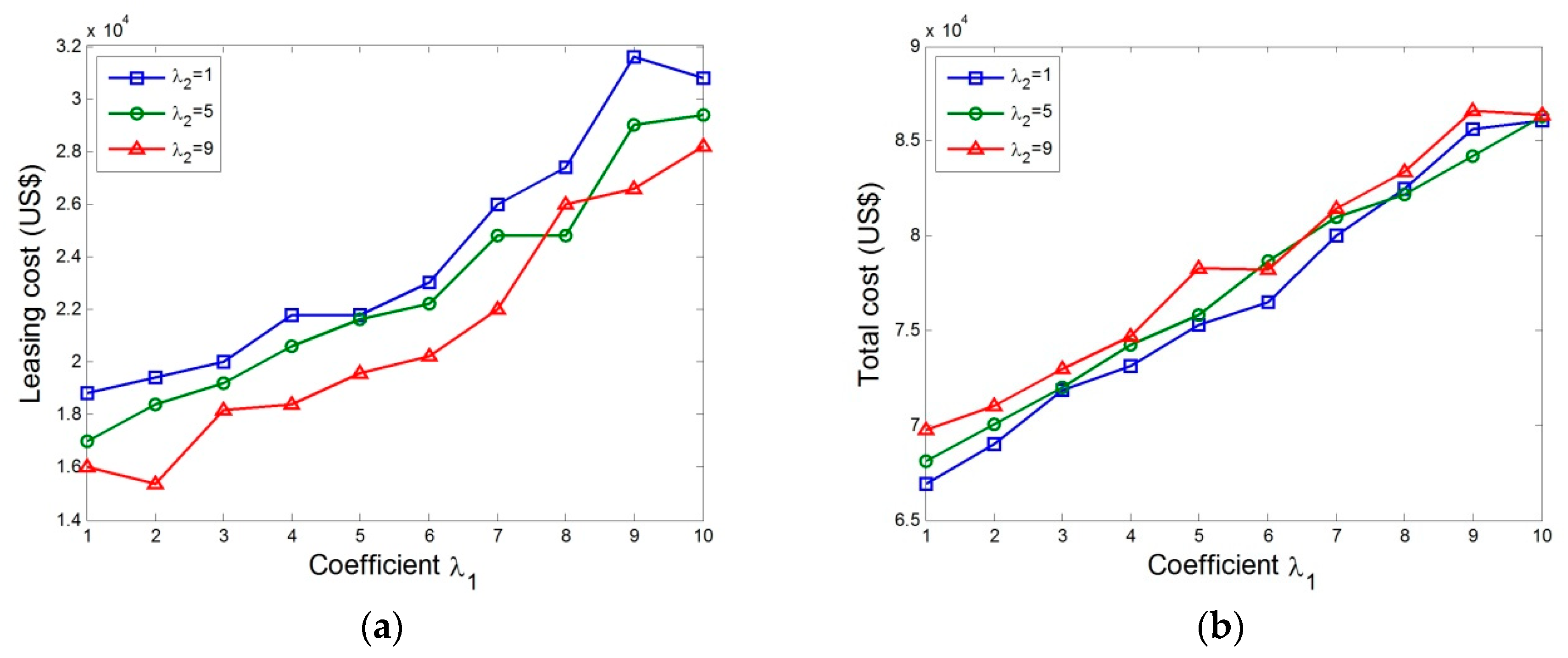

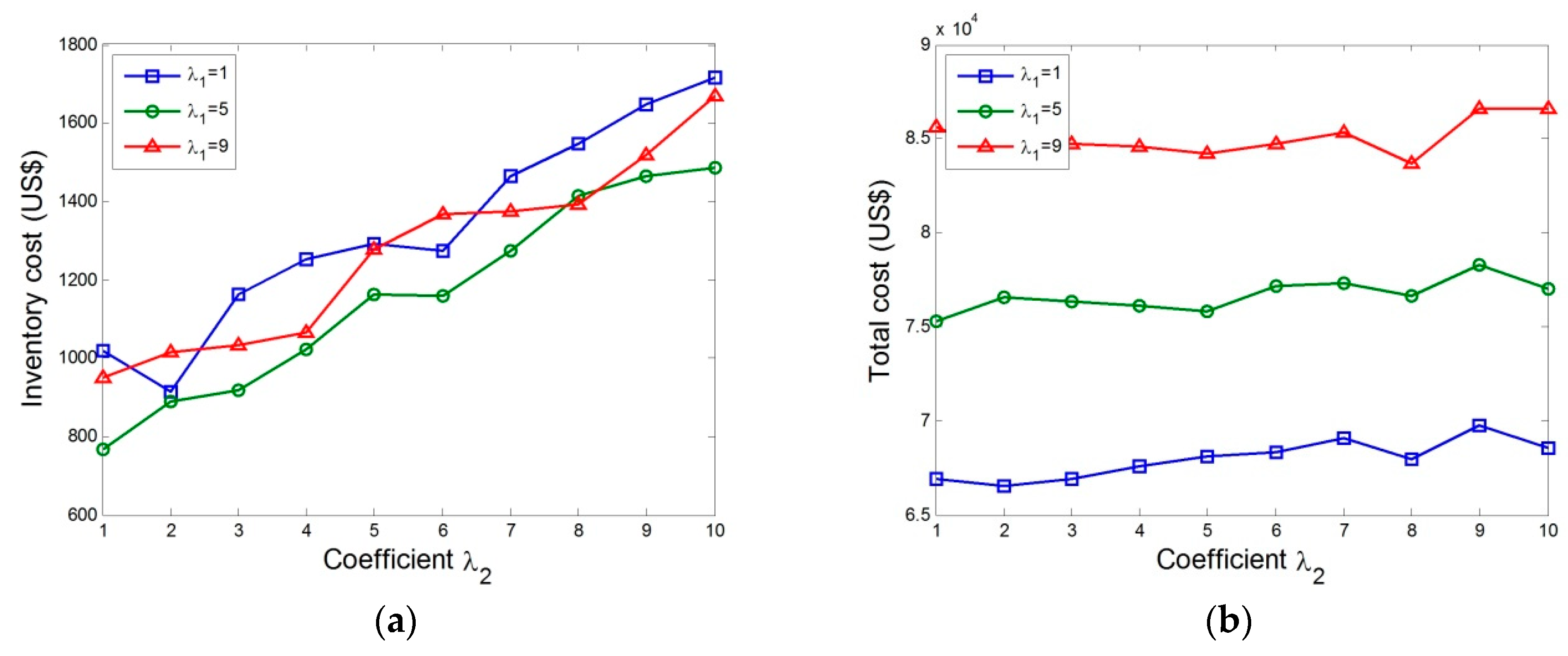

To incorporate environmental and stochastic characteristics of container shipping, this paper proposes a chance-constrained programming model for ECRP in an intermodal transportation system, which allows for, explicitly, CO2 emissions and uncertainty simultaneously. Stochastic demand and supply, in the model, are treated as random variables. The purpose of this paper is to determine how many empty containers should be repositioned, which route should be used to transport empty containers, as well as where and how many empty containers should be leased in order to satisfy the demands, which are referred to as distribution plan, routing plan, and leasing plan, respectively. In addition, we conduct a numerical example to evaluate the results obtained under deterministic and stochastic situations, as well as investigate the impact of model parameters and random variables on the total cost and component costs. The main contributions of this paper are three-fold. First and most significantly, it enriches the literature on ECRP by incorporating CO2 emissions, and stochastic demand and supply. The uncertainty of ECRP facilitates us to construct a chance-constrained programming model, achieving a minimal expected total cost. Second, we use sample average approximation (SAA) to convert this model into its deterministic equivalents, and develop a two-phase tabu search algorithm to solve the associated SAA problem. Third, we examine the effects of unit leasing cost, stochastic demand and supply, as well as weights on costs and CO2 emissions.

The rest of this paper is organised as follows.

Section 2 formulates stochastic ECRP with CO

2 emissions as a chance-constrained programming model.

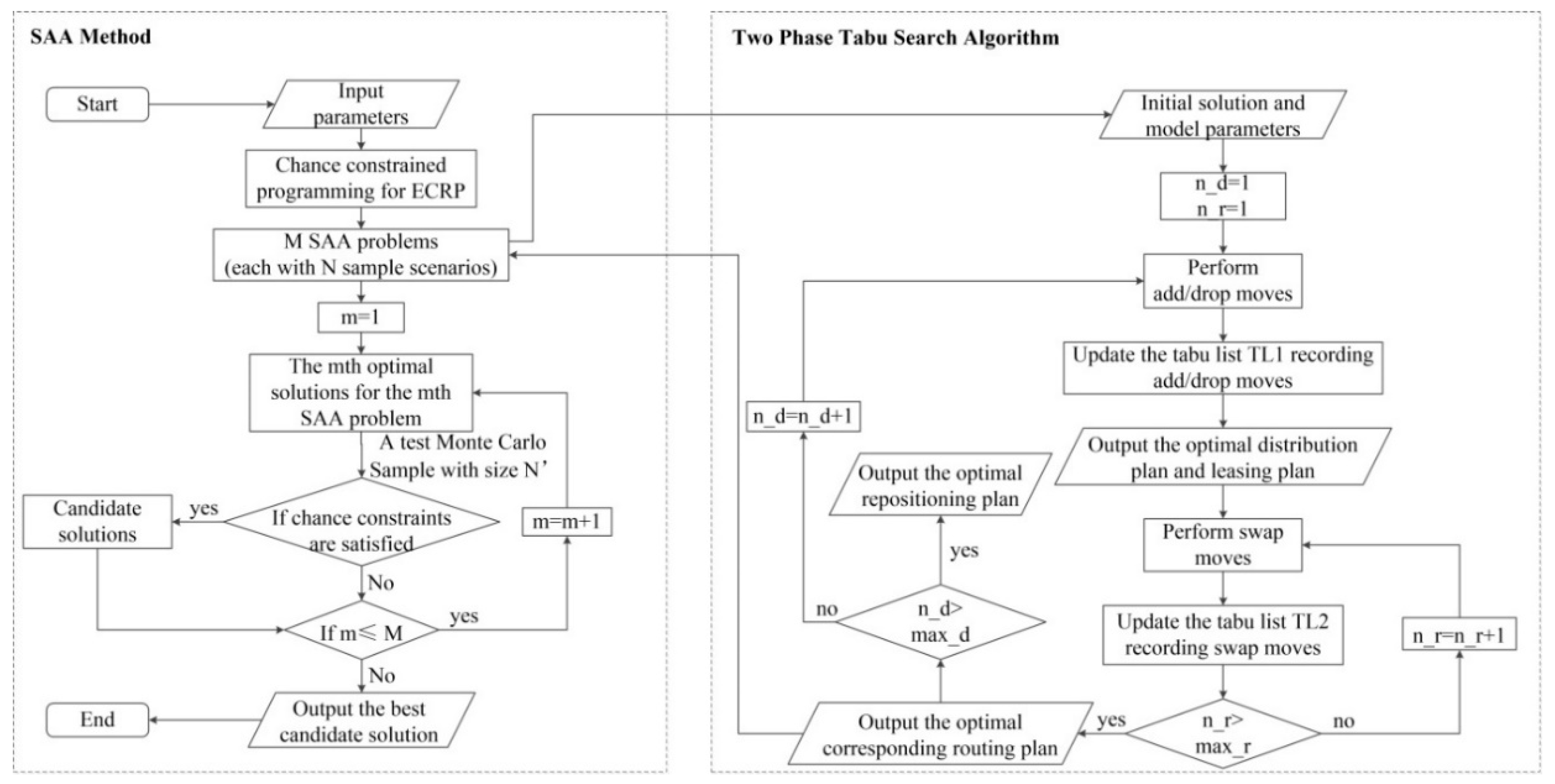

Section 3 presents a hybrid solution methodology integrating a two-phase tabu search algorithm and SAA method.

Section 4 illustrates the computational results. The conclusions and future research directions are given in

Section 5.

2. Mathematical Model for Stochastic ECRP with CO2 Emissions

The aim of this section is to present a chance-constrained mixed integer programming model for stochastic ECRP with CO

2 emissions, minimising the expected total cost.

Section 2.1 introduces notations and assumptions, whilst

Section 2.2 describes the mathematical model.

2.1. Notations and Assumptions

Table 2 lists notations to be used in the following sections.

The mathematic model for stochastic empty container repositioning is constructed reliant on the following assumptions.

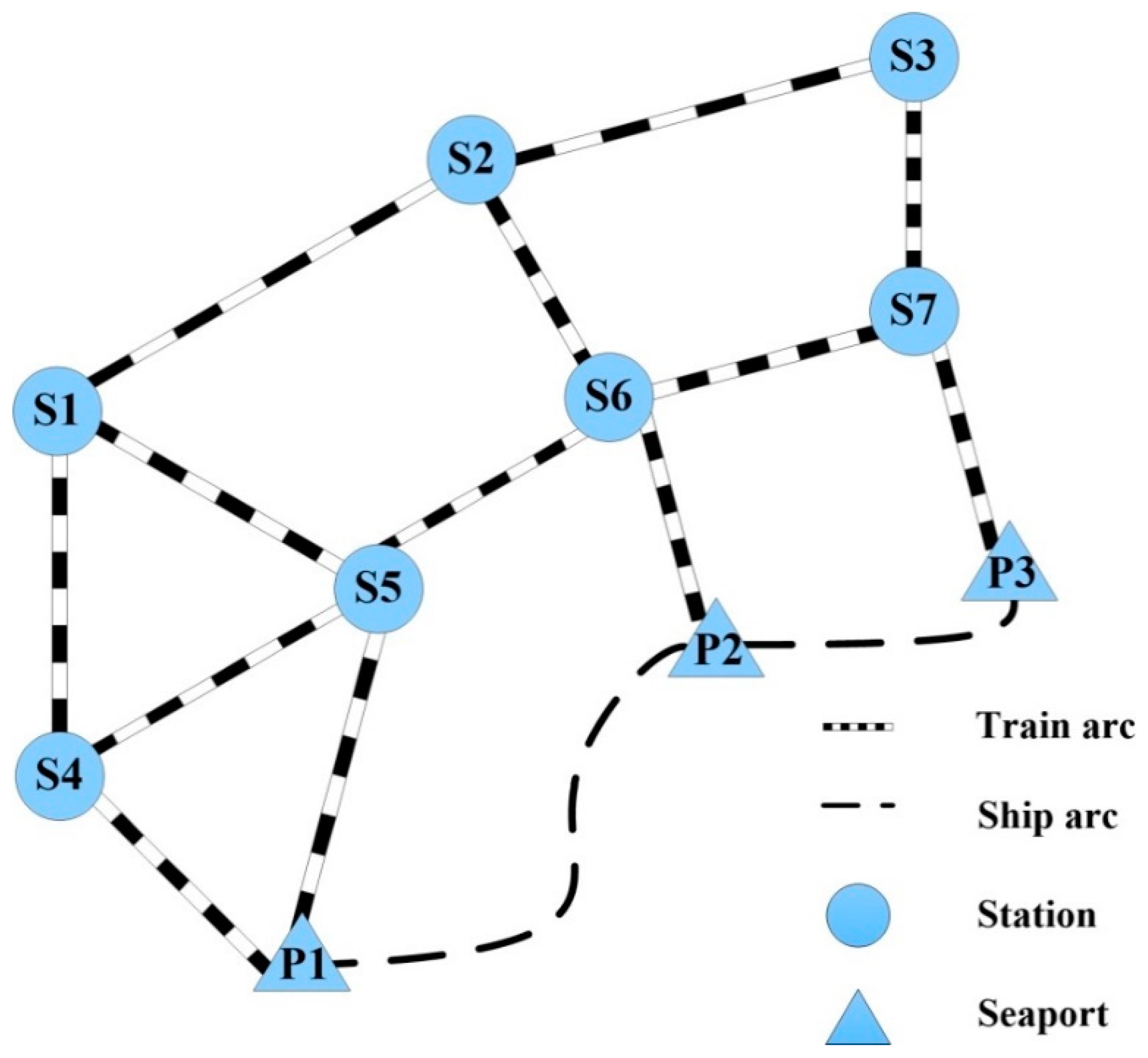

Assumption 1: Compared with other transportation modes, road transportation is unsuitable and costly for transporting containers over long distance, due to its working hour restrictions for truck drivers, infrastructure deficits, and relatively higher operation costs. In addition, because of the pollution caused by the burning process of fuel, it is not an eco-friendly transportation mode. Therefore, only two transportation modes are taken into account, i.e., railway transportation and maritime transportation. Thus, the intermodal network we discuss in this problem only includes two types of nodes, i.e., railway stations and ports.

Assumption 2: The stochastic demand and supply of empty containers at any railway station and port are independent of time periods. That is, the variabilities of stochastic demand and supply are kept the same during the planning horizon.

Assumption 3: CO2 emission is only incurred by transporting empty containers from the nodes with surplus empty containers to the nodes with deficit empty containers. In other words, it is assumed that leasing empty containers will not contribute to CO2 emission.

Assumption 4: There is no restriction on the amount of leased empty containers at any railway station and port at any time period. When surplus empty containers cannot satisfy the demand, sufficient empty containers are leased to fulfil the shortage in a complementary way. In addition, the leased empty containers are not required to be returned in the planning horizon.

Assumption 5: In order to simplify this model and reduce computational burden, the ECRP in this paper is addressed, regardless of multiple types of containers. Therefore, we only consider the standard containers, i.e., twenty-foot equivalent unit (TEU).

Assumption 6: All empty containers can be used without considering damage, repairs, and discards during the planning horizon. This assumption can be relaxed by adding the percentages of defective empty containers into the model if necessary.

Assumption 7: The scope of this study is limited to the regional intermodal network, including railway hinterland network of ports and the ship routes among these ports. Additionally, the train services are all assumed to be direct, to ensure that inland transportation time is short enough compared with the one time period. Similarly, the travel times of all ship routes are much smaller than one time period. Consequently, we assume that all repositioned empty containers can be transported from their origins to their destinations within one time period.

Assumption 8: All demands of empty containers can be satisfied at each time period by repositioning and leasing empty containers, which is consistent with Assumption 4.

Assumption 9: For the stochastic demands at each railway station and port, they follow different uniform distributions, respectively, with the same variability but different expected values. The stochastic supplies are in the same manner as illustrated in

Section 4.2.

2.2. A Chance-Constrained Nonlinear Integer Programming Model

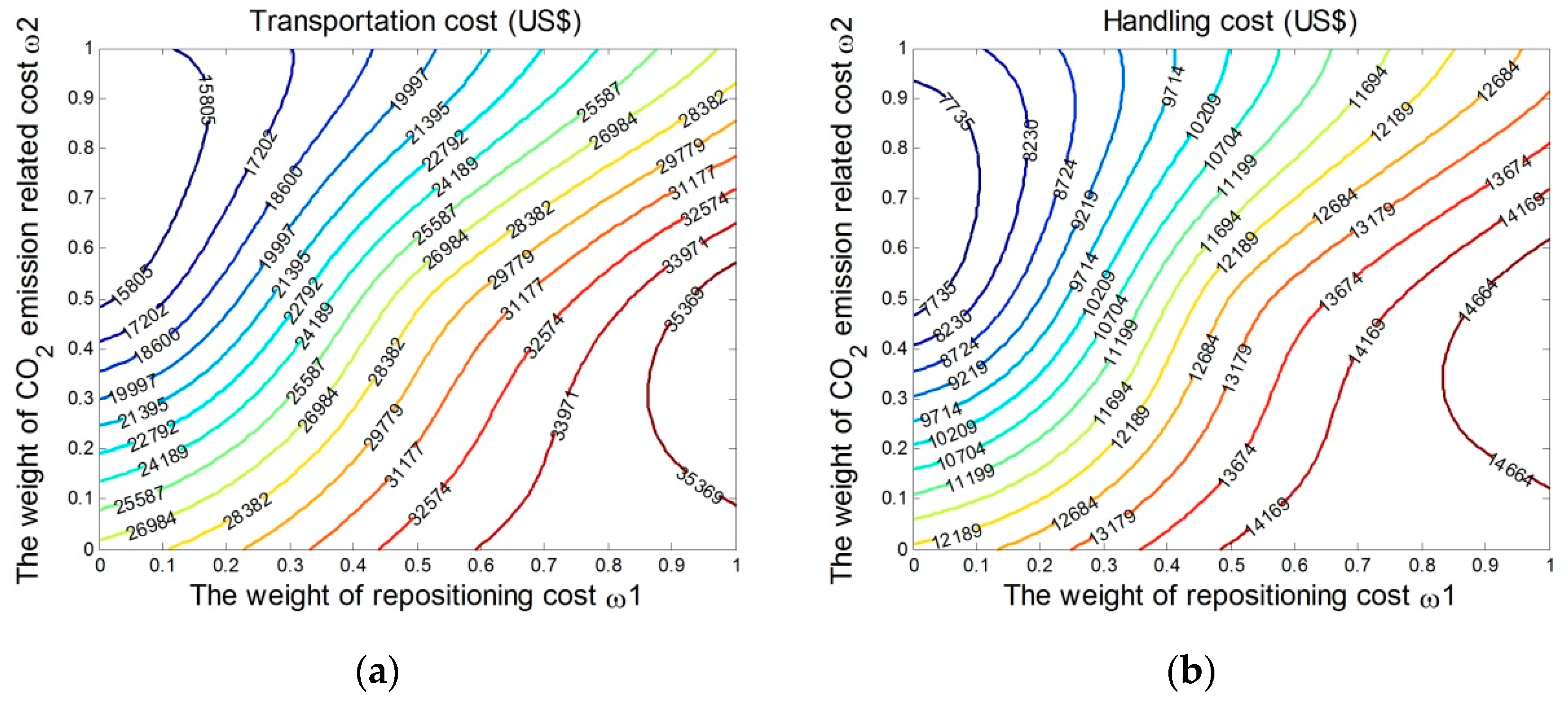

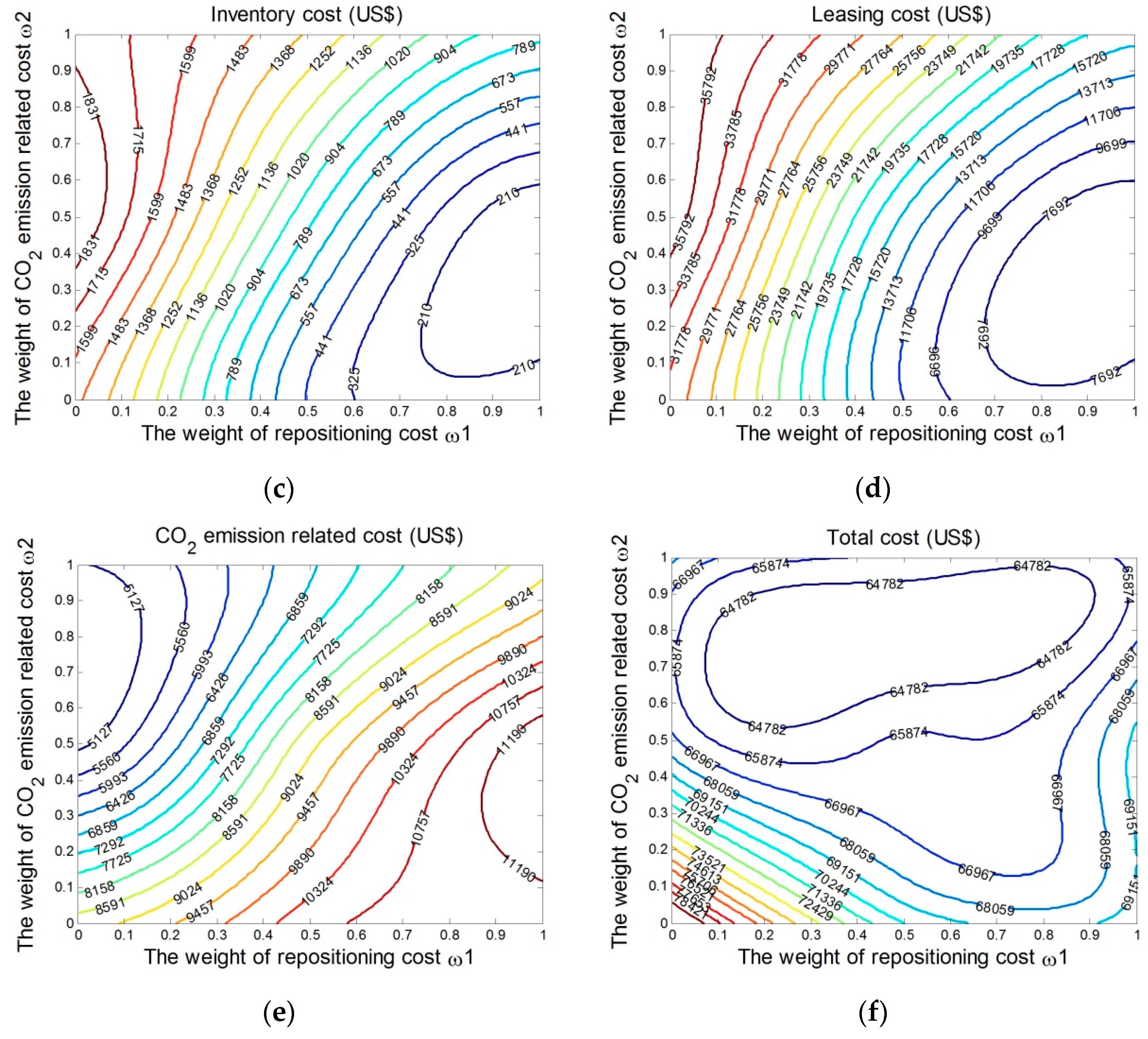

The objective function of the model is to minimise the expected value of total weighted cost, which is the weighted sum of repositioning cost and CO

2 emission-related cost. Thus, the total weighted cost at time period

t can be defined by Equation (1), where

and

are repositioning cost and CO

2 emission-related cost respectively, and

is the vector of decision variables at time period

t.

According to the notations as presented in

Section 2.1,

and

are defined as below.

The repositioning cost is represented by Equation (2), which includes transportation cost, handling cost (i.e., the sum of loading cost and unloading cost), inventory cost, and leasing cost, while CO2 emission-related cost is expressed by Equation (3).

Let

ξ be a random vector including all random variables at time periods, i.e.,

The proposed stochastic empty container repositioning problem can be formulated as a chance-constrained nonlinear integer programming model.

subject to

(i) Flow chance constraints

Constraints (6)–(7) impose that the maximum number of repositioned empty containers from surplus railway stations and ports cannot exceed their available empty containers with a possibility of at least . Constraints (8)–(9) enforce that all demands of empty containers must be satisfied by repositioning and/or leasing, with a possibility of at least at deficit railway stations and ports.

(ii) Flow conservation constraints

Constraints (10)–(13) guarantee the flow conservation of empty containers stored at all railway stations and ports. For example, the total number of empty containers stored at surplus railway station i at time t, equals the sum of empty containers stored at time t – 1, and those supplied minus the demand of empty containers, and those repositioned to deficit railway stations and ports at time period t.

(iii) Capacity constraints

Constraint (14) limits the total number of empty containers transported by a train on arc a, while Constraint (15) restricts the arc flow of empty containers on ship route r. Constraints (16)–(19) state that the amount of empty containers loaded and unloaded is within the handling capacity at railway stations and ports. Constraints (20)–(21) ensure that the number of empty containers stored cannot exceed the inventory capacity at railway stations and ports.

(iv) Route selection constraints

Constraints (22)–(24) ensure that only one route can be used to reposition empty containers from one node with surplus empty containers to another with deficit empty containers, that is, the repositioned empty containers with the same origin and destination cannot be split over different routes.

(v) Decision variables constraints

Constraints (25)–(27) require that all decision variables take non-negative values.