Biorefinery Based on Multiple Raw Materials and Wastes for the Production of Energy: A Proposal Tailored to Southwestern Europe

Definition

1. Introduction

1.1. Current Energy Scenario

1.2. The Role of Biorefineries

- The starting point of these biorefineries are renewable raw materials or wastes that can be valorized. Otherwise, their environmental management would be difficult, costly, and fruitless. Thus, the avoidance of fossil-based products is a key point to reduce many of the abovementioned environmental and geopolitical problems. For instance, there are biorefineries based on different wastes (such as fruit and vegetable wastes [5], including tropic agro-industrial waste [6], or biomass and waste in general [7]), whose implementation can be interesting.

- Considering that the products obtained are derived from natural sources, their environmental impact if there is an accidental release would be less negative compared to petroleum products. It should be taken into account that some of these processes obtain products that partially retain the molecular structure of their precursors, keeping some characteristics (such as high biodegradability).

- Different products are obtained, many of them as intermediate compounds that can be reused in further processes depending on the demand. Consequently, biorefineries can be adapted to current energy and product demands. In this sense, when necessary, the production of a certain biorefinery can be centered on goods that are scarce due to geopolitical aspects, as in the case of biofuels when abrupt changes in oil prices occur.

- The atom economy (or atom efficiency, defined as the amounts of desired products that are obtained compared to the amounts of reagents used, expressed in terms of percentage) of these processes is usually high, due to the high conversions obtained (with the contribution of catalysts in many cases) and the interconnection with other technologies to reuse intermediate products or wastes. As a consequence, low quantities of pollutants are released to the environment, with a subsequent low environmental impact. In any case, other factors such as the economy or social aspects should be taken into account in this context.

- Lastly, many wastes are derived from local or agricultural sources. Consequently, their valorization in a biorefinery context would imply an important contribution to the sustainable growth of developing countries or regions. In these areas, the main agricultural practices can provide products or wastes that could serve as the basis for the implementation of biorefineries specifically adapted to their specific circumstances. However, the real implementation of a biorefinery can be a challenge, requiring environmental and economic analysis to assess its feasibility.

- There has been a considerable number of patents about the use of biorefineries or green processes and technologies for the last 15 years, proving that this field is becoming a reality nowadays.

- There is a wide range of raw materials that are used as the basis of these biorefineries, from microalgae to wastes such as spent coffee grounds.

- The role of catalysts in these patents is essential. Indeed, some patents are exclusively focused on this issue.

- The conversion of old facilities for biorefinery implementation is also important in these patents, which could be a recurring possibility.

1.3. Aim and Scope

2. Components of the Proposed Biorefinery

2.1. Foundations of the Biorefinery

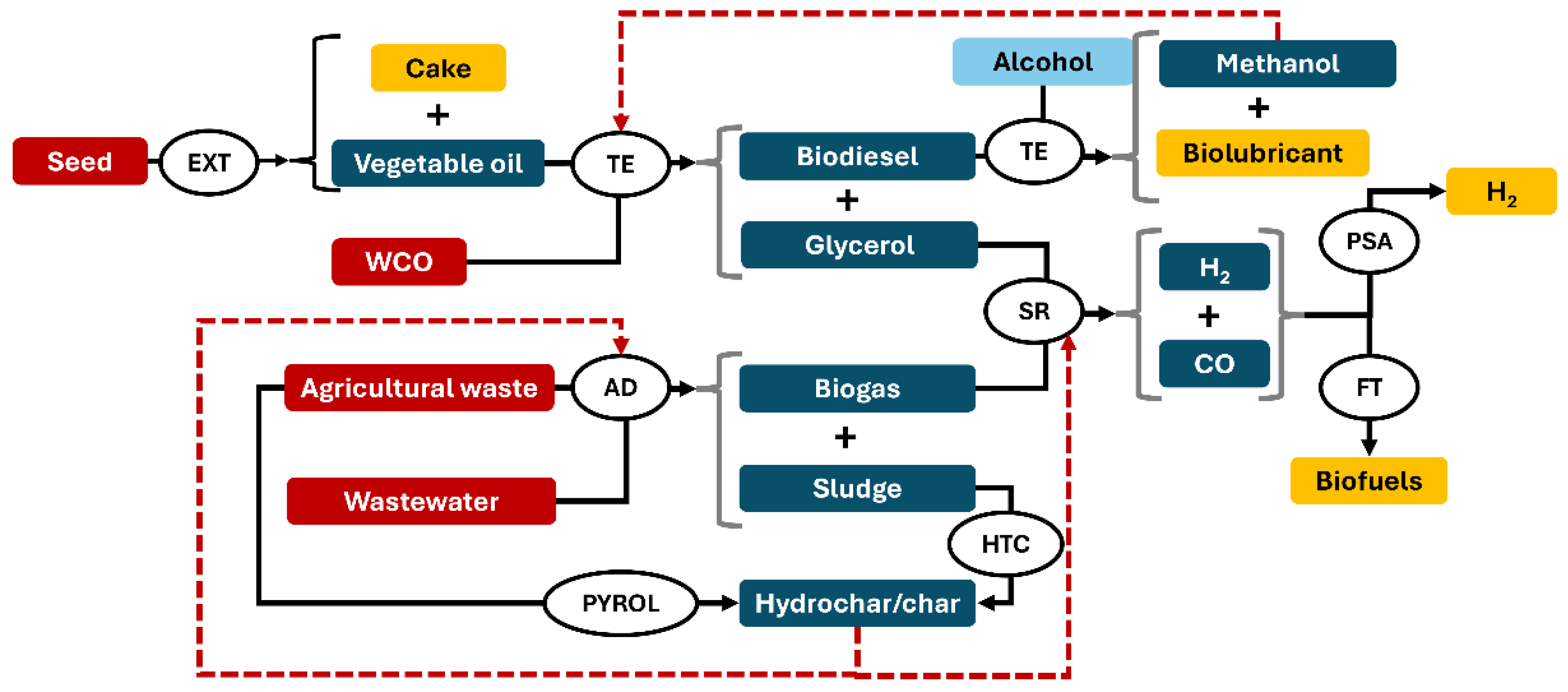

2.2. Technologies Included

- Biodiesel or biolubricant production through transesterification, which offers a wide range of products that can be used as intermediate products of other processes if suitable purification conditions and further technologies are implemented, as explained in the following section in the case of glycerol [24]. Concerning biodiesel, transesterification is carried out with methanol as a reagent to produce fatty acid methyl esters and glycerol. On the other hand, biolubricant is produced by reacting fatty acid methyl esters with superior alcohols (like pentaerythritol or trimethylolpropane) to produce biolubricants and release methanol (which could be reused in the previous transesterification step).

- Anaerobic digestion of agricultural wastes was also covered in order to obtain high-quality biogas (with around 60% methane). Thus, the higher the content of methane, the better for the further processing of biogas [25].

- Once biogas is purified, especially concerning H2S capture (which is essential to avoid the deactivation of catalytic processes through poisoning), biogas can undergo processes like steam reforming to obtain syngas or hydrogen (if purification processes are carried out) [26]. It should be noted that glycerol generated in transesterification to obtain biodiesel can be upgraded by using this technology [27]. Also, biogas can be used in local combustion engines to produce electricity and heat.

- Purification processes such as pressure swing adsorption or membrane reactors to obtain pure hydrogen from syngas (the flue gas obtained in steam reforming, with variable proportions of hydrogen and carbon monoxide) [28].

- Also, syngas can be upgraded to biofuels or other compounds through the use of Fischer–Tropsch synthesis, which offers a large variety of products depending on the reagents and chemical conditions [29].

2.3. Assessment of the Biorefinery

3. Advantages and Challenges of the Proposed Biorefinery

3.1. Main Components Included in the Biorefinery: Characteristics and Advantages

- The nature of the raw materials used (most of them natural sources or wastes) is essential to consider specific technologies. For example, high moisture content in solid wastes (for instance, sewage sludge or its mixture with agricultural waste) is essential to consider the implementation of HTC technologies for their valorization, whereas the use of pyrolysis is recommended for dry products (like agricultural wastes with a previous drying process). Especially interesting is the fact that one single crop, such as cardoon, safflower, or rapeseed, could provide different products that can be used as starting points in this biorefinery, like the corresponding vegetable oil (and the subsequent biodiesel) [32,33], cake (both of them from seeds after mechanical extraction, for example), and different agricultural wastes that can be combined in different processes like pyrolysis or HTC [34], among others. The same happens to gaseous compounds like biogas, whose methane and sulfhydric acid content will determine the performance of processes such as biogas (or methane) steam reforming or its use as biomethane.

- Similarly, the properties of intermediate products, as well as final products, are vital to consider the final use of these materials. For instance, glycerol can be used in a wide range of applications depending on its purity. High-purity glycerol is recommended for cosmetic use, whereas lower purities are required for energy purposes such as steam reforming [35,36]. Also, the role of viscosity in biodiesel and biolubricants is essential for their use in diesel engines or other industrial processes. On the other hand, syngas obtained in biogas steam reforming can be an interesting starting point for Fischer–Tropsch synthesis, depending on the H2/CO ratio. Otherwise, purification processes could be recommended to obtain pure hydrogen, depending on the final purpose of this technology.

- The role of catalysts is important in many steps included in this biorefinery in order to make the global process efficient, especially compared to traditional refineries. Indeed, most of the abovementioned processes require the use of catalysts to compete with fossil-based processes. Thus, homogeneous catalysts like sodium or potassium hydroxide or sodium methoxide are popular for their use in transesterification processes [37]. However, further purification processes are required, with the subsequent development of heterogeneous catalysts where only a physical separation after biodiesel or biolubricant production is required. On the other hand, heterogeneous compounds like nickel-based catalysts are normally used in steam reforming, presenting a wide spectrum of alternatives depending on many factors such as deactivation resistance due to different factors like poisoning (on account of the presence of H2S), sintering (due to the use of high temperatures), or coke deposition (because of methane conversion) [38,39]. Among these alternatives, the use of promoters that improve the interaction of the active phase (normally Ni) with the support (for instance, Al2O3, SiO2, etc.) is important, but also the operating conditions of the process (pressure, temperature, or steam-to-carbon ratio, among others). In this sense, new catalysts are being developed to improve some properties such as durability (in the case of heterogeneous catalysts) and efficiency, which is essential to improve the efficiency of the global process. Other catalysts such as zeolite are popular in the case of pyrolysis, whereas homogeneous and heterogeneous catalysts have been used in HTC, many of them focused on reducing tar and char formation such as Na2CO3 or K2CO3 [34]. Interestingly enough, some of these processes, in turn, could produce interesting carbonaceous materials that can act as photocatalytic or catalytic supports in different processes [40].

- As explained in Table 2, some technologies, such as transesterification and steam reforming, are extremely adaptable to different characteristics of the raw material by making slight modifications. In the case of the former, different alcohols can be used during transesterification to obtain biodiesel (by using methanol) or biolubricants with different viscosity values (by using, for instance, trimethylolpropane or pentaerythritol, among others). Concerning reforming, the foundation of this process is highly adaptable to plenty of reagents such as methane included in biogas, glycerol obtained in transesterification processes, or other hydrocarbons, obtaining relatively similar products like syngas with variable composition. Thus, the versatility of these technologies makes the combination of different routes possible, enhancing the efficiency of the process in general and reducing emissions to the environment.

- Finally, purification technologies are essential to offer interesting options when one single and pure product is desired for a certain usage. In this sense, purification in biodiesel production is basic in order to obtain a high-quality product for diesel engines (where specific standards are required for their correct performance), obtaining glycerol as a byproduct. On the other hand, technologies for syngas purification to obtain hydrogen are equally interesting, like the use of membrane reactors or pressure swing adsorption. However, not only purification technologies are necessary to offer a high-quality product. As previously explained, there are processes where impurities are a challenge that should be accomplished, especially affecting the poor catalytic performance of the process. In this sense, high acidity in oil is not desired in transesterification processes where NaOH is used as a homogeneous catalyst, whereas the presence of H2S is negative in reforming processes, requiring absorption or adsorption steps to remove this impurity, which is dangerous even at low concentrations (ppm) [41,42].Table 2. Main processes involved in the proposed biorefinery.

Process Details References Anaerobic digestion Biogas with high methane content (around 60%) was obtained from different wastes. Requirement of sulfhydric acid capture for further treatments such as steam reforming, to avoid corrosion and poisoning. It should be noted that other alternatives are available, especially concerning digestate, which can be used for different purposes like organic fertilizer or animal bedding, among others. [43,44,45] Oil extraction Through mechanical or chemical processes, high yields can be obtained, with the valorization of cake obtained for animal feeding, fermentation to produce bioethanol or anaerobic digestion. [46,47,48] Fischer–Tropsch If syngas composition obtained in steam reforming is suitable, then this process is interesting for obtaining different compounds like biofuels or biolubricants, depending on viscosity and high heating values. Other processes to convert syngas in dimethyl ether could be an interesting alternative. [49,50] Hydrothermal carbonization In order to produce hydrochar from wastes with high moisture levels, this is an interesting choice. These products can be transformed into activated carbons that can be reused in different processes such as desulfurization to clean biogas. Nevertheless, other interesting products can be obtained from HTC, such as liquid that can be used for fertigation. [34,51,52] Pressure swing adsorption Along with membrane reactors, it is essential to obtain hydrogen with high purity (over 99%). The quality of syngas is essential to obtain pure hydrogen and to contribute to the durability of membrane reactors. [53,54,55,56] Pyrolysis In this case, fast pyrolysis was selected, as it can enhance bio-oil fractions. One of the main products obtained in pyrolysis is carbon, along with oils and synthetic gas. Concerning the former, activated carbons can be generated for multiple purposes. [57,58,59,60,61] Steam reforming This is an interesting process that can be used with multiple materials, such as biogas or glycerol, to obtain hydrogen, among other products. High conversions (exceeding 95%) have been found in the literature, requiring hydrogen purification in many cases. [62,63,64,65] Transesterification Depending on the kind of alcohol, transesterification with methanol provides FAMEs (with high conversion, up to 98%), whereas transesterification with pentaerythritol (or trimethylolpropane) produces biolubricants (with conversions between 90–95% in most cases). [66,67,68,69,70,71,72]

3.2. Challenges Related to Biorefinery Implementation

- Carbon/water footprint: These are interesting factors that are normally included in a life cycle assessment (LCA). Concerning the activity of a biorefinery, all the processes should be controlled “from cradle to grave”, including carbon dioxide generation (directly or through energy consumption from conventional electricity generation) and water pollution. As previously stated, the higher the atom economy, the lower the emissions discharged into the environment, with a subsequent lower environmental impact. This is the reason why the perfect combination of technologies taking part in a biorefinery is required.

- Waste management: Again, different processes can produce undesirable wastes, which should be valorized by the implementation of further technologies that can bring, at the same time, new environmental challenges. The LCA is an interesting tool to classify these technologies according to their environmental impact, assessing the suitability of their implementation from different points of view.

- Extraction of raw materials: Equally, every aspect of a biorefinery is monitored from an LCA point of view, including the raw materials or wastes used. For the latter, every effort to valorize them is normally suitable, whereas for the former this is not always true. As explained in the following point, the use of different resources to produce a raw material can determine the suitability of the whole biorefinery.

- Land usage: In some cases, especially concerning the use of oilseed crops, there are continuous concerns about this issue. Thus, the use of land for this purpose instead of the food sector is problematic. Nevertheless, there are sustainable alternatives, like the use of wastes derived from vegetable oils (for instance, WCO) or different sustainable land practices such as the introduction of safflower or cardoon, which can take part in shifting cultivation to recover soils [66,68].

- Transportation/shipment: This is a key point in a biorefinery, as these practices could influence different factors such as carbon footprint. On many occasions, the location of a biorefinery is essential to make the most of the raw materials used or products obtained, as observed in the case of Germany [73]. In this case, the biorefinery could be located in Badajoz (Spain), where there is a wastewater treatment plant, and most crops (like cardoon, rapeseed or safflower) have been proven to be suitably grown. Thus, the transportation of wastes or raw materials would be minimized. Regarding the products, they could be locally commercialized for the same reason.

- Equipment crushing/wear: Obviously, the use of multiple pieces of equipment in a biorefinery implies a decrease in efficiency due to crushing or wear. For instance, a certain reactor with an electric resistance will exhibit lower efficiency over time, requiring more energy to maintain the same working temperature. These factors are important to carry out a suitable LCA of the whole process.

- Energy costs: With respect to this factor, it is important to consider the energy source used in this biorefinery. For this purpose, different points should be addressed, like the possibility of reusing the energy generated or the implementation of renewable energies (such as solar or wind energy) to reduce energy costs and CO2 emissions.

4. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vakulchuk, R.; Overland, I.; Scholten, D. Renewable Energy and Geopolitics: A Review. Renew. Sustain. Energy Rev. 2020, 122, 109547. [Google Scholar] [CrossRef]

- Palle, A. Bringing Geopolitics to Energy Transition Research. Energy Res. Soc. Sci. 2021, 81, 102233. [Google Scholar] [CrossRef]

- Liberato, V.; Benevenuti, C.; Coelho, F.; Botelho, A.; Amaral, P.; Pereira, N.; Ferreira, T. Chemicals Production in a Biorefinery Context. Catalysts 2019, 9, 962. [Google Scholar] [CrossRef]

- Caldeira, C.; Vlysidis, A.; Fiore, G.; De Laurentiis, V.; Vignali, G.; Sala, S. Sustainability of Food Waste Biorefinery: A Review on Valorisation Pathways, Techno-Economic Constraints, and Environmental Assessment. Bioresour. Technol. 2020, 312, 123575. [Google Scholar] [CrossRef]

- Râpă, M.; Darie-Niță, R.N.; Coman, G. Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials. Waste 2024, 2, 258–278. [Google Scholar] [CrossRef]

- Eixenberger, D.; Carballo-Arce, A.F.; Vega-Baudrit, J.R.; Trimino-Vazquez, H.; Villegas-Peñaranda, L.R.; Stöbener, A.; Aguilar, F.; Mora-Villalobos, J.A.; Sandoval-Barrantes, M.; Bubenheim, P.; et al. Tropical Agroindustrial Biowaste Revalorization through Integrative Biorefineries—Review Part II: Pineapple, Sugarcane and Banana by-Products in Costa Rica. Biomass Convers. Biorefin 2024, 14, 4391–4418. [Google Scholar] [CrossRef]

- Mukamwi, M.; Somorin, T.; Soloha, R.; Dace, E. Databases for Biomass and Waste Biorefinery—A Mini-Review and SWOT Analysis. Bioengineered 2023, 14, 2286722. [Google Scholar] [CrossRef]

- Mangut, V.; Sabio, E.; Gañán, J.; González, J.F.; Ramiro, A.; González, C.M.; Román, S.; Al-Kassir, A. Thermogravimetric Study of the Pyrolysis of Biomass Residues from Tomato Processing Industry. Fuel Process. Technol. 2006, 87, 109–115. [Google Scholar] [CrossRef]

- Situmorang, Y.A.; Zhao, Z.; Chaihad, N.; Wang, C.; Anniwaer, A.; Kasai, Y.; Abudula, A.; Guan, G. Steam Gasification of Co-Pyrolysis Chars from Various Types of Biomass. Int. J. Hydrogen Energy 2021, 46, 3640–3650. [Google Scholar] [CrossRef]

- Abo El-Enin, S.A.; Attia, N.K.; El-Ibiari, N.N.; El-Diwani, G.I.; El-Khatib, K.M. In-Situ Transesterification of Rapeseed and Cost Indicators for Biodiesel Production. Renew. Sustain. Energy Rev. 2013, 18, 471–477. [Google Scholar] [CrossRef]

- Rezania, S.; Oryani, B.; Park, J.; Hashemi, B.; Yadav, K.K.; Kwon, E.E.; Hur, J.; Cho, J. Review on Transesterification of Non-Edible Sources for Biodiesel Production with a Focus on Economic Aspects, Fuel Properties and by-Product Applications. Energy Convers. Manag. 2019, 201, 112155. [Google Scholar] [CrossRef]

- Pereira, V.G.F.; Rodrigues, C.P.; Toniolo, F.S. Ni/Al2O3 Supported on Cordierite Monoliths for Methane Steam Reforming: Influence of Catalyst Coating Methodology. Catal. Commun. 2023, 183, 106759. [Google Scholar] [CrossRef]

- Mortensen, P.M.; Aasberg-Petersen, K.; Klein, R. Hydrogen Production by Steam Methane Reforming. US20210238035A1, 28 February 2023. [Google Scholar]

- Herz, G.; Reichelt, E.; Jahn, M. Design and Evaluation of a Fischer-Tropsch Process for the Production of Waxes from Biogas. Energy 2017, 132, 370–381. [Google Scholar] [CrossRef]

- Zhao, S. Multi-Recycling Type Kitchen Waste Biorefinery System. China Patent CN220346856U, 16 January 2024. [Google Scholar]

- Azocar Ulloa, L.H.; Ciudad Bazaul, G.A.; Díaz Araneda, H.A.; Navia Diez, R.J.; Meier Figueroa, L.M.; Torres Aravena, A.; Jeison Núñez, D.A.; Rubilar Díaz, M.O.; Cancino González, B.N.R.; Valerio González, O.E. Microalgae Biorefinery for Biofuel and Valuable Products Production. WO2015044721A1, 2 April 2015. [Google Scholar]

- Wu, Z.; Hu, L.; Jiang, Y.; Xu, J.; He, A.; Zhu, A.; Song, J. Method for Preparing Phenolic Compounds by Catalyzing Pyrolysis of Biorefinery Residues with Attapulgite Catalyst. China Patent CN111138247A, 9 December 2022. [Google Scholar]

- Prandi, A. Method for Converting a Conventional Oil, Petrochemical or Chemical Plant into a Biorefinery. EP3450524A1, 3 June 2020. [Google Scholar]

- Crawford, L.A.; Schafer, W.B. Enhancing a Biorefinery with an Optional Vapor Recompression Unit While Maintaining the Ability to Operate without the Vapor Recompression Unit. U.S. Patent US11471784B2, 18 October 2022. [Google Scholar]

- Rispoli, G.F.; Prati, C.; Amoroso, A.; Pollesel, P. Method for Revamping a Conventional Mineral Oils Refinery to a Biorefinery. European Patent EP2949729A1, 4 September 2012. [Google Scholar]

- Bae, H.J.; Cho, E.J. An Integrated Process for Conversion of Spent Coffee Grounds into Value-Added Biochemicals and Biofuel. Korea Patent KR20230171667A, 26 August 2024. [Google Scholar]

- Feng, X.; Zhao, S.; Wang, Z. Integrated Biorefinery Process for Bagasse. China Patent CN115851464A, 24 November 2022. [Google Scholar]

- European Comission. European Regional Development Fund. Available online: https://ec.europa.eu/regional_policy/funding/erdf_en (accessed on 18 September 2024).

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Homogeneous, Heterogeneous and Enzymatic Catalysis for Transesterification of High Free Fatty Acid Oil (Waste Cooking Oil) to Biodiesel: A Review. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef]

- Liu, M.; Wei, Y.; Leng, X. Improving Biogas Production Using Additives in Anaerobic Digestion: A Review. J. Clean. Prod. 2021, 297, 126666. [Google Scholar] [CrossRef]

- Schiaroli, N.; Volanti, M.; Crimaldi, A.; Passarini, F.; Vaccari, A.; Fornasari, G.; Copelli, S.; Florit, F.; Lucarelli, C. Biogas to Syngas through the Combined Steam/Dry Reforming Process: An Environmental Impact Assessment. Energy Fuels 2021, 35, 4224–4236. [Google Scholar] [CrossRef]

- Sad, M.E.; Duarte, H.A.; Vignatti, C.; Padró, C.L.; Apesteguía, C.R. Steam Reforming of Glycerol: Hydrogen Production Optimization. Int. J. Hydrogen Energy 2015, 40, 6097–6106. [Google Scholar] [CrossRef]

- Nikolic, D.; Giovanoglou, A.; Georgiadis, M.C.; Kikkinides, E.S. Hydrogen Purification By Pressure Swing Adsorption. In Proceedings of the 10th Conference on Process Integration, Modelling and Optimisation for Energy Saving and Pollution Reduction (PRES), Ischia, Italy, 24–27 June 2007. [Google Scholar]

- Suo, Y.; Yao, Y.; Zhang, Y.; Xing, S.; Yuan, Z.-Y. Recent Advances in Cobalt-Based Fischer-Tropsch Synthesis Catalysts. J. Ind. Eng. Chem. 2022, 115, 92–119. [Google Scholar] [CrossRef]

- Serna-Loaiza, S.; García-Velásquez, C.A.; Cardona, C.A. Strategy for the Selection of the Minimum Processing Scale for the Economic Feasibility of Biorefineries. Biofuels Bioprod. Biorefin. 2019, 13, 107–119. [Google Scholar] [CrossRef]

- Ahlgren, S.; Björklund, A.; Ekman, A.; Karlsson, H.; Berlin, J.; Börjesson, P.; Ekvall, T.; Finnveden, G.; Janssen, M.; Strid, I. Review of Methodological Choices in LCA of Biorefinery Systems—Key Issues and Recommendations. Biofuels Bioprod. Biorefin. 2015, 9, 606–619. [Google Scholar] [CrossRef]

- Mihaela, P.; Josef, R.; Monica, N.; Rudolf, Z. Perspectives of Safflower Oil as Biodiesel Source for South Eastern Europe (Comparative Study: Safflower, Soybean and Rapeseed). Fuel 2013, 111, 114–119. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Cesur, C.; Aslan, V.; Yilbasi, Z. The Production of Biodiesel from Safflower (Carthamus tinctorius L.) Oil as a Potential Feedstock and Its Usage in Compression Ignition Engine: A Comprehensive Review. Renew. Sustain. Energy Rev. 2020, 119, 109574. [Google Scholar] [CrossRef]

- Díaz-Rasero, J.M.; Ledesma, B.; Alonso, M.; Román, S. Upgrading Carthamus by HTC: Improvement of Combustion Properties. Fire 2024, 7, 106. [Google Scholar] [CrossRef]

- Moreira, R.; Bimbela, F.; Gandía, L.M.; Ferreira, A.; Sánchez, J.L.; Portugal, A. Oxidative Steam Reforming of Glycerol. A Review. Renew. Sustain. Energy Rev. 2021, 148, 111299. [Google Scholar] [CrossRef]

- Marx, S. Glycerol-Free Biodiesel Production through Transesterification: A Review. Fuel Process. Technol. 2016, 151, 139–147. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Tandale, M.S. Optimization of Transesterification Process Using Homogeneous and Nano-Heterogeneous Catalysts for Biodiesel Production from Mangifera Indica Oil. Environ. Prog. Sustain. Energy 2018, 37, 533–545. [Google Scholar] [CrossRef]

- Li, G.; Zhang, X.; Wang, Y.; Zhang, J.; Liu, G. Mixed Valence Nickel-Based Methane Steam Reforming Catalyst and Preparation Method Thereof. CN202210938195, 5 August 2022. [Google Scholar]

- Matus, E.; Kerzhentsev, M.; Ismagilov, I.; Nikitin, A.; Sozinov, S.; Ismagilov, Z. Hydrogen Production from Biogas: Development of an Efficient Nickel Catalyst by the Exsolution Approach. Energies 2023, 16, 2993. [Google Scholar] [CrossRef]

- Villora-Pico, J.J.; Gonzalez-Arias, J.; Baena-Moreno, F.M.; Reina, T.R. Renewable Carbonaceous Materials from Biomass in Catalytic Processes: A Review. Materials 2024, 17, 565. [Google Scholar] [CrossRef]

- Pudi, A.; Rezaei, M.; Signorini, V.; Andersson, M.P.; Baschetti, M.G.; Mansouri, S.S. Hydrogen Sulfide Capture and Removal Technologies: A Comprehensive Review of Recent Developments and Emerging Trends. Sep. Purif. Technol. 2022, 298, 121448. [Google Scholar] [CrossRef]

- Izquierdo, U.; García-García, I.; Gutierrez, Á.M.; Arraibi, J.R.; Barrio, V.L.; Cambra, J.F.; Arias, P.L. Catalyst Deactivation and Regeneration Processes in Biogas Tri-Reforming Process. The Effect of Hydrogen Sulfide Addition. Catalysts 2018, 8, 12. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Álvez-Medina, C.M.; Montes, V.; González, J.F. A Review on the Use of Catalysis for Biogas Steam Reforming. Catalysts 2023, 13, 1482. [Google Scholar] [CrossRef]

- Seman, M.H.A.; Othman, N.H.; Osman, N.; Jani, A.M.M. Nickel Based Catalysts Supported on Porous Support for Methane Steam Reforming: Potential and Short Review. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Institute of Physics, Denpasar, Indonesia, 28–29 February 2023; Volume 1151. [Google Scholar]

- Mabaleha, S.S.; Gholizadeh, F.; Kalita, P. Recent Advances in Ni-Based Stable Catalysts for Methane Dry Reforming: Stable Catalysts’ Preparation Review. Mol. Catal. 2023, 547. [Google Scholar] [CrossRef]

- Dijkstra, A.J.; van Duijn, G. Vegetable Oils: Oil Production and Processing. In Encyclopedia of Food and Health; IOP Publishing: Bristol, UK, 2015; ISBN 9780123849533. [Google Scholar]

- Encinar, J.M.; Nogales, S.; González, J.F. Biorefinery Based on Different Vegetable Oils: Characterization of Biodiesel and Biolubricants. In Proceedings of the 3rd International Conference in Engineering Applications (ICEA), Sao Miguel, Portugal, 8–11 July 2019. [Google Scholar]

- Atabani, A.E.; Silitonga, A.S.; Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Badruddin, I.A.; Fayaz, H. Non-Edible Vegetable Oils: A Critical Evaluation of Oil Extraction, Fatty Acid Compositions, Biodiesel Production, Characteristics, Engine Performance and Emissions Production. Renew. Sustain. Energy Rev. 2013, 18, 211–245. [Google Scholar] [CrossRef]

- Marchese, M.; Chesta, S.; Santarelli, M.; Lanzini, A. Techno-Economic Feasibility of a Biomass-to-X Plant: Fischer-Tropsch Wax Synthesis from Digestate Gasification. Energy 2021, 228, 120581. [Google Scholar] [CrossRef]

- Martinelli, M.; Gnanamani, M.K.; LeViness, S.; Jacobs, G.; Shafer, W.D. An Overview of Fischer-Tropsch Synthesis: XtL Processes, Catalysts and Reactors. Appl. Catal. A Gen. 2020, 608, 117740. [Google Scholar] [CrossRef]

- Olivares-Marin, M.; Román, S.; Ledesma, B.; Álvarez, A. Optimizing Al and Fe Load during HTC of Water Hyacinth: Improvement of Induced HC Physicochemical Properties. Catalysts 2023, 13, 506. [Google Scholar] [CrossRef]

- García-Morato, R.; Román, S.; Ledesma, B.; Coronella, C. Co-Hydrothermal Carbonization of Grass and Olive Stone as a Means to Lower Water Input to HTC. Resources 2023, 12, 85. [Google Scholar] [CrossRef]

- Ongis, M.; Di Marcoberardino, G.; Baiguini, M.; Gallucci, F.; Binotti, M. Optimization of Small-Scale Hydrogen Production with Membrane Reactors. Membranes 2023, 13, 331. [Google Scholar] [CrossRef]

- Iulianelli, A.; Alavi, M.; Bagnato, G.; Liguori, S.; Wilcox, J.; Rahimpour, M.R.; Eslamlouyan, R.; Anzelmo, B.; Basile, A. Supported Pd-Au Membrane Reactor for Hydrogen Production: Membrane Preparation, Characterization and Testing. Molecules 2016, 21, 581. [Google Scholar] [CrossRef]

- Macedo, M.S.; Soria, M.A.; Madeira, L.M. Glycerol Steam Reforming for Hydrogen Production: Traditional versus Membrane Reactor. Int. J. Hydrogen Energy 2019, 44, 24719–24732. [Google Scholar] [CrossRef]

- Luberti, M.; Ahn, H. Review of Polybed Pressure Swing Adsorption for Hydrogen Purification. Int. J. Hydrogen Energy 2022, 47, 10911–10933. [Google Scholar] [CrossRef]

- Encinar, J.M.; González, J.F.; Martínez, G.; Román, S. Jerusalem Artichoke Pyrolysis: Energetic Evaluation. J. Anal. Appl. Pyrolysis 2009, 85, 294–300. [Google Scholar] [CrossRef]

- Boutaieb, M.; Guiza, M.; Román, S.; Nogales, S.; Ledesma, B.; Ouederni, A. Pine Cone Pyrolysis: Optimization of Temperature for Energy Recovery. Environ. Prog. Sustain. Energy 2020, 39, 13272. [Google Scholar] [CrossRef]

- Abou Rjeily, M.; Gennequin, C.; Pron, H.; Abi-Aad, E.; Randrianalisoa, J.H. Pyrolysis-Catalytic Upgrading of Bio-Oil and Pyrolysis-Catalytic Steam Reforming of Biogas: A Review. Environ. Chem. Lett. 2021, 19, 2825–2872. [Google Scholar] [CrossRef]

- Gutiérrez, J.; Galán, C.A.; Suárez, R.; Álvarez-Murillo, A.; González, J.F. Biofuels from Cardoon Pyrolysis: Extraction and Application of Biokerosene/Kerosene Mixtures in a Self-Manufactured Jet Engine. Energy Convers. Manag. 2018, 157, 246–256. [Google Scholar] [CrossRef]

- Wang, L.; Ok, Y.S.; Tsang, D.C.W.; Alessi, D.S.; Rinklebe, J.; Wang, H.; Mašek, O.; Hou, R.; O’Connor, D.; Hou, D. New Trends in Biochar Pyrolysis and Modification Strategies: Feedstock, Pyrolysis Conditions, Sustainability Concerns and Implications for Soil Amendment. Soil. Use Manag. 2020, 36, 358–386. [Google Scholar] [CrossRef]

- Sánchez, N.; Encinar, J.M.; Nogales, S.; González, J.F. Lanthanum Effect on Ni/Al2O3 as a Catalyst Applied in Steam Reforming of Glycerol for Hydrogen Production. Processes 2019, 7, 449. [Google Scholar] [CrossRef]

- González, J.F.; Álvez-Medina, C.M.; Nogales-Delgado, S. Biogas Steam Reforming in Wastewater Treatment Plants: Opportunities and Challenges. Energies 2023, 16, 6343. [Google Scholar] [CrossRef]

- Abd, A.A.; Othman, M.R.; Majdi, H.S.; Helwani, Z. Green Route for Biomethane and Hydrogen Production via Integration of Biogas Upgrading Using Pressure Swing Adsorption and Steam-Methane Reforming Process. Renew. Energy 2023, 210, 64–78. [Google Scholar] [CrossRef]

- Alipour-Dehkordi, A.; Neek, S.J.; Shahnazar, A. Sustainable H2 Production from Glycerol Steam Reforming in the Heat-Integrated Reactor: Using Reforming-Side by-Products as Feed for the Catalytic Combustion-Side. J. Ind. Eng. Chem. 2022, 113, 264–274. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Encinar, J.M.; González, J.F. Safflower Biodiesel: Improvement of Its Oxidative Stability by Using BHA and TBHQ. Energies 2019, 12, 1940. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Encinar, J.M.; González Cortés, Á. High Oleic Safflower Oil as a Feedstock for Stable Biodiesel and Biolubricant Production. Ind. Crops Prod. 2021, 170, 113701. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Sánchez, N.; Encinar, J.M. Valorization of Cynara cardunculus L. Oil as the Basis of a Biorefinery for Biodiesel and Biolubricant Production. Energies 2020, 13, 5085. [Google Scholar] [CrossRef]

- Gülüm, M.; Bilgin, A. Density, Flash Point and Heating Value Variations of Corn Oil Biodiesel-Diesel Fuel Blends. Fuel Process. Technol. 2015, 134, 456–464. [Google Scholar] [CrossRef]

- Rajkumar, S.; Thangaraja, J. Effect of Biodiesel, Biodiesel Binary Blends, Hydrogenated Biodiesel and Injection Parameters on NOx and Soot Emissions in a Turbocharged Diesel Engine. Fuel 2019, 240, 101–118. [Google Scholar] [CrossRef]

- Xie, Q.; Zhu, H.; Xu, P.; Xing, K.; Yu, S.; Liang, X.; Ji, W.; Nie, Y.; Ji, J. Transesterification of Methyl Oleate for Sustainable Production of Biolubricant: Process Optimization and Kinetic Study. Ind. Crops Prod. 2022, 182, 114879. [Google Scholar] [CrossRef]

- Hamid, H.A.; Yunus, R.; Rashid, U.; Choong, T.S.Y.; Al-Muhtaseb, A.H. Synthesis of Palm Oil-Based Trimethylolpropane Ester as Potential Biolubricant: Chemical Kinetics Modeling. Chem. Eng. J. 2012, 200, 532–540. [Google Scholar] [CrossRef]

- Heck, R.; Rudi, A.; Lauth, D.; Schultmann, F. An Estimation of Biomass Potential and Location Optimization for Integrated Biorefineries in Germany: A Combined Approach of GIS and Mathematical Modeling. Sustainability 2024, 16, 6781. [Google Scholar] [CrossRef]

- NASA. Technology Readiness Levels. Available online: https://www.nasa.gov/directorates/somd/space-communications-navigation-program/technology-readiness-levels/ (accessed on 12 September 2024).

- Maniscalco, M.P.; Longo, S.; Cellura, M.; Miccichè, G.; Ferraro, M. Critical Review of Life Cycle Assessment of Hydrogen Production Pathways. Environments 2024, 11, 108. [Google Scholar] [CrossRef]

- Li, N.; Guo, Y. Life Cycle Assessment of Rapeseed Biodiesel. World Electr. Veh. J. 2011, 4, 804–808. [Google Scholar] [CrossRef]

- Harris, T.M.; Hottle, T.A.; Soratana, K.; Klane, J.; Landis, A.E. Life Cycle Assessment of Sunflower Cultivation on Abandoned Mine Land for Biodiesel Production. J. Clean. Prod. 2016, 112, 182–195. [Google Scholar] [CrossRef]

- Lin, J.; Liu, S.; Han, Z.; Ma, R.; Cui, C.; Sun, S. Scaled-up Microwave Pyrolysis of Sludge for Hydrogen-Rich Biogas and Life Cycle Assessment: Parameters Synergistic Optimization, Carbon Footprint Analysis and Technology Upgrade. Chem. Eng. J. 2023, 452, 139551. [Google Scholar] [CrossRef]

- Mussagy, C.U.; Remonatto, D.; Picheli, F.P.; Paula, A.V.; Herculano, R.D.; Santos-Ebinuma, V.C.; Farias, R.L.; Onishi, B.S.; Ribeiro, S.J.; Pereira, J.F.; et al. A Look into Phaffia Rhodozyma Biorefinery: From the Recovery and Fractionation of Carotenoids, Lipids and Proteins to the Sustainable Manufacturing of Biologically Active Bioplastics. Bioresour. Technol. 2022, 362, 127785. [Google Scholar] [CrossRef]

- Singh, G.; Jawed, A.; Paul, D.; Bandyopadhyay, K.K.; Kumari, A.; Haque, S. Concomitant Production of Lipids and Carotenoids in Rhodosporidium Toruloides under Osmotic Stress Using Response Surface Methodology. Front. Microbiol. 2016, 7, 1686. [Google Scholar] [CrossRef]

| Inventors | Patent | Year | Reference |

|---|---|---|---|

| Shuangquan | Multi-recycling type kitchen waste biorefinery system | 2024 | [15] |

| Azocar Ulloa et al. | Microalgae biorefinery for biofuel and valuable products production | 2015 | [16] |

| Wu et al. | Method for preparing phenolic compounds by catalyzing pyrolysis of biorefinery residues with attapulgite catalyst | 2019 | [17] |

| Prandi | Method for converting a conventional oil, petrochemical or chemical plant into a biorefinery | 2017 | [18] |

| Crawford and Schafer | Enhancing a biorefinery with an optional vapor recompression unit while maintaining the ability to operate without the vapor recompression unit | 2016 | [19] |

| Rispoli et al. | Method for revamping a conventional mineral oils refinery to a biorefinery | 2012 | [20] |

| Bae and Cho | An integrated process for conversion of spent coffee grounds into value-added biochemicals and biofuel | 2022 | [21] |

| Feng et al. | Integrated biorefinery process for bagasse | 2022 | [22] |

| Technology | TRL |

|---|---|

| Anaerobic digestion | 9 |

| Transesterification | 9 |

| Biogas steam reforming | 9 |

| Fischer–Tropsch synthesis | 5–9 |

| Hydrothermal carbonization | 1–4 |

| Pyrolysis | 4–7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nogales-Delgado, S.; Álvez-Medina, C.M.; González González, J.F. Biorefinery Based on Multiple Raw Materials and Wastes for the Production of Energy: A Proposal Tailored to Southwestern Europe. Encyclopedia 2024, 4, 1381-1395. https://doi.org/10.3390/encyclopedia4040090

Nogales-Delgado S, Álvez-Medina CM, González González JF. Biorefinery Based on Multiple Raw Materials and Wastes for the Production of Energy: A Proposal Tailored to Southwestern Europe. Encyclopedia. 2024; 4(4):1381-1395. https://doi.org/10.3390/encyclopedia4040090

Chicago/Turabian StyleNogales-Delgado, Sergio, Carmen María Álvez-Medina, and Juan Félix González González. 2024. "Biorefinery Based on Multiple Raw Materials and Wastes for the Production of Energy: A Proposal Tailored to Southwestern Europe" Encyclopedia 4, no. 4: 1381-1395. https://doi.org/10.3390/encyclopedia4040090

APA StyleNogales-Delgado, S., Álvez-Medina, C. M., & González González, J. F. (2024). Biorefinery Based on Multiple Raw Materials and Wastes for the Production of Energy: A Proposal Tailored to Southwestern Europe. Encyclopedia, 4(4), 1381-1395. https://doi.org/10.3390/encyclopedia4040090