Simulated Annealing Integrated with Discrete-Event Simulation for Berth Allocation in Bulk Ports Under Demurrage Constraints

Abstract

1. Introduction

- (1)

- To propose a stochastic berth scheduling framework integrating metaheuristic optimisation and discrete-event simulation;

- (2)

- To formalise a mathematical model that explicitly minimises demurrage costs under discrete berth and shiploader constraints;

- (3)

- To demonstrate the computational efficiency and robustness of the hybrid Simulated Annealing–Simulation framework against other metaheuristics such as GA and ACO;

- (4)

- To provide operational insights regarding berth and shiploader utilization under uncertainty, relevant for decision-making in real bulk ports.

2. Related Works

2.1. Deterministics and Exact Optimisation Models

2.2. Metaheuristic Techniques

2.3. Discrete-Event Simulation in Port Operations

2.4. Hybrid and Simheuristic Frameworks

3. Materials and Methods

3.1. Mathematical Model

- •

- All berths are discrete, and any vessel can be berthed in any unoccupied section.

- •

- Multiple shiploaders can be assigned to a single vessel simultaneously.

- •

- There is a predefined maximum number of shiploaders that can serve each vessel.

- •

- Estimated times of vessel arrival and cargo volumes are known in advance.

- •

- Once assigned, a shiploader continues working with a vessel until loading is complete.

| Constraint | Description |

|---|---|

| (2) | Ensures that the size of the berth is not exceeded. |

| (3) | Ensures that vessels do not surpass the maximum depth allowed for the berth. |

| (4) | Guarantees that each vessel is assigned to only one berth. |

| (5) | Ensures that vessels must arrive before they can be serviced. |

| (6)–(8) | Impose limitations to prevent overlapping between two vessels berthed at the port. |

| (9) | Ensures that if vessel i is before vessel j, the opposite condition cannot occur. |

| (10) | States that vessels must complete loading operations before leaving the port. |

| (11) | Ensures that shiploader q is assigned to vessel i in berth k. |

| (12)–(13) | Require that at least one shiploader be assigned; if a shiploader is allocated to a specific berth for a vessel, it ensures that the vessel utilizes that shiploader. |

| (14)–(15) | Specify that if shiploader q continues loading vessel j after attending vessel i, it must begin only once vessel i has departed the port. |

| (16)–(21) | Represent additional technical restrictions of the model. |

3.2. Metaheuristics in a Simulation Model

| Begin Require: List control parameters (To, L, α) X ← Xo; X* ← Xo; T ← To; iteration ← 1; While (0.005 ≤ T) Generate a new solution X’; F(X’) − F(X) ← ΔE; If (ΔE ≤ 0) then X ← X’; X* ← X; Else p ← e(−∆E/T); End if If (N ≤ p) then X ← X’; iteration ← iteration + 1; End |

- •

- FlexSim is launched from a C++ script with parameter values passed via command-line arguments.

- •

- Upon model initialisation, the OnModelOpen trigger in FlexSim reads an input file containing the vessel scheduling decisions generated by the SA algorithm.

- •

- FlexSim executes the simulation using the provided schedule and collects performance metrics—such as total demurrage cost, shiploader utilisation, and berth occupancy.

- •

- These performance metrics are written to an output file.

- •

- C++ reads the output file and updates the SA search process based on the new objective function value.

4. Results

Statistical Validation

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Umang, N.; Bierlaire, M.; Vacca, I. Exact and Heuristic Methods to Solve the Berth Allocation Problem in Bulk Ports. Transp. Res. Part E Logist. Transp. Rev. 2013, 54, 14–31. [Google Scholar] [CrossRef]

- Buhrkal, K.; Zuglian, S.; Ropke, S.; Larsen, J.; Lusby, R. Models for the Discrete Berth Allocation Problem: A Computational Comparison. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 461–473. [Google Scholar] [CrossRef]

- Bierwirth, C.; Meisel, F. A Survey of Berth Allocation and Quay Crane Scheduling Problems in Container Terminals. Eur. J. Oper. Res. 2010, 202, 615–627. [Google Scholar] [CrossRef]

- Liang, C.; Guo, J.; Yang, Y. Multi-Objective Hybrid Genetic Algorithm for Quay Crane Dynamic Assignment in Berth Allocation Planning. J. Intell. Manuf. 2011, 22, 471–479. [Google Scholar] [CrossRef]

- Barros, V.H.; Costa, T.S.; Oliveira, A.C.M.; Lorena, L.A.N. Model and Heuristic for Berth Allocation in Tidal Bulk Ports with Stock Level Constraints. Comput. Ind. Eng. 2011, 60, 606–613. [Google Scholar] [CrossRef]

- Yan, S.; Lu, C.-C.; Hsieh, J.-H.; Lin, H.-C. A Dynamic and Flexible Berth Allocation Model with Stochastic Vessel Arrival Times. Netw. Spat. Econ. 2019, 19, 903–927. [Google Scholar] [CrossRef]

- Peng, Y.; Dong, M.; Li, X.; Liu, H.; Wang, W. Cooperative Optimization of Shore Power Allocation and Berth Allocation: A Balance between Cost and Environmental Benefit. J. Clean. Prod. 2021, 279, 123816. [Google Scholar] [CrossRef]

- Robenek, T.; Umang, N.; Bierlaire, M.; Ropke, S. A Branch-and-Price Algorithm to Solve the Integrated Berth Allocation and Yard Assignment Problem in Bulk Ports. Eur. J. Oper. Res. 2014, 235, 399–411. [Google Scholar] [CrossRef]

- Guo, L.; Wang, J.; Zheng, J. Berth Allocation Problem with Uncertain Vessel Handling Times Considering Weather Conditions. Comput. Ind. Eng. 2021, 158, 107417. [Google Scholar] [CrossRef]

- Osaba, E.; Villar-Rodriguez, E.; Del Ser, J.; Nebro, A.J.; Molina, D.; LaTorre, A.; Suganthan, P.N.; Coello Coello, C.A.; Herrera, F. A Tutorial On the Design, Experimentation and Application of Metaheuristic Algorithms to Real-World Optimization Problems. Swarm Evol. Comput. 2021, 64, 100888. [Google Scholar] [CrossRef]

- Tengku-Adnan, T.; Sier, D.; Ibrahim, R.N. Performance of Ship Queuing Rules at Coal Export Terminals. In Proceedings of the 2009 IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009; pp. 1795–1799. [Google Scholar]

- Wu, S.; Xu, A.; Song, W.; Li, X. Structural Optimization of the Production Process in Steel Plants Based on Flexsim Simulation. Steel Res. Int. 2019, 90, 1900201. [Google Scholar] [CrossRef]

- Juan, A.A.; Faulin, J.; Grasman, S.E.; Rabe, M.; Figueira, G. A Review of Simheuristics: Extending Metaheuristics to Deal with Stochastic Combinatorial Optimization Problems. Oper. Res. Perspect. 2015, 2, 62–72. [Google Scholar] [CrossRef]

- de León, A.D.; Lalla-Ruiz, E.; Melián-Batista, B.; Moreno-Vega, J.M. A Simulation–Optimization Framework for Enhancing Robustness in Bulk Berth Scheduling. Eng. Appl. Artif. Intell. 2021, 103, 104276. [Google Scholar] [CrossRef]

- Cheimanoff, N.; Féniès, P.; Kitri, M.N.; Tchernev, N. Exact and Metaheuristic Approaches to Solve the Integrated Production Scheduling, Berth Allocation and Storage Yard Allocation Problem. Comput. Oper. Res. 2023, 153, 106174. [Google Scholar] [CrossRef]

- Kastner, M.; Nellen, N.; Schwientek, A.; Jahn, C. Integrated Simulation-Based Optimization of Operational Decisions at Container Terminals. Algorithms 2021, 14, 42. [Google Scholar] [CrossRef]

- Zeng, Y.; Li, W.; Li, C. A Dynamic Simulation Framework Based on Hybrid Modeling Paradigm for Parallel Scheduling Systems in Warehouses. Simul. Model. Pract. Theory 2024, 133, 102921. [Google Scholar] [CrossRef]

- Dulebenets, M. A Diffused Memetic Optimizer for Reactive Berth Allocation and Scheduling at Marine Container Terminals in Response to Disruptions. Swarm Evol. Comput. 2023, 80, 101334. [Google Scholar] [CrossRef]

- Legato, P.; Mazza, R.M.; Gullì, D. Integrating Tactical and Operational Berth Allocation Decisions via Simulation–Optimization. Comput. Ind. Eng. 2014, 78, 84–94. [Google Scholar] [CrossRef]

- Rodrigues, F. The Berth Allocation Problem in Bulk Terminals under Uncertainty. Oper. Res. Perspect. 2025, 14, 100334. [Google Scholar] [CrossRef]

- Neagoe, M.; Hvolby, H.-H.; Taskhiri, M.S.; Turner, P. Using Discrete-Event Simulation to Compare Congestion Management Initiatives at a Port Terminal. Simul. Model. Pract. Theory 2021, 112, 102362. [Google Scholar] [CrossRef]

- Leithner, M.; Fikar, C. A Simulation Model to Investigate Impacts of Facilitating Quality Data within Organic Fresh Food Supply Chains. Ann. Oper. Res. 2022, 314, 529–550. [Google Scholar] [CrossRef]

- Mauri, G.R.; Oliveira, A.C.M.; Lorena, L.A.N. A Hybrid Column Generation Approach for the Berth Allocation Problem. In Proceedings of the Evolutionary Computation in Combinatorial Optimization, Naples, Italy, 26–28 March 2008; van Hemert, J., Cotta, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 110–122. [Google Scholar]

- Yang, P.; Cai, L.; Guo, W.; Li, W. A Proactive-Reactive Approach for Dynamic Hybrid Berth Allocation Problem Considering Vessels Arrival Delay. In Proceedings of the 2023 IEEE Symposium Series on Computational Intelligence (SSCI), Mexico City, Mexico, 5–8 December 2023; pp. 1753–1758. [Google Scholar]

- Lv, Y.; Wang, J.; Liu, Z.; Zou, M. From Heuristics to Multi-Agent Learning: A Survey of Intelligent Scheduling Methods in Port Seaside Operations. Mathematics 2025, 13, 2744. [Google Scholar] [CrossRef]

- Bouzekri, H.; Alpan, G.; Giard, V. Integrated Laycan and Berth Allocation Problem with Ship Stability and Conveyor Routing Constraints in Bulk Ports. Comput. Ind. Eng. 2023, 181, 109341. [Google Scholar] [CrossRef]

- Atencio, F.N.; Casseres, D.M. A Comparative Analysis of Metaheuristics for Berth Allocation in Bulk Ports: A Real World Application. IFAC-Pap. 2018, 51, 1281–1286. [Google Scholar] [CrossRef]

- Xu, L.-S.; Huang, T.; Zhao, B.; Gong, Y.; Liu, J. Continuous Berth Allocation and Time-Variant Quay Crane Assignment: Memetic Algorithm with a Heuristic Decoding Method. IEEE Trans. Intell. Transp. Syst. 2025, 26, 3387–3401. [Google Scholar] [CrossRef]

- Wu, J. Nearest-Better Clustering-Based Memetic Algorithm for Berth Allocation and Crane Assignment Problem. IEEE Access 2025, 13, 82247–82260. [Google Scholar] [CrossRef]

- Korekane, S.; Nishi, T.; Tierney, K.; Liu, Z. Neural Network Assisted Branch and Bound Algorithm for Dynamic Berth Allocation Problems. Eur. J. Oper. Res. 2024, 319, 531–542. [Google Scholar] [CrossRef]

- Chang, S.-C.; Lin, M.-H.; Tsai, J.-F. An Optimization Approach to Berth Allocation Problems. Mathematics 2024, 12, 753. [Google Scholar] [CrossRef]

- Martin-Iradi, B.; Pacino, D.; Røpke, S. The Multiport Berth Allocation Problem with Speed Optimization: Exact Methods and a Cooperative Game Analysis. Transp. Sci. 2020, 56, 972–999. [Google Scholar] [CrossRef]

- Ting, C.; Wu, K.-C.; Chou, H. Particle Swarm Optimization Algorithm for the Berth Allocation Problem. Expert Syst. Appl. 2014, 41, 1543–1550. [Google Scholar] [CrossRef]

| Study | Approach | Objective | Port Type | Main Limitation |

|---|---|---|---|---|

| [2] | Mixed-Integer Linear Programming (MILP) | Minimize vessel waiting time | Container | Deterministic assumptions; not adaptable to stochastic variations |

| [1] | MILP | Minimize total service time | Container | Applicable only to small-scale deterministic instances |

| [20] | Simulated Annealing (SA) | Minimize total turnaround time | Container | Does not consider uncertainty or variable arrivals |

| [9] | Genetic Algorithm (GA) | Reduce vessel waiting time | Container | Uses static input parameters; lacks stochastic representation |

| [10] | Ant Colony Optimization (ACO) | Optimize berth scheduling under congestion | Container | No stochastic inputs; limited scalability |

| [14] | Discrete-Event Simulation + Optimization | Robust berth scheduling | Mixed | Evaluated on limited data; lacks computational efficiency tests |

| [26] | Discrete-Event Simulation (DES) | Evaluate cargo-handling performance | Bulk | No optimization or feedback loop with scheduler |

| [15] | Simulation–Optimization | Analyze port performance under uncertainty | Bulk | No integration with metaheuristic algorithms |

| [17] | Simulation–Optimization Framework | Stochastic berth scheduling model | General | Limited validation for bulk port environments |

| Symbol/Notation | Description |

|---|---|

| Indices | |

| i ∈ N, j ∈ N | Index of vessels; N is the total number of vessels |

| k ∈ M | Index of berth positions; M is the total number of berths |

| q ∈ Q | Index of shiploaders; Q is the total number of shiploaders |

| Decision Variables | |

| Xik | Binary variable; 1 if vessel i ∈ N occupies berth position k ∈ M, 0 otherwise |

| Yij | Binary variable; 1 if vessel i ∈ N is berthed before vessel j ∈ N, 0 otherwise |

| Zikq | Binary variable; 1 if loader q ∈ Q is assigned to vessel i ∈ N in berth k ∈ M, 0 otherwise |

| Sik | Time for vessel i ∈ N to enter berth k ∈ M |

| miq | Start time of shiploader q working on vessel i ∈ N |

| fi | Departure time of vessel i ∈ N |

| x, y | Auxiliary binary variables used for sequencing and logical constraints |

| Ziq | Binary variable; 1 if shiploader q ∈ Q is assigned to vessel i ∈ N, 0 otherwise |

| Parameters Constants | |

| Pi | Demurrage cost rate per unit time for vessel i |

| Li | Length of vessel i |

| Lmax,k | Maximum allowable vessel length at berth k |

| Di | Draft (depth requirement) of vessel i |

| Dmax,k | Maximum allowable depth at berth k |

| hi | Cargo handling rate (tons/hour) for vessel i |

| T | Planning horizon (hours) |

| M | A sufficiently large positive constant used in linearization |

| α, β | Parameters controlling the temperature and cooling rate in the Simulated Annealing procedure |

| Parameter | Symbol | Value/Range | Justification |

|---|---|---|---|

| Initial temperature | T0 | 500–1000 | Provides sufficient diversification during early iterations; prevents premature convergence. |

| Final temperature | Tf | 1 | Ensures convergence and fine local search once the solution space is reduced. |

| Cooling rate | α | 0.90–0.95 | Balances exploration and exploitation; values below 0.9 slow convergence, while values above 0.9 may lose precision. |

| Number of iterations per temperature | Niter | 100–500 | Empirically defined to guarantee sufficient solution evaluation at each temperature level. |

| Stopping criterion | — | Temperature < Tf or no improvement after 100 iterations | Avoids unnecessary computation once the algorithm stabilises. |

| Neighborhood structure | — | Random vessel–berth reassignment | Enables local exploration of berth scheduling configurations while preserving feasibility. |

| Acceptance probability | P(ΔE) = exp(−ΔE/T) | — | Classical Boltzmann acceptance criterion allows uphill moves with decreasing probability as temperature decreases. |

| Objective function | Z = Σi Pi max{0, [min(mi1, mi2, …, miq) − fi]} | — | Minimises total demurrage cost by balancing scheduling efficiency and port resource utilisation. |

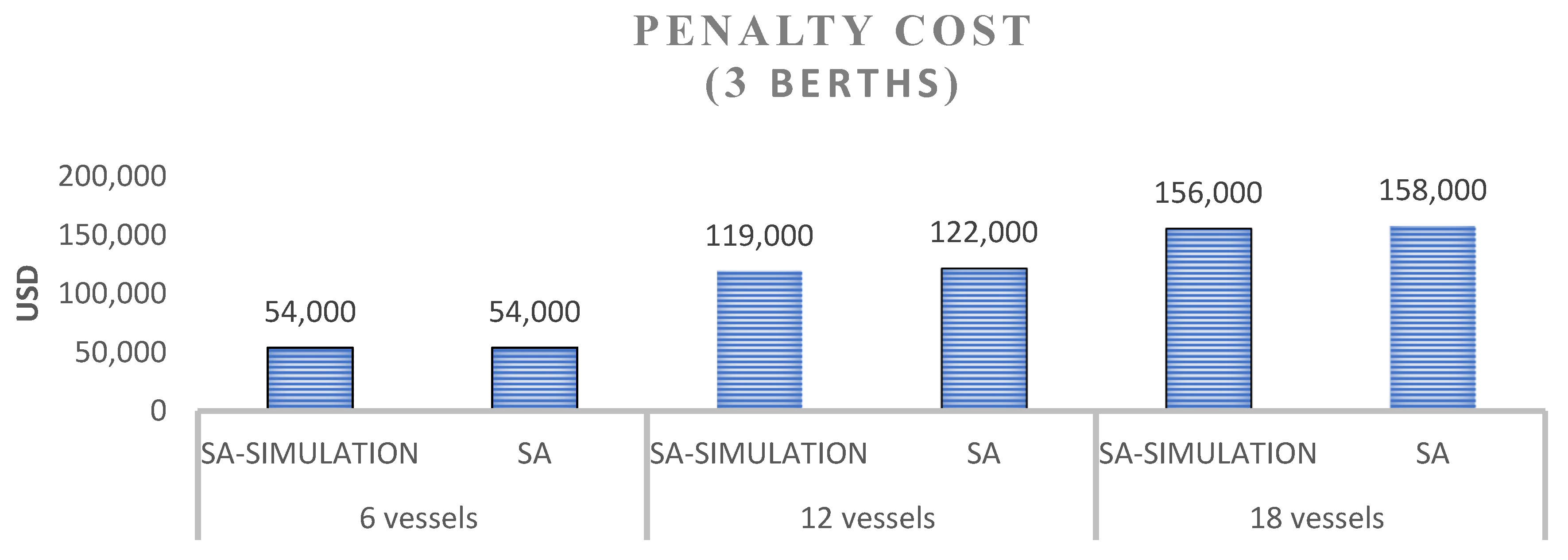

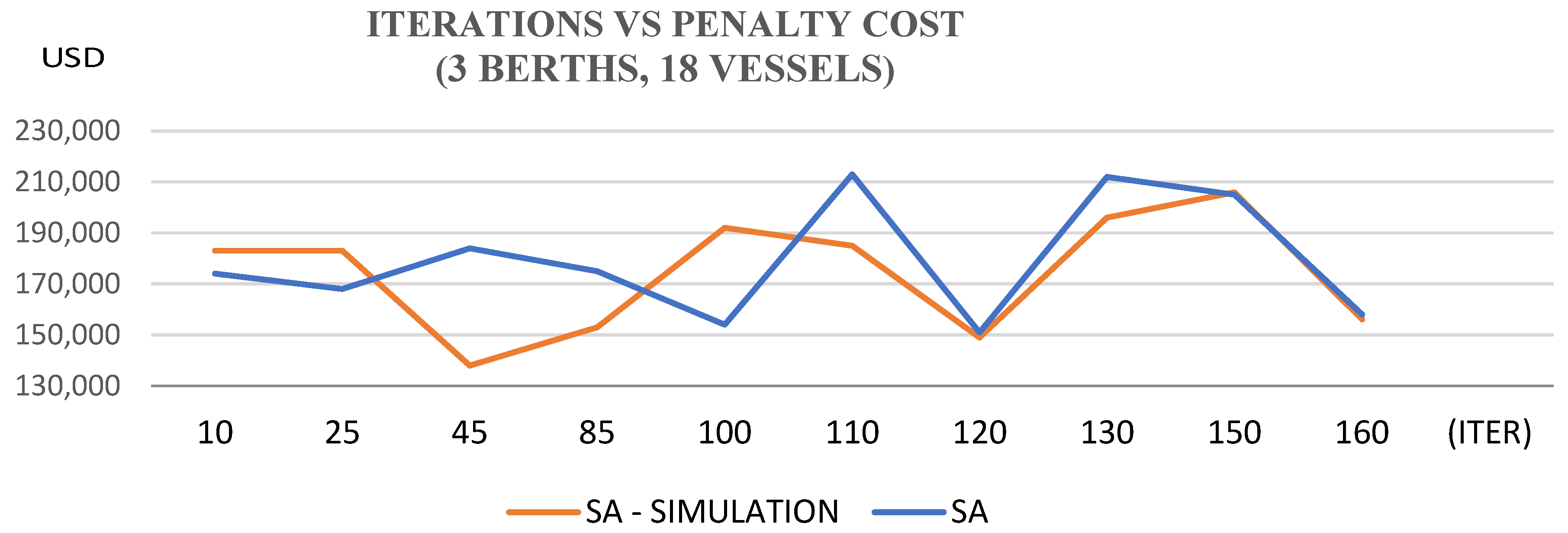

| Number of Vessels | 6 Vessels | 12 Vessels | 18 Vessels | |||

|---|---|---|---|---|---|---|

| Metaheuristic | SA–Simulation | SA | SA–Simulation | SA | SA–Simulation | SA |

| Best Solution ($) | 54.000 | 54.000 | 119.000 | 122.000 | 156.000 | 158.000 |

| Mean of the sample ($) | 55.284 | 55.098 | 120.050 | 123.875 | 158.800 | 160.451 |

| Standard Deviation ($) | 2.563 | 2.691 | 6.975 | 7.895 | 8.934 | 10.202 |

| Vessel number | 7 | 2 | 9 | 1 | 5 | 16 | 3 | 8 | 4 | 10 | 18 | 12 | 6 | 14 | 15 | 13 | 17 | 11 |

| Berth number | 1 | 2 | 3 | 2 | 1 | 3 | 1 | 1 | 2 | 3 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 |

| Uncertainty in the Bulk Port (Performance Measure) | |||

|---|---|---|---|

| Percentage Use of Shiploaders | Percentage Use of Berths | ||

| Shiploader 1 | 98% | Berth 1 | 96% |

| Shiploader 2 | 95% | Berth 2 | 94% |

| Shiploader 3 | 96% | Berth 3 | 95% |

| Statistic | Demurrage Cost (USD) |

|---|---|

| Minimum | 8740 |

| Mean | 8940 |

| Maximum | 9260 |

| Standard deviation | 178 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delahoz-Domínguez, E.; Mendoza-Mendoza, A.; Mendoza-Casseres, D. Simulated Annealing Integrated with Discrete-Event Simulation for Berth Allocation in Bulk Ports Under Demurrage Constraints. Eng 2025, 6, 352. https://doi.org/10.3390/eng6120352

Delahoz-Domínguez E, Mendoza-Mendoza A, Mendoza-Casseres D. Simulated Annealing Integrated with Discrete-Event Simulation for Berth Allocation in Bulk Ports Under Demurrage Constraints. Eng. 2025; 6(12):352. https://doi.org/10.3390/eng6120352

Chicago/Turabian StyleDelahoz-Domínguez, Enrique, Adel Mendoza-Mendoza, and Daniel Mendoza-Casseres. 2025. "Simulated Annealing Integrated with Discrete-Event Simulation for Berth Allocation in Bulk Ports Under Demurrage Constraints" Eng 6, no. 12: 352. https://doi.org/10.3390/eng6120352

APA StyleDelahoz-Domínguez, E., Mendoza-Mendoza, A., & Mendoza-Casseres, D. (2025). Simulated Annealing Integrated with Discrete-Event Simulation for Berth Allocation in Bulk Ports Under Demurrage Constraints. Eng, 6(12), 352. https://doi.org/10.3390/eng6120352