4D BIM for Construction Logistics Management

Abstract

:1. Introduction

2. Literature Review

2.1. Logistics Management in Construction

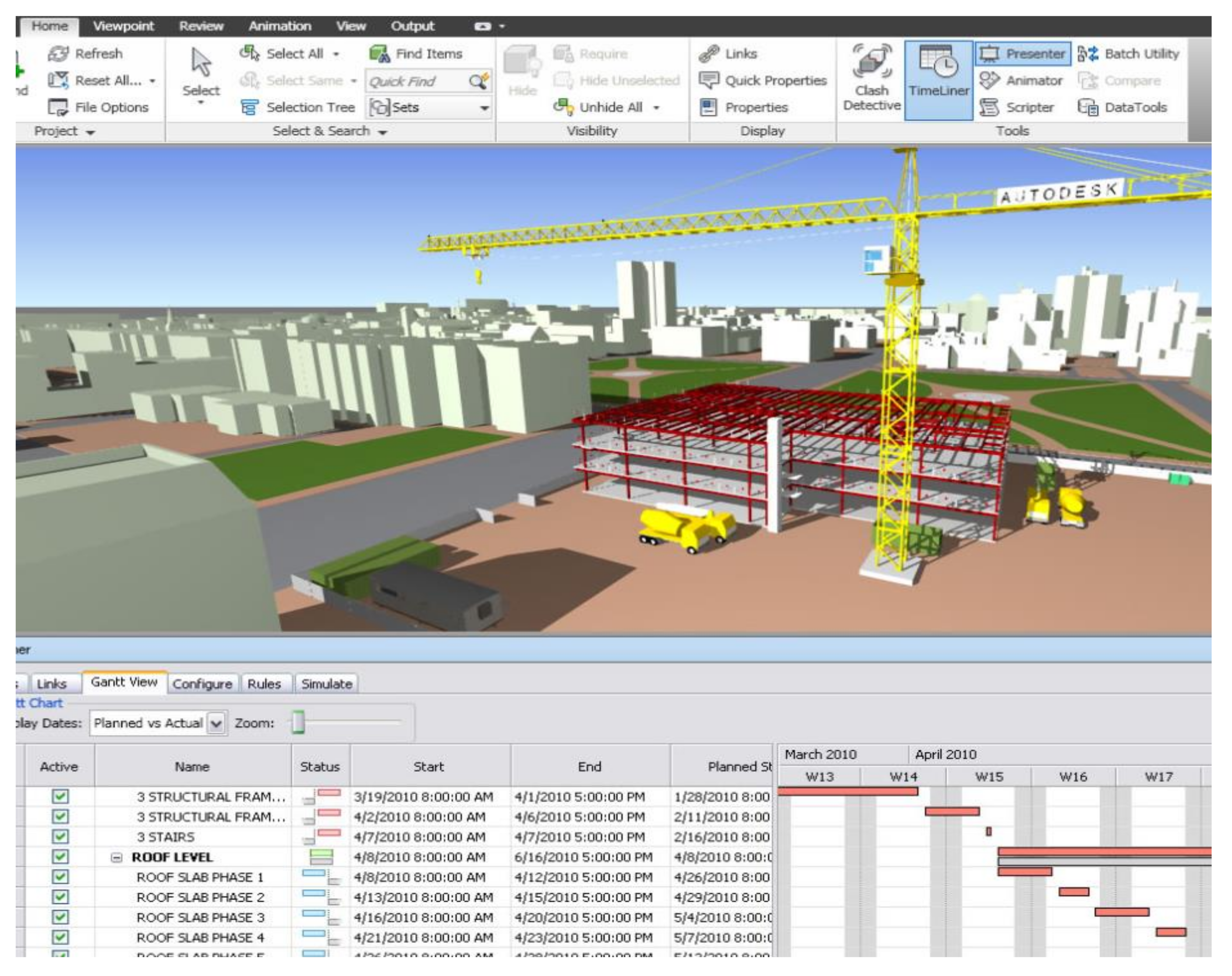

2.2. Building Information Modelling for Logistics Management

3. Research Methods

3.1. Research Design

3.2. Interview Recording and Transcription

4. Data Analysis

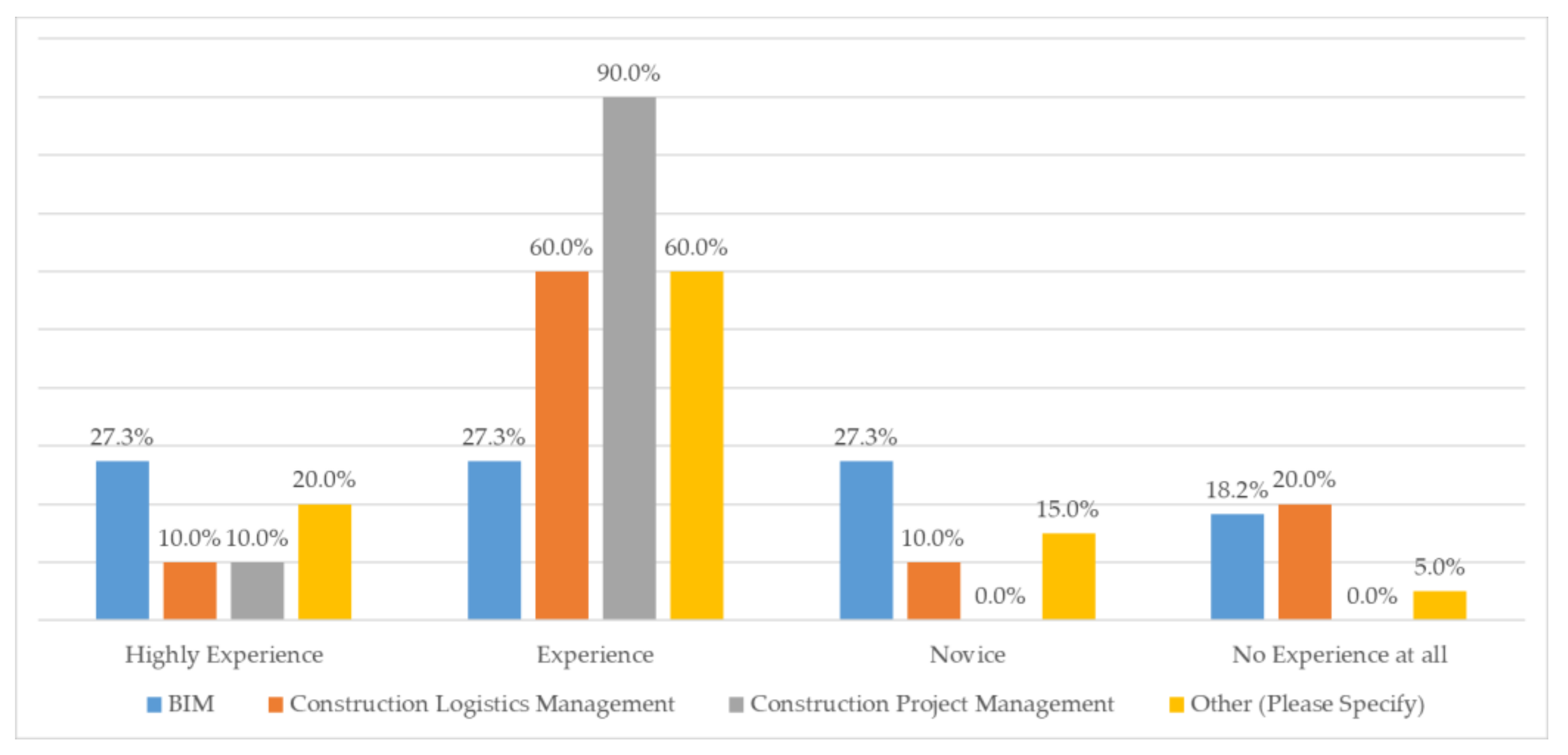

4.1. Involvement of Respondents in 4D BIM and CLM

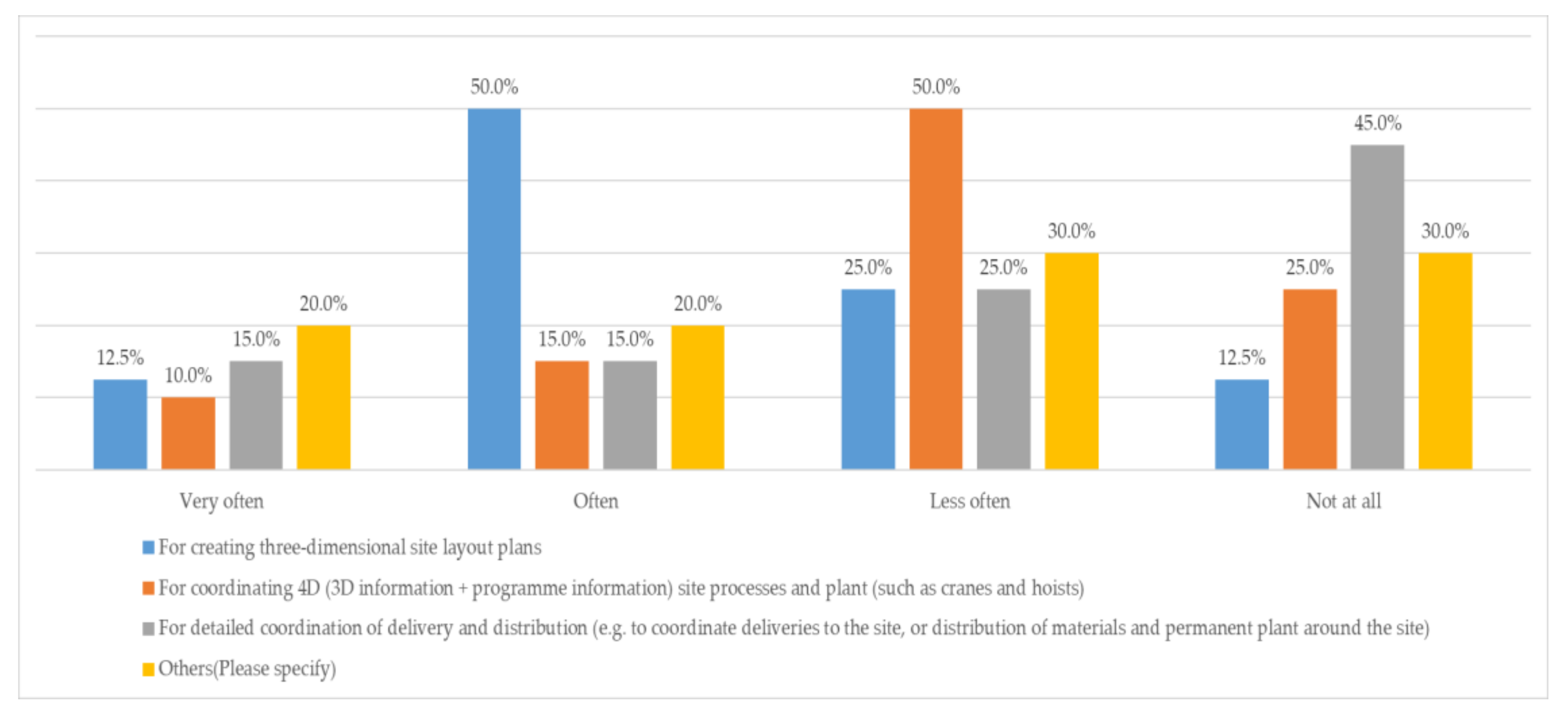

4.2. To What Extent Has BIM Been Used for Logistics on the Projects Respondents Have Been Involved in

4.2.1. Creation of Three-Dimensional Site Layout Plans and 4D Coordination of Site Processes and Common User Plant

The area that you’re looking at is plant, temporary works, and logistics. The interface with them, dynamically, in time, with the permanent works is what you’re looking for. So, therefore, the accuracy of those plant, temporary works, and logistics has got to be there… That’s critical. Absolutely critical.

… the finer details you’ll get in the 2D, where everything is more descriptive. You need to tell the clients “Okay I need this site boundary to be this big” and how you give that to the client is with a 2D drawing. You don’t give it to them with a 3D model.

4.2.2. Updating the 4D Logistics Plan as the Project Progressed

… that’s constantly being updated… [the planner has] gone away and is remodelling that as we speak, just to make sure “does the sequence work?” and then feeding that back into the programme, rather than the other way around: doing the programme first and feeding into BIM. We’re working it on the model to go back into a traditional programme.

Let’s say you have a team and you have a 4D resource, a 4D person, allocated to just doing logistics, that would be great. That person would be doing logistics every day, Synchro models and visualisations, and that is something you could do on a couple of weeks or couple of days basis, or weekly basis—but… there’s heavy resource needed in my opinion. You need a lot of input; you need a lot of time to get these things right. It’s very time-consuming.

A lot of the time it gets handed over and fair enough they use it to iron out all the issues pre-start and when they’ve just started, so it is valuable. But, once it’s there, and given the process, it should really be kept up to date. There’s not a lot involved in doing that.

What I tend to see is: “This is how we’re going to perform the logistics” and then whether it’s kept up to date… I’d love to say “Of course it is”, but I haven’t seen that.

4.2.3. Collaboration in BIM-Based Logistics Coordination

Jobs where we’ve actually had it in the beginning are absolutely minimal. We are slowly seeing it creep into tender documentation. We had a recent project where the document included a fly-through model (animation)… But, to be honest, there would be a handful of times where I’ve seen that before… the majority of projects where we get the logistics plans, relating to programme as well, are all just 2D.

At the beginning of the project, we did the Synchro model, but it was a visual on how everything gets built. And that’s great because you give it to the client and you tell them “Okay, this is how we’re going to build it”… in the 3D model that we present to the client, we’ll have the tower cranes going up, when the tower cranes go…

… but the logistics is purely only 2D. So, it’s not being done in 3D… the finer details you’ll get in the 2D, where everything is more descriptive…

[4D information is] certainly something that would add value to all our projects, but the best way of adding value is disseminating it to all the trades, so they get to have a look at it and it’s not just kept in isolation… maybe they’re just using it for visuals or as a marketing thing with clients…

… you could almost say it’s like a marketing tool. It gives you a good overview of the job, it doesn’t give you so much the detail … We’ve done sort of six-minute videos, so it gives everyone a broad idea of what we’re actually trying to achieve out on site… we would’ve done all the 3D and the 4D models, and we’ve done all the fly-throughs but then we just make it a 2D paper exercise for the sake of tendering… so that’s probably what everybody gets. When they come in for the tender interviews, we might show them on the screen… but it does tend to be part of the package that it’s more 2D drawings.

We want to work with the trades! We want full visibility, transparency with the team. We want everyone to look at it. We want the team to feed their ideas back into the logistics or the programme, and that’s how I think it should be done.

… you invite all your different suppliers, because, before you start on site, you need a very good idea of how you’re going to build the thing so, yes they did have an input… you know where the hoist is going to go, and the tower cranes are going to go, but to a limited amount of information. You probably know, like 80% sure, everything, but things change.

It was like going into a time machine almost; you could go forward in time and know exactly what the site was going to look like… so, the cladding guys, they did a bit of playing around with it… They would have a model and they would go on their floor plate, walk around their floor plate, put their cranes out, their launching tables, and see where they’re going to be.

… so, now we’re talking… as to how best to use all the logistics routes and the canti-decks… we are trying to minimise the amount of crane time, and also the amount of canti-decks by getting all three of them [the specialist trade contractors] together and all working through the model…

Well it often is that way, what with it being new technology, and a different way of working; implementation among a full team is… I’m not going to say rare… but it’s not uncommon for it to be not utilised to its maximum which would be getting it in front of the trades and anyone who’s involved in the project, getting their eyes on it…

… is that something that the main contractor should be leading? It was a perfect example this week… Everybody was in the room looking at the screen trying to work out the solution by looking at a model which is three months in the future—do we do that with everyone? No, we don’t. And again, do we do it coordinated like that? Not very often. We’ll still have our logistics meeting week by week, and that is on a 2D drawing just in front of everyone.

I don’t know if there was another [logistics] contractor involved… [but] obviously the amount of gates, even hoisting, getting materials to the point of use, etc. and the labour involved—it certainly would help to get early contractor involvement.

I think we could probably work a little closer with our logistics team in terms of the sort of BIM or the 3D modelling. We tend to do it all in house, and then just tell our contractors or our logistics provider, instead of them driving us… I think it’s an industry problem that what tends to happen is the main contractor gets the job, does all the plans, and then you go to tender and try and get a logistics contractor. Rather than the other way around and trying to get a logistics contractor in first, and working alongside in some sort of partnership, or collaboration, before the job has even been tendered.

We always say we should be working earlier with all of our sub-contractors, and, of course, when we actually get to the point, it’s always a bit too late… The nature is “let’s get someone to do the logistics for us and we can pass the risk down the line” and I think that if we work consistently with a logistics contractor, we can start to bring these things in. And we’re trying to do that with our supply chain, we are narrowing down our preferred supply chain, we are prequalifying on their capabilities for BIM. But… with the pre-qualification questionnaires (PQQ) and IT assessments… there’s a design bias.

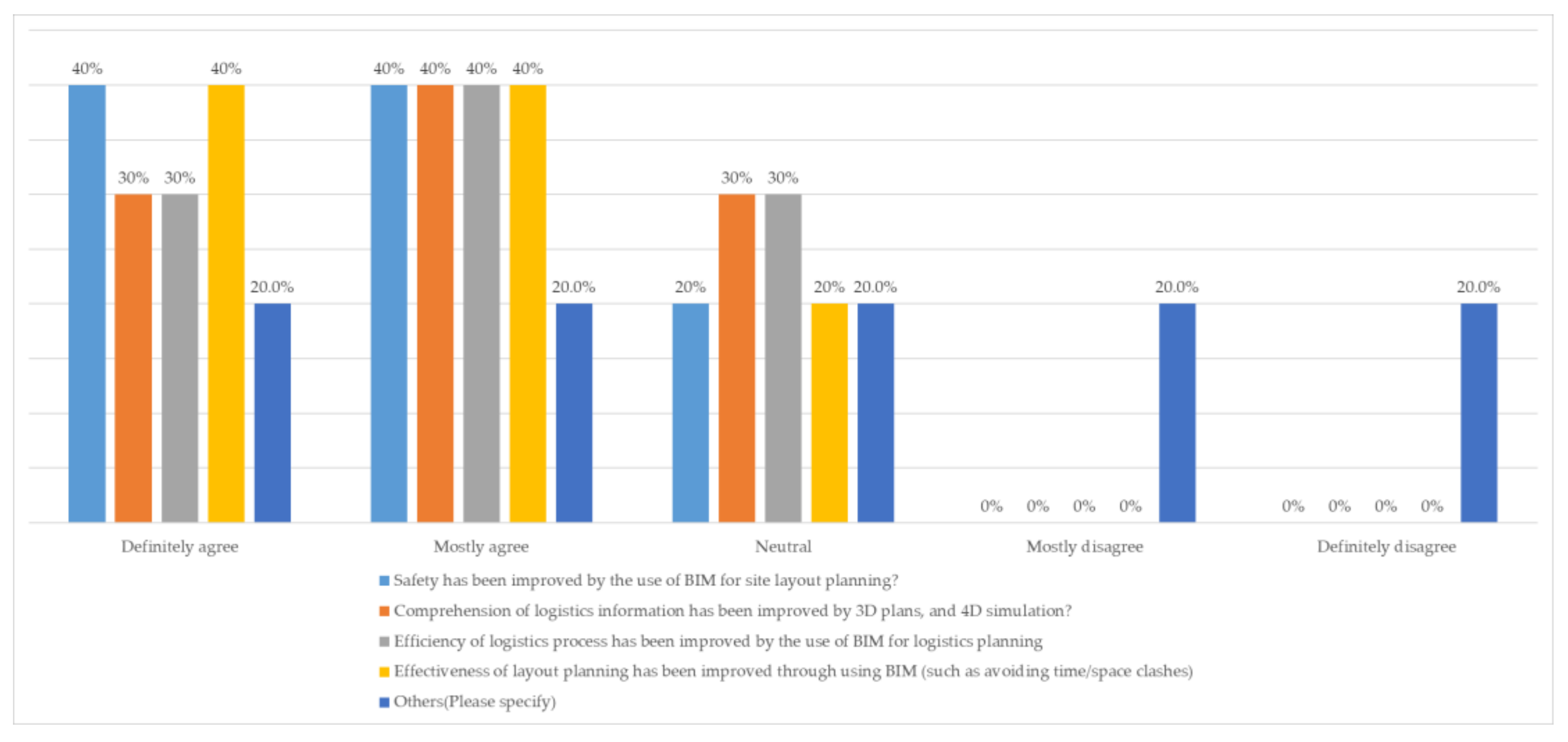

4.3. Improvements Experienced Using BIM Processes for Construction Logistics Management

Definitely, it was much, much easier. Particularly with the sequencing and temporary hoardings and changes to routes throughout the building… It made it a lot easier to realise how intricate it was with the sequencing and separating these people that were in the building from the actual building works… it undoubtedly makes things clearer.

It’s highlighted all the problems, and you can run the programmes again and again. It’s easy to do it on a bar chart but it’s much easier when you can see it on a 4D/3D model.

But you miss things: On a drawing you draw stuff and think “ah great, that works”, but you go to do it in the real world when it comes to it and it doesn’t quite work, and you have to adapt to it. That wastes time and money and resources... that was one of the things we found… you looked on the drawing and it was there, but as soon as it was modelled, of what that moment in time was going to look like off of the 4D snapshot, you knew straight away [whether it was going to work]…

Whatever you do on site, if you improve logistics, you’re going to improve health and safety. That’s because of the nature of construction.

Well how do we measure that? Of course, I am going to say “Yes, we’ve improved safety” and “Yes, we’ve improved logistics”, but if we’re not measuring it, we can’t put a figure on it.

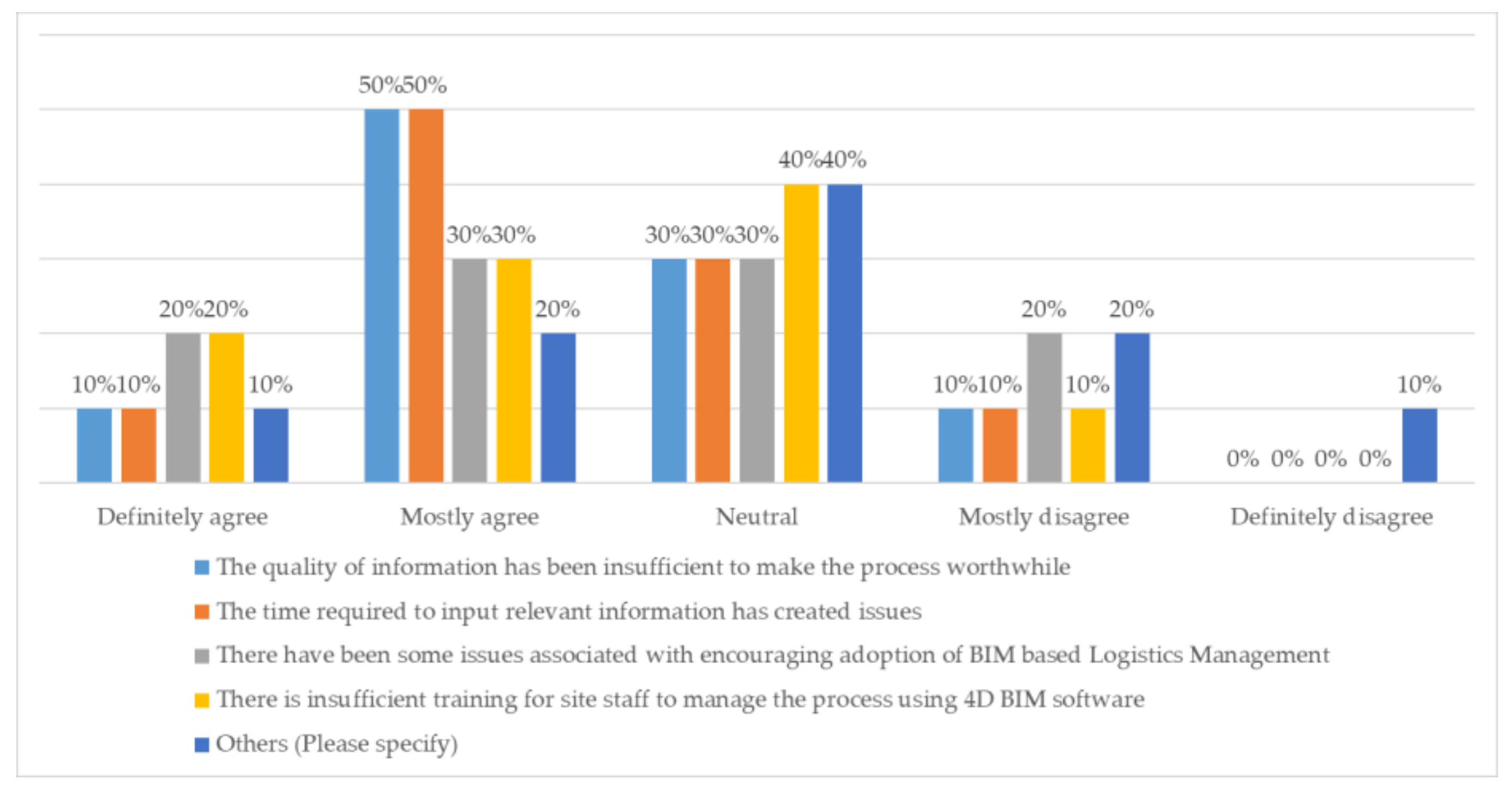

4.4. Issues Experienced Using BIM for Logistics Management

… when it comes to 4D, it’s the easiest one to adopt. Your planner is using planning software, you’re not asking him to use anything else… Your model is already there, if it’s a BIM project; the design team have modelled it… Well they’re the two main ingredients, the other one is the 3D model of the logistics… there’s not a massive amount of time in there to put a 4D model together.

Because site is not… a factory, where everything is static and you can say… “the plan is this” and, maybe if something changed, it would be a minor change. On site, everything changes and something I’ve planned in the morning may be completely different by this afternoon or tomorrow morning. So, in order to keep up with the changes, it would be one resource as least dedicated just to doing that; just to change the synchro model and update the models and update the plans.

I think the problems are more likely that we don’t always quite get the models that we need, and the training issue. I think what often happens is that you get on a project someone called a BIM coordinator, and unfortunately what will happen is often that BIM coordinator will be the go-to person, “Oh can you do the 4D to help us do logistics?”… and actually, what they should be doing is showing the planner, the logistics person, how to do it themselves.

I always have to ask [planner], who’s our man at 4D, to run the model, to do this, do that. I think it could be used a lot more with training. I’ve never been trained; I have no idea how to use Navisworks whatsoever; I don’t have it on my PC, so I am still the dinosaur using 2D and bits of paper…

I can’t think of a single problem… The biggest issue for 4D BIM is the adoption really. It’s like any new thing. It’s education, it’s a lack of understanding of what it is... I think the issue is the implementation and getting people to use it.

There are other people, older people, and they don’t understand how the model works, or they don’t see it. They’d rather have a piece of paper.(Respondent F)

4.5. Increasing and Improving the Use of BIM for Logistics Management

4.5.1. Advancing Collaborative Involvement from Trades

… the interesting idea I had, and we’ve never done it, is to treat it like a proper federated model… So, with Synchro, you can open up a blank [SP] file and you can import other Synchro files into that… So… you say “Right… [steelwork contractor], here’s your programme, and your steelwork, we want you to send that as an ‘SP’ file”… “Right, [concrete contractor], we want you to do the same with the concrete”… and you bring all these into the Master model… they keep it up to date, and they keep sending in their “SP” [files] and the main contractor has the overall one.

The only issue there is who does the logistics…? Who puts in the tower cranes, because they’re shared aren’t they? And who puts in the hoardings, and the hoists and access routes and welfare…? Maybe the main contractor does that little bit. I’m not sure, but I think it’s something I have always thought about, but never explored.

4.5.2. Application of 4D BIM Systems to Material Distribution and Delivery Management

Where does logistics break down for us? It’s actually trying to manage delivery tickets… How do we manage delivery tickets and how do we stop the blockage at the gate?… That’s where a lot of things breakdown I think and we’re looking at how to solve that as a problem.

… we would tend to just go with the feel of the job… Knowing you’ve got space for materials you don’t want to run out of… equally, you don’t want two hundred packs of blocks if there’s nowhere to put the damn things…

You know what’s coming up over the next few weeks. If you’re suddenly going to flood the job, you then just know through knowledge rather than computer programmes. You could argue that both ways really: the computer says, over the next certain weeks, you’re going to be building loads of walls for instance… obviously you’re going to need that space for materials to be hitting first.

Typically, on central London sites, we use a delivery management system so all the trades book in, so we know what’s coming to site. If we could tie that into the BIM model, then we could be a massive facilitator for the main contractor… I mentioned before about materials coming onto projects too early, we’d be able to police that for the main contractor… Knowing when materials are coming in, picking up defects, or if something is not the correct material… these are all, logistically, things I think we as a company could develop into providing for the main contractor, and at the same time assist all the specialist trade contractors as well. Make their lives easier. They want their materials on site at the right time, in the right place, so that they can get them installed, and install them correctly without coming across damage because they’ve been on site too long.

To be able to interrogate the model… if the model was online let’s say, and I know something has to come tomorrow… If there was a way that I could interrogate that model and say, “Okay, this piece of steel. When is it coming?”, click on it, and it tells me delivery is scheduled for tomorrow morning, that is information I can use to feed into my programme…

It’d be very helpful. It’s all about trying to solve problems earlier. The more data you have, the better at the end of the day.

The problem being there, and I mentioned before number of deliveries and wagons and things like that, Synchro 4D is a 3D programme. You’re visualising the programme. The main contractor’s programme or a trade contractor’s programme. They can only show the level of detail of their tasks. They haven’t got a task for every delivery. And the beauty of 4D is the job will be built in line with the programme. That’s why you visualise it. You’ve got a bar chart or all these lines that tell you that’s the best way to build it. It’s only when you do it in 4D you go “oh, I didn’t spot that missing link there. And, therefore, I’ve got a problem with the programme”. And that’s the fundamental part: that you’re viewing the actual programme. There’s no manual intervention in the sequence. And what you’re getting into with the deliveries and stuff like that, I’m not saying it wouldn’t be worthwhile sequencing it out, but it isn’t the programme.

There’s also space planning as well—when we’re certainly loading out some of the buildings—I think BIM could be used for that. We’re still quite old fashioned in the weight distribution of, you know, panels and blocks and everything like that. But could you do that through BIM to make sure “right, this is where the model is, you can’t put all your heavy cladding panels, for instance, all in a great big lump”.

5. Discussion and Recommendations

5.1. Update and Reference the 4D BIM Model as the Project Progresses

5.2. Increase 4D BIM Training for Project Management Staff

5.3. Increase Collaboration with Trade Contractors

5.4. Invite Specialist Logistics Contractors to Be a Part of the Construction Logistics Planning Process

5.5. Offer 4D BIM Model Access to Trade Contractors and Specialist Logistics Contractors

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chapman, I. The Right Information at the Right Time. AEC Magazine. 2013. Available online: http://www.aecmag.com/comment-mainmenu-36/575-the-right-information-at-the-right-time (accessed on 13 April 2021).

- Foy, A. Right Information. Right Person. Right Time, LinkedIn Articles. 2016. Available online: https://www.linkedin.com/pulse/right-information-person-time-andrew-foy (accessed on 15 August 2019).

- British Standards Institution. BS 1192-2:2013—Collaborative Production of Architectural, Engineering and Construction Information. Code of Practice; British Standards Institution, BSI Standards Ltd.: London, UK, 2013. [Google Scholar]

- BIS. Construction 2025; HM Government Department for Business, Innovation and Skills: London, UK, 2013; pp. 5–62.

- Waterhouse, R. National BIM Report 2014; RIBA Enterprises Ltd.: London, UK, 2014; p. 3. [Google Scholar]

- Malleson, A. BIM Survey: Summary of Findings; NBS National BIM Report 2017; RIBA Enterprises Ltd.: London, UK, 2017; pp. 10–26. [Google Scholar]

- van Ee, T. Construction Logistics Management (CLM) Construction Logistics Management (CLM). Master’s Thesis, University of Twente, Enschede, The Netherlands, 2020. [Google Scholar]

- Agapiou, A.; Clausen, L.E.; Flanagan, R.; Norman, G.; Notman, D. The role of logistics in the materials flow process. Constr. Manag. Econ. 1998, 16, 131–137. [Google Scholar] [CrossRef]

- Harker, A.; Allcorn, W.; Taylor, D. Material Logistics Plan Good Practice Guidance; Waste & Resources Action Programme: Banbury, UK, 2007; pp. 7–62. [Google Scholar]

- Browne, M. The Challenge of Construction Logistics. In Supply Chain Management and Logistics in Construction: Delivering Tomorrow’s Built Environment; Kogan Page: Philadelphia, PA, USA, 2015; pp. 9–24. [Google Scholar]

- Nolz, P.C. Optimizing construction schedules and material deliveries in city logistics: A case study from the building industry. Flex. Serv. Manuf. J. 2020. [Google Scholar] [CrossRef]

- Magill, L.G.; Jafarifar, N.; Watson, A.; Omotayo, T. 4D BIM integrated construction supply chain logistics to optimise on-site production. Int. J. Constr. Manag. 2020. [Google Scholar] [CrossRef]

- Munir, M.; Kiviniemi, A.; Jones, S.W.; Finnegan, S. BIM-based Operational Information Requirements for Asset Owners. Archit. Eng. Des. Manag. J. 2020, 16, 100–114. [Google Scholar] [CrossRef]

- Sullivan, G.; Barthorpe, S.; Robbins, S. Managing Construction Logistics; Wiley-Blackwell: Chichester, UK, 2011. [Google Scholar]

- Sobotka, A.; Czarnigowska, A.; Stefaniak, K. Logistics of construction projects. Found. Civ. Environ. Eng. 2005, 6, 203–216. [Google Scholar]

- Garbett, J.; Thomas Hartley, T.; Heesom, D. A multi-user collaborative BIM-AR system to support design and construction. Autom. Constr. 2021, 122, 103487. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F.; Faust, K.M. 4D-BIM to enhance construction waste reuse and recycle planning: Case studies on concrete and drywall waste streams. Waste Manag. 2020, 116, 79–90. [Google Scholar] [CrossRef]

- The Chartered Institute of Logistics and Transport. The Royal Charter. 2019. Available online: https://www.ciltuk.org.uk/AboutUs/InstituteStructure/Governance/TheRoyalCharter.aspx (accessed on 12 September 2019).

- Akinci, B.; Fischer, M.; Zabelle, T. Proactive Approach for Reducing Non-Value Adding Activities Due to Time-Space Conflicts. In Proceedings of the 6th Annual Conference of the International Group for Lean Construction (IGLC-6), Guaruja, Brazil, 13–15 August 1998. [Google Scholar]

- Guerlain, C.; Renault, S.; Ferrero, F.; Faye, S. Decision Support Systems for Smarter and Sustainable Logistics of Construction Sites. Sustainability 2019, 11, 2762. [Google Scholar] [CrossRef] [Green Version]

- Bortolini, R.; Shigaki, J.S.; Formoso, C.T. Site Logistic Planning and Control Using 4D Modelling: A Study in a Lean Car Factory Building Site. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 28–31 July 2015; pp. 361–370. [Google Scholar]

- Government Statistical Service. UK Statistics on Waste; Statistical Notice 15.12.2015; HM Government Department For Environment, Food and Rural Affairs: London, UK, 2015; pp. 4–5.

- WRAP. Reducing Material Wastage in Construction; Waste & Resources Action Programme: Banbury, UK, 2007; pp. 1–12. [Google Scholar]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A. Critical management practices influencing on-site waste minimization inconstruction projects. Waste Manag. 2017, 59, 330–339. [Google Scholar] [CrossRef]

- Johansson, E. Finding and Reducing Obstacles for Implementing New Logistics Systems in the Construction Industry. Master’s Thesis, Karlstad Business School, Karlstad University, Karlstad, Sweden, 2013; p. 7. [Google Scholar]

- Thomas Ng, S.; Fang, Y.; Ugwu, O.O. Modelling construction material logistics system with stochastic Petri nets. Constr. Innov. 2008, 8, 46–60. [Google Scholar]

- Robbins, S. Effective Management of a Construction Project Supply Chain. In Supply Chain Management and Logistics in Construction: Delivering Tomorrow’s Built Environment; Kogan Page: Philadelphia, PA, USA, 2015; pp. 62–75. [Google Scholar]

- Waddell, M. Resource Efficiency Benefits of Effective Construction Logistics. In Supply Chain Management and Logistics in Construction: Delivering Tomorrow’s Built Environment; Kogan Page: Philadelphia, PA, USA, 2015; pp. 139–158. [Google Scholar]

- Transport for London. The Directory of London Construction Consolidation Centres; Transport for London (TfL): London, UK, 2016; pp. 3–15. [Google Scholar]

- Whitlock, K.; Abanda, F.H.; Manjia, M.B.; Pettang, C.; Nkeng, G.E. BIM for Construction Site Logistics Management. J. Eng. Proj. Prod. Manag. 2018, 8, 47–55. [Google Scholar] [CrossRef] [Green Version]

- Reddy, K.P. BIM for Building Owners and Developers: Making a Business Case for Using BIM on Projects; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Harvard. Harvard University Construction Management Council: BIM Uses Guide. 2019, pp. 1–12. Available online: https://home.planningoffice.harvard.edu (accessed on 19 September 2019).

- Hardin, B.; McCool, D. BIM and Construction Management: Proven Tools, Methods, and Workflows; John Wiley & Sons: Indianapolis, IN, USA, 2015; pp. 188–190. [Google Scholar]

- Higgins, S.; Trevail, J.; Teglown, S. Dynamo. 2018. Available online: https://library.myebook.com/UBM/architectural-technology-journal-128-winter-2018-19/1521/#page/27 (accessed on 14 April 2021).

- Gebru, H.M.; Staub-French, S. Leveraging data to visualize and assess space planning compliance. In Proceedings of the CSCE Annual Conference Growing with Youth—Croître Avec les Jeunes, Laval (Greater Montreal), QC, Canada, 12–15 June 2019. [Google Scholar]

- UNIFI. Construction Logistics Planning with UNIFI. 2019. Available online: https://unifilabs.com/construction-site-logistics-planning-with-unifi/ (accessed on 14 April 2021).

- Moon, D.; Chung, S.; Kwon, S.; Seo, J.; Shin, J. Comparison and utilization of point cloud generated from photogrammetry and laser scanning: 3D world model for smart heavy equipment planning. Autom. Constr. 2019, 98, 322–331. [Google Scholar] [CrossRef]

- Zhang, J.P.; Ma, Z.Y.; Pu, C. 4D Visualisation of Construction Site Management. In Proceedings of the 5th International Conference on Information Visualisation, London, UK, 25–27 July 2001; pp. 382–387. [Google Scholar] [CrossRef]

- Hitech 4D Construction Scheduling, Hitech CAD Services. 2019. Available online: https://www.hitechcaddservices.com/bim/4d/ (accessed on 20 September 2019).

- Kumar, S.; Cheng, J. A BIM-based automated site layout planning framework for congested construction sites. Autom. Constr. 2015, 59, 24–37. [Google Scholar] [CrossRef]

- Demchak, G.; Dzambazova, T.; Krygiel, E. Mastering Revit Architecture 2010; John Wiley & Sons: Indianapolis, IN, USA, 2011; pp. 1–14. [Google Scholar]

- Amor, R.; Dimyadi, J. The promise of automated compliance checking. Dev. Built Environ. 2021, 5, 100039. [Google Scholar] [CrossRef]

- Irizarry, J.; Karan, E.P.; Jalaei, F. Integrating BIM and GIS to improve the visual monitoring of construction supply chain management. Autom. Constr. 2013, 31, 241–254. [Google Scholar] [CrossRef]

- Chen, Q.; de Soto, B.G.; Adey, B.T. Supplier-contractor coordination approach to managing demand fluctuations of ready-mix concrete. Autom. Constr. 2021, 21, 103423. [Google Scholar] [CrossRef]

- Rebolj, D.; Babič, N.C.; Magdič, A.; Podbreznik, P.; Pšunder, M. Automated Construction Activity Monitoring System. Adv. Eng. Inform. 2008, 22, 493–503. [Google Scholar] [CrossRef]

- Azhar, S. Building Information Modelling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry. In Leadership and Management in Engineering; American Society of Civil Engineers: Reston, VA, USA, 2011; pp. 241–252. [Google Scholar]

- Martins, S.S.; Evangelista, A.C.J.; Hammad, A.W.A.; Tam, V.W.Y.; Haddad, A. Evaluation of 4D BIM tools applicability in construction planning efficiency. Int. J. Constr. Manag. 2020. [Google Scholar] [CrossRef]

- Vigneault, M.A.; Boton, C.; Chong, H.Y.; Cooper-Cooke, B. An Innovative Framework of 5D BIM Solutions for Construction Cost Management: A Systematic Review. Arch. Comput. Methods Eng. 2020, 27, 1013–1030. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J. BIM-Based 4D Simulation to Improve Module Manufacturing Productivity for Sustainable Building Projects. Sustainability 2017, 9, 426. [Google Scholar] [CrossRef] [Green Version]

- BIS. UK Construction: An Economic Analysis of the Sector; HM Government Department for Business, Innovation and Skills: London, UK, 2013; p. 7. [Google Scholar]

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 322–326. [Google Scholar]

- Lundesjo, G. Consolidation Centres in Construction Logistics. In Supply Chain Management and Logistics in Construction: Delivering Tomorrow’s Built Environment; Kogan Page: Philadelphia, PA, USA, 2015; pp. 225–242. [Google Scholar]

- Si, T.; Li, H.X.; Hosseini, M.R.; Ji, Y.; Liu, C. A Solution to Just-in-Time Delivery for Off-Site Construction: A Conceptual Model. In Proceedings of the Construction Research Congress 2020, Tempe, AZ, USA, 3–8 March 2020. [Google Scholar]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modelling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Cookson, G.; Pishue, B. INRIX Global Traffic Scorecard; INRIX Research: London, UK, 2017. [Google Scholar]

- Carmona, M. London’s local high streets: The problems, potential and complexities of mixed street corridors. Prog. Plan. 2015, 100, 1–84. [Google Scholar] [CrossRef] [Green Version]

- Croydon Council. A Practical Guide to Drafting a Construction Logistics Plan. 2012. Available online: https://www.croydon.gov.uk/planningandregeneration/regeneration/construction-logistics-in-croydon (accessed on 21 July 2019).

- Transport for London. Construction Logistics Plan Guidance for Developers; Transport for London (TfL): London, UK, 2013; p. 3. [Google Scholar]

- Fellows, R.F.; Liu, A. Research Methods for Construction, 4th ed.; Wiley-Blackwell: Oxford, UK, 2015. [Google Scholar]

- Soliman, D.F. 3D Subdivision. 2010. Available online: https://blog.cafebim.com/3d-subdivision-part-1-of-3-646f6541d849 (accessed on 16 September 2019).

- Marefat, A.; Toosi, H.; Hasankhanlo, R.M. A BIM approach for construction safety: Applications, barriers and solutions. Eng. Constr. Archit. Manag. 2019, 26, 1855–1877. [Google Scholar] [CrossRef]

- Vilventhan, A.; Razin, S.; Rajadurai, R. 4D BIM models for smart utility relocation management in urban infrastructure projects. Facilities 2020, 39, 50–63. [Google Scholar] [CrossRef]

| Respondent Reference | Number of Projects (Using BIM) | Comments | Types of Projects |

|---|---|---|---|

| A | 1+ | Only 1 memorable instance where Respondent A was issued with 4D information; however, Respondent A was involved in a number of projects that had a 4D logistics model prepared (and not issued/shared). | Enabling project (for a future residential development). |

| B | 2 | Low number likely due to being resident on long-term developments. | Large commercial and residential developments. |

| C | Expected 100+ | No exact number given; however, Respondent C oversees all United Kingdom (UK) projects for a major contractor. 100+ is no doubt a low estimate. | General developments predominantly include hospitals and rail projects. All projects conducted by operating unit involved piling and ground engineering. |

| D | 400+ | High number due to being responsible for preparing 4D logistics plans for a number of global clients. | Large residential and commercial projects, major infrastructure developments including rail, highways, hospitals, and schools, and stadia, nuclear plants, and military installations in active warzones. |

| E | 3 | Low number likely due to being resident on long-term developments. | Schools and (the current) high-rise commercial project. |

| F | 1+ | Low number due to being resident on long-term developments. Respondent F has only been involved in logistics management (and to a limited extent) on the current project. | Large mixed-use commercial and residential development in Central London. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Whitlock, K.; Abanda, F.H.; Manjia, M.B.; Pettang, C.; Nkeng, G.E. 4D BIM for Construction Logistics Management. CivilEng 2021, 2, 325-348. https://doi.org/10.3390/civileng2020018

Whitlock K, Abanda FH, Manjia MB, Pettang C, Nkeng GE. 4D BIM for Construction Logistics Management. CivilEng. 2021; 2(2):325-348. https://doi.org/10.3390/civileng2020018

Chicago/Turabian StyleWhitlock, Kane, Fonbeyin Henry Abanda, Marcelline Blanche Manjia, Chrispin Pettang, and George Elambo Nkeng. 2021. "4D BIM for Construction Logistics Management" CivilEng 2, no. 2: 325-348. https://doi.org/10.3390/civileng2020018