This section shows results from the set of tests performed. Although the Horiba equipment can provide NO, NO2, and NOx values, the Tekber equipment only provides NOx concentration values, so the comparison was made exclusively with the NOx concentration.

Another difference between the equipment is the data acquisition frequency. The Horiba gas analyser can measure with a 10 Hz frequency, while the Tekber gas analyser can only measure with a 1 Hz frequency. This difference can be significant when analysing the behaviour of both devices, because the Tekber equipment could not detect some fast variations in NOx concentration (e.g., instantaneous peak values).

Currently, the gas emission measurements in PTI are always on a wet basis since the equipment must be as economical as possible. Consequently, the cost of installing (and maintaining) the necessary means for an accurate dry basis measurement is not justified by the advantage provided by the increase in accuracy. Converting the dry measurement obtained by the Horiba to a wet basis measurement would imply introducing uncertainty to the results obtained by the equipment. Moreover, it does not provide significant additional information to the objective of the analysis (which is to assess the suitability of the equipment for measuring NOx in PTI) that would justify the increase of uncertainty.

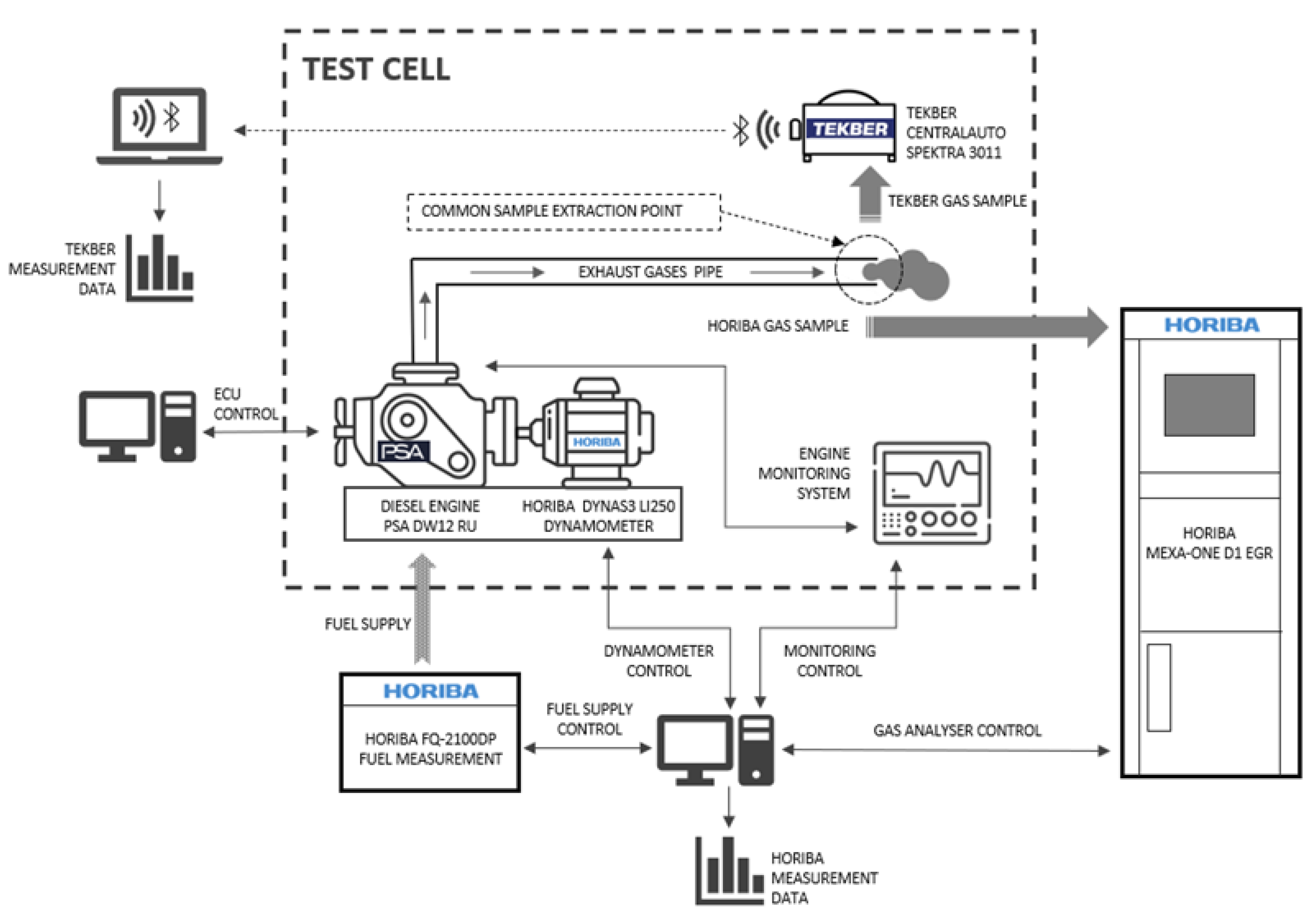

3.1. Results of Static Idling Internal Load Tests

The Static Idling Internal Load Test is a method designed to measure NO

x emissions from vehicles in PTI in static conditions. This method is based on the variation of NO

x concentration in the exhaust pipe of a vehicle and its relation with the variation of the load demand applied to the engine, and was identified by CITA as an effective way for current NO

x measurements in Euro 5 and Euro 6 diesel vehicles [

13].

An extensive description of the method can be found in [

14]. In summary, it consists of a measurement of NO

x concentration, while the engine is at idle speed, starting with all vehicle internal consumption switched off, i.e., starting with the lowest possible torque demand in the engine. The torque demand is increased by switching on various items of vehicle equipment (mainly the air-conditioning system, lighting system, and rear-window-heating system), which generates a variation in the load demand over the engine and, because of this, a variation in the NO

x concentration in the exhaust pipe.

The NO

x concentration in the pipe exhaust stream is measured with a gas analyser, and the load demand on the engine is controlled through the OBD system, with the value of “% engine load” provided by the ECU of the vehicle (PID

$04 according to SAE J1979/ISO 15031-5) [

27].

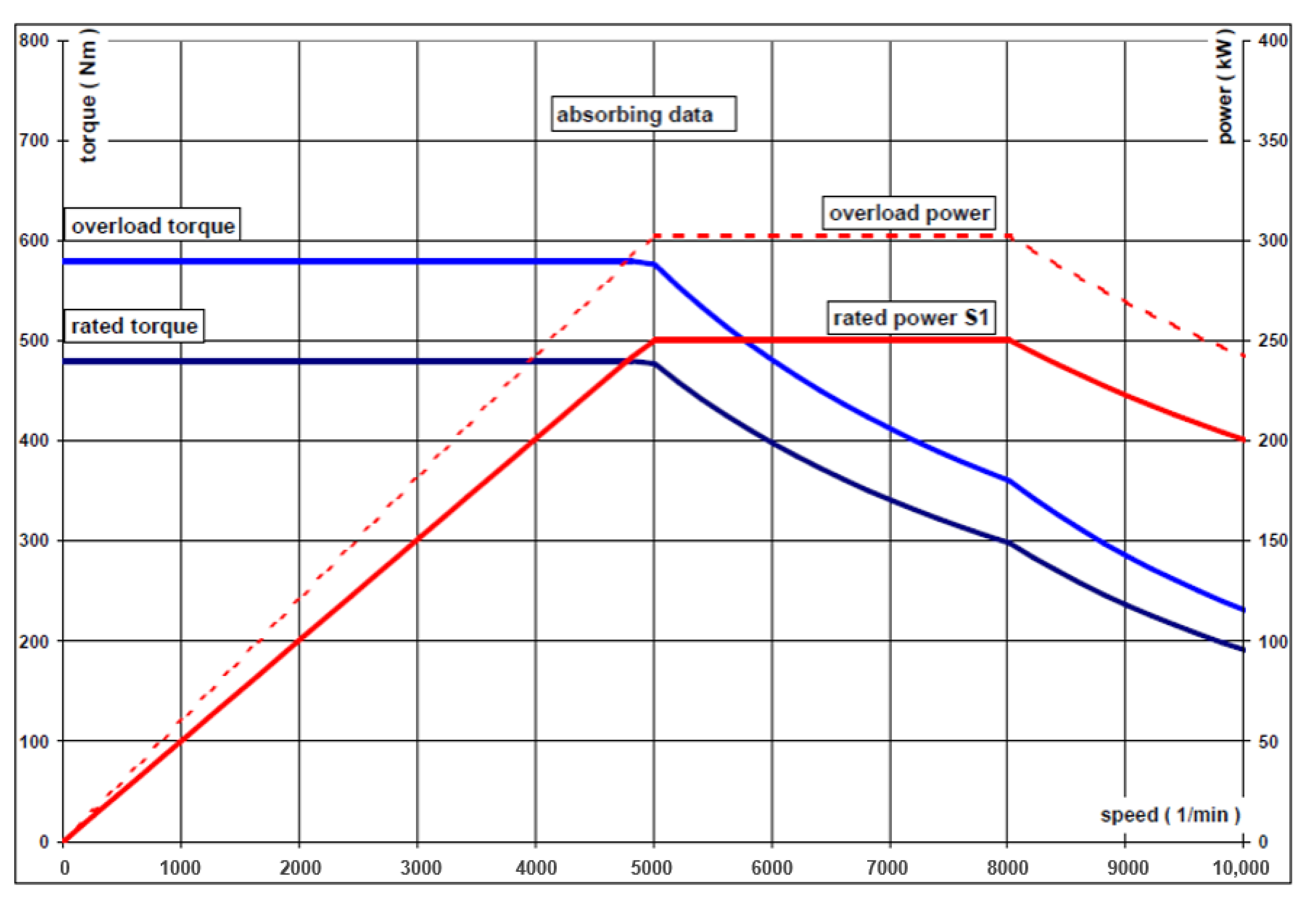

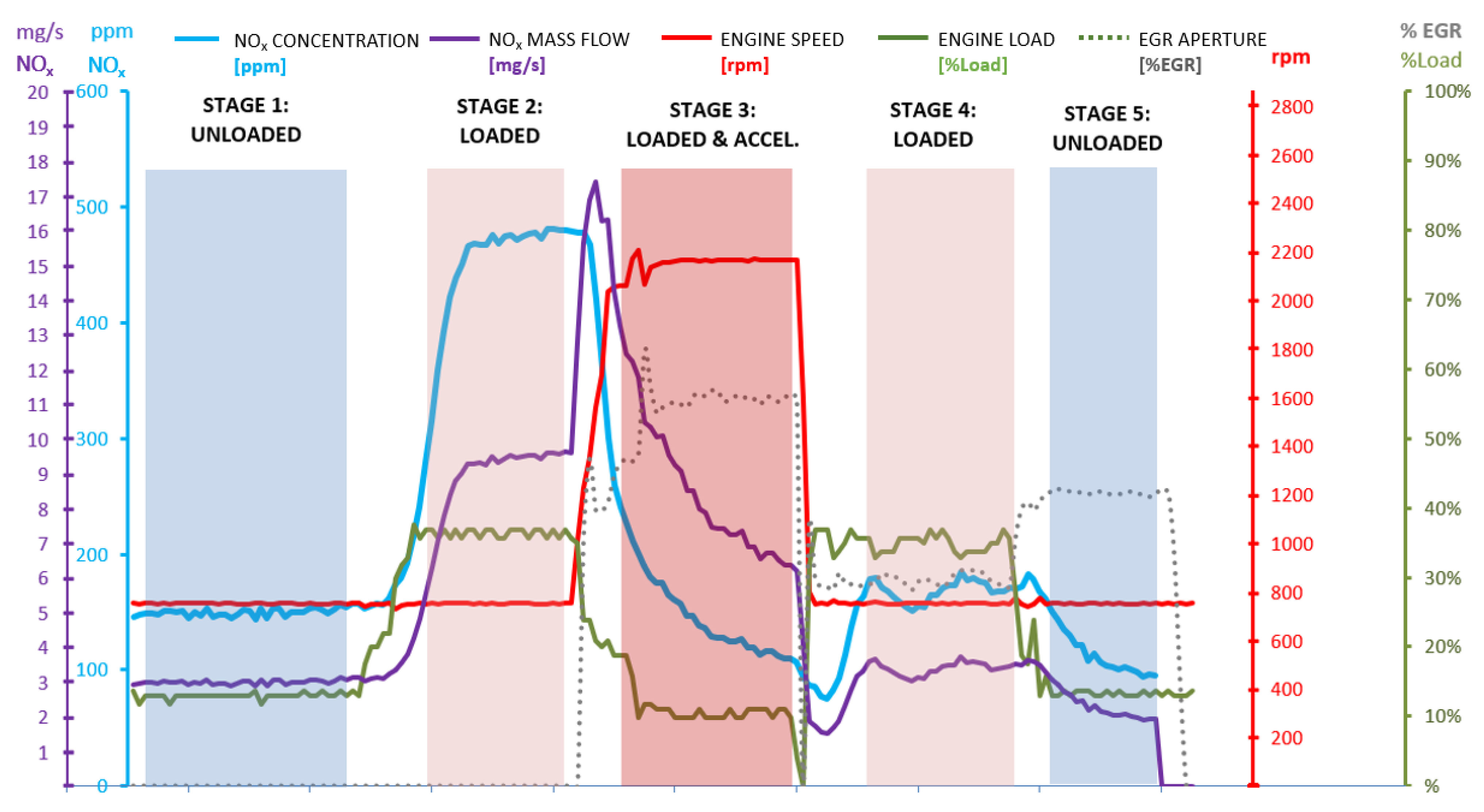

The test is a five-stage measurement process as shown in

Figure 2, according to the instructions in

Table 1. The time duration of each stage is associated with obtaining enough data to get a representative average value. Typically, at least 20 s of stable engine load data are recorded. Therefore, the duration of the stages may not be exactly the same between the several stages because it depends on the vehicle’s behaviour along the measurement process.

Tests were carried out in four different conditions for a wide range of results:

Static Idling Internal Load Test with EGR, low load condition;

Static Idling Internal Load Test with EGR, high load condition;

Static Idling Internal Load Test without EGR, low load condition;

Static Idling Internal Load Test without EGR, high load condition.

As explained, the method is designed to be performed on diesel vehicles in PTI. However, the test carried out in the test cell procedure cannot be exactly the same because there was no vehicle but only its engine. Therefore, it was necessary to simulate the variations of load demand generated over the engine by connecting and disconnecting the vehicle’s auxiliary equipment. In this way, load demand over the vehicle has been modified through the dynamometer connected to the engine’s power output.

If engine speed follows the instructions in

Table 1, and load demand behaviour is similar to the profile observed in

Figure 2, the measurement test can be performed in the test cell.

Sequences of 20 consecutive cycles were programmed to optimise the timing of the tests. Since a computer program commands the implementation of the test, the duration of every stage was the same for every cycle.

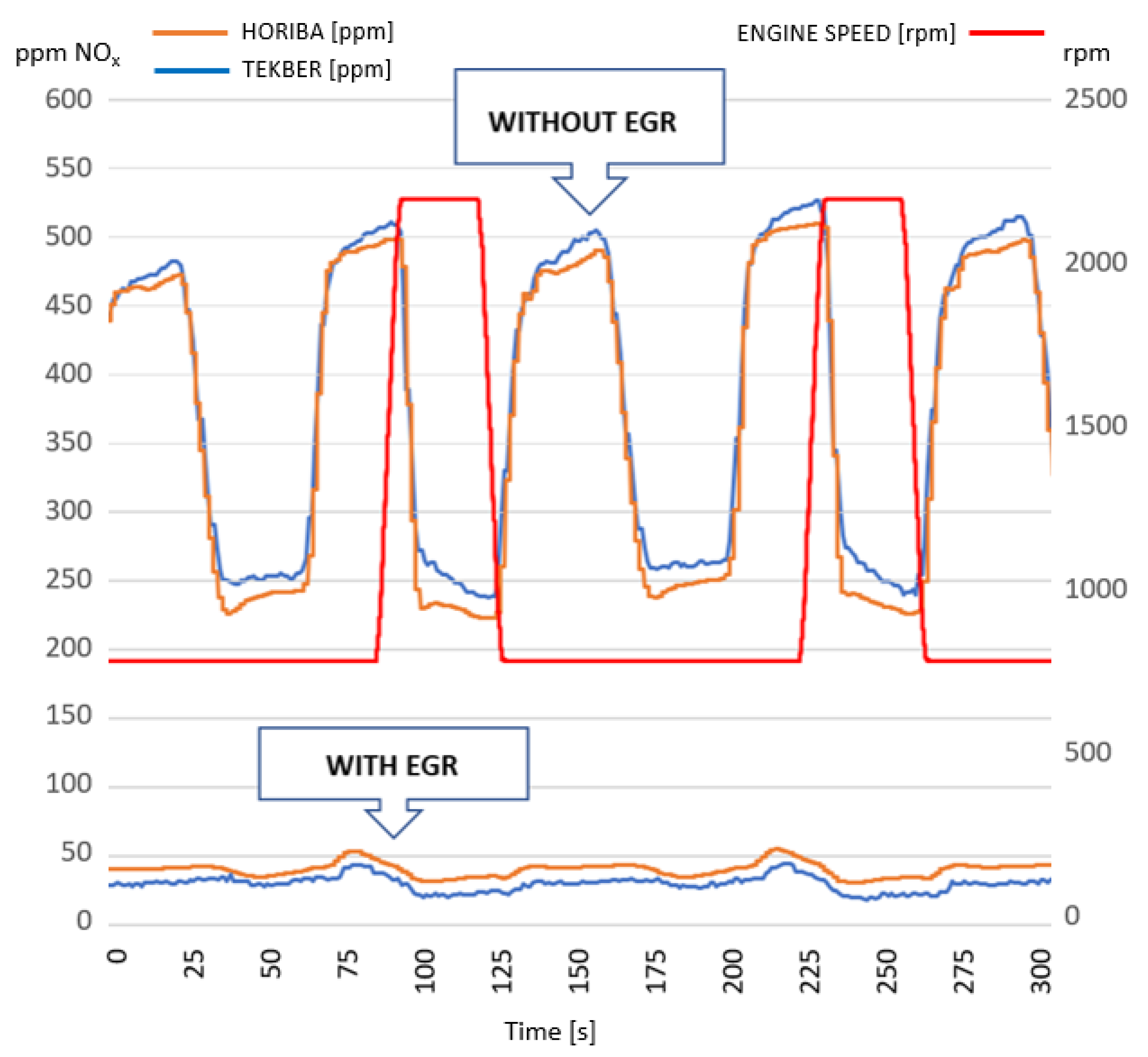

At the same time, the NO

x concentration was measured simultaneously by the two gas analysers. The blue-dotted square in

Figure 3 shows the five stages described in

Figure 2 that correspond to one single Static Idling Internal Load Test.

Figure 3 shows one of the tests performed with activated EGR. The purple line represents the load demand on the engine generated by the dynamometer, the red line is the engine speed, the green dotted line is the EGR aperture percentage, and the red and blue dotted lines are the exhaust gas temperature and engine oil temperature, respectively. Finally, the continuous orange line is the NO

x concentration (ppm) from the Horiba gas analyser, and the continuous blue line is the NO

x concentration (ppm) from the Tekber gas analyser.

When the Static Idling Internal Load Test was performed at low load conditions for the unloaded stages, the dynamometer demand was set at a 24% level (torque demand in the range 10–12 Nm), increasing to 33% in the loaded stages (torque demand in the range 37–40 Nm). When the Static Idling Internal Load Test was carried out at high load conditions, in the unloaded stages the engine brake demand was set at a 27% level (torque demand in the range of 19–22 Nm), increasing to 46% in the loaded stages (torque demand in the range 72–75 Nm).

Performing the test with and without EGR had two goals:

Every test conducted shows that the results of both analysers have the same trend and performance in each measurement section.

For the tests with the EGR activated and commanded by the engine’s ECU, the NOx concentration in the exhaust gas stream was reduced, usually in the interval of 30 to 70 ppm, although some peaks of higher concentration until 120 ppm could be detected. For this range of concentration, the behaviour of the Tekber gas analyser is similar to the Horiba gas analyser.

Figure 3 shows a sample of the tests performed, where it can be observed that the measured concentrations from Tekber and Horiba gas analysers are similar, without significant differences. Only for the peak values can differences of 10 ppm abs. and 11% rel. be found. The difference in the acquisition frequency (10 Hz for the Horiba vs. 1 Hz for the Tekber) can be responsible for the discrepancy between both measures. The average difference for this set of cycles between values of both devices was 1.7 ppm, which is an average of 3% rel. difference, in the sample shown. A similar behaviour was observed when the test was repeated in the same conditions and when the engine load demand was increased.

A summary of results from the tests performed with the EGR activated is shown in

Table 2.

The average absolute differences measured between the two devices with the activated EGR are 2.6 ppm for the low load tests and 8.6 ppm for the high load test, which, for the purpose of NOx measurement in PTI, are not significant.

When the same tests were carried out with deactivated EGR, the NOx concentration in the exhaust gas stream was up to seven times higher than in the first tests when the EGR was correctly working. In this situation, the NOx concentration usually varied between 150 ppm in the minimum point and more than 500 ppm, with only a few peak emissions over 600 ppm.

As seen in the idling test without EGR and low load conditions in

Figure 4, the NO

x concentrations from the Tekber gas analyser and the Horiba gas analyser were quite similar. The concentration values were 150 ppm in the lower zones, and between 300 ppm and 350 ppm for the upper zones. When the test was repeated with high load demand, the average concentration measured and the concentration values for the lower and upper zones increased.

A summary of results from the tests performed with a deactivated EGR is shown in

Table 3. The values of the absolute and relative differences between the results of both devices were low enough to evaluate the performance of the Tekber analyser as adequate for measuring NO

x emissions in PTI.

From the point of view of PTI measurement, the behavior of both devices was similar for the EGR activated and deactivated, as can be observed in

Figure 5.

For the Static Idling Internal Load Test, the average relative differences that are lower than 8% in the tests with the EGR deactivated, when the NOx concentration is higher, can be considered correct enough for PTI purposes. Absolute differences lower than 9 ppm for the EGR-activated tests when the NOx concentration is lower are also correct enough to get the same test result in PTI: assuring the roadworthiness of the vehicle.

From this point of view, the performance of the Tekber device can be considered satisfactory, increasing or decreasing the value measured of NOx concentration with a similar response to the Horiba device, even though the frequency is different: 1 Hz for the Tekber device and 10 Hz for the Horiba system. Although the PTI test is stationary, this is an important equipment feature.

The accuracy of the measurements may be the most important issue when analysing the suitability of this type of equipment. From the results of the measurements reproducing the Static Idling Internal Load Tests, the performance of the Tekber equipment, in the measurement range covered by the Static Idling Internal Load Test, is satisfactory.

In the test with the EGR activated, the average difference of the measurements was 8.6 ppm for the high load tests and only 2.6 ppm for the low load tests. These differences are not significant for determining the level of emissions of the vehicle.

When the engine was tested with the EGR deactivated, the average difference between measurements from both devices was 20.8 ppm for the low load test and 29.1 ppm for the high load test. The relative difference for the high load test was 7.1%, and even lower for the low load test, with a relative difference of 5.9%.

To summarise, the slight differences between both pieces of equipment when the Static Idling Internal Load Test was performed did not affect the test result because the concentration values obtained from both devices gave similar results.

3.2. Results for Fixed Engine Speed and Increasing Load Tests

Another kind of test was performed to check the performance of the Tekber measurements compared to the Horiba equipment: the engine was subjected to gradual increases in power demand while maintaining a fixed engine speed in two different conditions:

Fixed engine speed, increasing the load demand, with EGR;

Fixed engine speed, increasing the load demand, without EGR.

In this way, the variation profile of the engine NOx concentration could be analysed with changing torque demand. The wide variety of conditions (engine speed, load demand, EGR aperture, the temperature of exhaust gases, …) provides crucial information about the behaviour of the Tekber gas analyser.

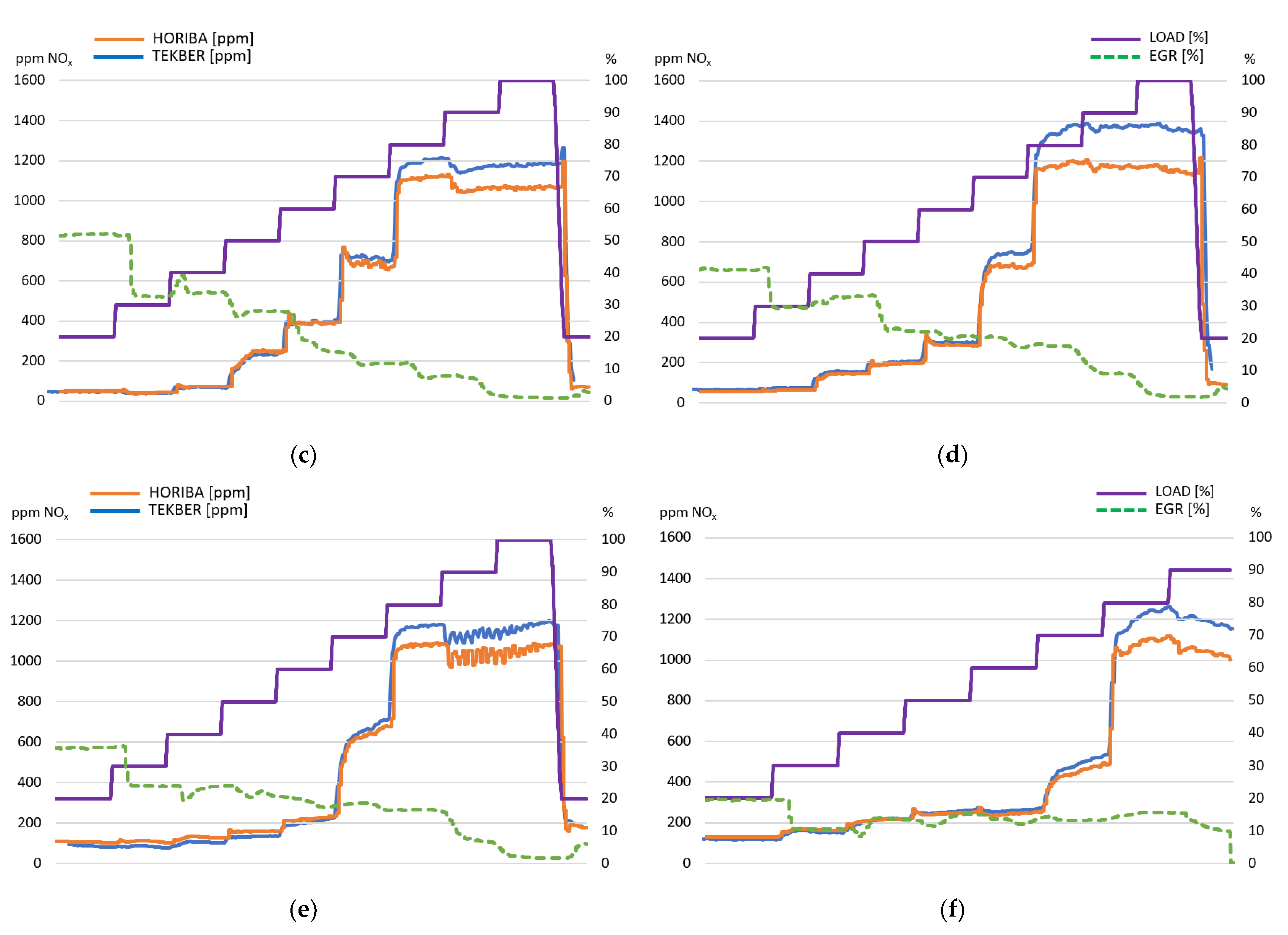

These tests were conducted for 800 rpm, and from 1000 rpm to 3000 rpm with 500 rpm increments. The engine was subjected to an increase in torque demand for each of these speed conditions through the dynamometer coupled to the engine power output. The increase in torque demand was performed in 10% increments of the demand capacity of the dynamometer. Due to the system’s technical requirements, measurements were started with a demand of 20%.

All the tests carried out with the EGR activated and commanded by the ECU show a similar behaviour. When load demand is low or medium, the %EGR opening is higher. It gradually closes as the power demand increases until it reaches the minimum value defined by the ECU at these conditions.

It can also be observed that the %EGR aperture is lower as engine speed increases. If at 1000 rpm and 20% of load demand the EGR value is 40%, with the same 20% of load demand at 3000 rpm the EGR value is 20%.

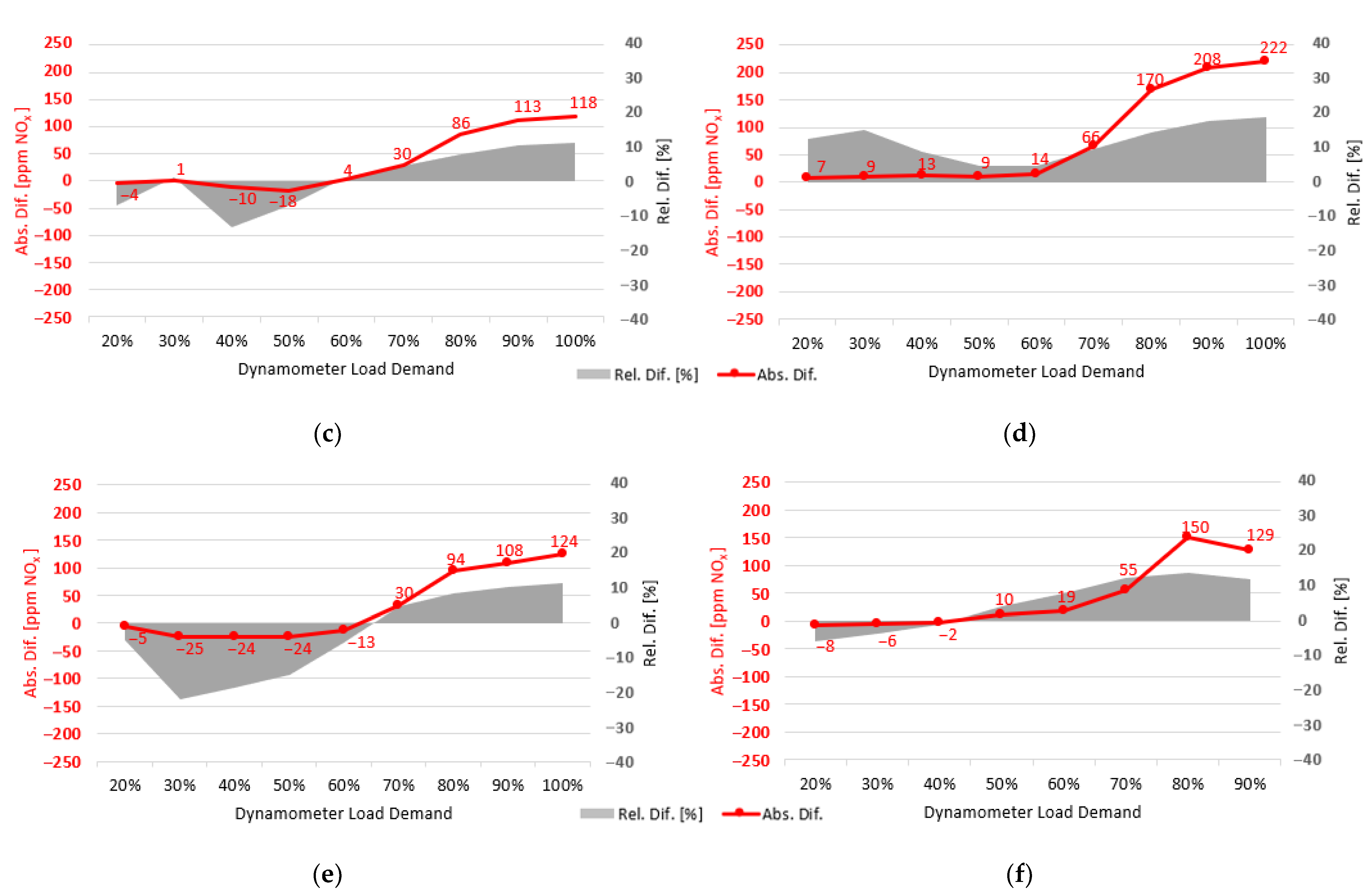

Figure 6 shows how the behaviour of the Tekber results is similar to Horiba’s measurements for every engine speed. For the first test at 800 rpm with an activated EGR and at a dynamometer load demand of 80%, the difference in the NO

x concentration values from both types of equipment was lower than 10 ppm abs., until the concentration increased to 900 ppm (

Figure 6a). From this concentration, the discrepancies increased until a maximum difference of 229 ppm abs. These average differences are represented in

Figure 7 for every engine speed. Although the relative differences are over 20%, this value corresponds to a NO

x concentration of 9 ppm, which can be considered to be a low deviation.

Regarding the emissions behaviour, it can be observed how the action of the EGR makes NO

x emissions decrease (to below 100 ppm) until demand rises to 70%. At this point, an increase in NO

x concentration to 200 ppm occurs. Above 90% load demand, the EGR closes, leading to the values included in

Appendix A,

Table A7, where average results for the whole set of tests are summarised.

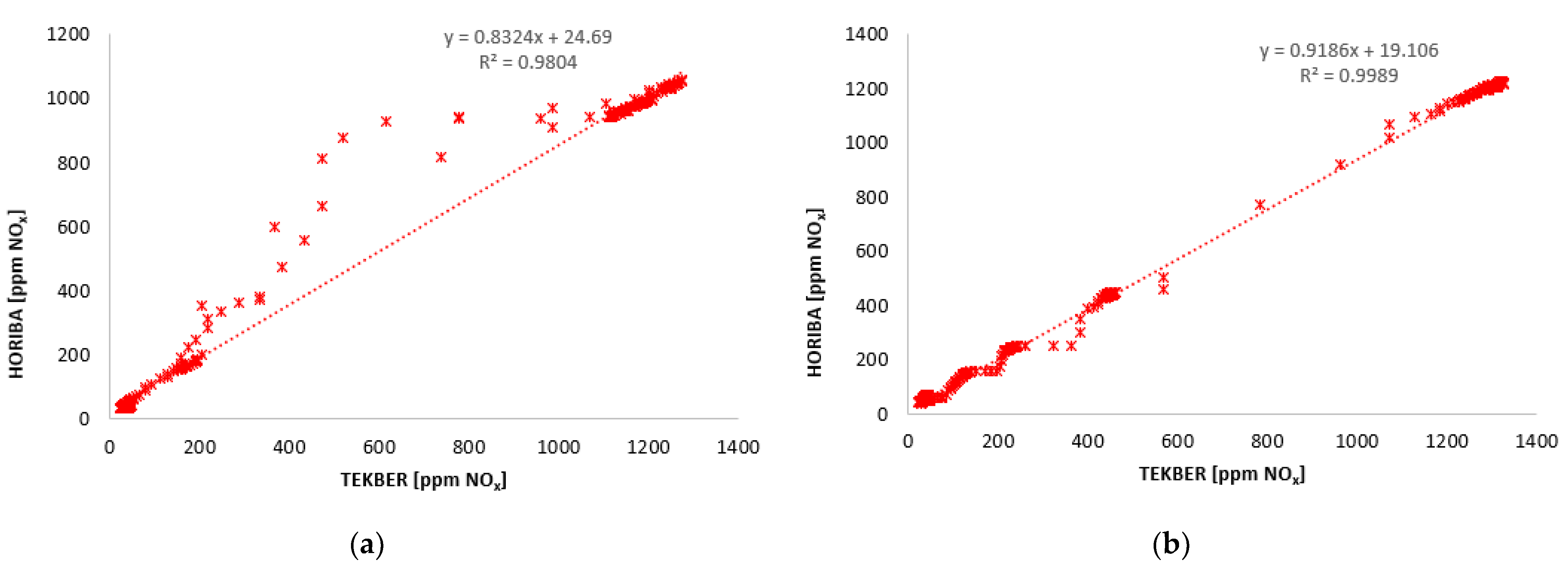

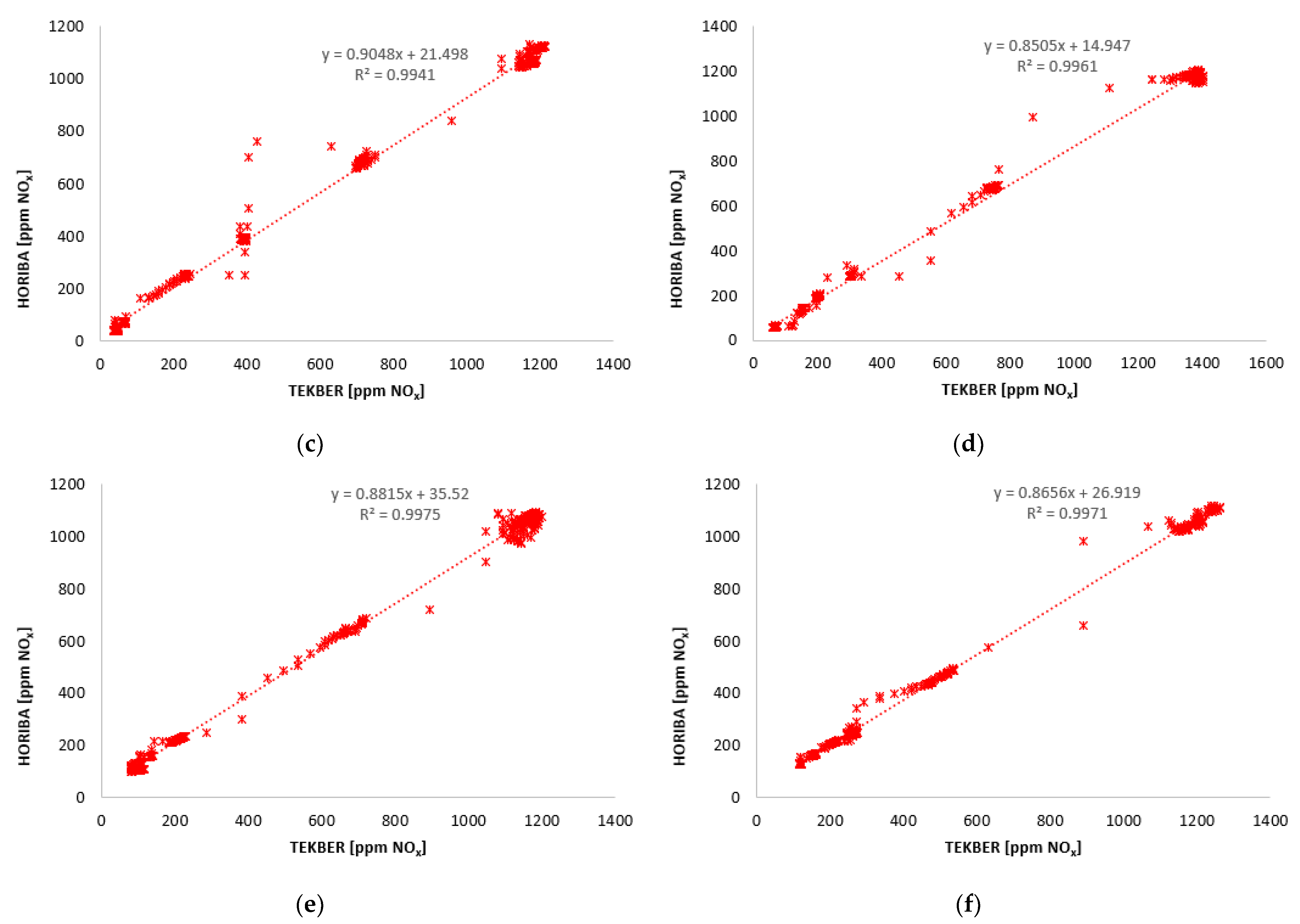

Figure 8 shows the correlation between results from Tekber equipment and Horiba, with R

2 > 0.98 for every engine speed.

The same situation could be observed for the test at 1000 rpm with EGR,

Figure 6b, where the difference between values from both types of equipment was close until reaching 1000 ppm (when load demand is at 90%). Until this point, the average difference between Horiba and Tekber devices was in the range of 10–18 ppm abs. From this point upwards, the difference increased but was lower than 100 ppm abs, and less than 8% rel.

For the test carried out at @1500 rpm, as shown in

Figure 6c, it was again observed how the Tekber analyser accurately reproduced the behaviour of the Horiba analyser. From 20% to 40% of load demand, the average difference was lower than 10 ppm. Once the concentration was stabilised, the section of 50% of load demand showed an average difference of 18 ppm, and for the 60% section, the average difference was lower than 4 ppm. When reaching 70% of demanded load and NO

x concentrations reached 700 ppm level, the average difference increased to 30 ppm. From this power demand value onwards, the absolute value of the measurement difference increased up to 120 ppm, although the relative difference stabilised at values of 11% rel.

The test at 2000 rpm shows again how the Tekber results reproduce the behaviour of the Horiba measures (as seen in

Figure 6d). Until reaching 70% load demand, the average absolute difference between them was lower than 15 ppm.

Figure 7d shows that the difference between both devices is small for NO

x concentrations under 600 ppm (that is until 60% load demand). With higher load demands and NO

x concentrations exceeding 600 ppm, the difference between the Tekber equipment and Horiba increases (in absolute and relative values). This behaviour could be observed in this kind of test every time it was carried out.

In the test at 2500 rpm, as can be observed in

Figure 6e, not only was the same profile of concentration obtained, but the behaviour of NO

x concentration in the sections of 90% and 100% was faithfully reproduced by both devices, with the only difference being the measured value. Again, the sections with concentrations below 600 ppm showed a reduced difference between both devices, with 25 ppm and 11% rel. being the highest average difference for these sections, as shown in

Figure 7e.

Another issue to be mentioned is that the exhaust gas temperature for the sections with higher concentrations reached between 600 °C and 700 °C. The Horiba equipment is designed to work under such conditions. However, the Tekber equipment is focused on another kind of measurement, where the time duration of the measurement is shorter. Moreover, the gas temperature of the sample is usually much lower than 300 °C. In the Static Idling Internal Load Test, the engine at 2500 rpm is not subjected to any load, so the gas temperature is below 300 °C.

Finally, the last test was carried out at 3000 rpm with the behaviour of NO

x concentration shown in

Figure 6f and the differences summarised in

Figure 7f. As can be seen, the last section of the 100% load demand could not be performed for technical reasons, so no data are available for this situation. The results of this last test were similar to the previous ones. The behaviour of both types of equipment was similar, with an absolute difference between values being lower than 20 ppm (and a relative difference below 8%) until reaching 60% load demand. From 70% of load demand, the relative difference was, on average, around 13% and the absolute difference was at a maximum of 150 ppm.

From this set of six tests, it can be concluded that the behaviour of the Tekber gas analyser faithfully reproduces the behaviour of the Horiba gas analyser. In addition, as can be seen in

Figure 8, the coefficient of determination R

2 was greater than 0.98 in all cases.

The difference in measurement precision varies depending on the concentration values measured. Still, the variation is typically low when the concentration of NOx in the gas stream is below 600 ppm, with an average value of 15 ppm for this condition.

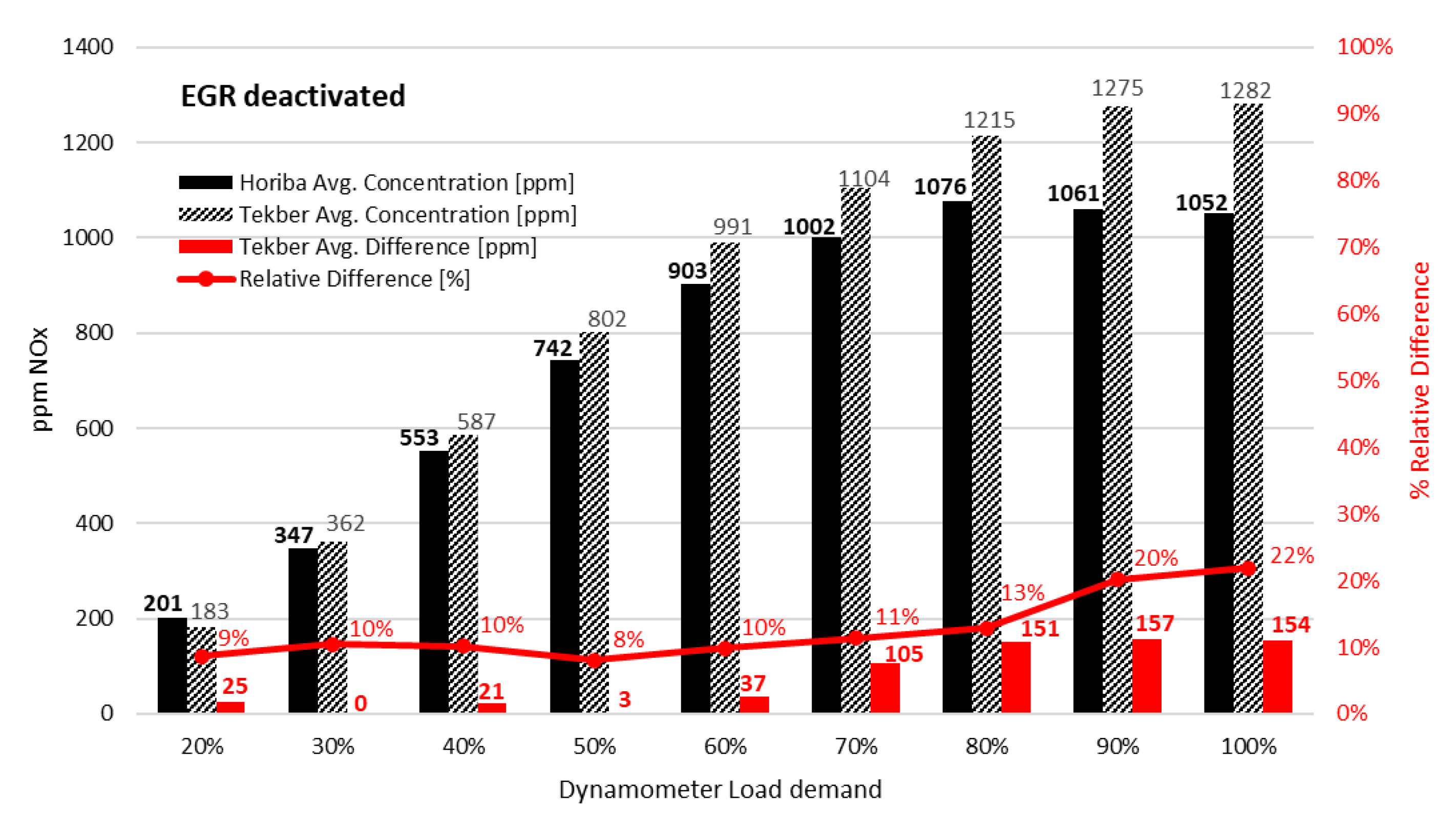

As with the Static Idling Internal Load Tests for PTI, the same set of tests was conducted with the EGR disconnected, directly resulting in increased NOx concentrations, especially for low load demand slots. In low-demand situations, where the EGR was clearly active, a significant difference in the NOx concentration measured by both devices was observed. Instead, the NOx concentration was similar to the EGR-activated tests for the high load states (when load demand is 80% or higher). This is because, in the EGR-activated tests, EGR was closed or nearly closed when the load demand was high.

As was observed in the first part of the tests, a higher concentration in the exhaust gases increases the discrepancies between both measuring devices. The higher concentrations of NOx with the EGR disconnected shows that the difference observed for the low load states between both devices was higher than for the EGR-activated tests.

Results are summarised from these sets of tests in

Appendix A,

Table A8, with the same information previously detailed in the EGR-activated case.

Table 4 shows the average differences calculated (in absolute values), from every test performed at the different engine speeds and load demand states, for the Tekber equipment with respect to the Horiba equipment results when the EGR was activated.

The deviation between both devices is lower than 14 ppm from the load demand scenarios below 70%. The relative difference is 13.6% in the situation of 100% of load demand when the NOx concentration is the highest.

Figure 9 shows the average deviation in absolute and relative terms from the Tekber equipment results compared to the average NOx concentration value measured by the Horiba and the Tekber equipment at every load demand slot. After analysing the data from several tests, it can be concluded that the absolute deviation increases when the load demand and the average NO

x concentration increase.

Below 700 ppm, the deviation between the two measures stayed below 65 ppm, with an average difference value of less than 15 ppm, in absolute terms, i.e., accumulating the deviations. This translates into differences of 9% in relative terms for these sections. It should be mentioned that there are occasional measurements with larger relative differences, mainly at very low concentrations, of the order of 20–30 ppm, where a small difference in the absolute value of 5 ppm can mean a difference in relative terms of 15–20%.

At 700 ppm NOx and above, the Tekber deviations were significantly larger, with an average difference of 136 ppm in absolute terms or 13% in relative terms.

For measurements performed with EGR deactivated, the results obtained are less homogeneous, due to the absence of the “normalising” performance of the vehicles’ EGR.

In addition, the NOx concentration values in the exhaust gas stream were clearly higher for the low load demand zones than those measured in the tests performed with the EGR system operating.

Table 5 shows a summary of the average differences from every test performed at the different engine speeds and load demand states when the EGR was deactivated.

As for the EGR-activated tests, it can be observed that the absolute values of the difference between the results of both types of equipment are lower from the load demand scenarios below 70%, although the absolute values are significantly higher. That said, the relative difference is similar to the values observed when the EGR was connected. Only for the highest load demand situation, at 90% and 100%, did the relative difference rise to more than 20%.

Figure 10 shows, for every slot of load demand, a comparison between the average concentration deviations in absolute and relative terms for both devices and the average value of NO

x concentration as measured by the Horiba and the Tekber equipment at this load demand slot. As mentioned, the behaviour is similar to that shown in

Figure 9, although the concentration values are higher, and because of this, the discrepancies increase too. When NO

x concentration is below 700 ppm, the deviation is less than 45 ppm, in absolute terms. This translates into differences of 9% in relative terms for these sections. As observed for the EGR-connected tests, when 700 ppm are exceeded, the discrepancies between both devices increase significantly, with an average difference of 142 ppm in absolute terms (14% rel.).

In summary, for NOx concentrations below 700 ppm in the exhaust gas stream, the deviation of Tekber results with respect to Horiba results is small, which makes the Tekber more accurate under these conditions.

In 2019, a measurement campaign was conducted at several PTI stations in Spain, where diesel vehicles were subjected to the Static Idling Internal Load Tests. As was explained in

Section 3.1, the engine was subjected to internal load to increase the engine NO

x emissions. From the measurements performed during the campaign, out of 1884 vehicles analysed, only 17 exceeded the 700 ppm of NO

x concentration values during the emission test’s execution (in the loaded or the unloaded stages). This means that only 0.90% of the vehicles in the analysed sample exceeded the value of 700 ppm during the measurement.

Therefore, at least for the realisation of NOx measurements using the Static Idling Internal Load Test, the usual effective NOx concentration measurement range is between 0–700 ppm, validating the use of the Tekber analyser for PTI purposes.