1. Introduction

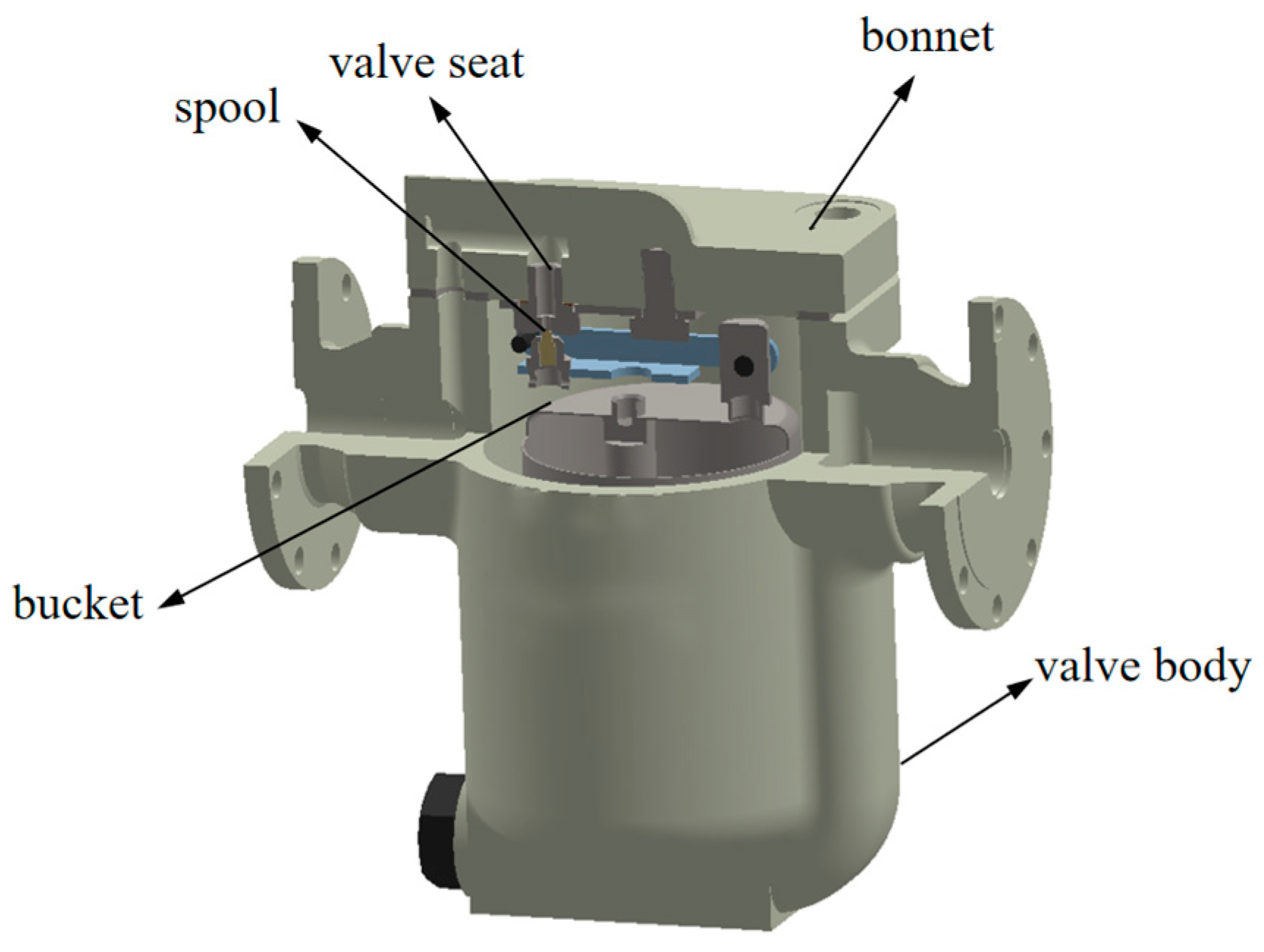

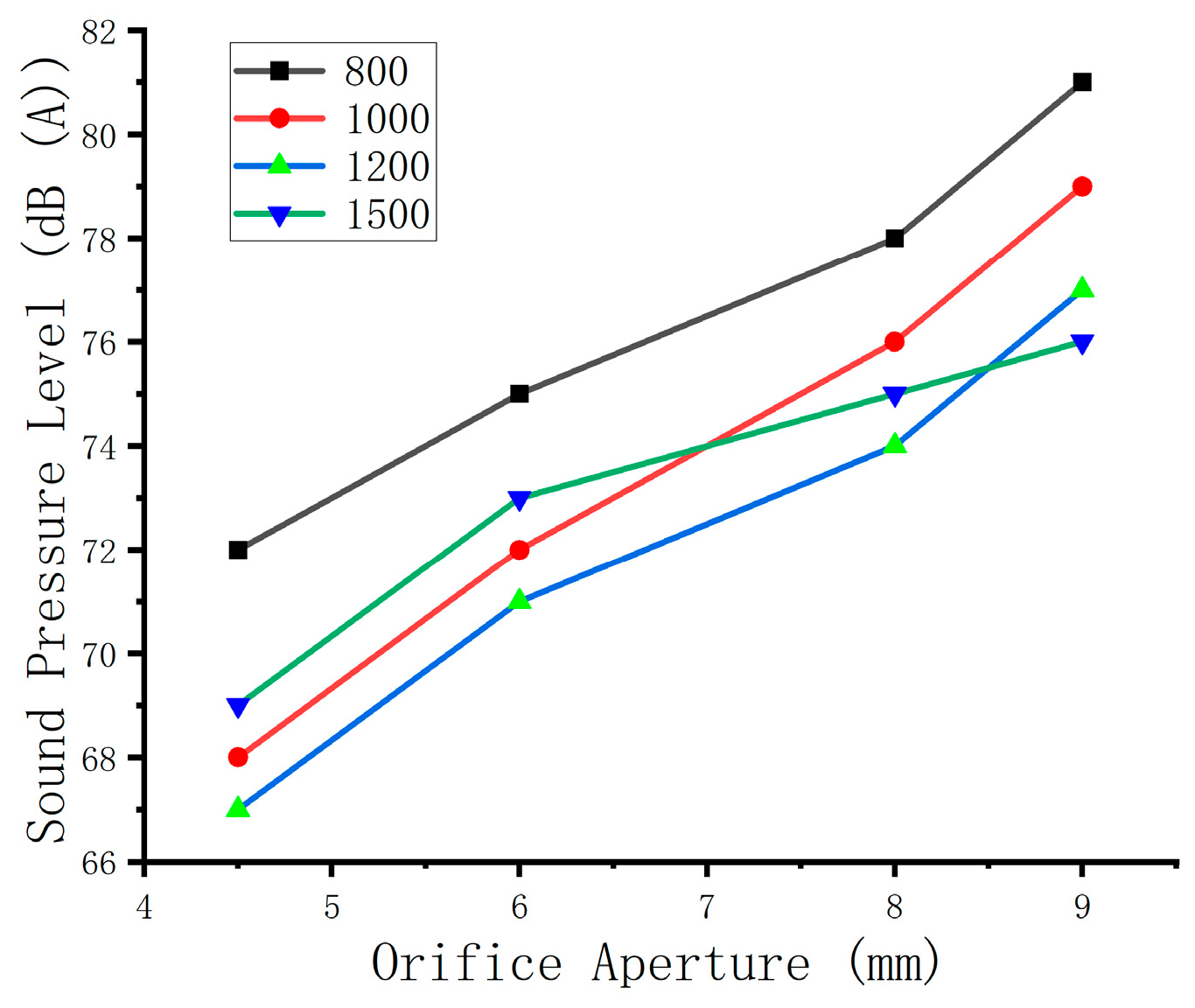

Steam energy is widely used as a secondary energy source in thermal power, petroleum, chemical, light industry and other fields. The inverted bucket steam valve is an important form of steam valve, an indispensable device in the steam system, and a key device for condensate recovery. It plays the role of a steam valve that blocks the passage of water and exhausts air and is of great significance in making full use of the latent heat of steam and improving the energy efficiency of the steam system. When working under high parameter conditions, inverted bucket steam valves have many problems. When condensate is throttled by the valve, the resulting turbulent pressure pulsation will produce intense turbulence, resulting in the loss of mechanical energy of the fluid medium, a portion of which will be transformed into acoustic energy and radiate outflow noise, which will cause damage to the valve and piping to varying degrees, and reduce the service life of the equipment and piping. In the initial state, the barrel naturally droops. After the valve is opened, condensed water is injected into the valve chamber to form a liquid seal. The barrel is reset by fluid impact. Due to the same density of the medium inside and outside the barrel, the buoyancy is insufficient to offset its own weight. When the barrel sinks, the linkage valve core component opens for drainage. When steam flows in, the inverted barrel generates buoyancy, which drives the valve core to move upward and close the valve. As the steam gradually condenses, the buoyancy weakens to the critical value. The barrel opens for drainage again under the action of gravity, and the cycle repeats. The hot condensed water in the valve is recovered, forming a hot condensed water recovery steam trap and valve control pipe system. Due to the coupling of turbulent pulsation and condensed water during the throttling process of valves, the noise of steam traps and valve control piping systems exhibits significant nonlinear acoustic characteristics during the operation of steam systems. Such noise is a visual representation of energy loss in steam systems. So, it is important to study the acoustic characteristics of inverted bucket steam valves. The study of acoustic characteristics of inverted bucket steam valves is of great significance. A study of the noise problem of high parameter pressure reducing valves by Chen et al. [

1] showed that porous plates can be effectively applied for noise control at the outlet of pipelines and French doors. Zhou et al. [

2] considered the effect of the vibration of the micro-porous plate itself on the cavity sound field, proposed a plate–cavity coupling model to calculate the noise reduction performance of the microporous plate, and optimized the micro-porous plate perforation rate, aperture diameter, and plate thickness. Li et al. [

3] used a reduced-pressure orifice plate as a simplified model of the multi-stage throttling internal parts of the valve regulator. Based on the computational fluid dynamics method of different opening spacings and different opening forms of the orifice plate model for jet flow characteristics of numerical simulations and the experimental validation, the results show that the orifice plate opening spacing of more than 20 mm, the media flow rate and so on have been reduced. Su et al. [

4] and others applied CFD technology to simulate the dynamic characteristics of the relief valve, derived the main reasons for the noise generated by the fuel pump system, and optimized the clearance between the spool and the valve body for noise reduction. Jiang et al. [

5] performed a numerical simulation of submarine hydrodynamic noise using the boundary element method and the traditional FW-H equation and compared the numerical simulation results with the experimental values, showing that the boundary element method is closer to the experimental results. Li et al. [

6] predicted the aerodynamic noise of steam turbine control valves by the sound path and source approximation method, which provides guidance for the control of aerodynamic noise of control valves. Meng et al. [

7] took the aerodynamic noise generated by gas flowing through the valve as the research object, and numerical simulation calculations were carried out by using the method of software linkage, and the results showed that the velocity pulsation and pressure pulsation of the fluid were the fundamental causes of aerodynamic noise generation, and the dipole sound source dominated at low Mach numbers. Zhang et al. [

8] used the computational fluid dynamics method to calculate the flow field of the minimum flow circulation valve of the boiler feed pump and used the FW-H equation to analyze the noise characteristics and noise sources of the valve. On this basis, the valve outlet structure is modified to better suppress the noise propagation. Yang et al. [

9] considered the reflection or transmission of incident waves at the exit boundary and applied passive metamaterials to sound absorption in the low-frequency domain with deep subwavelength dimensions; this approach has been widely used in one-dimensional inverse problems. However, the generalized problem of impedance boundary conditions remains unclear.

Valves, pumps, and other valve control system components of the noise reduction structure optimization, stability analysis, etc., are currently the main direction of the system optimization research. Xu et al. [

10], based on the accurate theory of a micro-perforated plate acoustic absorber, used the particle swarm optimization algorithm for the resonance frequency of micro-perforated plate structural parameters to optimize the perforated plate structural model by taking the urban rail traffic noise as an example and verified this by numerical experiments. Nie et al. [

11], based on the dynamic characteristics of the solenoid valve simulation model, the use of genetic algorithms to optimize the key structural parameters of the solenoid valve, the study of the structural parameters of the solenoid valve dynamic response characteristics of the influence of the law, and, through the comparison of the simulation results with the experimental results, verified the accuracy of the simulation model. The research results show that for the optimized solenoid valve, after the reduction in the overall response time of 0.25 ms, the dynamic response speed improved by 31.7%. Xie et al. [

12] proposed a multi-objective genetic algorithm-based axial-piston pump low-pulsation structure optimization design method; simulation results show that for the optimized structure, the flow pulsation rate is 12.02%. Compared with the pre-optimization flow pulsation rate, which was reduced by 43.59%, the pressure pulsation was reduced by 0.16%, proving that genetic algorithms can be applied to engineering practice. Ji et al. [

13] proposed an integrated optimal design method by combining intelligent optimization algorithms with generative design, and the results of the study showed that the mass of the structure generated by the integrated optimization method was reduced by 27%, the intrinsic energy was increased by a factor of 0.95, and the superiority of the proposed optimal structural design method was confirmed by the qualitative study and analysis of the experimental results. Jafari Malihe et al. [

14] proposed an efficient hybrid algorithm for the optimal design of truss structures based on the particle swarm optimization (PSO) algorithm and cultural algorithm (CA). The performance of PSOC was evaluated using a set of five common truss design examples, and the results show that PSOC is suiFigure for an engineering design to obtain the optimized design dimensions of the optimal truss structures. Chen et al. [

15] established an aerodynamic optimization design platform for a local inlet turbine using an artificial neural network combined with the particle swarm genetic hybrid method, and the results showed that the optimized turbine’s internal flow state was significantly improved, the flow separation due to the local inlet was eliminated, and the total static efficiency of the local inlet turbine was improved by 3.72% compared with that of the prototype. Xu et al. [

16] proposed an optimization method for an annular jet pump based on a radial basis function (RBF) neural network model and non-dominated sorting genetic optimization algorithm (NSGA-II); the results show that the optimized model’s suction angle increases, the diffusion angle, flow ratio, and area ratio decrease, and the head ratio increases by 30.46%. Nouhi B et al. [

17] proposed the group optimizer with a mechanism-based approach to find the optimal steel frame and the results show that the performance of the new approach can be demonstrated by solving two structural problems, and the weight efficiency of the optimized steel frame is increased. Zhu et al. [

18] proposed an optimization method to reduce the sound pressure level of composite laminates by combining the response surface method (RSM) with the genetic optimization algorithm, and the results show that the use of this method to analyze the noise characteristics of composite laminates can significantly improve the optimization efficiency and provide a reference for the engineering practice. The results show that using this method to analyze the noise characteristics of composite laminates can significantly improve the optimization efficiency and provide reference for engineering practice. Zhang et al. [

19] solved the application of dual indicators based on the reference point non-dominated genetic algorithm (PB-NSGA-III) and found a combination of geometric parameters to meet the performance requirements for the establishment of the impeller geometric parameters and the performance parameters of the pipe relationship between the impeller multi-objective optimization method and the optimized high-speed centrifugal pump. In the design of the working condition of the pump, hydraulic efficiency increased by 2.2%, and numerical simulation results and the performance parameters obtained by the optimization method have good consistency. The optimized high-speed centrifugal pump has improved hydraulic efficiency by 2.2% in the design working conditions, and the numerical simulation results are in good agreement with the performance parameters obtained by the optimization method. Jin et al. [

20] used a computational fluid dynamics (CFD) data set to train a CNN to establish the mapping relationship between the pressure fluctuation on the cylinder and the velocity field around the cylinder.

To summarize, although existing research has advanced the simulation of flow-induced noise and the optimization of noise-reducing structures, two key limitations remain. First, few studies have focused on the unique acoustic properties of high-temperature and high-pressure steam traps, and detailed analysis of flow field–acoustic field coupling within the valve is lacking. Second, most optimization studies have centered on the algorithms themselves, with insufficient experimental validation of optimization results and inadequate discussion of the underlying acoustic mechanisms.

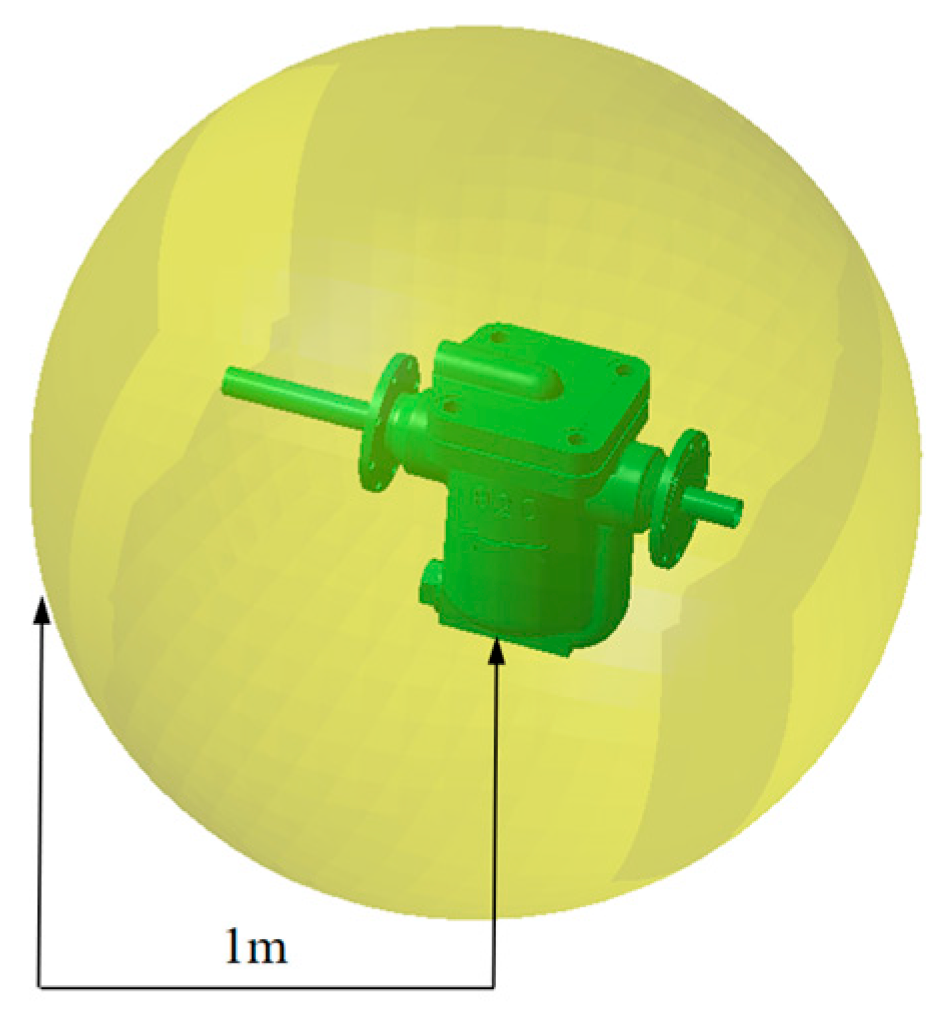

Therefore, this paper takes the PN40 DN100 inverted bucket steam trap as the research object and focuses on establishing its high-precision flow-induced acoustic prediction model and verifying it through experiments. In order to solve the computational cost problem in the optimization process, this paper uses the strategy of combining a SVM approximate model and the NOA to optimize the structure of the porous noise reduction plate. The ultimate goal of the study is to clarify the mechanism of noise reduction through detailed simulation and experimental comparison and provide a reliable methodology for a low-noise design of valves.

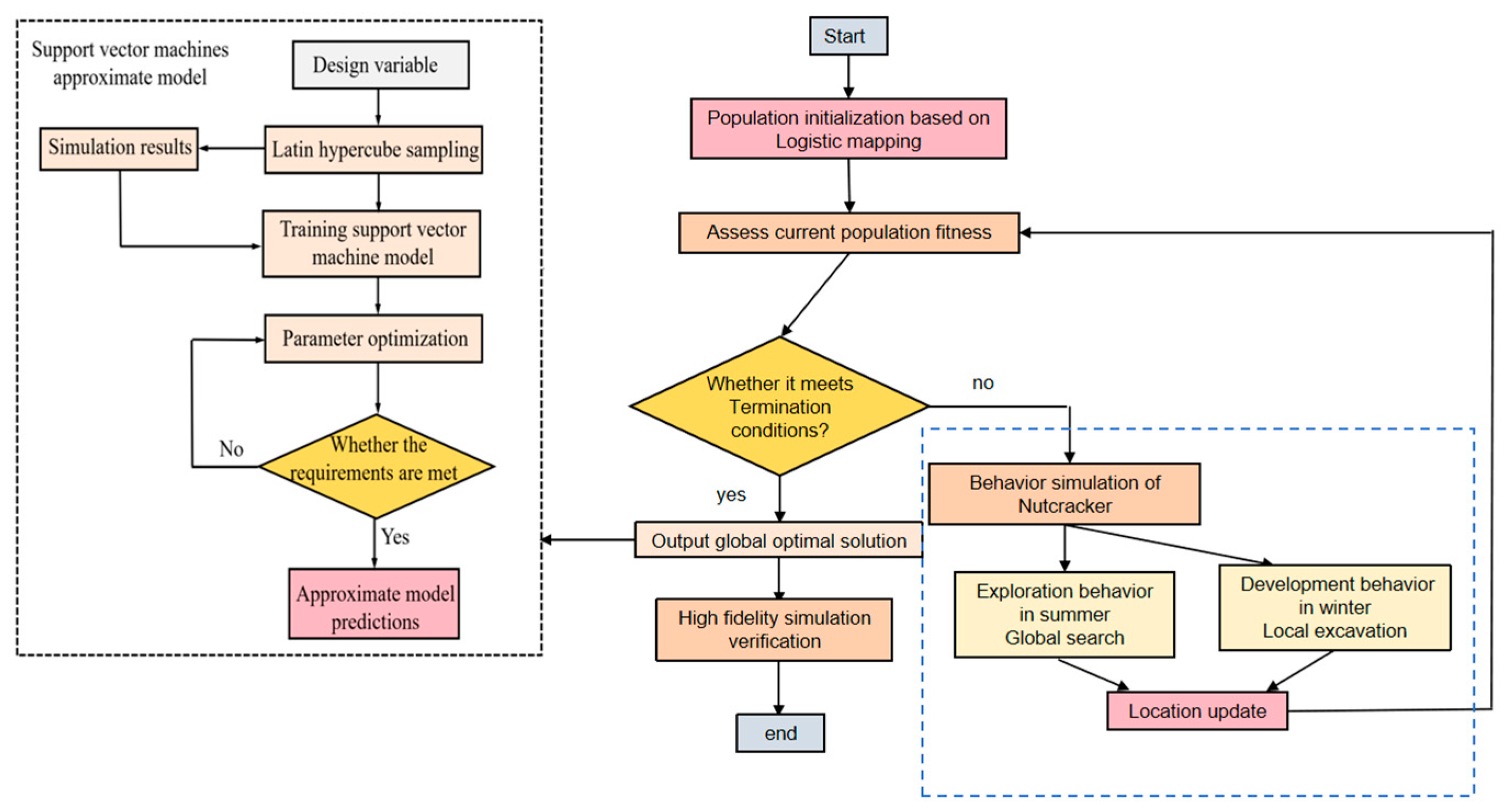

2. Nutcracker Optimization Algorithm

In the process of structural optimization for the inverted bucket steam valve noise reduction orifice plate, the efficiency can be improved by using optimization algorithms which have various forms. In this paper NOA is chosen; NOA is a novel algorithm based on the different behaviors of the nutcrackers’ nature-inspired meta-heuristic algorithm [

21].

Initially, the position of the nutcrackers is random, i.e., some points are randomly generated in the search space of the problem, assuming that the population size is

N and the problem dimension is

D. The initialization formula is as follows:

where

i = 1, 2 …,

N;

j = 1, 2 …,

D.

Xij denotes the

j th dimensional variable of individual

i, and

Lj and

Uj denote the next and previous terms of the

j th dimensional variable, respectively,

is the random vector between [0, 1].

By storing food in summer and retrieving cached food based on spatial memory in winter, the behavior of the nutcracker achieves a balance between global exploration and local development. During the optimization process, each nutcracker keeps updating the exploration position according to the reference point; they will apply the exploration mechanism to search for the most promising food area, and the algorithm will explore and utilize the area around the cache with appropriate

Rp in order to avoid falling into the local minima. The second stage of the exploitation position update formula is shown in Equation (2):

where

represents the new position of the first nutcracker at iteration (

t + 1),

is the current position of the

i th nutcracker in the current iteration

t.

Depending on the optimization problem, the balancing of the exploration and development phases in the balancing algorithm of Equation (3) is applied.

Logistic chaos mapping is used to improve the population initialization of the star sparrow optimization algorithm; logistic chaos mapping is a typical representative of chaotic mapping, and its mathematical expression is shown in Equation (4).

In Equation (4),

f(

xn) ∈ [0, 1],

ɑ is the logistic parameter, and the range of values is [0, 4]. According to experimental results [

22], the closer the logistic parameter gets to 4, the more evenly the range of values of

f(

xn) is distributed throughout the range [0, 1]. In the text,

ɑ = 3.9999 and

f(

xn) = 0.5.

6. Conclusions

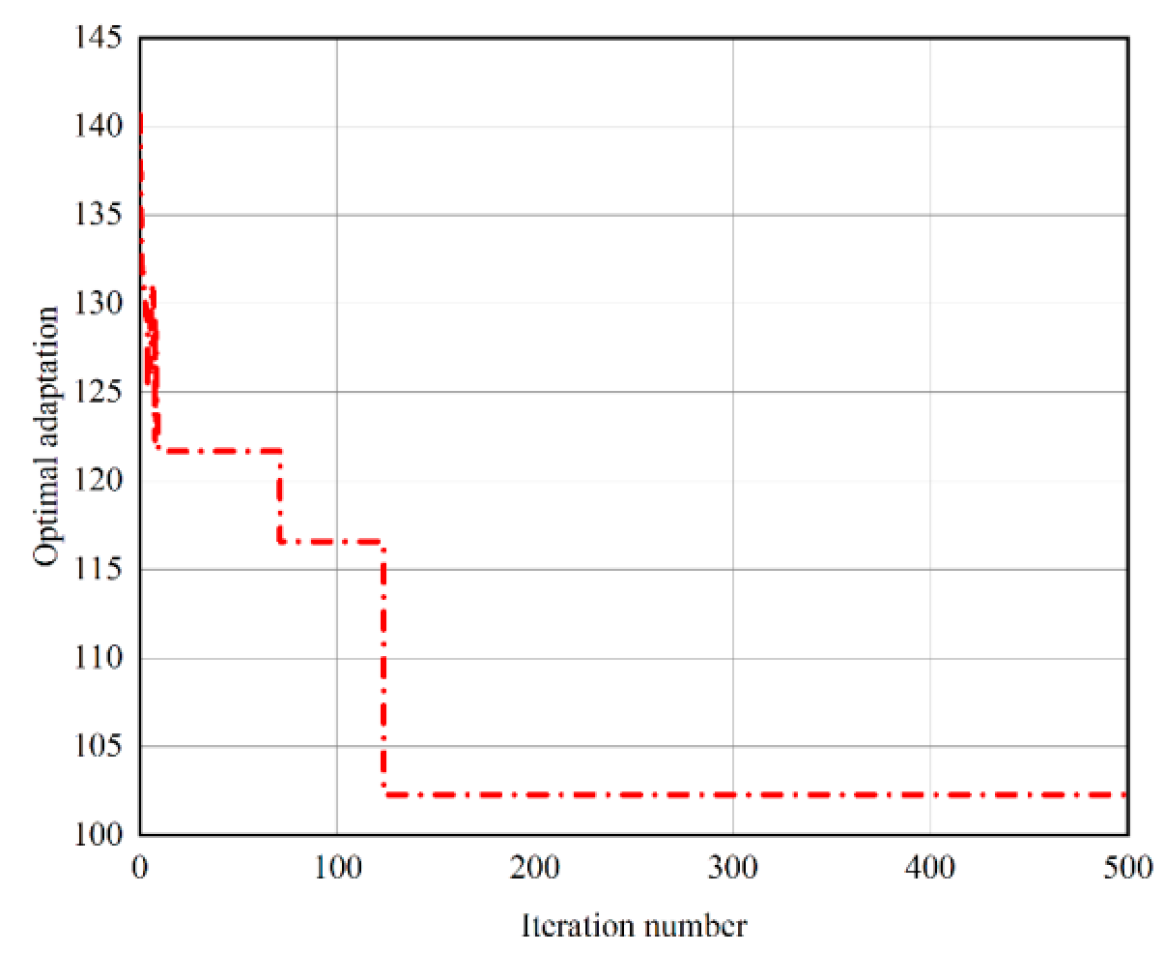

In the paper, the support vector machine approximation model is established instead of acoustic numerical simulation. and combined with the improved nutcracker optimization algorithm to optimize the structure of the noise reduction element inside the inverted bucket steam valve. The best structural parameters are obtained according to the optimization results, and the accuracy of the numerical simulation is verified through experiments. The specific conclusions are as follows:

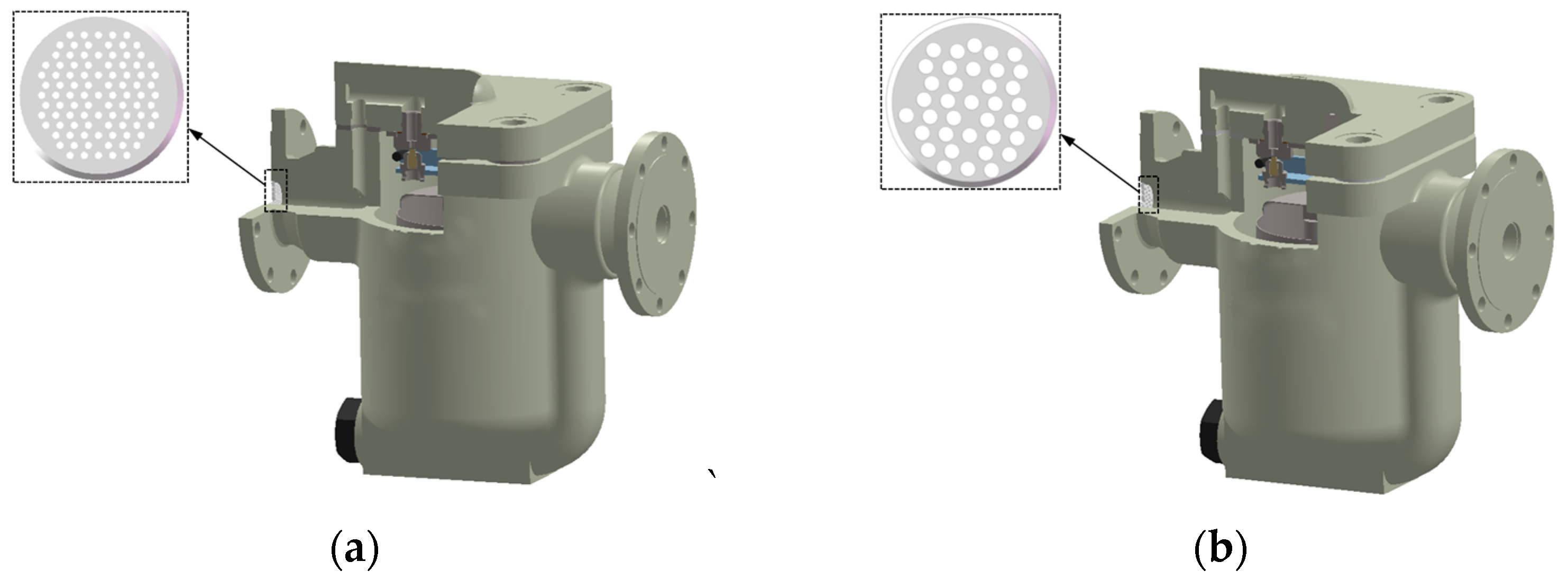

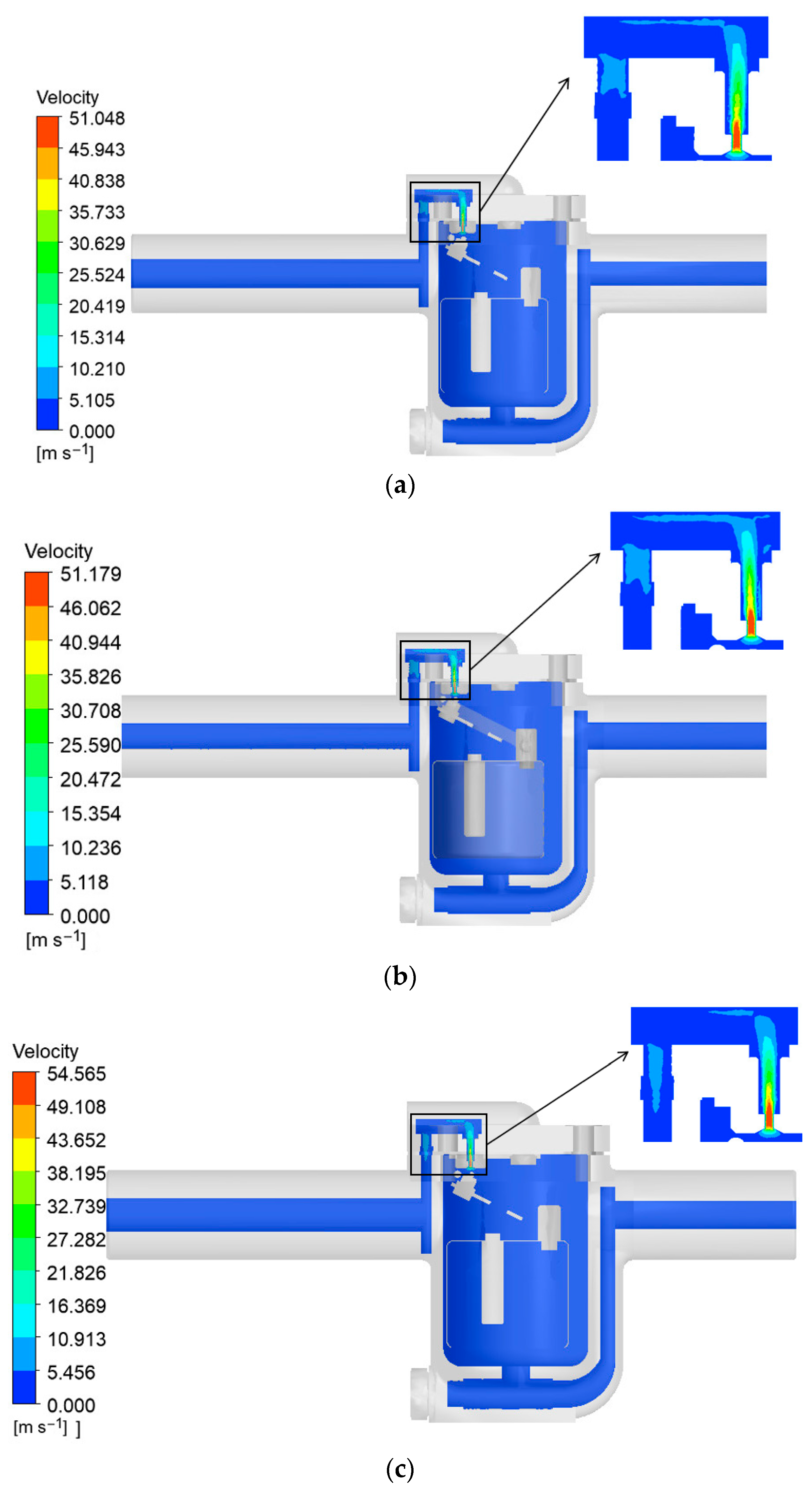

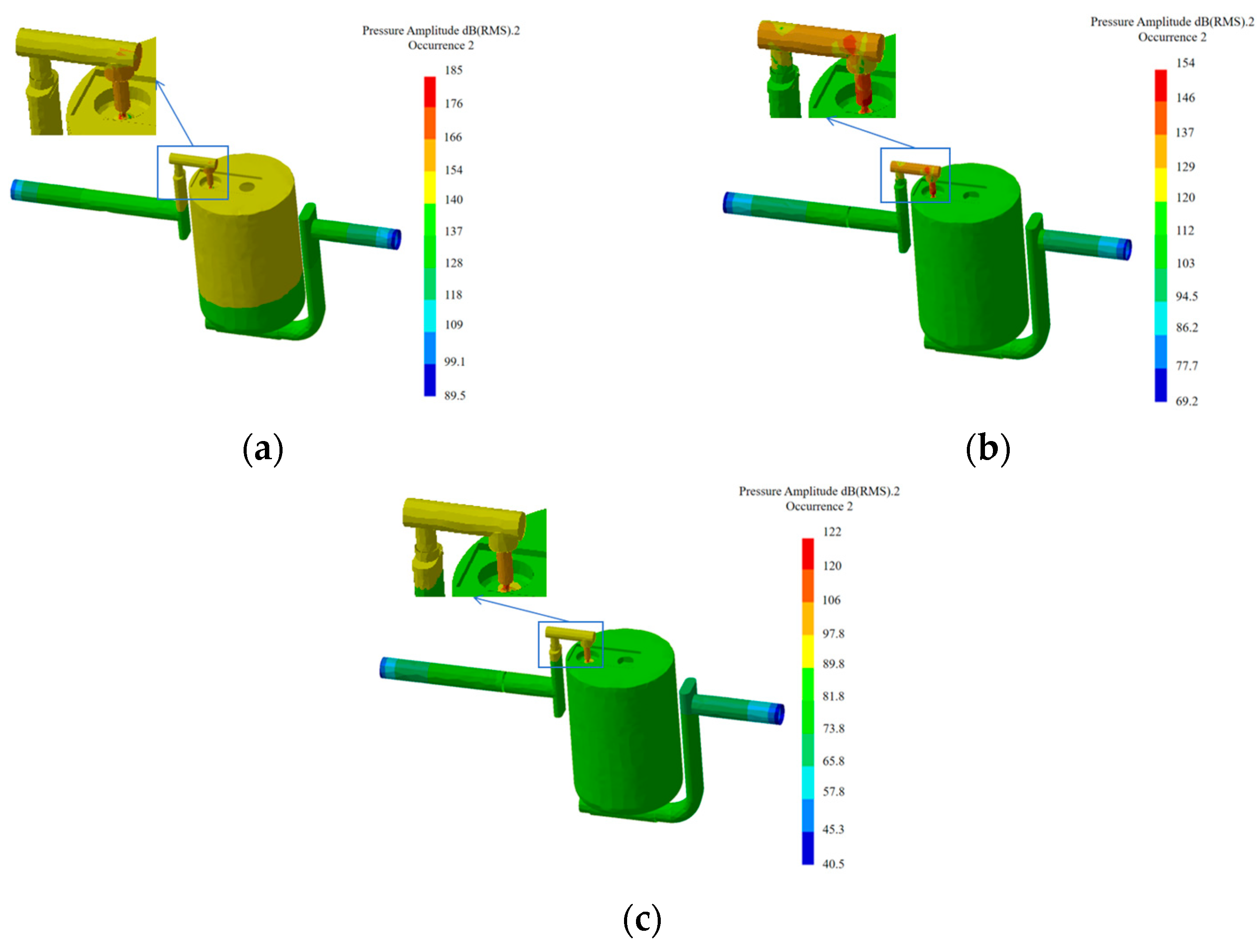

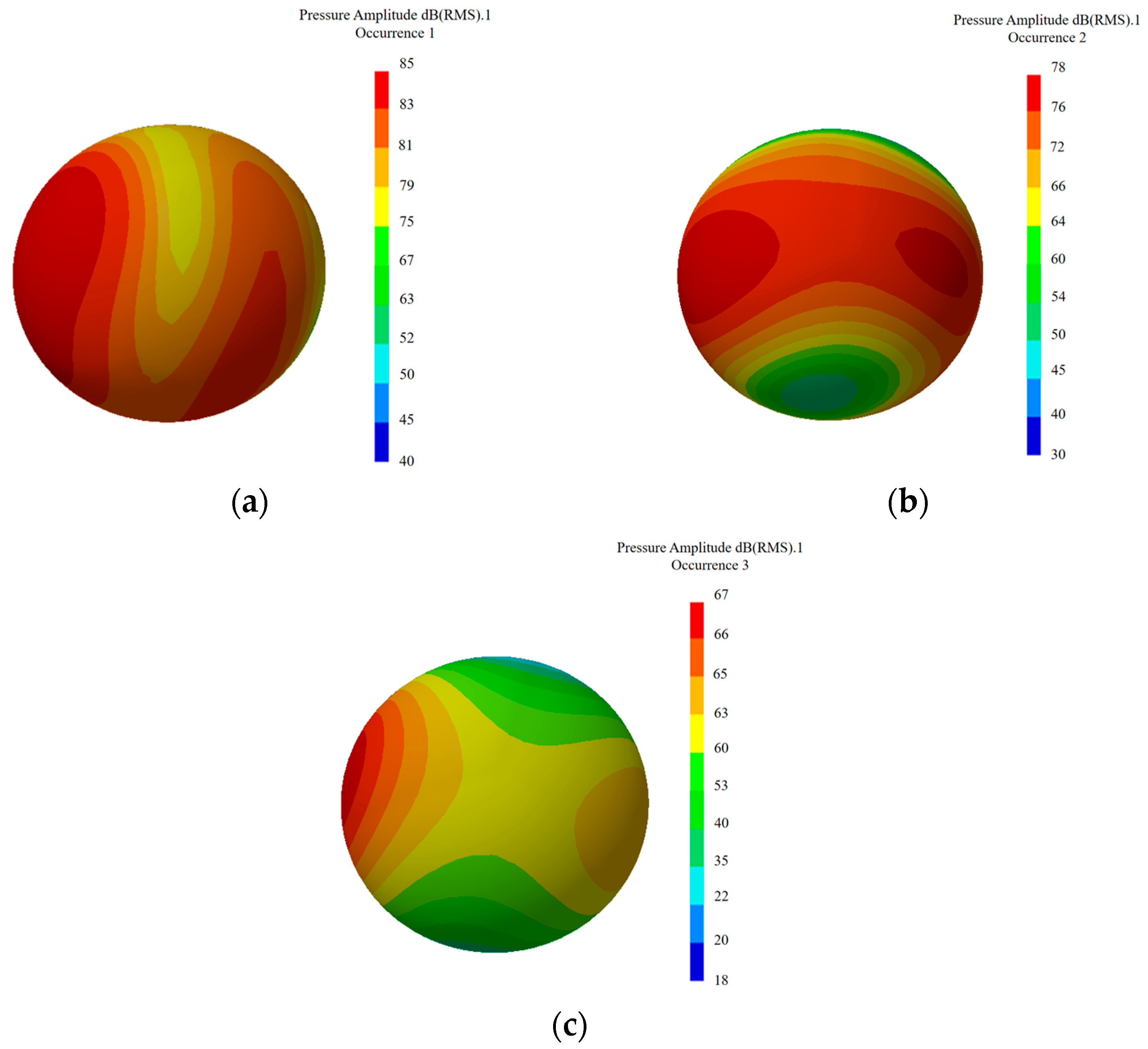

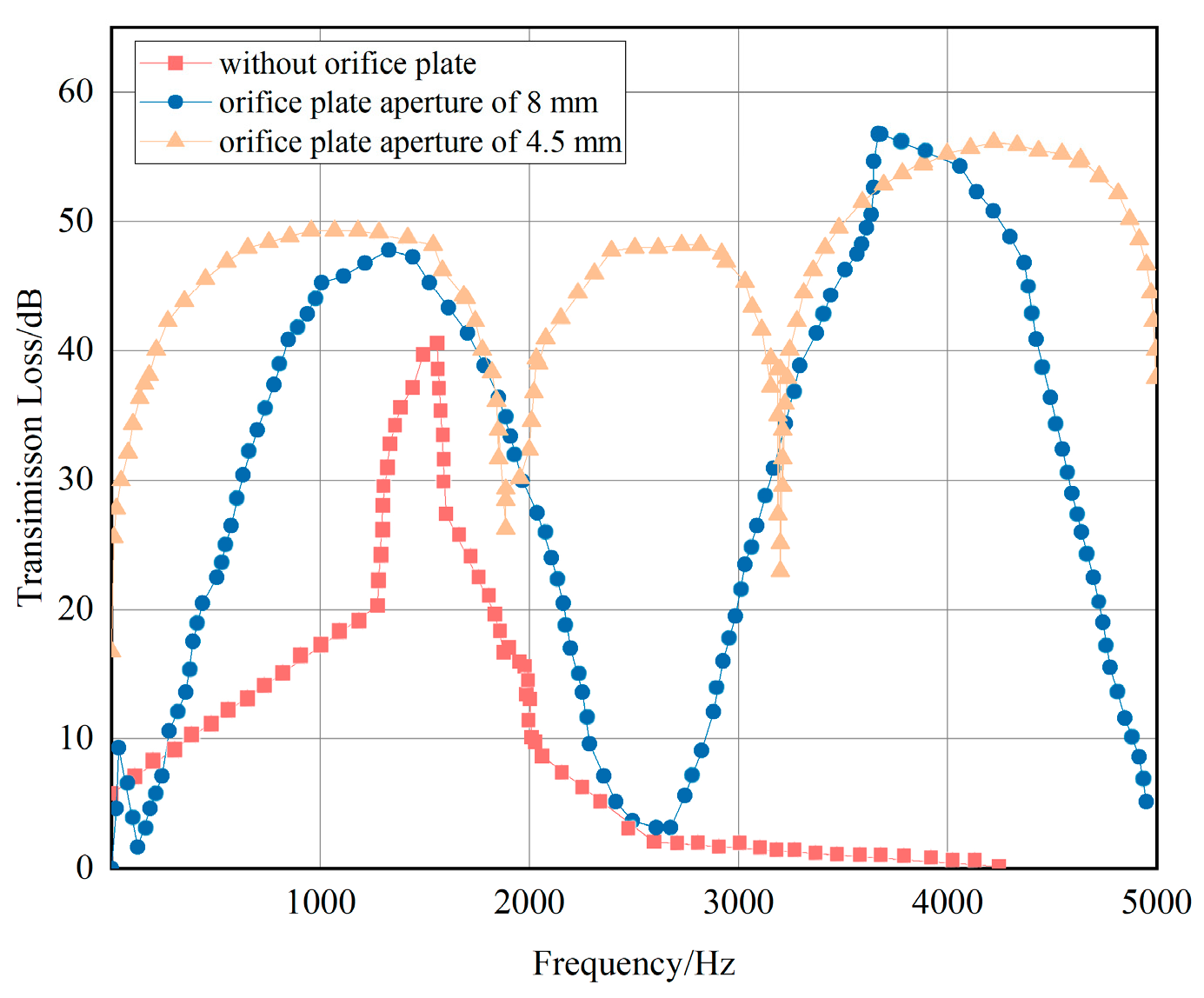

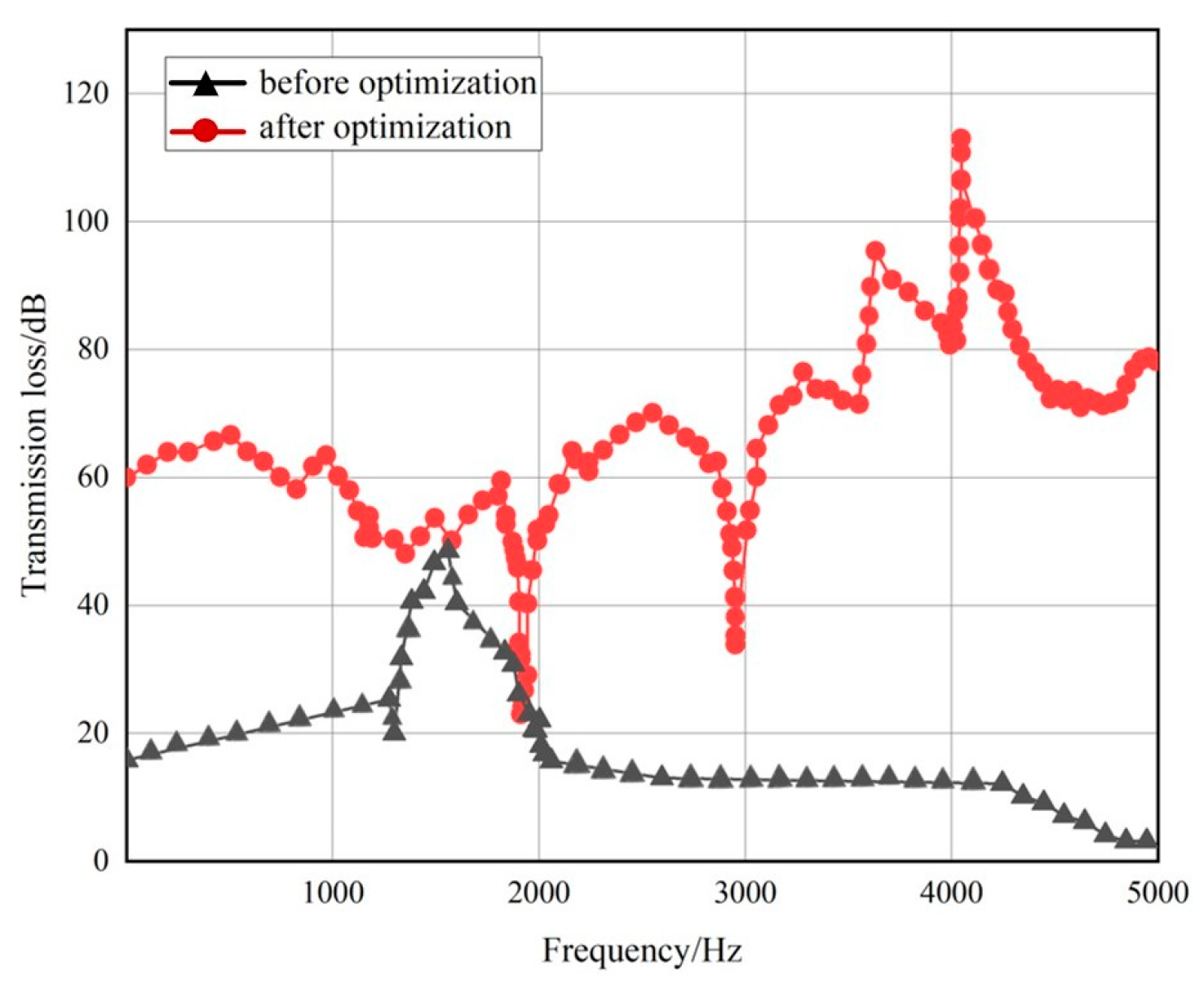

Based on the NOA, an improved NOA is proposed. According to the numerical simulation theory of multi-physical field coupling, the SST k-ԑ model is used in the steady-state calculation stage, the LES turbulence model is used in the unsteady state, and the acoustic software is combined to study the acoustic performance of the inverted bucket steam valve in three different cases, respectively. The maximum transmission loss of the steam valve without the noise-reducing orifice plate is 40.51 dB. After adding the 8 mm orifice plate, the peak value is two and the maximum transmission loss is 58 dB. After adding the 4.5 mm orifice plate, the peak value becomes three and the maximum transmission loss is 54 dB.

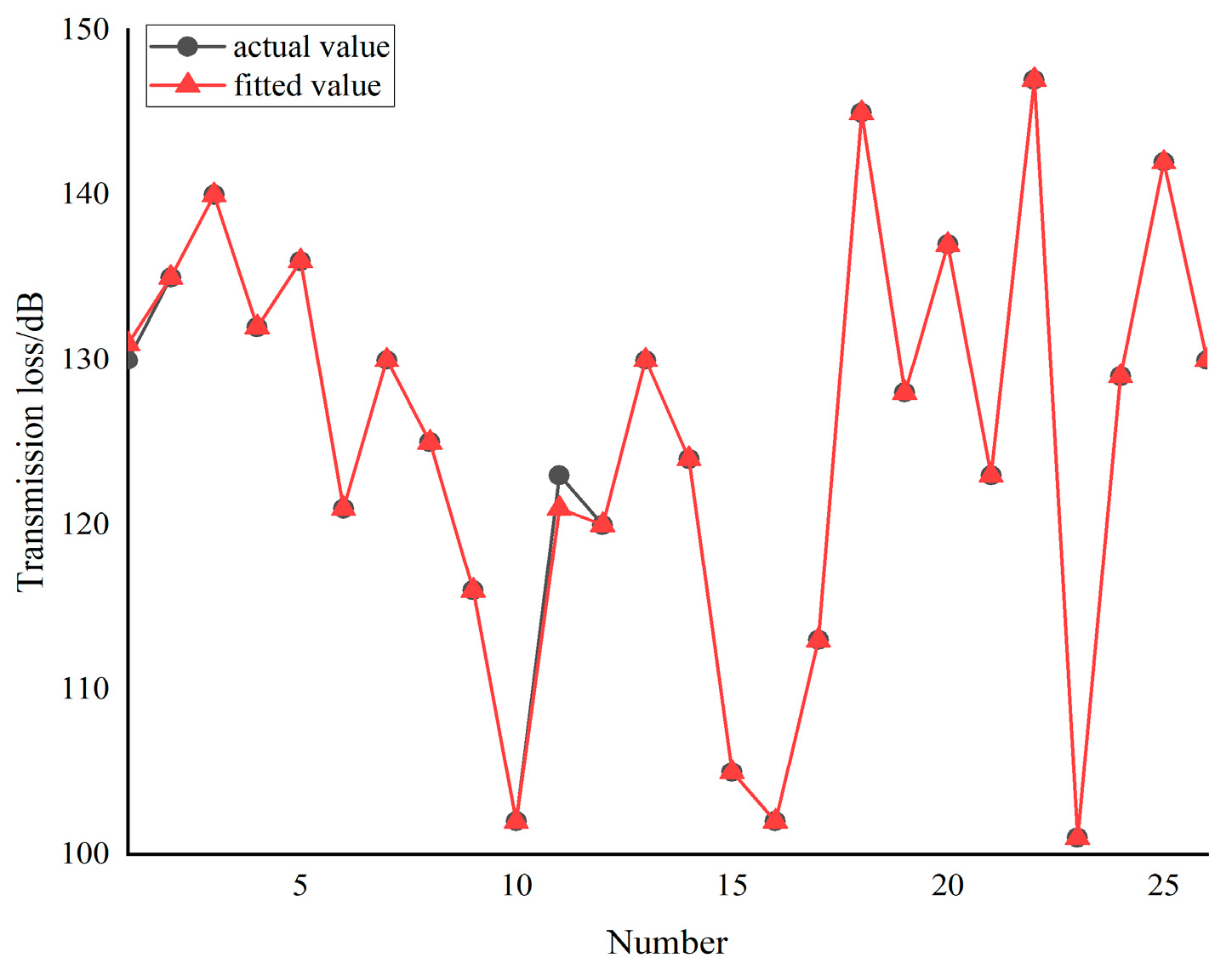

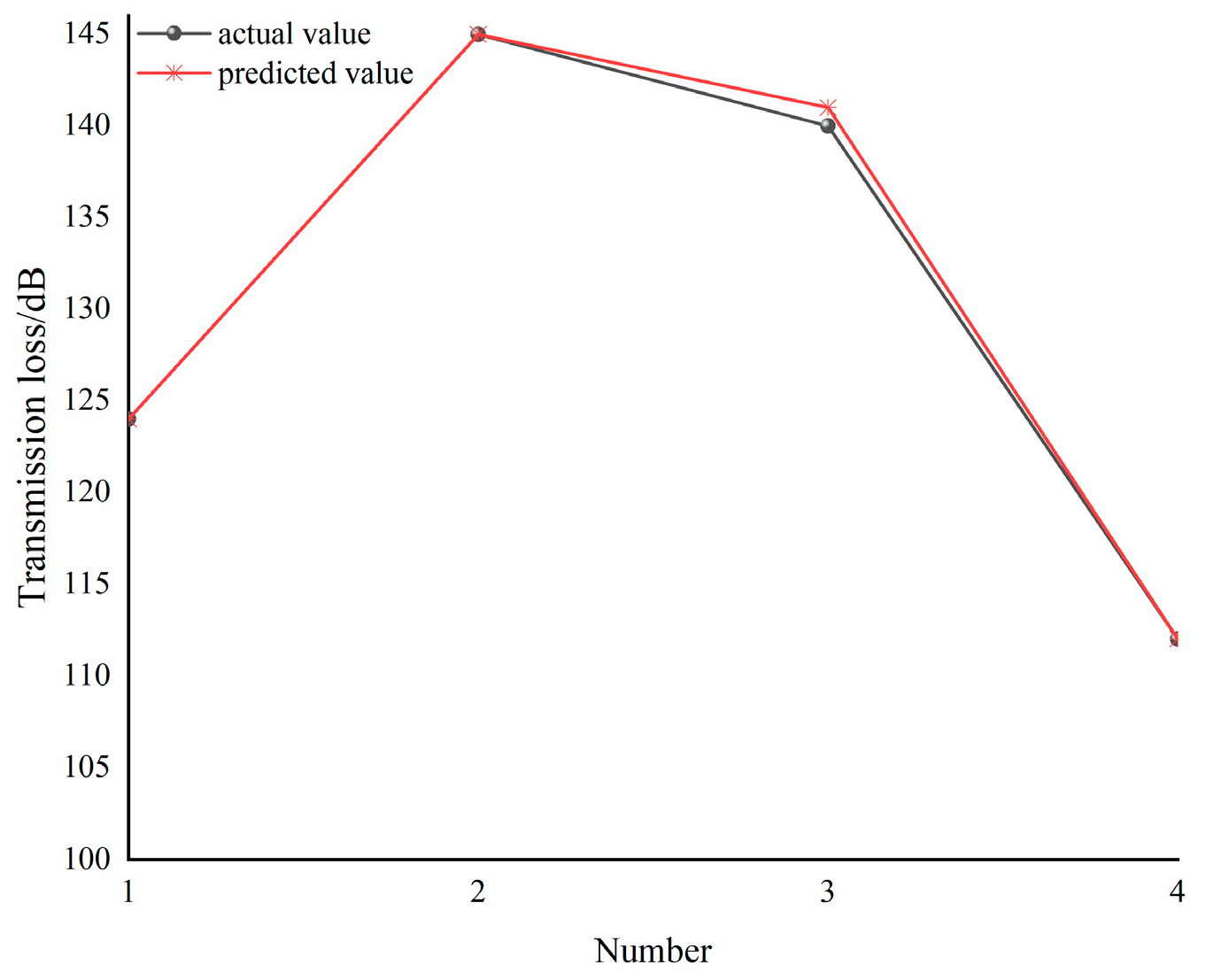

Based on the SVM algorithm, the maximum transmission loss approximation model of the inverted bucket steam valve is established and, through comparison with the numerical simulation results, it is proven that the model has high prediction accuracy with a relative error less than 3%.

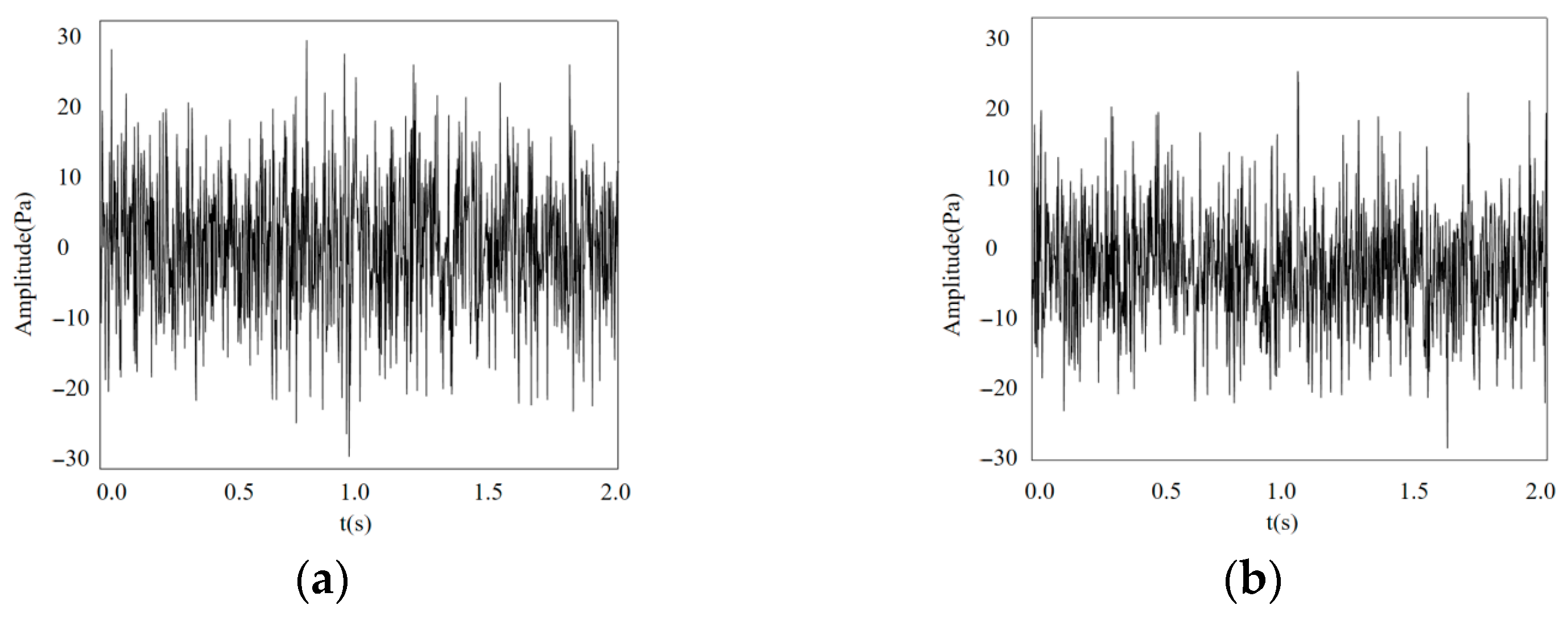

The acoustic performance of the inverted bucket steam valve before and after optimization is tested by means of experiments. The difference between the numerical simulation and experimental results of the inverted bucket steam valve without the orifice plate and with the improved orifice plate is less than 3%, which verifies the accuracy of the numerical simulation and provides theoretical guidance for the optimization of the valve control system for noise reduction.

The study has certain limitations: Firstly, the experimental verification is only applicable to the PN40 DN100 inverted bucket steam trap model and does not cover a wider range of nominal pressure, diameter, and supercritical conditions. The universality of the model needs further verification. Secondly, the noise reduction components only focus on the aperture, spacing, and thickness parameters of the orifice plate, without considering the influence of other structures such as porous materials and non-circular holes on the noise reduction effect and without in-depth analysis of the high-frequency noise suppression mechanism coupling between the orifice plate and the flow field inside the valve. Thirdly, the prediction accuracy of the SVM approximation model slightly decreases in the high-frequency range (>4000 Hz), which may be related to the simplification of the turbulence noise coupling law in this frequency band.

Future research can be conducted from three aspects: firstly, expanding experimental conditions to cover different specifications of drain valves and extreme conditions (such as high temperature and high pressure), to verify the applicability of the model; secondly, exploring the optimization design of composite noise reduction structures (such as orifice plates and sound-absorbing materials), and deepening the analysis of noise reduction mechanisms by combining fluid structure coupling theory; thirdly, introducing deep learning models (such as CNN-LSTM) to improve the accuracy of high-frequency noise prediction, and developing a fast optimization tool for noise reduction structural parameters for engineering applications.