Abstract

The use of wood waste as a component in cementitious composites represents a promising strategy for reducing environmental impact and promoting circular economy principles in the construction sector. This study examines the influence of five types of wood waste, spruce sawdust, spruce shavings, oak, beech, and oriented strand board (OSB), on the properties of Portland cement mortars. A constant 5% by mass of sand was replaced with each wood residue, and mixtures were tested for flowability, density, flexural, and compressive strength at 7, 14, and 28 days. Our results show that wood addition reduces density by 20–36% and compressive strength by 70–85%, depending on species and particle morphology. Denser materials (oak and OSB) resulted in composites with higher mechanical strength, suggesting a more effective particle packing and interfacial interaction compared to porous particles (spruce sawdust, shavings), which led to higher water demand and reduced strength. Beech showed the highest flexural strength, indicating potential for bending-dominated applications. The study demonstrates the feasibility of using selected wood residues for lightweight, non-structural cement composites and outlines the need for future microstructural validation through SEM and porosity analyses

1. Introduction

The construction industry is one of the largest consumers of natural resources and a significant contributor to environmental pollution. Traditional building materials, particularly cement-based composites, have a high carbon footprint due to the energy-intensive production processes of cement. cement production alone is responsible for approximately 8% of global CO2 emissions, making it one of the largest contributors to climate change. Reducing the amount of carbon emitted by cement production is critical to achieving global climate targets []. Buildings are responsible for around 50% of resource extraction and consumption and more than 30% of the EU’s total waste each year. In addition, buildings are responsible for 40% of the EU’s energy consumption and 36% of energy-related greenhouse gas emissions [].

The woodworking and furniture manufacturing industries generate substantial amounts of wood waste, much of which remains underutilized or is discarded as landfill waste. Among construction waste, wood waste is the second most significant type, accounting for approximately 40% of total construction and demolition waste, as reported by the Construction and Demolition Recycling Association [] in the United States.

In this context, a transition from a linear to a circular economy is being promoted. Within a circular economy, materials must be retained in the production cycle for as long as possible []. Thus, waste generated from construction and demolition activities can be transformed into valuable resources [], with wood occupying a particularly important position in this framework.

Combining the environmental benefits of wood with the benefits of concrete to produce a more sustainable building material is a better strategy []. This can be achieved by adding crushed wood pieces to the concrete mix. This solution implies the use of small pieces of wood; so in this mix, wood waste can also be used []. Since it is well known that waste management is a significant problem in the construction industry, developing a solution to further use a material considered as waste fits perfectly into circular economy principles [].

- Wood Waste Characteristics and Sources

Wood waste is a highly heterogeneous material generated at various stages of the wood product life cycle—from forest harvesting and sawmilling to furniture manufacturing and construction. In sawmills, up to 40% of log input can be lost as residues such as bark, sawdust, planer shavings, or offcuts []. In construction and furniture manufacturing, waste is produced in diverse forms, including sawdust, shavings, and irregular offcuts []. The particle size, shape, and moisture content of these residues depend on the processing techniques used, which in turn affect their behavior when incorporated into cementitious matrices.

Unlike materials such as steel or cement, wood is not homogeneous. Its density, porosity, and chemical composition vary significantly between species [], strongly influencing its performance when used as a component in composites. Softwoods, such as spruce (Picea abies), typically have lower densities (350–500 kg/m3) and are easier to process, while hardwoods such as oak (Quercus spp.) and beech (Fagus sylvatica) exhibit higher densities (650–750 kg/m3) and greater mechanical resistance but pose challenges in mixing and compatibility with cement binders []. These variations lead to differences in the resulting composite’s density, water absorption, and strength.

- Influence of Wood Species on Composite Behavior

The interaction between wood waste and cement is complex due to both physical and chemical factors. Lower-density softwoods, such as spruce, tend to increase water absorption and reduce the overall density of composites []. In contrast, denser hardwoods such as oak and beech may improve strength but can interfere with cement hydration because of their lower porosity and higher content of extractives and tannins. Engineered wood products like OSB (Oriented Strand Board) and MDF (Medium-Density Fiberboard) introduce additional complexity due to the presence of synthetic adhesives (e.g., urea–formaldehyde or phenol–formaldehyde) that may alter the hydration process or release volatile compounds [].

Table 1 summarizes the principal characteristics of the wood types investigated in this study, including their densities, mechanical properties, and implications for use in cement-based composites. These data (density, modulus, strength) help interpret the influence of each species when used as 5% replacement, since particle size and density govern volumetric packing fraction and porosity in the resulting composites.

Table 1.

Main physical and mechanical characteristics of wood types investigated and their potential influence on composite properties.

- Research Aim and Scope

While several studies have examined the use of plant-based fibers and biochar in cementitious materials, the specific influence of wood species on mechanical performance remains underexplored. The distinct physical and chemical nature of different wood types warrants a comparative evaluation to determine their suitability in sustainable cement-based composites.

The present study addresses this gap by comparing five wood residues under identical conditions and constant 5% mass substitution. Although the proportion is modest, it allows for quantifying the fundamental compatibility of each wood type while ensuring workability and mechanical integrity. The research provides a first step toward optimizing composition and treatment strategies for practical eco-construction applications.

This research aims to assess the effects of incorporating 5% wood waste from four sources, spruce, oak, beech, and OSB, on the mechanical behavior of cement mortars. This work provides the first direct comparison of spruce, oak, beech, and OSB at a fixed substitution level, isolating species effects on composite performance. Key parameters investigated include density, compressive strength, and flexural strength, measured at different curing ages. By identifying how wood species influence composite performance, this study contributes to the optimization of wood waste reuse strategies in eco-friendly construction materials.

A constant, low replacement rate of 5% by mass was selected to systematically isolate the effect of wood species without the confounding factor of excessively high porosity that dominates at higher substitution levels. This provides a clear baseline for understanding species-specific interactions. Although the replacement ratio is limited to 5% by mass, such inclusion of lightweight wood particles can significantly reduce the bulk density (up to 25–30%), lowering transport costs and the thermal conductivity of prefabricated elements. Previous studies [,] reported that small additions of treated lignocellulosic particles may improve toughness and crack bridging in cement composites. However, the comparative influence of different wood species under identical conditions has been scarcely reported. This work therefore provides a systematic comparison of four species at equal substitution levels to evaluate the feasibility of the approach for practical uses.

Although the 5% substitution may appear modest, such low-level replacement enables partial reduction of raw aggregate demand and transportation mass, contributing to marginal CO2 savings and resource efficiency consistent with circular economy goals.

2. Materials and Methods

2.1. The Materials Used

The cement used for all mixes was CEM I 42.5 R Portland cement, and natural river sand (0–2 mm) served as aggregate. Wood waste materials included spruce sawdust, spruce shavings, oak, beech, and oriented strand board (OSB). The spruce shavings mixture was introduced to evaluate the influence of particle morphology (elongated shavings versus fine sawdust) within the same species.

Wood waste materials were provided by a local prefabricated wood construction company (WoodStructure SRL, from Cluj Napoca, Romania). The five wood waste types—spruce, oak, beech, OSB, and spruce shavings—are shown in Figure 1.

Figure 1.

The five types of wood waste used in the experimental program.

The experimental compositions designed to assess the influence of wood species are presented in Table 2. The reference mix (R1) corresponds to a standard plaster mortar (CM IV) without additives. For each mixture, 5% by mass of sand was replaced with wood waste. The water-to-cement ratio (w/c) was adjusted to achieve a constant flow of 110 ± 5 mm, measured according to SR EN 1015. The variation in w/c reflects differences in wood porosity and water absorption, ensuring comparable workability across all mixes. In the modified mixtures, 5% of the aggregate mass was replaced with wood waste from each species. The dosage was scaled for laboratory preparation of 7 L batches per mix, ensuring consistent comparison across tests.

Table 2.

Mix proportions for the experimental phase.

The mix design (Table 2) was developed in the authors’ laboratory based on SR EN 998-2 proportions and previous internal experimental trials aimed at achieving uniform consistency.

An additional mix containing spruce shavings was included to examine the effect of particle morphology. The water-to-cement ratio (w/c) was adjusted for each mix in order to obtain a target flow table spread of 110 ± 5 mm (measured according to SR EN 1015). This value corresponds to the workability of the reference plaster mortar (R1) and was selected to ensure comparable fresh-state consistency across mixes. The final w/c values used for each mixture are reported in Table 2. By controlling the flow to the specified range, the influence of differing w/c on hardened properties was minimized; however, local water absorption by porous wood particles is discussed as a mechanistic factor. The workability of the fresh mortar was quantified using a flow table test according to SR EN 1015, with a target spread diameter of 110 ± 5 mm. The significantly different w/c ratios required are a direct consequence of the varying water absorption capacities of the different wood species and are a key factor in interpreting the hardened properties.

2.2. Experimental Procedures

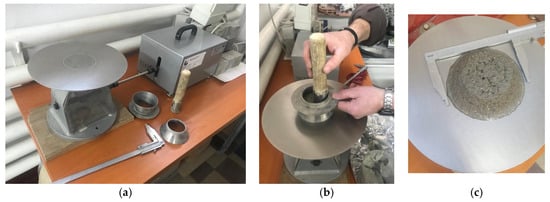

- Determination of fresh mortar properties

The consistency of the fresh mortar was determined using a flow table in accordance with SR EN 1015. The test apparatus consisted of a spreading table equipped with a conical mold. The procedure involved filling the mold in three layers, each compacted using a small tamping rod (20 cm long, 3 cm in diameter). After leveling the surface with a metal blade, the mold was lifted vertically and subjected to 15 controlled drops at one-second intervals to compact and spread the mortar.

The final spread diameter was measured along two perpendicular axes, and the mean value was recorded as the flow value (Figure 2).

Figure 2.

Determination of consistency of fresh mortar. (a) flow table setup; (b) compaction process; (c) diameter measurement.

- Sample Preparation and Curing

Specimens were cast in metal molds of dimensions 40 × 40 × 160 mm (Figure 3) for flexural and compressive strength tests and 50 mm × 15 mm cylindrical molds for adhesion tests. The molds were filled in two layers, each compacted by 10 manual impacts with a steel rod to remove air voids. After casting, the molds were covered with glass plates to prevent evaporation and stored at laboratory conditions for 24 h.

Figure 3.

Prism specimens used for mechanical testing.

Following demolding, all samples were cured under controlled conditions to maintain adequate humidity and temperature, preventing premature drying and ensuring consistent hydration.

- Flexural Strength Test

Flexural strength was determined on three prisms (40 × 40 × 160 mm) using a standard bending apparatus, as illustrated in Figure 4. The specimens were tested under a three-point bending configuration with a span of 100 mm. A uniform load ranging from 10 to 50 N/s was applied until failure, and the maximum load (F) was recorded according to SR EN 1015.

Figure 4.

(a) Automated apparatus for flexural strength testing; (b) loading configuration.

- Determination of compressive strength

Compressive strength was measured on the halves of the prisms remaining after the flexural tests, following SR EN 1015. Testing was performed using a hydraulic press (Figure 5) by applying a progressive vertical load perpendicular to the casting direction. The compressive strength (σc) was calculated automatically by the equipment as the ratio of the maximum load (F) to the loaded surface area (40 × 40 mm).

Figure 5.

Hydraulic press used for determining compressive strength.

3. Results and Discussion

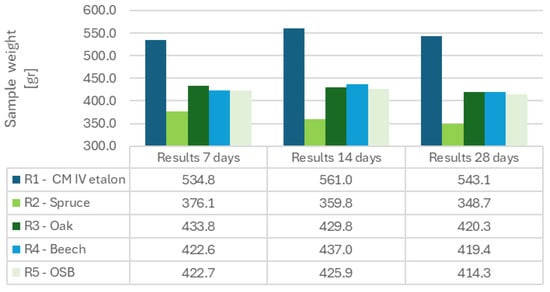

3.1. Weight and Density Evolution

The evolution of specimen weight over curing time is shown in Figure 6. As expected, the incorporation of wood waste led to a noticeable reduction in specimen weight compared with the reference mortar. This decrease is directly related to the lower density of lignocellulosic materials relative to mineral aggregates.

Figure 6.

The evolution of the sample weight on 7, 14 and 28 days.

The small apparent weight increases at 14 days for some mixtures (R1, R4, R5) reflect water retention by wood particles during ongoing hydration rather than actual mass gain.

At 7 days, all wood-based mortars presented significantly lower weights than the reference sample (534.8 g). The strongest reduction occurred in the spruce mixture (R2), which showed a 29.7% lower weight, followed by OSB (−20.9%), beech (−21.0%), and oak (−18.9%). These trends remained consistent throughout the curing period. After 28 days, the control sample reached 543.1 g, while spruce-based specimens remained at 348.7 g, indicating an overall 35.8% reduction in mass. Such differences confirm that adding wood waste decreases the density of the composite, resulting in lighter mortars.

While this property could be advantageous for applications where weight reduction is desirable (e.g., panels, decorative mortars, or insulating layers), it also implies higher porosity and potentially reduced mechanical performance. Among the species tested, the smallest density reduction was observed for oak and beech, suggesting that hardwood residues contribute to denser and more cohesive composites compared to softwood or engineered wood additions.

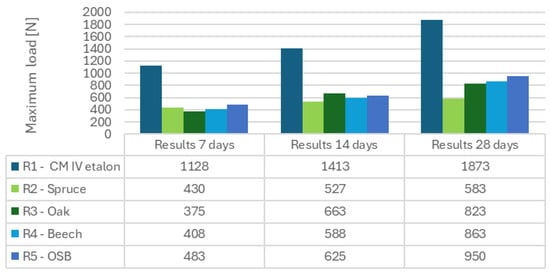

3.2. Flexural Strength

The results of flexural strength tests are presented in Figure 7. All wood-composite mortars exhibited lower bending resistance compared with the control sample across all curing ages. At 28 days, the reference mortar reached a flexural load of 1873 N, while the wood-containing samples achieved substantially lower values: spruce—583 N, oak—823 N, beech—863 N, and OSB—950 N. These correspond to decreases of approximately 69%, 56%, 54%, and 49%, respectively, compared with the reference.

Figure 7.

Flexural load at failure for reference and wood-modified mortars after 7, 14, and 28 days of curing.

However, clear distinctions were observed between species. OSB-based mixtures consistently exhibited the highest flexural strength among the wood-modified samples, surpassing oak by about 15% and beech by 10% at 28 days. This superior performance may be attributed to the engineered structure of OSB strands, which provides a more uniform particle size distribution and potentially better load transfer through the matrix.

Hardwood waste (oak and beech) provided intermediate results, reflecting their higher intrinsic strength and stiffness relative to softwoods. In contrast, the spruce mixture demonstrated the weakest flexural behavior, with a reduction of nearly 70% relative to the control at 28 days. This can be linked to its high porosity and water absorption capacity, which weaken the interfacial bond between wood particles and the cement paste.

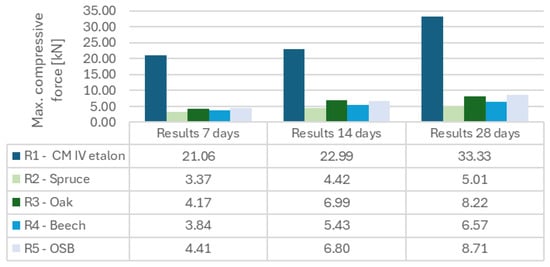

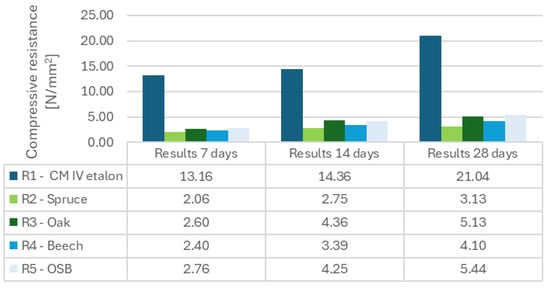

3.3. Compressive Strength

Compressive strength results are illustrated in Figure 8 and Figure 9, expressed both as maximum load (F, kN) and calculated strength (R, N/mm2). A similar trend to that observed for flexural strength was identified, with all modified mortars displaying lower compressive performance than the control sample.

Figure 8.

The results of the compressive force for the samples.

Figure 9.

The results of compressive resistance for the samples.

At 7 days, the reference sample achieved 13.16 N/mm2, while the wood-composite mixtures ranged from 2.06 N/mm2 (spruce) to 2.76 N/mm2 (OSB). The strength reduction ranged from 79% to 84%, depending on species. With ongoing curing, strength increased across all mixtures, indicating normal hydration progression despite the organic inclusions. After 28 days, the control sample reached 21.03 N/mm2, whereas the modified mortars attained 3.13 N/mm2 (spruce), 5.13 N/mm2 (oak), 4.10 N/mm2 (beech), and 5.44 N/mm2 (OSB). These represent reductions of 85%, 76%, 80%, and 74%, respectively, relative to the reference mortar.

When comparing the wood species among themselves, clear differences can be observed. OSB achieved the highest compressive strength, slightly outperforming oak by about 6% at 28 days. Both hardwoods (oak and beech) showed better performance than spruce, confirming that wood density and structure play decisive roles in the resulting composite strength. The engineered nature of OSB waste, containing adhesive-bonded wood strands, may also contribute to improved load transfer within the matrix despite potential interference with cement hydration.

The spruce-based mortar demonstrated the lowest compressive resistance at all curing ages. This result is consistent with its lower density and high internal porosity, which facilitate microcrack formation and hinder proper stress distribution within the composite.

3.4. Comparative Analysis and Mechanistic Interpretation

The overall comparison between wood species highlights the importance of particle density, stiffness, and surface characteristics in determining composite performance. Denser hardwood waste (oak and beech) leads to improved mechanical behavior compared to softwood waste (spruce), while engineered wood residues (OSB) appear to balance density and particle regularity, achieving the best results among the tested materials.

An approximate estimation of apparent porosity (P) was derived from the difference between theoretical and measured density using the relation:

Assuming a reference mortar density of 2125 kg/m3, the values measured in our laboratory tests correspond to porosities of 12–24%, confirming that the main reason for the reduced mass and strength is the increased pore volume introduced by the wood particles. The temporary weight increase at 14 days for some mixes (R1, R4, R5) is attributed to internal water retention by wood particles during hydration, later released during drying.

The observed differences in mechanical performance can be correlated with the inherent properties of the wood species, as summarized in Table 1. Mixtures incorporating higher-density wood residues (oak, beech, OSB) consistently yielded higher compressive and flexural strengths. This correlation suggests that particle density and stiffness play a key role in the load-bearing capacity of the composite. Conversely, the low-density spruce particles, which have a high capacity for water absorption (evidenced by the significantly higher w/c ratio required for workability), resulted in the lowest mechanical properties. The need for a higher w/c ratio likely led to a more porous cementitious matrix, explaining the reduction in strength. While chemical effects from extractives or adhesives cannot be ruled out, the physical characteristics of wood particles appear to be the dominant factor under the conditions of this study.

Despite the substantial reductions in strength compared with the control mix, the tested mortars exhibited sufficient mechanical performance for non-structural applications such as lightweight panels, partition elements, or eco-friendly plasters. The use of 5% wood waste achieved noticeable weight reduction (up to36%) while maintaining acceptable strength levels for such applications.

The observed species-dependent performance can be interpreted through three interacting mechanisms:

Particle density and stiffness. Hardwood residues (oak, beech) present higher particle density and intrinsic stiffness; they improve packing and load transfer in the mortar matrix, which reduces porosity and stress concentrators at the interface. As a result, hardwood mixes retain more compressive and flexural capacity than low-density softwood mixes.

Local water absorption and effective local w/c. porous softwood particles (spruce) absorb mixing water during casting, creating a locally higher effective water-to-cement ratio around the wood particles and producing micro voids after drying. This locally increased porosity degrades both compressive and flexural strength. The greater weight loss for spruce mixes (Table 3) supports the interpretation of higher particle porosity.

Table 3.

The comparative summary results.

Chemical interactions and surface extractives. Natural extractives (tannins, resins) and adhesives in engineered products (OSB) can interfere with cement hydration at the wood–paste interface by retarding hydration or forming weak interfacial phases. This effect reduces bond strength and can increase microcracking underload. In engineered OSB the presence of resin may also coat strands, reducing direct water uptake but simultaneously limiting matrix bonding; this trade-off likely explains OSB’s relatively better compressive but only moderate adhesive performance.

Evidence and limitations. While the current dataset (density, mechanical tests) strongly supports the role of density and water absorption, direct microstructural evidence (SEM imaging of the wood–cement interface, mercury intrusion porosimetry or gas adsorption porosimetry to quantify pore-size distribution, and thermal analysis to assess hydration degree) was not collected in this study. We therefore recommend follow-up microstructural analyses to quantify pore structure and interfacial phases and to correlate them with the mechanical trends reported here

Practical implication. For practical mix-design, to minimize strength loss while using wood waste: prefer denser hardwood or engineered residues, pre-treat porous softwood particles (pre-wetting or surface coating) to reduce local w/c fluctuations, and limit substitution rates for applications requiring higher mechanical performance

The results demonstrate that the type of wood waste significantly influences the mechanical performance of cement-based composites. While all additions reduce density and strength relative to conventional mortars, the magnitude of reduction depends strongly on wood species. OSB and oak provided the best balance between strength and lightness, whereas spruce, particularly in shaving form, led to the weakest mechanical results. These findings confirm that wood–cement compatibility is species-dependent, and careful selection of waste type is essential for designing sustainable composite materials with predictable performance.

The present mechanistic interpretation is based on macroscopic test data (density, strength, and weight change). Although this provides valuable insight into the species-dependent behavior, future work will include Scanning Electron Microscopy (SEM), X-ray Diffraction (XRD), and Mercury Intrusion Porosimetry (MIP) to directly observe hydration phases, pore structures, and interfacial morphology.

It should also be noted that the current study employed constant mass-based substitution (5%), leading to different volume fractions due to density variations. Future studies will adopt volume-based substitution to better quantify volumetric effects on porosity and strength.

4. Conclusions

This experimental study investigated the influence of four types of wood waste—spruce, oak, beech, and OSB—on the physical and mechanical properties of Portland cement mortars. A constant replacement rate of 5% (by mass of aggregates) was adopted to evaluate the effect of wood species on composite behavior at 7, 14, and 28 days of curing. Based on the results obtained, the following conclusions can be drawn:

- Density and weight reduction: The incorporation of wood residues decreased density by 20–36% and compressive strength by 70–85%, confirming that mechanical performance is species-dependent.

- Flexural strength behavior: The results indicate that the use of denser wood residues (oak, OSB) is associated with higher strength retention in the composite and improved bonding and strength retention, while low-density spruce particles increased porosity and mass loss. Beech specimens, despite an intermediate density, showed the highest flexural strength among wood-modified mortars, indicating their potential suitability for applications where bending resistance is prioritized.

- Compressive strength performance: Beech presented intermediate density but the highest flexural strength, suggesting advantages for bending-dominated applications.

- Comparative influence of wood species: The experimental results clearly show that the mechanical performance of wood–cement composites is strongly species-dependent. Engineered (OSB) and hardwood (oak, beech) waste exhibit superior mechanical behavior compared with softwood residues (spruce). Beech exhibited the highest flexural strength, making it more suitable for applications where bending or tensile performance dominate, such as thin panels, overlays, or pavement base layers. This finding emphasizes that not all wood waste is equally suitable for cement-based applications; species selection should be guided by density, particle morphology, and chemical compatibility with cement.

- Practical implications: Although the inclusion of wood waste leads to a reduction in mechanical strength, the resulting materials remain suitable for non-structural or lightweight applications, such as plaster mortars, prefabricated blocks, or insulating panels. The use of 5% wood waste also contributes to waste valorization and the principles of the circular economy by reducing the consumption of natural aggregates.

- Future work: The correlations established in this study suggest that mechanisms such as variations in interfacial bonding, matrix porosity due to water absorption, and potential chemical interactions are likely responsible for the performance differences. However, direct microstructural validation is required to confirm these hypotheses. Future work will therefore employ techniques such as Scanning Electron Microscopy (SEM) and Mercury Intrusion Porosimetry (MIP) to quantitatively analyze the wood–cement interface and pore structure. Such analyses are currently being planned as part of an extended study using SEM imaging and XRD phase identification on the same materials, to verify whether the hypothesized mechanisms—related to hydration inhibition, pore morphology, and particle–matrix bonding—can be experimentally confirmed. This will provide the microstructural evidence required to support the macroscopic trends described in this paper.

Author Contributions

Conceptualization, D.M. and D.L.M.; methodology, D.M.; software, D.M.; validation, D.M. and D.-R.T.-G.; formal analysis, D.M. and A.Ț.; investigation, D.M. and D.-R.T.-G.; resources, A.Ț.; data curation, P.C.; writing—original draft preparation, D.M., A.Ț. and P.C.; writing—review and editing, D.M., A.Ț., and P.C.; visualization, D.M. and D.-R.T.-G.; supervision, D.L.M.; project administration, D.M.; funding acquisition, D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research and the APC were funded by a research grant, number 7164, from the GNaC ARUT 2023 competition, with the financial support of the Technical University of Cluj-Napoca, Romania, Europe.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- WEF. Cement Is a Big Problem for the Environment. Here’s How to Make It More Sustainable. World Economic Forum. Available online: https://www.weforum.org/stories/2024/09/cement-production-sustainable-concrete-co2-emissions/ (accessed on 11 April 2025).

- EU Council. Building Materials: Council Adopts Law for Clean and Smart Construction Products. European Council. Available online: https://www.consilium.europa.eu/en/press/press-releases/2024/11/05/building-materials-council-adopts-law-for-clean-and-smart-construction-products/ (accessed on 13 April 2025).

- CDRA. Wood Waste. Construction & Demolition Recycling Association. Available online: https://www.cdrecycling.org/wood (accessed on 8 April 2025).

- Jahan, I.; Zhang, G.; Bhuiyan, M.; Navaratnam, S. Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability 2022, 14, 10478. [Google Scholar] [CrossRef]

- Leone, R.; Campisi, T.; Saeli, M. Wood Industry Wastes Valorisation and Reuse for a Greener Architecture. In Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2025; Volume 611 LNCE, pp. 439–455. [Google Scholar] [CrossRef]

- Liang, H.; Liu, H.; Bian, X.; Wang, Y.; Dong, L. Supporting zero-waste building: A novel spatial explicit material flow analysis model for construction waste. J. Clean. Prod. 2024, 456, 142369. [Google Scholar] [CrossRef]

- Yuan, L.; Yang, B.; Lu, W.; Peng, Z. Carbon footprint accounting across the construction waste lifecycle: A critical review of research. Environ. Impact Assess. Rev. 2024, 107, 107551. [Google Scholar] [CrossRef]

- Maier, D. A Review of the Environmental Benefits of Using Wood Waste and Magnesium Oxychloride Cement as a Composite Building Material. Materials 2023, 16, 1944. [Google Scholar] [CrossRef] [PubMed]

- Leone, R.; La Scalia, G.; Saeli, M. A critical review on reuse potentials of wood waste for innovative products and applications: Trends and future challenges. Sustain. Futures 2025, 10, 100869. [Google Scholar] [CrossRef]

- Farjana, S.H.; Tokede, O.; Tao, Z.; Ashraf, M. Life cycle assessment of end-of-life engineered wood. Sci. Total Environ. 2023, 887, 164018. [Google Scholar] [CrossRef] [PubMed]

- Maier, A.; Dan, H. Influence of the marketing innovation on the organizational performance. Int. J. Adv. Eng. Manag. Res. 2018, 3, 182–192. [Google Scholar]

- Ouellet-Plamondon, C.M.; Ramseier, L.; Balouktsi, M.; Delem, L.; Foliente, G.; Francart, N.; Garcia-Martinez, A.; Hoxha, E.; Lützkendorf, T.; Rasmussen, F.N.; et al. Carbon footprint assessment of a wood multi-residential building considering biogenic carbon. J. Clean. Prod. 2023, 404, 136834. [Google Scholar] [CrossRef]

- Farjana, S.H.; Tokede, O.; Ashraf, M. Environmental Impact Assessment of Waste Wood-to-Energy Recovery in Australia. Energies 2023, 16, 4182. [Google Scholar] [CrossRef]

- de la Caba, K.; Guerrero, P.; del Rio, M.; Mondragon, I. Weathering behaviour of wood-faced construction materials. Constr. Build. Mater. 2007, 21, 1288–1294. [Google Scholar] [CrossRef]

- Bartolucci, B.; De Rosa, A.; Bertolin, C.; Berto, F.; Penta, F.; Siani, A.M. Mechanical properties of the most common European woods: A literature review. Frat. Integrita Strutt. 2020, 14, 249–274. [Google Scholar] [CrossRef]

- Ziaee, S.; Kerr-Anderson, E.; Johnson, A.; Eastep, D.; Abdel-Magid, B. Effect of High Fiber Content on Properties and Performance of CFRTP Composites. J. Compos. Sci. 2024, 8, 364. [Google Scholar] [CrossRef]

- Mazloomi, M.S.; He, W.; Evans, P.D. Finite Element Modelling of the Effect of Adhesive Z-Connections on the Swelling of a Laminated Wood Composite. J. Compos. Sci. 2023, 7, 442. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).