Long-Term Environmental Aging of Polymer Composite Coatings: Characterization and Evaluation by Dynamic Mechanical Analysis

Abstract

1. Introduction

2. Materials and Methods

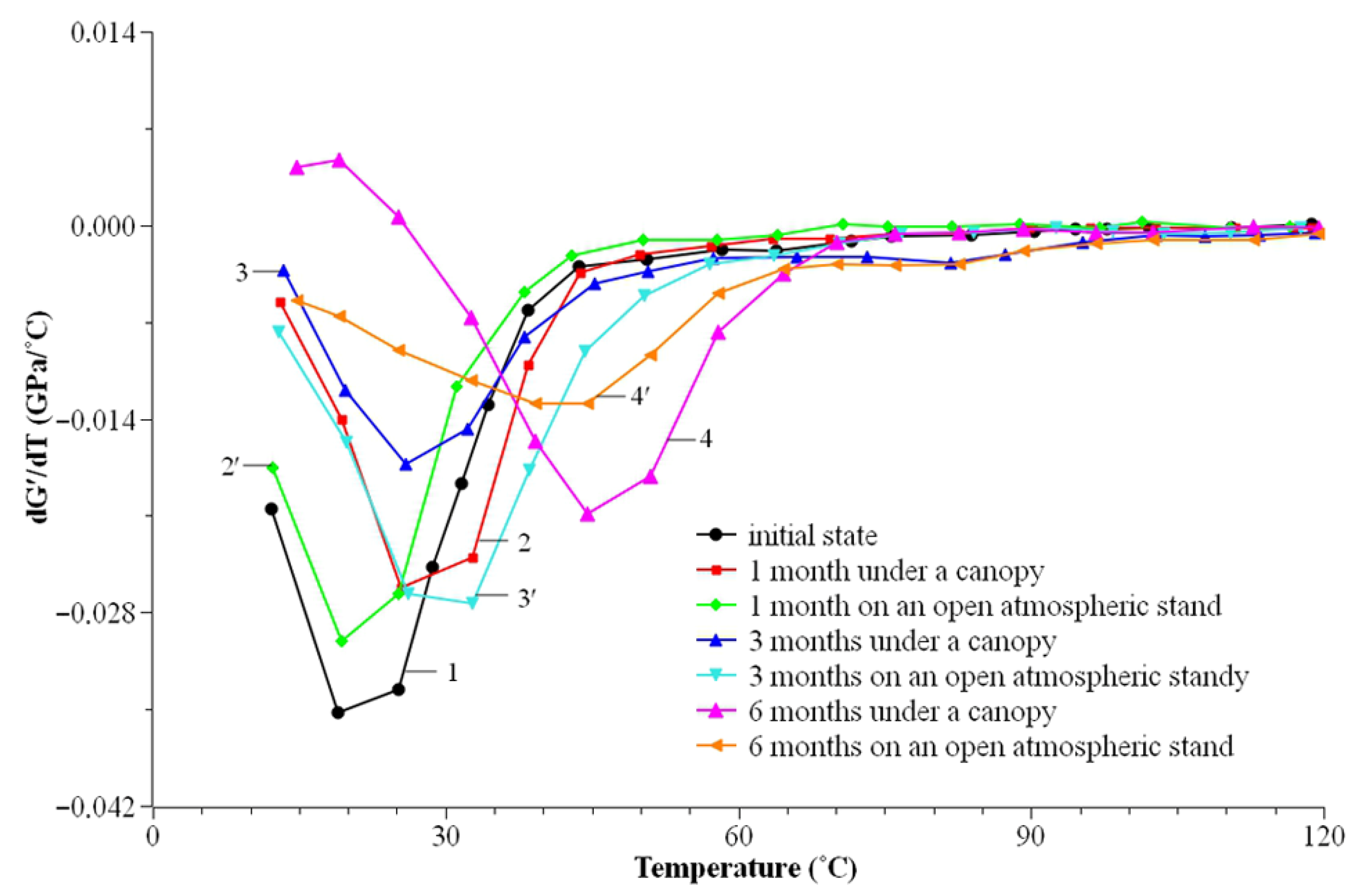

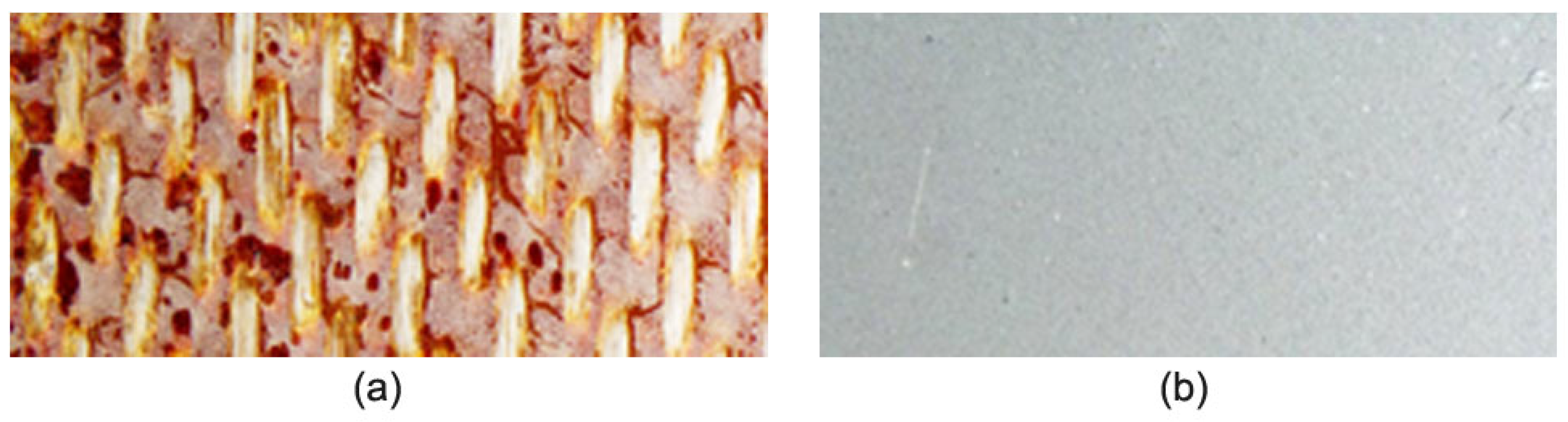

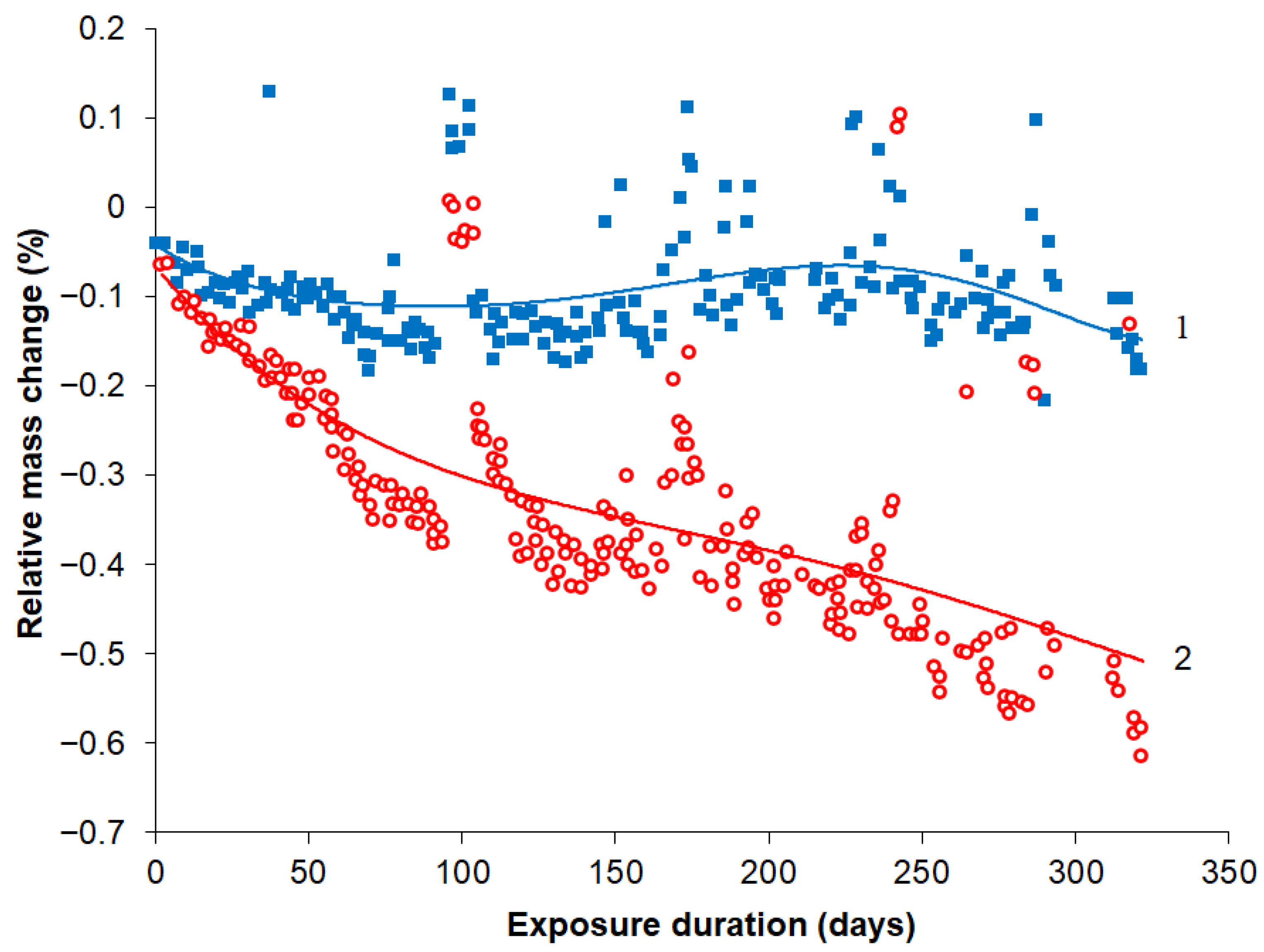

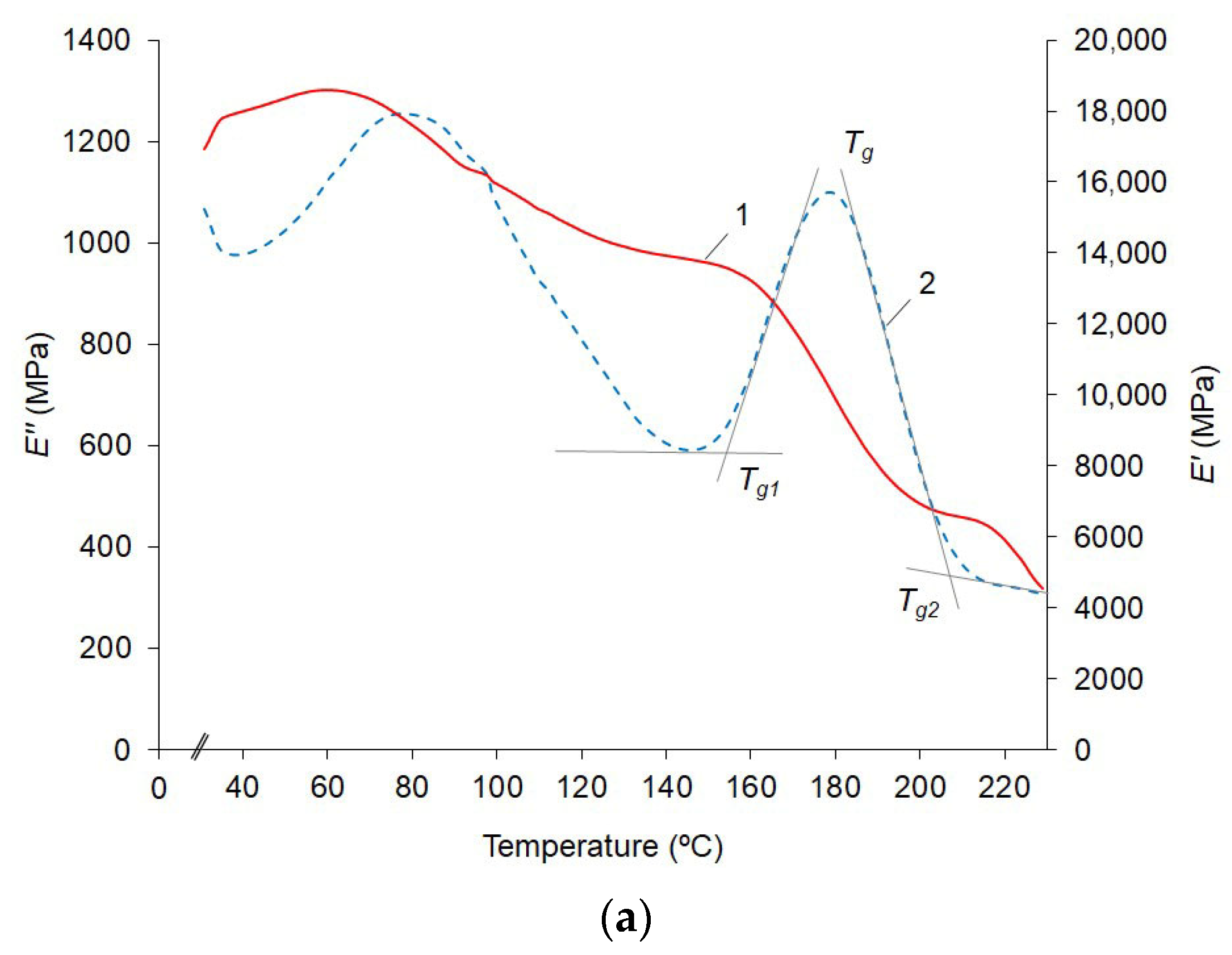

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mayandi, K.; Rajini, N.; Ayrilmis, N.; Indira Devi, M.P.; Siegchin, S.; Mohammad, F.; Al-Lohedan, H.A. An overview of endurance and ageing performance under various environmental conditions of hybrid polymer composites. Review. J. Mater. Res. Technol. 2020, 9, 15962–159888. [Google Scholar] [CrossRef]

- Yang, J.-W.; Cho, H.-J.; Gong, Y.-D. Analytical approach to degradation structural changes of epoxy-dicyandiamide powder coating by accelerated weathering. Review. Prog. Org. Coat. 2023, 175, 107357. [Google Scholar] [CrossRef]

- Kablov, E.N.; Bakradze, M.M.; Gromov, V.I.; Voznesenskaya, N.M.; Yakusheva, N.A. New high-strength structural and corrosion-resistant steels for aerospace technology developed by FSUE “VIAM” (review). Aviatsionnyye Mater. Tekhnologii 2020, 1, 3–11. (In Russian) [Google Scholar] [CrossRef]

- Kablov, E.N.; Antipov, V.V.; Oglodkova, Y.S.; Oglodkov, M.S. Experience and prospects for the use of aluminum-lithium alloys in aviation and space technology products. Metallurg 2021, 1, 62–70. (In Russian) [Google Scholar]

- Startsev, V.O.; Antipov, V.V.; Slavin, A.V.; Gorbovets, M.A. Modern domestic polymer composite materials for aircraft construction (review). Aviatsionnyye Mater. Tekhnologii 2023, 2, 122–144. (In Russian) [Google Scholar]

- Ramezanpour, J.; Ramezanzadeh, B.; Samani, N.A. Progress in bio-based anti-corrosion coatings; A concise overview of the advancements, constraints, and advantages. Prog. Org. Coat. 2024, 94, 108556. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, T.; He, Y.; Wang, Y.; Bi, Y. Corrosion and aging of organic aviation coatings: A review. Chin. J. Aeronaut. 2023, 36, 1–35. [Google Scholar] [CrossRef]

- Startsev, V.O.; Khrulev, K.A.; Evdokimov, A.A. The influence of seasonality of climatic influence on changes in the color characteristics of EP-140 epoxy enamel. Korroz. Mater. Zashchita 2017, 6, 31–36. (In Russian) [Google Scholar]

- Khan, A.R.; Zhang, H.-J.; Jun, Z.; Zhang, M.; Eldin, S.M.; Siddique, I. Electrochemical corrosion protection of neat and zinc phosphate modified epoxy coating: A comparative physical aging study on Al alloy 6101. Front. Chem. 2023, 11, 1142050. [Google Scholar] [CrossRef]

- Startsev, V.O.; Frolov, A.S. Influence of climatic influence on the color characteristics of paint and varnish coatings. Lakokrasochnyye Mater. Ikh Primen. 2015, 3, 16–18. (In Russian) [Google Scholar]

- Verma, A.; Tiwary, C.S.; Bhattacharya, J. Enhancement of hydrophobic, resistive barrier and anticorrosion performance of epoxy coating with addition of Clay-Modified Green Silico-Graphitic Carbon. Carbon Trends 2024, 15, 100347. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Le, X.H.; Dao, P.H.; Decker, C.; Nguyen-Tri, P. Stability of acrylic polyurethane coatings under accelerated aging tests and natural outdoor exposure: The critical role of the used photo-stabilizers. Prog. Org. Coat. 2018, 124, 137–146. [Google Scholar] [CrossRef]

- Gao, J.; Li, C.; Lv, Z.; Wang, R.; Wu, D.; Li, X. Correlation between the surface aging of acrylic polyurethane coatings and environmental factors. Prog. Org. Coat. 2019, 132, 362–369. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Zhang, L.; Hou, J.; Lu, Z.; Zhang, P.; Wang, B.; Jin, N. Degradation behavior and mechanism of polyurethane coating for aerospace application under atmospheric conditions in South China Sea. Prog. Org Coat. 2019, 136, 105310. [Google Scholar] [CrossRef]

- Chen, J.; Li, B.; Zeng, X.; Li, Z.; Wen, Y.; Hu, Q.; Yang, Q.; Zhou, M.; Yang, B. Study on the influence of accelerated aging on the properties of an RTV anti-pollution flashover coating. Polymers 2023, 15, 751. [Google Scholar] [CrossRef]

- Nefedov, N.I.; Semenova, L.V.; Kuznetsova, V.A.; Vereninova, N.P. Paint and varnish coatings for protecting metal and polymer composite materials from aging, corrosion and biodamage. Aviatsionnyye Mater. Tekhnologii 2017, S 29, 393–404. (In Russian) [Google Scholar] [CrossRef]

- Merkulova, Y.I.; Kuznetsova, V.A.; Novikova, T.A. Study of the properties of a paint coating system based on fluoropolyurethane enamel and primer with a reduced content of toxic pigments. Proc. VIAM 2019, 5, 68–75. (In Russian) [Google Scholar] [CrossRef]

- Cai, G.; Zhang, H.; Jiang, D.; Dong, Z. Degradation of fluorinated polyurethane coating under UVA and salt spray. Part II: Molecular structures and depth profile. Prog. Org. Coat. 2018, 124, 25–32. [Google Scholar] [CrossRef]

- Li, D.; Yu, L.; Lu, Z.; Kang, H.; Li, L.; Zhao, S.; Shi, N.; You, S. Synthesis, Structure, Properties, and Applications of Fluorinated Polyurethane. Polymers 2024, 16, 959. [Google Scholar] [CrossRef]

- Nichols, M.E. Paint weathering tests. In Handbook of Environmental Degradation of Materials; Kutz, M., Ed.; William Andrew Publishing: Norwish, NY, USA, 2005; pp. 597–619. [Google Scholar] [CrossRef]

- Nichols, M.; Boisseau, J.; Pattison, L.; Campbell, D.; Quill, J.; Zhang, J.; Smith, D.; Henderson, K.; Seebergh, J.; Berry, D.; et al. An improved accelerated weathering protocol to anticipate Florida exposure behavior of coatings. J. Coat. Technol. Res. 2013, 10, 153–173. [Google Scholar] [CrossRef]

- Pavlov, A.V.; Andreeva, N.P.; Pavlov, M.R.; Merkulova, Y.I. Climatic tests of paint and varnish coating based on fluoroplastic and features of its destruction. Proc. VIAM 2019, 5, 103–110. (In Russian) [Google Scholar] [CrossRef]

- Rudnev, V.P. The influence of the humid subtropical environment on the color characteristics of protective polymer coatings. Environ. Control. Syst. 2020, 3, 56–64. (In Russian) [Google Scholar] [CrossRef]

- Veligodsky, I.M.; Koval, T.V.; Kurnosov, A.O.; Marakhovsky, P.S. Study of the climatic resistance of fiberglass samples after full-scale exposure in various climatic zones. Proc. VIAM 2022, 11, 134–148. (In Russian) [Google Scholar]

- Manoli, Z.; Pecko, D.; Van Assche, G.; Stiens, J.; Pourkazemi, A.; Terryn, H. Transport of Electrolyte in Organic Coatings on Metal. Paint and Coatings Industry. In Paint and Coatings Industry; Yilmaz, F., Ed.; Intechopen: Rijeka, Croatia, 2019. [Google Scholar] [CrossRef]

- Yang, X.P.; Vang, C.; Tallman, D.E.; Bierwagen, G.P.; Croll, S.G.; Rohlik, S. Weathering degradation of a polyurethane coating. Polym. Degrad. Stabil. 2001, 74, 341–351. [Google Scholar] [CrossRef]

- Yang, X.P.; Li, J.; Croll, S.G.; Tallman, D.E.; Bierwagen, G.P. Degradation of low gloss polyurethane aircraft coatings under UV and prohesion alternating exposures. Polym. Degrad. Stabil. 2003, 80, 51–58. [Google Scholar] [CrossRef]

- Huang, H.; Guo, H.; Feng, Y. Study on UV-aging performance of fluorinated polymer coating and application on painted muds. Mater. Res. Express 2021, 8, 015301. [Google Scholar] [CrossRef]

- Molina, M.T.; Cano, E.; Ramirez-Barat, B. Testing protective coatings for metal conservation: The influence of the application method. Herit. Sci. 2023, 11, 94. [Google Scholar] [CrossRef]

- Gillham, J. Torsional braid analysis (TBA) of polymers. In Developments in Polymer Characterizations; Dworkins, J., Ed.; Springer: Dordrecht, The Netherlands, 1982; Volume 3, pp. 159–227. [Google Scholar] [CrossRef]

- Menard, R.P.; Menard, N. Dynamic Mechanical Analysis. A Practical Introduction, 3rd ed.; CRC Press LLC: New York, NY, USA, 2020; p. 280. [Google Scholar] [CrossRef]

- Skrovanec, D.J.; Schoff, C.K. Thermal mechanical analysis of organic coatings. Prog. Org. Coat. 1988, 16, 135–163. [Google Scholar] [CrossRef]

- Johnson, B.W.; McIntyre, R. Analysis of test methods for UV durability predictions of polymer coatings. Prog. Org. Coat. 1996, 27, 95–106. [Google Scholar] [CrossRef]

- Barbosa, A.P.C.; Fulco, A.P.P.; Guerra, E.S.S.; Arakaki, F.K.; Tosatto, M.; Costa, M.C.B.; Melo, J.D.D. Accelerated aging effects on carbon fiber/epoxy composites. Compos. Part B 2017, 110, 298–306. [Google Scholar] [CrossRef]

- Bartolomeo, P.; Irigoyen, M.; Aragon, E.; Frizzi, M.A.; Perrin, F.X. Dynamic mechanical analysis and Vickers micro hardness correlation for polymer coating UV ageing characterisation. Polym. Degrad. Stabil. 2001, 72, 63–68. [Google Scholar] [CrossRef]

- Startsev, O.V.; Bolonin, A.B.; Vapirov, Y.M.; Krivov, V.A.; Vladimirsky, V.N.; Ofitserova, M.G. Improving the viscoelastic properties of acrylic enamel AC-1115. Paint. Varn. Their Appl. 1986, 4, 16–18. (In Russian) [Google Scholar]

- Perrin, F.X.; Merlatti, C.; Aragon, E.; Margaillan, A. Degradation study of polymer coating: Improvement in coating weatherability testing and coating failure prediction. Prog. Org. Coat. 2009, 64, 466–473. [Google Scholar] [CrossRef]

- Kotnarowska, D. Influence of ageing with UV radiation on physicochemical properties of acrylic-polyurethane coatings. J. Surf. Eng. Mater. Adv. Technol. 2018, 8, 95–109. [Google Scholar] [CrossRef]

- Croll, S.G. Quantitative evaluation of photodegradation in coatings. Prog. Org. Coat. 1987, 15, 223–247. [Google Scholar] [CrossRef]

- ISO 9227:2022; Corrosion Tests in Artificial Atmospheres—Salt Spray Tests. International Organization for Standardization (ISO): Geneva, Switzerland, 2022.

- ASTM D5894-21; Standard Practice for Cyclic Salt Fog/UV Exposure of Painted Metal, (Alternating Exposures in a Fog/Dry Cabinet and a UV/Condensation Cabinet). ASTM International: West Conshohocken, PA, USA, 2021.

- Osterhold, M.; Glöckner, P. Influence of weathering on physical properties of clear coats. Prog. Org. Coat. 2001, 41, 177–182. [Google Scholar] [CrossRef]

- Startseva, L.T.; Jelesina, G.F.; Startsev, O.V.; Mashinskaya, G.P.; Perov, B.V. Effect of corrosive medium on properties of metal-plastics laminates. Int. J. Polymeric Mater. 1997, 37, 151–160. [Google Scholar] [CrossRef]

- Skaja, A.; Fernando, D.; Croll, S. Mechanical property changes and degradation during accelerated weathering of polyester-urethane coatings. J. Coat. Technol. Res. 2006, 3, 41–51. [Google Scholar] [CrossRef]

- Deev, I.S.; Nikishin, E.F.; Kurshev, E.V.; Lonsky, S.L. Research of structure and composition of KMU-4l carbon fiber reinforced plastic after 12 years of exposure to space environment. 1. Macrostructure and surface composition. Quest. Mater. Sci. 2015, 2, 65–75. (In Russian) [Google Scholar]

- Cataldi, A.; Corcione, C.E.; Frigione, M.; Pegoretti, A. Photocurable resin/nanocellulose composite coatings for wood protection. Prog. Org. Coat. 2017, 106, 128–136. [Google Scholar] [CrossRef]

- Startsev, O.V.; Molokov, M.V.; Smirnov, V.F.; Gudozhnikov, S.S. Mechanisms of climatic aging of wood. In Climatic Testing of Building Materials; Izdatel’stvo ASV: Moscow, Russia, 2017; pp. 322–366. (In Russian) [Google Scholar]

- Haris, N.I.N.H.; Hassan, M.Z.; Ilyas, R.A.; Suhat, M.A.; Sapuan, S.M.; Dolah, R.; Mohammad, R.; Asyraf, M.R.M. Dynamic mechanical properties of natural fiber reinforced hybrid polymercomposites: A review. J. Mater. Res. Technol. 2022, 19, 167–182. [Google Scholar] [CrossRef]

- Ridzuan, M.J.M.; Majid, M.S.A.; Afendi, M.; Mazlee, M.N.; Gibson, A.G. Thermal behaviour and dynamic mechanical analysis of Pennisetum purpureum/glass-reinforced epoxy hybrid composites. Compos. Struct. 2016, 152, 850–859. [Google Scholar] [CrossRef]

- Manral, A.; Ahmad, F.; Chaudhary, V. Static and dynamic mechanical properties of PLA bio-composite with hybrid reinforcement of flax and jute. Mater. Today Proc. 2019, 25, 577–580. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Abdul Majid, M.S. Analysis of dynamic mechanical, low-velocity impact and compression after impact behaviour of benzoyl treated sugar palm/glass/epoxy composites. Compos. Struct. 2019, 226, 111308. [Google Scholar] [CrossRef]

- Perrin, P.; Prud’homme, R.E. Miscibility behaviour of PVC/polymeth acrylate blends: Temperature and composition analysis. Polymer 1991, 32, 1468–1474. [Google Scholar] [CrossRef]

- Hill, L.W.; Grande, J.S.; Kozlowski, K. Dynamic mechanical analysis of weathered (Q-U-V) acrylic clearcoats with and without stabilizers. Polymeric Materials Science and Engineering. ACS Polym. Mater. Sci. Eng. Conf. Pap. 1990, 63, 654. [Google Scholar]

- Hill, L.W.; Korzeniowski, H.M.; Ojunga-Andrew, M.; Wilson, R.C. Accelerated clearcoat weathering studied by dynamic mechanical analysis. Prog. Org. Coat. 1994, 24, 147–173. [Google Scholar] [CrossRef]

- Bergamasco, D.; Bulian, F.; Melchior, A.; Menotti, D.; Tirelli, P.; Tolazzi, M. DMA analysis to predict the performance of waterborne coatings. J. Therm. Anal. Calorim. 2011, 103, 65–68. [Google Scholar] [CrossRef]

- Crawford, D.M.; Escarsega, J.A. Dynamic mechanical analysis of novel polyurethane coating for military applications. Thermochim. Acta 2000, 357–358, 161–168. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, Q.; Chen, P.; Xu, Y.; Nie, W.; Zhou, Y. Controllable hydrolytic stability of novel fluorinated polyurethane films by incorporating fluorinated side chains. Prog. Org. Coat. 2022, 165, 106729. [Google Scholar] [CrossRef]

- Roshan, S.; Jafari, R.; Momen, G. Multifunctional polyurethane-based coating with corrosion resistance and anti-icing performance for AA2024-T3 alloy protection. Colloids Surf. A Physicochem. Eng. Asp. 2024, 698, 134581. [Google Scholar] [CrossRef]

- Tian, Y.; Li, H.; Wang, M.; Yang, C.; Yang, Z.; Liu, X. Insights into the stability of fluorinated super-hydrophobic coating in different corrosive solutions. Prog. Org. Coat. 2021, 151, 106043. [Google Scholar] [CrossRef]

- Wang, Z.; Mei, J.; Liu, M.; Zhang, C. Preparation of mechanically robust, self-healing superhydrophobic coatings based on novel fluorinated polyurethane via a “two-step” polycondensation process for applications in self-cleaning and anti-icing. Prog. Org. Coat. 2025, 207, 109385. [Google Scholar] [CrossRef]

- White, C.; White, K.M.; Pickett, J.E. (Eds.) Service Life Prediction of Polymers and Plastics Exposed to Outdoor Weathering; A Volume in Plastics Design Library; William Andrew Publishing: Norwish, NY, USA, 2018; pp. 1–342. [Google Scholar]

- Salnikov, V.G. Seasonal moisture absorption of aeronautical carbon fiber reinforced plastic in conditions of warm humid climate. Monit. Syst. Environ. 2021, 2, 46–53. (In Russian) [Google Scholar] [CrossRef]

- Nikolaev, E.V.; Barbotko, S.L.; Andreeva, N.P.; Pavlov, M.R. Comprehensive study of the impact of climatic and operational factors on a new generation of epoxy binder and polymer composite materials based on it. Part 1. Investigation of the effect of sorbed moisture on the epoxy matrix and carbon fiber based on it. Tr. VIAM 2016, 6, 86–99. (In Russian) [Google Scholar] [CrossRef]

- ASTM D4065-2020; Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures. ASTM International: West Conshohocken, PA, USA, 2020.

- GOST R 52490-2005 (ISO 7724-3:1984); Paint Materials. Colorimetry. Part 3. Calculation of Colour Differences. Standardinform: Moscow, Russia, 2006. (In Russian)

- Andreeva, N.P.; Skirta, A.A.; Nikolaev, E.V. Study of the preservation of the properties of paint and varnish coatings for aviation purposes under the influence of climatic factors in atmospheric conditions. In Multifunctional Paint and Varnish Coatings. Materials of the All-Russian Scientific and Technical Conference, Moscow, Russia; FGUP «VIAM»: Moscow, Russia, 2018; pp. 29–38. (In Russian) [Google Scholar]

- Kablov, E.N.; Startsev, V.O.; Inozemtsev, A.A. Moisture saturation of structural-like elements made of polymer composite materials in open climatic conditions with the imposition of thermal cycles. Aviat. Mater. Technol. 2017, 2, 56–68. (In Russian) [Google Scholar] [CrossRef]

- ISO 6721:2019; Plastics—Determination of Dynamic Mechanical Properties. Part 1: General Principles. International Organization for Standardization (ISO): Geneva, Switzerland, 2019.

- Melnikov, D.A.; Gromova, A.A.; Gorodilova, N.A.; Zagora, A.G. Determination of heat resistance of epoxy matrixes by DMA method. Tr. VIAM 2023, 7, 114–121. (In Russian) [Google Scholar]

- Bensley, K.A.; Chimenti, R.V.; Lofland, S.E. Low-Frequency Raman Spectroscopy of Polymers. Macromol. Chem. Phys. 2025, 226, 70004. [Google Scholar] [CrossRef]

- ISO 2813:14; Paints and varnishes—Determination of Gloss Value at 20°, 60° and 85°. International Organization for Standardization (ISO): Geneva, Switzerland, 2014.

- Startsev, V.O. Climate aging of paint coating systems. Part 2. Influence of different climatic zones. Tr. VIAM 2025, 6, 7. (In Russian) [Google Scholar]

- Startsev, O.V.; Koval, T.V.; Krotov, A.S.; Dvirnaya, E.V.; Velegodsky, I.M. Investigation of the properties of carbon fiber reinforced plastic with coatings after 8 and 13 years of exposure in a moderately warm climate. Part 2. The condition of protective paint coatings. Proc. VIAM 2024, 11, 9. (In Russian) [Google Scholar]

- Kohutiar, M.; Studeny, Z.; Krbaťa, M.; Jus, M.; Mikuš, P.; Kovaříková, I. Frequency Dependence of Glass Transition Temperature of Thermoplastics in DMA Analysis. Manuf. Technol. 2025, 25, 340–347. [Google Scholar] [CrossRef]

- Paramita, V.D.; Panyoyai, N.; Kasapis, S. The Mechanical Glass Transition Temperature Affords a Fundamental Quality Control in Condensed Gels for Innovative Application in Functional Foods and Nutraceuticals. Foods 2025, 14, 2098. [Google Scholar] [CrossRef] [PubMed]

- Krauklis, E. Predicting Environmental Ageing of Composites: Modular Approach and Multiscale Modelling. Mater. Proc. 2021, 6, 11. [Google Scholar] [CrossRef]

- Nanoth, R.; Jayanarayanan, K.; Kumar, P.S.; Balachandran, M.; Pegoretti, A. Static and dynamic mechanical properties of hybrid polymer composites: A comprehensive review of experimental, micromechanical and simulation approaches. Review. Compos. Part A Appl. Sci. Manuf. 2023, 174, 107741. [Google Scholar] [CrossRef]

- Arora, N.; Dua, S.; Singh, V.K.; Singh, S.K.; Senthilkumar, T. A comprehensive review on fillers and mechanical properties of 3D printed polymer composites. Mater. Today 2024, 40, 109617. [Google Scholar] [CrossRef]

| Place of Exposure | Climate Type | Average Annual Temperature, °C | Average Relative Humidity, % | Dose of Total Solar Radiation, GJ/m2 |

|---|---|---|---|---|

| Yakutsk | Very cold climate | −7.5 | 68 | 3.52 |

| Dalnie Zelentsy | Seaside temperate climate | 1.9 | 80 | 2.52 |

| Vladivostok | Seaside moderately humid climate | 5.2 | 64 | 3.25 |

| Zvenigorod | Rural temperate climate | 5.6 | 78 | 4.34 |

| Moscow | Industrial temperate climate | 7.9 | 72 | 4.34 |

| Sochi | Seaside temperate climate | 14.9 | 77 | 5.11 |

| Gelendzhik | Seaside moderately warm climate with mild winters | 15.5 | 70 | 4.87 |

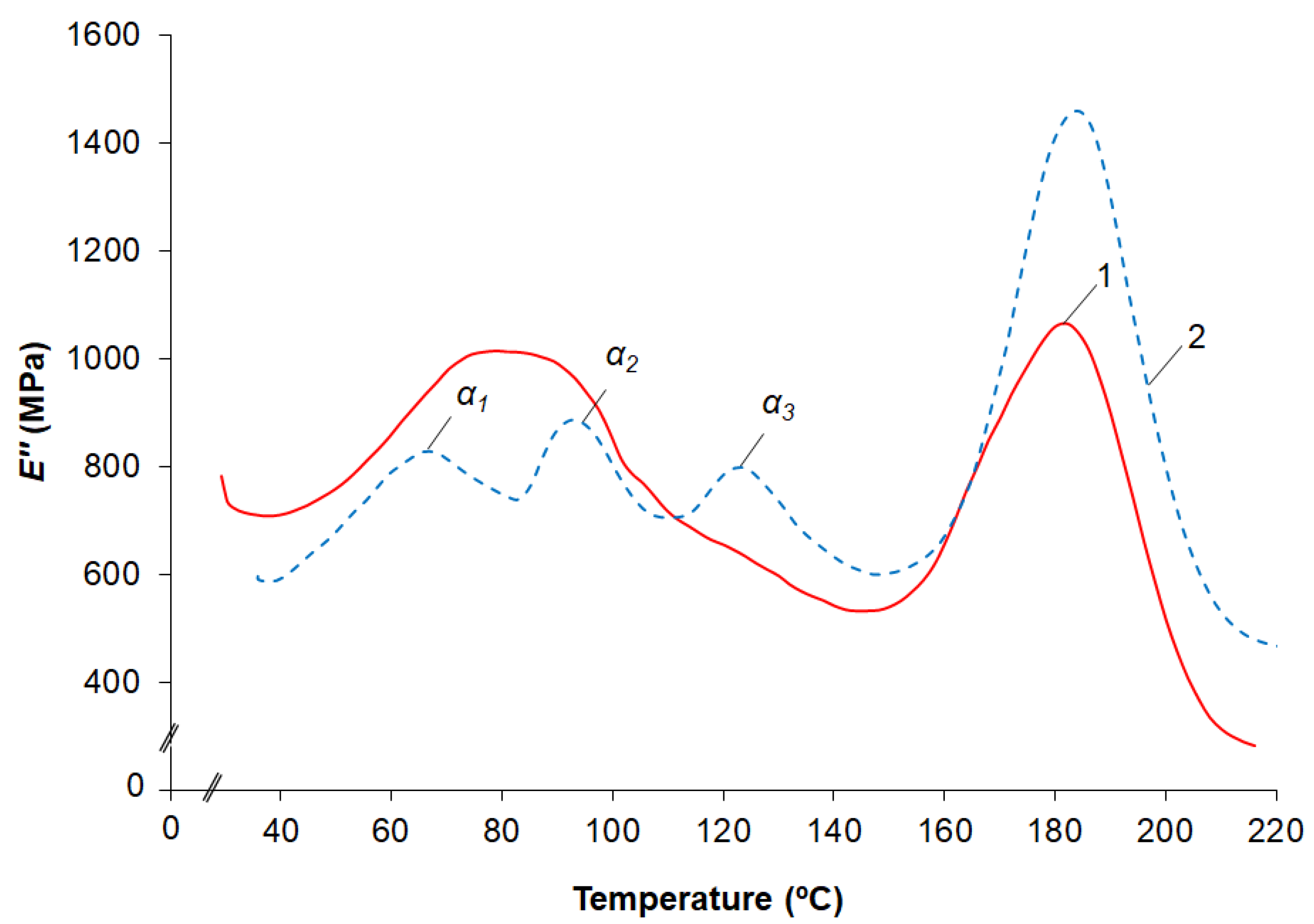

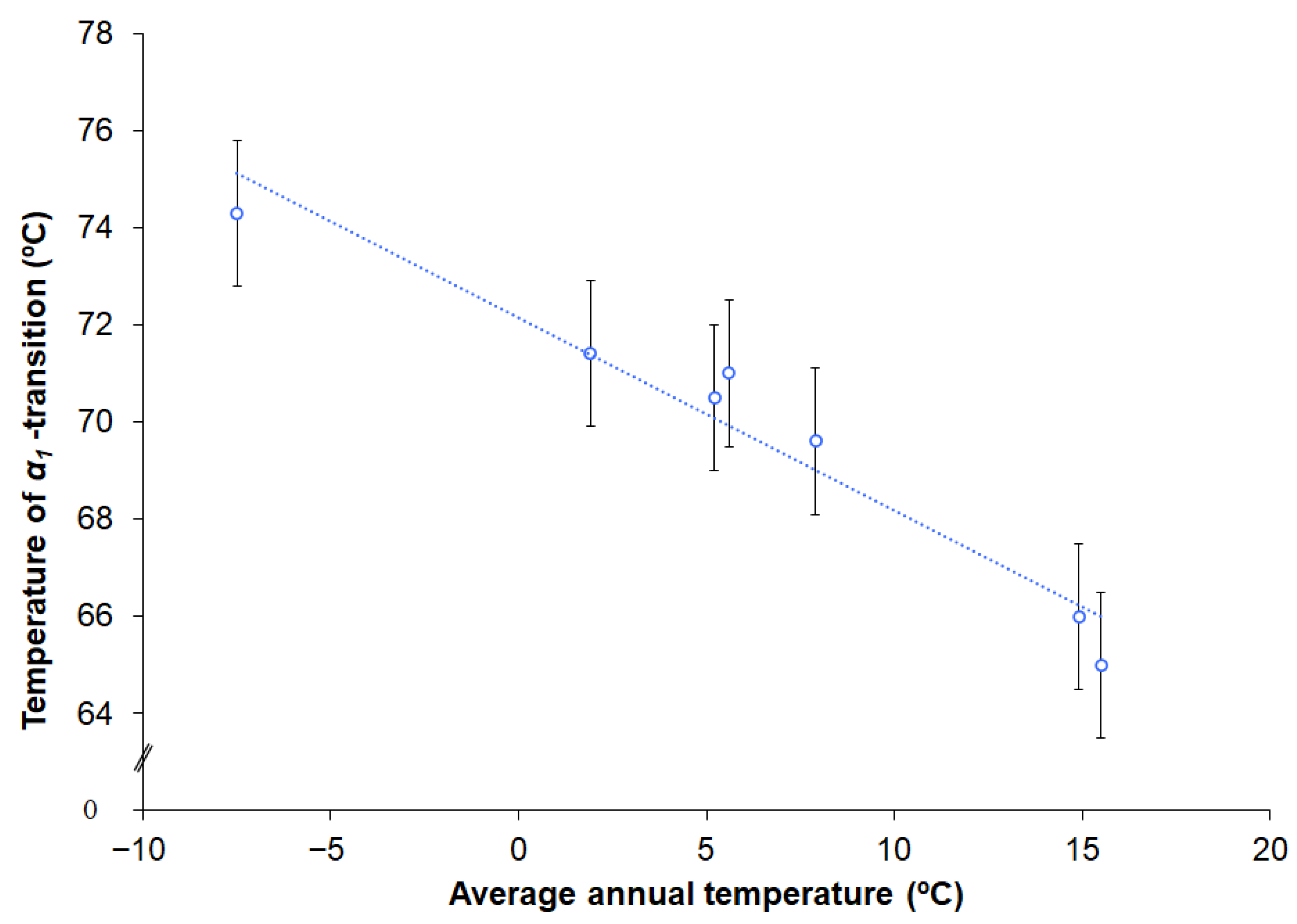

| Place of Exposure | Average Annual Temperature, °C | Dose of Total Solar Radiation, GJ/m2 | Temperature of Transitions for Coating After Drying Samples, °C * | ||

|---|---|---|---|---|---|

| α1 | α2 | α3 | |||

| Initial state | − | 0 | 76.0 | 85.0 | 110.0 |

| Yakutsk | −7.5 | 3.52 | 74.3 | 99.7 | 122.9 |

| Dalnie Zelentsy | 1.9 | 2.52 | 71.4 | 98.5 | 122.3 |

| Vladivostok | 5.2 | 3.25 | 70.5 | 98.8 | 123.3 |

| Zvenigorod | 5.6 | 4.34 | 71.0 | 98.2 | 122.1 |

| Moscow | 7.9 | 4.34 | 69.6 | 98.7 | 123.3 |

| Sochi | 14.9 | 5.11 | 66.0 | 100.7 | 122.8 |

| Gelendzhik | 15.5 | 4.87 | 65.0 | 101.1 | 123.3 |

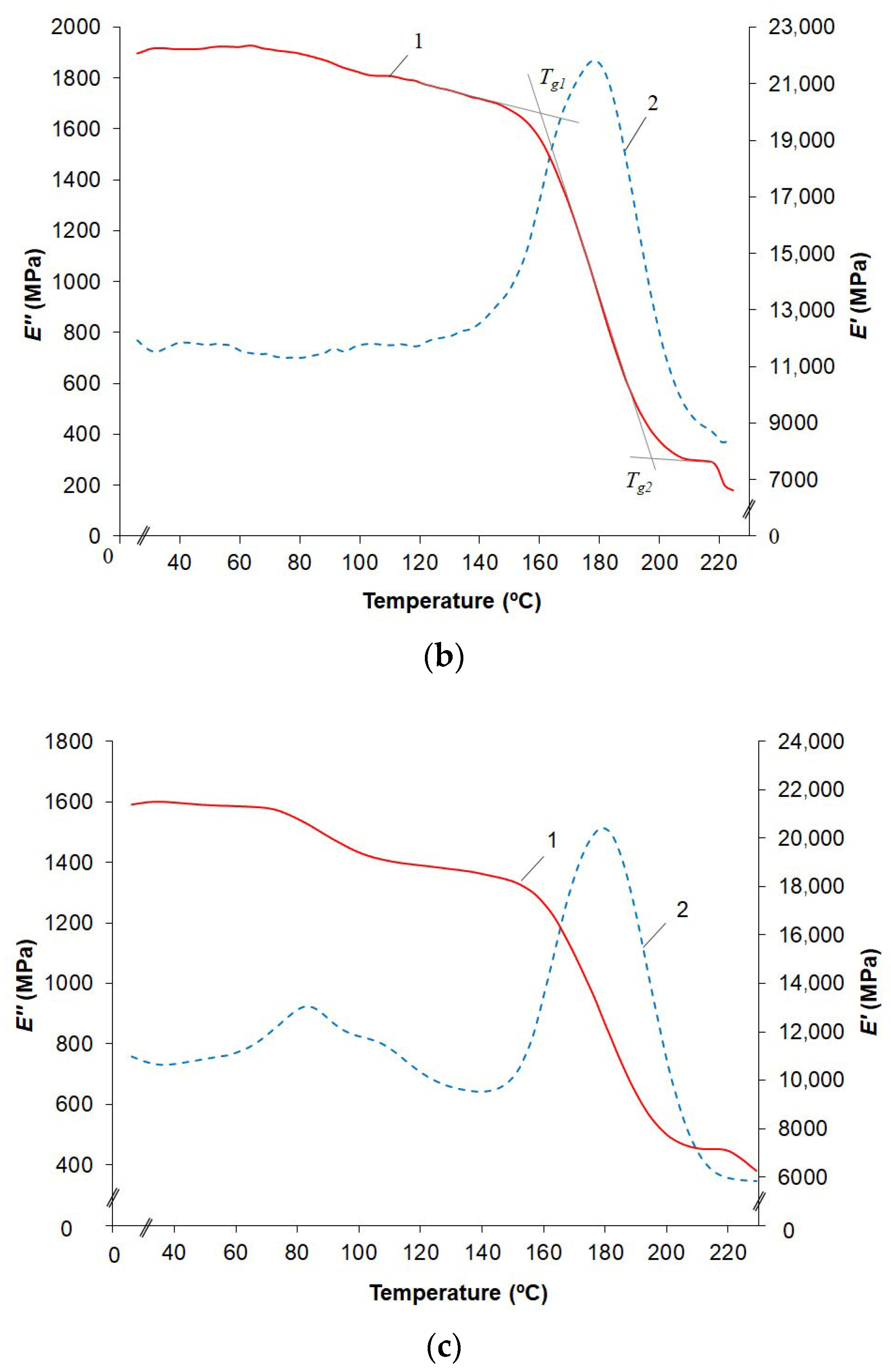

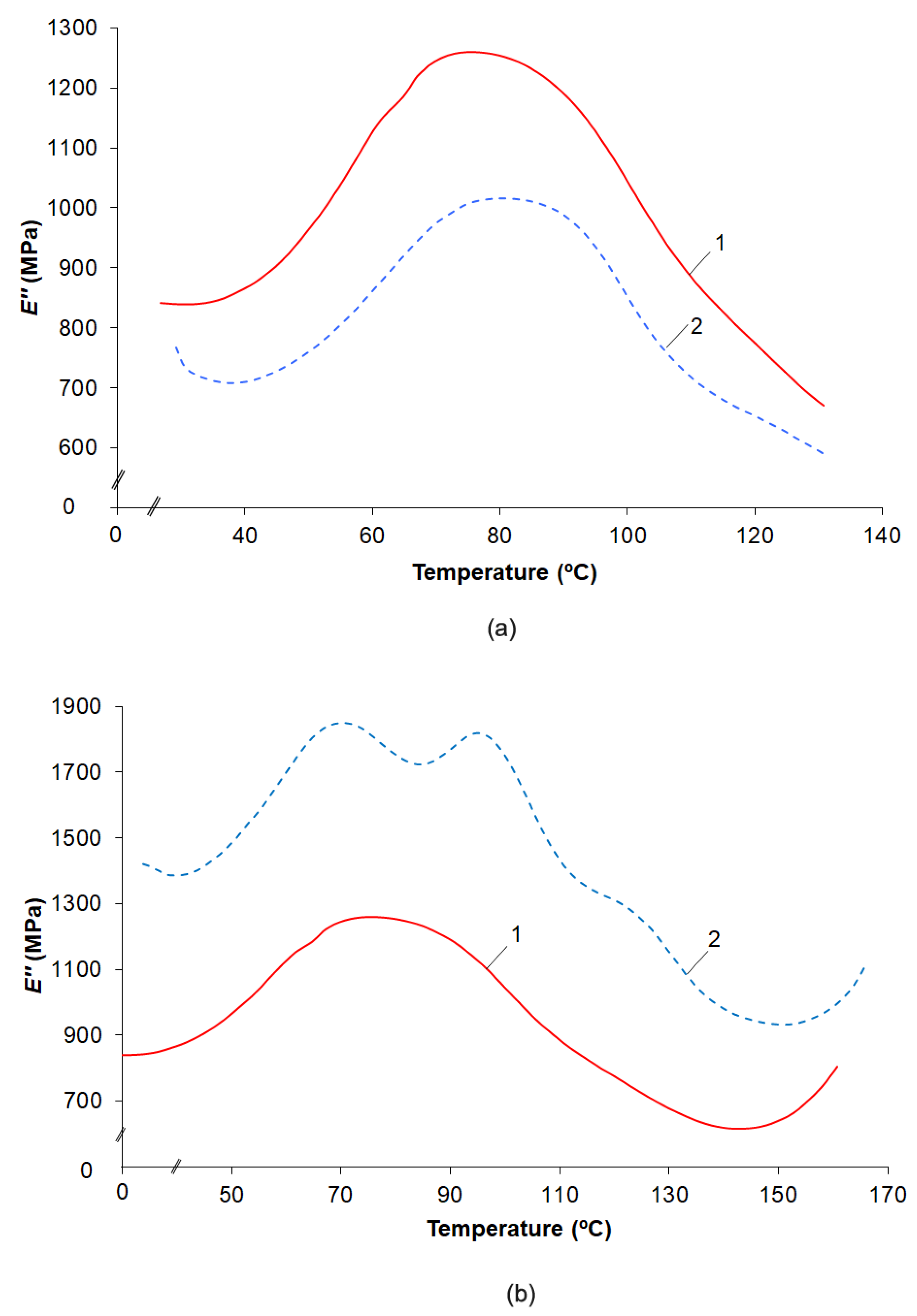

| Place of Exposure | Glass Transition Temperatures of the Polymer Matrix of VSE-1212, °C * | |||

|---|---|---|---|---|

| Without the VE-69 Coating and the EP-0215 Primer | With the VE-69 Coating and the EP-0215 Primer | |||

| Without Pre-Conditioning | After Drying at 60 °C | Without Pre-Conditioning | After Drying at 60 °C | |

| Initial state | 178 | 178 | 178 | 178 |

| Yakutsk | 152 | 182 | 170 | 189 |

| Dalnie Zelentsy | 151 | 184 | 167 | 188 |

| Vladivostok | 148 | 185 | 166 | 190 |

| Zvenigorod | 151 | 186 | 168 | 191 |

| Moscow | 152 | 180 | 169 | 191 |

| Sochi | 150 | 190 | 176 | 194 |

| Gelendzhik | 152 | 182 | 174 | 194 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Startsev, O.V.; Mastalygina, E.E.; Vetcher, A.A.; Koval, T.V.; Veligodsky, I.M.; Dvirnaya, E.V.; Iordanskii, A.L. Long-Term Environmental Aging of Polymer Composite Coatings: Characterization and Evaluation by Dynamic Mechanical Analysis. J. Compos. Sci. 2025, 9, 645. https://doi.org/10.3390/jcs9120645

Startsev OV, Mastalygina EE, Vetcher AA, Koval TV, Veligodsky IM, Dvirnaya EV, Iordanskii AL. Long-Term Environmental Aging of Polymer Composite Coatings: Characterization and Evaluation by Dynamic Mechanical Analysis. Journal of Composites Science. 2025; 9(12):645. https://doi.org/10.3390/jcs9120645

Chicago/Turabian StyleStartsev, Oleg V., Elena E. Mastalygina, Alexandre A. Vetcher, Tatyana V. Koval, Iliya M. Veligodsky, Elena V. Dvirnaya, and Alexey L. Iordanskii. 2025. "Long-Term Environmental Aging of Polymer Composite Coatings: Characterization and Evaluation by Dynamic Mechanical Analysis" Journal of Composites Science 9, no. 12: 645. https://doi.org/10.3390/jcs9120645

APA StyleStartsev, O. V., Mastalygina, E. E., Vetcher, A. A., Koval, T. V., Veligodsky, I. M., Dvirnaya, E. V., & Iordanskii, A. L. (2025). Long-Term Environmental Aging of Polymer Composite Coatings: Characterization and Evaluation by Dynamic Mechanical Analysis. Journal of Composites Science, 9(12), 645. https://doi.org/10.3390/jcs9120645