Size Effects on Process-Induced Porosity in Ti6Al4V Thin Struts Additively Manufactured by Laser Powder-Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

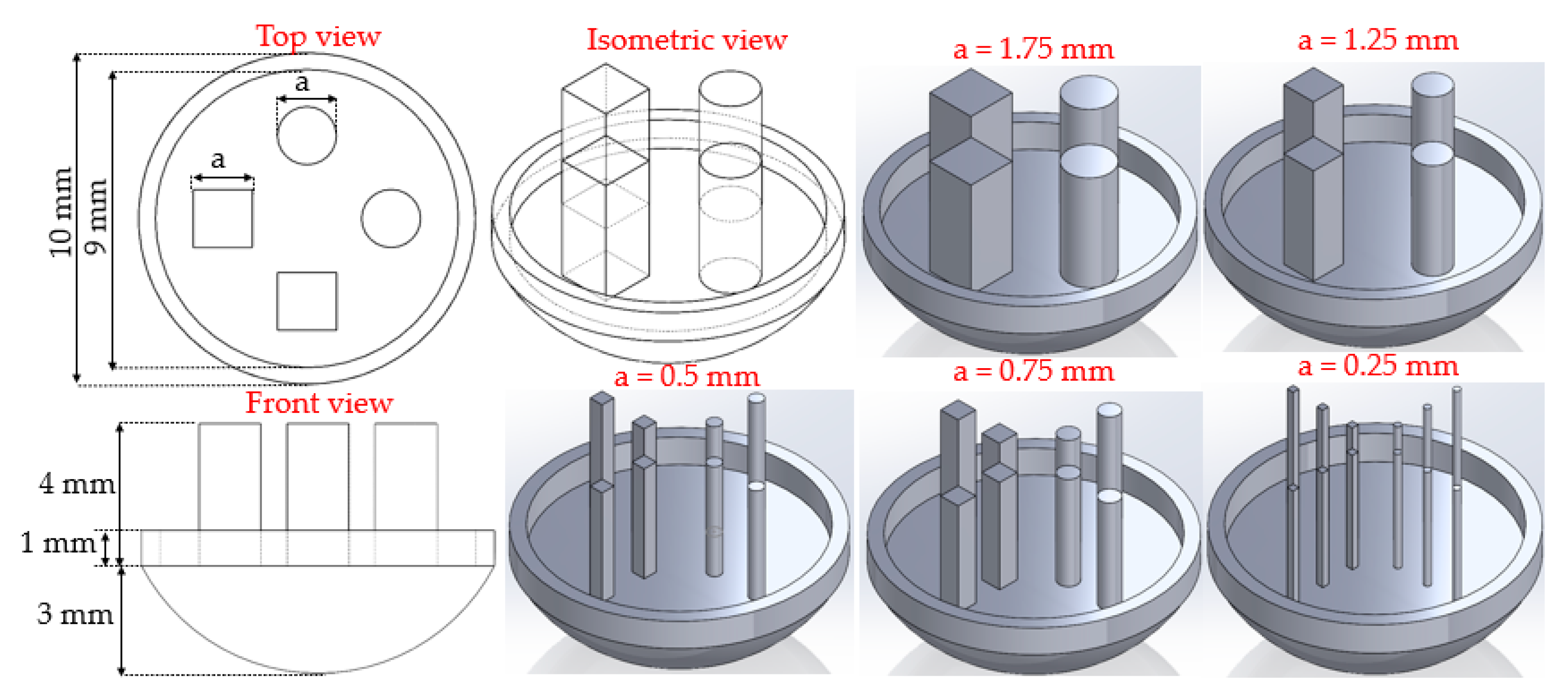

2.1. Specimen Fabrication

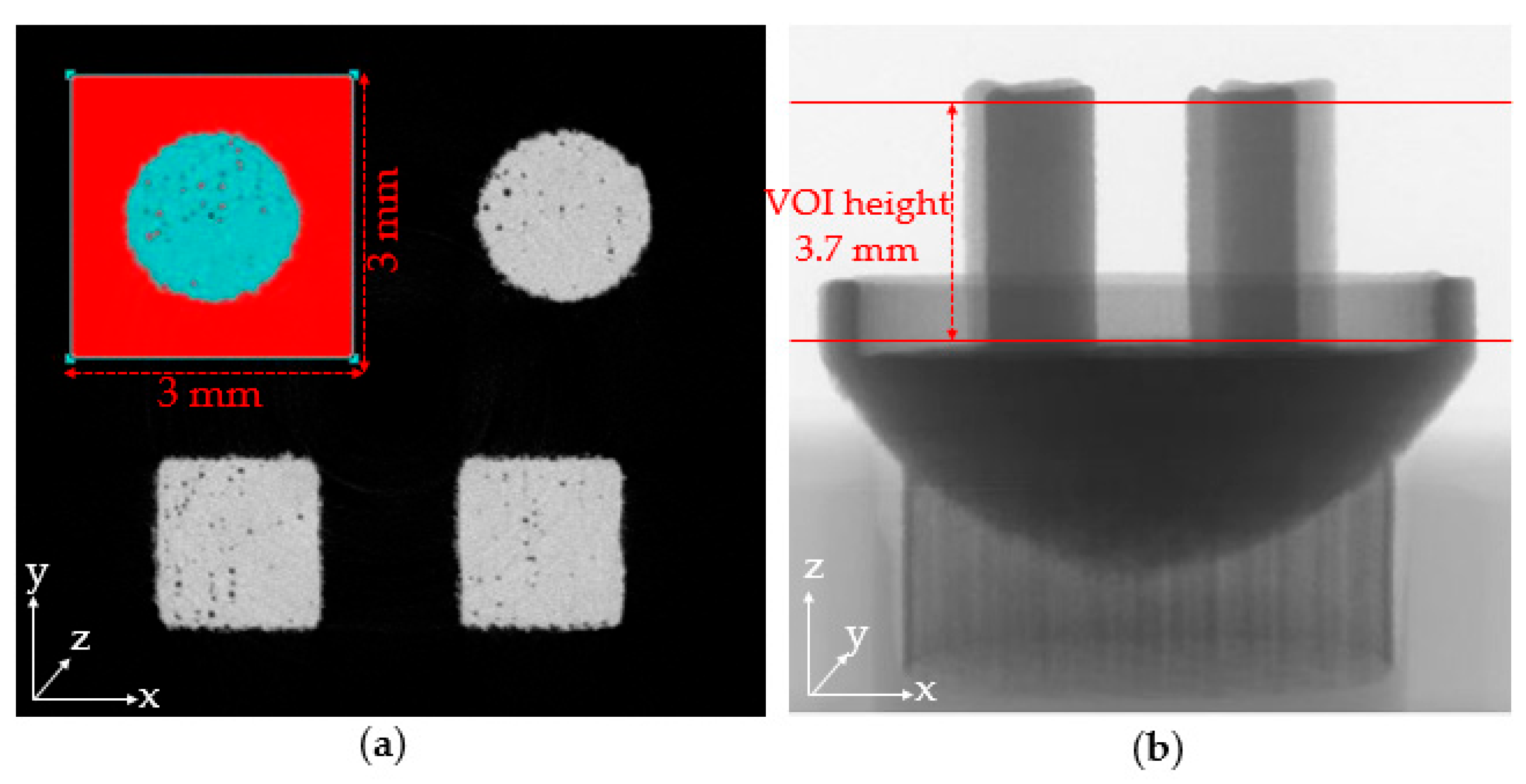

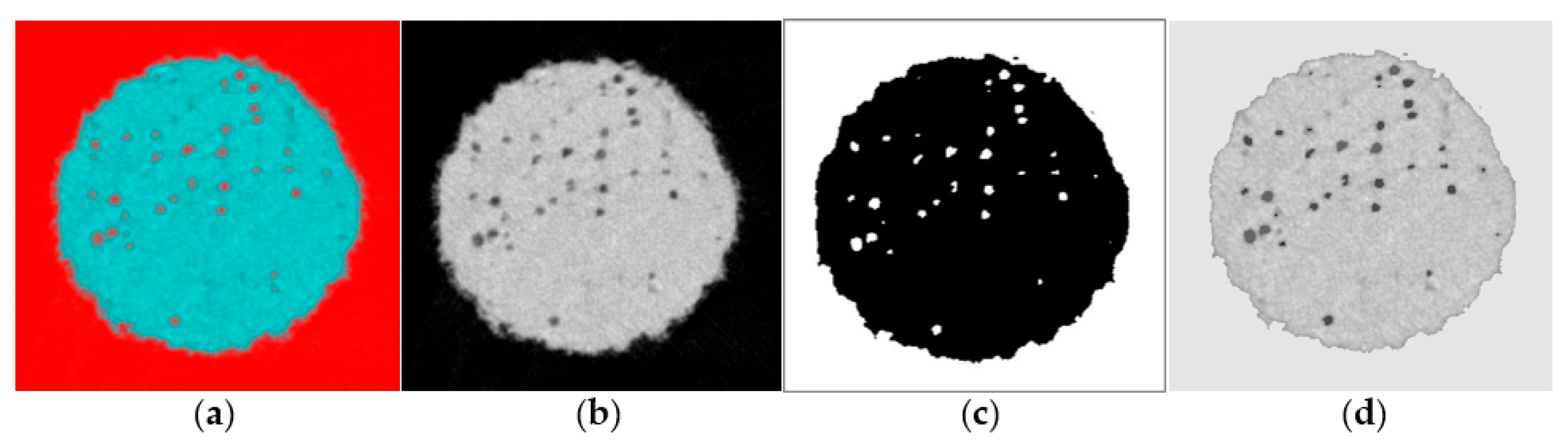

2.2. Porosity Evaluation

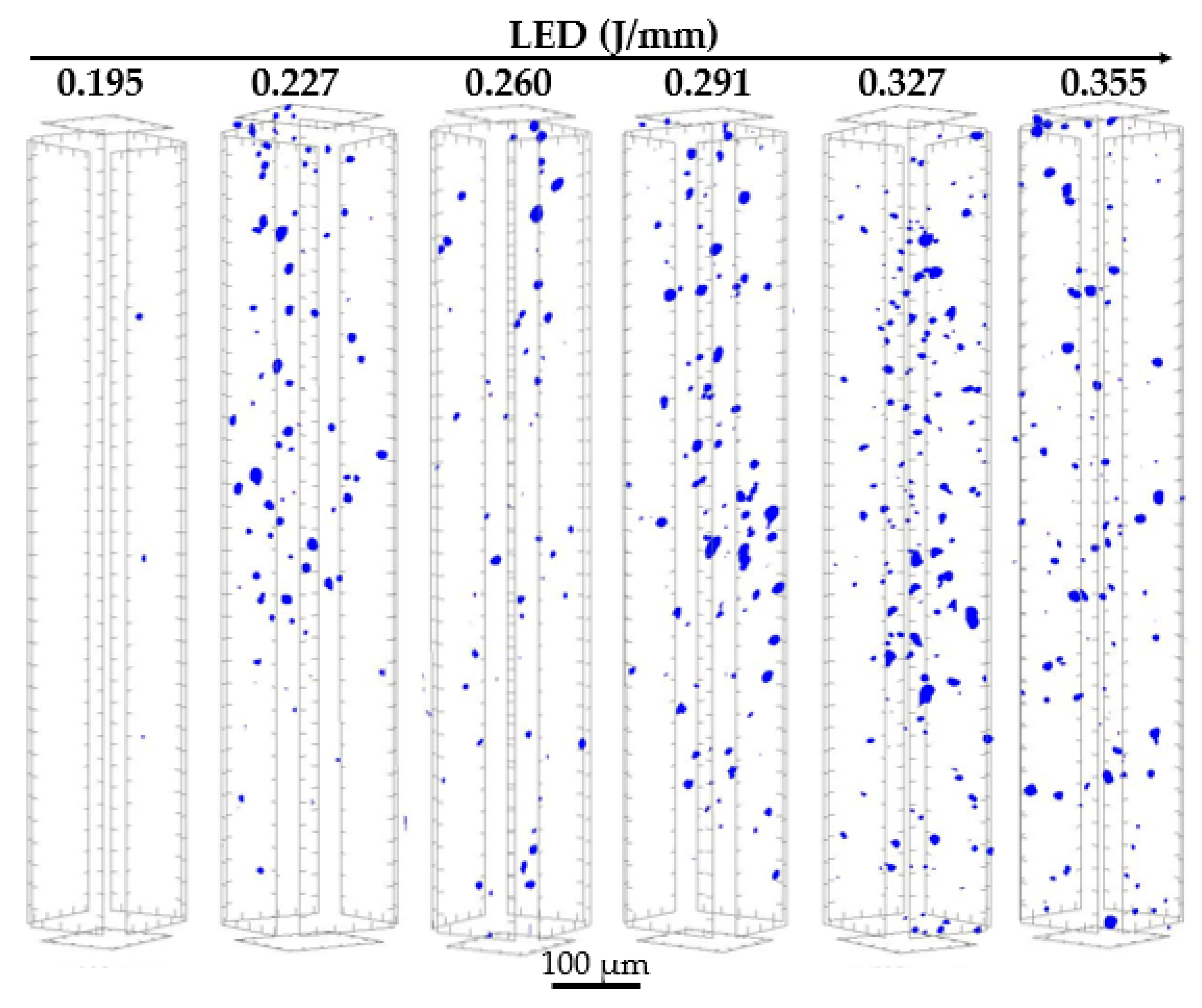

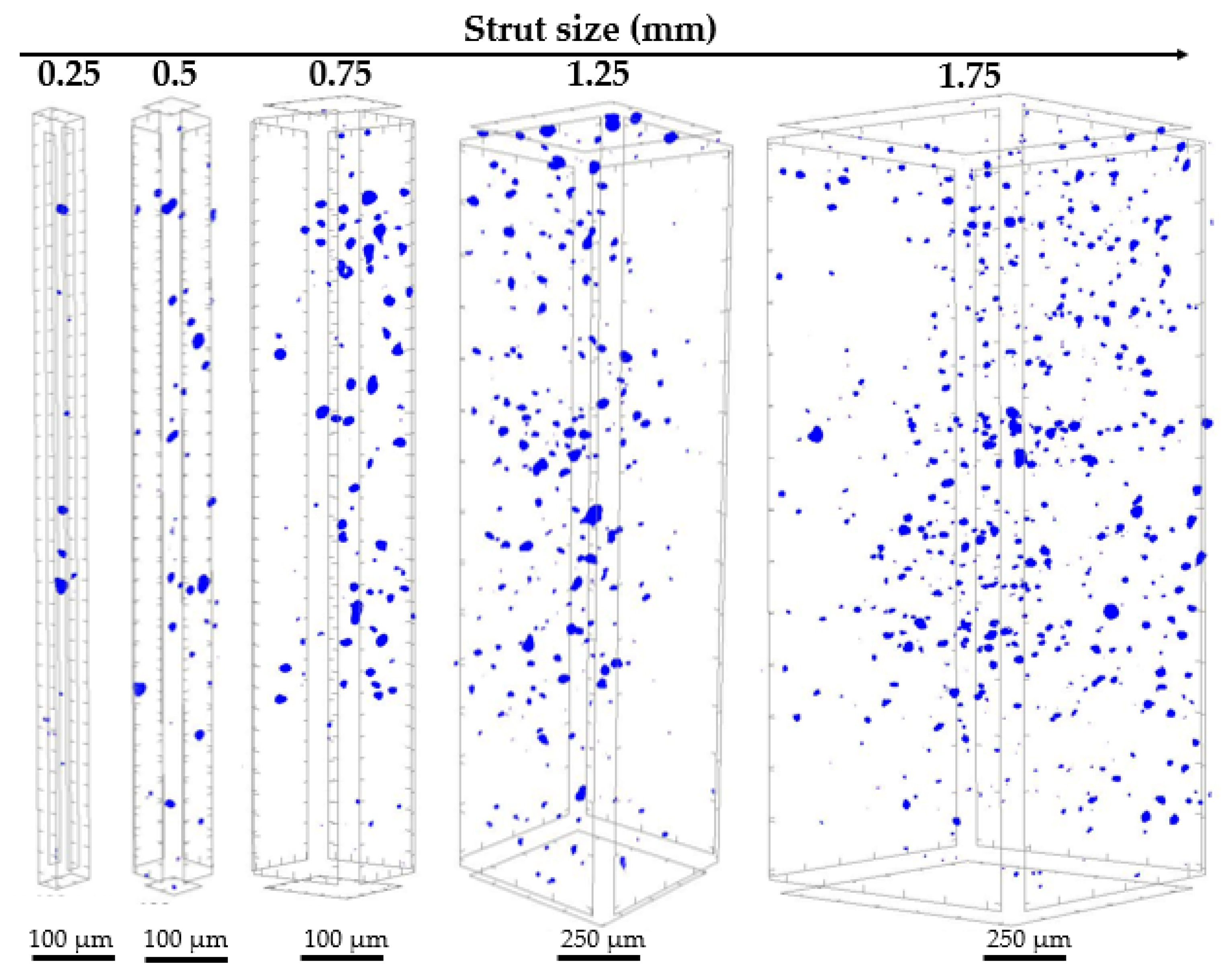

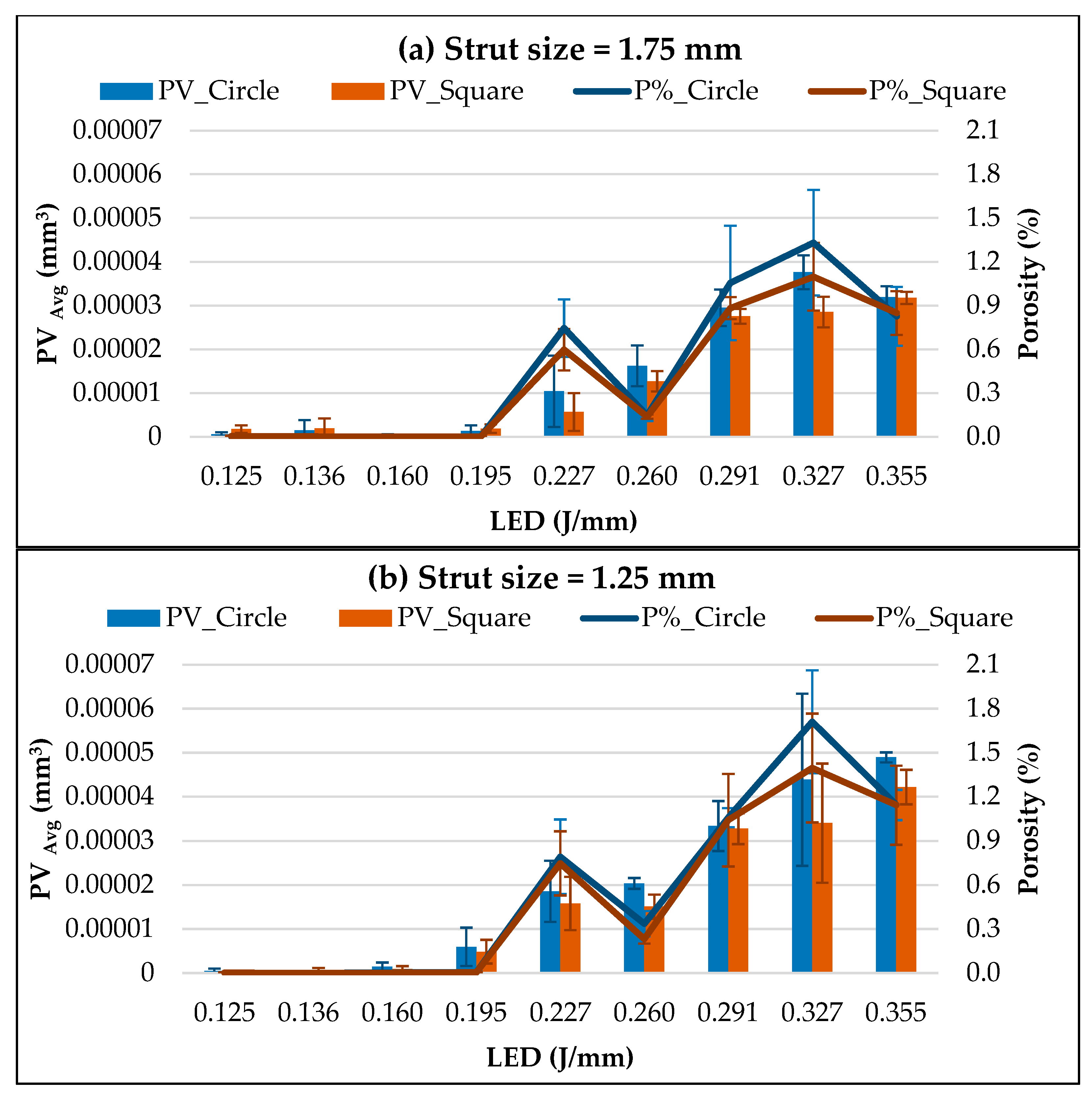

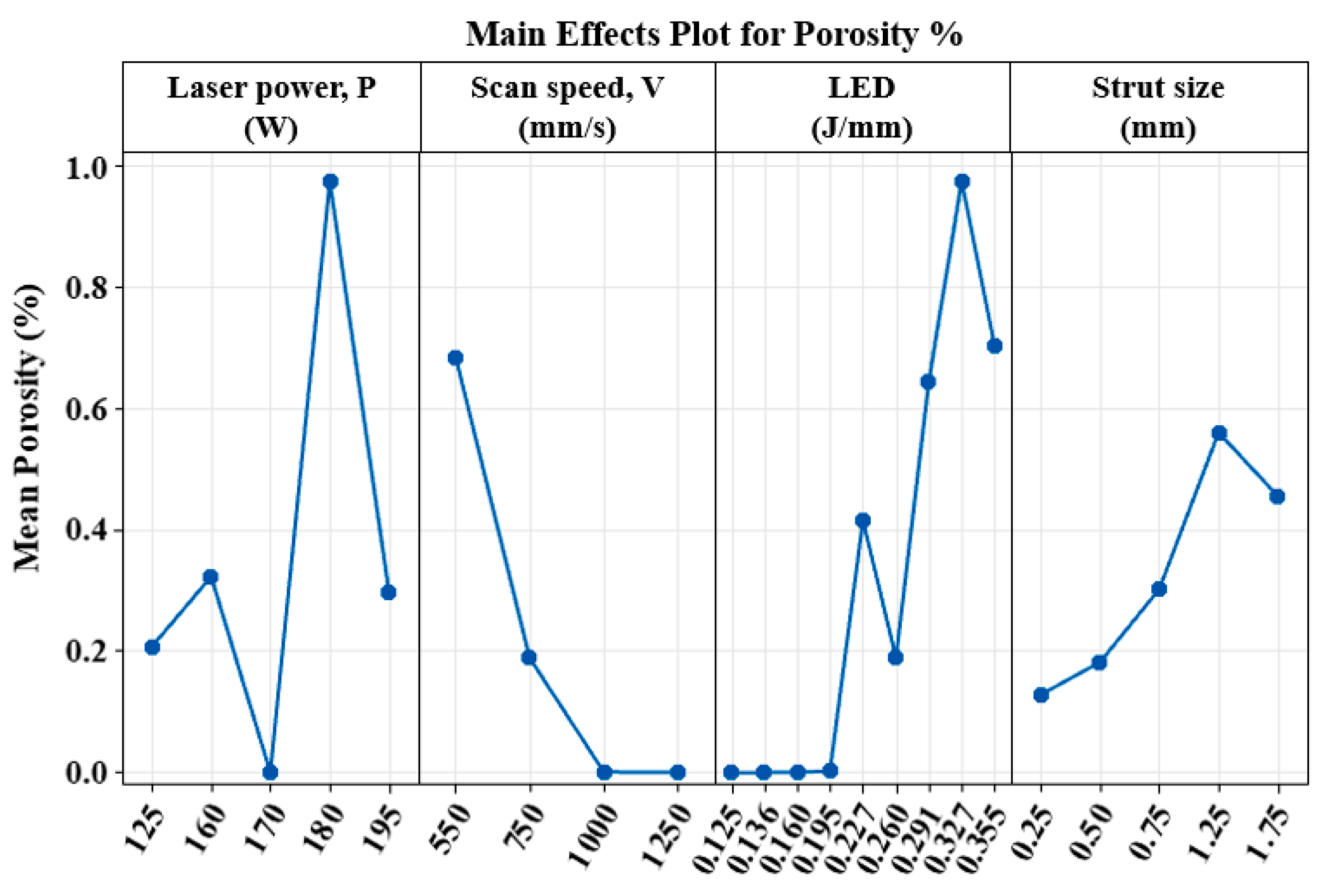

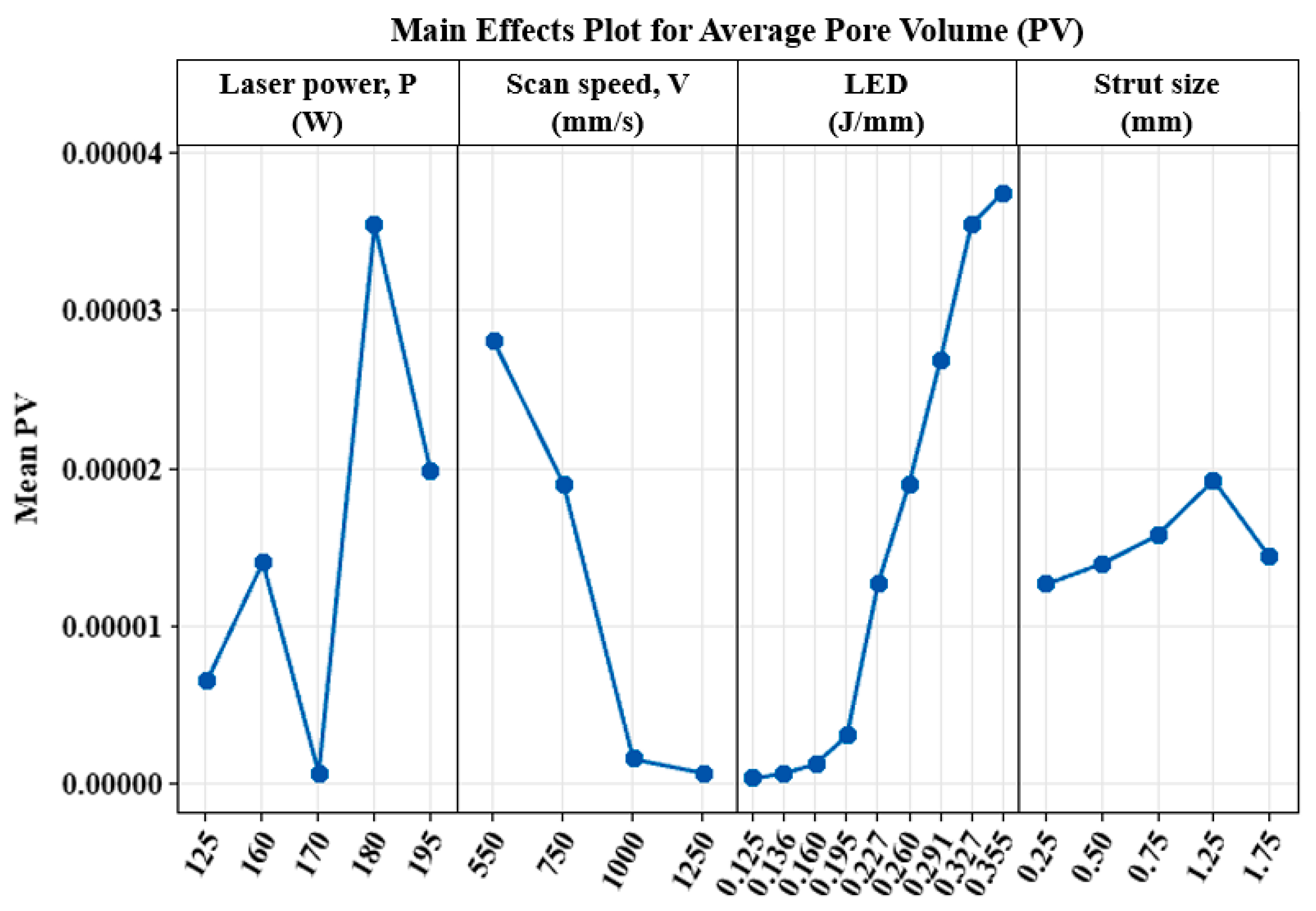

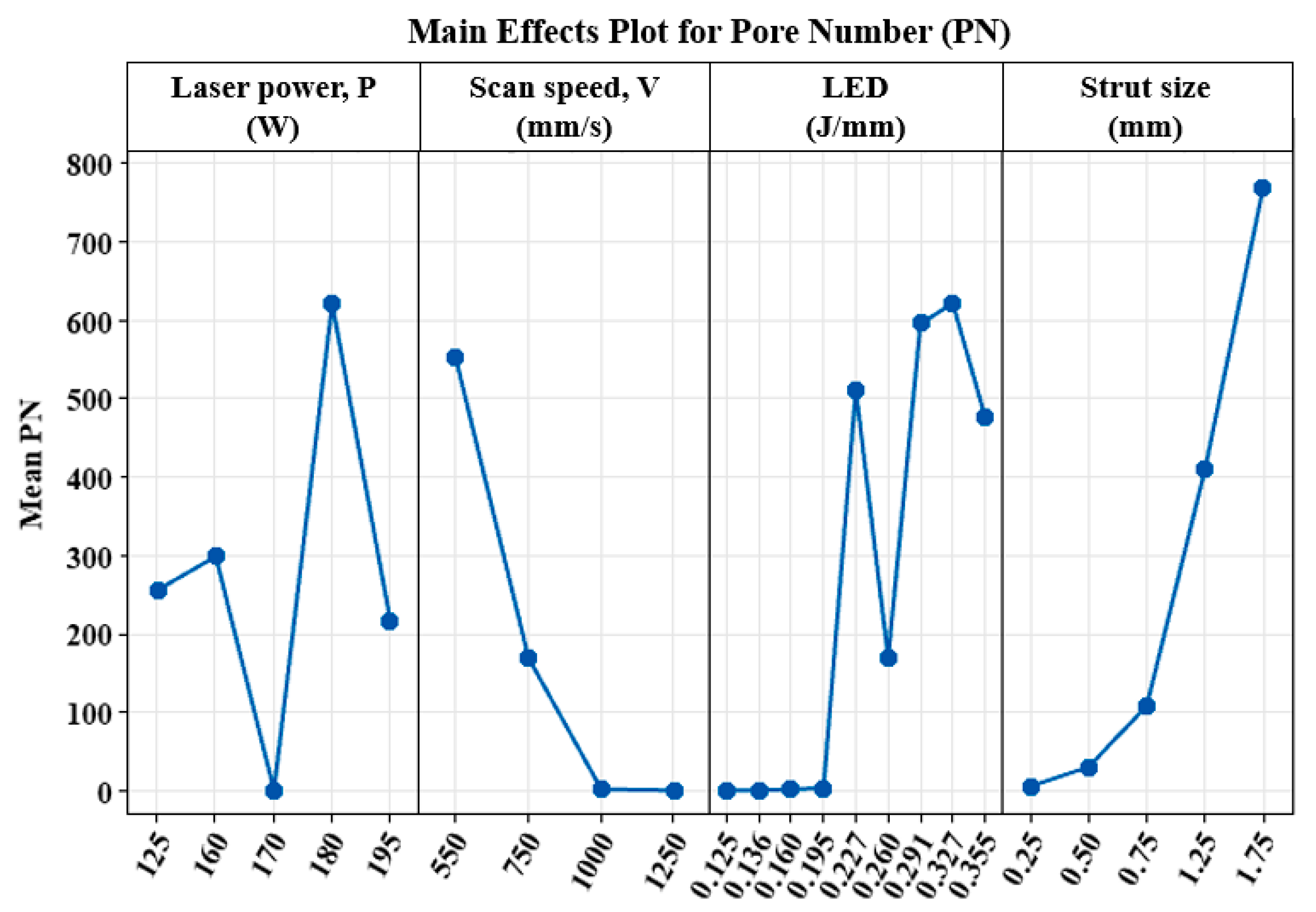

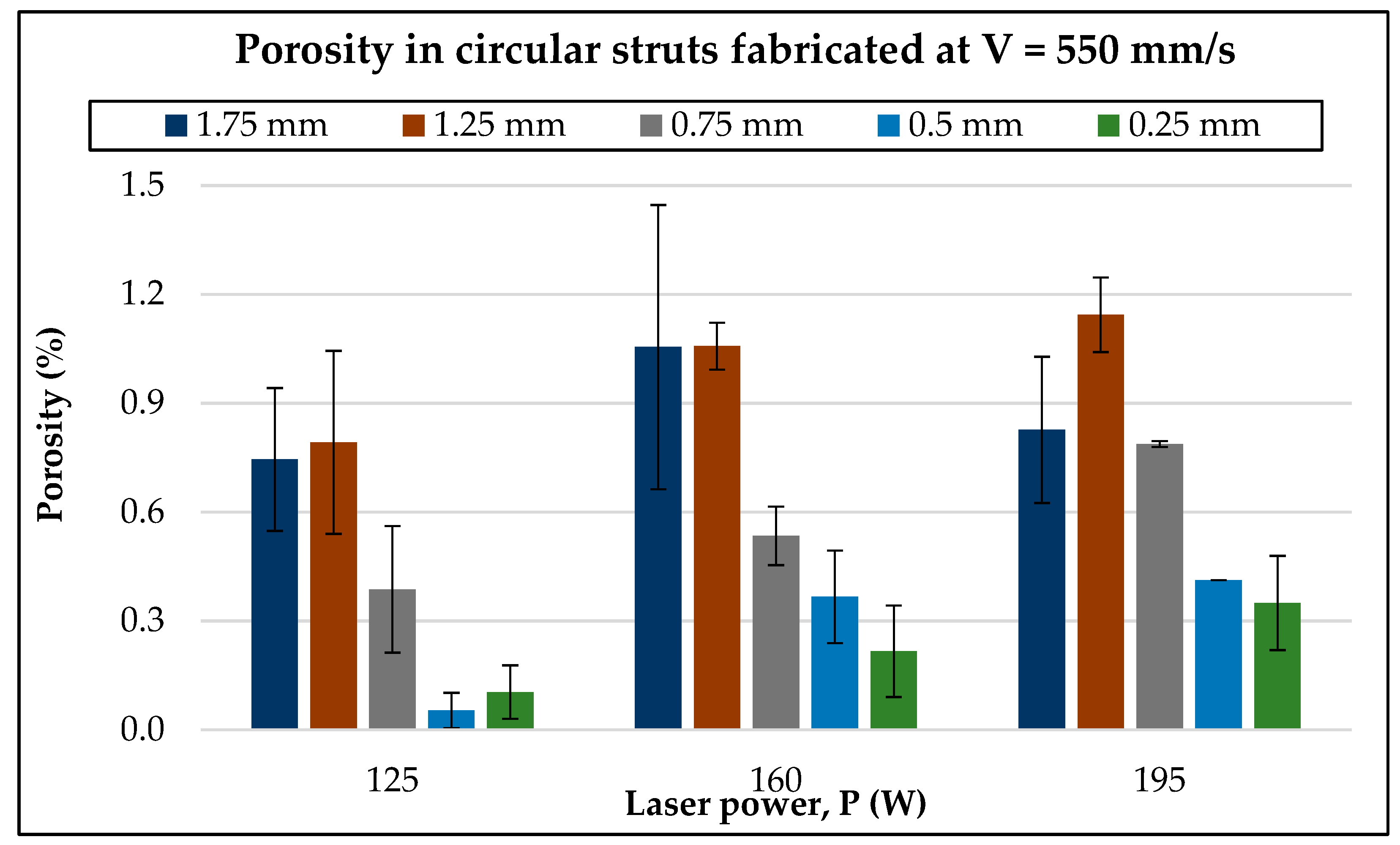

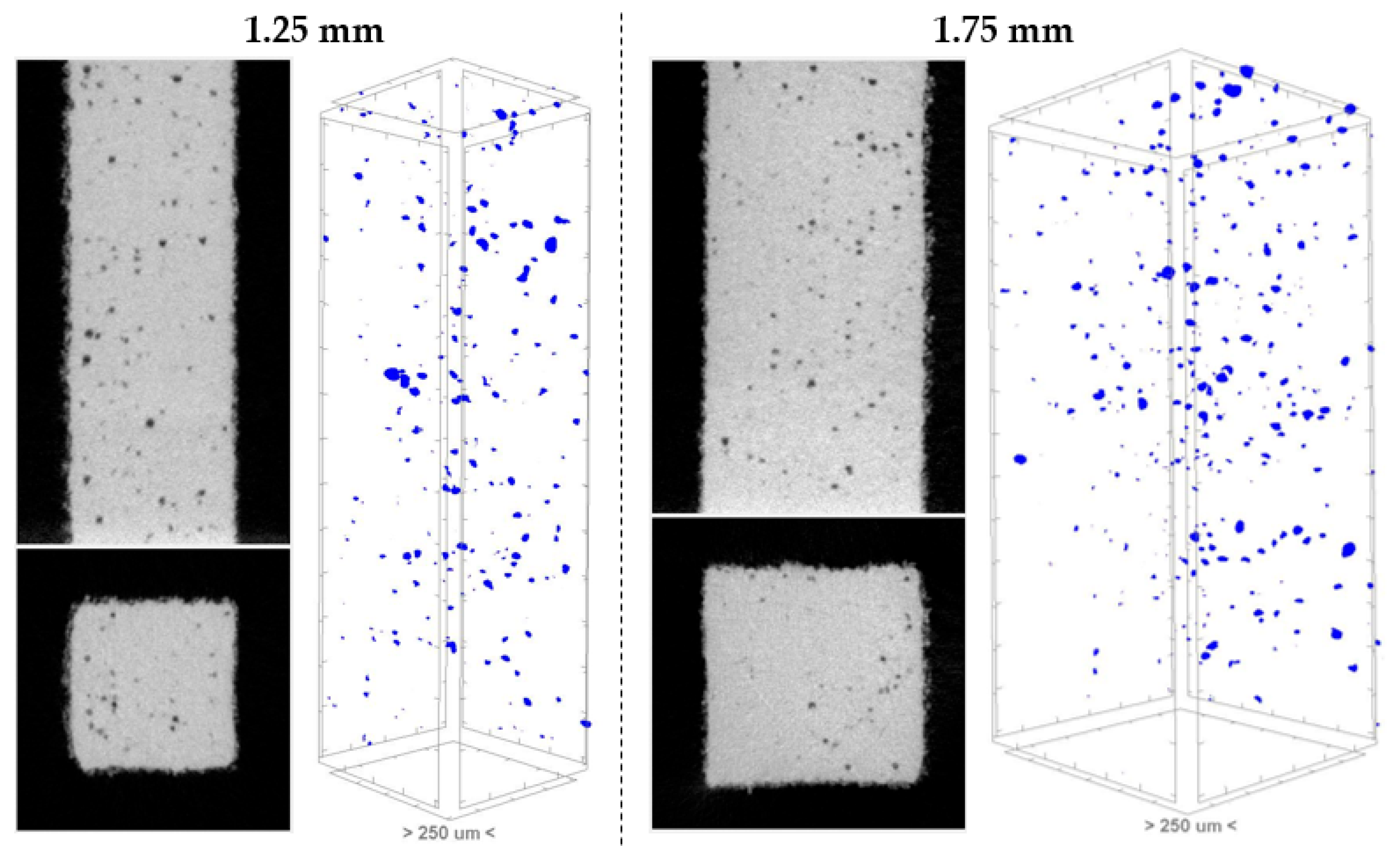

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schaedler, T.A.; Jacobsen, A.J.; Torrents, A.; Sorensen, A.E.; Lian, J.; Greer, J.R.; Valdevit, L.; Carter, W.B. Ultralight Metallic Microlattices. Science 2011, 334, 962–965. [Google Scholar] [CrossRef] [PubMed]

- Ashby, M.F. The properties of foams and lattices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef]

- Vrána, R.; Koutný, D.; Paloušek, D.; Pantělejev, L.; Jaroš, J.; Zikmund, T.; Kaiser, J. Selective Laser Melting Strategy for Fabrication of Thin Struts Usable in Lattice Structures. Materials 2018, 11, 1763. [Google Scholar] [CrossRef] [PubMed]

- Evans, A.G.; Hutchinson, J.W.; Fleck, N.A.; Ashby, M.F.; Wadley, H.N.G. The topological design of multifunctional cellular metals. Prog. Mater. Sci. 2001, 46, 309–327. [Google Scholar] [CrossRef]

- Nakajima, H. Fabrication, properties and application of porous metals with directional pores. Prog. Mater. Sci. 2007, 52, 1091–1173. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Weißmann, V.; Drescher, P.; Bader, R.; Seitz, H.; Hansmann, H.; Laufer, N. Comparison of Single Ti6Al4V Struts Made Using Selective Laser Melting and Electron Beam Melting Subject to Part Orientation. Metals 2017, 7, 91. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.; Maier, H. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. Fatigue performance of selective laser melted Ti6Al4V components: State of the art. Mater. Res. Express 2018, 6, 012002. [Google Scholar] [CrossRef]

- Mullen, L.; Stamp, R.C.; Brooks, W.K.; Jones, E.; Sutcliffe, C.J. Selective Laser Melting: A regular unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2009, 89B, 325–334. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Starr, T.; Stucker, B. Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes. Addit. Manuf. 2014, 1–4, 87–98. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Corfield, M.R.; Tuck, C.; Clare, A.T.; Leach, R.K.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J. Quantification and characterisation of porosity in selectively laser melted Al–Si10–Mg using X-ray computed tomography. Mater. Charact. 2016, 111, 193–204. [Google Scholar] [CrossRef]

- Spierings, A.B.; Schneider, M.; Eggenberger, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Siddique, S.; Imran, M.; Rauer, M.; Kaloudis, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Computed tomography for characterization of fatigue performance of selective laser melted parts. Mater. Des. 2015, 83, 661–669. [Google Scholar] [CrossRef]

- Wits, W.W.; Carmignato, S.; Zanini, F.; Vaneker, T.H.J. Porosity testing methods for the quality assessment of selective laser melted parts. CIRP Ann. 2016, 65, 201–204. [Google Scholar] [CrossRef]

- Maire, E.; Withers, P.J. Quantitative X-ray tomography. Int. Mater. Rev. 2013, 59, 1–43. [Google Scholar] [CrossRef]

- Rauniyar, S.; Chou, K. Transient Melt Pool Formation in Laser-Powder Bed Fusion Process. In Proceedings of the International Manufacturing Science and Engineering Conference, Virtual, 3 September 2020. [Google Scholar]

- Rauniyar, S.; Shrestha, S.; Chou, K. An Investigation Into Multi-Track Deposition in Laser Powder-Bed Fusion: Transient Regions Analysis and Scan Length Effects. In Proceedings of the ASME 2022 17th International Manufacturing Science and Engineering Conference, West Lafayette, IN, USA, 27 June–1 July 2022. [Google Scholar]

- Vilardell, A.; Takezawa, A.; du Plessis, A.; Takata, N.; Krakhmalev, P.; Kobashi, M.; Yadroitsava, I.; Yadroitsev, I. Topology optimization and characterization of Ti6Al4V ELI cellular lattice structures by laser powder bed fusion for biomedical applications. Mater. Sci. Eng. A 2019, 766, 138330. [Google Scholar] [CrossRef]

- Koju, N.; Hermes, J.; Saghaian, S.E.; Yang, L. Laser powder bed fusion additively manufactured thin lightweight Ti6Al4V features: An experimental investigation on the influence of powder feedstock, geometry, and process parameters on property/quality. Int. J. Adv. Manuf. Technol. 2024, 130, 1541–1561. [Google Scholar] [CrossRef]

- Pehlivan, E.; Roudnicka, M.; Dzugan, J.; Koukolikova, M.; Králík, V.; Seifi, M.; Lewandowski, J.J.; Dalibor, D.; Daniel, M. Effects of build orientation and sample geometry on the mechanical response of miniature CP-Ti Grade 2 strut samples manufactured by laser powder bed fusion. Addit. Manuf. 2020, 35, 101403. [Google Scholar] [CrossRef]

- Qiu, C.; Yue, S.; Adkins, N.J.; Ward, M.; Hassanin, H.; Lee, P.D.; Withers, P.J.; Attallah, M.M. Influence of processing conditions on strut structure and compressive properties of cellular lattice structures fabricated by selective laser melting. Mater. Sci. Eng. A 2015, 628, 188–197. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mech. Work. Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Miranda, G.; Faria, S.; Bartolomeu, F.; Pinto, E.; Alves, N.; Peixinho, N.; Gasik, M.; Silva, F. A study on the production of thin-walled Ti6Al4V parts by selective laser melting. J. Manuf. Process. 2019, 39, 346–355. [Google Scholar] [CrossRef]

- Van Bael, S.; Kerckhofs, G.; Moesen, M.; Pyka, G.; Schrooten, J.; Kruth, J.P. Micro-CT-based improvement of geometrical and mechanical controllability of selective laser melted Ti6Al4V porous structures. Mater. Sci. Eng. A 2011, 528, 7423–7431. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Young, P.; Raymont, D. Advanced lightweight 316L stainless steel cellular lattice structures fabricated via selective laser melting. Mater. Des. 2014, 55, 533–541. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Noronha, J.; Qian, M.; Leary, M.; Kyriakou, E.; Almalki, A.; Brudler, S.; Brandt, M. Additive manufacturing of Ti-6Al-4V horizontal hollow struts with submillimetre wall thickness by laser powder bed fusion. Thin-Walled Struct. 2022, 179, 109620. [Google Scholar] [CrossRef]

- Vrána, R.; Jaroš, J.; Koutný, D.; Nosek, J.; Zikmund, T.; Kaiser, J.; Paloušek, D. Contour laser strategy and its benefits for lattice structure manufacturing by selective laser melting technology. J. Manuf. Process. 2022, 74, 640–657. [Google Scholar] [CrossRef]

- Liang, H.; Xie, D.; Mao, Y.; Shi, J.; Wang, C.; Shen, L.; Tian, Z. The Size Effect on Forming Quality of Ti–6Al–4V Solid Struts Fabricated via Laser Powder Bed Fusion. Metals 2019, 9, 416. [Google Scholar] [CrossRef]

- Suard, M.; Barrière, L.; Lhuissier, P.; Perusin, S.; Filloux, B.; Dendievel, R. Influence of manufacturing orientations on the morphology of alloy 718 single struts manufactured by selective laser melting. Mater. Des. Process. Commun. 2021, 3, e140. [Google Scholar] [CrossRef]

- Murchio, S.; Dallago, M.; Zanini, F.; Carmignato, S.; Zappini, G.; Berto, F.; Maniglio, D.; Benedetti, M. Additively manufactured Ti–6Al–4V thin struts via laser powder bed fusion: Effect of building orientation on geometrical accuracy and mechanical properties. J. Mech. Behav. Biomed. Mater. 2021, 119, 104495. [Google Scholar] [CrossRef]

- Hossain, U.; Ghouse, S.; Nai, K.; Jeffers, J.R. Mechanical and morphological properties of additively manufactured SS316L and Ti6Al4V micro-struts as a function of build angle. Addit. Manuf. 2021, 46, 102050. [Google Scholar] [CrossRef]

- Kumar, V.P.; Jebaraj, A.V. Comprehensive review on residual stress control strategies in laser-based powder bed fusion process– Challenges and opportunities. Lasers Manuf. Mater. Process. 2023, 10, 400–442. [Google Scholar] [CrossRef]

- Shrestha, S.; Starr, T.; Chou, K. Porosity Analysis in Metal Additive Manufacturing by Micro-CT. In Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition, Pittsburgh, PA, USA, 9–15 November 2018. [Google Scholar]

- Shrestha, S.; Starr, T.; Chou, K. A Study of Keyhole Porosity in Selective Laser Melting: Single-Track Scanning With Micro-CT Analysis. J. Manuf. Sci. Eng. 2019, 141, 071004. [Google Scholar] [CrossRef]

- Rauniyar, S.K. Experimental and Numerical Studies of Laser Powder-Bed Fusion Process with Ti-6Al-4V Powder: (1) Porosity and Mechanical Properties, and (2) Transient Phenomena in One- and Two-Dimensional Fabrications. Ph.D. Thesis, University of Louisville, Louisville, KY, USA, 2023. [Google Scholar] [CrossRef]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.-P.R.; Schoenung, J.M. On the limitations of Volumetric Energy Density as a design parameter for Selective Laser Melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Benyounis, K.Y.; Olabi, A.G.; Hashmi, M.S.J. Effect of laser welding parameters on the heat input and weld-bead profile. J. Mech. Work. Technol. 2005, 164–165, 978–985. [Google Scholar] [CrossRef]

- Trapp, J.; Rubenchik, A.M.; Guss, G.; Matthews, M.J. In situ absorptivity measurements of metallic powders during laser powder-bed fusion additive manufacturing. Appl. Mater. Today 2017, 9, 341–349. [Google Scholar] [CrossRef]

| Strut Size, a (mm) | Strut Shape |

|---|---|

| 1.75. 1.25, 0.75, 0.5, 0.25 | Circle, Square |

| Element | Ti | Al | V | Fe | O | C |

| wt. % | Balance | 6.09 | 4.13 | 0.25 | 0.13 | 0.08 |

| Parameter No. | Linear Energy Density, LED (J/mm) | Laser Power, P (W) | Scan Speed, V (mm/s) |

|---|---|---|---|

| 1 | 0.125 | 125 | 1000 |

| 2 | 0.136 | 170 | 1250 |

| 3 | 0.160 | 160 | 1000 |

| 4 | 0.195 | 195 | 1000 |

| 5 | 0.227 | 125 | 550 |

| 6 | 0.260 | 195 | 750 |

| 7 | 0.291 | 160 | 550 |

| 8 | 0.327 | 180 | 550 |

| 9 | 0.355 | 195 | 550 |

| Parameter No. | Strut Size | Number of Fabricated Struts | Total Number of Fabricated Struts | |

|---|---|---|---|---|

| Circle | Square | |||

| 1–9 | 1.75 | 6 | 6 | 108 |

| 1–9 | 1.25 | 6 | 6 | 108 |

| 1–9 | 0.75 | 12 | 12 | 216 |

| 1–9 | 0.50 | 12 | 12 | 216 |

| 1–9 | 0.25 | 18 | 18 | 324 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valiyakath Vadakkan Habeeb, N.; Chou, K. Size Effects on Process-Induced Porosity in Ti6Al4V Thin Struts Additively Manufactured by Laser Powder-Bed Fusion. J. Manuf. Mater. Process. 2025, 9, 226. https://doi.org/10.3390/jmmp9070226

Valiyakath Vadakkan Habeeb N, Chou K. Size Effects on Process-Induced Porosity in Ti6Al4V Thin Struts Additively Manufactured by Laser Powder-Bed Fusion. Journal of Manufacturing and Materials Processing. 2025; 9(7):226. https://doi.org/10.3390/jmmp9070226

Chicago/Turabian StyleValiyakath Vadakkan Habeeb, Nismath, and Kevin Chou. 2025. "Size Effects on Process-Induced Porosity in Ti6Al4V Thin Struts Additively Manufactured by Laser Powder-Bed Fusion" Journal of Manufacturing and Materials Processing 9, no. 7: 226. https://doi.org/10.3390/jmmp9070226

APA StyleValiyakath Vadakkan Habeeb, N., & Chou, K. (2025). Size Effects on Process-Induced Porosity in Ti6Al4V Thin Struts Additively Manufactured by Laser Powder-Bed Fusion. Journal of Manufacturing and Materials Processing, 9(7), 226. https://doi.org/10.3390/jmmp9070226