1. Introduction

The root pass consists of the first weld bead deposited in a groove. Deposition of a root pass requires a greater ability of the welder, since it must guarantee penetration, consistently and without perforations. The aspect and quality of a root pass are dependent of the forces that act directly on the weld pool. When there are no backing strips, the weld pool is supported by the shear stress induced by the surface tension gradient, which causes the liquid metal to flow from the center of the pool surface towards the joint edges. Considering the flat position, the weld pool is pressed down by the force induced by the plasma jet, the Lorentz force, and the gravity force. In this way, the welding current and the size of the weld pool tend to govern the stability of the root pass. However, conceptually, the formation of a root pass happens at two continuous yet distinct stages.

At the first stage, the arc is over the pool, heating and melting the metal (groove metal and filler). In the case of flat position welding, the arc jet and the gravitational and electromagnetic forces, the last one to a lesser extent, act pressing down the pool (although the arc jet avoids the pool collapse in the case of overhead position). The pool itself is sustained inside the groove by surface tension, which demands less free surface energy between the surrounding non-molten metal and the pool than between the environment and the pool. Therefore, in the flat position, small size pools (lower gravitational force), a lower number of slags (which reduces the free surface energy between the environment and the pool), and low currents (less arc force pushing down the pool) favor the formation of a stable pool during the first stage.

It is worth noting two characteristics of this first stage. Although gravitational force can be assumed to depend only upon the molten metal mass, the action of the gravitational force is more pronounced in the overhead welding position, since there is a wider molten area on the lower surface of the pool than in the flat position. In the flat position, there is a more permanent backrest (joint faces) to the pool. Therefore, the positive effect of the arc jet towards sustaining the pool in the overhead welding position is counterbalanced by a higher negative effect of the gravitational force, and root pass in the overhead welding position is even more difficult. It is important to clarify that root faces with no gap demand a higher current to melt the metal at the groove root, also making more difficult (higher arc jet/electrical magnetic forces and larger molten metal volume) the formation of sound root passes. Too wide gaps, on the other hand, demand more molten metal to fill the volume, increasing the gravity force, yet requiring less current, since there is no need to melt the whole root face neighborhood.

A second characteristic is related to the mentioned reached pool stability at the end of the first stage. In fact, it would be more precise to say a pseudo-stable pool, since the molten metal is fluid and it would sag down eventually if the second stage of root pass formation would not take place. Regarding the second stage, as long as the arc is moving forward, the pool starts to cool down. Then, the molten metal viscosity increases, preventing the pool collapse before the full solidification (the reader must realize that viscosity is a dynamic property of a fluid, different from surface tension). Excessively fluid weld metal is not desirable for root pass in this concern, making the molten metal spillage faster (before full solidification). Therefore, small and deeply penetrated pools, as well as a reduced number of slags (all leading to faster solidification) favor the formation of sound root beads at the end of the second stage.

Considering all the above, the manual process with shielded metal arc welding (SMAW) is the most commonly used for root pass welding, especially with cellulose coating. The possibility of using transverse oscillation, relatively low currents and a short arc (low plasma jet) facilitates the control of the weld pool. Another widely used process for making a root pass is gas tungsten arc welding (GTAW), which, because of its independence between the material feed and the heat source, provides a skilled welder with the possibility of balancing the heat and the wire feeding, thereby controlling the weld pool. In these processes, the root pass can be made in different positions, but with relatively low welding speeds and deposition rates (slightly higher with SMAW) compared to other processes and welding techniques, generating limitations in terms of production. Finally, new versions of the gas metal arc welding (GMAW) process, using a controlled waveform format, brought new perspectives to build root passes, as demonstrated by Martikainen and Kah [

1], in an interesting study which comparatively evaluated the quality and productivity of GMAW, SMAW, and GTAW root pass welding under different fit-up gaps. In a similar study, Adi et al. [

2] demonstrated the ability to increase up to three times the travel speed of root pass with a version of a waveform-controlled process in comparison to SMAW or GTAW processes, with weld quality similar to GTAW process.

Nowadays, the reduction in the availability of skilled manual welders, an essential condition to build up root passes, has forced the use of automation. However, unlike manual welding, automation does not rely on the ability of the welder to control the weld pool. In order to get around this problem, one solution is to emulate the manual welder in automated operations, for tasks which are not so simple. Another solution would be to work on the concept of the root pass formation as summarized above. In this sense, the potentiality of the switchback technique with the GMAW process is presented.

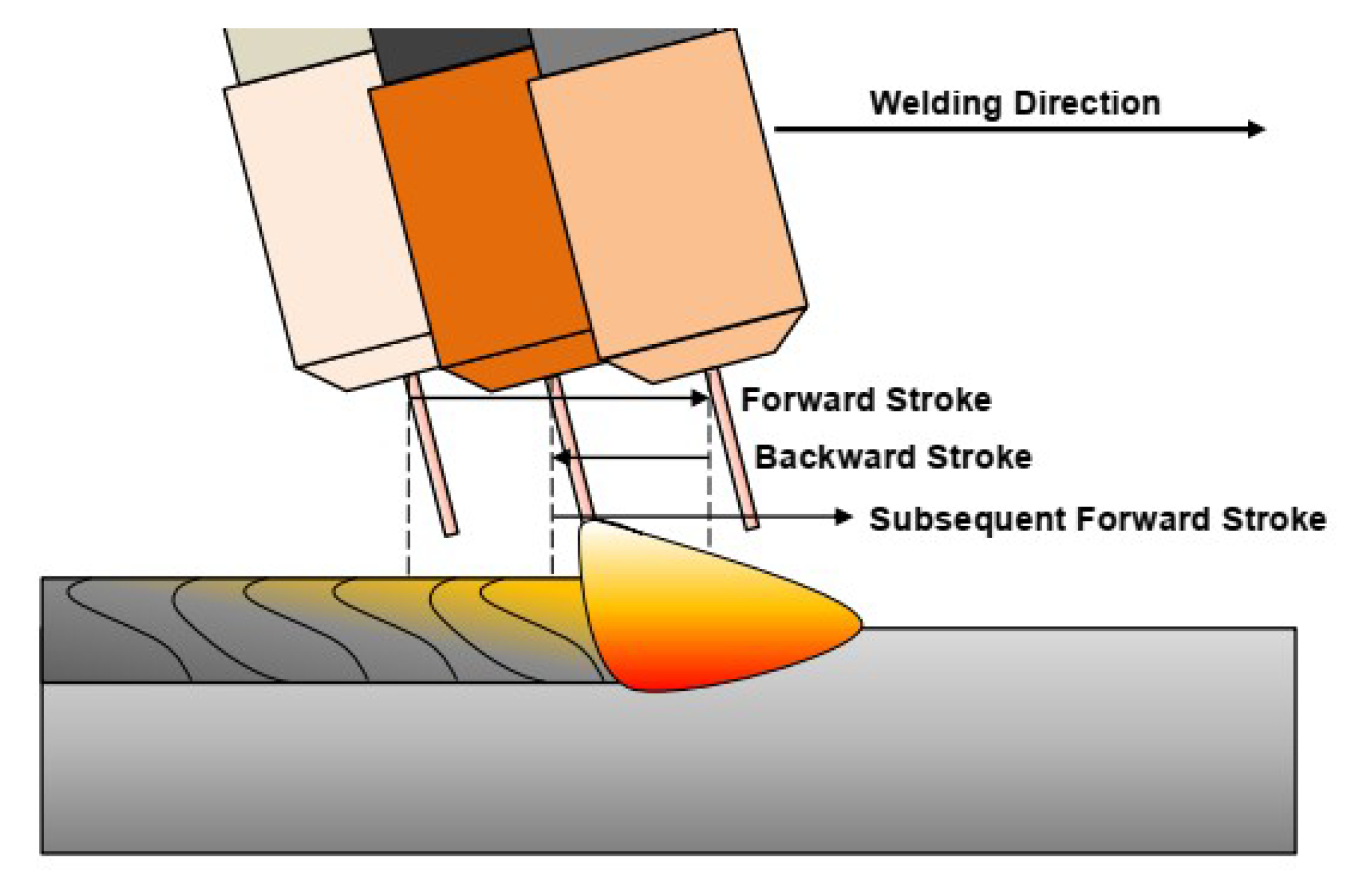

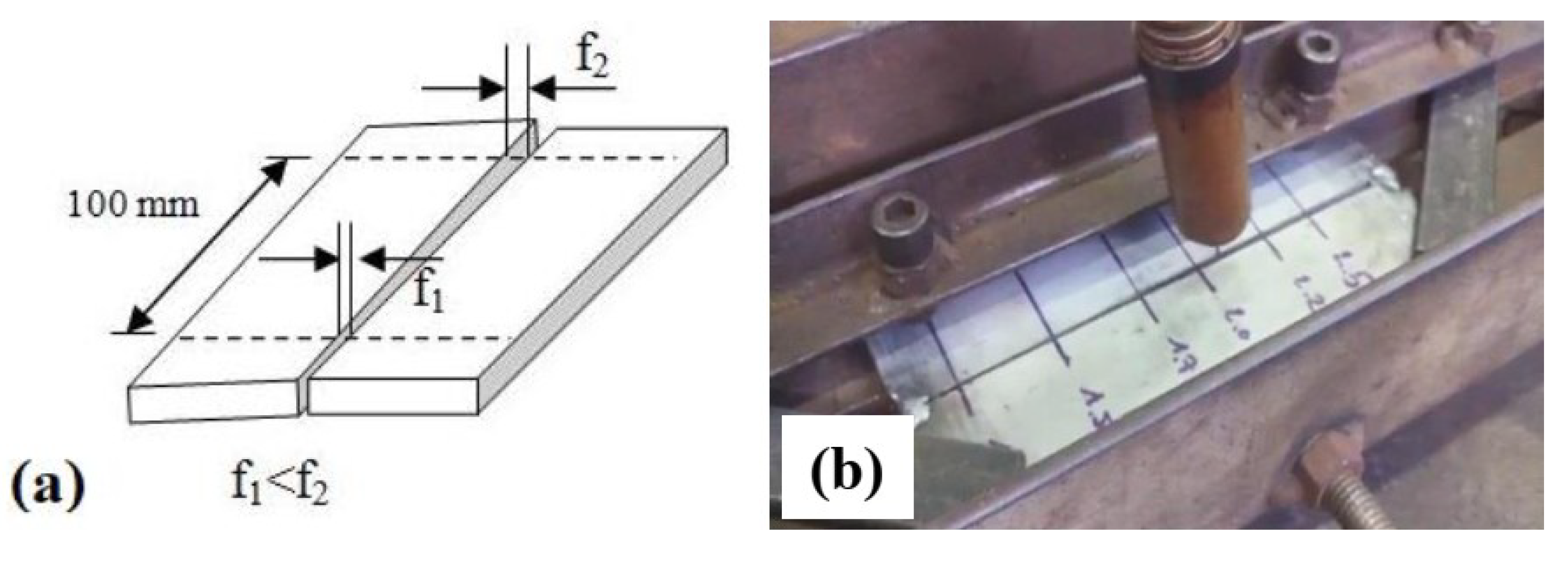

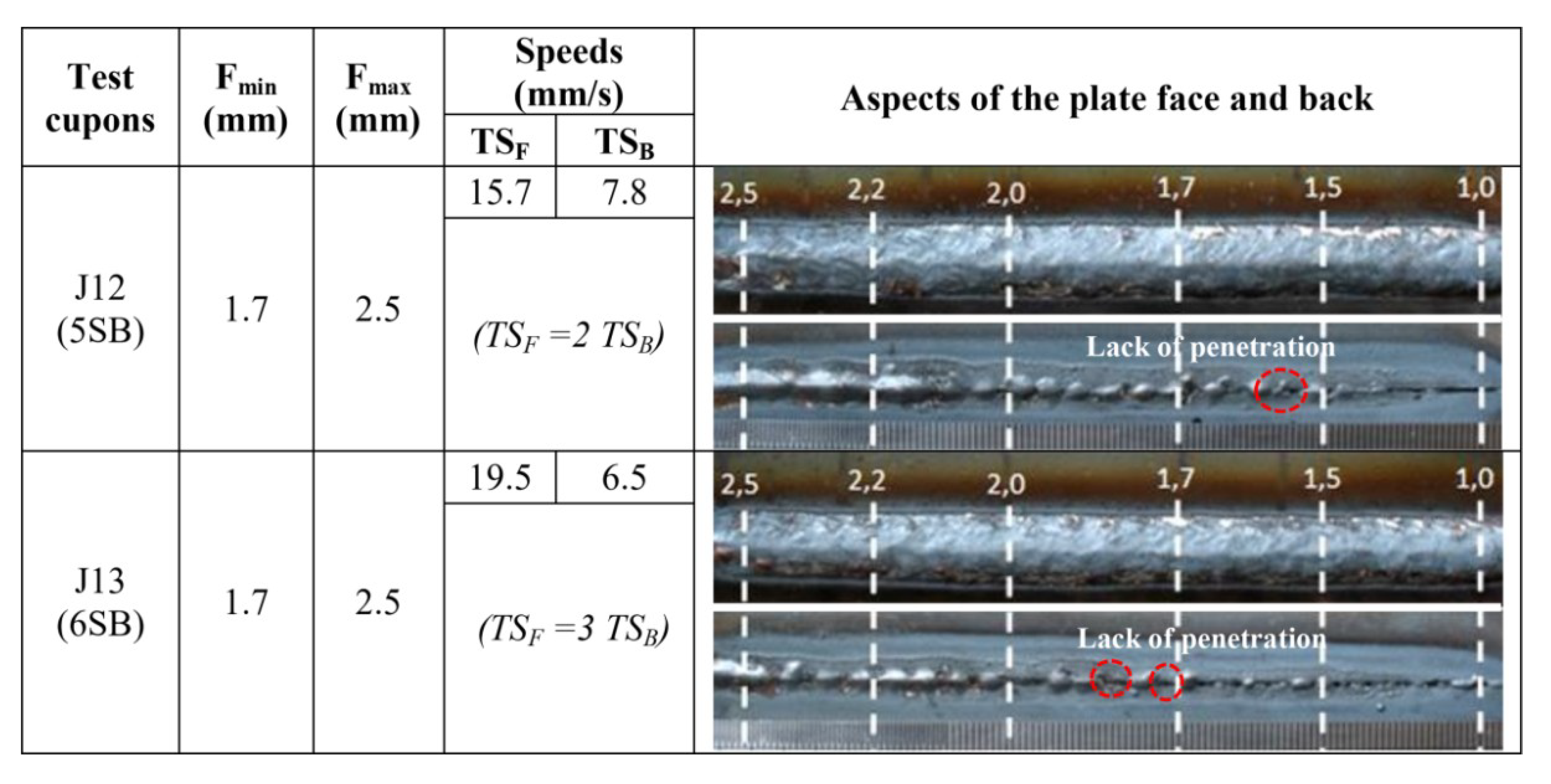

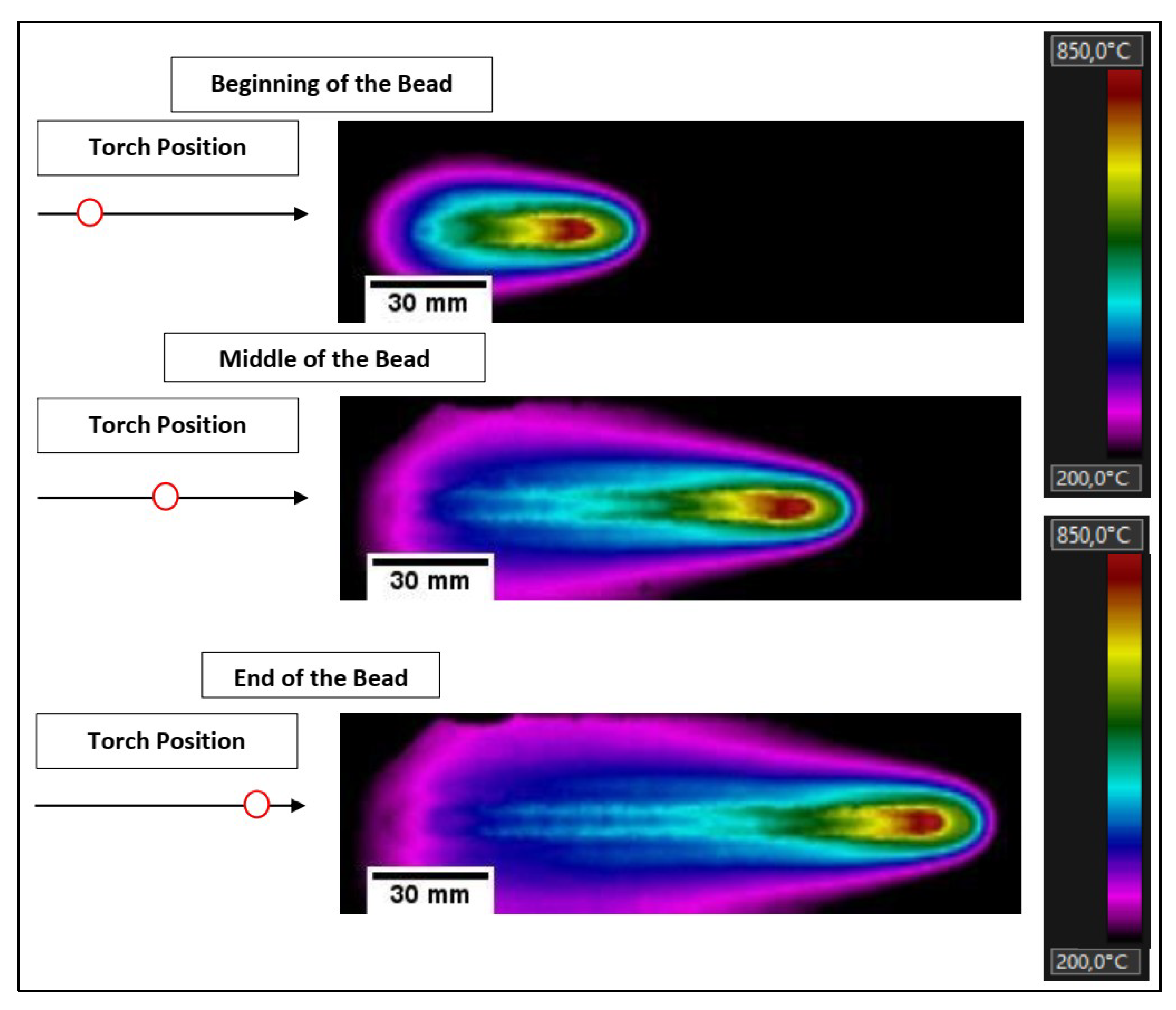

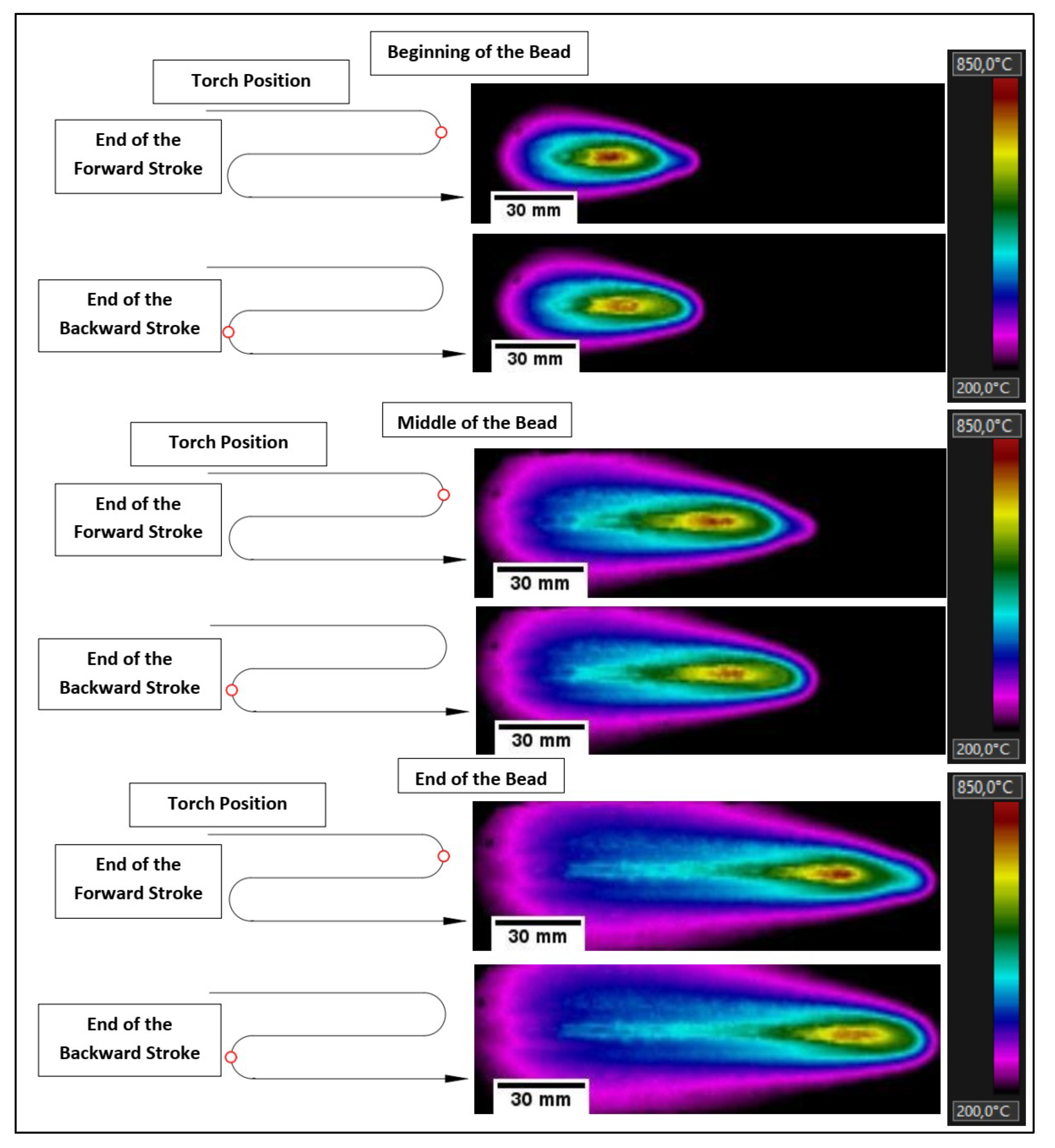

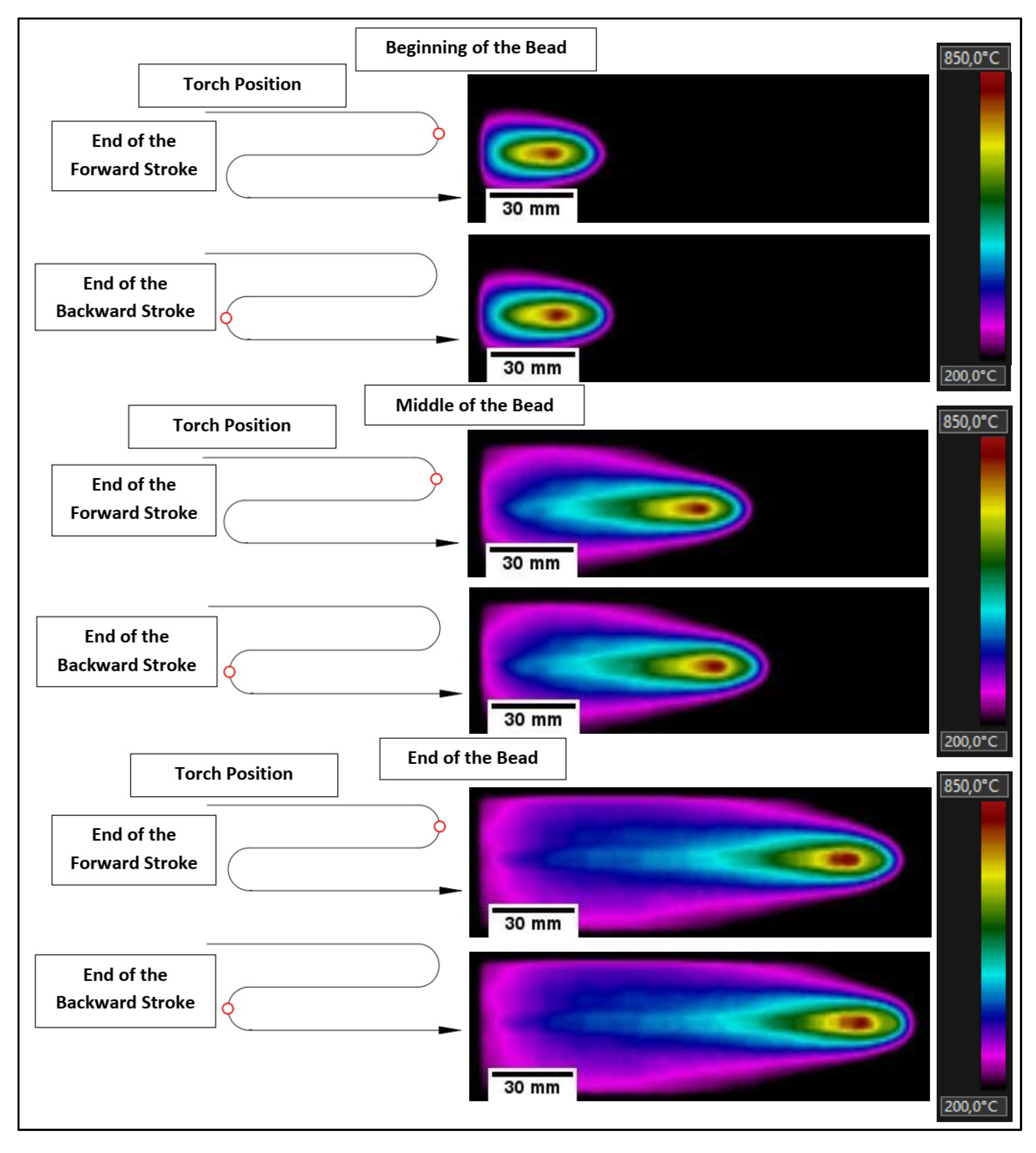

The switchback technique consists of the periodic oscillation of the torch, a consequence of the arc (heat source), along the longitudinal direction of the groove during the welding operation. As illustrated in

Figure 1, the arc cyclically moves forward with the weld pool along the joint by a certain linear amplitude, forming a first layer, so that it returns with a lesser length than that of the forward stroke over the previous layer. Because the torch passes several times in the same location, the weld pool is heated slowly. Therefore, depending on the welding energy as well as the forward and backward strokes lengths and speeds, solid, liquid, and/or mushy phases will coexist in greater or lesser volumes. The angle of the torch in relation to the welding direction (with the arc pushing or pulling the pool) is another essential variable of the process.

The potential of the switchback technique in terms of root pass formation was reported for the first time likely by Yamane et al. [

3]. The authors obtained stable beads for large root gaps (between 2.3 mm and 4.9 mm and misalignments between 0.1 and 2.8 mm) in V-groove joints and without backing plates, through the continuous control of switchback technique parameters and GMAW process parameters. Based on this result, Yamane et al. [

4] carried out another work and proposed the use of the switchback technique to control bead height and root pass, but this time with narrow gap welding. They claimed that a stable back bead is formed, since the arc pre-heats the root edges when moving forwards. When the welding torch is moved backwards, a suitable bead height is formed. In this way, the technique has been shown to be able to produce stable root passes also for narrow gap welding, provided that a suitable combination of switchback parameters is used. For this, numerical simulations were performed to obtain the adequate length of the course.

Further simulation studies on the switchback technique were realized by Kaneko et al. [

5,

6] in butt joints with thin plates. Heat conduction analysis was carried out to investigate the effect of the travel speed, as well as the backward stroke length of the torch on the weld pool. When the travel speed of the forward stroke was faster than that of the backward stroke, the weld pool length became shorter than a constant travel speed. On the other hand, if the backward stroke length became longer than half of the forward stroke length, continuous root passes could be obtained, regardless of such a disturbance as fluctuation of the arc length. Teixeira et al. [

7] used experiments to study the switchback parametrization. The found operational envelope for the GMAW process with switchback was established with low values of speeds and lengths of forward and backward strokes.

In order to improve control of the root pass in welding without backing plates, Yamane et al. [

8] designed and applied a cooperative control to integrate a robot, a welding power source, and a wire feed unit, so that the movements of the robot were adaptatively adjusted according to a root gap variation. Good quality welds were obtained by the control system. In other publications, Yamane et al. [

9,

10] gave more details of a switchback application in a V-groove joint with a root gap from 2 to 4 mm, without a backing plate. The assumption was that if the torch was rapidly moved forward, the heat source from the weld pool would disappear quickly and the temperature of the weld pool would fall, preventing burn-through. Therefore, in terms of the switchback technique, the proposed welding procedures were performed in two stages. In the first stage, the welding torch performed the forward and reverse strokes with high speeds, depositing the molten material only on the walls of the joint. Thereafter, a new forward stroke was performed with the same prior length, however, with a reduced speed capable of merging and joining the previously deposited material on the walls of the joint. Thus, due to successfully combining the switchback technique with a transverse oscillation and a pulsed current GMAW, a good root pass could be obtained by setting an appropriate amplitude for the torch oscillation.

In order to improve control of the weld pool, Scotti et al. [

11] registered a patent for a switchback welding device using the GMAW process. In this device, the weld pool control is performed by changing the operational mode of the process (polarity and/or metallic transfer) in synchrony with the position of the torch in the joint. However, unlike Yamane et al. [

9,

10], in which the torch oscillated transversely at the same time as the switchback movement, this device causes the torch to first travel one side of the groove face during the forward movement, changing to the other side in a backward movement, and concluding the cycle at the center of the groove with another forward movement. In this control device, the forward and backward lengths were the same. During displacement on the groove sides, the device makes the power supply impose a higher arc energy, while during the displacement over the center of the groove (root centerline), the control changes the operational mode to a lower energy. In this way, the device contributed to a greater heat distribution and control of the viscosity of the weld pool, avoiding the collapse of the same in different geometric tolerances in the root gap, either by misalignment or unevenness.

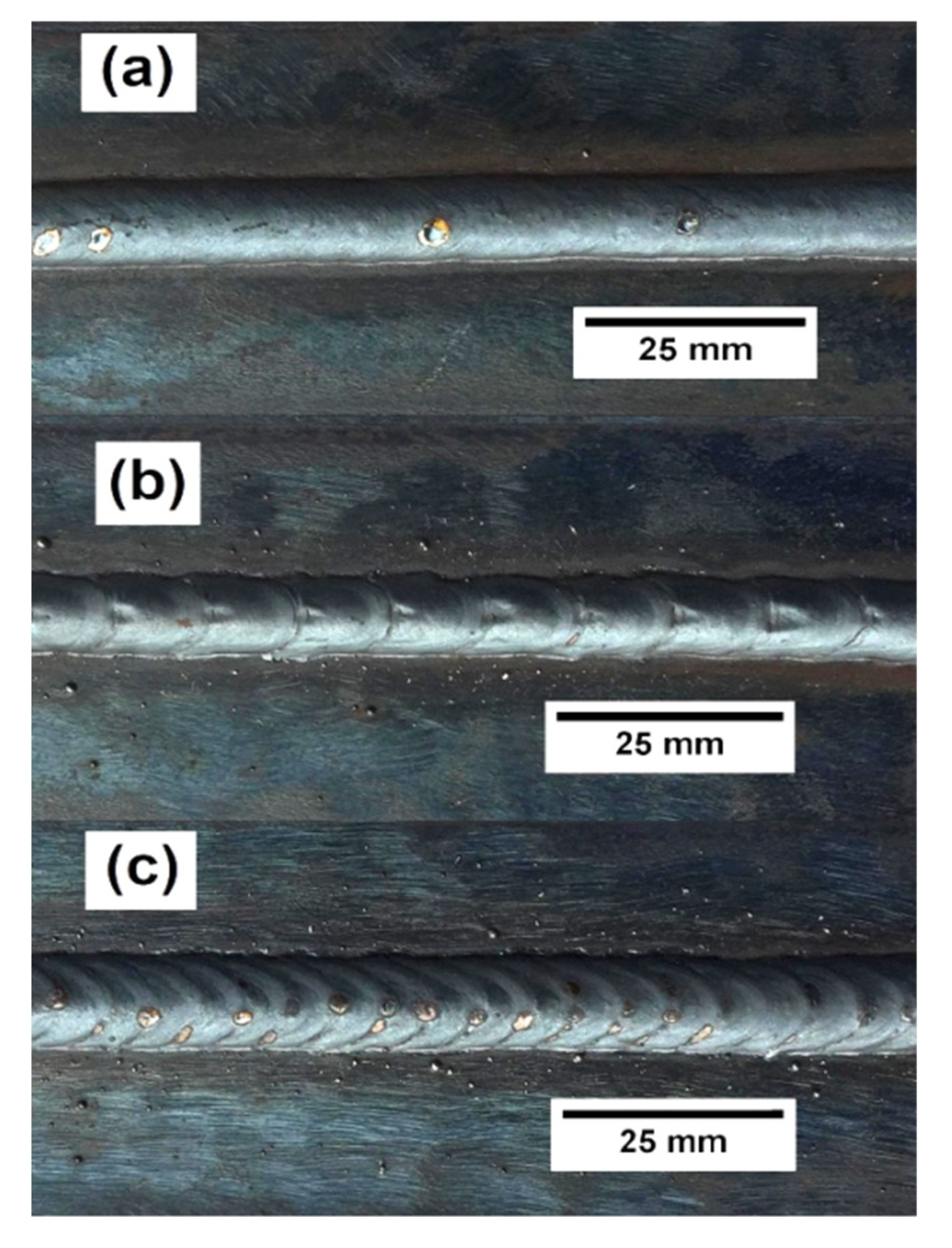

The possibility of increasing the limit travel speed in fillet welds (overspeed leads to a humping formation) has been also appointed as a beneficial characteristic of switchback. Aiming to use GMAW switchback to increase production with quality, Bonacorso et al. [

12] compared linear conventional and switchback trajectories (forward speed four times faster than the backward and with pool pushing movement). However, the results showed a non-significant increase in the production with the switchback technique (limit increase of only 5%). This result contrasts with that mentioned in the review by Almeida et al. [

13], where an increase of up to 60% in the limit travel speed was observed in the welding of a 3 mm thick steel overlap joint. Applying switchback to GTAW at high currents, Schwedersky et al. [

14] showed that the incidence of humping-like discontinuities, typical of GTAW with high currents, was reduced. This improvement was clearer when the backward stroke length was more than half of the forward stroke length. Using thermography on the back of the plate, the authors suggested that the heat tends to penetrate into the plate less when switchback is applied, following the same trend observed in the simulations of Kaneko et al. [

5,

6].

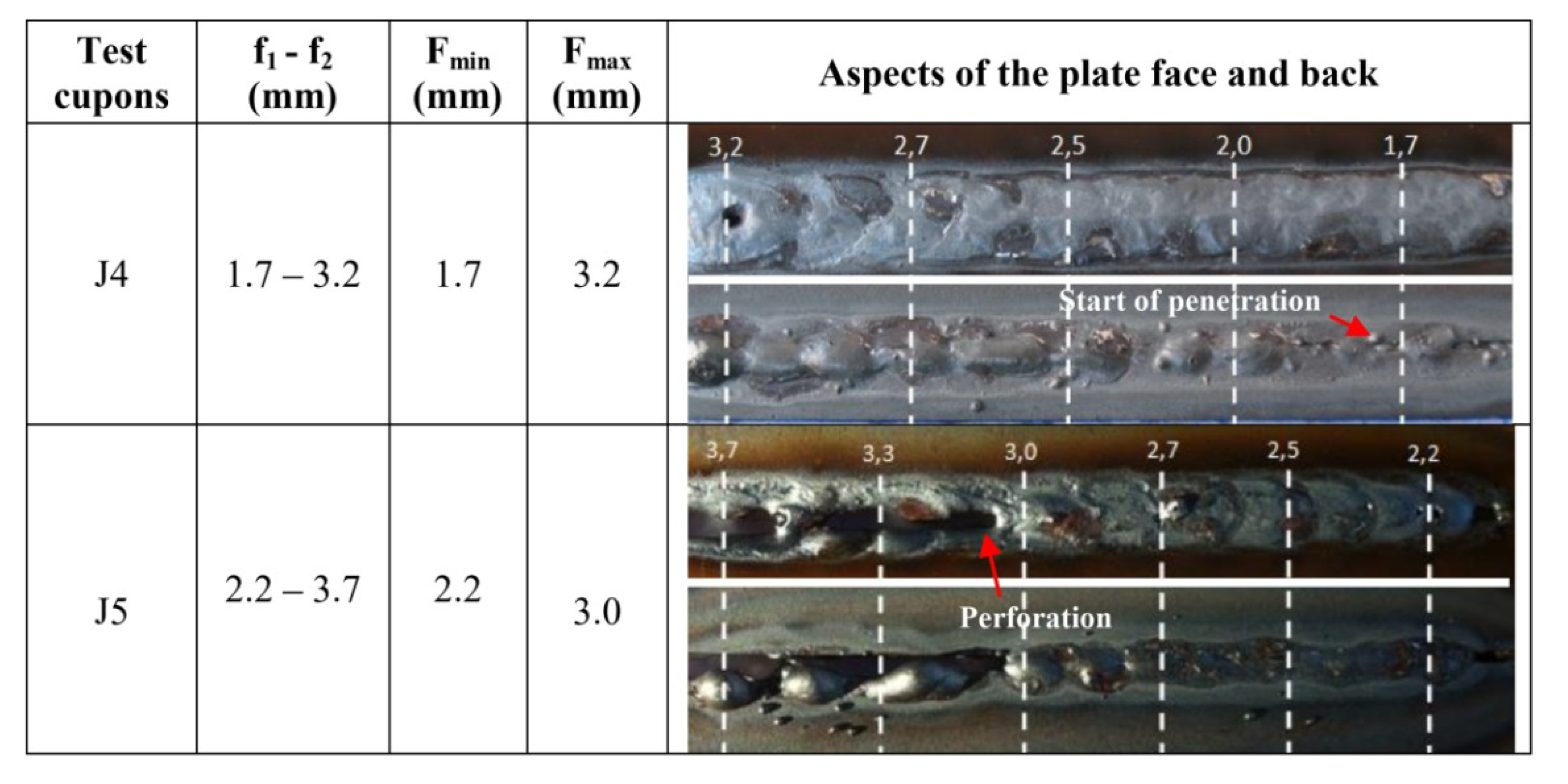

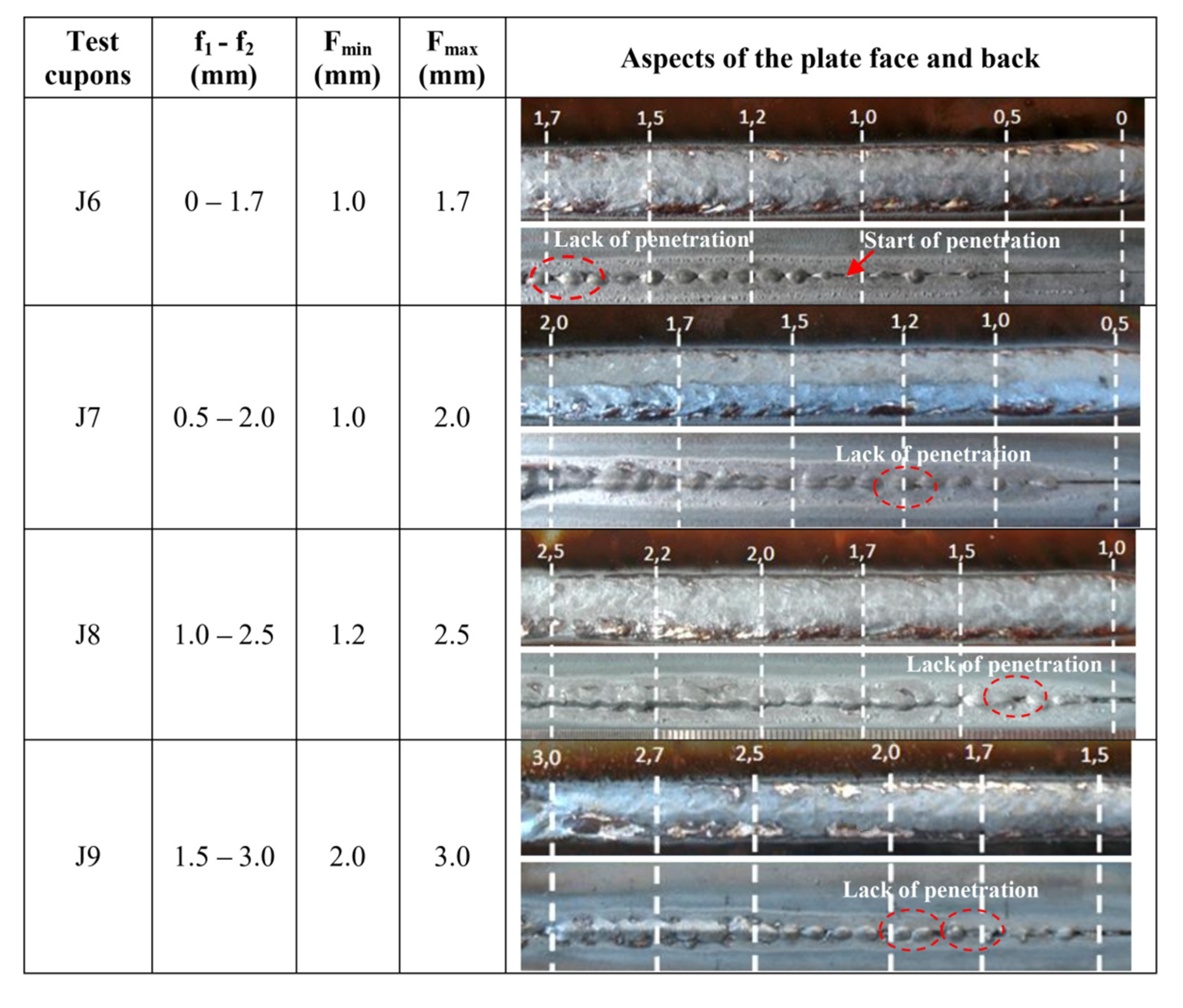

As seen above, despite the fact that GMAW switchback has been acknowledged for some years, there is not much information in current literature about this technique and its application is unknown in the industrial environment. One reason for this fact would be the lack of robust information on parametrization, for example, about the reliability of the technique to manufacture root passes in butt joints with a variable root gap. Therefore, the objective of this work was to experimentally determine the potential gain in root gap tolerances (operational gap range) when switchback replaces the conventional linear progression welding (a typical application of GMAW), with the view of pool formation at the root pass.