Analytical Study of Microstructural Effects on the Degradation of Elastic Properties in Cement Paste

Abstract

1. Introduction

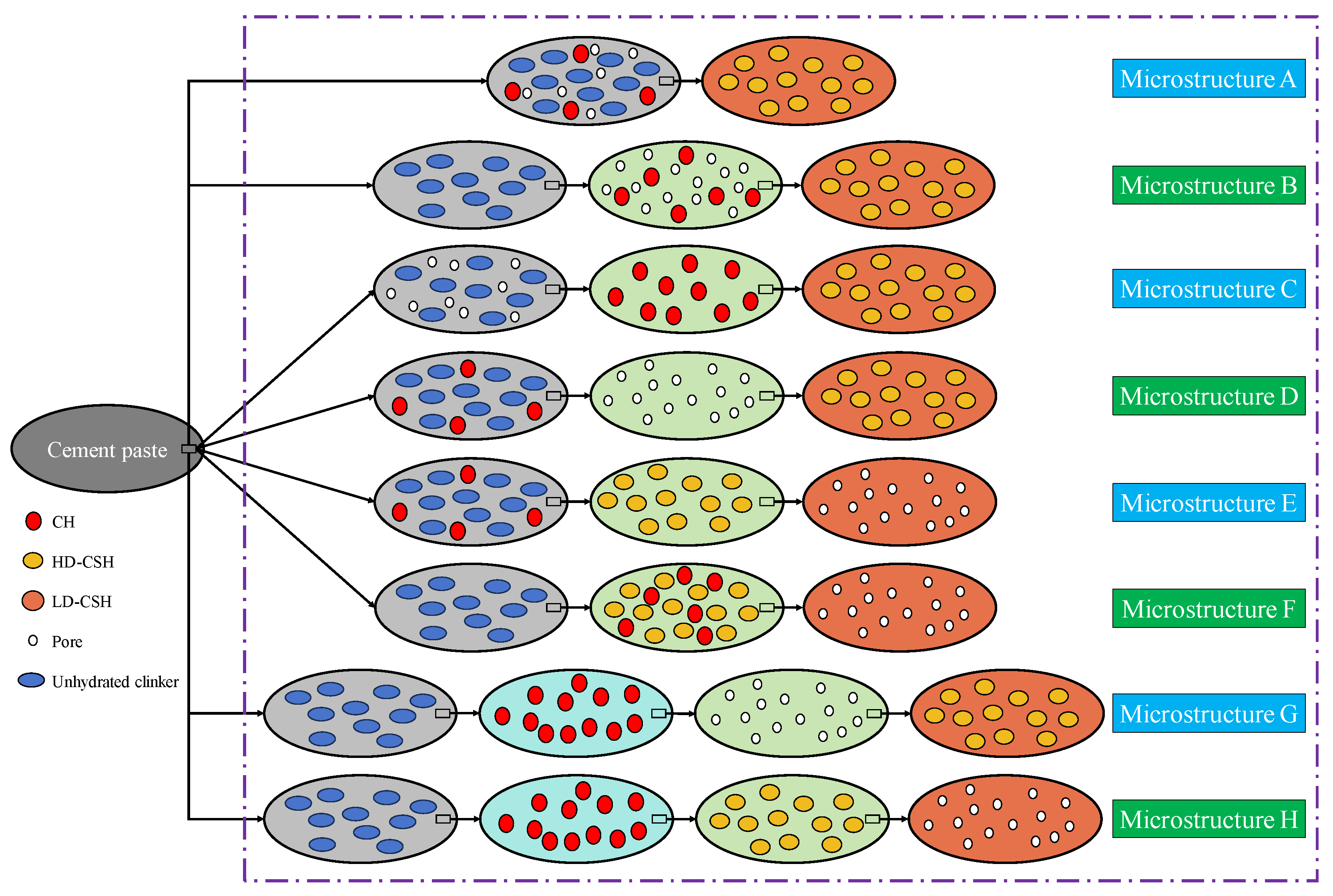

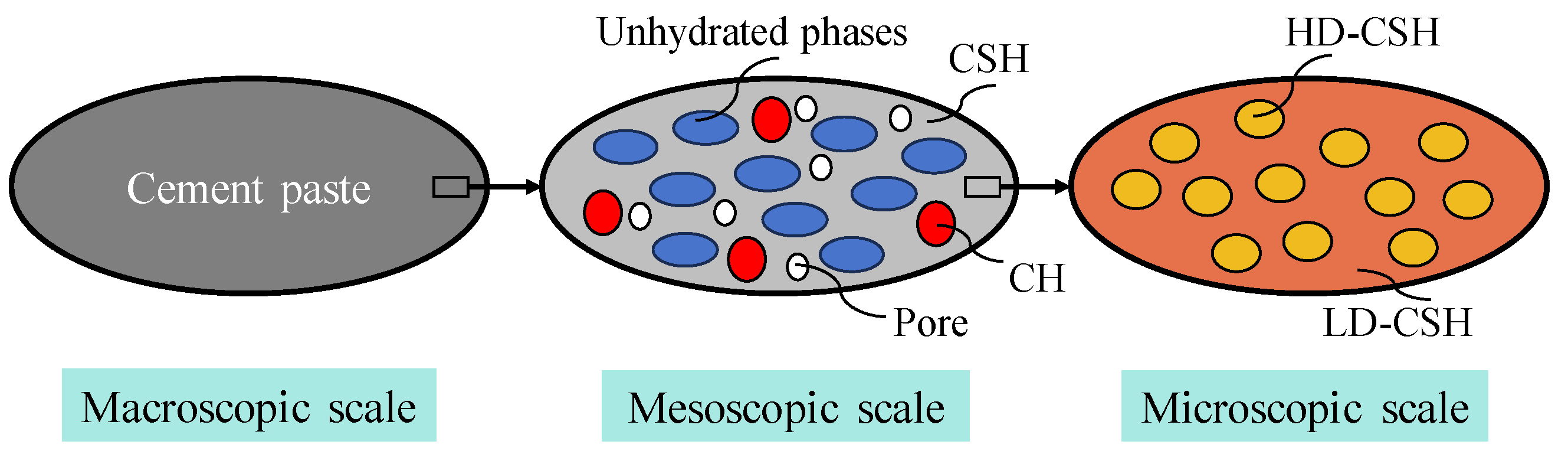

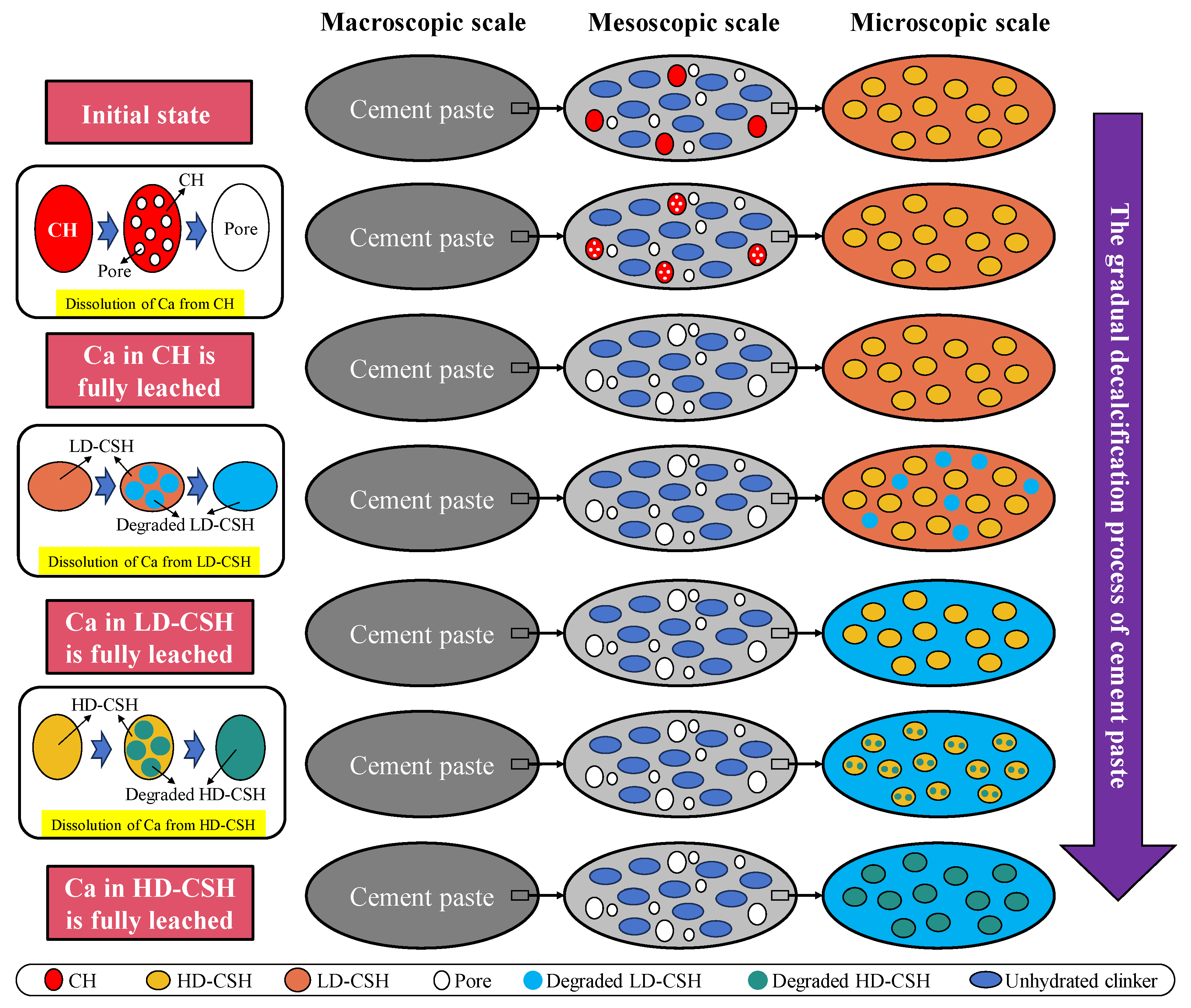

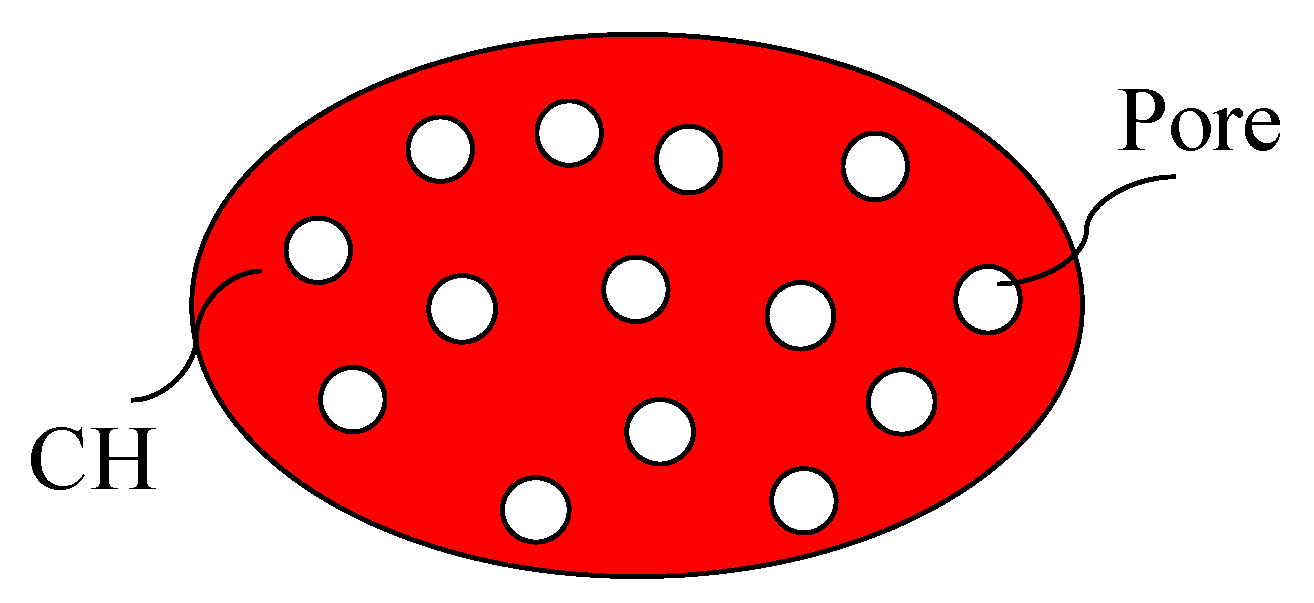

2. Evaluating Microstructures and Homogenization Schemes

3. Multi-Scale Model for Predicting Elastic Modulus

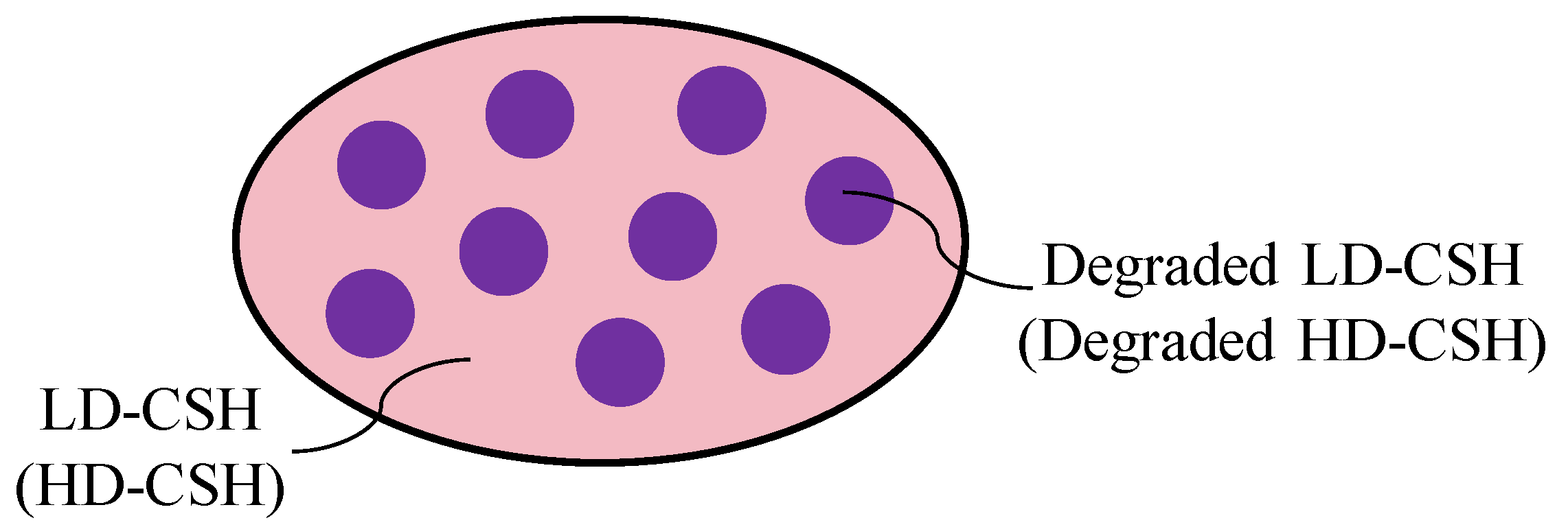

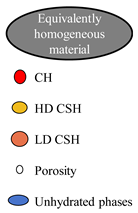

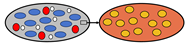

3.1. Multi-Scale Model of Hardened Cement Paste

3.2. Multi-Scale Model of Leached Cement Paste

4. Model Analysis and Application

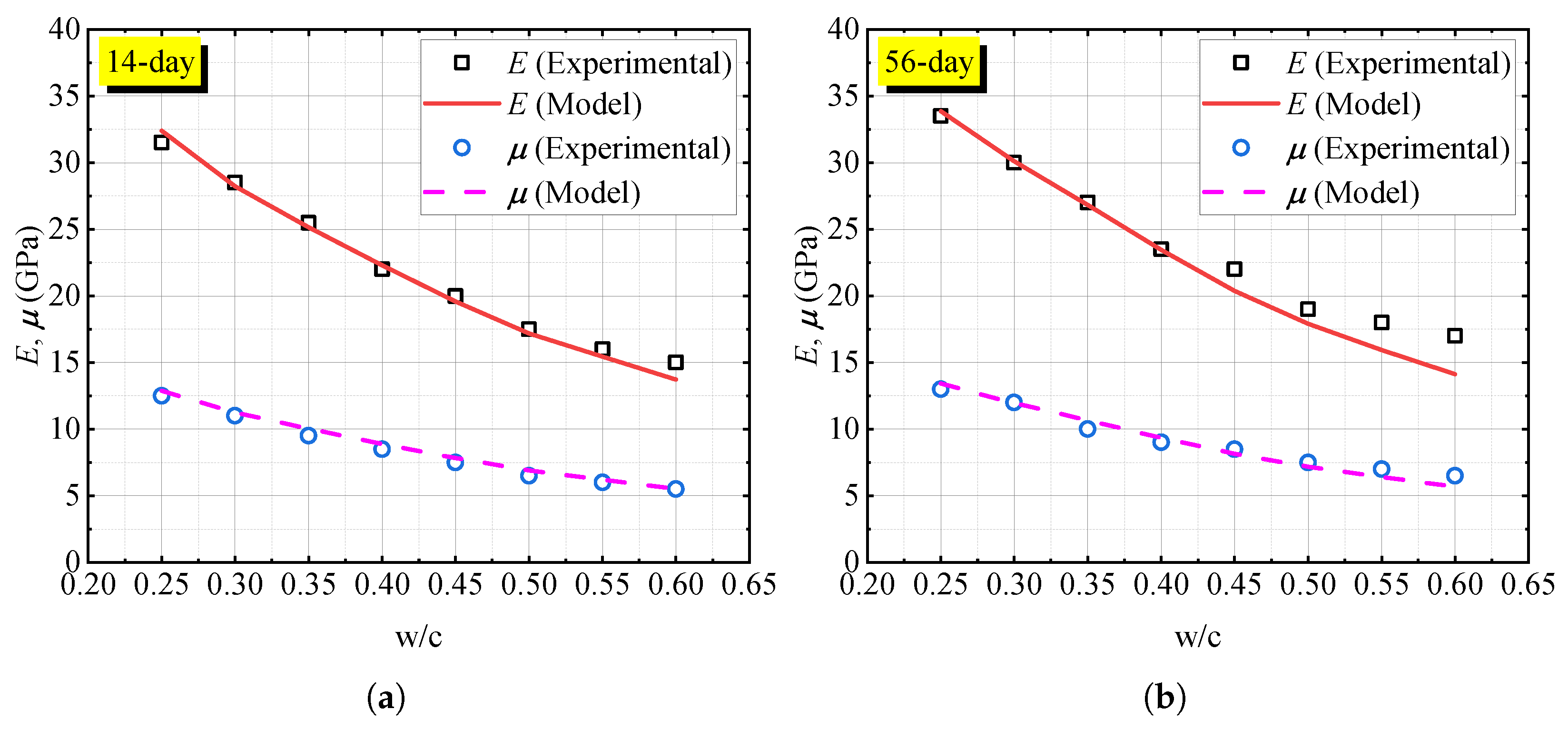

4.1. Validation and Analysis of Hardened Cement Paste Model

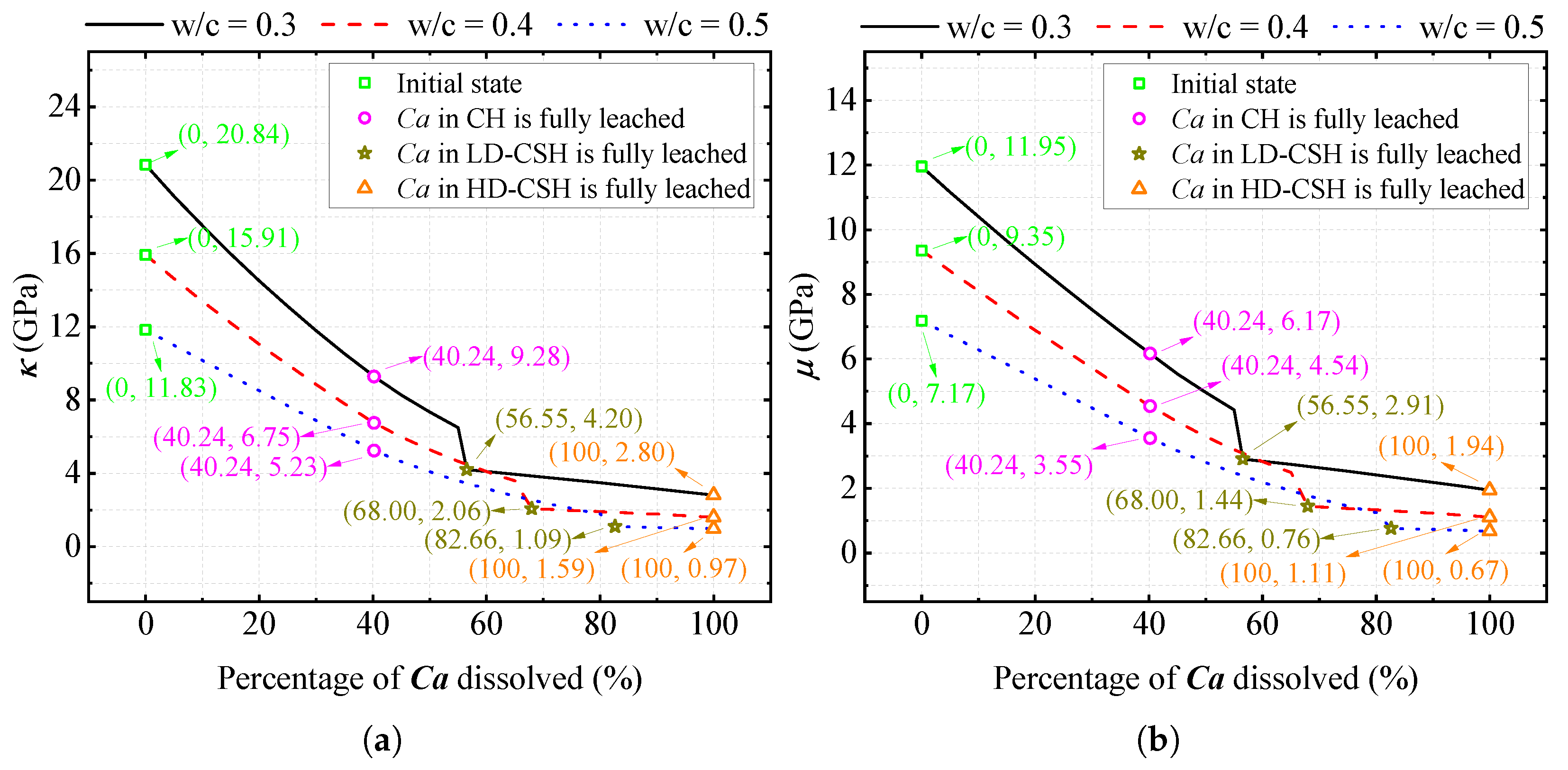

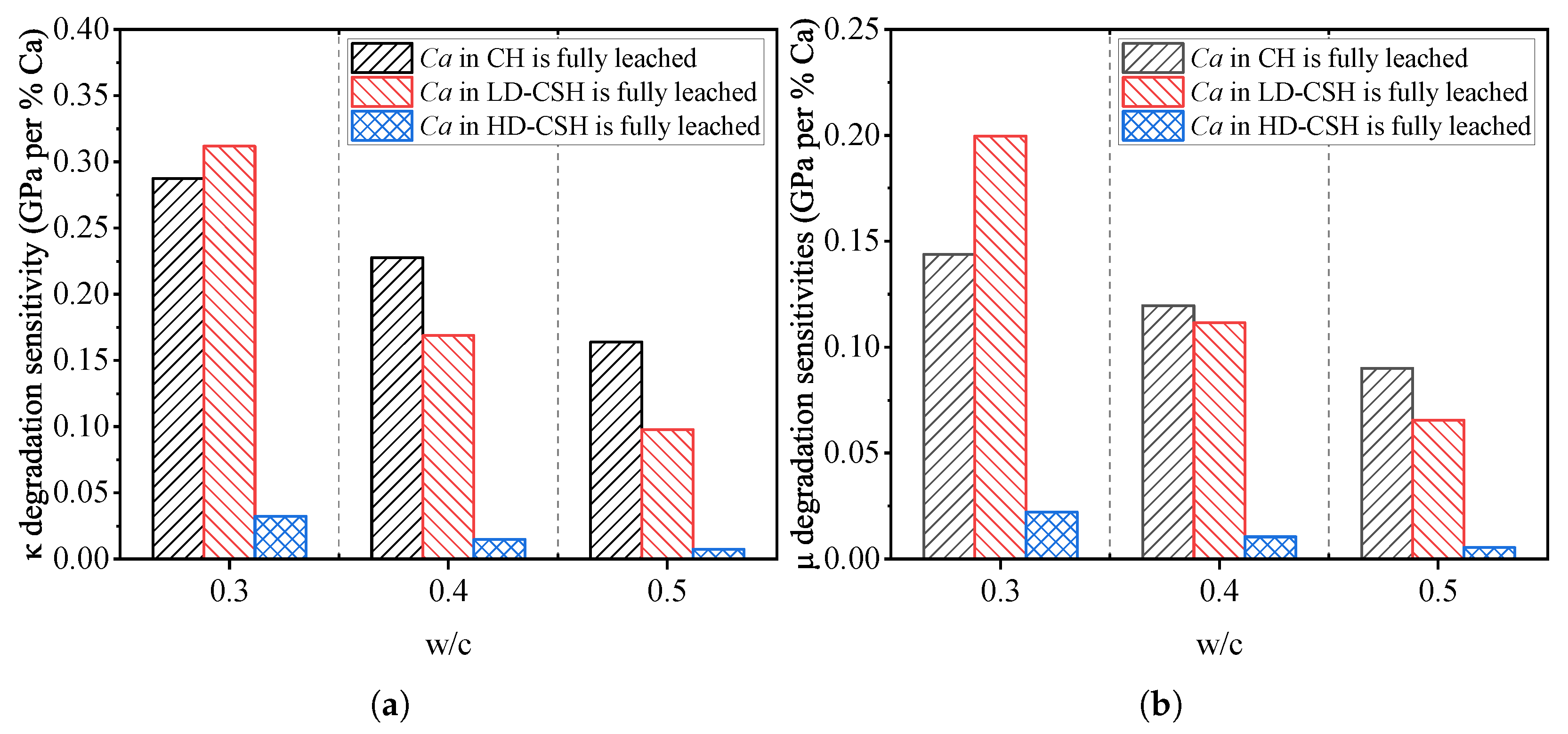

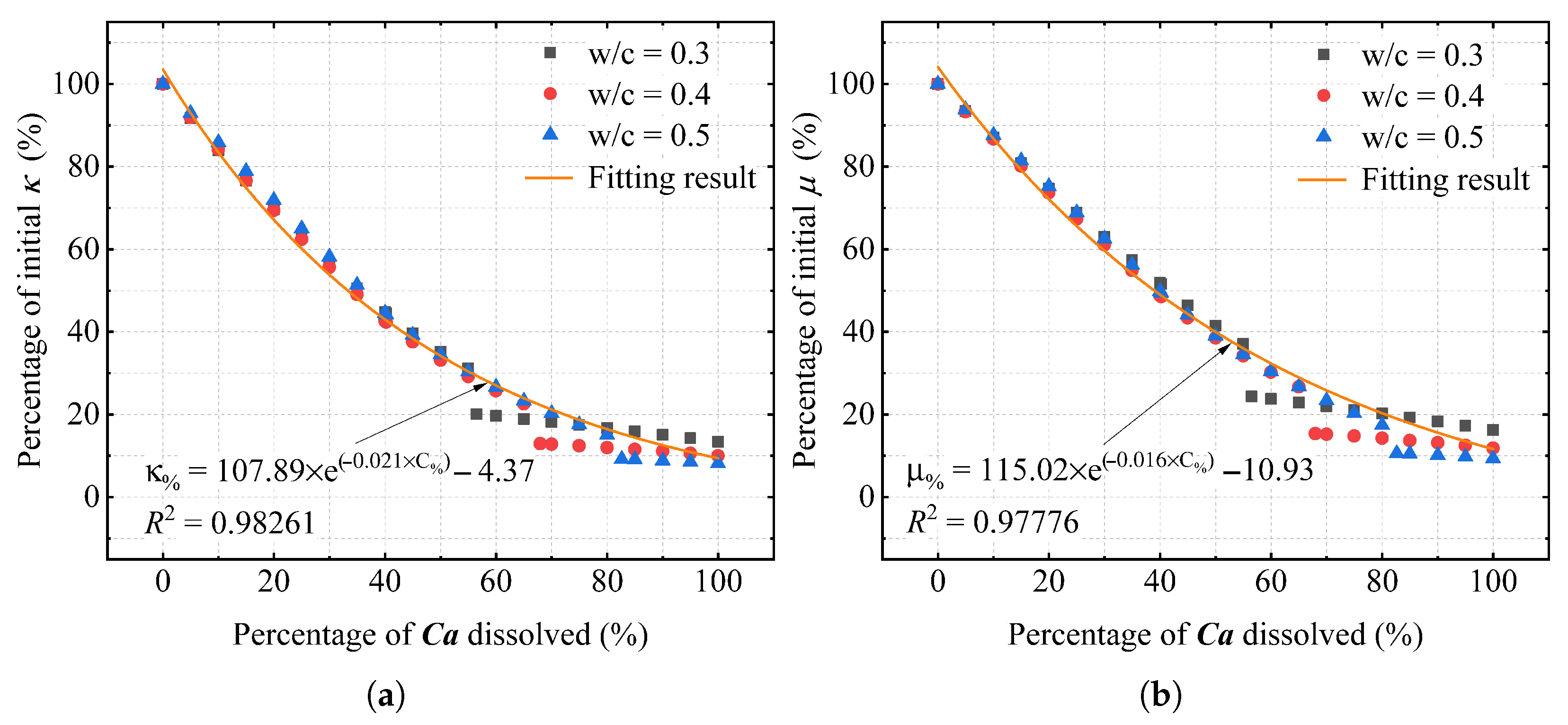

4.2. Investigation of Leached Cement Paste

5. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Homogenization Scheme

- Voigt upper bound [41]:where , , and are the bulk modulus, shear modulus, and volume fraction of the r-th phase, respectively. In this paper, is effective bulk moduli, and is effective shear moduli. is the total number of phases contained in the material.

- The upper bound is obtained when the highest values of constituent moduli are used for and .

References

- Makul, N. Modern sustainable cement and concrete composites: Review of current status, challenges and guidelines. Sustain. Mater. Technol. 2020, 25, e00155. [Google Scholar] [CrossRef]

- Tian, Q.; Zhou, J.; Hou, J.; Zhou, Z.; Liang, Z.; Sun, M.; Hu, J.; Huang, J. Building the future: Smart concrete as a key element in next-generation construction. Constr. Build. Mater. 2024, 429, 136364. [Google Scholar] [CrossRef]

- Phung, Q.T.; Maes, N.; Jacques, D. Current concerns on durability of concrete used in nuclear power plants and radioactive waste repositories. In Proceedings of the 4th Congrès International de Géotechnique-Ouvrages-Structures: CIGOS 2017, Ho Chi Minh City, Vietnam, 26–27 October 2018; pp. 1107–1121. [Google Scholar]

- Kanagaraj, B.; Anand, N.; Andrushia, A.D.; Naser, M. Recent developments of radiation shielding concrete in nuclear and radioactive waste storage facilities—A state of the art review. Constr. Build. Mater. 2023, 404, 133260. [Google Scholar] [CrossRef]

- Al-Neshawy, F.; Abo Ba Ragaa, B.; Punkki, J. Comprehensive State-Of-The-Art Report for Long-Term Behaviour of Concrete Structures in Repository Environment; Aalto University: Espoo, Finland, 2023. [Google Scholar]

- Gawin, D.; Pesavento, F.; Schrefler, B.A. Modeling deterioration of cementitious materials exposed to calcium leaching in non-isothermal conditions. Comput. Methods Appl. Mech. Eng. 2009, 198, 3051–3083. [Google Scholar] [CrossRef]

- Zhou, X.Z.; Han, Z.Y.; Zheng, J.J.; Zheng, Z.Y.; Zhang, Y.X.; Zhang, X.H. A multi-step scheme for evaluating the elastic moduli of partially leached cement paste. Constr. Build. Mater. 2022, 344, 128095. [Google Scholar] [CrossRef]

- Bernard, F.; Kamali-Bernard, S.; Prince, W. 3D multi-scale modelling of mechanical behaviour of sound and leached mortar. Cem. Concr. Res. 2008, 38, 449–458. [Google Scholar] [CrossRef]

- Luo, Q.; Liu, D.; Qiao, P.; Zhou, Z.; Zhao, Y.; Sun, L. Micro-CT-based micromechanics and numerical homogenization for effective elastic property of ultra-high performance concrete. Int. J. Damage Mech. 2020, 29, 45–66. [Google Scholar] [CrossRef]

- Stora, E.; Bary, B.; He, Q.C.; Deville, E.; Montarnal, P. Modelling and simulations of the chemo–mechanical behaviour of leached cement-based materials: Leaching process and induced loss of stiffness. Cem. Concr. Res. 2009, 39, 763–772. [Google Scholar] [CrossRef]

- Constantinides, G. The elastic properties of calcium leached cement pastes and mortars: A multi-scale investigation. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2002. [Google Scholar]

- Xie, S.; Shao, J.F.; Burlion, N. Experimental study of mechanical behaviour of cement paste under compressive stress and chemical degradation. Cem. Concr. Res. 2008, 38, 1416–1423. [Google Scholar] [CrossRef]

- Gîrboveanu, A.; Jebli, M.; Jamin, F.; Huon, V.; Bonnet, L.; Georgescu, D.; El Youssoufi, M.S. Mechanical tensile behaviour of cement paste/aggregate bond exposed to leaching. Constr. Build. Mater. 2023, 369, 130592. [Google Scholar] [CrossRef]

- Shen, W.; Shao, J.F.; Burlion, N.; Liu, Z. A microstructure-based constitutive model for cement paste with chemical leaching effect. Mech. Mater. 2020, 150, 103571. [Google Scholar] [CrossRef]

- Jia, Y.; Bian, H.; Xie, S.; Burlion, N.; Shao, J. A numerical study of mechanical behavior of a cement paste under mechanical loading and chemical leaching. Int. J. Numer. Anal. Methods Geomech. 2017, 41, 1848–1869. [Google Scholar] [CrossRef]

- Constantinides, G.; Ulm, F.J. The effect of two types of CSH on the elasticity of cement-based materials: Results from nanoindentation and micromechanical modeling. Cem. Concr. Res. 2004, 34, 67–80. [Google Scholar] [CrossRef]

- Yuan, L.; Qiu, J.; Guo, Z.; Zhang, S.; Wan, X.; Sun, X. Microscale and macroscale strength behaviors of blast furnace slag-cement based materials: Modeling and analysis. Constr. Build. Mater. 2023, 376, 131016. [Google Scholar] [CrossRef]

- Tong, L.y.; Xiong, Q.X.; Zhang, M.; Meng, Z.; Meftah, F.; Liu, Q.F. Multi-scale modelling and statistical analysis of heterogeneous characteristics effect on chloride transport properties in concrete. Constr. Build. Mater. 2023, 367, 130096. [Google Scholar] [CrossRef]

- Jia, H.; Hong, Y.; Qiao, G.; Han, P. Quantifying the evolution of mechanical behaviours of concrete materials resting on realistic microstructural characteristics: A micro-to-macro validated combination analysis method. Constr. Build. Mater. 2023, 409, 133843. [Google Scholar] [CrossRef]

- Lavergne, F.; Fraj, A.B.; Bayane, I.; Barthélémy, J. Estimating the mechanical properties of hydrating blended cementitious materials: An investigation based on micromechanics. Cem. Concr. Res. 2018, 104, 37–60. [Google Scholar] [CrossRef]

- Pichler, B.; Hellmich, C. Upscaling quasi-brittle strength of cement paste and mortar: A multi-scale engineering mechanics model. Cem. Concr. Res. 2011, 41, 467–476. [Google Scholar] [CrossRef]

- Sanahuja, J.; Dormieux, L.; Chanvillard, G. Modelling elasticity of a hydrating cement paste. Cem. Concr. Res. 2007, 37, 1427–1439. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, Q.; Yuan, J.; Chen, X.; Yang, J. Micro-scale characterization of the heterogeneous properties of in-service cement-treated base material. Constr. Build. Mater. 2020, 264, 120696. [Google Scholar] [CrossRef]

- Pal, B.; Ramaswamy, A. A multi-physics-based approach to predict mechanical behavior of concrete element in a multi-scale framework. Mech. Mater. 2023, 176, 104509. [Google Scholar] [CrossRef]

- Tian, Z.; Bian, C. Numerical modeling of elastic modulus for cement paste using homogenization method. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2013, 28, 751–760. [Google Scholar] [CrossRef]

- Haile, B.F.; Jin, D.; Yang, B.; Park, S.; Lee, H.K. Multi-level homogenization for the prediction of the mechanical properties of ultra-high-performance concrete. Constr. Build. Mater. 2019, 229, 116797. [Google Scholar] [CrossRef]

- Honorio, T.; Bary, B.; Benboudjema, F. Estimation of elastic properties of cement based materials at early age based on a combined numerical and analytical multiscale micromechanics approach. In Proceedings of the CONMOD 2014-RILEM International Symposium on Concrete Modelling, Beijing, China, 12–14 October 2014; Volume 91, pp. 236–243. [Google Scholar]

- Bernard, O.; Ulm, F.J.; Lemarchand, E. A multiscale micromechanics-hydration model for the early-age elastic properties of cement-based materials. Cem. Concr. Res. 2003, 33, 1293–1309. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Wang, R. Evaluation of the elastic modulus of concrete based on indentation test and multi-scale homogenization method. J. Build. Eng. 2021, 43, 102758. [Google Scholar] [CrossRef]

- Liang, S.; Wei, Y.; Wu, Z. Multiscale modeling elastic properties of cement-based materials considering imperfect interface effect. Constr. Build. Mater. 2017, 154, 567–579. [Google Scholar] [CrossRef]

- Tennis, P.D.; Jennings, H.M. A model for two types of calcium silicate hydrate in the microstructure of Portland cement pastes. Cem. Concr. Res. 2000, 30, 855–863. [Google Scholar] [CrossRef]

- Igarashi, S.I.; Watanabe, A.; Kawamura, M. Evaluation of capillary pore size characteristics in high-strength concrete at early ages. Cem. Concr. Res. 2005, 35, 513–519. [Google Scholar] [CrossRef]

- Huang, J.; Krabbenhoft, K.; Lyamin, A. Statistical homogenization of elastic properties of cement paste based on X-ray microtomography images. Int. J. Solids Struct. 2013, 50, 699–709. [Google Scholar] [CrossRef]

- Igarashi, S.I.; Kawamura, M.; Watanabe, A. Analysis of cement pastes and mortars by a combination of backscatter-based SEM image analysis and calculations based on the Powers model. Cem. Concr. Compos. 2004, 26, 977–985. [Google Scholar] [CrossRef]

- Wan, K.; Li, Y.; Sun, W. Experimental and modelling research of the accelerated calcium leaching of cement paste in ammonium nitrate solution. Constr. Build. Mater. 2013, 40, 832–846. [Google Scholar] [CrossRef]

- Patel, R.A.; Churakov, S.V.; Prasianakis, N.I. A multi-level pore scale reactive transport model for the investigation of combined leaching and carbonation of cement paste. Cem. Concr. Compos. 2021, 115, 103831. [Google Scholar] [CrossRef]

- Feng, P.; Miao, C.; Bullard, J.W. A model of phase stability, microstructure and properties during leaching of portland cement binders. Cem. Concr. Compos. 2014, 49, 9–19. [Google Scholar] [CrossRef]

- Haecker, C.J.; Garboczi, E.J.; Bullard, J.W.; Bohn, R.; Sun, Z.; Shah, S.P.; Voigt, T. Modeling the linear elastic properties of Portland cement paste. Cem. Concr. Res. 2005, 35, 1948–1960. [Google Scholar] [CrossRef]

- Monteiro, P. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Publishing: Columbus, OH, USA, 2006. [Google Scholar]

- Taylor, H.F.W. Cement Chemistry; Thomas Telford: London, UK, 1997; Volume 2. [Google Scholar]

- Watt, J.P.; Davies, G.F.; O’Connell, R.J. The elastic properties of composite materials. Rev. Geophys. 1976, 14, 541–563. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 1963, 11, 127–140. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Benveniste, Y. A new approach to the application of Mori-Tanaka’s theory in composite materials. Mech. Mater. 1987, 6, 147–157. [Google Scholar] [CrossRef]

| Phase | E (GPa) | Ref. | |

|---|---|---|---|

| LD-CSH | 21.70 | 0.24 | [16,27,28,29,30] |

| HD-CSH | 29.40 | 0.24 | [16,27,28,29,30] |

| CH | 38.00 | 0.31 | [16,27,28,29,30] |

| Unhydrated clinker | 104.00 | 0.30 | [29,30] |

| Capillary pore | 0 | 0 | [16,30] |

| Degraded LD-CSH | 3.00 | 0.24 | [16] |

| Degraded HD-CSH | 12.00 | 0.24 | [16] |

| Phase | LD-CSH | HD-CSH | CH | Unhydrated Clinker | Pore |

|---|---|---|---|---|---|

| Unit volume | 0.239 | 0.277 | 0.252 | 0.083 | 0.149 |

| Microstructure | MT Scheme | HS Upper Bound | Voigt Upper Bound | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A |  | 15.51 | 9.24 | 23.12 | 0.25 | 19.67 | 11.00 | 27.81 | 0.26 | 24.14 | 12.35 | 31.65 | 0.28 |

| B |  | 15.38 | 9.16 | 22.94 | 0.25 | 17.73 | 10.35 | 25.99 | 0.26 | 24.14 | 12.35 | 31.65 | 0.28 | |

| C |  | 15.88 | 9.44 | 23.64 | 0.25 | 19.26 | 10.95 | 27.61 | 0.26 | 24.14 | 12.35 | 31.65 | 0.28 | |

| D |  | 14.89 | 8.98 | 22.42 | 0.25 | 18.11 | 10.22 | 25.80 | 0.26 | 24.14 | 12.35 | 31.65 | 0.28 | |

| E |  | 13.80 | 8.42 | 20.99 | 0.25 | 17.99 | 10.16 | 25.65 | 0.26 | 24.14 | 12.35 | 31.65 | 0.28 | |

| F |  | 13.59 | 8.38 | 20.85 | 0.24 | 17.13 | 10.04 | 25.19 | 0.25 | 24.14 | 12.35 | 31.65 | 0.28 | |

| G |  | 14.99 | 9.04 | 22.59 | 0.25 | 17.12 | 10.00 | 25.12 | 0.26 | 24.14 | 12.35 | 31.65 | 0.28 | |

| H |  | 13.91 | 8.49 | 21.16 | 0.25 | 16.98 | 9.94 | 24.96 | 0.26 | 24.14 | 12.35 | 31.65 | 0.28 | |

| Model | MT Scheme | HS Upper Bound | Voigt Upper Bound |

|---|---|---|---|

| Microstructure-A | 6.54 | 28.16 | 45.85 |

| Microstructure-B | 5.71 | 19.77 | 45.85 |

| Microstructure-C | 8.94 | 27.24 | 45.85 |

| Microstructure-D | 3.32 | 18.89 | 45.85 |

| Microstructure-E | 3.27 | 18.20 | 45.85 |

| Microstructure-F | 3.92 | 16.08 | 45.85 |

| Microstructure-G | 4.10 | 15.76 | 45.85 |

| Microstructure-H | 2.49 | 15.02 | 45.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, J.; Shao, J. Analytical Study of Microstructural Effects on the Degradation of Elastic Properties in Cement Paste. Sci 2025, 7, 173. https://doi.org/10.3390/sci7040173

Xue J, Shao J. Analytical Study of Microstructural Effects on the Degradation of Elastic Properties in Cement Paste. Sci. 2025; 7(4):173. https://doi.org/10.3390/sci7040173

Chicago/Turabian StyleXue, Jing, and Jianfu Shao. 2025. "Analytical Study of Microstructural Effects on the Degradation of Elastic Properties in Cement Paste" Sci 7, no. 4: 173. https://doi.org/10.3390/sci7040173

APA StyleXue, J., & Shao, J. (2025). Analytical Study of Microstructural Effects on the Degradation of Elastic Properties in Cement Paste. Sci, 7(4), 173. https://doi.org/10.3390/sci7040173