An Overview of AI Methods for in-Core Fuel Management: Tools for the Automatic Design of Nuclear Reactor Core Configurations for Fuel Reload, (Re)arranging New and Partly Spent Fuel

Abstract

:1. Introduction

1.1. Aims

1.2. Considerations about Artificial Intelligence for Nuclear Engineers

“(t)he separation of the problem-solving knowledge and the inference engine makes it possible to represent knowledge in a more natural fashion. If … then … rules […] are closer to the way in which human beings describe their own problem-solving techniques than a program that embeds this knowledge in lower-level computer code. […] Because the knowledge base is separated from the program’s lower-level control structures, expert system builders can focus directly on capturing and organizing problem-solving knowledge rather than on the details of its computer implementation. […] The separation of knowledge and control, along with the modularity provided by rules and other representational structures used in building knowledge bases, allows changes to be made in one part of the knowledge base without creating side effects in other parts of the program. […] The separation of the knowledge and control elements of the program allows the same control and interface software to be used in a variety of systems. […]”

“Neurally inspired models, also known as parallel distributed processing (PDP) or connectionist systems, de-emphasize the explicit use of symbols in problem solving. […] Processing in these systems is distributed across collections or layers of neurons. Problem solving is parallel in the sense that all the neurons within the collection or layer process their inputs simultaneously and independently. […] In connectionist models there is, however, a strong representational character both in the creation of input parameters as well as in the interpretation of output values. To build a neural network, for example, the designer must create a scheme for encoding patterns in the world into numerical quantities in the net. The choice of an encoding scheme can play a crucial role in the eventual success or failure of the network to learn.

In connectionist systems, processing is parallel and distributed with no manipulation of symbols as symbols. Patterns in a domain are encoded as numerical vectors. The connections between components, or neurons, are also represented as numerical values. Finally, the transformation of patterns is the result of a numerical operation, usually, matrix multiplications. These “designer choices” for a connectionist architecture constitute the inductive bias of the system.

The algorithms and architectures that implement these techniques are usually trained or conditioned rather than explicitly programmed. Indeed, this is a major strength of the approach: an appropriately designed network architecture and learning algorithm can often capture invariances in the world, even in the form of strange attractors,7 without being explicitly programmed to recognize them.”

“challenge to satisfy the energy demand using green energy resources is to balance energy supply and demand. Territory design deals with the problem of grouping geographic areas into larger geographic clusters called territories in such a way that the grouping is acceptable according to a planning criterion. The aim of this study is to group geographic areas so that energy requirement in a geographic cluster matches the available green energy potential in the same cluster. In this way, investments may be supported through region specific policies. The problem is formulated as a mixed-integer linear programming model. A location-allocation approach is employed to solve the model. The location and allocation problems are solved iteratively. In order to solve the initial location problem, a Genetic Algorithm is developed to find the results of the p-median problem. Then, the allocation problem is solved optimally using the ILOG Cplex solver.”

“Annealing is the physical process of heating up a solid until it melts, followed by cooling it down until it crystallizes into a state with a perfect lattice. During this process, the free energy of the solid is minimized. Practice shows that the cooling must be done carefully in order not to get trapped in locally optimal lattice structures with crystal imperfections.

In combinatorial optimization, we can define a similar process. This process can be formulated as the problem of finding—among a potentially very large number of solutions— a solution with minimal cost. Now, by establishing a correspondence between the cost function and the free energy, and between the solutions and the physical states, we can introduce a solution method in the field of combinatorial optimization based on a simulation of the physical annealing process. The resulting method is called Simulated Annealing.

Salient features of this method are its general applicability and its ability to obtain solutions arbitrarily close to an optimum. A major drawback however is that finding high-quality solutions may require large computational efforts.

A substantial reduction of the computational effort required by the simulated annealing algorithm may be achieved by using computational models based on massively parallel execution. An example of such a model is the Boltzmann machine.

The Boltzmann machine is a neural network and belongs to the class of connectionist models. A Boltzmann machine consists of a large network of simple computing elements, called units, that are connected in some way. The units can have two states, either ‘on’ or ‘off’, and the connections have real-valued strengths that impose local constraints on the states of the individual units. A consensus function gives a quantitative measure for the ‘goodness’ of a global configuration of the Boltzmann machine, determined by the states of all individual units.”

1.3. Preliminary Notions in Nuclear Engineering, Concerning Fuel at Nuclear Reactor Plants

2. Safety, Materials, and Options for Nonproliferation Aims

3. Computer Tools for Designing Fuel Reload Configurations

3.1. Pressurized Water Reactors

3.2. Nuclear Fuel Cycle

3.3. Manual Design Packages

“Pressurized water reactor core designs have become more complex and must meet a plethora of design constraints. Trends have been toward longer cycles with increased discharge burnup, increased burnable absorber (BA) number, 19 mixed BA types, reduced radial leakage, axially blanketed fuel, and multiple-batch feed fuel regions. Obtaining economical reload core loading patterns (LPs) that meet design criteria is a difficult task to do manually. Automated LP search tools are needed. An LP search tool cannot possibly perform an exhaustive search because of the sheer size of the combinatorial problem. On the other hand, evolving complexity of the design features and constraints often invalidates expert rules based on past design experiences.”

3.4. Expert Systems

3.5. Validation by Simulations of the Reactor Physics

“Nodal diffusion is currently the preferred neutronics model for industrial reactor core calculations, which use few-group cross-section libraries generated via standard assembly homogenization. The infinite-medium flux-weighted cross sections fail to capture the spectral effects triggered in the core environment by nonreflective boundary conditions at the fuel-assembly edges. This poses a serious limitation to the numerical simulation of current- and next-generation reactor cores, characterized by strong interassembly heterogeneity.”

3.6. Ruleset Improvement, and the Involvement of Neural Revision

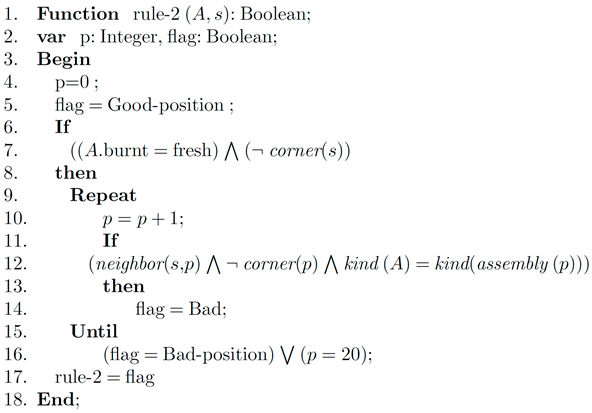

| Algorithm 1 Code written by Hava Siegelmann for the rule elimination rule: “Do not load a fresh assembly in such a position that is adjacent to another position where there is another assembly of the same kind, except when one of those two positions is in a corner position.” [193,194]. |

|

| Algorithm 2 Code written by Hava Siegelmann for the rule preference rule: “If it is a once-burned assembly that is currently being considered, then choose for it — from amongst those positions that were not forbidden by Rules 1 to 6 (the elimination rules)—that position whose distance from the centre of the core is minimal.” [193,194]. |

|

3.7. An Expert System Based on a Genetic Algorithm

3.8. A Survey of the Application of Other Techniques: Genetic, Fuzzy, Particle Swarm, Tabu Search, Simulated Annealing

“is a metaheuristic search method employing local search methods used for mathematical optimization. Local (neighborhood) searches take a potential solution to a problem and check its immediate neighbors (that is, solutions that are similar except for very few minor details) in the hope of finding an improved solution. Local search methods have a tendency to become stuck in suboptimal regions or on plateaus where many solutions are equally fit.

Tabu search enhances the performance of local search by relaxing its basic rule. First, at each step worsening moves can be accepted if no improving move is available (like when the search is stuck at a strict local minimum). In addition, prohibitions (henceforth the term tabu) are introduced to discourage the search from coming back to previously-visited solutions.

The implementation of tabu search uses memory structures that describe the visited solutions or user-provided sets of rules. If a potential solution has been previously visited within a certain short-term period or if it has violated a rule, it is marked as “tabu” (forbidden) so that the algorithm does not consider that possibility repeatedly.”

4. Current Trends

“Nuclear fuel cycle studies have provided a wealth of information on the potential impacts of advanced recycling systems. Deciding on fuel cycle implementation pathways, however, requires synthesizing volumes of data and navigating trade-offs between fuel cycle options. This research presents a framework intended to aid fuel cycle decision makers by focusing on the cost reduction/waste mitigation trade-off as a lens for choosing a near-term strategy. The framework consists of a fuel cycle simulation coupled to a decision tree model that maps evolution scenarios. System scenarios are constructed by considering the technological options for fuel cycle evolution and key uncertainties expected to affect the desirability of those options. For this study, the once-through fuel cycle is compared to a self-sustaining fast reactor (FR) fuel cycle. Scenarios are compared using a value function that incorporates cost and waste metrics. …”

“Experience with modeling fuel cycle options reveals that the large amount of generated data makes it difficult to understand trade-offs among fuel cycle policies. This paper shows that numerical optimization can be used to better identify impacts of fuel cycle policies and condense the generated data against a few significant criteria. The once-through cycle is considered the baseline case, while advanced technologies with fuel recycling characterize the alternative fuel cycle options available in the future. The options include, among others, recycling the fissile materials from spent light water reactor fuel in fast reactors (FRs) as well as deployment of innovative recycling reactor technologies, such as the 235U initiated FRs. Additionally, a first-of-a-kind optimization scheme for the nuclear fuel cycle analysis is described. Optimization metrics of interest to different stakeholders in the fuel cycle (economics, fuel resource utilization, high-level waste, transuranic materials/proliferation management, and environmental impact) are utilized for two different optimization techniques: a linear one and a stochastic one. …”

“In the breed and burn (B&B) strategy,24 low-reactivity fuels are loaded in a core. It is difficult to keep criticality in operating a small core. To enhance the potential for achieving criticality, the neutron economy in a core should be improved. One improvement method is to increase the core size and reduce neutron leakage. If it is necessary to avoid the large-sized core, another method is to locate high-reactivity fuels in high-neutron-importance region continuously through an equilibrium burnup state. On the other hand, to stabilize the change of neutron flux and power distribution during the operation, the B&B regions need to be kept stationary in the same region.

5. Concluding Remarks

Remark about the References

Funding

Acknowledgments

Conflicts of Interest

References

- Convolutional Neural Network. Available online: https://en.wikipedia.org/wiki/Convolutional_neural_network (accessed on 15 February 2019).

- Negnevitsky, M. Artificial Intelligence: A Guide to Intelligent Systems; Addison Wesley (of Pearson Education): Harlow, Essex, UK; Reading, MA, USA, 2002. [Google Scholar]

- Luger, G.F.; Stubblefield, W.A. Artificial Intelligence: Structures and Strategies for Complex Problem Solving, 3rd ed.; Addison Wesley Longman: Harlow, Essex, UK; Reading, MA, USA, 1998. [Google Scholar]

- Dyer, M.G. In-Depth Understanding: A Computer Model of Integrated Processing of Narrative Comprehension; The MIT Press: Cambridge, MA, USA, 1983. [Google Scholar]

- Schank, R.C.; Abelson, R.P. Scripts, Plans, Goals and Understanding: An Inquiry into Human Knowledge Structure; Lawrence Erlbaum Associates: Hillsdale, NJ, USA, 1977. [Google Scholar]

- Dean, T.; Allen, J.; Aloimonos, Y. Artificial Intelligence: Theory and Practice; Addison-Wesley: Menlo Park, CA, USA, 1995. [Google Scholar]

- Knuth, D.E. Sorting and Searching, Vol. 3 of His The Art of Computer Programming; Addison-Wesley: Reading, MA, USA, 1973. [Google Scholar]

- Korf, R. Depth-First Iterative Deepening: An Optimal Admissible Tree Search. Artificial Intelligence 1985, 29, 97–109. [Google Scholar] [CrossRef]

- Korf, R. Planning as Search: A Quantitative Approach. Artificial Intelligence 1987, 33, 65–88. [Google Scholar] [CrossRef]

- Pearl, J. A Solution for the Branching Alfa-Beta Pruning Algorithm and Its Optimality. Communications of the ACM 1982, 25, 559–564. [Google Scholar] [CrossRef]

- Mitchell, T.M. Generalization as Search. Artificial Intelligence 1982, 18, 203–226. [Google Scholar] [CrossRef]

- Pearl, J. Heuristics: Intelligent Strategies for Computer Problem Solving; Addison-Wesley: Reading, MA, USA, 1984. [Google Scholar]

- Davis, R. Knowledge Acquisition in Rule-Based Systems: Knowledge about Representation as a Basis for System Construction and Maintenance. In Pattern-Directed Inference Systems; Waterman, D.A., Hayes-Roth, F., Eds.; Academic Press: Orlando, FL, USA, 1978; pp. 99–134. [Google Scholar]

- Diaper, D. Knowledge Elicitation: Principles, Techniques and Applications; Ellis Horwood Limited: Chichester, West Sussex, UK, 1989. [Google Scholar]

- Cordingley, E.S. Knowledge-Elicitation Techniques for Knowledge-Based Systems. In Knowledge Elicitation: Principles, Techniques and Applications; Diaper, D., Ed.; Ellis Horwood Limited: Chichester, West Sussex, UK, 1989; Chapter 3; pp. 87–175. [Google Scholar]

- Hertz, J.; Krogh, A.; Palmer, R.G. Introduction to the Theory of Neural Computation; Addison Wesley: Redwood city, CA, USA, 1991. [Google Scholar]

- Zurada, J.M. Introduction to Artificial Neural Systems; West Publishing: New York, NY, USA, 1992. [Google Scholar]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization, and Machine Learning; Addison-Wesley: Reading, MA, USA, 1989. [Google Scholar]

- Davis, L. Handbook of Genetic Algorithms; Van Nostrand Reinhold: New York, NY, USA, 1996. [Google Scholar]

- Koza, J.R. Genetic Programming: On the Programming of Computers by Means of Natural Selection; The MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Koza, J.R. Genetic Programming II: Automatic Discovery of Reusable Programs; The MIT Press: Cambridge, MA, USA, 1994. [Google Scholar]

- Chambers, L. The Practical Handbook of Genetic Algorithms. Applications, 2nd ed.; Chapman & Hall/CRC: Boca Raton, FL, USA, 2001; Volume 1. [Google Scholar]

- Chambers, L.D. Practical Handbook of Genetic Algorithms. Complex. Coding Systems; CRC Press: Boca Raton, FL, USA, 1999; Volume 3. [Google Scholar]

- Ramirez Muñoz, A.; Garza Rodriguez, I. Handbook of Genetic Algorithms: New Research; Nova Science Publishers: New York, NY, USA, 2012. [Google Scholar]

- Cantú-Paz, E. Efficient and Accurate Parallel Genetic Algorithms; Kluwer Academic: Boston, MA, USA, 2000. [Google Scholar]

- Liepins, G.E. Genetic Algorithms in Artificial Intelligence; Thematic issue of Annals of Mathematics and Artificial Intelligence; Baltzer: Basel, Switzerland, 1992; Volume 5. [Google Scholar]

- Moghadampour, G. Genetic Algorithms, Parameter Control and Function Optimization: A New Approach; Acta Wasaensia, 160; Computer Science, 6; Universitas Wasaensis [University of Vaasa]: Vaasa, Finland, 2003. [Google Scholar]

- Rajasekaran, S.; Vijayalakshmi Pai, G.A. Neural Networks, Fuzzy Logic., and Genetic Algorithms: Synthesis and Applications; Eastern economy, ed.; Prentice-Hall of India: New Delhi, India, 2003. [Google Scholar]

- Jha, R.; Sen, P.K.; Chakraborti, N. Multi-Objective Genetic Algorithms and Genetic Programming Models for Minimizing Input Carbon Rates in a Blast Furnace Compared with a Conventional Analytic Approach. Steel Research International 2014, 85, 219–232. [Google Scholar] [CrossRef]

- Chakraborti, N. Critical Assessment 3: The Unique Contributions of Multi-Objective Evolutionary and Genetic Algorithms in Materials Research. Materials Science and Technology 2014, 30, 1259–1262. [Google Scholar] [CrossRef]

- Jeong, M.; Choi, J.-H.; Koh, B.-H. Performance Evaluation of Modified Genetic and Swarm-Based Optimization Algorithms in Damage Identification Problem. Structural Control and Health Monitoring 2013, 20, 878–889. [Google Scholar] [CrossRef]

- Yanik, S.; Sürer, Ö.; Öztayşi, B. Designing Sustainable Energy Regions Using Genetic Algorithms and Location-Allocation Approach. Energy 2016, 97, 161–172. [Google Scholar] [CrossRef]

- Steeb, W.-H. The Nonlinear Handbook: Chaos, Fractals, Cellular Automata, Neural Networks, Genetic Algorithms, Gene Expression Programming, Wavelets, Fuzzy Logic. with C++, Java, and SymbolicC++ Programs, 2nd ed.; World Scientific: London, UK; Singapore, 2002; 1st ed. was of 1999. [Google Scholar]

- Zadeh, L.A. Commonsense Knowledge Representation Based on Fuzzy Logic. Computer 1983, 16, 61–65. [Google Scholar] [CrossRef]

- Yager, R.R.; Zadeh, L.A. Fuzzy Sets, Neural Networks and Soft Computing; Van Nostrand Reinhold: New York, NY, USA, 1994. [Google Scholar]

- Ross, T. Fuzzy Logic with Engineering Applications; McGraw-Hill: New York, NY, USA, 1995. [Google Scholar]

- Davis, E. Representations of Commonsense Knowledge; Morgan Kaufmann: Los Altos, CA, USA, 1990. [Google Scholar]

- Hobbs, J.E.; Moore, R.C. Formal Theories of the Common Sense World; Ablex: Norwood, NJ, USA, 1985. [Google Scholar]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by Simulated Annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

- Aarts, E.H.L.; Korst, J. Simulated Annealing and Boltzmann Machines: A Stochastic Approach to Combinatorial Optimization and Neural Computing; Wiley: Chichester, West Sussex, UK, 1989. [Google Scholar]

- Types of Artificial Neural Networks. Available online: http://en.wikipedia.org/wiki/Types_of_artificial_neural_networks (accessed on 15 February 2019).

- Aguiar e Oliveira, H., Jr.; Ingber, L.; Petraglia, A.; Rembold Petraglia, M.; Soares Machado, M.A. Stochastic Global Optimization and Its Applications with Fuzzy Adaptive Simulated Annealing; Intelligent Systems Reference Library, 35; Springer: Berlin, Germany, 2012. [Google Scholar]

- Jung, J.; Jayakrishnan, R.; Park, J.Y. Dynamic Shared-Taxi Dispatch Algorithm with Hybrid-Simulated Annealing. Computer-Aided Civil and Infrastructure Engineering 2016, 31, 275–291. [Google Scholar] [CrossRef]

- Yu, V.-F.; Lin, S.-Y. Solving the Location-Routing Problem with Simultaneous Pickup and Delivery by Simulated Annealing. International Journal of Production Research 2016, 54, 526–549. [Google Scholar] [CrossRef]

- Bagheri Tolabi, H.; Hosseini, R.; Shakarami, M.R. A Robust Hybrid Fuzzy–Simulated Annealing–Intelligent Water Drops Approach for Tuning a Distribution Static Compensator Nonlinear Controller in a Distribution System. Engineering Optimization 2016, 48, 999–1018. [Google Scholar] [CrossRef]

- Arbalaez Garces, G.; Rakotondranaivo, A.; Bonjour, E. Improving Users’’ Product Acceptability: An Approach Based on Bayesian Networks and a Simulated Annealing Algorithm. International Journal of Production Research 2016, 54, 5151–5168. [Google Scholar] [CrossRef]

- Roshani, A.; Ghazi Nezami, F. Mixed-Model Multi-Manned Assembly Line Balancing Problem: A Mathematical Model and a Simulated Annealing Approach. Assembly Automation 2017, 37, 34–50. [Google Scholar] [CrossRef]

- Sen, G.; Krishnamoorthy, M.; Rangaraj, N.; Narayanan, V. Mathematical Models and Empirical Analysis of a Simulated Annealing Approach for Two Variants of the Static Data Segment Allocation Problem. Networks 2016, 68, 4–22. [Google Scholar] [CrossRef]

- Moschakis, I.A.; Karatza, H.D.; Mustafee, N.; Bessis, N.; Barolli, L.; Chen, X.; Xhafa, F. Towards Scheduling for Internet-of-Things Applications on Clouds: A Simulated Annealing Approach. Concurrency and Computation 2015, 27, 1886–1899. [Google Scholar] [CrossRef]

- Particle Swarm Optimization. Available online: https://en.wikipedia.org/wiki/Particle_swarm_optimization (accessed on 15 February 2019).

- Kennedy, J. The Particle Swarm: Social Adaptation of Knowledge. In Proceedings of the IEEE International Conference on Evolutionary Computation, Indianapolis, IN, USA, 13–16 April 1997; pp. 303–308. [Google Scholar]

- Trelea, I.C. The Particle Swarm Optimization Algorithm: Convergence Analysis and Parameter Selection. Information Processing Letters 2003, 85, 317–325. [Google Scholar] [CrossRef]

- Roy, R.; Dehuri, S.; Cho, S.B. A Novel Particle Swarm Optimization Algorithm for Multi-Objective Combinatorial Optimization Problem. International Journal of Applied Metaheuristic Computing (IJAMC) 2012, 2, 41–57. [Google Scholar] [CrossRef]

- Xinchao, Z. A perturbed Particle Swarm Algorithm for Numerical Optimization. Applied Soft Computing 2010, 10, 119–124. [Google Scholar] [CrossRef]

- Zhan, Z.-H.; Zhang, J.; Li, Y.; Chung, H.S.-H. Adaptive Particle Swarm Optimization. IEEE Transactions on Systems, Man, and Cybernetics 2009, 39, 1362–1381. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pedersen, M.E.H.; Chipperfield, A.J. Simplifying Particle Swarm Optimization. Applied Soft Computing 2010, 10, 618–628. [Google Scholar] [CrossRef]

- Kolodner, J.L. Case-Based Reasoning; Morgan Kaufmann: San Mateo, CA, USA, 1993. [Google Scholar]

- Schank, R.C.; Kass, A.; Riesbeck, C.K. Inside Case-Based Explanation; Lawrence Erlbaum Associates: Hillsdale, NJ, USA, 1994. [Google Scholar]

- Hammond, K.J. Case-Based Planning; Academic Press: New York, NY, USA, 1989. [Google Scholar]

- Hanks, S.; Weld, D.S. Systematic Adaptation for Case-Based Planning. In Proceedings of the First International Conference on Artificial Intelligence Planning Systems, College Park, MD, USA, 1992; Morgan Kaufmann Publishers Inc.: San Francisco, CA, USA, 1992; pp. 96–105. [Google Scholar]

- Leake, D.B. CBR in context: The present and the future. In Case-Based Reasoning: Experiences, Lessons, and Future Directions; Leake, D.B., Ed.; AAAI Press: Menlo Park, CA, USA; Cambridge, MA, USA; The MIT Press: Cambridge, MA, USA, 1996; Chapter 1. [Google Scholar]

- Veloso, M.; Aamodt, A. Case-Based Reasoning Research and Development: Proceedings of the First International Conference on Case-Based Reasoning; Springer: Berlin, Germany, 1995. [Google Scholar]

- Veloso, M. Planning and Learning by Analogical Reasoning; Springer: Berlin, Germany, 1994. [Google Scholar]

- Stranieri, A.; Zeleznikow, J. Knowledge Discovery from Legal Databases; Springer Law and Philosophy Library, 69; Springer: Dordrecht, The Netherlands, 2005. [Google Scholar]

- Bain, W.M. Case-Based Reasoning: A Computer Model of Subjective Assessment. Ph.D. Thesis, Computer Science Department, Yale University, New Haven, CT, USA, 1986. [Google Scholar]

- Bain, W.M. JUDGE. In Inside Case-Based Reasoning; Riesbeck, C.E., Schank, R.C., Eds.; Lawrence Erlbaum Associates: Hillsdale, NJ, USA, 1989; pp. 93–140. [Google Scholar]

- Bain, W.M. MICROJUDGE. In Inside Case-Based Reasoning; Riesbeck, C.E., Schank, R.C., Eds.; Lawrence Erlbaum Associates: Hillsdale, NJ, USA, 1989; pp. 141–163. [Google Scholar]

- Wooldridge, M. An Introduction to MultiAgent Systems; Wiley: Chichester, West Sussex, UK, 2002. [Google Scholar]

- Engelmore, R.; Morgan, T. Blackboard Systems; Addison-Wesley: Reading, MA, USA, 1988. [Google Scholar]

- Newell, A. Some Problems of the Basic Organisation in Problem Solving Programs. In Proceedings of the 2nd Conference on Self-Organizing Systems, Venezia, Italy, 20–24 October 2008; Yovits, M.C., Jacobi, G.T., Goldstein, G.D., Eds.; Spartan Books: Washington, DC, USA, 2008; pp. 393–423. [Google Scholar]

- Halabuk, D.; Navrat, T. Thermomechanical Assessment of Fuel Rod Cladding Made of Zirconium Alloy and Silicon Carbide Material During Reactivity-Initiated Accident. Nuclear Science and Engineering 2018, 189, 69–81. [Google Scholar] [CrossRef]

- Cochran, R.G.; Tsoulfanidis, N. The Nuclear Fuel Cycle: Analysis and Management; American Nuclear Society: La Grange Park, IL, USA, 1990. [Google Scholar]

- Unsigned. Perry’s 29-Day Refueling Outage Is Shortest in Its Operating History. Nuclear News (American Nuclear Society) 2017, 60, 42–48. Available online: http://cdn.ans.org/advertising/nn/docs/october2017.pdf (accessed on 15 February 2019).

- Ballesteros, A.; Sanda, R.; Maqua, M.; Stephan, J.-L. Operational Experience Data Analysis on Events Related to Maintenance at Nuclear Power Plants. Nuclear Science and Engineering 2016, 184, 575–583. [Google Scholar] [CrossRef]

- Duthie, J.C.; Robertson, M.I.; Clayton, A.M.; Lidbury, D.P.G. Risk-Based Approaches to Ageing and Maintenance Management. Nuclear Engineering and Design 1998, 184, 27–38. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Yu, S.D. Simulation of Unsteady Flow Through a String of CANDU Fuel Bundles in a Pressure Tube. Nuclear Science and Engineering 2013, 174, 60–78. [Google Scholar] [CrossRef]

- Martin, C.R. January Meeting Highlights. Notes & News (American Nuclear Society, Washington DC Section). March 2006, pp. 4–6. Available online: http://local.ans.org/dc/wp-content/uploads/2014/01/2006mar.pdf (accessed on 15 February 2019).

- Lapa, C.M.F.; Pereira, C.M.N.A.; de Mol, A.C.A. Maximization of a Nuclear System Availability Through Maintenance Scheduling Optimization Using a Genetic Algorithm. Nuclear Engineering and Design 2000, 196, 219–231. [Google Scholar] [CrossRef]

- Havlíček, L. Nuclear Fuel Cycle Evaluation and Real Options. Acta Polytechnica 2008, 48, 30–34. Available online: http://ctn.cvut.cz/ap/download.php?id=301 (accessed on 15 February 2019).

- Turinsky, P.J.; Parks, G.T. Advances in Nuclear Fuel Management for Light Water Reactors. In Advances in Nuclear Science and Technology; Lewins, J., Becker, M., Eds.; Springer: Berlin, Germany, 2002; Volume 26, pp. 137–165. [Google Scholar]

- International Atomic Energy Agency [IAEA]. Safety of Nuclear Power Plants: Design; Specific Safety Requirements: IAEA Safety Standards Series No. SSR-2/1 (Revision 1); International Atomic Energy Agency: Vienna, Austria, 2016. [Google Scholar]

- Electric Power Research Institute. Guidance for the Design and Use of Automation in Nuclear Power Plants; Report No. 1011851; Electric Power Research Institute: Palo Alto, CA, USA, 2005. [Google Scholar]

- Boring, R.L. As Low as Reasonable Assessment (ALARA): Applying Discount Usability to Control Room Verification and Validation. In Risk, Reliability and Safety: Innovating Theory and Practice; Walls, L., Revie, M., Bedford, T., Eds.; Taylor & Francis Group: London, UK, 2017; pp. 950–955. [Google Scholar]

- Boring, R.L.; Ulrich, T.A.; Joe, J.C.; Lewb, R.T. Guideline for Operational Nuclear Usability and Knowledge Elicitation (GONUKE). In Proceedings of the 6th International Conference on Applied Human Factors and Ergonomics, Las Vegas, NV, USA, 26–30 July 2015. [Google Scholar]

- Harunuzzaman, M.; Aldemir, T. Optimization of Standby Safety System Maintenance Scheduling in Nuclear Power Plants. Nuclear Technology 1996, 113, 354–367. [Google Scholar] [CrossRef]

- Fischetti, M.A. Inherently Safe Reactors: They’d Work If We’d Let Them. IEEE Spectrum 1987, 24, 28–33. [Google Scholar] [CrossRef]

- Hale, A.; Kirwan, B.; Kjellén, U. Safe by Design: Where Are We Now? Safety Science 2007, 45, 305–327. [Google Scholar] [CrossRef]

- Hollnagel, E. A tale of two safeties. Nuclear Safety and Simulation 2013, 4, 1–9. [Google Scholar]

- Bajorek, S.M. A Regulator’s Perspective on the State of the Art in Nuclear Thermal Hydraulics. Nuclear Science and Engineering 2016, 184, 305–311, Concerning Bajorek: an understanding of thermal hydraulics, its basic phenomena, and its application to nuclear power plants is vital to safe as well as efficient design and operation. There remain safety issues, and the licensing of new light water reactor designs or new analysis methodologies is rarely simple. [Google Scholar] [CrossRef]

- Peplow, D.E.; Sulfredge, C.D.; Sanders, R.L.; Morris, R.H.; Hann, T.A. Calculating Nuclear Power Plant Vulnerability Using Integrated Geometry and Event/Fault-Tree Models. Nuclear Science and Engineering 2004, 146, 71–87. [Google Scholar] [CrossRef]

- Sermer, P.; Hoppe, F.M.; Pun-Quach, D.; Weaver, K.R.; Olive, C.; Cheng, I. Statistical Foundation for Decision Making in Nuclear Safety–Related Problems Using Best Estimate Plus Uncertainty Analyses. Nuclear Science and Engineering 2014, 178, 119–155. [Google Scholar] [CrossRef]

- Roberts, J.A.; Rearden, B.T.; Wilson, P.P.H. Determination and Application of Partial Biases in Criticality Safety Validation. Nuclear Science and Engineering 2013, 173, 43–57. [Google Scholar] [CrossRef]

- Ranta, T.; Cameron, F. Heuristic Methods for Assigning Spent Nuclear Fuel Assemblies to Canisters for Final Disposal. Nuclear Science and Engineering 2012, 171, 41–51. [Google Scholar] [CrossRef]

- Sheu, R.J.; Chen, A.Y.; Liu, Y.-W.H.; Jiang, S.H. Shielding Calculations for a Spent Fuel Storage Cask: A Comparison of Discrete Ordinates, Monte Carlo, and Hybrid Methods. Nuclear Science and Engineering 2009, 159, 23–36. [Google Scholar] [CrossRef]

- Zerovnik, G.; Snoj, L.; Ravnik, M. Optimization of Spent Nuclear Fuel Filling in Canisters for Deep Repository. Nuclear Science and Engineering 2009, 163, 183–190. [Google Scholar] [CrossRef]

- Hummel, A.J.; Palmer, T.S. Analysis of Multiple TRIGA-Based Molybdenum Production Reactor Cores Using a New Low-Enriched Uranium Target as Fuel. Nuclear Science and Engineering 2016, 183, 149–159. [Google Scholar] [CrossRef]

- Burr, T.; Trellue, H.; Tobin, S.; Favalli, A.; Dowell, J.; Henzl, V.; Mozin, V. Integrated Nondestructive Assay Systems to Estimate Plutonium in Spent Fuel Assemblies. Nuclear Science and Engineering 2015, 179, 321–332. [Google Scholar] [CrossRef]

- Youinou, G.; Vasile, A. Plutonium Multirecycling in Standard PWRs Loaded with Evolutionary Fuels. Nuclear Science and Engineering 2005, 151, 25–45. [Google Scholar] [CrossRef]

- Monti, L.; Lee, K.-B.; Fratoni, M.; Sumini, M.; Greenspan, E. Recycling-Independent Core Design for the ENHS Fuel Self-Sustaining Reactor. Nuclear Science and Engineering 2009, 161, 1–21. [Google Scholar] [CrossRef]

- Peltz, J.J.; Cacuci, D.G. Predictive Modeling Applied to a Spent Fuel Dissolver Model—I: Adjoint Sensitivity Analysis. Nuclear Science and Engineering 2016, 183, 305–331. [Google Scholar] [CrossRef]

- Peltz, J.J.; Cacuci, D.G.; Badea, A.F.; Badea, M.C. Predictive Modeling Applied to a Spent Fuel Dissolver Model—II: Uncertainty Quantification and Reduction. Nuclear Science and Engineering 2016, 183, 332–346. [Google Scholar] [CrossRef]

- Peltz, J.J.; Cacuci, D.G. Inverse Predictive Modeling of a Spent-Fuel Dissolver Model. Nuclear Science and Engineering 2016, 184, 1–15. [Google Scholar] [CrossRef]

- Talamo, A.; Gudowski, W. A Deep Burn Fuel Management Strategy for the Incineration of Military Plutonium in the Gas Turbine-Modular Helium Reactor Modeled in a Detailed Three-Dimensional Geometry by the Monte Carlo Continuous Energy Burnup Code. Nuclear Science and Engineering 2006, 153, 172–183. [Google Scholar] [CrossRef]

- Pilat, J.F.; Busch, N.E. Routledge Handbook of Nuclear Proliferation and Policy; Routledge: London, UK, 2017. [Google Scholar]

- Ronen, Y.; Aboudy, M.; Regev, D. Proliferation-Resistant Fuel for CANDU Reactors. Nuclear Science and Engineering 2012, 170, 16–26. [Google Scholar] [CrossRef]

- Whitlock, J. Comments on “Proliferation-Resistant Fuel for CANDU Reactors”. Nuclear Science and Engineering 2013, 173, 99. [Google Scholar]

- Ronen, Y. Reply to “Comments on ‘Proliferation-Resistant Fuel for CANDU Reactors’”. Nuclear Science and Engineering 2013, 173, 99. [Google Scholar]

- Zacharia, J. Friendly Fuel: A Tel Aviv Scientist Promises an Energy Revolution, Through Nuclear Power That Can’t Be Misused for Bomb-Building. The Jerusalem Report, 7 August 1997; 24–25. [Google Scholar]

- Chang, K. Alvin Radkowsky, 86, Developer of a Safer Nuclear Reactor Fuel. New York Times. 5 March 2002. Available online: http://www.nytimes.com/2002/03/05/world/alvin-radkowsky-86-developer-of-a-safer-nuclear-reactor-fuel.html (accessed on 15 February 2019).

- Nuclear Poison. Available online: http://en.wikipedia.org/wiki/Nuclear_poison (accessed on 15 February 2019).

- History. Available online: http://www.thoriumpower.com/english/about/history.htm (accessed on 15 February 2019).

- Kasten, P.R. Review of the Radkowsky Thorium Reactor. Science & Global Security 1998, 7, 237–269. [Google Scholar]

- Galperin, A. Utilization of Thorium in Light Water Reactors. Nuclear Science and Engineering 1984, 86, 112–115. [Google Scholar] [CrossRef]

- Galperin, A. Feasibility of the Once-Through Thorium Fuel Cycle for CANDU Reactors. Nuclear Technology USA 1986, 73, 343–349. [Google Scholar] [CrossRef]

- Radkowski, A.; Galperin, A. The Nonproliferative Light Water Thorium Reactor: A New Approach to Light Water Reactor Core Technology. Nuclear Technology 1998, 124, 215–222. [Google Scholar] [CrossRef]

- Morozov, A.G.; Galperin, A.; Todosow, M. Thorium-Based Fuel Cycle for VVERs & PWRs: A Nonproliferative Solution to Renew Nuclear Power. Nuclear Engineering International 1999, 44, 13–14. [Google Scholar]

- Galperin, A.; Reichert, P.; Radkowsky, A. Thorium Fuel for Light Water Reactors—Reducing Proliferation Potential of Nuclear Power Fuel Cycle. Science & Global Security 1997, 6, 265–290. [Google Scholar]

- Galperin, A.; Segev, M.; Todosow, M. Pressurized Water Reactor Plutonium Incinerator Based on Thorium Fuel and Seed-Blanket Assembly Geometry. Nuclear Technology 2000, 132, 214–226. [Google Scholar] [CrossRef]

- Galperin, A.; Shwageraus, E.; Todosow, M. Assessment of Homogeneous Thorium/Uranium Fuel for Pressurized Water Reactors. Nuclear Technology 2002, 138, 111–122. [Google Scholar] [CrossRef]

- Todosow, M.; Galperin, A.; Morozov, A.G. A Novel Nonproliferative Thorium-Based Seed-Blanket Fuel Concept for PWRs. Transactions of the American Nuclear Society (USA) 1999, 80, 46–47. [Google Scholar]

- Todosow, M.; Galperin, A.; Herring, S.; Kazimi, M.; Downar, T.; Morozov, A. Use of Thorium in Light Water Reactors. Nuclear Technology 2005, 151, 168–176. [Google Scholar] [CrossRef]

- Yamanaka, M.; Pyeon, C.H.; Yagi, T.; Misawa, T. Accuracy of Reactor Physics Parameters in Thorium-Loaded Accelerator-Driven System Experiments at Kyoto University Critical Assembly. Nuclear Science and Engineering 2016, 183, 96–106. [Google Scholar] [CrossRef]

- Pyeon, C.H.; Yagi, T.; Sukawa, K.; Yamaguchi, Y.; Misawa, T. Mockup Experiments on the Thorium-Loaded Accelerator-Driven System at the Kyoto University Critical Assembly. Nuclear Science and Engineering 2014, 177, 156–168. [Google Scholar] [CrossRef]

- Colton, A.V.; Bromley, B.P.; Wojtaszek, D.; Dugal, C. Evaluation of Uranium-Based Fuels Augmented by Low Levels of Thorium for Near-Term Implementation in Pressure Tube Heavy Water Reactors. Nuclear Science and Engineering 2017, 186, 48–65. [Google Scholar] [CrossRef]

- Bromley, B.P.; Edwards, G.W.R.; Sambavalingam, P. Effects and Modeling of Power History in Thorium-Based Fuels in Pressure-Tube Heavy Water Reactors. Nuclear Science and Engineering 2016, 182, 263–286. [Google Scholar] [CrossRef]

- Dolan, T.J. Molten Salt Reactors and Thorium Energy; Elsevier: Amsterdam, The Netherlands, 2017; Dolan is a comprehensive reference on the status of research into molten salt reactors (MSR) and thorium fuel utilization. Written in cooperation with the International Thorium Molten-Salt Forum. [Google Scholar]

- Singh, I.; Gupta, A.; Kannan, U. Studies on Reactivity Coefficients of Thorium-Based Fuel (Th-233U)O2 with Molten Salt (Flibe) Cooled Pebble. Nuclear Science and Engineering 2018, 191, 161–177. [Google Scholar] [CrossRef]

- Utilization of Thorium in Light Water Reactors—Radkowsky Thorium Fuel (RTF). Webpage Update of 18 Dec. 2005. Available online: http://web.bgu.ac.il/Eng/engn/nuclear/research/NucEnergy/ (accessed on 15 February 2019).

- Galperin, A. Gd Burnable Poison System for Reactivity Control of the First Cycle of a PWR. Annals of Nuclear Energy (UK) 1987, 14, 53–57. [Google Scholar] [CrossRef]

- Galperin, A.; Segev, M.; Radkowsky, A. Substitution of the Soluble Boron Reactivity Control System of a Pressurized Water Reactor by Gadolinium Burnable Poisons. Nuclear Technology (USA) 1986, 75, 127–133. [Google Scholar] [CrossRef]

- Galperin, A.; Segev, M.; Radkowsky, A. The Effect of Boron and Gadolinium Burnable Poisons on the Hot-to-Cold Reactivity Swing of a Pressurized Water Reactor Assembly. Nuclear Technology (USA) 1986, 75, 123–126. [Google Scholar] [CrossRef]

- Galperin, A.; Foskolos, K.; Grimm, P.; Knoglinger, E.; Maeder, C. The Poison Zoning Technique for Power Peaking Control in District Heating Boiling Water Reactors. Kerntechnik (West Germany) 1987, 50, 170–172. [Google Scholar]

- Galperin, A.; Grimm, P.; Raizes, V. Modeling and Verification of the PWR Burnable Poison Designs by Elcos Code System. Annals of Nuclear Energy 1995, 22, 317–325. [Google Scholar] [CrossRef]

- Liu, B.; Fu, J.; Lyu, X.; Li, W.; Han, J. Three Loading Patterns for 99Tc Transmutation in PWR Burnable Poison Rods. Nuclear Science and Engineering 2018, 192, 298–310. [Google Scholar] [CrossRef]

- Kang, Y.-R.; Lee, M.W.; Kim, G.N.; Ro, T.-I.; Danon, Y.; Williams, D.; Leinweber, G.; Block, R.C.; Barry, D.P.; Rapp, M.J. Neutron Capture Measurements and Resonance Parameters of Gadolinium. Nuclear Science and Engineering 2015, 180, 86–116. [Google Scholar] [CrossRef]

- Lee, D.; Rhodes, J.; Smith, K. Quadratic Depletion Method for Gadolinium Isotopes in CASMO-5. Nuclear Science and Engineering 2013, 174, 79–86. [Google Scholar] [CrossRef]

- Tran, H.N.; Kato, Y.; Muto, Y. Optimization of Burnable Poison Loading for HTGR Cores with OTTO Refueling. Nuclear Science and Engineering 2008, 158, 264–271. [Google Scholar] [CrossRef]

- Andersson, M.; Blanchet, D.; Nylén, H.; Jacqmin, R. Control Rod Calculation in Axially Heterogeneous Fast Reactors—I: Influence of the Absorber Environment. Nuclear Science and Engineering 2017, 185, 263–276. [Google Scholar] [CrossRef]

- Andersson, M.; Blanchet, D.; Nylén, H.; Jacqmin, R. Control Rod Calculation in Axially Heterogeneous Fast Reactors—II: Impact of Three-Dimensional Homogenization on Core Parameters. Nuclear Science and Engineering 2017, 185, 277–293. [Google Scholar] [CrossRef]

- Andersson, M.; Blanchet, D.; Nylén, H.; Jacqmin, R. Influence of Local Spectral Variations on Control-Rod Homogenization in Fast Reactor Environments. Nuclear Science and Engineering 2015, 181, 204–215. [Google Scholar] [CrossRef]

- Blanchet, D.; Fontaine, B. Control Rod Depletion in Sodium-Cooled Fast Reactor: Models and Impact on Reactivity Control. Nuclear Science and Engineering 2014, 177, 260–274. [Google Scholar] [CrossRef]

- Pascal, V.; Prulhière, G.; Vanier, M.; Fontaine, B. Interpretation of the Control Rod Withdrawal Test in the Sodium-Cooled Fast Reactor Phénix. Nuclear Science and Engineering 2013, 175, 109–123. [Google Scholar] [CrossRef]

- Galperin, A.; Nissan, E. Application of a Heuristic Search Method for Generation of Fuel Reload Configurations. Nuclear Science and Engineering 1988, 99, 343–352. [Google Scholar] [CrossRef]

- Nissan, E. Intelligent Technologies for Electric and Nuclear Power Systems; Special issue of the journal Computers and Artificial Intelligence; The Slovak Academy of Sciences: Bratislava, Slovakia, 1998; Volume 17. [Google Scholar]

- Nissan, E. Forum on Refuelling Techniques for Nuclear Power Plants: One Decade with FUELCON. Thematic Section; In the journal New Review of Applied Expert Systems; Taylor Graham: London, UK, 1998; Volume 4, pp. 139–194. [Google Scholar]

- Nissan, E. Legal Evidence, Police Investigation, Case Argumentation, and Computer Tools; Law, Governance and Technology Series, 5; Springer: Dordrecht, The Netherlands, 2012; 2 volumes. [Google Scholar]

- Nissan, E. Knowledge Engineering for Word-Formation: Generating and Evaluating Candidate Neologisms. In Language, Culture, Computation: Essays Dedicated to Yaacov Choueka, Volume 3: Computational Linguistics and Linguistics; Dershowitz, N., Nissan, E., Eds.; LNCS, Volume 8003; Springer: Heidelberg/Berlin, Germany, 2014; pp. 365–434. [Google Scholar]

- Nissan, E. Epistemic Formulae, Argument Structures, and a Narrative on Identity and Deception: A Formal Representation from the AJIT Subproject Within AURANGZEB. Annals of Mathematics and Artificial Intelligence 2008, 54, 293–362. [Google Scholar] [CrossRef]

- Nissan, E. Modelli informatici dell’uomo: un’esperienza a 360 gradi. In Uomini e Macchine; Negrotti, M., Ed.; I Quaderni della Associazione Francesco Barone; Armando Editore: Rome, Italy, 2017; pp. 247–272, Table of contents of this chapter, on p. 8. [Google Scholar]

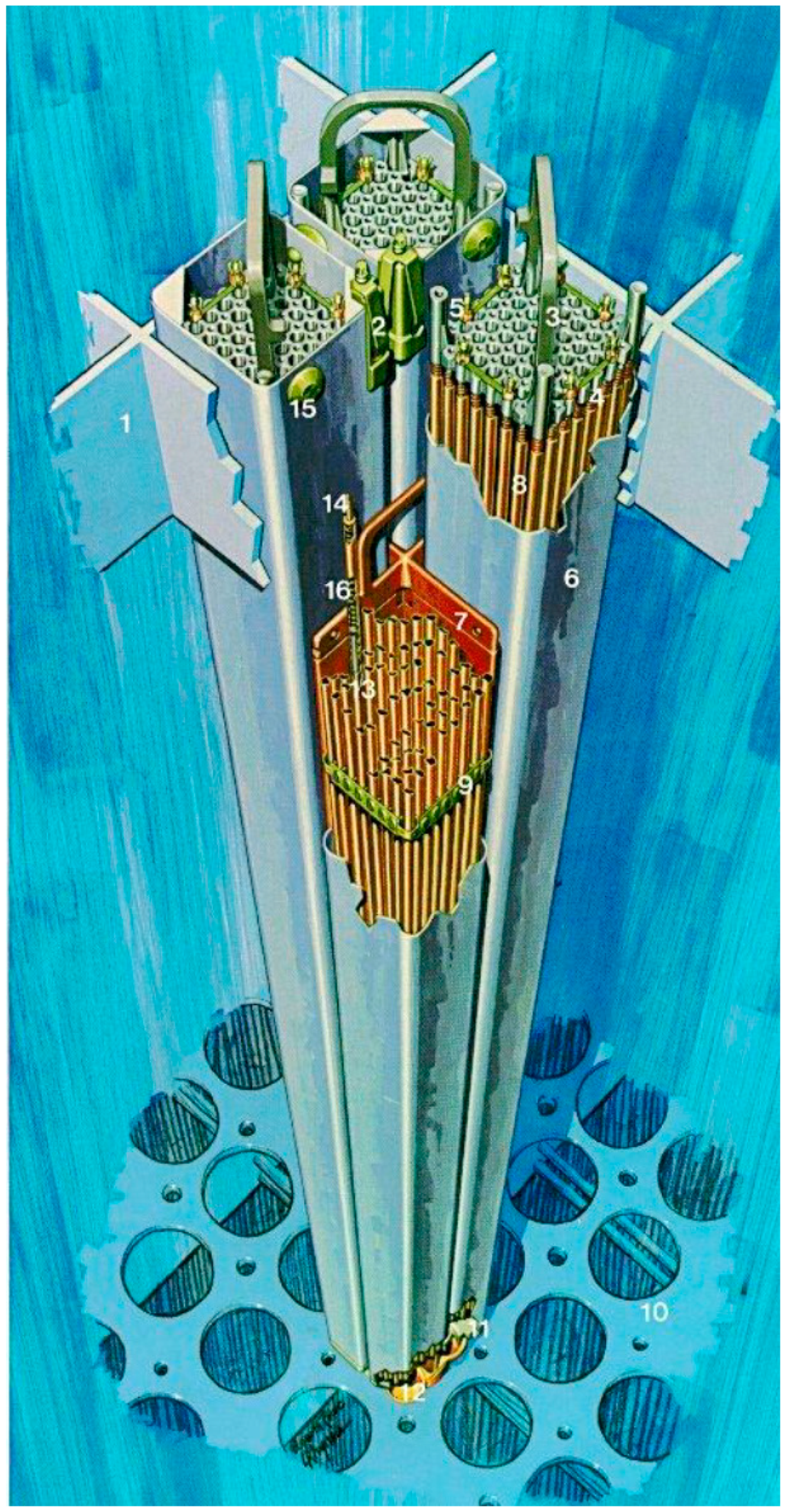

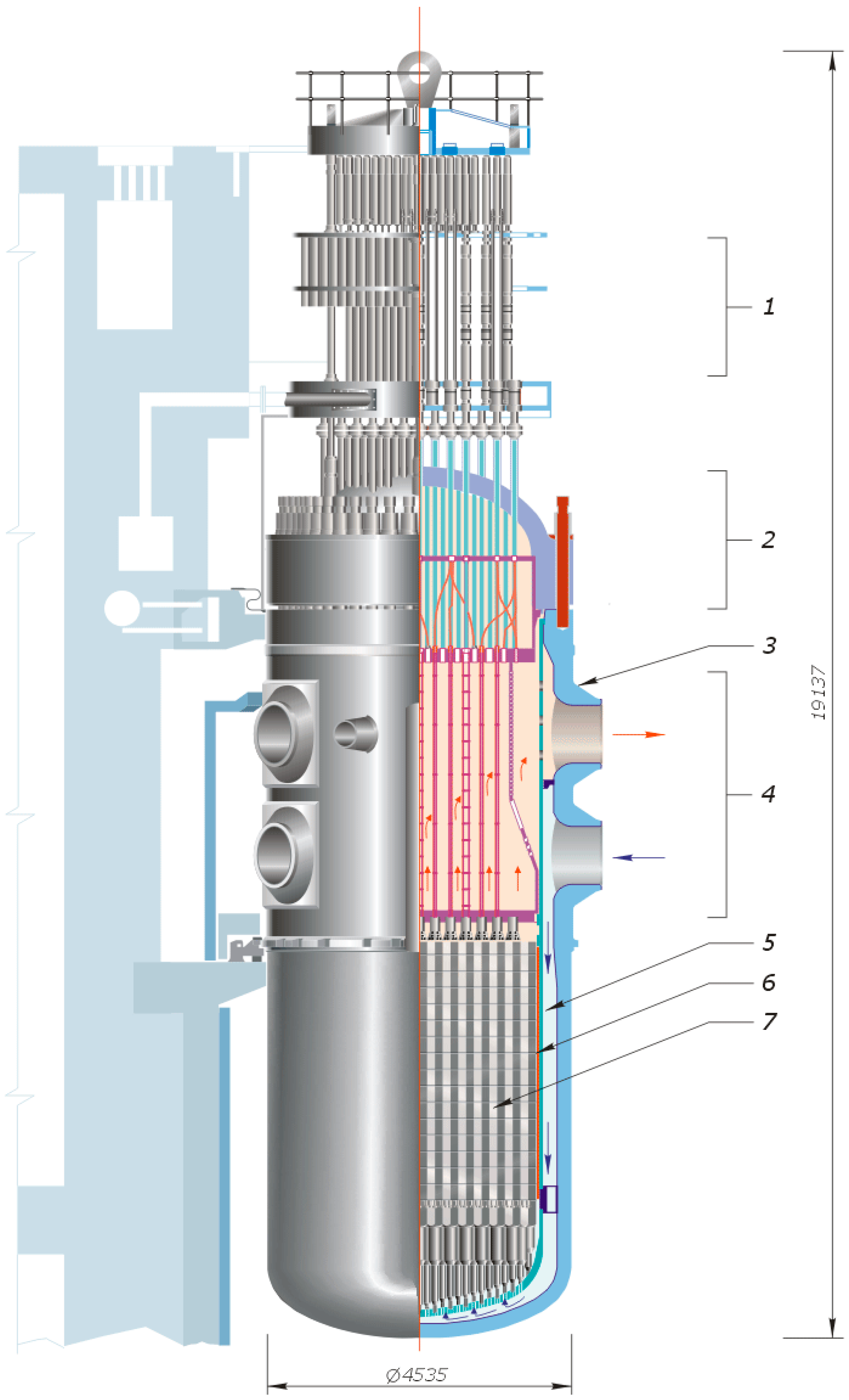

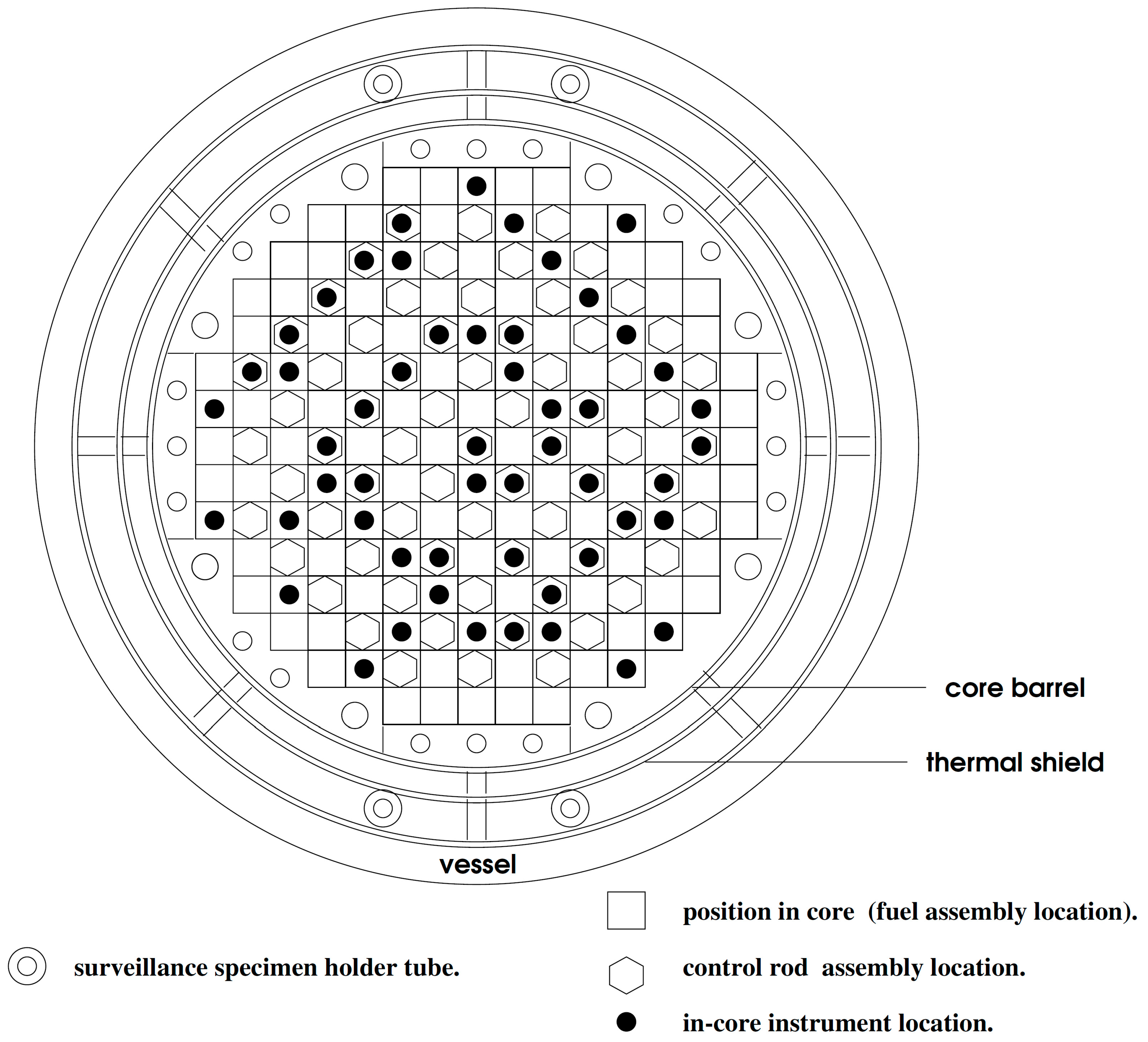

- Pressurized Water Reactor. Available online: http://en.wikipedia.org/wiki/Pressurized_water_reactor (accessed on 15 February 2019).

- Chao, Y.A.; Alsop, B.H.; Johansen, B.J.; Morita, T. Westinghouse Loading Pattern Search Methodology for Complex Core Designs. In Proceedings of the Annual meeting of the American Nuclear Society (ANS), Orlando, FL, USA, 2–6 June 1991. Transactions of the American Nuclear Society 1991, 63, 409–410. [Google Scholar]

- Parks, G.T.; Lewins, J.D. In-Core Fuel Management and Optimization: The State of the Art. Nuclear Europe Worldscan 1992, 12, 41. [Google Scholar]

- Alsop, B.H.; Chao, Y.A.; Johansen, B.J.; Morita, T. Evaluation and Performance of Westinghouse Loading Pattern Search Methodology. In Proceedings of the International Topical Meeting on Advances in Mathematics, Computations, and Reactor Physics, Pittsburgh, PA, USA, April 18–May 2 1991. Part 5, 22.2, 2–1. [Google Scholar]

- Faught, W.S. Prototype Fuel Shuffling System Using a Knowledge-Based Toolkit; Technical Report; IntelliCorp: Mountain View, CA, USA, 1987. [Google Scholar]

- Poetschat, G.R.; Rothleder, B.M.; Faught, W.S.; Eich, W.J. Interactive Fuel Shuffle Assistant Graphics Interface and Automation for Nuclear Fuel Shuffle with PDQ7. In Proceedings of the Topical Meeting on Advances in Fuel Management, Pinehurst, NC, USA, 2–5 March 1986; American Nuclear Society: La Grange, IL, USA, 1986. [Google Scholar]

- Rothleder, B.M.; Poetschat, G.R.; Faught, W.S.; Eich, W.J. The Potential for Expert System Support in Solving the Pressurized Water Reactor Fuel Shuffling Problem. Nuclear Science and Engineering 1988, 100, 440–450. [Google Scholar] [CrossRef]

- Tahara, Y.; Hamamoto, K.; Takase, M. Computer Aided System for Generating Fuel Shuffling Configuration Based on Knowledge Engineering. Journal of Nuclear Science and Technology 1991, 28, 399–408. [Google Scholar] [CrossRef]

- Bernard, J.A.; Washio, T. Expert Systems Applications Within the Nuclear Industry; American Nuclear Society: La Grange Park, IL, USA, 1989. [Google Scholar]

- Jardon, P.; Dubois, D. NUCLEXPERT: Un progiciel d’Intelligence Artificielle pour l’optimisation des séquences de rechargement de centrales nucléaires. Nouvelles de la Science et des Technologies 1986, 4, 99–102. [Google Scholar]

- Smith, D.E. Documentation of Knowledge in the Development of CLEO, a Refueling Assistant for FFTF. In Proceedings of the ANS International Topical Meeting on Artificial Intelligence and Other Innovative Computer Applications in the Nuclear Industry; Majumdar, D., Sackett, J., Eds.; Plenum Press: New York, NY, USA, 1988; p. 607 ff. [Google Scholar]

- Smith, D.E.; Kocher, L.F.; Seeman, S.E. CLEO: A Knowledge-Based Refueling Assistant at FFTF. [FFTF = Fast Flux Test Facility.]. In Proceedings of the American Nuclear Society Winter Meeting, San Francisco, CA, USA, 10 November 1985. [Google Scholar]

- Naser, J.; Colley, R.; Gaiser, J.; Brookmire, T.; Engle, S. A Fuel Insert Shuffle Planner Expert System. In Proceedings of the 1987 Conference on Expert-System Applications in Power Plants, Boston, MA, USA, 27–29 May 1987; Divakaruni, S.M., Cain, D., Baytch, E., Saylor, C., Eds.; Electric Power Research Institute (EPRI): Palo Alto, CA, USA, 1988; pp. 5-19–5-30. [Google Scholar]

- Naser, J.; Colley, R.; Gaiser, J.; Brookmire, T.; Engle, S. Fuel Insert Shuffler: A Case Study of Expert System Development. In Proceedings of the ANS International Topical Meeting on Artificial Intelligence and Other Innovative Computer Applications in the Nuclear Industry, Snowbird, UT, USA, 31 August–2 September 1988; Majumdar, D., Sackett, J., Eds.; Plenum Press: New York, NY, USA, 1988; pp. 625–633. [Google Scholar]

- Baranov, S. Examples of Control Units Design. In Logic. Synthesis for Control. Automata; Kluwer (now Springer): Dordrecht, The Netherlands, 1994; Chapter 8; pp. 340–386. [Google Scholar]

- Galperin, A. Exploration of the Search Space of the In-Core Fuel Management Problem by Knowledge-Based Techniques. Nuclear Science and Engineering 1985, 119, 144–152. [Google Scholar] [CrossRef]

- Li, Z.; Levine, H. AUTOLOAD, an Automatic Optimal Pressurized Water Reactor Reload Design System with an Expert Module. Nuclear Science and Engineering 1994, 118, 67–78. [Google Scholar] [CrossRef]

- Parks, G.T.; Turinsky, P.J.; Maldonado, G.I. Solving the PWR Reload Core Optimization Problem. In Scientific Excellence in Supercomputing, The IBM 1990 Contest Prize Papers; Baldwin Press: Athens, GA, USA, 1992; Volume 1, pp. 281–310. [Google Scholar]

- Lin, K.-J.; Lin, C. Pressurized Water Reactor Reload Design by an Expert System. Nuclear Science and Engineering 1998, 130, 128–140. [Google Scholar] [CrossRef]

- Galperin, A.; Kimhi, S.; Segev, M. A Knowledge-Based System for Optimization of Fuel Reload Configurations. Nuclear Science and Engineering 1989, 102, 43–53. [Google Scholar] [CrossRef]

- Kimhi [sic], Y. A Non-Algorithmic Approach to the In-Core Fuel Management Problem of a PWR Core. Ph.D. Thesis, Nuclear Engineering, Ben-Gurion University of the Negev, Beer-Sheva, Israel, 1992. [Kimhi’s forename is “Yehoshua”; the form “Shuky” is also used.]. (In Hebrew). [Google Scholar]

- Galperin, A.; Kimhy [sic], S. Application of Knowledge-Based Methods to In-Core Fuel Management. Nuclear Science and Engineering 1991, 109, 103–110. [Google Scholar] [CrossRef]

- Galperin, A.; Kimhi, S.; Nissan, E. Fuelcon: An Expert System for Assisting the Practice and Research of In-Core Fuel Management and Optimal Design in Nuclear Engineering. Computers and Artificial Intelligence 1993, 12, 369–415. [Google Scholar]

- Nissan, E.; Galperin, A. Refueling in Nuclear Engineering: The FUELCON Project. Computers in Industry 1998, 37, 43–54. [Google Scholar] [CrossRef]

- Nissan, E. The FUELCON Meta-Architecture, in the Landscape of Intelligent Technologies for Refuelling. New Review of Applied Expert Systems (Taylor Graham: London, UK) 1998, 4, 141–149. [Google Scholar]

- Galperin, A.; Nissan, E. The FUELCON Meta-Architecture, II: Alternatives for Parameter Prediction. New Review of Applied Expert Systems (Taylor Graham: London, UK) 1998, 4, 151–161. [Google Scholar]

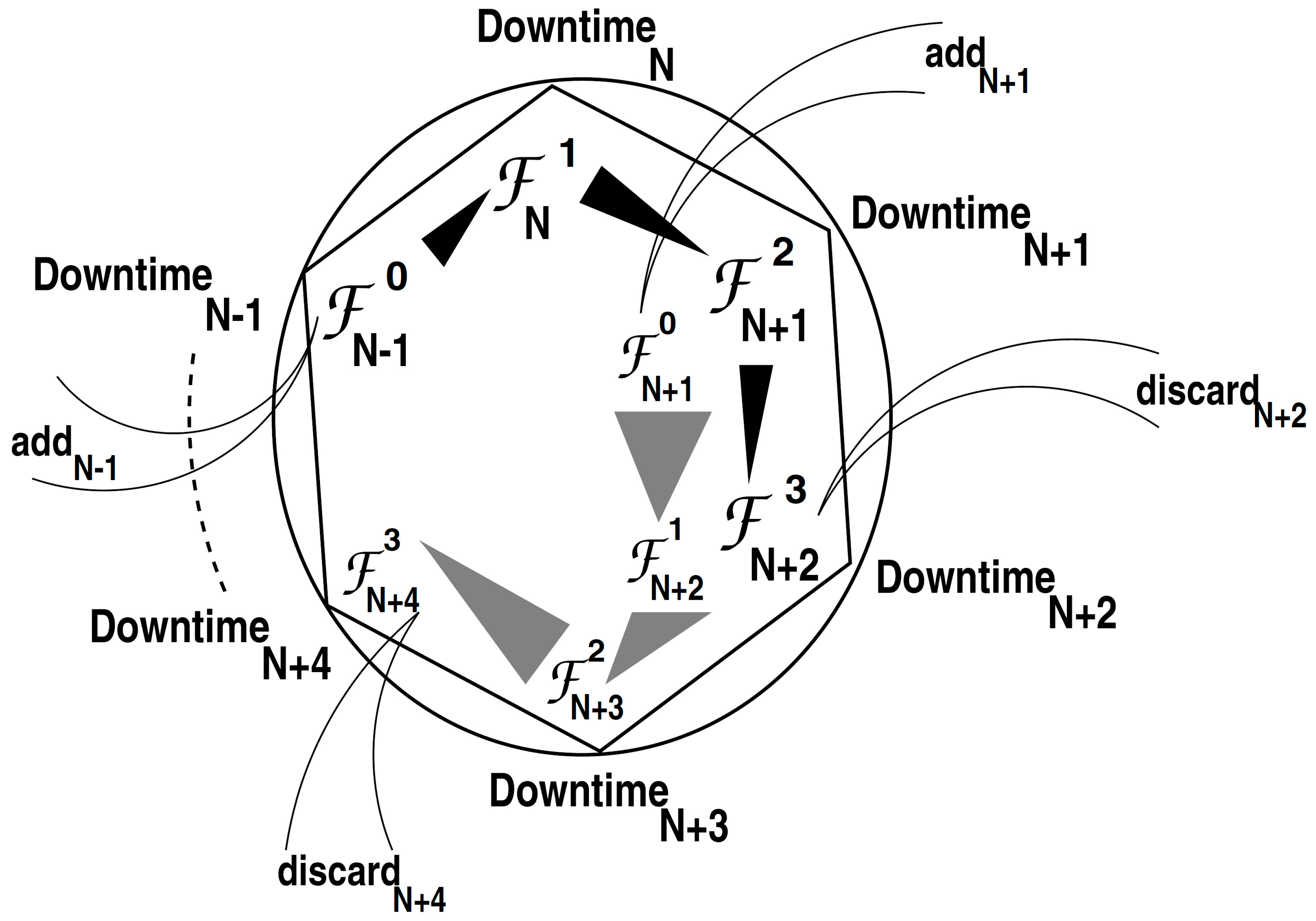

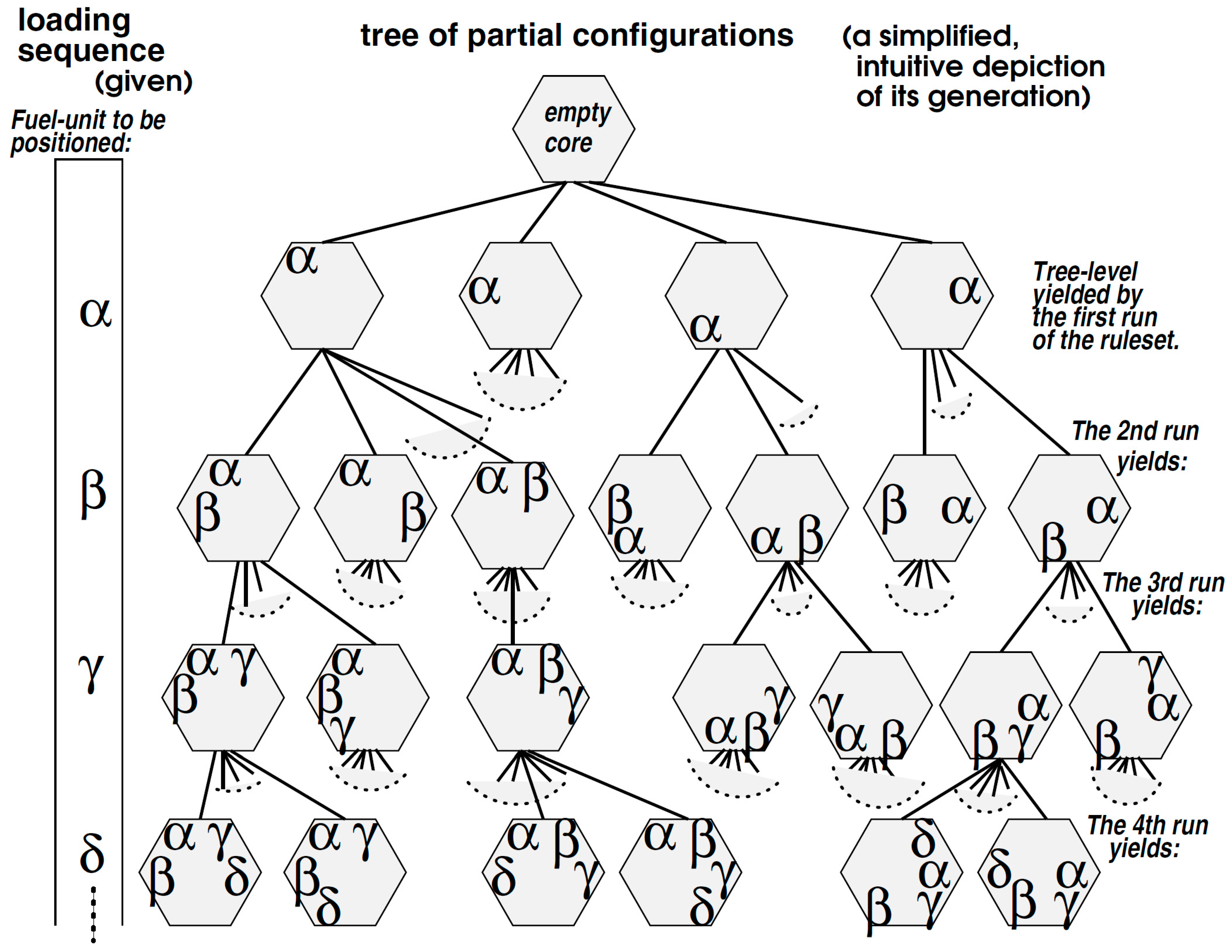

- Nissan, E. Nuclear In-Core Fuel Reload Design: The Trajectory of a Project. In Language, Culture, Computation: Essays Dedicated to Yaacov Choueka, Volume 1: Computing—Theory and Technology; Dershowitz, N., Nissan, E., Eds.; LNCS, Volume 8001; Springer: Heidelberg/Berlin, Germany, 2014; pp. 263–363. [Google Scholar]

- Kim, H.G.; Chang, S.H.; Lee, B.H. Pressurized Water Reactor Core Parameter Prediction Using an Artificial Neural Network. Nuclear Science and Engineering 1993, 113, 70–76. [Google Scholar] [CrossRef]

- Ortiz, J.J.; Requena, I. Using Neural Networks to Predict Core Parameters in a Boiling Water Reactor. Nuclear Science and Engineering 2003, 143, 254–267. [Google Scholar] [CrossRef]

- Kim, H.G.; Chang, S.H.; Lee, B.H. Optimal Fuel Loading Pattern Design Using an Artificial Neural Network and a Fuzzy Rule-Based System. Nuclear Science and Engineering 1993, 113, 152–163. [Google Scholar] [CrossRef]

- Ortiz, J.J.; Requena, I. Optimization of Fuel Reload in a BWR Nuclear Reactor Using a Recurrent Neural Network. In Proceedings of the 5th International FLINS Conference on Computational Intelligent Systems for Applied Research, Gent, Belgium, 16–18 September 2002; Ruan, D., D’hondt, P., Kerre, E.E., Eds.; World Scientific: Singapore, 2002; pp. 544–551. [Google Scholar]

- Ortiz, J.J.; Castillo, A.; Montes, J.L.; Perusquía, R.; Hernández, J.L. Nuclear Fuel Lattice Optimization Using Neural Networks and a Fuzzy Logic System. Nuclear Science and Engineering 2009, 162, 148–157. [Google Scholar] [CrossRef]

- Fitzpatrick, W.E. Developments in Nodal Reactor Analysis Tools for Hexagonal Geometry. Ph.D. Thesis, Dissertation in Nuclear Engineering (supervisor: A.M. Ougouag). University of Illinois at Urbana-Champaign, Champaign, IL, USA, 1995. [Google Scholar]

- Tran, H.N.; Demazière, C. Neutron Noise Calculations in Hexagonal Geometry and Comparison with Analytical Solutions. Nuclear Science and Engineering 2013, 175, 340–351. [Google Scholar] [CrossRef]

- Gamarino, M.; Dall’Osso, A.; Lathouwers, D.; Kloosterman, J.L. Rehomogenization of Nodal Cross Sections via Modal Synthesis of Neutron Spectrum Changes. Nuclear Science and Engineering 2018, 190, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Li, Z.; Wu, H.; Zheng, Y. Improved Variational Nodal Method Based on Symmetry Group Theory. Nuclear Science and Engineering 2018, 190, 134–155. [Google Scholar] [CrossRef]

- Zhou, X.; Li, F. Jacobian-Free Newton-Krylov Nodal Expansion Methods with Physics-Based Preconditioner and Local Elimination for Three-Dimensional and Multigroup k-Eigenvalue Problems. Nuclear Science and Engineering 2018, 190, 238–257. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Y.; Lewis, E.E.; Smith, M.A.; Yang, W.S.; Wu, H. A Three-Dimensional Variational Nodal Method for Pin-Resolved Neutron Transport Analysis of Pressurized Water Reactors. Nuclear Science and Engineering 2017, 188, 160–174. [Google Scholar] [CrossRef]

- Kim, W.; Heo, W.; Kim, Y. Improvement of Nodal Accuracy by Using Albedo-Corrected Parameterized Equivalence Constants. Nuclear Science and Engineering 2017, 207–245. [Google Scholar] [CrossRef]

- Yamamoto, A.; Sakamoto, T.; Endo, T. A CMFD Acceleration Method for SP3 Advanced Nodal Method. Nuclear Science and Engineering 2016, 184, 168–173. [Google Scholar] [CrossRef]

- Li, Y.; Lewis, E.E.; Smith, M.A.; Wu, H.; Cao, L. Preconditioned Multigroup GMRES Algorithms for the Variational Nodal Method. Nuclear Science and Engineering 2015, 179, 42–58. [Google Scholar] [CrossRef]

- Zhang, T.; Lewis, E.E.; Smith, M.A.; Yang, W.S.; Wu, H. A Variational Nodal Approach to 2D/1D Pin Resolved Neutron Transport for Pressurized Water Reactors. Nuclear Science and Engineering 2017, 186, 120–133. [Google Scholar] [CrossRef]

- Galperin, A.; Nissan, E. Discovery as Assisted by an Expert Tool: A Refinement Loop for Heuristic Rules in an Engineering Domain. In Proceedings of the 16th Convention of Electrical and Electronics Engineers, Tel-Aviv, 7–9 March 1989; Paper 1.4.3. IEEE: New York, NY, USA, 1989. [Google Scholar]

- Nissan, E.; Siegelmann, H.; Galperin, A.; Kimhi, S. Upgrading Automation for Nuclear Fuel In-Core Management: From the Symbolic Generation of Configurations, to the Neural Adaptation of Heuristics. Engineering with Computers 1997, 13, 1–19. [Google Scholar] [CrossRef]

- Siegelmann, H.; Nissan, E.; Galperin, A. A Novel Neural/Symbolic Hybrid Approach to Heuristically Optimized Fuel-Allocation and Automated Fuel-Allocation in Nuclear Engineering. Advances in Engineering Software 1997, 28, 581–592. [Google Scholar] [CrossRef]

- Nissan, E.; Siegelmann, H.; Galperin, A. An Integrated Symbolic and Neural Network Architecture for Machine Learning in the Domain of Nuclear Engineering. In Proceedings of the 12th IAPR International Conference on Pattern Recognition, Jerusalem, Israel, 9–13 October 1994; Volume 2, pp. 494–496. Available online: http://www.cs.umass.edu/~binds/papers/1994_Nissan_ProcPatRec.pdf (accessed on 15 February 2019).

- Nissan, E.; Siegelmann, H.; Galperin, A.; Kimhi, S. Towards Full Automation of the Discovery of Heuristics in a Nuclear Engineering Project, by Combining Symbolic and Subsymbolic Computation. In Proceedings of the 8th International Symposium on Methodologies for Intelligent Systems (ISMIS 1994), Charlotte, NC, USA, 16–19 October 1994; Raś, Z.W., Zemankova, M., Eds.; LNCS, Volume 869. Springer: Heidelberg, Germany, 1994; pp. 427–436. [Google Scholar]

- Galperin, A.; Kimhi, S.; Nissan, E.; Siegelmann, H. FUELCON’s Heuristics, Their Rationale, and Their Representations. New Review of Applied Expert Systems (Taylor Graham: London, UK) 1998, 4, 163–176. [Google Scholar]

- Wang, S. Neural Networks in Generalizing Expert Knowledge. Computers and Industrial Engineering 1997, 32, 67–76. [Google Scholar] [CrossRef]

- Nissan, E. Intelligent Technologies for Nuclear Power Systems: Heuristic and Neural Tools. Expert Systems with Applications 1998, 14, 443–460. [Google Scholar] [CrossRef]

- Zhao, J. An Examination of the Macro Genetic Algorithm and its Application to Loading Pattern Design in Nuclear Fuel Management. Ph.D. Thesis, Computer Science, The University of Greenwich, London, UK, November 1996. [Google Scholar]

- Zhao, J.; Knight, B.; Nissan, E.; Petridis, M.; Soper, A. The FUELGEN Alternative: An Evolutionary Approach. The Architecture. New Review of Applied Expert Systems (Taylor Graham: London, UK) 1998, 4, 177–183. [Google Scholar]

- Soper, A. Exploring Genetic Alternative Concepts for FUELGEN. New Review of Applied Expert Systems (Taylor Graham: London, UK) 1998, 4, 185–194. [Google Scholar]

- Zhao, J.; Knight, B.; Nissan, E.; Soper, A. FUELGEN: A Genetic-Algorithm Based System for Fuel Loading Pattern Design in Nuclear Power Reactors. Expert Systems with Applications 1997, 14, 461–470. [Google Scholar] [CrossRef]

- Zhao, J.; Knight, B.; Nissan, E.; Soper, A. FUELGEN: Effective Evolutionary Design of Refuellings for Pressurized Water Reactors. Computers and Artificial Intelligence 1998, 17, 105–125. [Google Scholar]

- Nissan, E.; Soper, A.; Zhao, J.; Knight, B.; Petridis, M. Fuel Reload Pattern Design Within a Family of Hybrid Architectures. In Proceedings of the FLINS 1998: Third International FLINS Workshop on Fuzzy Logic and Intelligent Technologies for Nuclear Science and Industry (FLINS 1998), Antwerp, Belgium, 14–16 September 1998; pp. 408–415. [Google Scholar]

- Nissan, E.; Galperin, A.; Zhao, J.; Knight, B.; Soper, A. From FUELCON to FUELGEN: Tools for Fuel Reload Pattern Design. In Fuzzy Systems and Soft Computing in Nuclear Engineering; Ruan, D., Ed.; STUDFUZZ, Volume 38; Springer: Heidelberg, Germany, 2000; pp. 432–448. [Google Scholar]

- Nissan, E.; Galperin, A.; Soper, A.; Knight, B.; Zhao, J. Future States for a Present-State Estimate, in the Contextual Perspective of In-Core Nuclear Fuel Management. International Journal of Computing Anticipatory Systems 2001, 9, 256–271. [Google Scholar]

- Galperin, A.; Kimhi, S.; Nissan, E.; Siegelmann, H.; Zhao, J. Symbolic and Subsymbolic Integration in Prediction and Rule-Revision Tasks for Fuel Allocation in Nuclear Reactors. In Proceedings of the 3rd European Congress on Intelligent Techniques and Soft Computing (EUFIT 1995), Aachen, Germany, 28–31 August 1995; Volume 3, pp. 1546–1550. [Google Scholar]

- Poon, P.W. Genetic Algorithms and Fuel Cycle Optimization. The Nuclear Engineer 1990, 31, 173–177. [Google Scholar]

- Poon, P.W.; Parks, G.T. Application of Genetic Algorithms to In-Core Nuclear Fuel Management Optimization. In Proceedings of the Joint International Conference on Mathematical Methods and Supercomputing in Nuclear Applications, Karlsruhe, Germany, 19–23 April 1993; p. 777. [Google Scholar]

- Parks, G.T. Multiobjective PWR Reload Core Optimization Using a Genetic Algorithm. In Proceedings of the International Conference on Mathematics and Computations, Reactor Physics, and Environmental Analyses, Portland, OR, USA, 30 April–4 May 1995; Volume 1, pp. 615–624. [Google Scholar]

- Parks, G.T. Multiobjective Pressurized Water Reactor Reload Core Design by Nondominated Genetic Algorithm Search. Nuclear Science and Engineering 1996, 124, 178–187. [Google Scholar] [CrossRef]

- Parks, G.T. Multiobjective Pressurised Water Reactor Reload Core Design using a Genetic Algorithm. In Artificial Neural Nets and Genetic Algorithms; Springer: Vienna, Austria, 1998; pp. 53–57. [Google Scholar]

- Tanker, E.; Tanker, A.Z. Application of a Genetic Algorithm to Core Reload Pattern Optimization. In Proceedings of the International Conference on Mathematics and Computations, Reactor Physics, and Environmental Analysis, Portland, OR, USA, 30 April–4 May 1995; Volume 1. [Google Scholar]

- Tanker, E.; Tanker, A.Z. Application of a Genetic Algorithm to Core Reload Pattern Optimization. In Reactor Physics and Reactor Computations; Ronen, Y., Elias, E., Eds.; Ben Gurion University of the Negev Press: Beer-Sheva, Israel, 1994. [Google Scholar]

- DeChaine, M.D.; Feltus, M.A. Comparison of Genetic Algorithm Methods for Fuel Management Optimization. In Proceedings of the International Conference on Mathematics and Computations, Reactor Physics, and Environmental Analysis, Portland, OR, USA, 30 April–4 May 1995; Volume 1. [Google Scholar]

- DeChaine, M.D.; Feltus, M.A. Nuclear Fuel Management Optimization Using Genetic Algorithms. Nuclear Technology 1995, 111, 109–114. [Google Scholar] [CrossRef]

- DeChaine, M.D.; Feltus, M.A. Fuel Management Optimization Using Genetic Algorithms and Expert Knowledge. Nuclear Science and Engineering 1996, 124, 188–196. [Google Scholar] [CrossRef]

- Carter, J.N. Genetic Algorithms for Incore Fuel Management and Other Recent Developments in Optimisation. Advances in Nuclear Science & Technology 2002, 25, 113–154. [Google Scholar]

- Chapot, J.L.C.; Silva, F.C.; Schirru, R. A New Approach to the Use of Genetic Algorithms to Solve Pressurized Water Reactor’s Fuel Management Optimization Problem. Annals of Nuclear Energy 1999, 26, 641–655. [Google Scholar] [CrossRef]

- Pereira, C.M.N.A.; Schirru, R.; Martinez, A.S. Basic Investigations Related to Genetic Algorithms in Core Designs. Annals of Nuclear Energy 1999, 26, 173–193. [Google Scholar] [CrossRef]

- Schirru, R.; Pereira, C.M.N.A.; Chapot, L.; Carvalho, F. A Genetic Algorithm Solution for Combinatorial Problems: The Nuclear Core Reload Example. In XI Encontro Nacional de Fisica de Reatores; Instituto de Engenharia Nuclear: Poços de Caldas, Brazil, 1997; pp. 357–360. [Google Scholar]

- Ortiz, J.J.; Requena, I. An Order Coding Genetic Algorithm to Optimize Fuel Reloads in a Nuclear Boiling Water Reactor. Nuclear Science and Engineering 2004, 146, 88–98. [Google Scholar] [CrossRef]

- Ortiz, J.J.; Castillo, A.; Montes, J.L.; Perusquía, R. A New System to Fuel Loading and Control Rod Pattern Optimization in Boiling Water Reactors. Nuclear Science and Engineering 2007, 157, 236–244. [Google Scholar] [CrossRef]

- Martín del Campo, C.; François, J.L.; López, H.A. AXIAL: A System for Boiling Water Reactor Fuel Assembly Axial Optimization Using Genetic Algorithms. Annals of Nuclear Energy 2001, 28, 1667–1682. [Google Scholar] [CrossRef]

- Martín-del-Campo, C.; François, J.L.; Avendaño, L.; González, M. Development of a BWR Loading Pattern Design System Based on Modified Genetic Algorithms and Knowledge. Annals of Nuclear Energy 2004, 31, 1901–1911. [Google Scholar] [CrossRef]

- Martín-del-Campo, C.; Palomera-Pérez, M.-Â.; François, J.-L. Advanced and Flexible Genetic Algorithms for BWR Fuel Loading Pattern Optimization. Annals of Nuclear Energy 2009, 36, 1553–1559. [Google Scholar] [CrossRef]

- Toshinsky, V.G.; Sekimoto, H.; Toshinsky, G.I. Multiobjective Fuel Management Optimization for Self-Fuel-Providing LMFBR Using Genetic Algorithms. Annals of Nuclear Energy 1999, 26, 783–802. [Google Scholar] [CrossRef]

- Raza, W.; Kim, K.-Y. Shape Optimization of 19-Pin Wire-Wrapped Fuel Assembly of LMR Using Multiobjective Evolutionary Algorithm. Nuclear Science and Engineering 2009, 161, 245–254. [Google Scholar] [CrossRef]

- Wahed, M.E.-S.; Ibrahim, W.Z.; Effat, A.M. Multiobjective Optimization of the Plate Element of Egyptian Research Reactor Using Genetic Algorithm. Nuclear Science and Engineering 2009, 162, 275–281. [Google Scholar] [CrossRef]

- Marseguerra, M.; Zio, E.; Cadini, F. Optimized Adaptive Fuzzy Controller of the Water Level of a Pressurized Water Reactor Steam Generator. Nuclear Science and Engineering 2007, 155, 386–394. [Google Scholar] [CrossRef]

- Nissan, E. Review of Fuzzy Logic. Foundations and Industrial Applications. Computers and Artificial Intelligence 1998, 17, 248–249. [Google Scholar]

- Nissan, E. Review of Intelligent Systems and Soft Computing for Nuclear Science and Industry: Proceedings of the 2nd International FLINS Workshop; Ruan, D., D’hondt, P., Govaerts, P., Kerre, E.E., Eds.; World Scientific: Singapore, 1996. [Google Scholar]

- Domingos, R.P.; Schirru, R.; Pereira, C.M.N.A. Particle Swarm Optimization in Reactor Core Design. Nuclear Science and Engineering 2006, 152, 197–203. [Google Scholar] [CrossRef]

- Ahila, R.; Sadavasivam, V.; Manimala, K. Particle Swarm Optimization-Based Feature Selection and Parameter Optimization for Power System Disturbances Classification. Applied Artificial Intelligence 2012, 26, 832–861. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R.C.; Shi, Y. Swarm Intelligence; Morgan Kaufmann Publishers: San Francisco, CA, USA, 2001. [Google Scholar]

- Khoshahval, F.; Minuchehr, H.; Zolfaghari, A. Performance Evaluation of PSO and GA in PWR Core Loading Pattern Optimization. Nuclear Engineering and Design 2011, 241, 799–808. [Google Scholar] [CrossRef]

- Alamaniotis, M.; Ikonomopoulos, A.; Tsoukalas, L.H. Swarm Intelligence Optimization: Applications of Particle Swarms in Industrial Engineering and Nuclear Power Plants. In Computational Intelligence Systems in Industrial Engineering: With Recent Theory and Applications; Atlantis Computational Intelligence Systems, 6; Kahraman, C., Ed.; Atlantis Press: Paris, France, 2012; pp. 181–202. [Google Scholar]

- De Moura Meneses, A.A.; Machado, M.D.; Schirru, R. Particle Swarm Optimization Applied to the Nuclear Reload Problem of a Pressurized Water Reactor. Progress in Nuclear Energy 2009, 51, 319–326. [Google Scholar] [CrossRef]

- De Lima, A.M.; Schirru, R.; da Silva, F.C.; Medeiros, J.A.C.C. A Nuclear Reactor Core Fuel Reload Optimization Using Artificial Ant Colony Connective Networks. Annals of Nuclear Energy 2008, 35, 1606–1612. [Google Scholar] [CrossRef]

- Nissan, E. Review of Animal Communication Networks; McGregor, P., Ed.; Cambridge University Press: Cambridge, UK, 2005; and of Pheromones and Animal Behaviour: Communication by Smell and Taste; Wyatt, T.D., Ed.; Cambridge University Press: Cambridge, UK, 2003 (reprinted with corrections, 2004). Pragmatics & Cognition 2009, 17, 482–490. [Google Scholar]

- Brown, R.E.; Macdonald, D.W. Social Odours in Mammals; Oxford University Press: Oxford, UK, 1985; Volume 2. [Google Scholar]

- Maniezzo, V.; Carbonaro, A. Ant Colony Optimisation: An Overview. In Essays and Surveys in Metaheuristics; Ribeiro, C., Ed.; Kluwer: Dordrecht, The Netherlands, 2001; pp. 21–44. [Google Scholar]

- Maniezzo, V.; Roffilli, M. Very Strongly Constrained Problems: An Ant Colony Optimization Approach. In Papers in Sensing and in Reasoning: Marco Somalvico Memorial Issue. Nissan, E.; Gini, G.; Colombetti, M., Eds. A thematic issue of Cybernetics and Systems 2008, 39, 395–424.

- Dorigo, M.; Maniezzo, V.; Colorni, A. The Ant System: Optimisation by a Colony of Cooperating Ants. IEEE Transactions on Systems, Man and Cybernetics, Part B 1996, 26, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Dorigo, M.; Gambardella, L.M. Ant Colony System: A Cooperative Learning Approach to the Traveling Salesman Problem. IEEE Transactions in Evolutionary Computation 1997, 1, 53–66. [Google Scholar] [CrossRef]

- Di Caro, G.; Dorigo, M. AntNet: Distributed Stigmergetic Control for Communication Networks. Journal of Artificial Intelligence Research 1998, 9, 317–365. [Google Scholar] [CrossRef]

- Marshall, A.A.R.; Kovacs, T.; Dornhaus, A.R.; Franks, N.R. Simulating the Evolution of Ant Behaviour in Evaluating Nest Sites. In Advances in Artificial Life: Proceedings of the 7th European Conference on Artificial Life (ECAL’2003); Banzhaf, W., Christaller, T., Dittrich, P., Kim, J.T., Ziegler, J., Eds.; Lecture Notes in Artificial Intelligence, Volume 2801; Springer: Berlin, Germany, 2003; pp. 643–650. [Google Scholar] [Green Version]

- Engelbrecht, A.P. Computational Intelligence: An. Introduction; Wiley: Chichester, West Sussex, UK, 2002. [Google Scholar]

- Hood, E. RoboLobsters: The Beauty of Biomimetics. Environmental Health Perspectives 2004, 112, A486–A489. Available online: http://ehp.niehs.nih.gov/members/2004/112-8/innovations.html (accessed on 15 February 2019). [CrossRef] [PubMed]

- Beer, R.D.; Chiel, H.J.; Quinn, R.D.; Ritzmann, R.E. Biorobotic Approaches to the Study of Motor Systems. Current Opinion in Neurobiology 1998, 8, 777–782. [Google Scholar] [CrossRef]

- Grasso, F.; Consi, T.; Mountain, D.; Atema, J. Locating odor sources in turbulence with a lobster inspired robot. In Animals to Animats 4: Proceedings of the Fourth International Conference on the Simulation of Adaptive Behavior; Maes, P., Mataric, M., Meyer, J.-A., Pollack, J., Wilson, S.W., Eds.; The MIT Press: Cambridge, MA, USA, 1996; pp. 104–113. [Google Scholar]

- Blazis, D.; Grasso, F.W. Introduction to Invertebrate Sensory Information Processing, Biological Inspiration of Autonomous Robots. Biological Bulletin 1999, 200, 147–149. [Google Scholar] [CrossRef] [PubMed]

- Blazis, D.E.J.; Grasso, F.W. (Eds.) Proceedings of Invertebrate Sensory Information Processing: Implications for Biologically Inspired Autonomous Systems. Biological Bulletin 2001, 200, 147–242. [Google Scholar]

- Wyatt, T.D. Pheromones and Animal Behaviour: Communication by Smell and TasteI; Cambridge University Press: Cambridge, UK, 2003; (reprinted with corrections, 2004). [Google Scholar]

- Bushmann, P.J.; Atema, J. Shelter Sharing and Chemical Courtship Signals in the Lobster Homarus americanus. Canadian Journal of Fisheries and Aquatic Sciences 1997, 54, 647–654. [Google Scholar] [CrossRef]

- Ben Hmaida, I.A.; Carter, J.N.; De Oliveira, C.R.E.; Goddard, A.J.H.; Parks, G.T. Nuclear In-Core Fuel Management Optimization Using the Tabu Search Method. In Proceedings of the Conference on Mathematics & Computation, Reactor Physics and Environmental Analysis in Nuclear Applications (M&C’99), Madrid, Spain, 20–30 September 1999; Volume 2, pp. 1658–1666. [Google Scholar]

- Castillo, A.; Alonso, G.; Morales, L.B.; Martín del Campo, C.; François, J.L.; del Valle, E. BWR Fuel Reloads Design Using a Tabu Search Technique. Annals of Nuclear Energy 2003, 31, 151–161. [Google Scholar] [CrossRef]

- Jagawa, S.; Yoshii, T.; Fukao, A. Boiling Water Reactor Loading Pattern Optimization Using Simple Linear Perturbation and Modified Tabu Search Methods. Nuclear Science and Engineering 2001, 138, 67–77. [Google Scholar] [CrossRef]

- Tabu Search. Available online: https://en.wikipedia.org/wiki/Tabu_search (accessed on 15 February 2019).

- Ghisu, T.; Parks, G.T.; Jaeggi, D.M.; Jarrett, J.P.; Clarkson, P.J. The Benefits of Adaptive Parametrization in Multi-Objective Tabu Search Optimization. Engineering Optimization 2010, 42, 959–981. [Google Scholar] [CrossRef]

- Jaeggi, D.M.; Parks, G.T.; Kipouros, T.; Clarkson, P.J. The Development of a Multi-Objective Tabu Search Algorithm for Continuous Optimisation Problems. European Journal of Operational Research 2008, 185, 1192–1212. [Google Scholar] [CrossRef]

- Park, T.K.; Joo, H.G.; Kim, C.H.; Lee, H.C. Multiobjective Loading Pattern Optimization by Simulated Annealing Employing Discontinuous Penalty Function and Screening Technique. Nuclear Science and Engineering 2009, 162, 134–147. [Google Scholar] [CrossRef] [Green Version]

- Stephens, G.; Smith, K.S.; Rempe, K.R.; Downar, T.J. Optimization of Pressurized Water Reactor Shuffling by Simulated Annealing with Heuristics. Nuclear Science and Engineering 1995, 121, 67. [Google Scholar] [CrossRef]

- Parks, G.T.; Suppapitnarm, A. Multiobjective Optimization of PWR Reload Core Designs Using Simulated Annealing. In Proceedings of the Conference on Mathematics & Computation, Reactor Physics and Environmental Analysis in Nuclear Applications (M&C’99), Madrid, Spain, 20–30 September 1999; Volume 2, pp. 1435–1444. [Google Scholar]

- Kropaczek, D.J.; Parks, G.T.; Maldonado, G.I.; Turinsky, P.J. Application of Simulated Annealing to In-Core Nuclear Fuel Management Optimization. In Proceedings of the 1991 International Topical Meeting on Advances in Mathematics, Computations and Reactor Physics, Pittsburgh, PA, USA, 18 April–2 May 1991. [Google Scholar]

- Fadaei, A.H.; Setayeshi, S.; Kia, S. An Optimization Method Based on Combination of Cellular Automata and Simulated Annealing for VVER-1000 NPP Loading Pattern. Nuclear Engineering and Design 2009, 239, 2800–2808. [Google Scholar] [CrossRef]

- Kropaczek, D.J.; Parks, G.T.; Maldonado, G.I.; Turinsky, P.J. The Efficiency and Fidelity of the In-Core Nuclear Fuel Management Code FORMOSA-P. In Reactor Physics and Reactor Computations; Ronen, Y., Elias, E., Eds.; Ben Gurion University of the Negev Press: Beer-Sheva, Israel, 1994. [Google Scholar]

- Jessee, M.A.; Kropaczek, D.J. Coupled Bundle-Core Design Using Fuel Rod Optimization for Boiling Water Reactors. Nuclear Science and Engineering 2007, 155, 378–385. [Google Scholar] [CrossRef]

- Maag, E.M.; Knott, D. BWR Reload Strategy Based on Fixing Once-Burnt Fuel Between Cycles. Nuclear Technology 2001, 136, 278–291. [Google Scholar] [CrossRef]

- Unsigned editorial. A Few Bright Spots. Under the rubric Nuclear Notes. Nuclear News (American Nuclear Society). October 2017, Volume 60, p. 4. Available online: http://cdn.ans.org/advertising/nn/docs/october2017.pdf (accessed on 15 February 2019).

- Pierpoint, L.M. Illuminating Fuel Cycle Decision Drivers Using a Decision Analysis Framework. Nuclear Science and Engineering 2017, 186, 66–82. [Google Scholar] [CrossRef]

- Passerini, S.; Kazimi, M.S.; Shwageraus, E. A Systematic Approach to Nuclear Fuel Cycle Analysis and Optimization. Nuclear Science and Engineering 2014, 178, 186–201. [Google Scholar] [CrossRef]

- Phathanapirom, U.B.; Schneider, E.A. Nuclear Fuel Cycle Transition Analysis Under Uncertainty. Nuclear Science and Engineering 2016, 182, 502–522. [Google Scholar] [CrossRef]

- [Unsigned.]. NuScale Launches SMR Action Plan for Britain. Nuclear News (American Nuclear Society). October 2017, Volume 60, No. 11. p. 75. Available online: http://cdn.ans.org/advertising/nn/docs/october2017.pdf (accessed on 15 February 2019).

- Kuwagaki, K.; Nishiyama, J.; Obara, T. Concept of Stationary Wave Reactor with Rotational Fuel Shuffling. Nuclear Science and Engineering 2018, 191, 178–186. [Google Scholar] [CrossRef]

- Qvist, S.; Greenspan, E. Design Space Analysis for Breed-and-Burn Reactor Cores. Nuclear Science and Engineering 2016, 182, 197–212. [Google Scholar] [CrossRef]

- Steinhauer, L.C. Summary of the U.S.–Japan Workshop on D-3He Fuels in Field-Reversed Configurations, Fukuoka, Japan, November 28–30, 1990. Fusion Technology 1991, 20, 373–377. Available online: http://www.ans.org/pubs/journals/download/a_29681 (accessed on 15 February 2019).

- Feinberg, S.M. Discussion Comment. Record of Proceedings Session B-10, ICPUAE; United Nations: Geneva, Switzerland, 1958. [Google Scholar]

- Traveling Wave Reactor. Available online: https://en.wikipedia.org/wiki/Traveling_wave_reactor (accessed on 15 February 2019).

- Huang, J.; Han, J. Breed-and-Burn Strategy in a Fast Reactor with Optimized Starter Fuel. Progress in Nuclear Energy 2015, 85, 11–16. [Google Scholar] [CrossRef]

- Teller, E.; Ishikawa, M.; Wood, L. Completely Automated Nuclear Reactors for Long-Term Operation. Proceedings of ICENES’96. 1996. Available online: https://www.researchgate.net/publication/255036699_Completely_automated_nuclear_reactors_for_long-term_operation (accessed on 15 February 2019).

- Garrun, D. Breed and Burn Reactors—Could Recycling Waste Redeem Nuclear Power? Analysis paper in Power Technology. 23 May 2012. Available online: https://www.power-technology.com/features/featurenuclear-waste-disposal-reactor-technology-recycle-clean-energy/ (accessed on 15 February 2019).

| 1 | The name FUELCON was patterned after the phrase “fuel configurations”. |

| 2 | The name FUELGEN is a compound of fuel and gen (etic). |

| 3 | An introduction to convolutional neural networks can be found in [1]. That technique is most commonly applied to analyzing visual imagery. Its inspiration is biological, in that the connectivity pattern between its artificial neurons resembles the organization of the animal visual cortex. |

| 4 | |

| 5 | |

| 6 | Frame-based expert systems are the subject of, e.g., [2] (Chapter 5). |

| 7 | Attractor networks are the subject of [2] (Section 14.6, pp. 701–711). |

| 8 | |

| 9 | |

| 10 | The contrast between rule-based and case-based intelligent systems from artificial intelligence should not be mistaken for the contrast (in legal studies) between such legal jurisdictions that mainly judge based on precedent (which is the case of Anglo-Saxon countries), and such jurisdictions (such as France) where adjudication is mainly based on rules as stated in law as made by legislators. Moreover, the two opposite pairs do not overlap, even when either rule-based or case-based reasoning is adopted in intelligent software systems applied to the legal domain. Bain’s JUDGE system [65,66,67] is a tool whose AI mechanism is case-based reasoning. It adopts a hybrid approach, both rule-based and case-based. JUDGE is a cognitive model of judges’ decision-making when sentencing (and indeed it was based on interviews with judges). |

| 11 | “FirstEnergy Nuclear Operating Company’s (FENOC) Perry nuclear power plant—a 1270-MWe boiling water reactor located in North Perry, Ohio—completed its 16th refueling outage on April 3, 2017. The 29-day outage, which began on March 5, marks the shortest refueling outage in Perry’s 30 years of operation (the previous record was 34 days in 2001). More than 1400 contract workers and FENOC employees from the company’s other nuclear plants supplemented Perry’s 700-person workforce during the outage. In addition to replacing 280 of the plant’s 748 fuel assemblies, workers completed more than 9600 outage work activities. A new, massive transformer that provides power from the off-site transmission network was also installed” [73]. (p. 42). “Perry’s 1270-MWe reactor will operate for approximately 24 months until its next refuelling in spring 2019” [73] (p. 48). |

| 12 | The paper by Bhattacharya and Yu [76] “presents the development of comprehensive computational fluid dynamics models for unsteady flows of coolant through a string of 12 CANDU 6 fuel bundles with angular misalignments inside a pressure tube by means of large eddy simulation”. |