1. Introduction

Millions of tons of losses and waste produced in the food processing industries every year cause economic, environmental, and nutritional problems. The effective utilization of these by-products, by translating waste and byproducts into resources through shifts in technology, ensures the sustainable development of food industries and a reduction of their environmental pollution.

Salted egg whites, a by-product in the manufacturing process of salted egg yolks, are usually discarded as waste due to the difficulty in treatment. Abandoned salted egg whites contain a high content of salt and organic, which is commonly regarded as an environmental problem whose disposal is troublesome for the food industry [

1,

2]. Salted egg white protein is a mixture of proteins that consists mainly of ovalbumin (OVA), lysozyme, ovotransferrin, ovomucoid [

3]. OVA is the major protein in salted egg whites, accounting for approximately 54% of the total protein in salted egg whites. Containing a well-balanced amino acid composition, OVA is an excellent source of essential amino acids. It consists of 385 amino acids (45 kDa) with an isoelectric point (pI) of approximately 4.5 [

4,

5]. Although being well studied, the function of ovalbumin in eggs is still unknown. However, some studies suggested ovalbumin to be a storage protein [

6]. In view of nutrition and function, OVA is one of the highest quality food proteins. Further, OVA has been proved to have biological activities, such as antibacterial activity, antihypertensive activity and immunomodulating activity [

7]. In addition to displaying several functional properties including emulsification, heat-setting and foaming, OVA also has been used as an effective drug carrier [

8]. Therefore, there is considerable technical interest in its separation if costs can be controlled. The current methods for separating OVA from egg white are mainly isoelectric precipitation [

9,

10], membrane [

11] and chromatography [

12]. In recent years, a few new materials were applied to separate OVA with good selectivity. However, aniline-doped cobalt mono-substituted silicotungstic acid was reported to separate OVA with an adsorption efficiency of 92% for OVA at pH 9 [

13]. Liu [

14] prepared a nano-composite based on reduced graphene oxide nanosheets functionalized with polymeric ionic liquid. It was used to selectively isolate OVA from egg white with an adsorption capacity of 917.4 mg g

−1. Chen [

15] described a three-dimensional reduced graphene oxide aerogel with embedded nickel oxide nanoparticles which was prepared by a one-step self-assembly reaction, which was proved to selectively isolate ovalbumin from chicken egg white. Nevertheless, the methods above are difficult to be used in the industry due to their low yield, expensive operating costs or high equipment requirements. In addition, most previous research focused on the separation of OVA from unsalted egg white solution. Extracting OVA from salted egg whites can reprocess and utilize the waste and byproducts in the production of new commercially valuable products, as well as support an abundant and cheap source of bioactive compounds. Therefore, it is necessary to develop an economical and simple method to separate OVA from salted egg whites.

The model of the unidirectional rising bubbles mass transfer was applied to an aqueous two-phase system (ATPS), which was called aqueous two-phase flotation (ATPF). Compared with aqueous two-phase extraction (ATPE), ATPF was considered as a novel technique with low consumption of organic solvents and high concentration coefficients [

16]. Thus far, ATPF has been applied in the enrichment and separation of some biomolecules, such as protein and Chinese herbal medicines. Sankaran et al. [

17] established a 1-propanol/(NH

4)

2SO

4 ATPF to separate lipase from fermentation broth. Jiang et al. [

18] used ATPF containing PEG 1000 and citrate to extract

α-lactalbumin from whey. Under optimal conditions, the purification factor, purity and flotation efficiency were 5.33 ± 0.05, 96.78 ± 0.79% and 87.54 ± 0.76%, respectively. The use of ATPF to extract proteins could save process time and cost, and the use of biodegradable salts as the bottom phase could avoid environmental pollution problems. Pakhale et al. [

19] used ATPF consisting of PEG and phosphate to isolate bromelain. Under optimal conditions, the purification ratio reached 4.26, and the recovery rate was 91.47%. Jiang et al. [

20] used ATPF to separate antioxidant peptides from whey protein hydrolysate. The recovery rate of peptides from the top phase was 11.71% and the free radical scavenging per unit concentration was 29.18%. The result was significantly better than ATPE. Bi et al. [

21] established an effective and non-polluting ATPF which isolated and enriched baicalin from Astragalus membranaceus extract. The experimental results showed that under optimal conditions of ATPF, the above method was successfully applied to the separation of baicalin, the enrichment ratio was more than 27, and the separation efficiency was 90%. Chang et al. [

22] established a method for separating four flavonoids using ATPF. Under optimal conditions, the flotation efficiency was 96.03%, 92.07%, 94.27% and 90.51%, respectively. ATPF proved to be a potentially effective method for the separation of biomolecules, therefore, more and more attempts on the application of ATPF were carried out.

The aim of this study was to develop an inexpensive, simple, efficient separation and pollution-free process for the separation of OVA from salted egg whites to realize the reutilization of food waste while minimizing the environmental impact. With this goal, the separation of OVA from salted egg whites by ATPF of PEG 1000/ammonium sulphate was studied for the first time.

2. Materials and Methods

2.1. Instruments

The Waters e2695 liquid chromatograph equipped with 2998 PDA detector, C8 and C18 columns (Waters, Waters Corporation, Milford, MA, USA) was applied to detect the samples. The solution pH was measured by a PHS-3C pH meter (Shanghai Instrument Electric Scientific Instrument Co., Ltd. Shanghai, China). An AL-04 electronic analytical balance (Mettler Toledo Instruments Co., Ltd., Shanghai, China) was used for weighing. The sample was dialyzed with a 13000 Da MWCO filter (Spectrum Labs, Los Angeles, CA, USA). The glass rotameter (Shenyang Beixing flow meter factory, Shenyang, China) and buoy type oxygen inhalator (Shandong Huachen high pressure container Co., Ltd. Jinan, China) were used in the preparation of ATPF.

2.2. Materials

Salted eggs were purchased from the local supermarket. The OVA standard sample was purchased from Sigma (Burlington, MA, USA). Trifluoroacetic acid (TFA) and acetonitrile were chromatographically pure (Dikma, Beijing, China). Further, 1000 g·mol−1 polyethylene glycol (PEG 1000) was purchased from Aladdin (Shanghai, China) and ammonium sulphate and other reagents were analytical reagent grade.

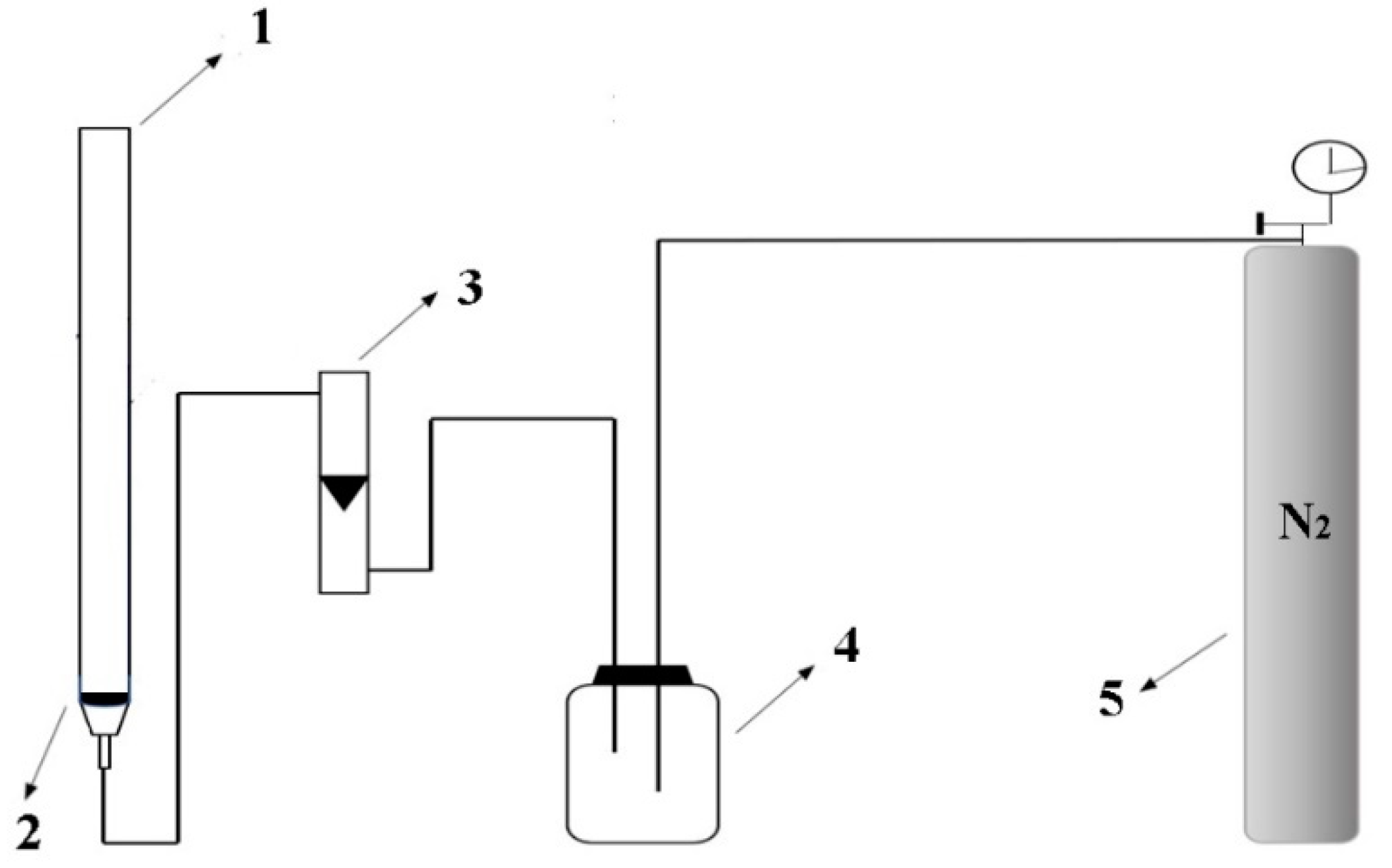

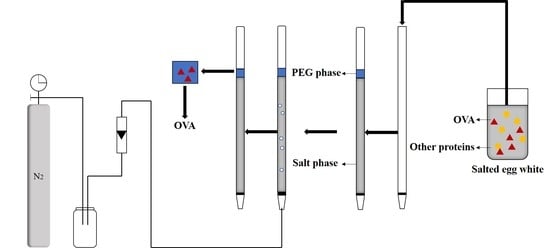

2.3. Preparation of ATPF and Purification

The ATPF was prepared in a flotation column by mixing 2 mL of the salted egg white solution (salted egg white (

v): water (

v) = 1:4) and appropriate volume of stock solution of ammonium sulfate. The gas flow outputted from the nitrogen cylinder formed a steady flow by a gas buffer, which was adjusted by the flowrator. When the nitrogen flow rate was stable, 5 mL PEG was added. The nitrogen gas was bubbling through the bottom of the column at a certain flotation time and flow velocity. The flotation unit is described in

Figure 1. The OVA was carried to the PEG phase by nitrogen gas. By measuring the

Y and

P in the systems, the optimum conditions, including the concentration of PEG and (NH

4)

2SO

4, the flotation time and the flow rate of nitrogen, were obtained.

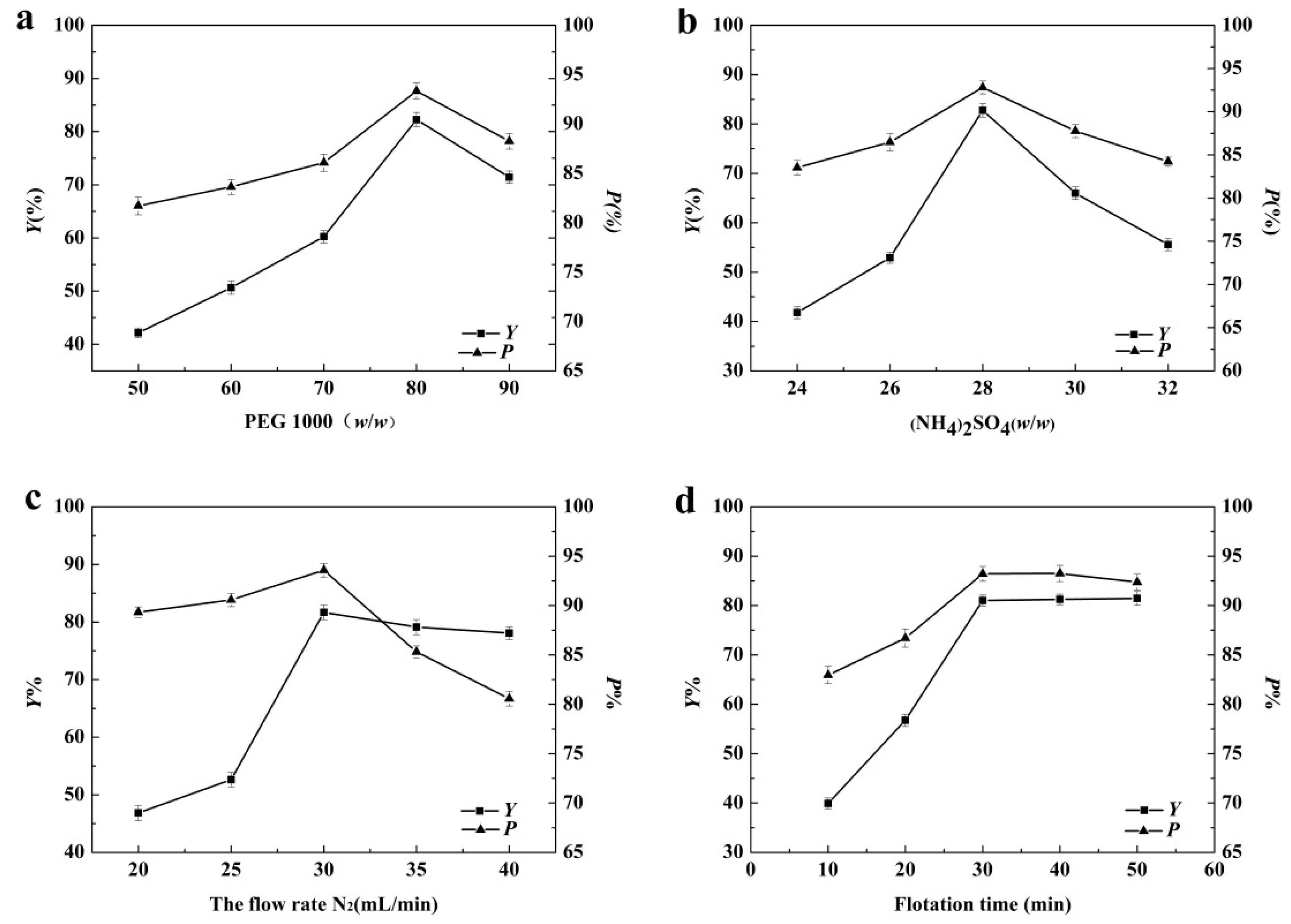

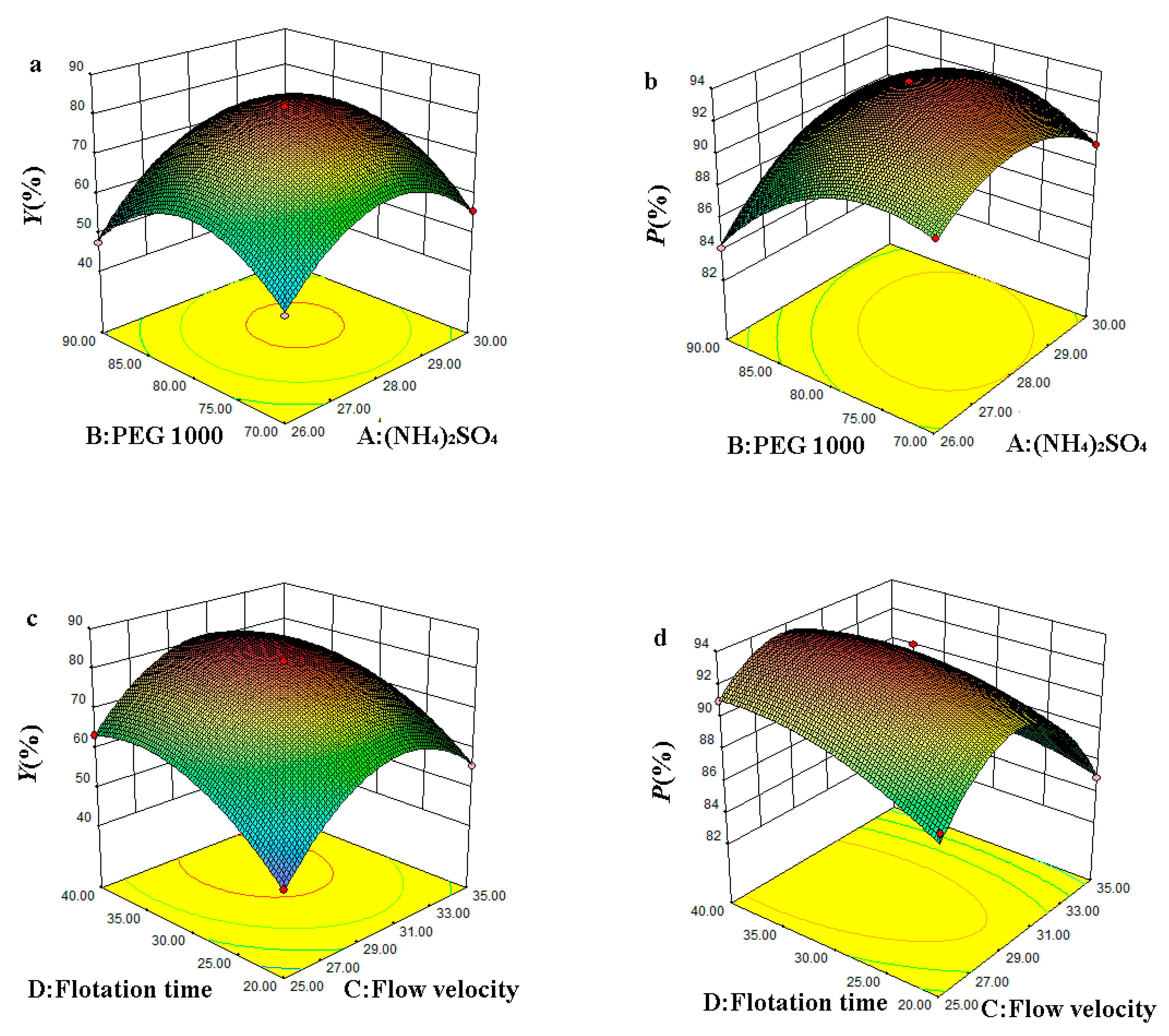

2.4. Experimental Design

The response surface method (RSM) experiment was applied to optimize the interaction between the parallel factors and separation parameters. The effects of various factors, including

X1 (the mass fraction of PEG),

X2 (the mass fraction of (NH

4)

2SO

4),

X3 (the flow rate of nitrogen) and

X4 (the flotation time), were studied. The experimental design was shown in

Table 1.

Y and

P were taken as the responses and each experiment was replicated three times

The top phase of ATPF and salted egg white solution were dialyzed against deionized water overnight by a dialysis bag with 13,000 Da molecular weight cutoffs to remove the PEG 1000 and salt. Then, the dialysate was lyophilized to obtain the purified OVA.

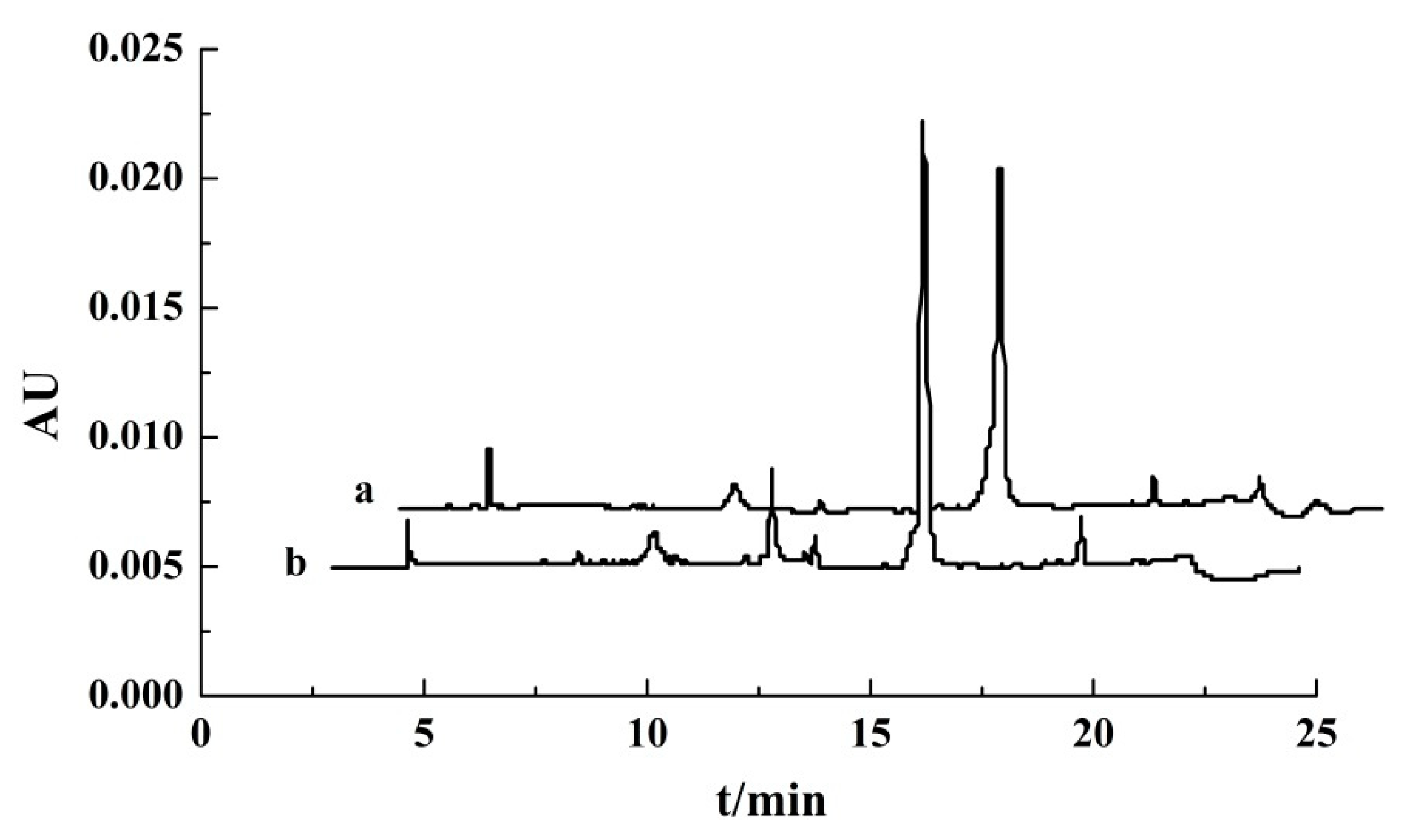

2.5. Determining of Protein

The Bradford [

23] was used to determine the concentration of total protein in the top phase. RP-HPLC was used to determine the concentration of OVA in salted egg white solution and in the top phase. The waters C

8 column (4.6 mm × 150 mm) was used and mobile phase A was 0.05% of aqueous TFA, while the mobile phase B was 0.05% TFA in acetonitrile. The flow rate was set to 1.00 mL/min while the concentration of mobile phase A decreased from 93% to 30% in 17 min and increased to 93% before 22 min [

24]. The effluent was detected at a wavelength of 280 nm.

2.6. Definition of the Distribution of Protein in ATPF

The flotation efficiency (

Y) and purification (

P) of OVA were used to evaluation the enrichment and separation of OVA by ATPF, and were calculated by the following equations:

where

COVA,

CSample and

CTop were the concentrations of OVA in the top phase and salted egg white solution and total protein in top phase, respectively; while

VTop and

VSample were the volume of the top phase and salted egg white solution, respectively.

2.7. Characterization of Ovalbumin Structure

2.7.1. Electrophoresis

The proteins were identified by sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS–PAGE) in a gel of 12% bis-acrylamide homogeneous. The constant voltage was set at 80 V for approximately 20 min for stacking the gel and at 120 V for 55 min to separate the gel. At the end of the electrophoresis, the tape was stained with Coomassie Brilliant Blue R-250 for 30 min and decolorized with eluent [

25].

2.7.2. Nano LC-ESI-MS/MS

The digested protein sample was carried out by an HPLC system with a C18 column (75 μm × 80 mm). The HPLC solvent A was 9.5% water, 90% acetonitrile, and 0.5% formic acid. The HPLC solvent B was 97.5%water, 2% acetonitrile, and 0.5% formic acid. The gradient elution process was described as follows. The concentration of mobile phase A was improved from 2% to 90% within 60 min. The column flow rate was approximately 800 nanoliter per minute after splitting. The typical sample injection volume was 3 µL. The HPLC system was coupled with a linear ion trap mass spectrometer (LTQ, Thermofisher, Shaihai, China), therefore, a sample eluted from the HPLC column was directly ionized by an electrospray ionization (ESI) process and entered into the mass spectrometer. The ionization voltage was often optimized in the instrument tuning process and it ranged from 1.5 kv to 1.8 kv. The capillary temperature was set at 100 °C. The mass spectrometer was set at the data-dependent mode to acquire MS/MS data via a low energy collision induced dissociation (CID) process. The default charge state was 3 and the default collision energy was 33%. One full scan with one microscan with a mass range of 350 amu to 1650 amu was acquired, followed by nine MS/MS scans of the nine most intense ions with a full mass range and three microscans. The dynamic exclusion feature was set as follows: Repeat the count of 1 and the exclusion duration of 1 min. The exclusion width was 4Da [

26].

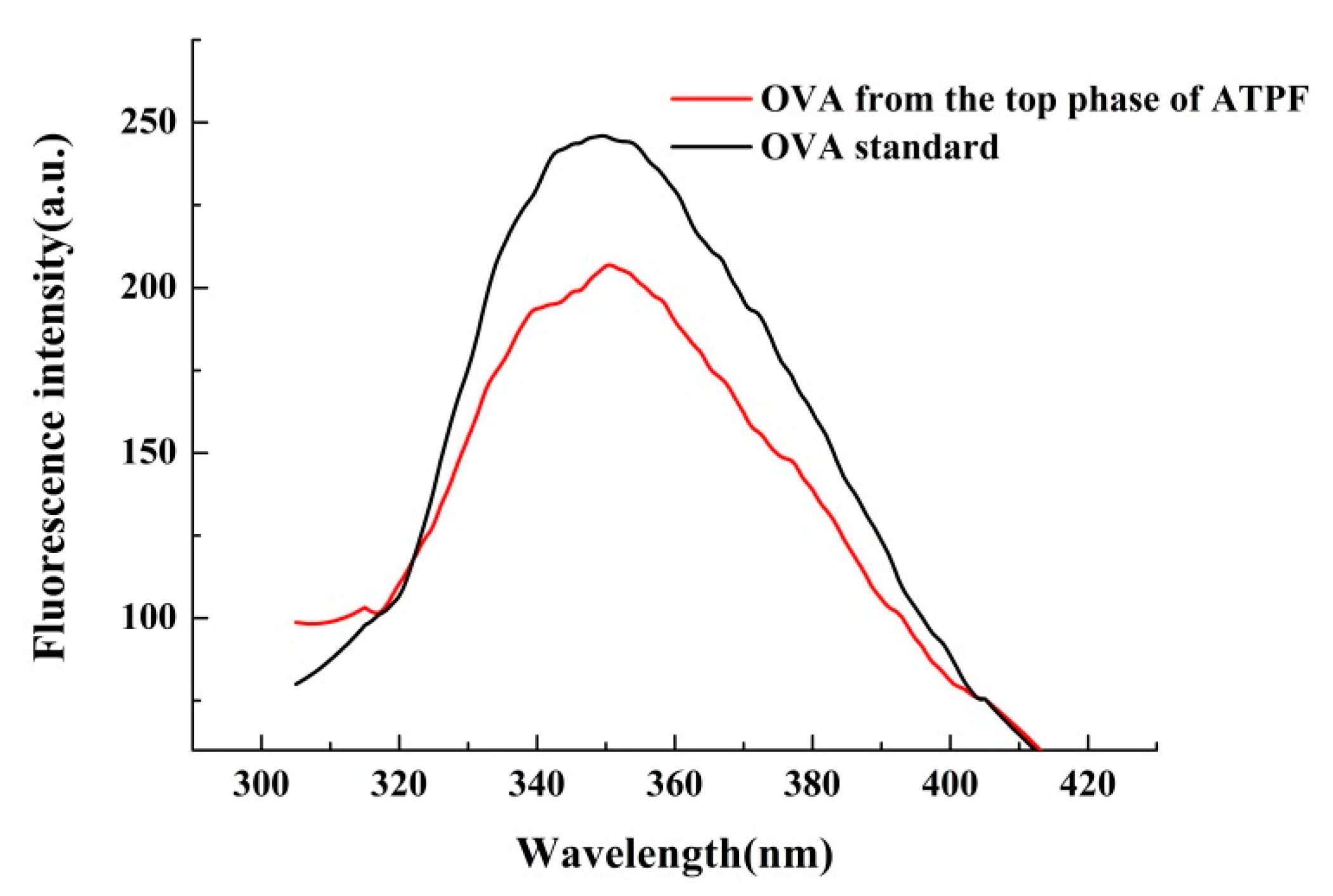

2.7.3. Spectrum Analysis

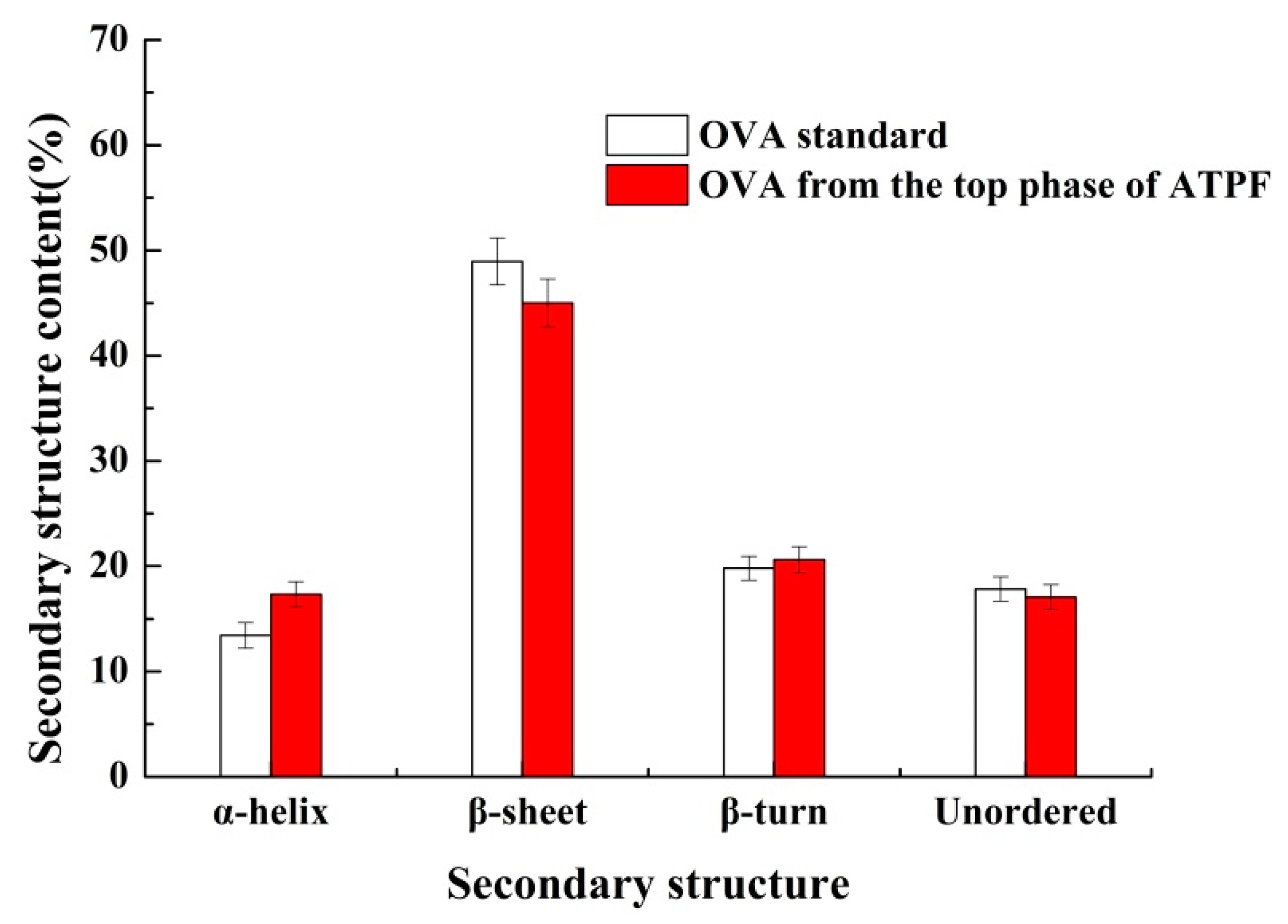

The OVA structure was analyzed using a fluorescence spectrometer PerkinElmer LS55. After being dissolved in 10 mmol/L phosphate buffer (pH = 7.2) and diluted to the appropriate concentration. The sample was measured at fluorescence excitation wavelengths of 295 nm and 280 nm, respectively. The emission spectrum was scanned from 315 nm to 415 nm. The fluorescence spectroscopy was performed at both slit and excitation slit widths of 5 nm. The ultraviolet spectrophotometer UV-2550 was used to scan the sample solution in the range of 250–360 nm.

Then, 2 mg of the sample powder was mixed with 200 mg of potassium bromide powder, which was ground under an infrared baking lamp for 10 min and pressed in a mold. The FT-IR spectra were measured at 400 cm

−1~4000 cm

−1. The experiment was repeated three times. After the infrared spectra was obtained, the protein conformation was analyzed by Peak Fit v4.12 software [

27].

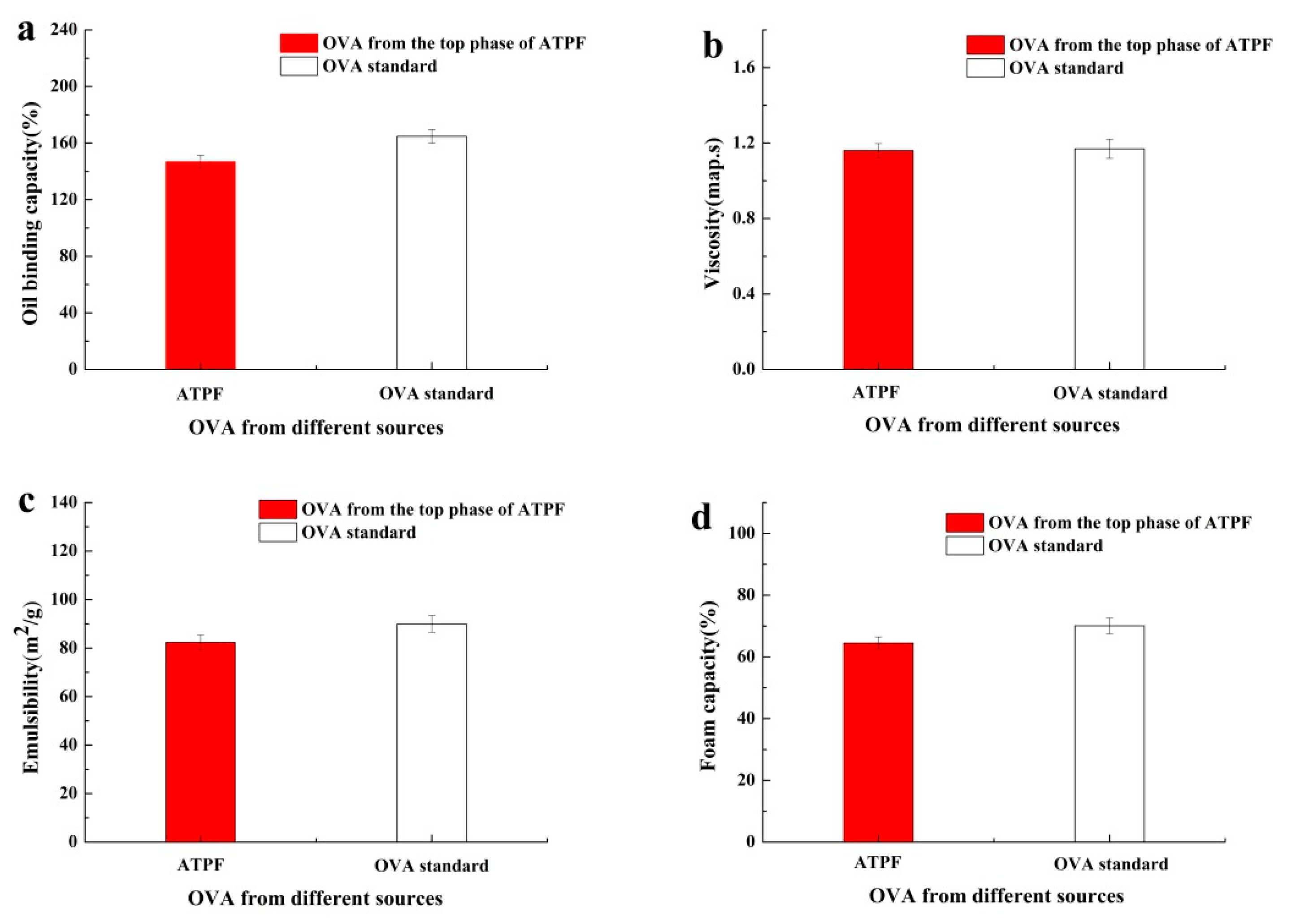

2.8. Determination of Functional Properties of Ovalbumin

2.8.1. Oil Binding Capacity (OBC)

Further, 0.100 g of ovalbumin sample and 1 mL of edible oil were mixed in a 10 mL centrifuge tube by shaking, and the mixture was centrifuged at 716×

g for 30 min, which was weighed as

W1. The top layer of oil was removed and the residual mixture and the tube weighed as

W2. The quality of the sample was recorded as

WSample. The formula for calculating was as follows:

2.8.2. Viscosity

The sample solution with a concentration of 10 g/L was prepared in a 30 °C water bath, which was determined by a digital viscometer.

2.8.3. Emulsibility

The measurement was carried out according to the method of Xiong [

28]. The sample was dissolved in a 10 mmol/L phosphate buffer solution and the final concentration of the sample was 5 mg/mL. The protein solution was mixed with soybean oil by a volume ratio 9:1 (oil:protein solution) and placed in a high-speed homogenizer at 10,000 rpm for 1 min. Further, 50 μL of the above sample was diluted 100 times with 0.1% (

w/

v) SDS, and then measured by an ultraviolet-visible spectrophotometer at 500 nm. The formula for calculating the emulsifying index (

EAI, m

2/g) was as follows:

where

C was the concentration of protein,

DF was the dilution factor (100),

θ was the proportion of the oil phase in the emulsion (1:10),

φ was the cuvette optical path (1 cm) and

A was the absorbance value.

2.8.4. Foam Capacity

Furthermore, 100 mL of 1% (

w/

v) OVA solution was added into a 250 mL beaker, which was dispersed by a high-speed disperser at 10,000 r/min for 2 min. Then, the volume of foam was measured. The foaming capacity (

FC) was calculated as follows [

29]:

where

V0 was the total volume of liquid and foam at the time of dispersion stop (mL); 100 was the volume of the stock solution (mL).