Andean Pseudocereal Flakes with Added Pea Protein Isolate and Banana Flour: Evaluation of Physical–Chemical, Microstructural, and Sensory Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Extrusion Process

2.3. Physico-Chemical Characterisation of Extruded Products

2.4. Physical Characterisation

2.4.1. Colour Determination

2.4.2. Expansion and Conversion Properties of Starch

2.4.3. Hardness

2.5. Scanning Electron Microscopy (SEM)

2.6. Sensorial Characterisation

2.6.1. Flash Profile

2.6.2. Free Sorting Task

2.7. Statistical Data Analysis

3. Results and Discussion

3.1. Physico-Chemical Characterisation

3.2. Physical Characterisation

3.2.1. Colour Parameters

3.2.2. Expansion and Conversion Properties of Starch

3.2.3. Hardness

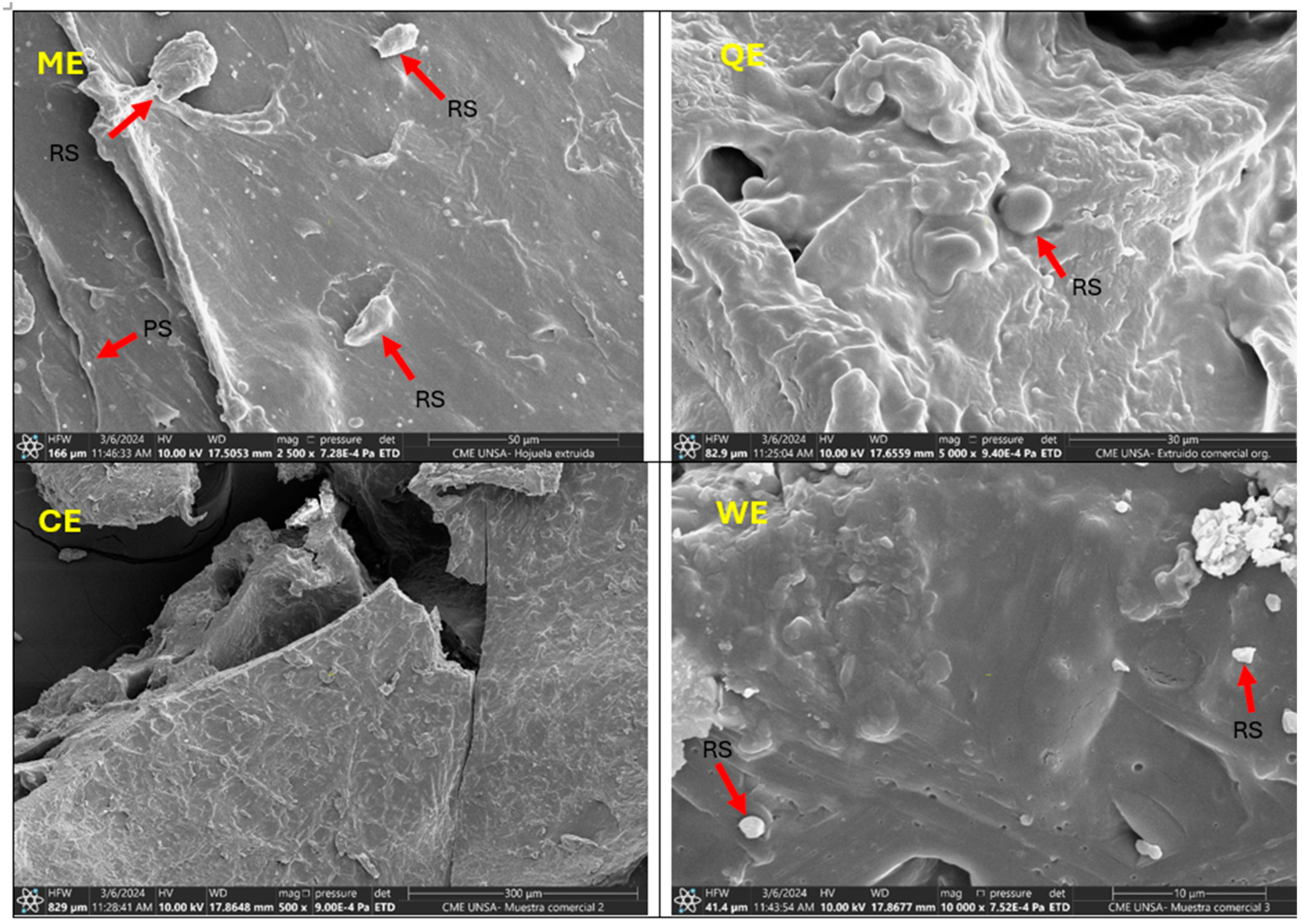

3.3. SEM

3.4. Sensorial Characterisation

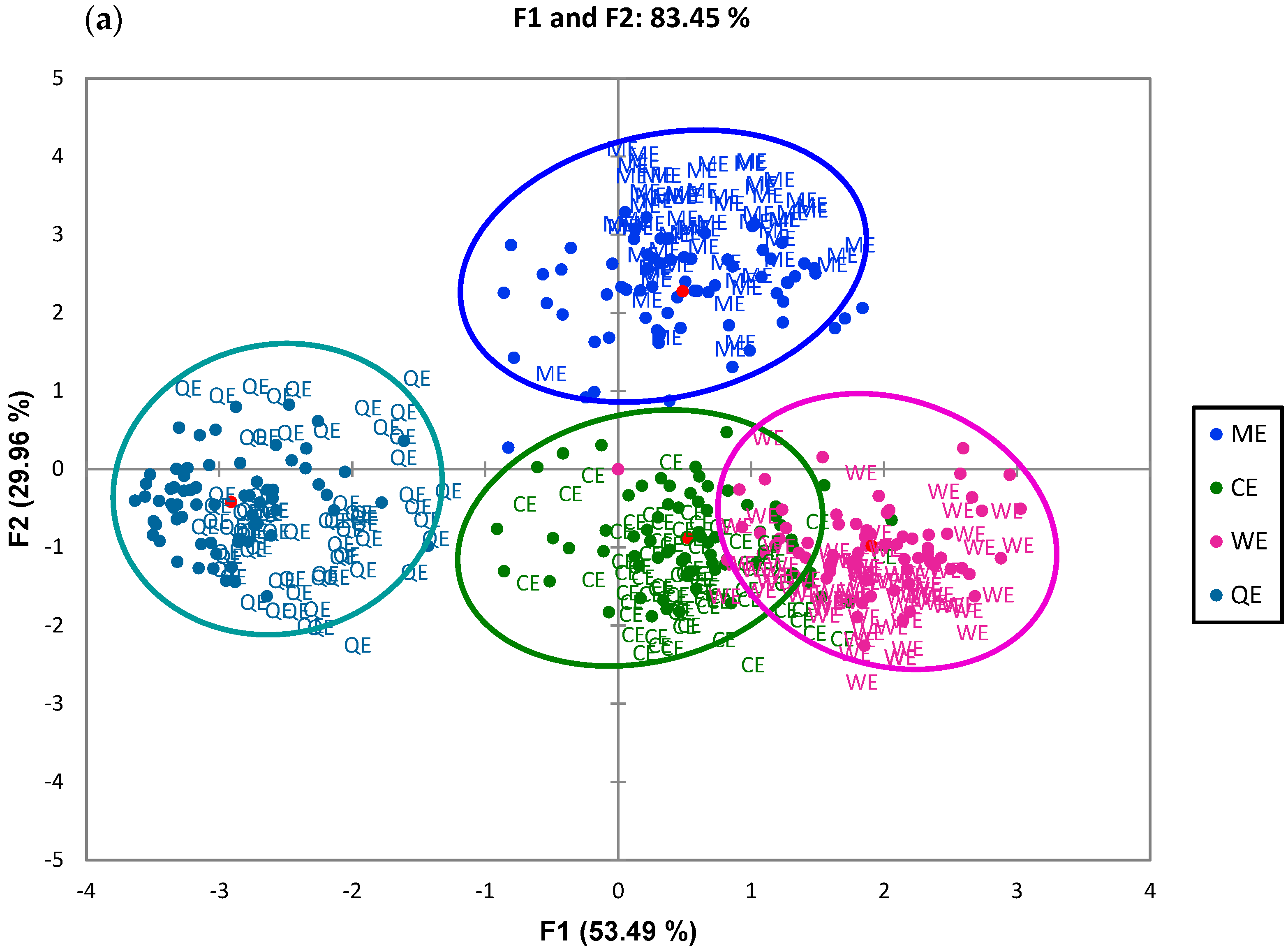

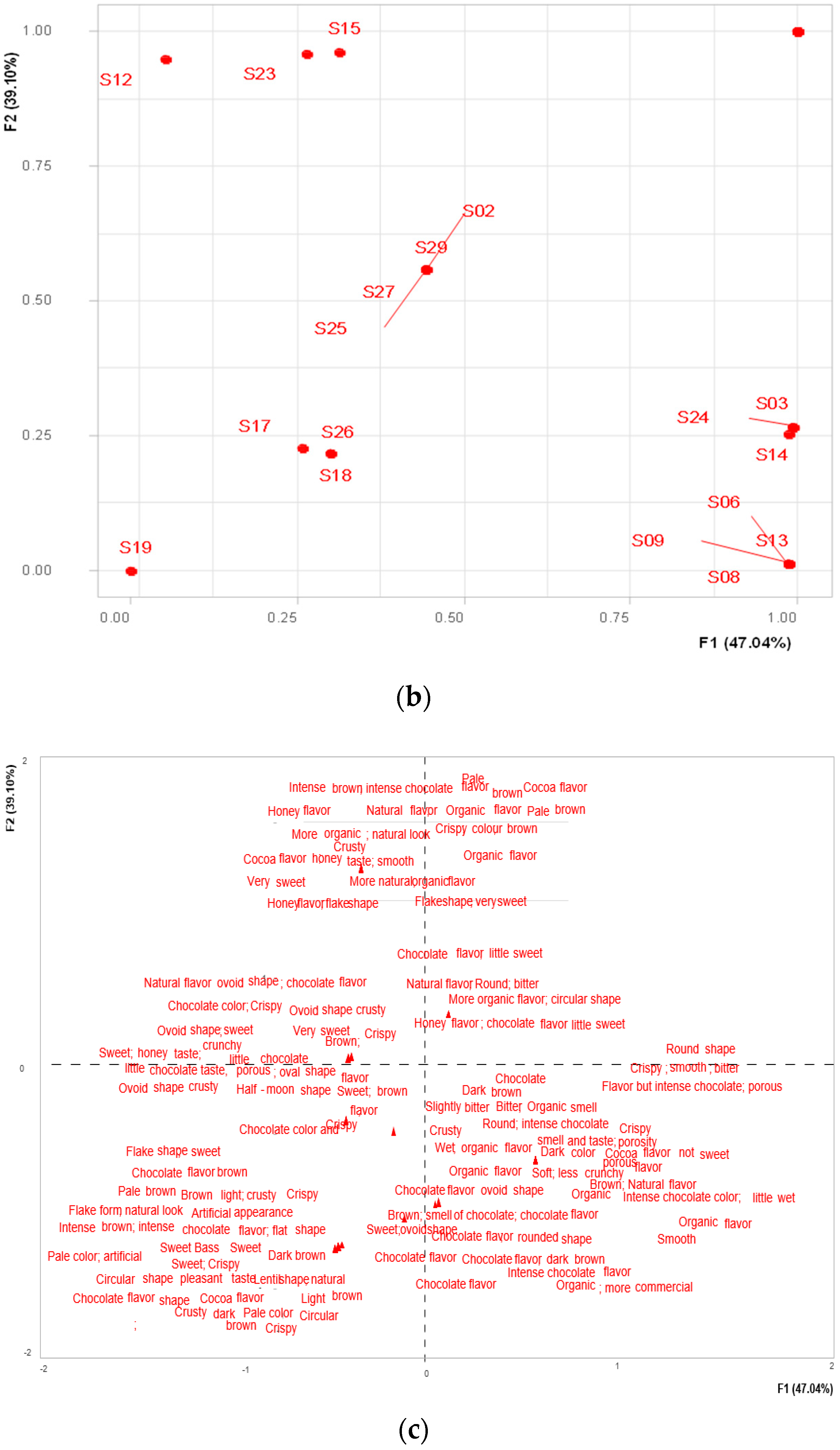

3.4.1. Flash Profile

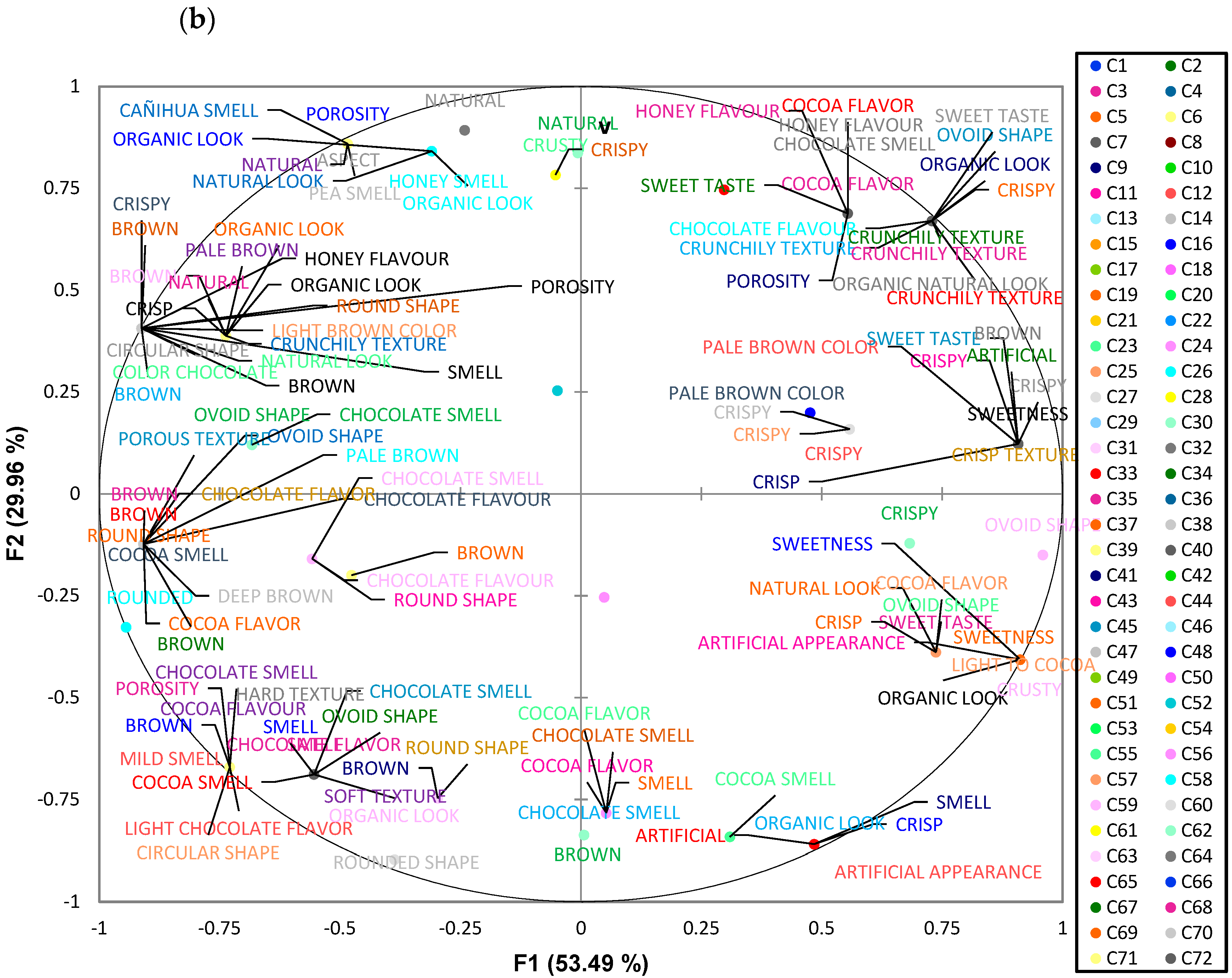

3.4.2. Free Sorting Task

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ek, P.; Ganjyal, G.M. Basics of Extrusion Processing. In Extrusion Cooking; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–28. ISBN 978-0-12-815360-4. [Google Scholar]

- Huang, X.; Liu, H.; Ma, Y.; Mai, S.; Li, C. Effects of Extrusion on Starch Molecular Degradation, Order–Disorder Structural Transition and Digestibility—A Review. Foods 2022, 11, 2538. [Google Scholar] [CrossRef] [PubMed]

- Offiah, V.; Kontogiorgos, V.; Falade, K.O. Extrusion Processing of Raw Food Materials and By-Products: A Review. Crit. Rev. Food Sci. Nutr. 2019, 59, 2979–2998. [Google Scholar] [CrossRef] [PubMed]

- Sciammaro, L.; Ferrero, C.; Puppo, C. Physicochemical and Nutritional Characterization of Sweet Snacks Formulated with Prosopis alba Flour. LWT 2018, 93, 24–31. [Google Scholar] [CrossRef]

- Martínez-Villaluenga, C.; Peñas, E.; Hernández-Ledesma, B. Pseudocereal Grains: Nutritional Value, Health Benefits and Current Applications for the Development of Gluten-Free Foods. Food Chem. Toxicol. 2020, 137, 111178. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 7 September 2024).

- Hussain, M.I.; Farooq, M.; Syed, Q.A.; Ishaq, A.; Al-Ghamdi, A.A.; Hatamleh, A.A. Botany, Nutritional Value, Phytochemical Composition and Biological Activities of Quinoa. Plants 2021, 10, 2258. [Google Scholar] [CrossRef] [PubMed]

- Paucar-Menacho, L.M.; Schmiele, M.; Lavado-Cruz, A.A.; Verona-Ruiz, A.L.; Mollá, C.; Peñas, E.; Frias, J.; Simpalo-Lopez, W.D.; Castillo-Martínez, W.E.; Martínez-Villaluenga, C. Andean Sprouted Pseudocereals to Produce Healthier Extrudates: Impact in Nutritional and Physicochemical Properties. Foods 2022, 11, 3259. [Google Scholar] [CrossRef]

- Quispe, A.J.; Moreno, M.C.; Leon, A.M.; Bouchon, P.; Medina, W.T. Design of Cañihua-Rice: Development and Characterization of an Analogue of Rice by Warm-Extrusion of Cañihua (Chenopodium pallidicaule Aellen) and Rice (Oryza sativa) Flours. Food Humanit. 2024, 2, 100193. [Google Scholar] [CrossRef]

- Quiroga Ledezma, C.C. Chapter 1—Native Food Crops for Present and Future Generations: Their Role in Nutrition and Health. In Sustainability of the Food System; Betoret, N., Betoret, E., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 3–23. ISBN 978-0-12-818293-2. [Google Scholar]

- Ge, J.; Sun, C.-X.; Corke, H.; Gul, K.; Gan, R.-Y.; Fang, Y. The Health Benefits, Functional Properties, Modifications, and Applications of Pea (Pisum sativum L.) Protein: Current Status, Challenges, and Perspectives. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1835–1876. [Google Scholar] [CrossRef]

- Wu, D.-T.; Li, W.-X.; Wan, J.-J.; Hu, Y.-C.; Gan, R.-Y.; Zou, L. A Comprehensive Review of Pea (Pisum sativum L.): Chemical Composition, Processing, Health Benefits, and Food Applications. Foods 2023, 12, 2527. [Google Scholar] [CrossRef]

- Texture, Sensory Properties and Functionality of Extruded Snacks from Pulses and Pseudocereal Proteins. J. Sci. Food Agric. 2022, 102, 5011–5021. [CrossRef]

- Sarawong, C.; Schoenlechner, R.; Sekiguchi, K.; Berghofer, E.; Ng, P.K.W. Effect of Extrusion Cooking on the Physicochemical Properties, Resistant Starch, Phenolic Content and Antioxidant Capacities of Green Banana Flour. Food Chem. 2014, 143, 33–39. [Google Scholar] [CrossRef] [PubMed]

- Chang, L.; Yang, M.; Zhao, N.; Xie, F.; Zheng, P.; Simbo, J.; Yu, X.; Du, S. Structural, Physicochemical, Antioxidant and in Vitro Digestibility Properties of Banana Flours from Different Banana Varieties (Musa spp.). Food Biosci. 2022, 47, 101624. [Google Scholar] [CrossRef]

- Muñoz-Pabon, K.S.; Roa-Acosta, D.F.; Hoyos-Concha, J.L.; Bravo-Gómez, J.E.; Ortiz-Gómez, V. Quinoa Snack Production at an Industrial Level: Effect of Extrusion and Baking on Digestibility, Bioactive, Rheological, and Physical Properties. Foods 2022, 11, 3383. [Google Scholar] [CrossRef] [PubMed]

- Tapia, M.; Marimón, S.J.; Salazar, N. Development of Extruded Snacks with Protein Hydrolysed from Jumbo Squid (Dosidicus gigas) by-Product and Cañihua (Chenopodium pallidicaule Aellen). Biol. Life Sci. Forum 2023, 25, 4. [Google Scholar] [CrossRef]

- Edima-Nyah, A.P.; Amande, E.I.; Ekanem, K.E. Functional Properties, Nutrient Content, Digestibility and Acceptability of Breakfast Cereals Made from Yellow Maize-Soybean Composite and Firm-Ripe Banana Flour. Afr. J. Adv. Sci. Technol. Res. 2024, 15, 99–120. [Google Scholar] [CrossRef]

- Jenniss, S.W.; Katz, S.A.; Lynch, R.W. Books in Brief. J. AOAC Int. 1997, 80, 127A–128A. [Google Scholar] [CrossRef]

- Košutić, M.; Djalović, I.; Filipović, J.; Jakšić, S.; Filipović, V.; Nićetin, M.; Lončar, B. The Development of Novel Functional Corn Flakes Produced from Different Types of Maize (Zea mays L.). Foods 2023, 12, 4257. [Google Scholar] [CrossRef]

- A General Model for Expansion of Extruded Products. J. Food Sci. 1988, 53, 609–615. [CrossRef]

- Comettant-Rabanal, R.; Hidalgo Chávez, D.W.; Ascheri, J.L.R.; Elías-Peñafiel, C.; Carvalho, C.W.P. Functionality of Pre-Cooked Whole-Grain Corn, Rice and Sorghum Flours for Gluten-Free Bread. Int. J. Food Sci. Technol. 2023, 58, 5781–5795. [Google Scholar] [CrossRef]

- Collantes, N.F.; Carvalho, C.W.P.; Ascheri, J.L.R.; Chávez, D.W.H.; Comettant-Rabanal, R.; Bernardo, C.O.; Queiroz, V.A.V. Effect of Sucrose on the Extrusion of Varied Whole Sorghum Grits Genotypes. J. Food Process. Preserv. 2022, 46, e17204. [Google Scholar] [CrossRef]

- Barraza Jáuregui, G.D.C.; Miano Pastor, A.C.; Espinoza Aguilar, M.S.; Obregón Domínguez, J.A. Barras Energéticas a Base de Quinua, Kiwicha y Chía: Características Texturales, Acústicas y Sensoriales; LACCEI Inc.: Boca Raton, FL, USA, 2020; p. 377. [Google Scholar] [CrossRef]

- Yoon, G.; Kwak, H.S.; Heo, J.; Lee, Y. Comparison of Conventional and Consumer-Based Sensory Profiling Methods for Ready-to-Drink Coffee Beverages. J. Sens. Stud. 2023, 38, e12839. [Google Scholar] [CrossRef]

- Montanuci, F.D.; Marques, D.R.; Monteiro, A.R.G. Flash Profile for Rapid Descriptive Analysis in Sensory Characterization of Passion Fruit Juice. Acta Scientiarum. Technol. 2015, 37, 337–344. [Google Scholar] [CrossRef]

- O’Sullivan, M.G. Chapter Eight—Rapid Sensory Methods for Reformulation. In Salt, Fat and Sugar Reduction; O’Sullivan, M.G., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2020; pp. 183–214. ISBN 978-0-12-819741-7. [Google Scholar]

- Puma-Isuiza, G.G.; Núñez-Saavedra, C. Comparación del Perfil Flash y Napping®-UPF en la caracterización sensorial de hot-dog. Rev. Investig. Altoandinas J. High Andean Res. 2020, 22, 135–145. [Google Scholar] [CrossRef]

- Ares, G.; Varela, P. Chapter 8—Consumer-Based Methodologies for Sensory Characterization. In Methods in Consumer Research, Volume 1; Ares, G., Varela, P., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2018; pp. 187–209. ISBN 978-0-08-102089-0. [Google Scholar]

- Pineau, N.; Girardi, A.; Lacoste Gregorutti, C.; Fillion, L.; Labbe, D. Comparison of RATA, CATA, Sorting and Napping® as Rapid Alternatives to Sensory Profiling in a Food Industry Environment. Food Res. Int. 2022, 158, 111467. [Google Scholar] [CrossRef]

- Marque, C.; Motta, C.; Richard, T.J.C. Free Sorting Task of Chocolate Proteins Bars: Pilot Study and Comparison between Trained and Untrained Panelists. J. Sens. Stud. 2022, 37, e12744. [Google Scholar] [CrossRef]

- Santacruz Soto, C.L. Formulación de un Cereal Extruido a base de Arroz (Oryza sativa), trigo (Triticum aestivum), Cañihua (Chenopodium pallidicaule) y Fortificado con Harina de Sangre de Vacuno. 2022. Available online: https://repositorio.unprg.edu.pe/handle/20.500.12893/10136 (accessed on 14 March 2024).

- Carrasco Calle, J.J.; Saucedo Guevara, J.M. Formulación y evaluación de un alimento instantáneo por extrusión a base de maíz mote (Zea mays L.) y trigo (Triticum aestivum). 2019. Available online: https://repositorio.unprg.edu.pe/handle/20.500.12893/4599 (accessed on 7 February 2024).

- Perez-Rea, D.; Antezana-Gomez, R. Chapter 15—The Functionality of Pseudocereal Starches. In Starch in Food, 3rd ed.; Nilsson, L., Ed.; Woodhead Publishing: Sawston, UK, 2024; pp. 377–403. ISBN 978-0-323-96102-8. [Google Scholar]

- Abogunrin, S.O.; Ujiroghene, O.J. Formulation and Quality Evaluation of Breakfast Flakes Produced from Blends of Maize (Zea mays) and Quinoa (Chenopodium quinoa Willd) Flour. Asian Food Sci. J. 2022, 21, 38–51. [Google Scholar] [CrossRef]

- Figueroa, J.G.; Borrás-Linares, I.; Lozano-Sánchez, J.; Segura-Carretero, A. Comprehensive Identification of Bioactive Compounds of Avocado Peel by Liquid Chromatography Coupled to Ultra-High-Definition Accurate-Mass Q-TOF. Food Chem. 2018, 245, 707–716. [Google Scholar] [CrossRef]

- Aydın, S.; Özdemir, Y. Development and Characterization of Carob Flour Based Functional Spread for Increasing Use as Nutritious Snack for Children. J. Food Qual. 2017, 2017, 5028150. [Google Scholar] [CrossRef]

- Rolandelli, G.; Favre, L.C.; Mshicileli, N.; Vhangani, L.N.; Farroni, A.E.; van Wyk, J.; Buera, M.d.P. The Complex Dependence of Non-Enzymatic Browning Development on Processing Conditions in Maize Snacks. LWT 2021, 147, 111636. [Google Scholar] [CrossRef]

- Ondo, S.E.; Ryu, G.-H. Physicochemical and Antioxidant Properties of Extruded Cornmeal with Natural Cocoa Powder. Food Sci. Biotechnol. 2013, 22, 167–175. [Google Scholar] [CrossRef]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and Extruded Products: Changes in Quality Attributes as Affected by Extrusion Process Parameters: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef]

- dos Santos, T.B.; Chávez, D.W.H.; Mellinger, C.G.; de Carvalho, C.W.P. In Vitro Digestibility of Carbohydrates and Physicochemical Properties of Pearl Millet and Corn Whole Grain Flour Extrudates. J. Food Process Eng. 2024, 47, e14478. [Google Scholar] [CrossRef]

- Pérez Ramos, K.P. Elaboración de un Bocadito Extruido de Quinua, Tarwi y Fécula de Camote para Niños Escolares; Universidad Nacional Agraria La Molina: La Molina, Peru, 2019. [Google Scholar]

- Cork, S.D.; Blanchard, C.; Mawson, A.J.; Farahnaky, A. Pulse Flaking: Opportunities and Challenges, a Review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2873–2897. [Google Scholar] [CrossRef]

- Zhu, F.; Li, H. Effect of High Hydrostatic Pressure on Physicochemical Properties of Quinoa Flour. LWT 2019, 114, 108367. [Google Scholar] [CrossRef]

- Romano, A.; Masi, P.; Nicolai, M.A.; Falciano, A.; Ferranti, P. QUINOA (Chenopodium quinoa Willd.) Flour as Novel and Safe Ingredient in Bread Formulation. Chem. Eng. 2019, 75, 301–306. [Google Scholar]

- Kumar, P.S.; Saravanan, A.; Sheeba, N.; Uma, S. Structural, Functional Characterization and Physicochemical Properties of Green Banana Flour from Dessert and Plantain Bananas (Musa spp.). LWT 2019, 116, 108524. [Google Scholar] [CrossRef]

- Pumacahua-Ramos, A.; Demiate, I.M.; Travalini, A.P.; Granza, A.G.; Farias, F.O.; Schnitzler, E.; Lopes-Filho, J.F. Morphological, Thermal, and Physicochemical Characteristics of Nano Starch from Cañihua (Chenopodium pallidicaule Aellen). Starch—Stärke n/a 2023, 2023, 2300095. [Google Scholar] [CrossRef]

- Ahmed, J.; Al-Ruwaih, N.; Mulla, M.; Rahman, M.H. Effect of High Pressure Treatment on Functional, Rheological and Structural Properties of Kidney Bean Protein Isolate. LWT 2018, 91, 191–197. [Google Scholar] [CrossRef]

- Sivakumar, C.; Stobbs, J.A.; Tu, K.; Karunakaran, C.; Paliwal, J. Unravelling Particle Morphology and Flour Porosity of Roller-Milled Green Lentil Flour Using Scanning Electron Microscopy and Synchrotron X-Ray Micro-Computed Tomography. Powder Technol. 2024, 436, 119470. [Google Scholar] [CrossRef]

- Ferroukhi, I.; Bord, C.; Lavigne, R.; Chassard, C.; Mardon, J. Exploring Alternative Salting Methods to Reduce Sodium Content in Blue-Veined Cheeses. Int. Dairy J. 2023, 138, 105555. [Google Scholar] [CrossRef]

- Schmelter, L.; Rohm, H.; Struck, S. Gluten-Free Bakery Products: Cookies Made from Different Vicia faba Bean Varieties. Future Foods 2021, 4, 100038. [Google Scholar] [CrossRef]

- Kalschne, D.L.; Biasuz, T.; De Conti, A.J.; Viegas, M.C.; Corso, M.P.; Benassi, M.d.T. Sensory Characterization and Acceptance of Coffee Brews of C. Arabica and C. Canephora Blended with Steamed Defective Coffee. Food Res. Int. 2019, 124, 234–238. [Google Scholar] [CrossRef] [PubMed]

- Nacef, M.; Lelièvre-Desmas, M.; Drider, D.; Flahaut, C.; Chollet, S. Artisanal and Industrial Maroilles Cheeses: Are They Different? Comparison Using Sensory, Physico-Chemical and Microbiological Approaches. Int. Dairy J. 2019, 89, 42–52. [Google Scholar] [CrossRef]

| Sample | List of Ingredients | Image |

|---|---|---|

| ME 1 | Cañihua flour (59.52%), banana flour (29.76%), pea protein concentrate (5.95%), chocolate powder (3%), quinoa flour (1.77%), and honey and water solution (5%). |  |

| QE 2 | Organic quinoa, organic cane sugar, cocoa paste, salt. |  |

| CE 3 | Cereal grains (whole corn flour, wheat flour, whole wheat flour), sugar, cocoa powder, malt extract, fractionated palm oil, vitamins and minerals, emulsifier (dicalcium phosphate), salt, cocoa liquor, natural flavouring (vanillin), and antioxidant (mixed tocopherol concentrate). |  |

| WE 4 | Fortified wheat flour, sugar, cocoa, marshmallows, malt extract, malt flour, calcium and phosphorus (tricalcium phosphate), salt, glucose, flavourings (chocolate and evaporated milk flavour), iron and vitamins, colouring (caramel IV), emulsifier (sunflower lecithin), sweetener (steviol glycosides from stevia), and antioxidant (concentrated tocopherol blend). |  |

| Sample (g/100 g) (d.b.) | Protein (Nt × 6.25) | Lipids | Crude Fibre | Carbohydrates | Ashes | Moisture |

|---|---|---|---|---|---|---|

| ME 1 | 13.60 ± 0.01 a | 2.60 ± 0.01 b | 2.20± 0.01 a | 74.50± 0.07 c | 2.08± 0.11 b | 5.02 ± 0.02 b |

| QE 2 | 12.57 ± 0.01 b | 14.19 ± 0.03 a | 2.56± 0.30 a | 61.33± 0.26 d | 2.18± 0.06 b | 7.16 ± 0.03 a |

| CE 3 | 9.03 ± 0.07 d | 1.01 ± 0.08 c | 1.07± 0.03 b | 81.12± 0.76 b | 3.14± 0.01 a | 4.14 ± 0.08 c |

| WE 4 | 10.06 ± 0.14 c | 0.37 ± 0.17 d | 0.67± 0.23 b | 83.65± 0.13 a | 1.48± 0.04 c | 3.77 ± 0.03 d |

| Parameters | ME | QE | CE | WE |

|---|---|---|---|---|

| L | 53.98 ± 0.88 b | 49.56 ± 0.39 c | 49.60 ± 1.13 c | 58.62 ± 0.310 a |

| a* | 5.52 ± 0.19 c | 7.84 ± 0.26 a | 7.16 ± 0.07 b | 7.69 ± 0.26 a |

| b* | 11.06 ± 0.53 b | 11.71 ± 0.62 b | 9.46 ± 0.44 c | 14.60 ± 0.60 a |

| C | 12.36 ± 0.54 c | 14.10 ± 0.66 b | 11.86 ± 0.39 c | 16.51 ± 0.65 a |

| H | 63.47 ± 0.67 a | 56.18 ± 0.53 b | 52.87 ± 1.02 c | 62.22 ± 0.20 a |

| ΔE* | - | 5.77 ± 0.73 a | 3.30 ± 0.98 b | 5.64 ± 0.41 a |

| Hardness (N) | 46.62 ± 0.01 a | 21.91 ± 0.01 b | 17.84 ± 0.17 c | 13.30 ± 0.09 d |

| Property | ME | QE | CE | WE |

|---|---|---|---|---|

| SEI 1 | 2.74 ± 0.13 a | 2.58 ± 0.13 a | 4.40 ± 0.31 b | 4.78 ± 0.38 c |

| BD 2 (g/cm3) | 0.27 ± 0.01 c | 0.26 ± 0.01 bc | 0.25 ± 0.01 a | 0.25 ± 0.01 b |

| WAI 3 | 4.46 ± 0.07 c | 4.23 ± 0.06 b | 2.88 ± 0.13 a | 4.23 ± 0.14 b |

| WSI 4 | 21.42 ± 0.60 a | 22.73 ± 1.46 a | 51.86 ± 3.03 c | 33.15 ± 0.74 b |

| Extrudate images |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leiva-Castro, B.; Mamani-Benavente, L.; Elías-Peñafiel, C.; Comettant-Rabanal, R.; Silva-Paz, R.; Olivera-Montenegro, L.; Paredes-Concepción, P. Andean Pseudocereal Flakes with Added Pea Protein Isolate and Banana Flour: Evaluation of Physical–Chemical, Microstructural, and Sensory Properties. Foods 2025, 14, 620. https://doi.org/10.3390/foods14040620

Leiva-Castro B, Mamani-Benavente L, Elías-Peñafiel C, Comettant-Rabanal R, Silva-Paz R, Olivera-Montenegro L, Paredes-Concepción P. Andean Pseudocereal Flakes with Added Pea Protein Isolate and Banana Flour: Evaluation of Physical–Chemical, Microstructural, and Sensory Properties. Foods. 2025; 14(4):620. https://doi.org/10.3390/foods14040620

Chicago/Turabian StyleLeiva-Castro, Briggith, Liliana Mamani-Benavente, Carlos Elías-Peñafiel, Raúl Comettant-Rabanal, Reynaldo Silva-Paz, Luis Olivera-Montenegro, and Perla Paredes-Concepción. 2025. "Andean Pseudocereal Flakes with Added Pea Protein Isolate and Banana Flour: Evaluation of Physical–Chemical, Microstructural, and Sensory Properties" Foods 14, no. 4: 620. https://doi.org/10.3390/foods14040620

APA StyleLeiva-Castro, B., Mamani-Benavente, L., Elías-Peñafiel, C., Comettant-Rabanal, R., Silva-Paz, R., Olivera-Montenegro, L., & Paredes-Concepción, P. (2025). Andean Pseudocereal Flakes with Added Pea Protein Isolate and Banana Flour: Evaluation of Physical–Chemical, Microstructural, and Sensory Properties. Foods, 14(4), 620. https://doi.org/10.3390/foods14040620