Abstract

In order to address the issue of inadequate negative pressure distribution in the gas extraction pipeline network and to enhance the efficiency of gas extraction, a study was conducted on the mechanisms of mutual influence between various branches within the gas extraction pipeline network. Using graph theory principles, a gas extraction network graph was built, and the gas extraction pipeline network was solved through the assignment adjustment iterative method. The study summarizes the sensitivity analysis of various control parameters, regulation patterns of branch valves and extraction pump control parameters at different network positions, and the impact of time parameters on the network’s operational conditions. Based on the solution results, an intelligent gas extraction control strategy was proposed. The results indicate that, under safety and efficiency constraints, gas concentration increased by approximately 11%, and gas purity increased by 0.3 m3/min, resulting in a 4.7% improvement after the implementation of intelligent control. The overall performance of the pipeline network was significantly enhanced. These research findings are of great significance for achieving efficient gas extraction.

1. Introduction

Mine gas, a toxic and harmful gas produced during the process of coal mining, can potentially lead to gas disasters and accidents [1,2,3]. However, if utilized properly, it can serve as a clean source of energy [4]. In recent years, as mining has entered the phase of deep mining, the combined effects of in situ stress and coal seam permeability have led to increased gas pressure within the coal seam. Gas disasters have evolved into complex dynamic disasters, posing new challenges to the management of mine gas [5,6,7].

At present, in China, coal seam gas is mainly extracted by drilling boreholes in the coal seam and utilizing extraction pumps to create a specified negative pressure [8]. The underground borehole gas extraction technology has been widely applied in high gas mines and coal and gas outburst mines [9,10]. However, the effectiveness of many borehole gas extraction methods does not meet expectations. Changes in extraction negative pressure directly affect the extraction results. For instance, increasing the extraction negative pressure generally improves gas flow extraction, expanding the effective range and radius of extraction. However, it may also increase air leakage during drilling gas extraction, leading to a decrease in gas concentration and potentially raising the risk of coal self-ignition and fire [11]. Therefore, it is crucial to study and analyze the impact of extraction negative pressure on extraction effectiveness and to improve the rationality of the overall negative pressure of the extraction system. This issue is complex because, for each extraction borehole in the extraction system, the optimal extraction negative pressure varies under different extraction conditions [12].

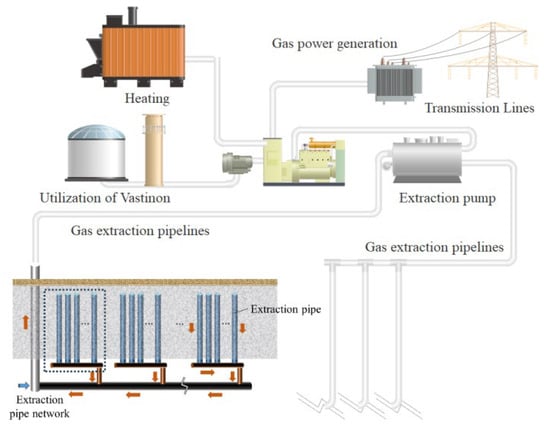

The extraction negative pressure has a significant impact on the gas extraction concentration and flow rate [13,14,15]. When the sealing quality of the borehole is constant, a higher extraction negative pressure may lead to a larger amount of gas leakage during the extraction process, resulting in a faster attenuation rate of extraction concentration. Air leakage can cause an increase in oxygen concentration, which can potentially lead to coal self-ignition and other disasters [16,17,18]. Conversely, if the negative pressure is too small, it may not overcome the resistance along the borehole and pipeline, potentially causing suffocation or blockage in the pipeline and borehole. This can lead to ineffective extraction or low extraction efficiency [19]. Scholars have studied the rules of extraction negative pressure. Cheng et al. [20] simulated and explored the impact of negative pressure on the extraction process by constructing a gas-solid coupled coal and gas model. Zhang et al. [21] studied the variation law of gas flow rate over time and pointed out that the effect of extraction negative pressure is more significant under negative pressure at the borehole mouth. Zhou et al. [22] introduced safety evaluation indicators for gas extraction and found that as the extraction pressure increases, the gas leakage inside the borehole also increases, leading to an increased accident rate and reduced extraction safety. Wang et al. [23] have identified factors affecting the extraction effect during negative pressure extraction and discussed the impact of extraction negative pressure on the early and late stages of extraction. Zhang et al. [24] conducted physical simulation experiments on negative pressure extraction and explored the rules by changing various parameter conditions during the negative pressure extraction experiment. Currently, the analysis of extraction hole negative pressure extraction is mostly based on boreholes, and systematic research is lacking. For research on pipeline networks, the current focus is mainly on ventilation networks [25,26] and natural gas networks [27]. There is limited research on the flow model and solution model of the gas extraction pipeline network, with most studies providing qualitative judgments but lacking quantitative research. The implementation of intelligent control in gas extraction pipeline networks can effectively enhance both gas concentration and extraction volume, ultimately achieving graded utilization of gas for applications such as heating, gas power generation, and regenerative thermal oxidation, as specifically illustrated in Figure 1.

Figure 1.

Schematic diagram of gas classification and utilization.

The gas extraction pipeline network constitutes an integrated system characterized by mutual coupling of extraction conditions across different zones. In addressing the nonlinear, strongly coupled, and time-varying dynamics inherent to the extraction process, the regulation of extraction negative pressure-a critical determinant of extraction efficiency-must be temporally adaptive. Current domestic research on the systemic operational characteristics of gas extraction networks remains underdeveloped, particularly regarding interaction mechanisms among branching conduits and quantitative correlations between negative pressure distribution and extraction efficacy. Existing studies predominantly offer qualitative assessments without robust quantitative verification. Furthermore, investigations into fluid dynamic modeling and computational methodologies for extraction networks lack both breadth and depth, while practical control strategies capable of quantitatively modulating gas parameters in field applications remain unrealized. This knowledge gap results in insufficient theoretical support for operational debugging of mine gas extraction networks. The present study establishes a real-time dynamic optimization and intelligent control system that enables rational dynamic distribution of negative pressure throughout the extraction network.

2. Theoretical Model

2.1. Graph Theoretical Model of Gas Drainage Pipeline Network

This passage describes the use of graph theory [28] to abstractly describe the gas extraction pipeline network in the mine. It sets nodes and branches and the gas extraction network they constitute. The vertices of the graph are drawn with gas extraction pumps, and the pipeline is represented as a branch in the graph, with the direction of the branches corresponding to the direction of gas flow. The intersecting points of the branches represent the nodes in the network graph. In the graph, the nodes and pipeline segments are labeled with numbers. For any pipeline segment between two adjacent nodes, the line connecting the two endpoints can also be used as the identifier for that pipeline segment. As the end branch directly connects to the drill site, the drill site has a similar drilling structure and a large number of drills. Therefore, the branch of the drill site and the connected drills can be treated as a whole, equivalent to a gas extraction source end. The gas flow in the underground coal seam gas extraction pipeline network is fixed in the direction of the extraction pump, and the connecting structure belongs to a simple tree-shaped branching single outlet pipeline structure, all of which exhibit directional flow. By analogizing the gas flow as one-dimensional unidirectional flow, the gas extraction network diagram can be obtained.

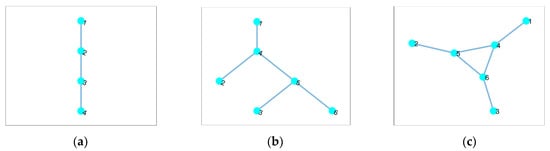

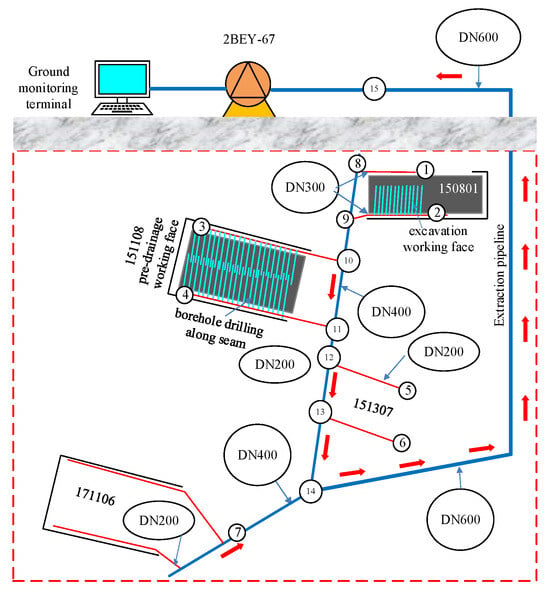

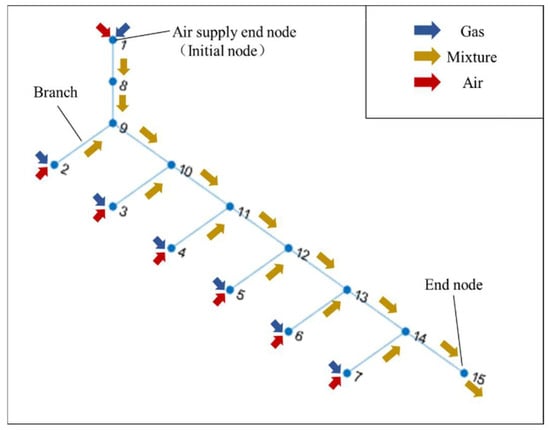

The pipeline system determines the topological structure of the network, which consists of three basic structures: linear pipeline network (a), tree-like pipeline network (b), and looped pipeline network (c), as shown in Figure 2. Taking a certain mining extraction system as an example, Figure 3 shows a schematic diagram of the gas extraction system in a mine. Utilizing the principles of graph theory, it can be equivalently represented as a network diagram of the gas extraction pipeline network, as shown in Figure 4.

Figure 2.

Schematic diagram of the basic topology of the pipe network: (a) linear pipeline network; (b) tree-like pipeline network; and (c) looped pipeline network.

Figure 3.

Schematic diagram of gas extraction system in coal mine.

Figure 4.

Network diagram of gas extraction pipe network in coal mine.

According to the principles of graph theory, the relationship between the maximum number of loops, the number of nodes, and the number of edges in a directed network graph is as follows:

where n is the number of edges; m is the number of nodes; c is the number of independent loops.

In comparison to the underground ventilation network, the gas extraction pipeline network typically forms a tree-like structure, which exhibits stronger network connectivity. In a tree-like network, where the number of independent loops is 0, the relationship between the number of edges (n) and the number of nodes (m) in its network diagram is as follows:

Establish a pipe section flow matrix to represent the mass flow rate of a certain component gas in each pipe section. Establish a node flow matrix to represent the absolute value of the mass flow rate of a component gas at each node. Construct a node flow characteristic matrix to represent the location and attributes of nodes in the pipe network. is defined as follows:

According to graph theory, the correlation matrix of directed graphs can be used to represent the structural relationships between nodes and edges in a pipe network [29].

Let be the correlation matrix of the mine gas pipe network, and the association matrix of the pipe network is

According to Kirchhoff’s first law, the sum of all traffic entering a node is equal to the sum of all traffic leaving the node. Therefore, the relationship between the node flow matrix and the pipe segment flow matrix can be established:

According to Formula (5), the network flow balance equation can be derived. Moreover, for a tree-like pipeline network, it is sufficient to know the flow at each gas source node and the flow at each branch node (where the flow at non-terminal and non-gas source nodes is 0) in order to determine the flow in each pipeline segment and the flow at the terminal node. Based on the actual conditions in the underground coal mine, the positions and lengths can be determined, and the gas flow can be used as the weight of the edges. By inputting this data into drawing software using computer programming, graphical results can be obtained.

2.2. Gas Drainage Pipe Network Flow Model

By applying graph theory and gas flow equations, (m − 1) distinct pipe pressure drop equations, one gas drainage pump characteristic equation, and (n − 1) × 2 gas source characteristic equations can be formulated for the gas drainage pipe network. The count of unknown parameters corresponds to the number of independent equations, specifically m + 2n − 2. Through solving this system, it becomes possible to establish the correlation between extraction negative pressure and extraction concentration and quantity, thereby enabling effective control of negative pressure.

From the gas-air mixed flow model of the pipeline network, the resistance equation along the gas pipeline, and the local resistance equation of the pipeline network, alongside the resistance regulation facilities’ local resistance equation, a model for branch resistance of the pipeline network was formulated. This led to the construction of the gas extraction pipeline network flow model. The equations for solving the gas extraction pipeline network are as follows [30]:

- (1)

- Gas-air mixed flow equation

The gas extraction mixture enters the pipeline network, flows through the confluence of the branch main pipe, and is pumped out by the gas extraction pump.

An equation for a rotational speed curve is expressed as

is the gas pressure at the inlet of the pump, Pa; Msum is the mixed flow rate of the main pipe network, m3/min.

The relationship can be fitted with quadratic terms:

is the local atmospheric pressure, take 0.101 MPa; is the mixed gas flow at the source end of i, kg/s; n is the number of last nodes; and n − 1 is the number of ingress nodes. a, b, and c are the working coefficients of the pump.

- (2)

- Mass flow equation

The boundary conditions for the pure gas flow rate and air flow rate of the negative pressure at the extraction gas source end are established [31]:

Ma is the air quality flow, kg/s; Mg is the mass flow rate of gas, kg/s; is the initial natural gas flow, kg/s; is the negative pressure increment coefficient, d−1; p is the nodal pressure, Pa; is the wind leakage drag coefficient; T is the thermodynamic temperature of the gas, K; is the general gas constant, 8.314 kJ/(kmol K); and Z is the compressibility coefficient.

- (3)

- Equation of resistance along the gas pipeline

Through the data collection of the opening of the control valve, the pressure loss and the mass flow rate of the mixed gas, the functional relationship between the pressure loss and the opening of the control valve and the mass flow rate of the mixed gas is obtained, as shown in Equation (10) [31]:

Among them, is the pumping pressure loss, and is the opening of the control valve.

So, on a roadway there is the following formula:

j and k are the node numbers, and pj and pk are the negative pressure of the nodes, Pa.

The system of equations is

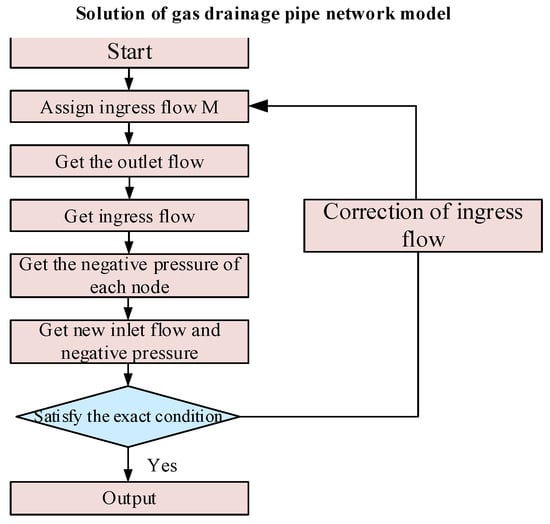

Leveraging the tree-like pipeline features of the gas extraction network, the impact of negative pressure on gas extraction, and the pipe section’s pressure drop pattern, the initially assigned flow rate undergoes continuous adjustments. This process leads to the iterative approximation of a specific nonlinear equation, enabling the solution of the intricate nonlinear equation system for resolving the gas extraction pipeline network.

2.2.1. Gas Extraction Pipe Network Calculation Process

This calculation model differs from the ventilation network calculation, which involves one-dimensional, incompressible fluid flow. The current calculation considers two-dimensional compressible fluid flow, converted into mass flow for computation, making the calculation more complex and precise.

Create a network diagram of the pipeline system, label key basic data, and assign numbers to each node and pipe segment. When assigning numbers, place the gas extraction pump node at the end. Determine the direction of gas flow, establish a correlation matrix, and formulate node flow balance equations. Identify the parameters in each equation, which can be based on empirical values or fitted based on real-time data from the pipeline network. Assign values of and to the node flow at the extraction inlet based on extraction data. It is advisable to use relatively small numerical values to avoid the risk of excessively large computation results. For instance, set and . For a valve-closed pipeline, the flow is considered to be zero.

Based on the correlation matrix and the node flow balance law, the flow rates of each pipe section and the drainage pump were determined. Combined with the characteristic curve of the gas drainage pump, the negative pressure P at the pump node under a fixed rotational speed was calculated. Using the equivalent length method, valves were treated equivalently. The pressure drop in each pipe section was obtained by applying the pipe section pressure drop equation, thereby determining the negative pressure at each node. This determination process should proceed in the reverse direction of gas flow.

Based on the negative pressure at the drainage pump node and the pressure drops in each pipe section, the negative pressures at all nodes were derived. Using the negative pressure and flow rate boundary conditions at the suction inlet nodes, new flow rates and at the inlet ends were obtained. The flow rates at the inlet ends were then adjusted for balance correction, with the reassignment performed using the bisection method. The calculation accuracy was checked. If the requirements were not met, the originally assigned gas source end values were balance-corrected using the recalculated air-gas flow rates from the gas source end. The pipe section resistances and pressure losses were then computed again. This iterative calculation cycle was repeated until the accuracy requirements were met.

Figure 5 illustrates the flow chart for solving the network:

Figure 5.

Flowchart of the solution.

2.2.2. Pipe Section Flow Assignment Method

The method of reassigning the flow rate of the pipe segment is the bisection method, which is the most commonly used method for solving equations. According to the zero-point theorem: if is continuous on , and , then there is at least one point such that . The fundamental principle of the bisection method is to first determine the interval in which the root exists, then bisect the interval containing the root, and then determine whether the function value at the bisection point is positive or negative. This reduces the interval with the root to half. Based on this method, a new approximate algorithm has been proposed, namely the method of gradually expanding the value range at the root. By continuously repeating the above process, the interval in which the root is located is reduced to a small enough range, and finally an approximate root that meets the accuracy requirements is obtained.

In the actual solving process, if the opening of the extraction valve is very small and the network resistance is too large, it is easy to cause the absolute pressure in the calculation to be greater than the atmospheric pressure, resulting in the airflow leakage at the boundary condition becoming negative. Therefore, using the bisection method alone may result in negative flow rates and cause the entire calculation process to not converge. To address this issue, a separate assignment method is set for this situation, where negative flow is set to zero, and then the bisection method is used to solve the flow rate. Additionally, to prevent the step size from being too large and causing the flow rate to be too large, leading to unsatisfactory network calculation results, the convergence step can also be artificially reduced.

2.2.3. Parameter Fitting Optimization

In the calculation of gas extraction pipe network, some measured data can be obtained to provide references for model construction. However, due to limitations in current technology and economic levels, it is challenging to obtain all operating conditions of the network through measurements. Currently, in the simulation or computation software for gas flow in extraction pipeline networks, theoretical or empirical values are mostly used to calculate certain parameters. However, in practical production, these empirical parameters may vary due to differences in the years of use of the network or variations in gas composition, leading to errors in the calculation results. Therefore, it is necessary to re-identify and fit the parameters with significant errors to achieve better computation and simulation of the network. An important parameter that influences pipe resistance is the pipe resistance coefficient, which includes equivalent roughness, pipe diameter, and other influencing factors, with the equivalent roughness having the most significant impact on the pipe resistance coefficient [32]. Additionally, other parameters related to gas extraction boundary conditions, especially those related to gas extraction operating conditions and geological conditions, can be optimized through fitting to reduce computational errors. The evaluation of the network model and parameter fitting effectiveness can be assessed by comparing the errors between simulated conditions and actual conditions during the computation process.

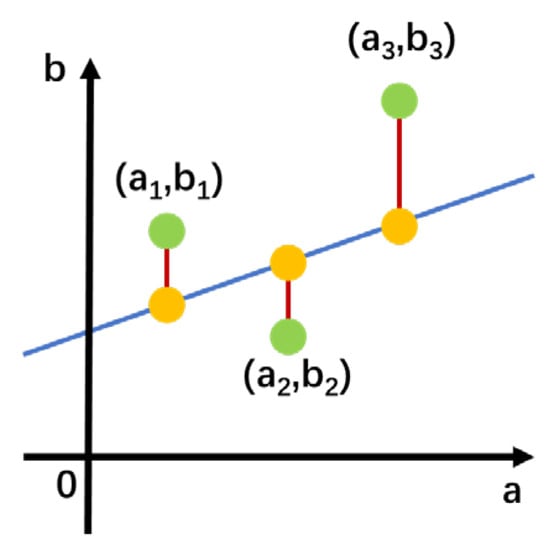

The parameter fitting optimization in this article employs the method of least squares. The least squares method is commonly used in solving the analytical solution of machine learning regression models [33]. Geometrically, it represents the projection of a vector in high-dimensional space onto a lower-dimensional subspace. Using the example of the least squares solution for simple linear regression as an illustration, Figure 6 depicts the basic principle of the least squares method in simple linear regression. The fitting does not necessarily require the approximating curve or line to pass precisely through all data points. However, it minimizes the overall deviation between the obtained approximation function and the known function according to a certain method. The loss function for the least squares method is as follows:

Figure 6.

Schematic diagram of the principle of least squares.

To minimize the loss function, which means setting its first derivative to 0, we can derive a system of equations with respect to the parameters ‘a’ and bias ‘b’ using partial derivatives:

By substituting numerical values into the above system of linear equations, the parameter values of ‘a’ and ‘b’ can be solved, resulting in the solution for the fitting line as illustrated in Figure 6.

3. Regulatory Parameter Sensitivity Analysis

3.1. The Influence of Control Parameters on the Pumping Network

Using the Western section of the Liuzhuang Mine in Anhui as a case study, a network diagram and mathematical model of the gas extraction system at the Liuzhuang Mine have been developed. The parameters of the pipeline network can be found in Table 1, with the extraction parameters at the gas source end provided in Table 2. Refer to Figure 3 for an illustrative overview of the pipeline network and to Figure 4 for the network diagram. The extraction operations are all conducted on the first day.

Table 1.

Parameter table of extraction pipe network in western mining area of Liuzhuang Mine in Anhui Province.

Table 2.

Extraction gas source end parameter table.

Based on the actual conditions of the case study mine illustrated in Figure 3. By applying principles of graph theory, we can designate a branch that passes through a certain gas source end as a path. Constructing the “gas source end to extraction pump” path, we can derive a total of 7 distinct paths.

To analyze the impact patterns of key parameters on the network, seven sets of control parameters are established, as shown in Table 3.

Table 3.

Table of governance parameters for different scenarios.

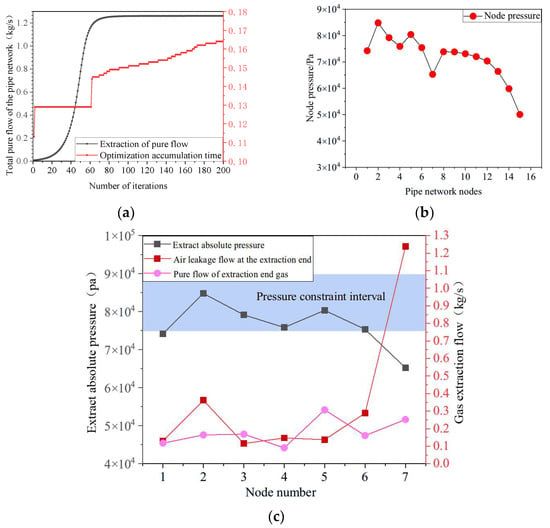

For Scheme 1, the calculations begin to converge at approximately the 70th iteration due to step size constraints, as depicted in Figure 7a. The pressure at the nodes of the Scheme 1 pipeline network is illustrated in Figure 7b, while the pure gas and leaked air flow at the gas source end are displayed in Figure 7c.

Figure 7.

Scenario 1 result graph of Solve.(a) Flow diagram of pure gas extraction in pipeline network; (b)Node pressure in pipeline network of Scheme 1; (c) Flow rate of pure gas and air leakage at the gas supply end.

For the remaining schemes, the computational process is the same, and the details will not be reiterated. The pressure at the gas source end for each scheme is depicted in Figure 7.

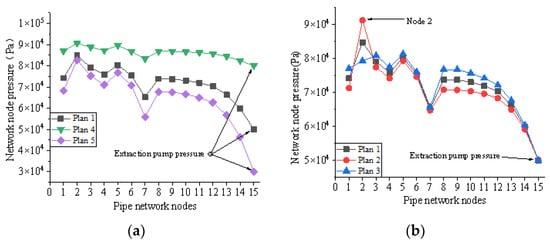

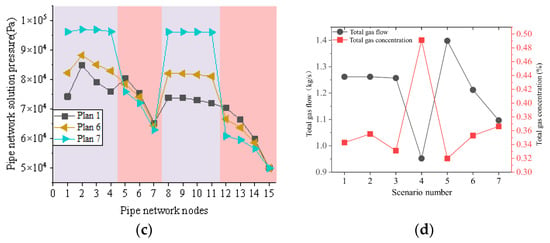

From the analysis of Figure 8a, it can be concluded that when increasing the gas extraction pump’s negative pressure, the negative pressure at all nodes in the network increases and vice versa.

Figure 8.

Air source pressure diagram of different schemes. (a) Comparison of Schemes 1, 4, and 5; (b) Comparison of Schemes 1, 2, and 3; (c) Comparison of Schemes 1, 6, and 7; (d) Comparison of Gas Concentration and Flow Rate.

Analyzing Figure 8b, it can be inferred that when regulating a specific terminal branch, reducing the valve opening of that terminal branch leads to an increase in the gas source end pressure (reduction in negative pressure) of that branch. At the same time, the gas source end pressure of the adjacent branches decreases (negative pressure increases), and the pressure at the remaining nodes also decreases, and vice versa.

From the analysis of Figure 8c, it can be deduced that when regulating a specific non-terminal branch, reducing the valve opening of that non-terminal branch results in an increase in the pressure at the nodes through which the non-terminal branch flows (reduction in negative pressure), while the pressure at nodes not traversed by the non-terminal branch decreases (negative pressure increases) and vice versa.

The above conclusions are the result of inductive analysis, and due to the existence of boundary conditions, these conclusions implicitly contain certain premises. This premise is that when the negative pressure of a certain gas source end increases, the flow rate of the mixed gas also increases. These conclusions can be demonstrated through the combined use of proof by contradiction and mathematical induction. Using the gas extraction network of the Liuzhuang Mine as an example, with the network diagram shown in Figure 3, the proof process is as follows:

- (1)

- Proof of the conclusion of Figure 8a

When increasing the negative pressure at node 8, let us assume that the negative pressure at node 7 decreases. From the boundary conditions of the source end, we can deduce that the gas pure flow and the leakage air flow at the 7th source end decrease. Consequently, the mixed flow in the branch segment of this source end decreases, leading to a decrease in branch resistance. Therefore, the negative pressure at the downstream node, i.e., node 8, must decrease compared to the pressure before regulation. However, this conclusion contradicts the premise of increasing the negative pressure at node 8, thus rendering the assumption invalid. Consequently, we can conclude that when increasing the negative pressure at node 8, the negative pressure at node 7 must increase, and vice versa.

Furthermore, when increasing the negative pressure at node 9, assuming that the negative pressure at its upstream node decreases, based on the earlier inference at node 8, we find that when the negative pressure at node 9 increases, the pressure at node 2 must also increase. Consequently, when the pressure at node 8 decreases, the pressure at node 7 decreases, leading to a decrease in flow, resulting in a reduction in resistance in the 7–9 path. Hence, the negative pressure at node 9 should also decrease, contradicting the assumption of increasing the negative pressure at node 9. Therefore, the assumption is invalid, and we can conclude that when increasing the negative pressure at node 9, the negative pressure at the upstream node must increase and vice versa.

By mathematical induction, it follows that when increasing the negative pressure at the extraction pump node, the negative pressure at the adjacent upstream node increases, and the negative pressure at the adjacent upstream’s adjacent upstream node also increases. Consequently, the negative pressure at all nodes in the network increases. This inference holds true for any tree-shaped gas extraction network.

- (2)

- Proof of the conclusion of Figure 8b

When increasing the valve opening of the 2–9 branch, the pipe resistance coefficient decreases. We can first prove that the total flow in the network will increase. The proof process is as follows:

Assume that the total flow in the network decreases, i.e., the flow in the 14–15 segment decreases, leading to reduced resistance and an increase in the negative pressure at the 14th extraction point. This, in turn, leads to an increase in the negative pressure at the 7th point (as previously inferred in the proof of Conclusion 3–8a). Consequently, the flow in the 7–14 segment increases, and the 14–15 segment is the sum of the flows in the 13–14 and 7–14 segments. Therefore, the flow in the 13–14 segment must decrease, reducing the resistance as well. At this point, based on the increase in the negative pressure at the 14th extraction point and the decrease in resistance in the 13–14 segment, the negative pressure at the 13th point must increase. Similarly, the flow in the 9–10 segment must decrease, leading to an increase in the negative pressure at the 9th point, thus increasing the negative pressure at the 1st point and consequently the flow. Therefore, the flow in the 2–9 segment must decrease, but since the resistance coefficient in the 2–9 segment decreases, the resistance in the 2–9 segment must also decrease, resulting in an increase in the negative pressure at the 2nd point. However, the increase in the negative pressure at the 2nd point would lead to a decrease in the flow, thus contradicting the initial assumption. This proves that when the valve opening of the 2–9 branch increases, the total flow in the network must increase.

Additionally, when the flow in the 14–15 segment increases and the negative pressure of the extraction pump (at node 15) remains unchanged, the negative pressure at node 14 decreases, leading to a decrease in the negative pressure at node 7. Therefore, the flow in the 13–14 segment increases, resulting in a decrease in the negative pressure at node 13 and subsequently at node 6. Consequently, the flow in the 12–13 segment increases. Similarly, this can be extended to show that the flow in the 9–10 segment increases, leading to a decrease in the negative pressure at node 9, and consequently, a decrease in the negative pressure at node 1. Consequently, the flow in the 1–9 segment decreases, resulting in an increase in the 2–9 flow and an increase in the negative pressure at node 2. Therefore, when the valve opening of the 2–9 branch increases, the negative pressure at node 2 increases, while the negative pressure at other nodes decreases.

The above inferences hold true vice versa and can be applied to deduce the change pattern in the network conditions for the regulation of any terminal branch.

- (3)

- Proof of the conclusion of Figure 8c

When increasing the valve opening of the 11–12 branch, the pipe segment resistance coefficient decreases. The process can be proven with the aid of the reductio ad absurdum method as depicted in Figure 8b, making it easy to demonstrate that when the valve opening of the 11–12 branch increases, the negative pressure at the 11th node increases, and the negative pressure at all other nodes decreases. Moreover, according to the proof in Figure 8a, when the negative pressure at the 11th node increases, the negative pressure at all upstream nodes of the 11th node also increases. These conclusions can be reversed and applied to the derivation of the network operating rules for the regulation of any terminal branch.

Therefore, based on the above conclusions, when the pressure at a certain gas source is relatively high (negative pressure is relatively low), the regulation of the network can be achieved in the following three ways to reduce the pressure at the gas source and increase the negative pressure:

- ①

- Increase the valve opening of the current path branch.

- ②

- Increase the extraction pump negative pressure.

- ③

- Decrease the valve opening of other branches outside the current path branch.

From the analysis of Figure 8d, it is evident that typically, when the gas purity flow of extraction is heightened, the gas concentration of the extracted gas tends to decline. This outcome arises due to the necessity of augmenting the negative pressure at the gas source in order to increase the gas purity flow of extraction. However, the increase in negative pressure brings a relatively small increment in gas purity flow and a larger increment in leaked gas flow, leading to a decrease in gas concentration. However, this is not always the case; for instance, if a gas source has almost no gas purity flow, reducing the negative pressure at this gas source will not only reduce the leaked gas flow at this source, thereby increasing the overall extraction gas concentration, but will also decrease the total flow in the network, leading to a decrease in network resistance and an increase in the extraction gas purity flow at other gas sources. Therefore, for the optimization and regulation of the network, it is necessary to consider not only the extraction negative pressure at each extraction end but also the actual extraction gas and leakage situation at each extraction end, in order to achieve the optimal operating conditions and the best extraction results for the network.

In addition, the control valves of each branch in an extraction network have an equivalent effect. For example, in this network, since only the 1st path contains the 1st and 8th branches, the valve actions of the 1st and 8th branches are the same. Moreover, the effect of the 8th branch valve can be achieved by the joint control of the 1st branch valve and the equivalent valve of the 2nd branch. Hence, when there are control valves in all branches, the optimal control solution is not unique. This can lead to equipment waste in terms of economy and can also increase the difficulty and accuracy of optimization and control. To address this problem, in practical production, it is essential to analyze key areas and install valves at critical locations to achieve optimization and regulation adaptable to production needs.

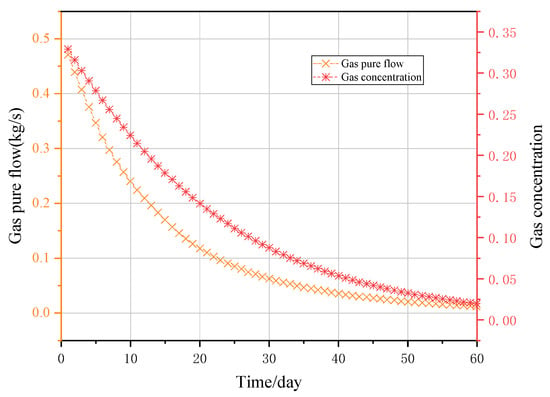

3.2. The Influence of Time Parameters on the Pumping Network

For Scheme 1, while keeping other parameters constant, we set the time parameter from 1 to 60 days and observe the changes in the network during this period. This is to simulate the scenario where the gas flow in the entire network changes over time without considering the inflow of gas from other mining areas, keeping the extraction conditions and overall structure of the extraction network unchanged. The findings depicted in Figure 9 reveal that in the absence of network control, both the gas concentration and the pure gas flow from the mine decline with the passage of time. This occurrence stems from the decrease in pure gas flow from the extraction over time under the same negative pressure, while the inflow of air remains relatively stable over time. Consequently, due to the combined impact of these factors, the gas extraction concentration continues to decrease, significantly affecting the efficient utilization of gas. To uphold the gas extraction concentration, it is recommended to reduce the extraction negative pressure at the end of the extraction phase to minimize air leakage and enhance gas concentration. Additionally, continuous connection of new gas source ends is necessary to maintain the pure gas flow and achieve improved gas concentration and resource utilization.

Figure 9.

Graph of pipe network extraction parameters over time.

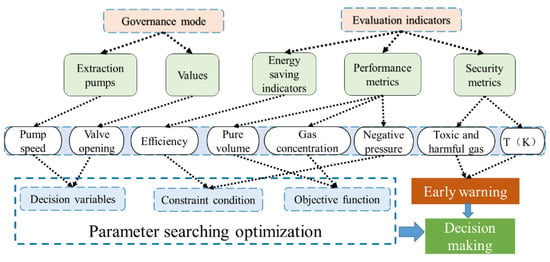

4. Intelligent Regulation and Control Strategies for Gas Extraction Pipeline Networks

4.1. Regulation Mode

The regulation of gas extraction networks can generally be divided into two parts: power control and resistance control. Power control involves adjusting the power equipment of the extraction network, while resistance control involves modifying the network’s resistance. In practical applications, various methods can be used to control and regulate the network and extraction pipelines according to specific requirements. Resistance control typically involves valve adjustment and changes in pipeline diameter in order to regulate the network’s resistance and extraction negative pressure. Valve control is primarily used to regulate significant pressure differentials in single wells or small areas within the extraction system. Its advantage lies in effectively managing pressure fluctuations, but it increases resistance loss. Changing the pipe diameter is suitable during the design and renovation of gas extraction pipelines. By selecting appropriate diameters, the method adjusts the resistance of various branches in the network, thereby optimizing the control of the extraction system. However, this method can be costly and lacks real-time adjustability. The advantage of valve control lies in its flexibility and adaptability, making it more operable compared to changes in pipe diameter.

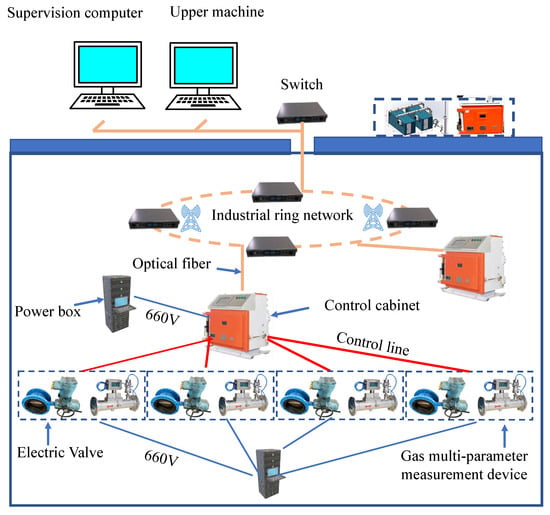

This paper adopts a combined approach of power control and resistance control to regulate gas extraction. In terms of power control, the overall regulation of the network is achieved by altering the negative pressure of the extraction pump. As for resistance control, valve adjustment is employed to alter the resistance of individual branches, facilitating localized regulation of the network. The specific control framework is illustrated in Figure 10. The intelligent monitoring and regulation system for mine gas drainage primarily consists of three components: the surface intelligent integrated management platform, underground monitoring and regulation substations, and system communication transmission. The intelligent integrated management platform features real-time data display capabilities, while the underground monitoring and regulation substations are equipped with control functions. The underground terminal devices mainly include electric valves and gas multi-parameter measurement device. These are connected to the underground monitoring and regulation substations via communication cables and optical fibers, enabling timely and effective transmission of monitoring data to the substations. The substations then access the mining industrial Ethernet ring network via optical fibers to transmit the data to the surface intelligent integrated management platform.

Figure 10.

Intelligent control architecture for gas extraction.

4.2. Evaluation Indicators

- (1)

- Safety indicators for gas extraction

In the process of borehole gas extraction, the risk of spontaneous combustion of coal will be aggravated by air leakage caused by pumping. At the beginning of spontaneous combustion, the temperature rises, and CO or a large amount of CO2 indicator gas is generated. Therefore, , and temperature were selected as the safety indicators for gas extraction. In addition, whether the gas extraction concentration is at the explosion limit is also an important indicator to judge the safety of the pipe network.

- (2)

- Gas extraction effect index

The primary goal of gas extraction is to achieve standard extraction in the mine and prevent gas exceeding the limit. Gas extraction pure flow can intuitively reflect the extraction effect. In addition, whether the negative pressure at the gas source end is within a reasonable range is also a key indicator for evaluating the rationality of the network operation and the effectiveness of extraction. Therefore, the choice of extraction pure flow and negative pressure as performance indicators is appropriate.

- (3)

- Gas extraction efficiency index

Gas extraction network regulation can reduce energy consumption, improve economic efficiency, and meet green and low-carbon requirements. Therefore, gas extraction efficiency ratio and extraction power consumption are chosen as efficiency indicators.

4.3. Regulation Strategy

According to the safety constraints for gas extraction, if CO or CO2 gas is detected in the borehole, indicating a risk of coal spontaneous combustion in the extraction area, timely warnings should be issued, and the gas extraction boreholes in that area should be immediately closed ( > 0 or > 0).

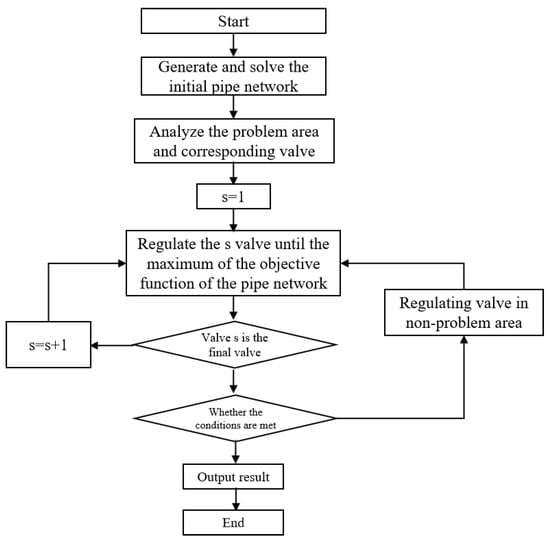

In the event of anomalies in the gas extraction system, parameter optimization can be conducted, and corresponding decisions can be made based on the optimization results to achieve intelligent control of the gas extraction network. The control strategy is illustrated in Figure 11. It is undeniable that our current optimization process, which may have certain limitations, will be addressed in future research by incorporating deep learning theories, such as algorithms like artificial neural networks, for optimization purposes.

Figure 11.

Diagram of pipe network intelligent control policy.

In practical gas pipeline network control, regulation is typically performed manually. This method involves manually adjusting valves in problematic areas based on an analysis of the current pipeline network status. However, due to the integrated and interconnected nature of gas pipeline networks, regulating a specific area can cause operational changes in other areas. Therefore, it is necessary to use network calculation and intelligent algorithms to impose constraints on regulation schemes and select the optimal one. This section simulates the on-site regulation of a mine gas extraction pipeline network. Based on the impact patterns of regulation parameters on the operational conditions at the gas source end of the pipeline network, a decision-making optimization model and algorithm for pipeline network regulation, characterized by global cycling and local optimization, are established.

In gas extraction pipeline network regulation, it is reasonable to achieve local optimization of the objective function while minimizing the number of valves being adjusted. The method proposed here first adjusts the valve openings in the problematic area of the extraction pipeline network to optimize the extraction conditions in that area. Then, it sequentially adjusts valve openings in other areas to mitigate the extraction impacts caused by the regulation of the problematic area. Following this, the valve openings in the problematic area are fine-tuned again to achieve optimal performance. This cycle repeats until the entire pipeline network operates under optimal conditions and converges. The flowchart for the mine gas extraction pipeline network regulation process is shown in Figure 12. It is undeniable that our current optimization approach has certain limitations. In future research, we plan to incorporate deep learning theories, such as artificial neural networks [34], to enhance the optimization process.

Figure 12.

Optimization Control Flowchart.

4.4. Apply Performance Analysis

By installing intelligent regulating valves in the pipeline network, control over the negative pressure can be achieved, as shown in Figure 13.

Figure 13.

Equipment installation diagram.

- ①

- Control the entire Western section extraction network, located at the wellhead pump station.

- ②

- Control the 151,108 belt roadway extraction pipeline.

- ③

- Control the 151,108 track roadway extraction pipeline.

- ④

- Control the 150,801 working face extraction area.

- ⑤

- Control the negative pressure of the pipeline network in the 171,106 working face area.

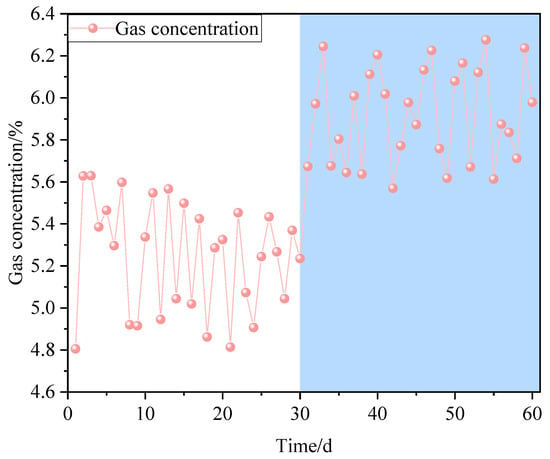

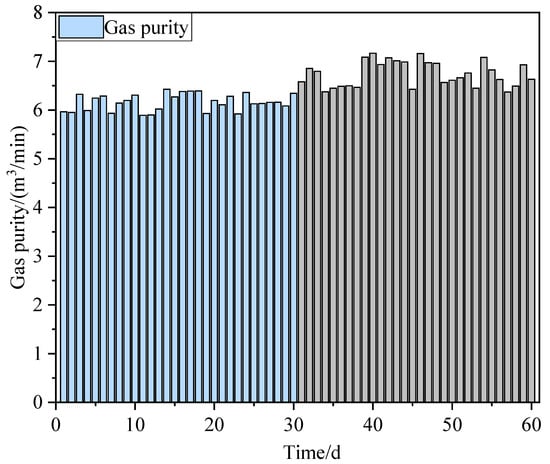

The control effect is shown in Figure 14 and Figure 15. Before the regulation, the gas concentration in the main pipeline of the extraction network was maintained at around 5.3%. After the adjustment, continuous observation of the extraction negative pressure in the main pipeline was conducted for a month, resulting in a gas extraction concentration of approximately 5.9%, representing an average increase of 11%. Gas concentration is not the sole indicator for evaluating the effectiveness of gas extraction. While ensuring an increase in concentration, it is also crucial to ensure that the pure gas extraction volume does not decrease. Before the regulation, the gas extraction pure volume in the main network was maintained at around 6.3 m3/min. After the implementation of intelligent control, the gas extraction pure volume was maintained at around 6.6 m3/min, representing an increase of 0.3 m3/min, thus achieving a positive outcome.

Figure 14.

The graph depicting the changes in gas concentration before and after regulation.

Figure 15.

Diagram of the change in gas purity before and after regulation.

5. Discussion

The gas extraction pipeline network is a complex and highly coupled integrated system. When conducting gas flow simulations within the pipeline network, it remains essential to account for the influence of other facilities on the flow dynamics. Furthermore, improving the accuracy of parameter fitting and optimization—particularly at extraction gas sources and pipeline junctions—is crucial to enhance the effectiveness of pipeline network simulation and, consequently, the performance of intelligent gas extraction control. That said, our study has certain limitations. When addressing the boundary conditions at the gas source end of the extraction pipeline network, the complexity of fluid dynamics interacts with the coal-gas solid–fluid coupling phenomenon. This interplay evolves over time due to ongoing mining or extraction activities, making it a time-varying problem. As a result, both modeling and parameter fitting present considerable challenges. We propose two potential research directions: First, utilizing big data and artificial intelligence methods to monitor coal seam parameters in real time, automatically generate relevant parameters for boundary condition functions, and continuously adjust these parameters during the control process. This approach would allow pipeline network regulation and parameter modification to operate simultaneously, ultimately achieving parameter convergence and dynamic equilibrium. Second, building on our previous research on coal seam and gas characteristics, we could identify key parameters—such as matrix gas pressure and gas content—and combine them with field data to calculate parameters like the gas leakage coefficient. The first method appears more feasible and practical, whereas the second involves substantial workload and may still carry a risk of significant errors. Nevertheless, it could contribute to understanding the mechanisms of coal seam gas behavior, thereby indirectly advancing gas extraction technology. Moreover, integrating both approaches could not only improve the efficiency of parameter fitting but also help uncover previously unrecognized patterns through data-driven analysis, further advancing our knowledge and research on coal seam gas. Additionally, this study did not address occupational health and safety issues, nor did it examine potential risks at production sites where the system is operational. However, relevant literature is available for reference [35,36], and this aspect will form an important part of our future work.

6. Conclusions

- 1

- Theoretical and Practical Contributions of the Study

- (1)

- Based on the method of value iteration adjustment, a gas extraction network solution model has been established. This solution method has good convergence effects and can be applied in gas extraction network calculations, providing guidance for network regulation. Sensitivity analysis of different control parameters was conducted based on the network solution model. The control rules for the distribution of network negative pressure at different branch valve control parameters and extraction pump control parameters were summarized and demonstrated. Based on these rules, control strategies were developed.

- (2)

- When increasing the gas extraction pump’s extraction pressure, the pressure at all nodes in the network increases and vice versa. When decreasing the valve opening of a certain terminal branch, the gas source end pressure of that branch increases, while the pressure at the remaining nodes decreases and vice versa. It is observed that when reducing the valve opening of a certain non-terminal branch, the pressure at the nodes flowing through that branch increases, while the pressure at the nodes not flowing through that branch decreases and vice versa.

- (3)

- Analyze the network’s structure and operating conditions and install valves at crucial points. Implement the intelligent gas extraction network control system for regulating the gas extraction network at Liuzhuang Coal Mine. Post-regulation, the pressures at different gas extraction sources have achieved equilibrium, leading to an overall gas concentration rise from the initial 5.3% to 5.99%, marking an improvement of approximately 11%. Prior to the regulation, the pure gas extraction volume in the primary network remained stable at approximately 6.3 m3/min. With intelligent control, the pure gas extraction volume now hovers around 6.6 m3/min, signifying a 0.3 m3/min increase. This advancement has facilitated the equitable distribution of extraction negative pressure and real-time dynamic intelligent control of the gas extraction network.

- 2

- Limitations of the Study

The gas extraction pipeline network is a complex and highly coupled comprehensive system. When simulating gas flow within the pipeline network, it is essential to account for the influence of other ancillary components on the flow dynamics. Additionally, further improving the accuracy of parameter calibration and optimization—particularly at extraction gas sources and pipeline junctions—is crucial for enhancing the accuracy and reliability of the simulation results, thereby ultimately improving the effectiveness of intelligent control in gas extraction. Within the current framework and findings of this paper, a detailed analysis of the energy consumption characteristics of gas drainage pumps has not been included, nor has the trade-off relationship between “efficiency and energy consumption” been systematically demonstrated.

- 3

- Future Research

The intelligent control system still relies on manual methods for selecting valve installation locations and fitting parameters of the gas extraction pipeline network. Given that the gas extraction pipeline network is time-varying, future research could focus on developing an intelligent decision-making system for optimal valve placement. Additionally, by leveraging extraction data collected through the intelligent control system, the introduction of intelligent algorithms could enable automated calibration and dynamic adjustment of pipeline network parameters. This would achieve end-to-end intelligent participation in the gas extraction control process.

Author Contributions

Conceptualization, C.D. and L.S.; methodology, Z.H. and Y.L.; validation, C.D., L.S. and Z.H.; visualization, Y.G. Writing—original draft, C.D., Writing—review and draft, L.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research is financially supported by the National Natural Science Foundation of China (52504226; 52404223), Funded by China Postdoctoral Science Foundation (Grant No. 2024M761258), Supported by the China Postdoctoral Science Foundation-CCTEG Joint Support Program under Grant Number 2025T041ZGMK.

Data Availability Statement

The data are available from the corresponding author on reasonable request.

Acknowledgments

We would like to thank the anonymous reviewers for their valuable comments and suggestions that led to a substantially improved manuscript.

Conflicts of Interest

Author Chang’ang Du, Longyong Shu, Zhonggang Huo, Yangyang Guo, Yang Li were employed by the company China Coal Research Institute Co., Ltd., Beijing 100013, China.

References

- Wang, K.; Wang, D.X.; Zhou, A.T. Intelligent decision-making and regulation method of gas extraction “borehole-pipe network” system. J. China Coal Soc. 2025, 50, 3235−3251. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, K.; Ju, Y.; Fan, L.; Cao, H.; Yang, Y.; Wang, L. Quantification of the asynchronous gas diffusivity in macro-/micropores using a Nelder-Mead simplex algorithm and its application on predicting desorption-based indexes. Fuel 2023, 332, 126149. [Google Scholar] [CrossRef]

- Liu, Q.; Cheng, Y.; Zhou, H.; Guo, P.; An, F.; Chen, H. A mathematical model of coupled gas flow and coal deformation with gas diffusion and Klinkenberg effects. Rock Mech. Rock Eng. 2015, 48, 1163–1180. [Google Scholar] [CrossRef]

- Kuang, Y.; Lin, B. Unwatched pollution reduction: The effect of natural gas utilization on air quality. Energy 2023, 273, 127247. [Google Scholar] [CrossRef]

- Li, Z.; Ren, T.; Li, X.; Cheng, Y.; He, X.; Lin, J.; Yang, X. Full-scale pore structure characterization of different rank coals and its impact on gas adsorption capacity: A theoretical model and experimental study. Energy 2023, 277, 127621. [Google Scholar] [CrossRef]

- Ding, Y.; Yue, Z. An experimental investigation of the roles of water content and gas decompression rate for outburst in coal briquettes. Fuel 2018, 234, 1221–1228. [Google Scholar] [CrossRef]

- Si, L.; Ding, N.; Wei, J.; Sheng, L.; Wang, L.; Li, Z.; Chen, X. Gas-liquid competitive adsorption characteristics and coal wetting mechanism under different pre-adsorbed gas conditions. Fuel 2022, 329, 125441. [Google Scholar] [CrossRef]

- Shi, Y.; Lin, B.; Liu, T.; Zhao, Y.; Hao, Z. Synergistic ECBM extraction technology and engineering application based on hydraulic flushing combing gas injection displacement in low permeability coal seams. Fuel 2022, 318, 123688. [Google Scholar] [CrossRef]

- Zhou, A.; Du, C.; Wang, K.; Hu, J.; Fan, X. Experimental research on the law of the deformation and damage characteristics of raw coal/briquette adsorption-instantaneous pressure relief. Fuel 2022, 308, 122062. [Google Scholar] [CrossRef]

- Li, W.; Yang, K.; Deng, D.; Zhao, C.; Yang, S.; Cheng, Y. A lattice Boltzmann model for simulating gas transport in coal nanopores considering surface adsorption and diffusion effects. Fuel 2023, 340, 127507. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, L.; Liu, Z.; Wang, G.; Ma, J. Effects of air volume and pre-oxidation on re-ignition characteristics of bituminous coal. Energy 2023, 265, 126124. [Google Scholar] [CrossRef]

- Zhou, F.; Xia, T.; Wang, X.; Zhang, Y.; Sun, Y.; Liu, J. Recent developments in coal mine methane extraction and utilization in China: A review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Tang, M.; Jiang, B.; Zhang, R.; Yin, Z.; Dai, G. Numerical analysis on the influence of gas extraction on air leakage in the gob. J. Nat. Gas Sci. Eng. 2016, 33, 278–286. [Google Scholar] [CrossRef]

- Xia, T.; Zhou, F.; Liu, J. A fully coupled coal deformation and compositional flow model for the control of the pre-mining coal seam gas extraction. Int. J. Rock Mech. Min. Sci. 2014, 72, 138–148. [Google Scholar] [CrossRef]

- Zhou, F.; Sun, Y.; Li, H. Research on the theoretical model and engineering technology of the coal seam gas drainage hole sealing. J. China Univ. Min. Technol. 2016, 45, 433–439. [Google Scholar]

- Xia, T.; Zhou, F.; Liu, J. Evaluation of the pre-drained coal seam gas quality. Fuel 2014, 130, 296–305. [Google Scholar] [CrossRef]

- Gao, F.; Xue, Y.; Gao, Y.; Zhang, Z.; Teng, T.; Liang, X. Fully coupled thermo-hydro-mechanical model for extraction of coal seam gas with slotted boreholes. J. Nat. Gas Sci. Eng. 2016, 31, 226–235. [Google Scholar] [CrossRef]

- Ziółkowski, P.; Badur, J.; Ziółkowski, P. An energetic analysis of a gas turbine with regenerative heating using turbine extraction at intermediate pressure-Brayton cycle advanced according to Szewalski’s idea. Energy 2019, 185, 763–786. [Google Scholar] [CrossRef]

- Zhou, A.; Li, J.; Gong, W.; Wang, K.; Du, C. Theoretical and numerical study on the contribution of multi-hole arrangement to coalbed methane extraction. Energy 2023, 284, 128598. [Google Scholar] [CrossRef]

- Cheng, Y.; Dong, J.; Li, W. Effect of negative pressure on coalbed methane extraction and application in the utilization of methane resource. J. China Coal Soc. 2017, 42, 1466–1474. [Google Scholar] [CrossRef]

- Zhang, T.; Pang, M.; Jiang, X. Influence of negative pressure on gas percolation characteristics of coal body in perforated drilling hole. Rock Soil Mech. 2019, 40, 2517–2525. [Google Scholar]

- Zhou, F.; Wang, X.; Xia, T. A model of safe drainage of coal seam gas. J. China Coal Soc. 2014, 39, 1659–1666. [Google Scholar]

- Wang, Z.; Ying, Z.; Sun, Y. Drainage negative pressure optimization based on negative pressure influence factor. Saf. Coal Mines 2015, 46, 12–16. [Google Scholar]

- Zhang, K. Study on the Influence Mechanism of Gas Drainage Concentration in Bedding Boreholes and Its Control Optimization. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2021. [Google Scholar]

- Zhong, D.; Wang, L.; Wang, J.; Jia, M. An efficient mine ventilation solution method based on minimum independent closed loops. Energies 2020, 13, 5862. [Google Scholar] [CrossRef]

- Zhou, A.; Wang, K. A transient model for airflow stabilization induced by gas accumulations in a mine ventilation network. J. Loss Prev. Process Ind. 2017, 47, 104–109. [Google Scholar] [CrossRef]

- Lu, J.; Yue, J.; Jiang, C.; Liang, H.; Zhu, L. Feature extraction based on variational mode decomposition and support vector machine for natural gas pipeline leakage. Trans. Inst. Meas. Control 2020, 42, 759–769. [Google Scholar] [CrossRef]

- Dehmer, M.; Emmert-Streib, F.; Shi, Y. Quantitative graph theory: A new branch of graph theory and network science. Inf. Sci. 2017, 418, 575–580. [Google Scholar] [CrossRef]

- Wang, Q.; Dai, W.; Yang, C.; Ma, X. Modeling and analysis of coal mine main fan switchover system. J. China Coal Soc. 2018, 43, 606–614. [Google Scholar] [CrossRef]

- Zhou, A.; Du, C.; Wang, K.; Fan, X.; Wang, D.; Zhao, W.; Gao, H. Research on intelligent control theory and strategy of gas drainage pipe network based on graph theory. Fuel 2024, 357, 129867. [Google Scholar] [CrossRef]

- Zhang, H.; Qin, J.; Su, W. Study on Influence Mechanism of Negative Pressure on Gas Drainage Effect. Saf. Coal Mines 2019, 50, 23–26+31. [Google Scholar] [CrossRef]

- Wang, C.; Yu, L. Darcy flow through bumpy tubes. J. Porous Media 2015, 18, 457–461. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, Q. Perturbation analysis and condition numbers of mixed least squares-scaled total least squares problem. Numer. Algorithms 2022, 89, 1223–1246. [Google Scholar] [CrossRef]

- Jolfaei, S.; Lakirouhani, A. Sensitivity analysis of effective parameters in borehole failure, using neural network. Adv. Civ. Eng. 2022, 2022, 4958004. [Google Scholar] [CrossRef]

- Yıldız, T.D. Loss of profits occurring due to the halting of mining operations arising from occupational accidents or reasons related to legislation. Gospod. Surowcami Miner. Miner. Resour. Manag. 2021, 37, 153–176. [Google Scholar] [CrossRef]

- Kahraman, M.M. Analysis of mining lost time incident duration influencing factors through machine learning. Min. Metall. Explor. 2021, 38, 1031–1039. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).