Emergency Plugging and Killing of Blowout Preventer Failure

Abstract

1. Introduction

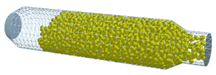

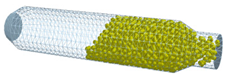

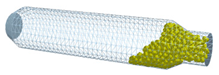

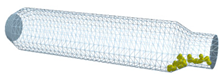

2. Plugging Experiment

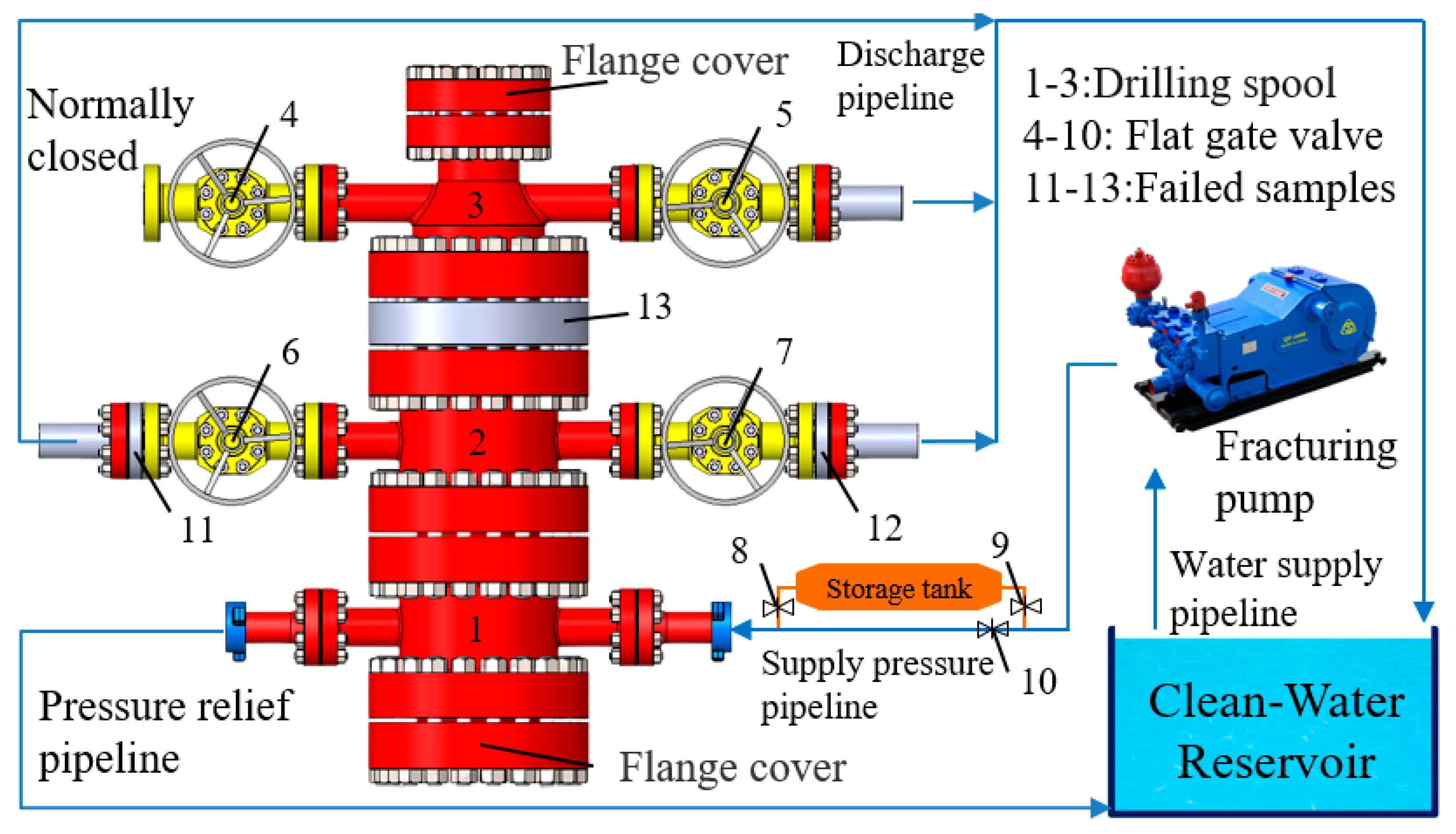

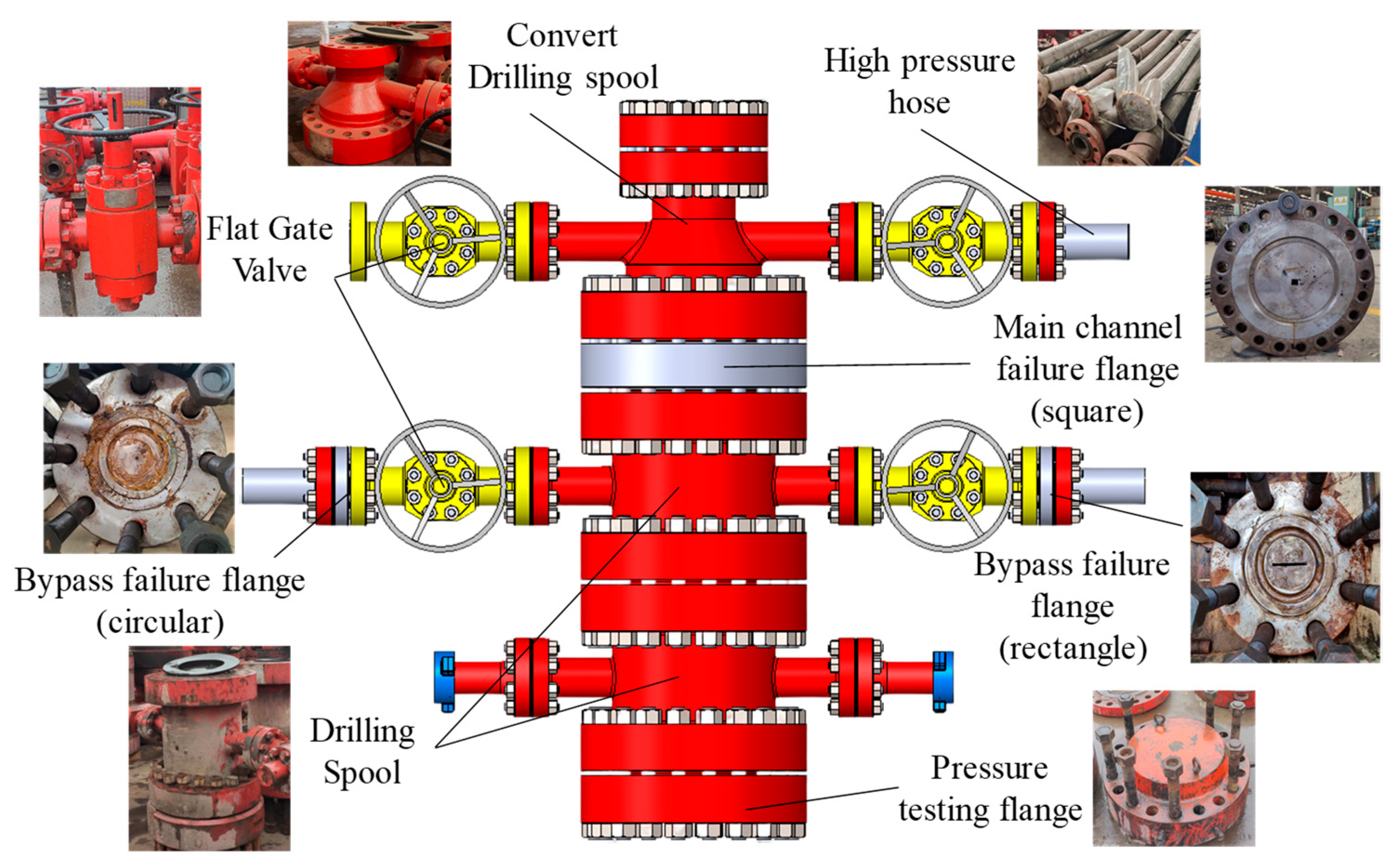

2.1. Plugging Experimental System

2.2. Plugging Materials

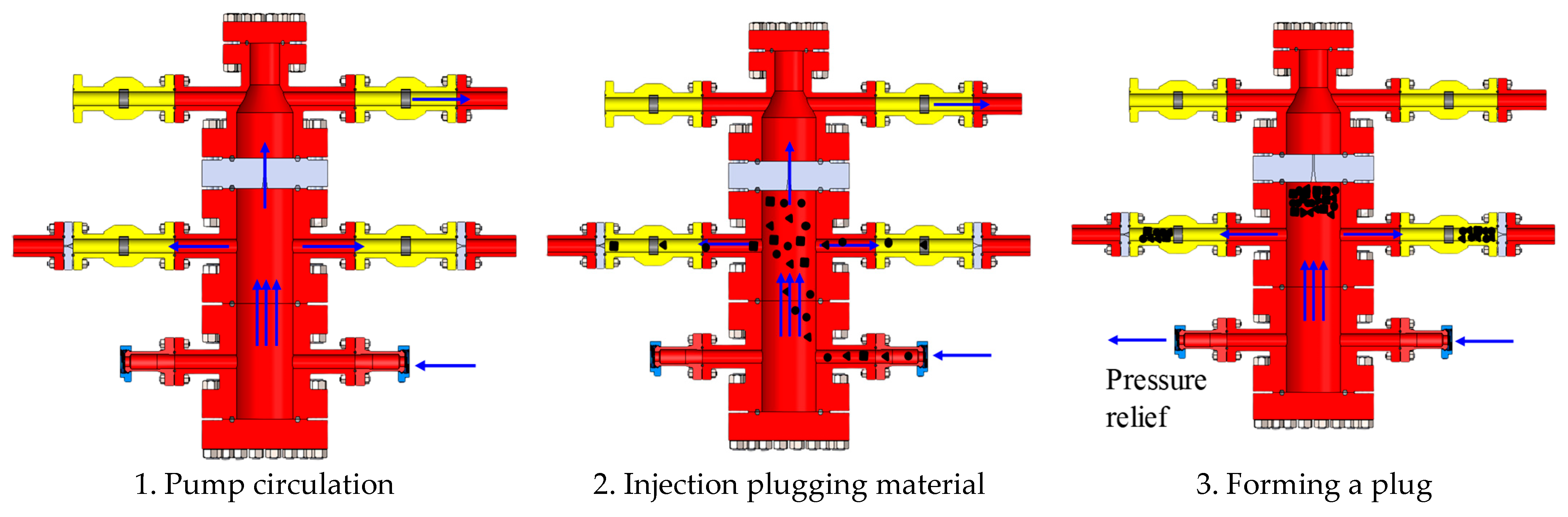

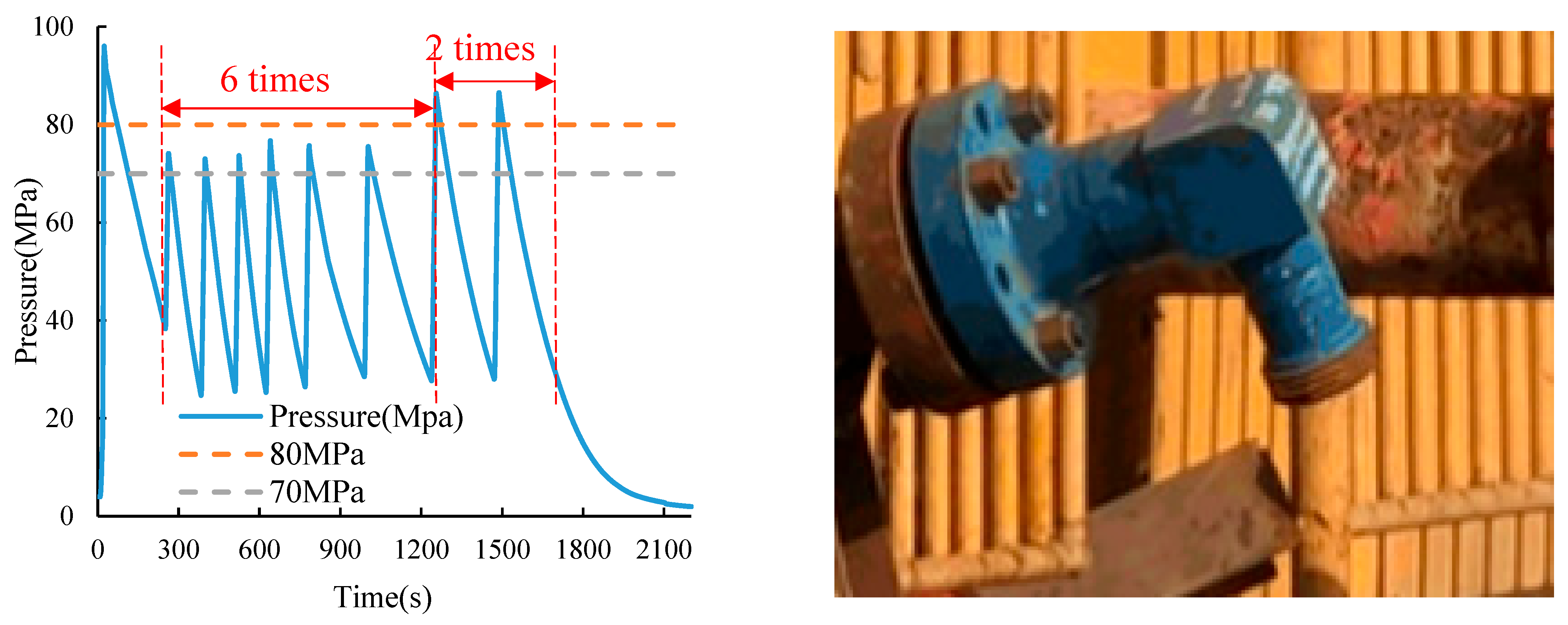

2.3. Experimental Process and Results

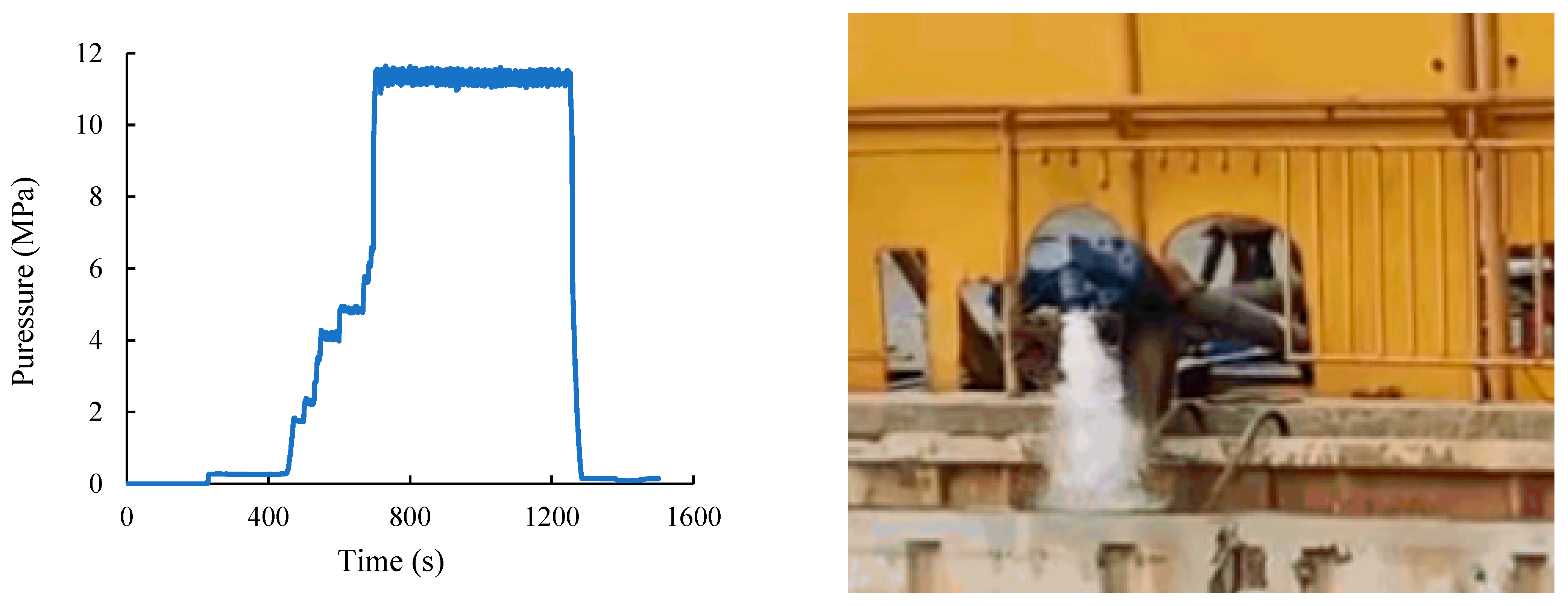

2.3.1. Blank Experiment

2.3.2. Plugging Experiment

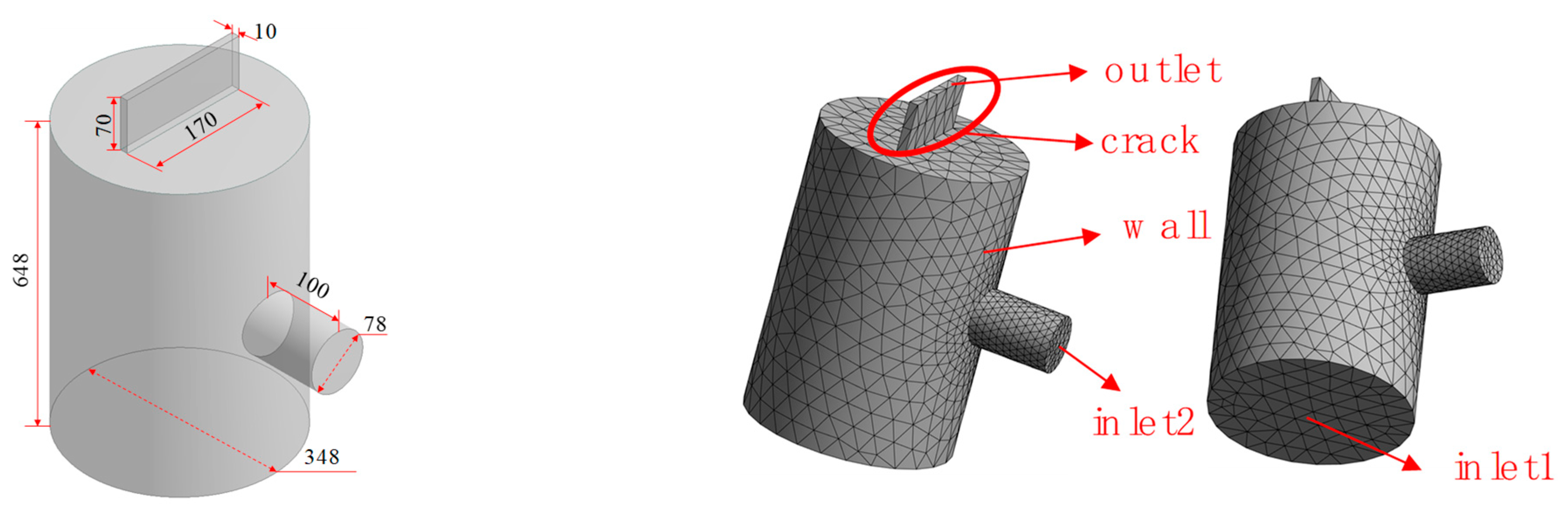

3. Modeling

3.1. Governing Equations

3.1.1. Translational and Rotational Motion of a Particle

3.1.2. Mass and Momentum Conservation Equations of Fluids

3.1.3. Interaction Force Between Particle and Fluid

3.2. Validation

4. Killing Analysis

4.1. Pumping PEEK

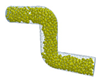

4.2. The Impact of Displacement on Plugging Effect

4.3. Simulation of the Entire Plugging and Killing

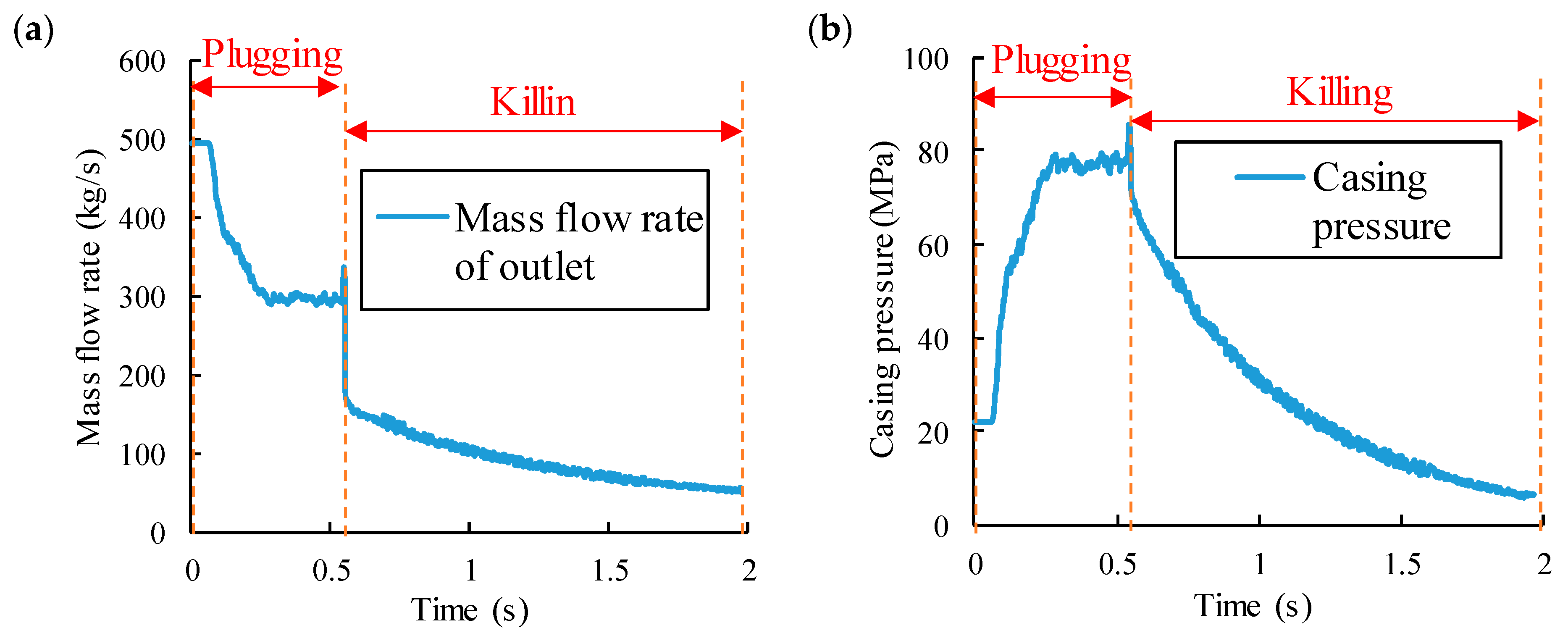

4.3.1. The Most Ideal Scenario

4.3.2. The Least Ideal Scenario

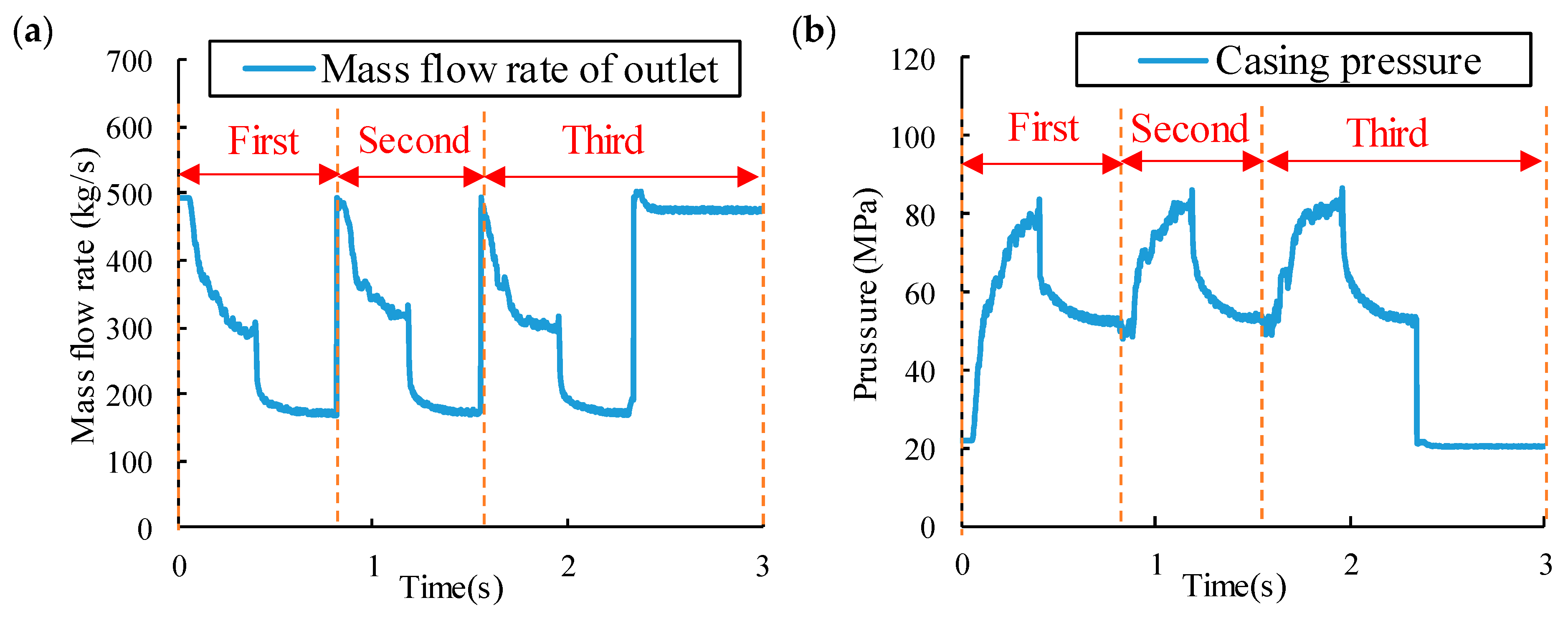

4.3.3. Operative Target

4.3.4. Limitations and Recommendations

5. Conclusions

- Experimental verification has shown that PEEK can withstand pressure of over 80 MPa during the plugging process, making it an excellent bridging material, and provides an experimental reference for BOP failure rescue.

- Both columnar and spherical particles passed smoothly through the storage tank and double bends. During pumping, a large displacement may exacerbate the particle ejection from the failure port. The use of small and medium-sized displacements in the early stages of plugging is recommended.

- After a blowout, it is difficult to clarify the internal situation of the BOP, and it is necessary to use multiple plugging and killing methods to combine small and large victories to achieve better killing effects.

- Numerical simulations of the plugging and killing process showed that, during the most ideal scenario, the outlet mass flow rate decreased rapidly from approximately 500 kg/s to below 100 kg/s within 0.6 s after plugging initiation, indicating an effective sealing response and stable flow control in the BOP.

- The casing pressure–time relationship demonstrated that, following plugging, the internal pressure initially rose from 20 MPa to about 84 MPa within 0.5 s and then gradually decreased to below 30 MPa during the killing stage, confirming that the proposed plugging–killing strategy can achieve progressive pressure relief and well stabilization.

- Theoretically, PEEK’s superior wear resistance and toughness mitigate material degradation during high-speed collisions, improving the long-term integrity of bridging structures under turbulent flow conditions. This insight advances the understanding of how thermoplastic material properties influence dynamic sealing behavior in blowout environments.

- From an engineering standpoint, the combined CFD–DEM modeling and experimental results suggest that PEEK-based plugging can be feasibly scaled to field applications using existing high-pressure pumping systems. The material’s high temperature and impact tolerance, coupled with its reusability and low maintenance demand, make it a practical option for emergency well control and industrial deployment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A′ | Projected particle area in the flow direction, m2 |

| αf | Fluid volume fraction |

| CD | Drag coefficient |

| CT | Torque coefficient |

| dp | Diameter of the particle, m |

| Ff→p | Forces generated by the fluid on the particles, N |

| Fp→f | The source term of momentum between the fluid and particle phases, N·s |

| Fc | Force due to contact, N |

| FD | Drag force, N |

| F∇p | Pressure gradient force, N |

| g | Gravitational acceleration vector, m/s2 |

| Jp | Particle moment of inertia, kg |

| Mc | Torque due to contact, N⋅ m |

| Mf→p | Additional torque due to the fluid phase velocity gradient, N⋅m |

| N | Number of particles inside the computational cell volume |

| mp | Particle mass, kg·m2 |

| ∇p | Pressure gradient, mPa/m |

| Relative angular velocity, rad/s | |

| u | Fluid phase velocity vector, m/s |

| Vc | Computational cell volume, m3 |

| Vp | Volume of the particle, m3 |

| vp | Relative velocity between particle and fluid, m/s |

| Greek Letters | |

| Angular velocity vector, rad/s | |

| Relative fluid-particle angular velocity, rad/s | |

| Fluid density, kg/m3 | |

| μf | Fluid dynamic viscosity, N/m2·s |

References

- Jing, J.; Zou, J.; Wang, G.; Zhang, X.; He, P. Emergency Plugging Test System and Experiment for Blowout Preventer Seal Failure under Ultrahigh-Pressure and Large Displacement Conditions. SPE J. 2025, 30, 6112–6130. [Google Scholar] [CrossRef]

- Kong, L.; He, S.; Tang, M.; Zhang, G.; Wang, S.; Xie, Y.; Zhang, X.; Qin, H.; Deng, F. Emergency plugging of shear ram failure. Geoenergy Sci. Eng. 2023, 231, 212400. [Google Scholar] [CrossRef]

- Nedwed, T.; Kulkarni, K.; Jain, R.; Mitchell, D.; Meeks, B.; Allen, D.P.; Edgecombe, B.; Christopher, J.C. Rapid crosslinking polymer provides an additional blowout-preventer barrier. SPE Drill. Complet. 2019, 34, 296–305. [Google Scholar] [CrossRef]

- Xiong, Y.; Xu, Y.; Zhang, Y.; Fu, Z. Study of gel plug for temporary blocking and well-killing technology in low-pressure, leakage-prone gas well. SPE Prod. Oper. 2021, 36, 234–244. [Google Scholar] [CrossRef]

- Burton, M.J. An Experimental and Numerical Study of Plug Formation in Vertical Pipes During Cryogenic Pipe Freezing. Ph.D. Thesis, University of Southampton, Southampton, UK, 1986. Available online: http://eprints.soton.ac.uk/id/eprint/460752 (accessed on 30 November 2025).

- Yugay, A.; Albadi, M.M.; Agarwal, A.; Nadder, M.A.; Gadelhak, A.M.; Mark, M. Ice Plug as a Well Barrier: The Story of Success—Paper Number: D021S044R001. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 12–15 November 2018; SPE: Richardson, TX, USA, 2018. [Google Scholar] [CrossRef]

- Powers, B.S.; Pruitt, R.D.; Tuppen, J. Dynamic Freeze Plug Process Proves a Viable Barrier Technique in Sajaa Field, United Arab Emirates—Paper Number: SPE-79882-MS. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, 19–21 February 2003; SPE: Richardson, TX, USA, 2003. [Google Scholar] [CrossRef]

- Zhang, M.; Yue, W.; Lang, X.; Wang, X.; Yang, J. Development and Application of Special Engineering Plastics: Semi-aromatic Polyamide. China Plast. 2020, 34, 115–122. [Google Scholar] [CrossRef]

- Tippur, H. Introduction to plastics engineering. J. Eng. Mater. Technol. 2021, 143, 036501. [Google Scholar] [CrossRef]

- Drew, D.A. Mathematical Modeling of Two-Phase Flow. Annu. Rev. Fluid Mech. 1983, 15, 261–291. [Google Scholar] [CrossRef]

- Xing, J.; Ni, Q.Q.; Deng, B.; Liu, Q. Morphology and properties of polyphenylene sulfide (PPS)/polyvinylidene fluoride (PVDF) polymer alloys by melt blending. Compos. Sci. Technol. 2016, 134, 184–190. [Google Scholar] [CrossRef]

- Rahate, A.S.; Nemade, K.R.; Waghuley, S.A. Polyphenylene sulfide (PPS): State of the art and applications. Rev. Chem. Eng. 2013, 29, 471–489. [Google Scholar] [CrossRef]

- Shen, L.; Xing, J. The history, interests and future of polyphenylene sulfide: A bibliometric analysis. High Perform. Polym. 2024, 36, 52–68. [Google Scholar] [CrossRef]

- Hicyilmaz, A.S.; Bedeloglu, A.C. Applications of polyimide coatings: A review. SN Appl. Sci. 2021, 3, 363. [Google Scholar] [CrossRef]

- Terraza, C.; Tagle, L.H.; Santiago-García, J.L.; Canto-Acosta, R.J.; Aguilar-Vega, M.; Hauyon, R.A.; Coll, D.; Ortiz, P.; Perez, G.; Herrán, L.; et al. Synthesis and properties of new aromatic polyimides containing spirocyclic structures. Polymer 2018, 137, 283–292. [Google Scholar] [CrossRef]

- Liao, C.; Zhang, Z.; Yang, M.; Yuan, J.; Liu, M.; He, Y.; Li, P.; Jiang, W.; Liu, W. The cooperatively crosslinking between GO-COOH/TiO2@PAO microcapsules and polyimide to improve the mechanical and tribological properties of PEEK/PI composites. Tribol. Int. 2024, 191, 109209. [Google Scholar] [CrossRef]

- Zol, S.M.; Alauddin, M.S.; Said, Z.; Mohd Ghazali, M.I.; Hao-Ern, L.; Mohd Farid, D.A.; Zahari, N.A.H.; Al-Khadim, A.H.A.; Abdul Aziz, A.H. Description of Poly(aryl-ether-ketone) Materials (PAEKs), Polyetheretherketone (PEEK) and Polyetherketoneketone (PEKK) for Application as a Dental Material: A Materials Science Review. Polymers 2023, 15, 2170. [Google Scholar] [CrossRef]

- Ahmad, F.; Luqman, M.; Jamil, M. Advances in the metal nanoparticles (MNPs) doped liquid crystals and polymer dispersed liquid crystal (PDLC) composites and their applications—A review. Mol. Cryst. Liq. Cryst. 2022, 745, 1–33. [Google Scholar] [CrossRef]

- Wen, Z.; Yang, K.; Raquez, J.-M.; Peponi, L.; Sessini, V. A Review on Liquid Crystal Polymers in Free-Standing Reversible Shape Memory Materials. Molecules 2020, 25, 1241. [Google Scholar] [CrossRef]

- Ye, Y.; Guo, L.; Zhong, T. A Review of Developments in Polymer Stabilized Liquid Crystals. Polymers 2023, 15, 2962. [Google Scholar] [CrossRef]

- Dumbrava, O.; Filimon, A.; Marin, L. Tailoring properties and applications of polysulfone membranes by chemical modification: Structure-properties-applications relationship. Eur. Polym. J. 2023, 196, 112316. [Google Scholar] [CrossRef]

- Serbanescu, O.S.; Voicu, Ş.I.; Thakur, V.K. Polysulfone functionalized membranes: Properties and challenges. Mater. Today Chem. 2020, 17, 100302. [Google Scholar] [CrossRef]

- Storozhuk, I.P.; Alekseev, V.M.; Kalinnikov, A.N.; Borodulin, A.S. Chemically Modified Polysulfones and Their Properties. Polym. Sci. Ser. D 2021, 14, 580–587. [Google Scholar] [CrossRef]

- Wang, F.; Kobina, F. The Influence of Geological Factors and Transmission Fluids on the Exploitation of Reservoir Geothermal Resources: Factor Discussion and Mechanism Analysis. Reserv. Sci. 2025, 1, 3–18. [Google Scholar] [CrossRef]

- Wu, J.; Ansari, U. From CO2 Sequestration to Hydrogen Storage: Further Utilization of Depleted Gas Reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Li, Q. Reservoir Science: A Multi-Coupling Communication Platform to Promote Energy Transformation, Climate Change and Environmenta Protection. Reserv. Sci. 2025, 1, 1–2. [Google Scholar] [CrossRef]

- Aydin, G.; Karakurt, I.; Amiri, M.R.; Kaya, S. Improvement of Rock Cutting Performance through Two-Pass Abrasive Waterjet Cutting. Sustainability 2022, 14, 12704. [Google Scholar] [CrossRef]

- Kalin, M.; Zalaznik, M.; Novak, S. Wear and friction behaviour of poly-ether-ether-ketone (PEEK) filled with graphene, WS2 and CNT nanoparticles. Wear 2015, 332–333, 855–862. [Google Scholar] [CrossRef]

- Zalaznik, M.; Kalin, M.; Novak, S.; Jakša, G. Effect of the type, size and concentration of solid lubricants on the tribological properties of the polymer PEEK. Wear 2016, 364–365, 31–39. [Google Scholar] [CrossRef]

- Kaya, S.; Aydin, G.; Karakurt, I. An experimental study on the cutting depth produced by abrasive waterjet: How do abrasive and rock properties affect the cutting process? Int. J. Adv. Manuf. Technol. 2023, 125, 4811–4823. [Google Scholar] [CrossRef]

- ASTM-D785; Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating. ASTM International: West Conshocken, PA, USA, 2004.

| Principle | Researcher | Main Conclusions | Insufficient |

|---|---|---|---|

| Physical plugging | [1] | Uses hemp rope knots as bridging materials for BOP plugging, with a maximum pressure-bearing capacity of up to 40 MPa. | The maximum pressure bearing capacity is only 40 MPa. |

| [2] | Studied the feasibility of particle plugging under high-pressure conditions (70 MPa). Analyzed the influence of a series of factors and concluded that it is feasible to use particles with sufficient strength for plugging in the early stage of BOP failure. | The research only remained in the theoretical stage. | |

| Polymer plugging | [3,4] | Polymer monomers and catalysts are pumped separately from both sides of the BOP, and polymers are formed through polymerization reactions below the failure point of the BOP. This method can complete the reaction within 45 s with 20% drilling fluid pollution, forming a plugging layer with a pressure bearing of 100 MPa | Polymerization reactions require a relatively stable environment; the reliability of this method is insufficient. |

| Plugging with liquid nitrogen freezing | [5,6,7] | Refrigerant is injected into the annulus, then cooling around the casing is implemented and maintained at approximately −70 °C to form a plugging. | Refrigerants require high purity and are difficult to maintain in an environment of formation fluid erosion. |

| Name | Density (g/cm3) | Pressure and Temperature Resistance | Advantage | Disadvantage | Purpose |

|---|---|---|---|---|---|

| PPS [11,12,13] | 1.9 | 110 °C 100 MPa | High temperature resistance, corrosion resistance, and good thermal stability | Poor toughness, easy brittleness, and lack of impact resistance | Electronics, aerospace, automotive transportation |

| PI [14,15] | 1.43 | 360 °C 86 MPa | High temperature resistance, insulation, corrosion resistance, and high strength | Not wear-resistant under high load | Aerospace, microelectronics, nano liquid crystals |

| PEEK [16,17] | 1.3 | 152 °C 100 MPa | Balancing rigidity and toughness, lightweight, and wear-resistant | High cost | Food processing, automotive, and aerospace |

| LCP [18,19,20] | 1.4~1.7 | 100–350 °C 50–180 MPa | Good optical performance, electrical performance, self-flame retardancy, and processability | Mechanical properties at high temperatures are not as good as PEEK | High-speed connector, 5G antenna |

| PSU [21,22,23] | 1.29 | 160 °C 70 MPa | Wide range of working temperature and pH, good film-forming ability | Weak fatigue resistance | Medical devices and food contact applications |

| Thermal Properties | Mechanical Properties | Physical Properties | |||

|---|---|---|---|---|---|

| Max. service temperature | 250 °C | Tensile strength | 115 MPa | Density | 1.31 g/cm3 |

| Color | Natural (beige), Black, Red | ||||

| Min. service temperature | −50 °C | Water absorption after 24 h immersion in water at 23 °C | 0.06% | ||

| Glass transition temperature | 145 °C | Flexural strength | 170 MPa | Water absorption at saturation in water at 23 °C | 0.45% |

| Melting temperature | 340 °C | Rockwell M hardness (ISO 2039-2) [31] | 105 | Wear rate (ISO 7148-2 (18)) | 28 µm/km |

| Thermal conductivity (23 °C) | 0.25 W/(K·m) | Charpy impact strength—unnotched | no break | Dynamic coefficient of friction | 0.3~0.5 |

| Name | Density | Max. Service Temperature | Sieve Residue ≥50% | Composition |

|---|---|---|---|---|

| WNDK-1 | 2.65 g/cm3 | 200 °C | 0.45~2 mm | Mainly composed of rigid mineral materials and mixed polymers |

| WNDK-2 | 2.65 g/cm3 | 200 °C | 0.28~0.9 mm | Mainly composed of rigid mineral materials and mixed polymers |

| NTBASE | 1.92 g/cm3 | 150 °C | 0.045~2 mm | Mineral fiber, rigid bridge plugging agent |

| JD-5 | 0.95 g/cm3 | 150 °C | 0.28~1 mm | Mainly composed of resin and fiber, mixed calcium carbonate |

| Ultra-fine Calcium | 2.65 g/cm3 | >500 °C | 0.001~0.01 mm | Calcium carbonate |

| Fluent | EDEM | Others | ||

|---|---|---|---|---|

| Viscous Model | k-epsilon (2 eqn) | Particle | Poisson’s ratio: 0.3 Density: 1300 kg/m3 Shear Modulus: 1 × 108 Pa | Particle/fluid coupling method: Euler |

| Inlet1 | Velocity Inlet: 5 m/s Turbulent Intensity: 5% Hydraulic Diameter: 0.01 m | |||

| Inlet2 | Velocity Inlet: 5 m/s Turbulent Intensity: 5% Hydraulic Diameter: 0.01 m | Wall | Poisson’s ratio: 0.13 Density: 7800 kg/m3 Shear Modulus: 7 × 1010 Pa | Drag Model: Freestream Equation |

| Outlet | Pressure Outlet | Particle/ particle/ wall Interaction | Restitution: 0.5 Static Friction: 0.5 Rolling Friction: 0.01 | |

| Fluid | Density: 1000 kg/m3 Viscosity: 0.01 Pa·s | Lift Model: Saffman Lift | ||

| Time Step | 0.0001 s | Time step | 0.000005 s | |

| Particle Shape | Time | Internal Situation | Time | Internal Situation |

|---|---|---|---|---|

| Cylinder | 0.25 s |  | 0.58 s |  |

| 0.71 s |  | 1.01 s |  | |

| 1.29 s |  | 1.45 s |  | |

| Spherical | 0.25 s |  | 0.37 s |  |

| 0.75 s |  | 1.00 s |  | |

| 1.30 s |  | 1.59 s |  |

| Particle Shape | The Transport State of Particles in the Elbow at Different Times | |||||

|---|---|---|---|---|---|---|

| Cylinder 0.86 m3/min | 0.01 s | 0.1 s | 0.2 s | 0.3 s | 0.5 s | 0.8 s |

|  |  |  |  |  | |

| 1.1 s | 1.4 s | 1.7 s | 1.75 s | 1.8 s | 1.92 s | |

|  |  |  |  |  | |

| Cylinder 2 m3/min | 0.01 s | 0.1 s | 0.2 s | 0.3 s | 0.4 s | 0.5 s |

|  |  |  |  |  | |

| 0.6 s | 0.7 s | 0.8 s | 1 s | 1.05 s | 1.1 s | |

|  |  |  |  |  | |

| Spherical 0.86 m3/min | 0.01 s | 0.05 s | 0.1 s | 0.15 s | 0.2 s | 0.3 s |

|  |  |  |  |  | |

| 0.4 s | 0.5 s | 0.55 s | 0.6 s | 0.65 s | 0.68 s | |

|  |  |  |  |  | |

| Spherical 2 m3/min | 0.01 s | 0.05 s | 0.1 s | 0.2 s | 0.4 s | 0.6 s |

|  |  |  |  |  | |

| 0.8 s | 1 s | 1.02 s | 1.04 s | 1.06 s | 1.1 s | |

|  |  |  |  |  | |

| Displacement (m3/min) | 0.1 s | 0.2 s | 0.3 s | 0.4 s | 0.5 s | All Particles Enter | Thickness of Plugging Layer |

|---|---|---|---|---|---|---|---|

| 0.86 |  |  |  |  |  |  |  |

| 1.15 |  |  |  |  |  |  |  |

| 1.43 |  |  |  |  |  |  |  |

| 2.00 |  |  |  |  |  |  |  |

| 2.87 |  |  |  |  |  |  |  |

| 4.30 |  |  |  |  |  |  |  |

| 5.73 |  |  |  |  |  |  |  |

| Scenario | Assumption | Inlet1 | Inlet2 | Well Killing Time |

|---|---|---|---|---|

| Most Ideal | One-time plugging and well killing; when the well killing is completed, the danger is lifted | 1. When plugging, it is the inlet of the bottomhole fluid; 2. When well killing, it is the outlet; 3. Formation fluid density 1.5 kg/m3, viscosity 0.05 kg/m-s | Well killing fluid density 1.9 kg/m3, viscosity 0.1 kg/m-s | Plugging completed |

| Least Ideal | Multiple plugging and well killing; additional plugging when the blowout intensifies | Well killing fluid density 1.5 kg/m3 viscosity 0.05 kg/m-s | Plugging completed | |

| Target | Multiple plugging and well killing, additional plugging on time | Well killing fluid density 1.5 kg/m3 viscosity 0.05 kg/m-s | Timely well killing after plugging |

| Operation Steps | The Situation Within the BOP at Different Times | ||||

|---|---|---|---|---|---|

| Plugging |  |  |  |  |  |

| Killing |  |  |  |  |  |

|  |  |  |  | |

|  |  |  |  | |

| Operation Steps | The Situation Within the BOP at Different Times | ||||

|---|---|---|---|---|---|

| First plugging |  |  |  |  |  |

| First killing |  |  |  |  |  |

| Second plugging |  |  |  |  |  |

| Second killing |  |  |  |  |  |

| Third plugging |  |  |  |  |  |

| Third killing |  |  |  |  |  |

| Operation Steps | The Situation Within the BOP at Different Times | ||||

|---|---|---|---|---|---|

| First plugging |  |  |  |  |  |

| First killing |  |  |  |  |  |

| Second plugging |  |  |  |  |  |

| Second killing |  |  |  |  |  |

| Third plugging |  |  |  |  |  |

| Third killing |  |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, Z.; Li, Q.; Wang, H.; Cui, H.; Wang, H.; Gao, F. Emergency Plugging and Killing of Blowout Preventer Failure. Processes 2025, 13, 3959. https://doi.org/10.3390/pr13123959

Zhang X, Zhang Z, Li Q, Wang H, Cui H, Wang H, Gao F. Emergency Plugging and Killing of Blowout Preventer Failure. Processes. 2025; 13(12):3959. https://doi.org/10.3390/pr13123959

Chicago/Turabian StyleZhang, Xuliang, Zhi Zhang, Qingfeng Li, Haitao Wang, Hangbo Cui, Hua Wang, and Fumin Gao. 2025. "Emergency Plugging and Killing of Blowout Preventer Failure" Processes 13, no. 12: 3959. https://doi.org/10.3390/pr13123959

APA StyleZhang, X., Zhang, Z., Li, Q., Wang, H., Cui, H., Wang, H., & Gao, F. (2025). Emergency Plugging and Killing of Blowout Preventer Failure. Processes, 13(12), 3959. https://doi.org/10.3390/pr13123959