Investigation on Creep Behavior of Aggregates of Loess by a Discrete Element Method

Abstract

:1. Introduction

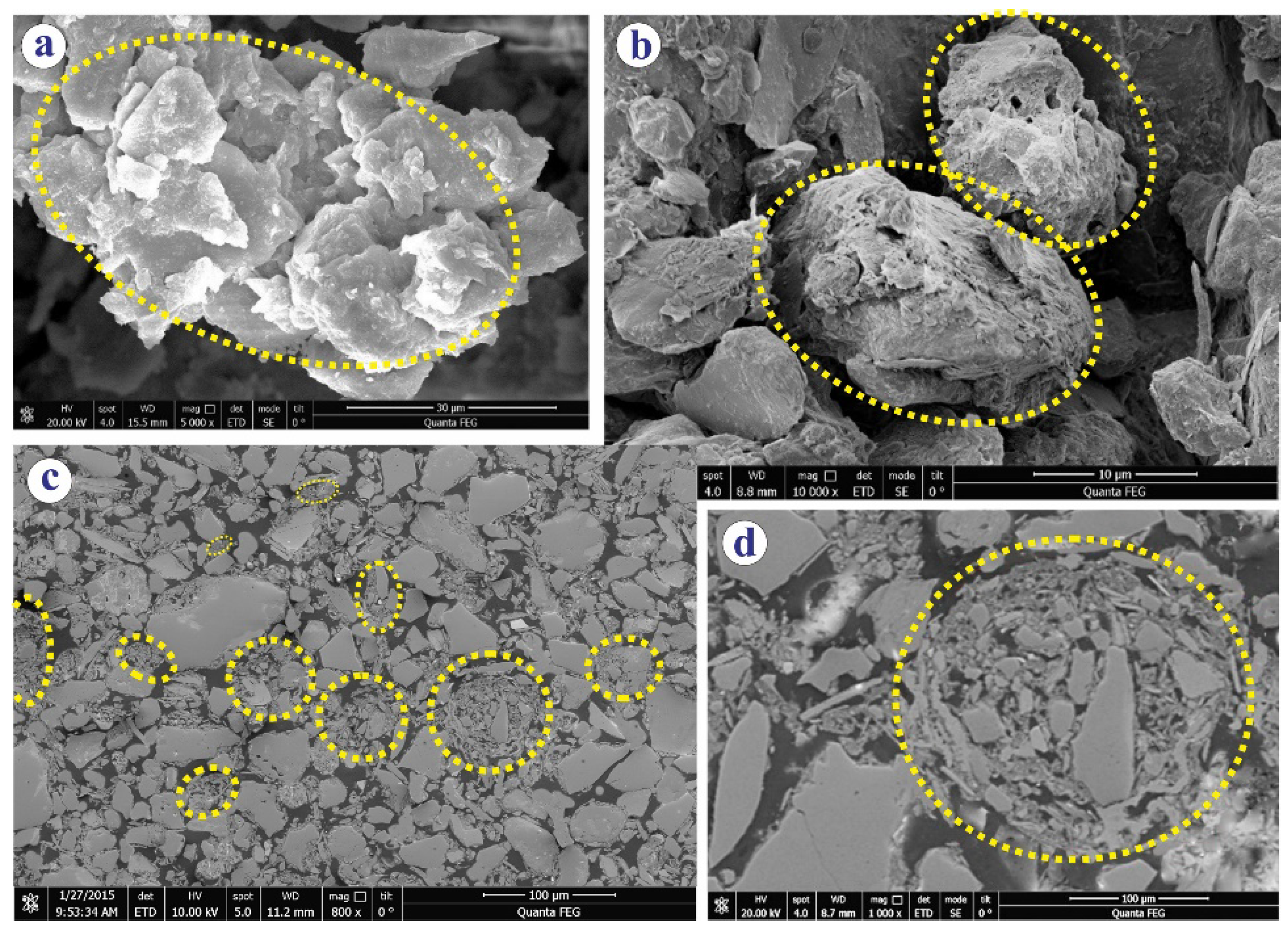

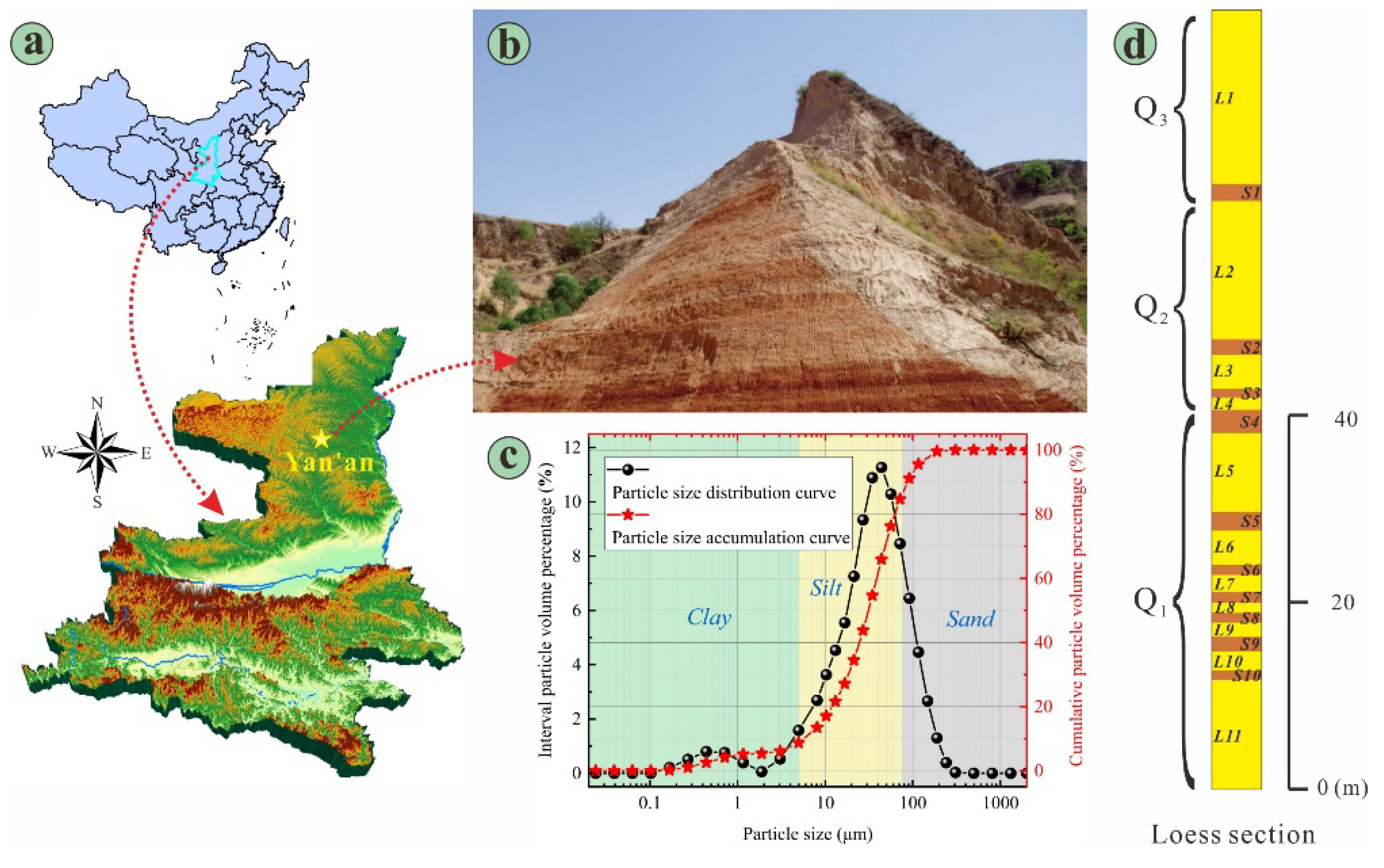

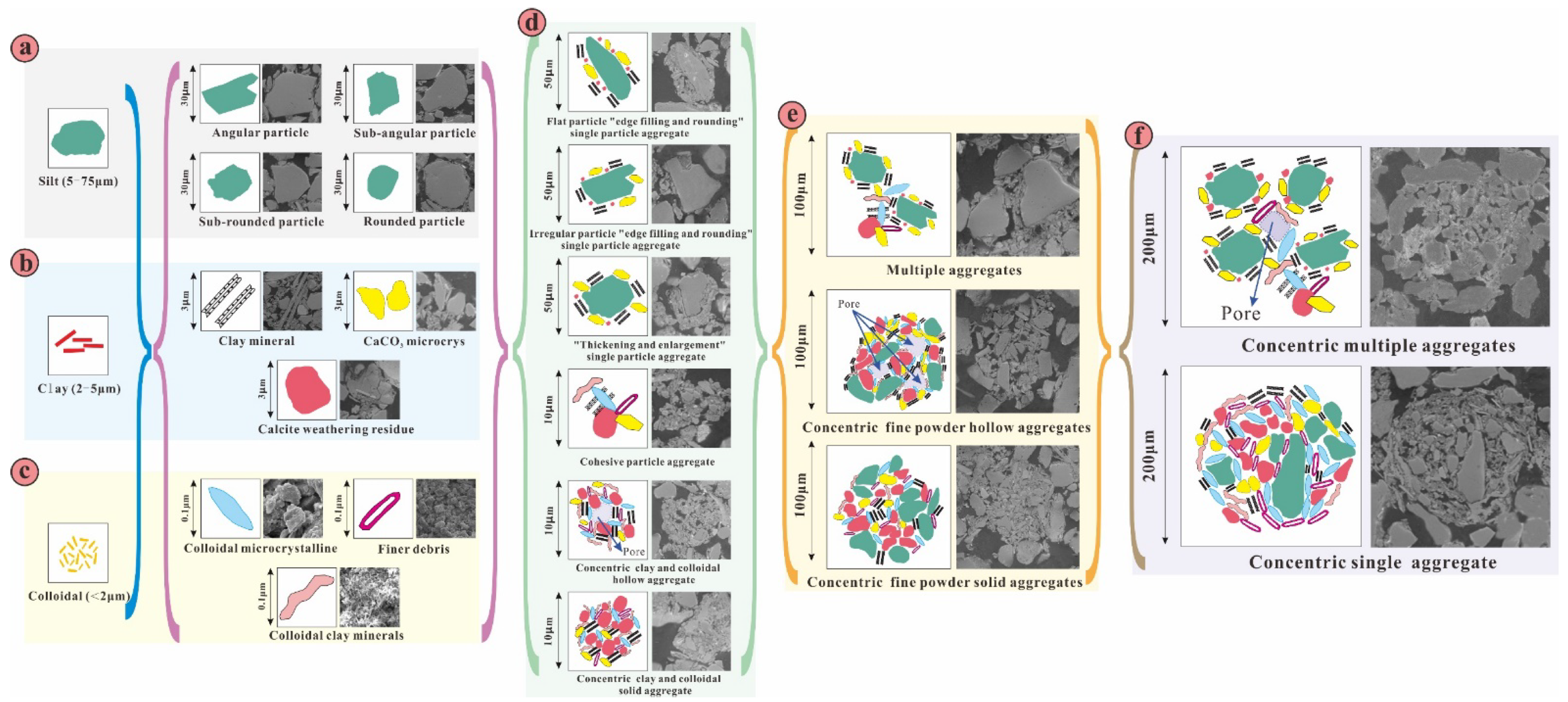

2. Experimental Study

2.1. Sample Preparation

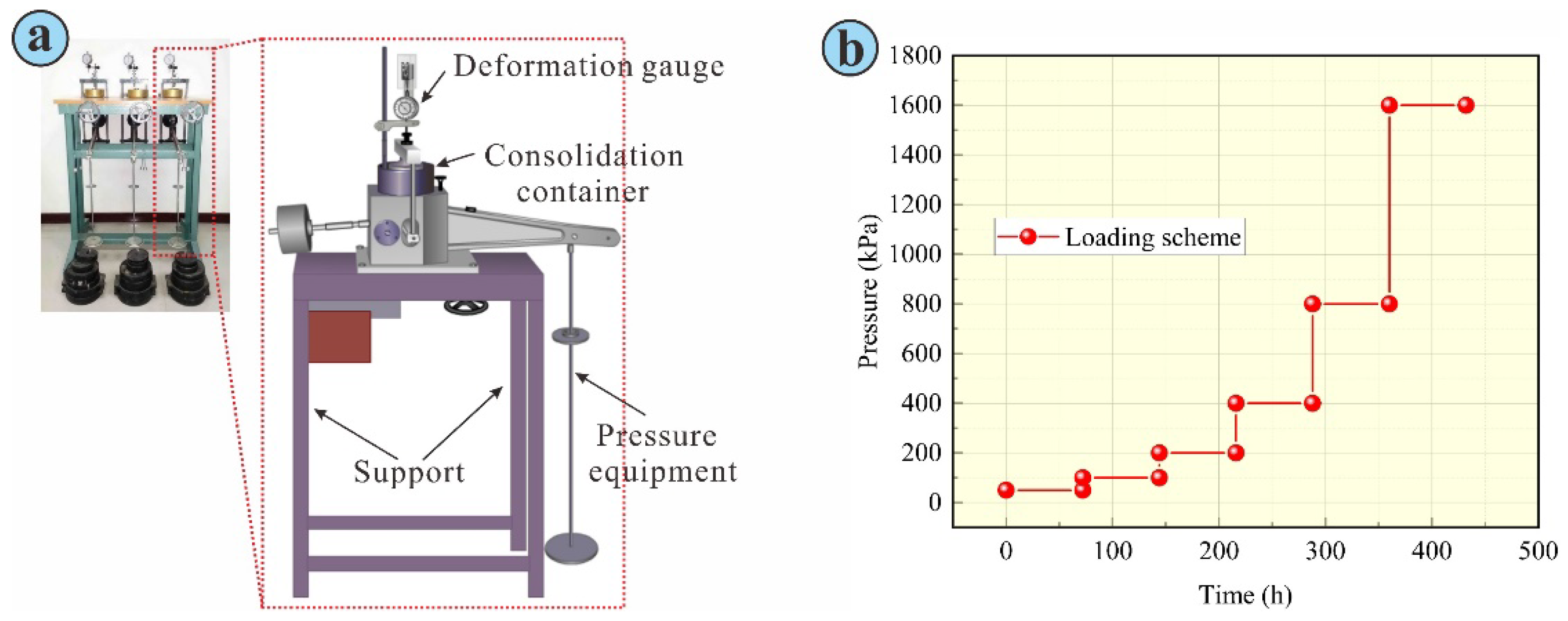

2.2. Consolidation Creep Test

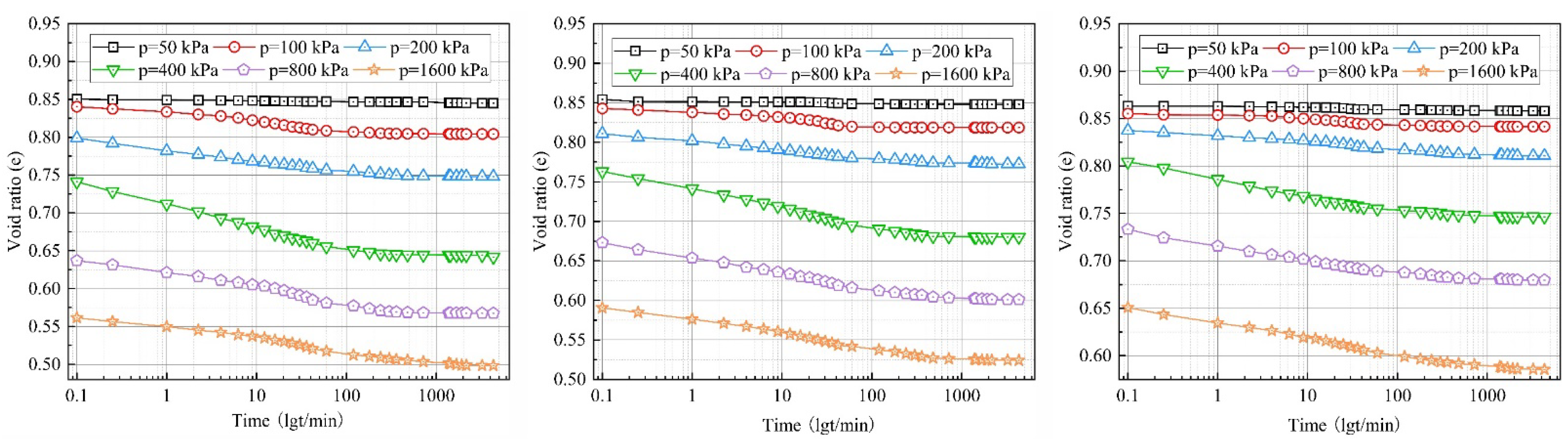

2.3. Experimental Result

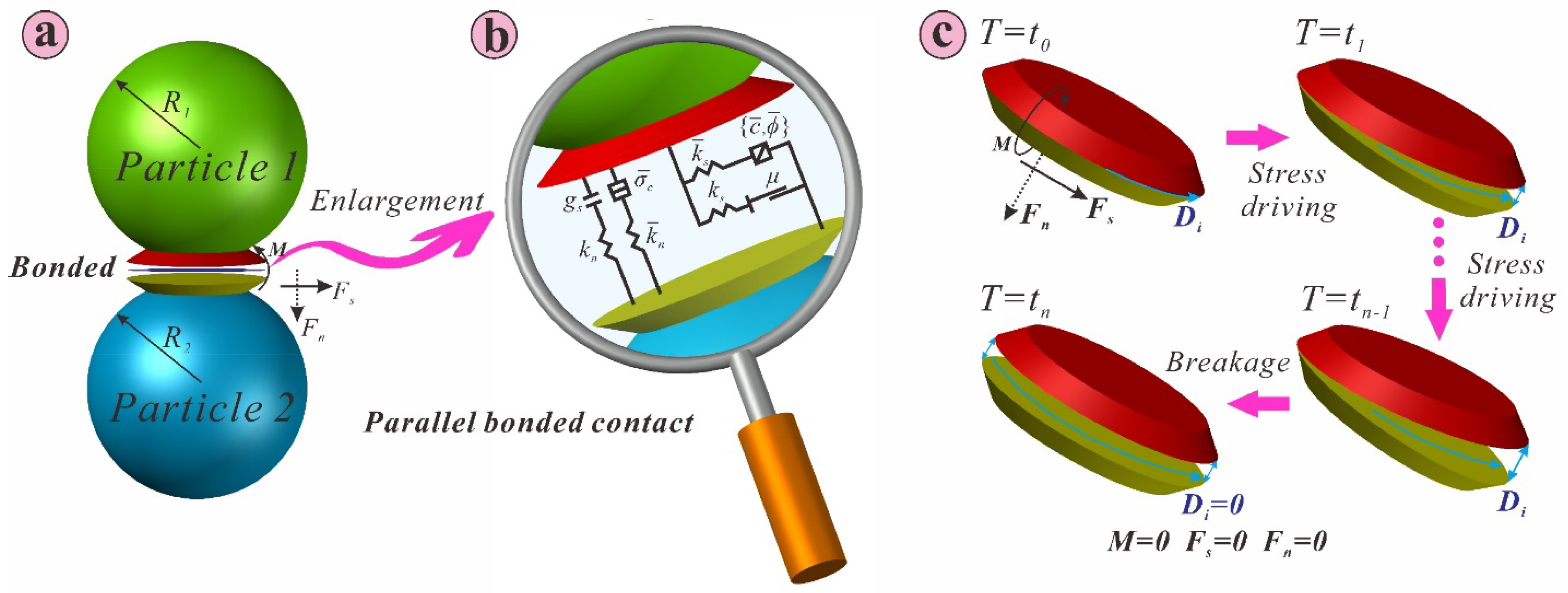

3. DEM Simulation

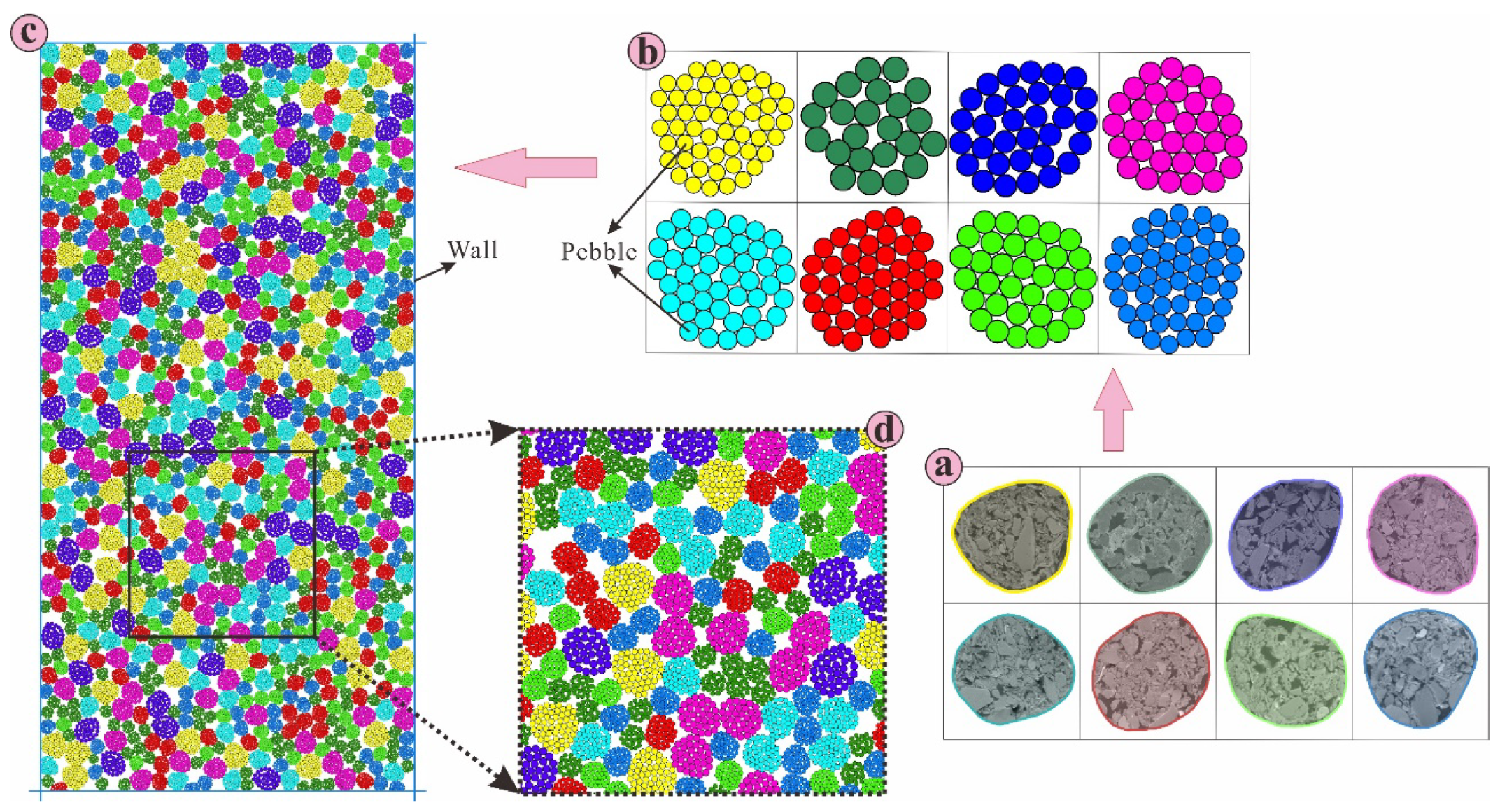

3.1. DEM Model Setup

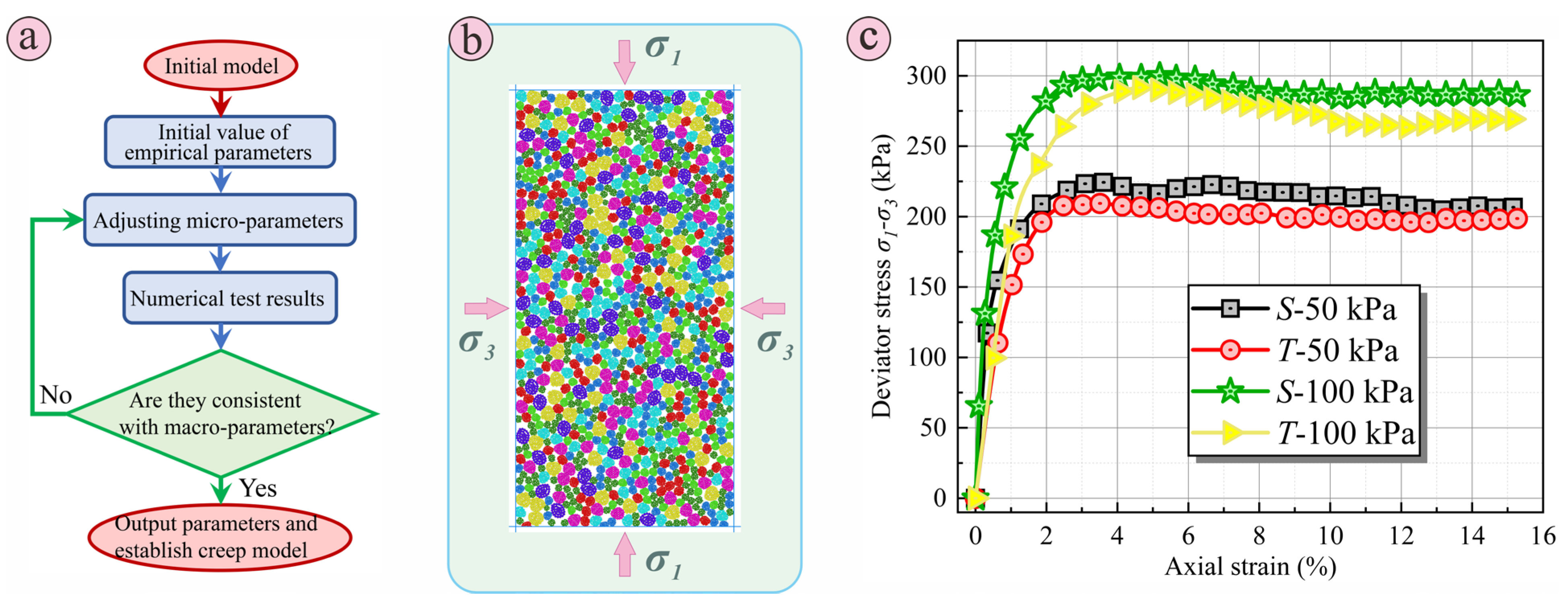

3.2. Calibration of PFC Parameters

3.3. Creep Numerical Simulation Scheme

4. Results and Discussion

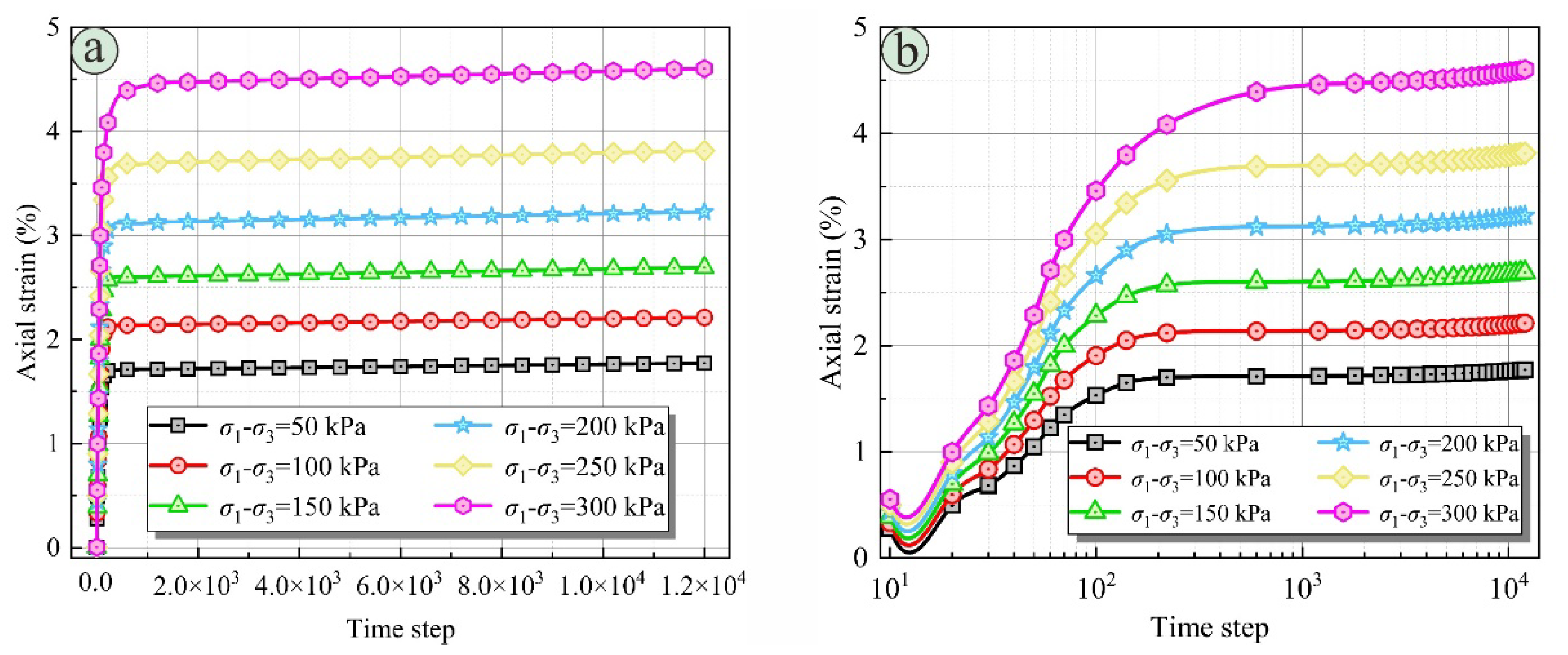

4.1. Analysis of Axial Strain-Time Step Curve

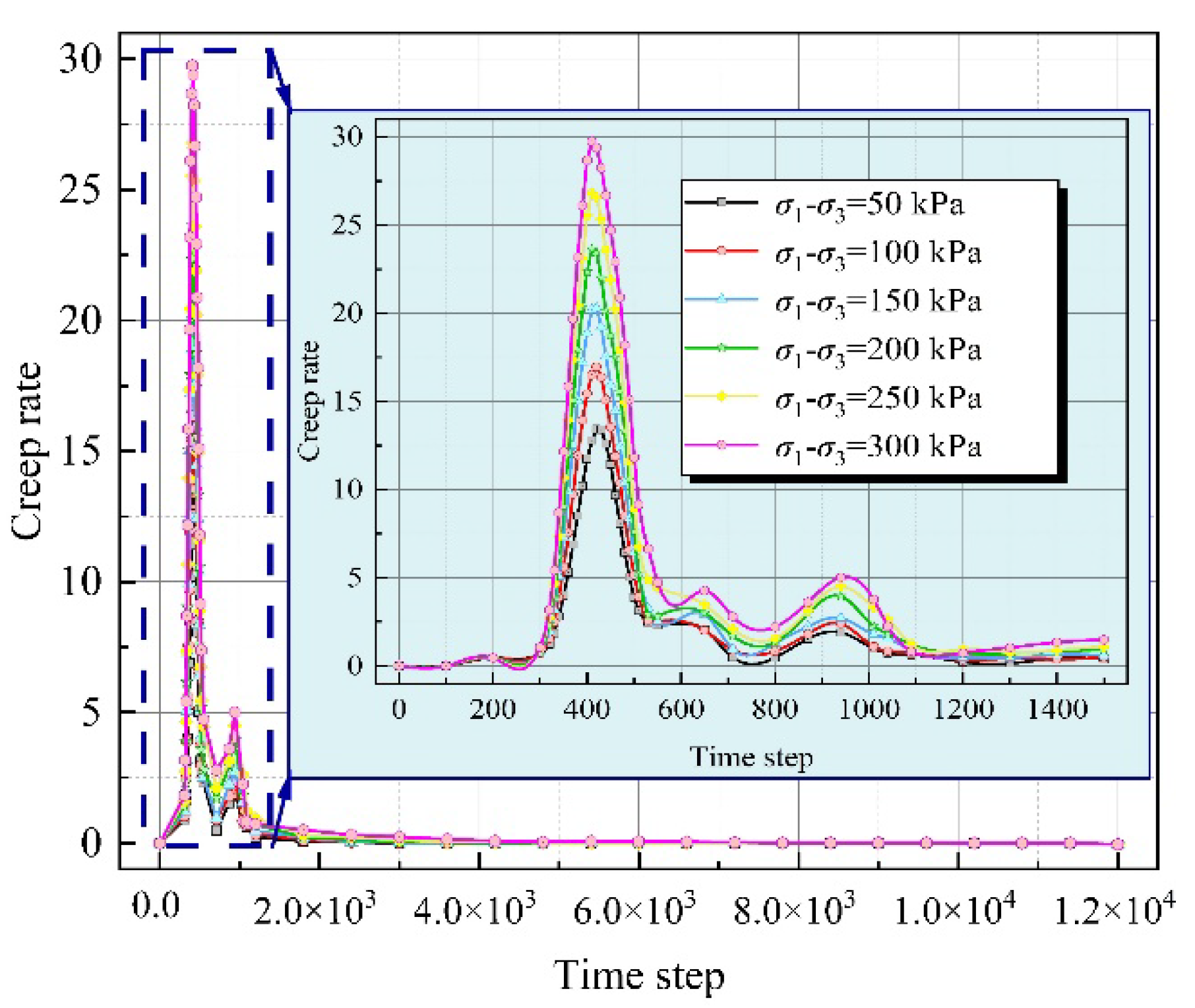

4.2. Variation of Creep Rate with Time Step

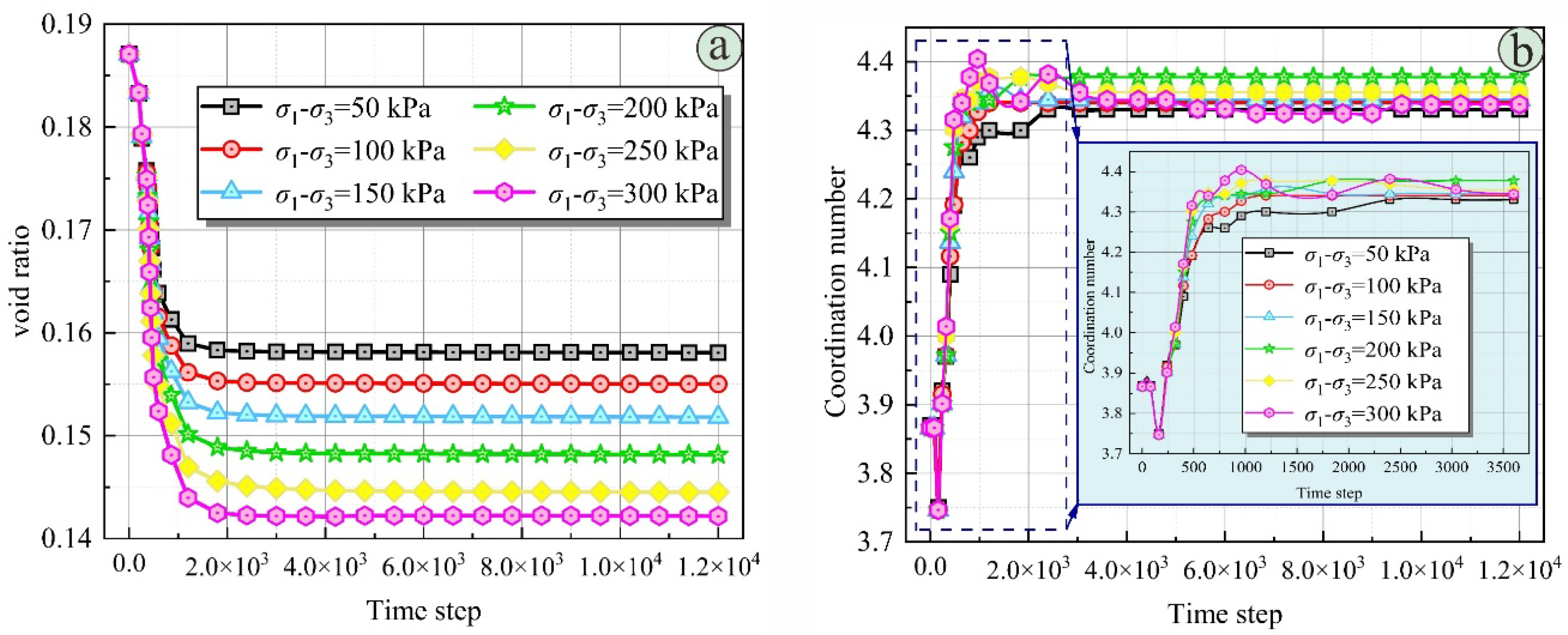

4.3. Variation of Void Ratio and Coordination Number with Time Step

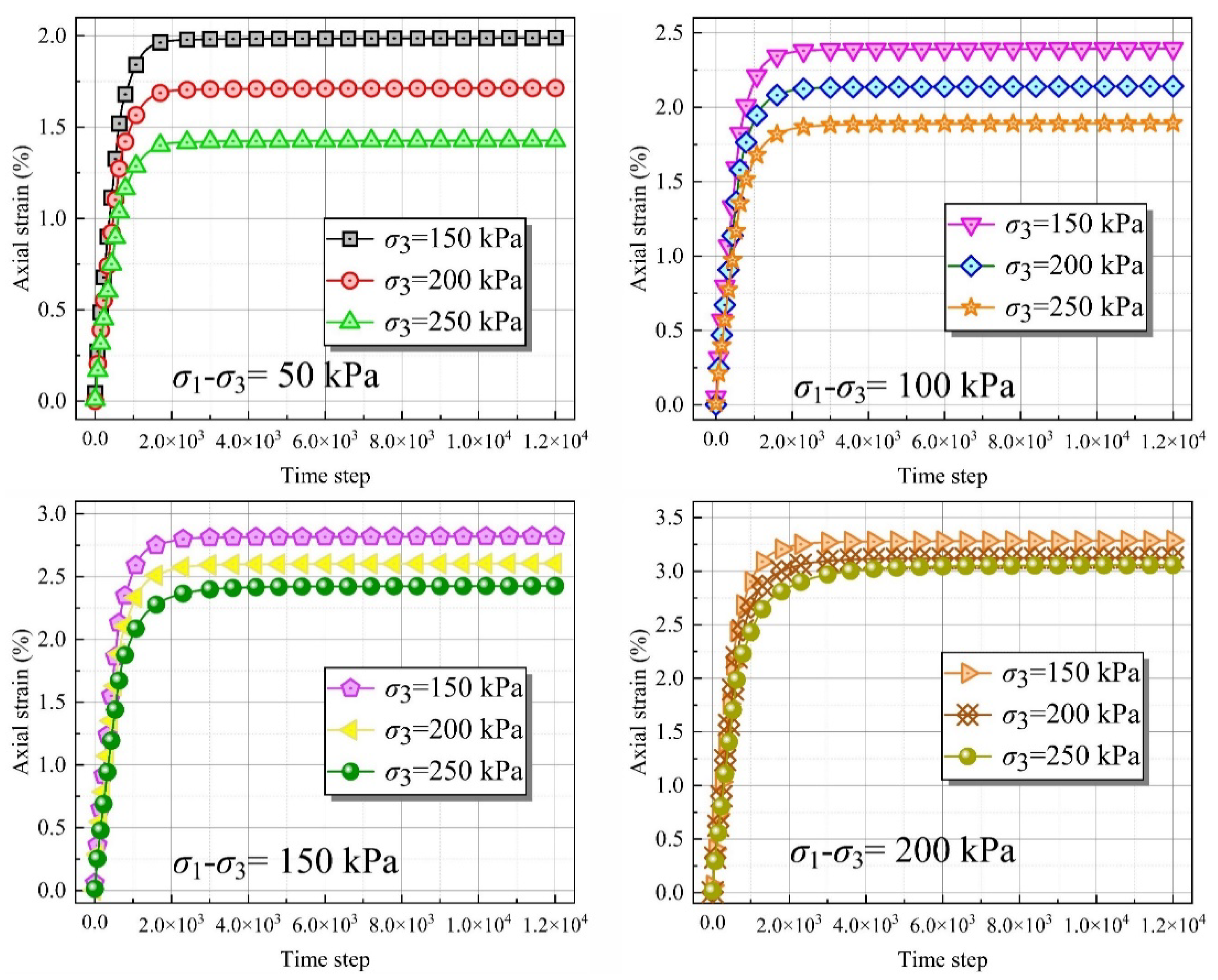

4.4. Effect of Confining Pressure on Creep Properties of Aggregates

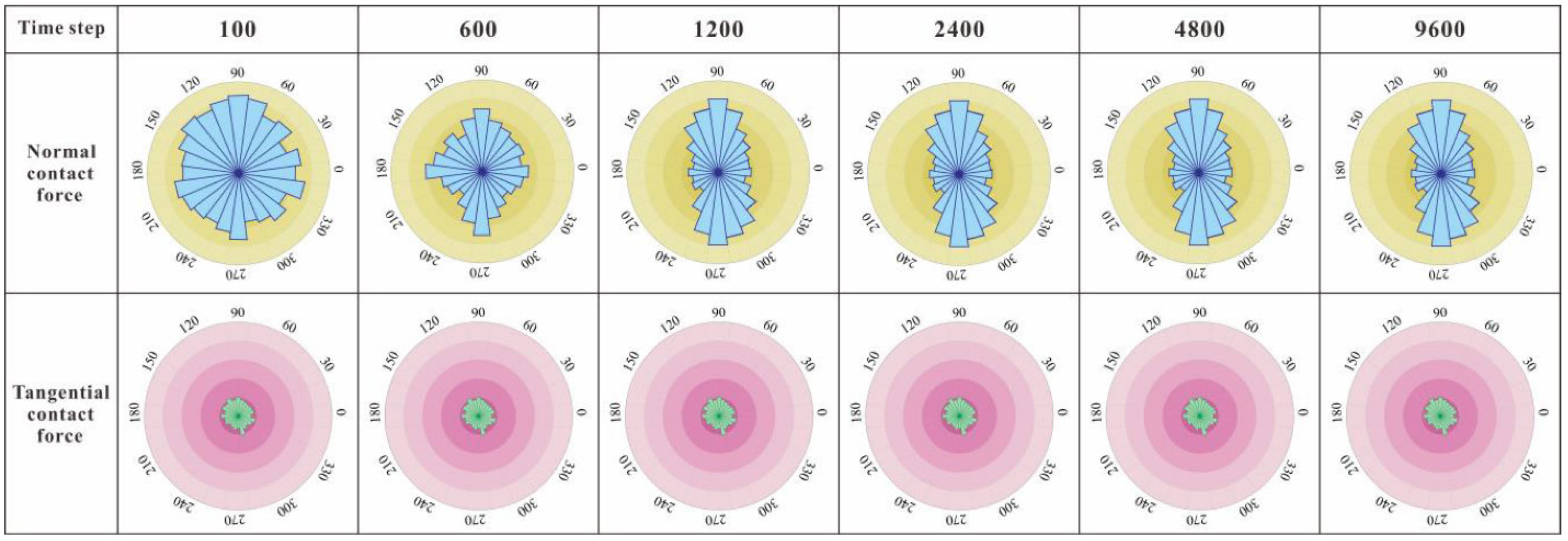

4.5. Micromechanical Evolution of Specimen during Creep

5. Conclusions

- (1)

- The development of axial strain at any time step is characterized by obvious nonlinear, and for the overall attenuation, deformation characteristics, It has three stages: rapid creep, deceleration creep and stable creep, and the time needed to stabilize the deformation and stress size present positive correlation that well reflects this kind of typical structural soil, and loess has strong initial structural strength, The trend of coordination number at any time is basically consistent with axial strain.

- (2)

- Under the same deviatoric stress level, the axial strain of the sample is negatively correlated with the confining pressure. Due to the increase of confining pressure, the occluding effect of the aggregate unit in the aggregate is enhanced and the structural strength is improved. When the deviatoric stress level is low, the deviatoric stress-axial strain relationship is approximately linear, and the isochronous curve shifts to the strain axis with the increase of deviatoric stress level. With the increase of time step, the deviant stress-time step curve gradually draws closer and the deviation of the strain axis increases, which are caused by the deterioration effect inside the sample becoming more obvious.

- (3)

- The discrete element model based on loess structural parameters can simulate the macroscopic phenomenon of aggregate creep and the evolution of the underlying mesoscopic parameters and micromechanical fabric. With the creep process, the creep stress is gradually borne by the normal contact force rather than the tangential contact force and has anisotropic characteristics. The microscopic parameters and evolution characteristics of fabric can reveal the microscopic mechanism behind the macroscopic creep phenomenon.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yates, K.; Fenton, C.H.; Bell, D.H. A review of the geotechnical characteristics of loess and loess-derived soils from Canterbury, South Island, New Zealand. Eng. Geol. 2018, 236, 11–21. [Google Scholar] [CrossRef]

- Peng, J.; Ma, P.; Wang, Q.; Zhu, X.; Zhang, F.; Tong, X.; Huang, W. Interaction between landsliding materials and the underlying erodible bed in a loess flowslide. Eng. Geol. 2018, 234, 38–49. [Google Scholar] [CrossRef]

- Costantini, E.A.; Carnicelli, S.; Sauer, D.; Priori, S.; Andreetta, A.; Kadereit, A.; Lorenzetti, R. Loess in Italy: Genesis, characteristics and occurrence. Catena 2018, 168, 14–33. [Google Scholar] [CrossRef]

- Yuan, Z.; Wang, L. Collapsibility and seismic settlement of loess. Eng. Geol. 2009, 105, 119–123. [Google Scholar] [CrossRef]

- Juang, C.H.; Dijkstra, T.; Wasowski, J.; Meng, X. Loess geohazards research in China: Advances and challenges for mega engineering projects. Eng. Geol. 2019, 251, 1–10. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, F.; Hu, H.; Cui, Y.; Peng, J. Structural characterization of natural loess and remolded loess under triaxial tests. Eng. Geol. 2014, 181, 249–260. [Google Scholar] [CrossRef]

- Wen, B.-P.; Yan, Y.-J. Influence of structure on shear characteristics of the unsaturated loess in Lanzhou, China. Eng. Geol. 2014, 168, 46–58. [Google Scholar] [CrossRef]

- Li, P.; Vanapalli, S.; Li, T. Review of collapse triggering mechanism of collapsible soils due to wetting. J. Rock Mech. Geotech. Eng. 2016, 8, 256–274. [Google Scholar] [CrossRef]

- Xu, L.; Coop, M.R. Influence of structure on the behavior of a saturated clayey loess. Can. Geotech. J. 2016, 53, 1026–1037. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Mu, Q.Y.; Zhou, C. Effects of soil structure on the shear behaviour of an unsaturated loess at different suctions and temperatures. Can. Geotech. J. 2017, 54, 270–279. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, F.; Ma, F.; Wang, M.; Bai, X.; Zheng, Y.; Yin, H.; Zhang, G. Collapsibility, composition, and microstructure of loess in China. Can. Geotech. J. 2016, 53, 673–686. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Z.; Li, X.-A.; Wang, L.; Li, L.; Shi, J.; Bi, M. A new approach to evaluation of loess collapsibility based on quantitative analyses of colloid-clay coating with statistical methods. Eng. Geol. 2021, 288, 106167. [Google Scholar] [CrossRef]

- Karimpour, H.; Lade, P.V. Creep behavior in Virginia Beach sand. Can. Geotech. J. 2013, 50, 1159–1178. [Google Scholar] [CrossRef]

- Li, J.X.; Wang, C.M.; Zhang, X.W. Creep properties and micropore changes of soft soil under different drainage conditions. Rock Soil Mech. 2010, 31, 3493–3498. [Google Scholar] [CrossRef]

- Xie, X.; Qi, S.; Zhao, F.; Wang, D. Creep behavior and the microstructural evolution of loess-like soil from Xi’an area, China. Eng. Geol. 2018, 236, 43–59. [Google Scholar] [CrossRef]

- Tang, H.; Duan, Z.; Wang, D.; Dang, Q. Experimental investigation of creep behavior of loess under different moisture contents. Bull. Eng. Geol. Environ. 2020, 79, 411–422. [Google Scholar] [CrossRef]

- Xin, P.; Liang, C.; Wu, S.; Liu, Z.; Shi, J.; Wang, T. Kinematic characteristics and dynamic mechanisms of large-scale landslides in a loess plateau: A case study for the north bank of the Baoji stream segment of the Wei River, China. Bull. Eng. Geol. Environ. 2016, 75, 659–671. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Zhan, H.; Li, P.; Qiu, H.; Hu, S. Moisture content effect on the creep behavior of loess for the catastrophic Baqiao landslide. Catena 2020, 187, 104371. [Google Scholar] [CrossRef]

- Barthès, B.; Roose, E. Aggregate stability as an indicator of soil susceptibility to runoff and erosion; validation at several levels. Catena 2002, 47, 133–149. [Google Scholar] [CrossRef] [Green Version]

- Munkholm, L.; Schjønning, P.; Kay, B. Tensile strength of soil cores in relation to aggregate strength, soil fragmentation and pore characteristics. Soil Tillage Res. 2002, 64, 125–135. [Google Scholar] [CrossRef]

- Murungu, F. Effects of seed priming, aggregate size and soil matric potential on emergence of cotton (Gossypium hirsutum L.) and maize (Zea mays L.). Soil Tillage Res. 2003, 74, 161–168. [Google Scholar] [CrossRef]

- Reuss, S.; Buhler, D.; Gunsolus, J. Effects of soil depth and aggregate size on weed seed distribution and viability in a silt loam soil. Appl. Soil Ecol. 2001, 16, 209–217. [Google Scholar] [CrossRef]

- Nichols, K.A.; Halvorson, J.J. Roles of biology, chemistry, and physics in soil macroaggregate formation and stabilization. Open Agric. J. 2013, 7, 107–117. [Google Scholar] [CrossRef] [Green Version]

- Jiao, F.; Wen, Z.-M.; An, S.-S. Changes in soil properties across a chronosequence of vegetation restoration on the Loess Plateau of China. Catena 2011, 86, 110–116. [Google Scholar] [CrossRef]

- An, S.; Mentler, A.; Mayer, H.; Blum, W.E. Soil aggregation, aggregate stability, organic carbon and nitrogen in different soil aggregate fractions under forest and shrub vegetation on the Loess Plateau, China. Catena 2010, 81, 226–233. [Google Scholar] [CrossRef]

- Amézketa, E. Soil Aggregate Stability: A Review. J. Sustain. Agric. 1999, 14, 83–151. [Google Scholar] [CrossRef]

- Li, X.; Li, L. Quantification of the pore structures of Malan loess and the effects on loess permeability and environmental significance, Shaanxi Province, China: An experimental study. Environ. Earth Sci. 2017, 76, 523. [Google Scholar] [CrossRef]

- Al Mahbub, A.; Haque, A. X-ray Computed Tomography Imaging of the Microstructure of Sand Particles Subjected to High Pressure One-Dimensional Compression. Materials 2016, 9, 890. [Google Scholar] [CrossRef] [Green Version]

- Wei, T.; Fan, W.; Yu, N.; Wei, Y.-N. Three-dimensional microstructure characterization of loess based on a serial sectioning technique. Eng. Geol. 2019, 261, 105265. [Google Scholar] [CrossRef]

- Wei, Y.-N.; Fan, W.; Yu, B.; Deng, L.-S.; Wei, T. Characterization and evolution of three-dimensional microstructure of Malan loess. Catena 2020, 192, 104585. [Google Scholar] [CrossRef]

- Asano, M.; Wagai, R. Evidence of aggregate hierarchy at micro- to submicron scales in an allophanic Andisol. Geoderma 2014, 216, 62–74. [Google Scholar] [CrossRef]

- Al-Kaisi, M.M.; Douelle, A.; Kwaw-Mensah, D. Soil microaggregate and macroaggregate decay over time and soil carbon change as influenced by different tillage systems. J. Soil Water Conserv. 2014, 69, 574–580. [Google Scholar] [CrossRef] [Green Version]

- Nie, X.; Li, Z.; Huang, J.; Liu, L.; Xiao, H.; Liu, C.; Zeng, G. Thermal stability of organic carbon in soil aggregates as affected by soil erosion and deposition. Soil Tillage Res. 2018, 175, 82–90. [Google Scholar] [CrossRef]

- Jiang, M.; Yan, H.; Zhu, H.; Utili, S. Modeling shear behavior and strain localization in cemented sands by two-dimensional distinct element method analyses. Comput. Geotech. 2011, 38, 14–29. [Google Scholar] [CrossRef]

- Lopez, R.D.F.; Larsson, S.; Silfwerbrand, J. Discrete element modelling of rockfill railway embankments. Granul. Matter 2021, 23, 1–14. [Google Scholar] [CrossRef]

- Shirinabadi, R.; Moosavi, E.; Gholinejad, M. Application of Distinct Element Method to Analyze the Fracture and In-situ Stress on Wellbore Stability under Triaxial Compression. Indian Geotech. J. 2021, 51, 1384–1398. [Google Scholar] [CrossRef]

- Li, H.; Ma, H.; Shi, X.; Zhou, J.; Zhang, H.; Daemen, J.J.K. A 3D Grain-Based Model for Simulating the Micromechanical Behavior of Salt Rock. Rock Mech. Rock Eng. 2020, 53, 2819–2837. [Google Scholar] [CrossRef]

- China, Ministry of Water Resources of the People’s Republic of China. Standard for Geotechnical Testing Method; China Planning Press: Beijing, China, 1999. [Google Scholar]

- Hong, B.; Li, X.-A.; Wang, L.; Li, L.-C. Temporal variation in the permeability anisotropy behavior of the Malan loess in northern Shaanxi Province, China: An experimental study. Environ. Earth Sci. 2019, 78, 1–12. [Google Scholar] [CrossRef]

- PFC2D Particle Flow Code in 2 Dimensions User’s Guide; Itasca Consulting Group Inc.: Minneapolis, MN, USA, 2014.

- Huang, Y.-H.; Yang, S.-Q.; Ranjith, P.; Zhao, J. Strength failure behavior and crack evolution mechanism of granite containing pre-existing non-coplanar holes: Experimental study and particle flow modeling. Comput. Geotech. 2017, 88, 182–198. [Google Scholar] [CrossRef]

- Wang, P.; Yin, Z.-Y.; Wang, Z.-Y. Micromechanical Investigation of Particle-Size Effect of Granular Materials in Biaxial Test with the Role of Particle Breakage. J. Eng. Mech. 2022, 148, 04021133. [Google Scholar] [CrossRef]

- Ovalle, C.; Dano, C.; Hicher, P.-Y.; Cisternas, M. Experimental framework for evaluating the mechanical behavior of dry and wet crushable granular materials based on the particle breakage ratio. Can. Geotech. J. 2015, 52, 587–598. [Google Scholar] [CrossRef] [Green Version]

| Nature Density | Water Content (%) | Void Ratio | Liquid Limit (%) | Plastic Limit (%) | Particle Composition (%) | ||

|---|---|---|---|---|---|---|---|

| Sand >0.075 mm | Silt 0.005–0.075 mm | Clay <0.005 mm | |||||

| 1.86 | 16.3 | 0.66 | 29.9 | 15.9 | 11.3 | 71.9 | 16.8 |

| 1.82 | 15.6 | 0.71 | 30.2 | 16.5 | 13.6 | 72.5 | 13.9 |

| 1.81 | 14.9 | 0.72 | 29.7 | 16.4 | 12.5 | 72.9 | 14.6 |

| Parameters | Value |

|---|---|

| Particle density (kg/m3) | 2500 |

| Inter-particle frictional coefficient,μ | 0.5 |

| Wall-particle frictional coefficient | 0 |

| Effective modulus, Ec (Pa) | 3 × 108 |

| Stiffness ratio (kn/ks) | 4/3 |

| Tensile strength, σc (Pa) | 1 × 106 |

| Bond strength, c (Pa) | 5 × 106 |

| Damping factor | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.-Q.; Li, X.-A.; Bi, M.-L.; Zhang, K.-X.; Zhang, J. Investigation on Creep Behavior of Aggregates of Loess by a Discrete Element Method. Processes 2022, 10, 795. https://doi.org/10.3390/pr10040795

Sun J-Q, Li X-A, Bi M-L, Zhang K-X, Zhang J. Investigation on Creep Behavior of Aggregates of Loess by a Discrete Element Method. Processes. 2022; 10(4):795. https://doi.org/10.3390/pr10040795

Chicago/Turabian StyleSun, Jian-Qiang, Xi-An Li, Mei-Le Bi, Kai-Xuan Zhang, and Jing Zhang. 2022. "Investigation on Creep Behavior of Aggregates of Loess by a Discrete Element Method" Processes 10, no. 4: 795. https://doi.org/10.3390/pr10040795

APA StyleSun, J.-Q., Li, X.-A., Bi, M.-L., Zhang, K.-X., & Zhang, J. (2022). Investigation on Creep Behavior of Aggregates of Loess by a Discrete Element Method. Processes, 10(4), 795. https://doi.org/10.3390/pr10040795