Environmental and Energy Performance of Ethanol Production from the Integration of Sugarcane, Corn, and Grain Sorghum in a Multipurpose Plant

Abstract

:1. Introduction

2. Contextualization and Methodological Aspects

2.1. Socioeconomic Context of Rural Production in Mato Grosso

2.2. Materials and Methods

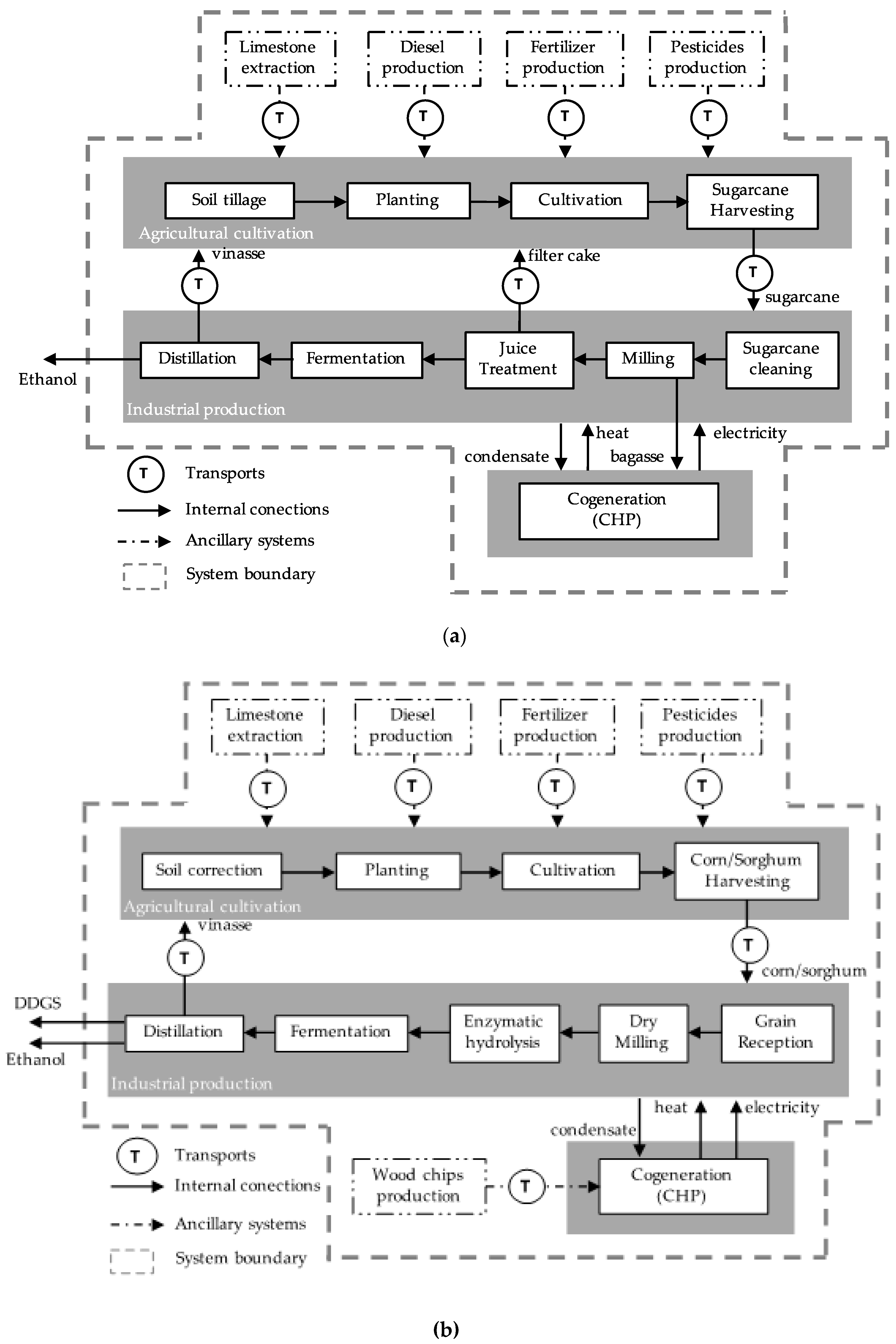

3. Description of the Models for Producing Ethanol from Sugarcane, Corn and Grain Sorghum in the State of Mato Grosso

4. Life Cycle Assessment: Flex Mill in Mato Grosso

4.1. Scope Definition

4.2. Life Cycle Inventory (LCI)

4.3. Life Cycle Impact Assessment

5. Results and Discussion

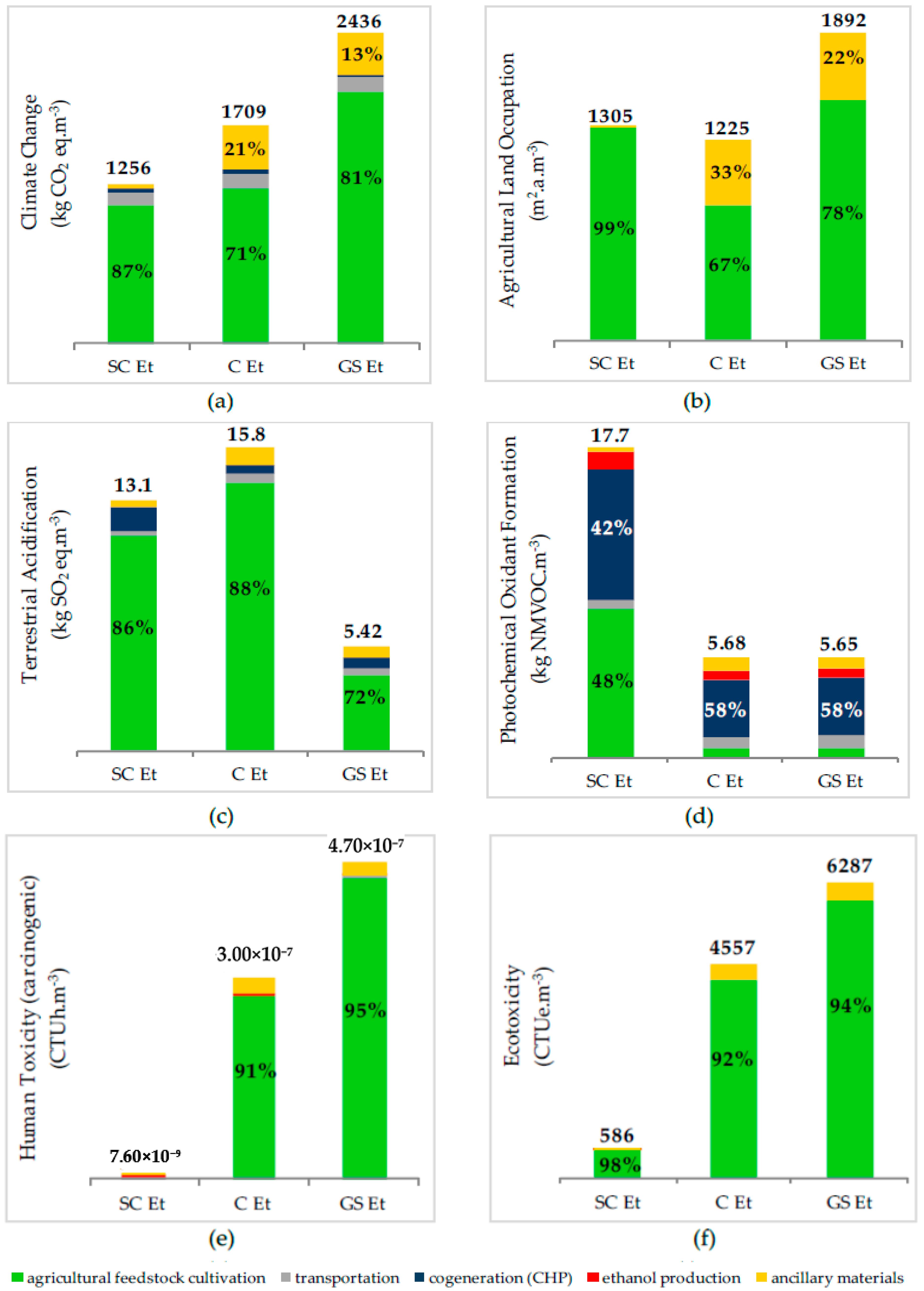

5.1. Individual Assessment of Ethanol Production from Sugarcane, Corn and Grain Sorghum

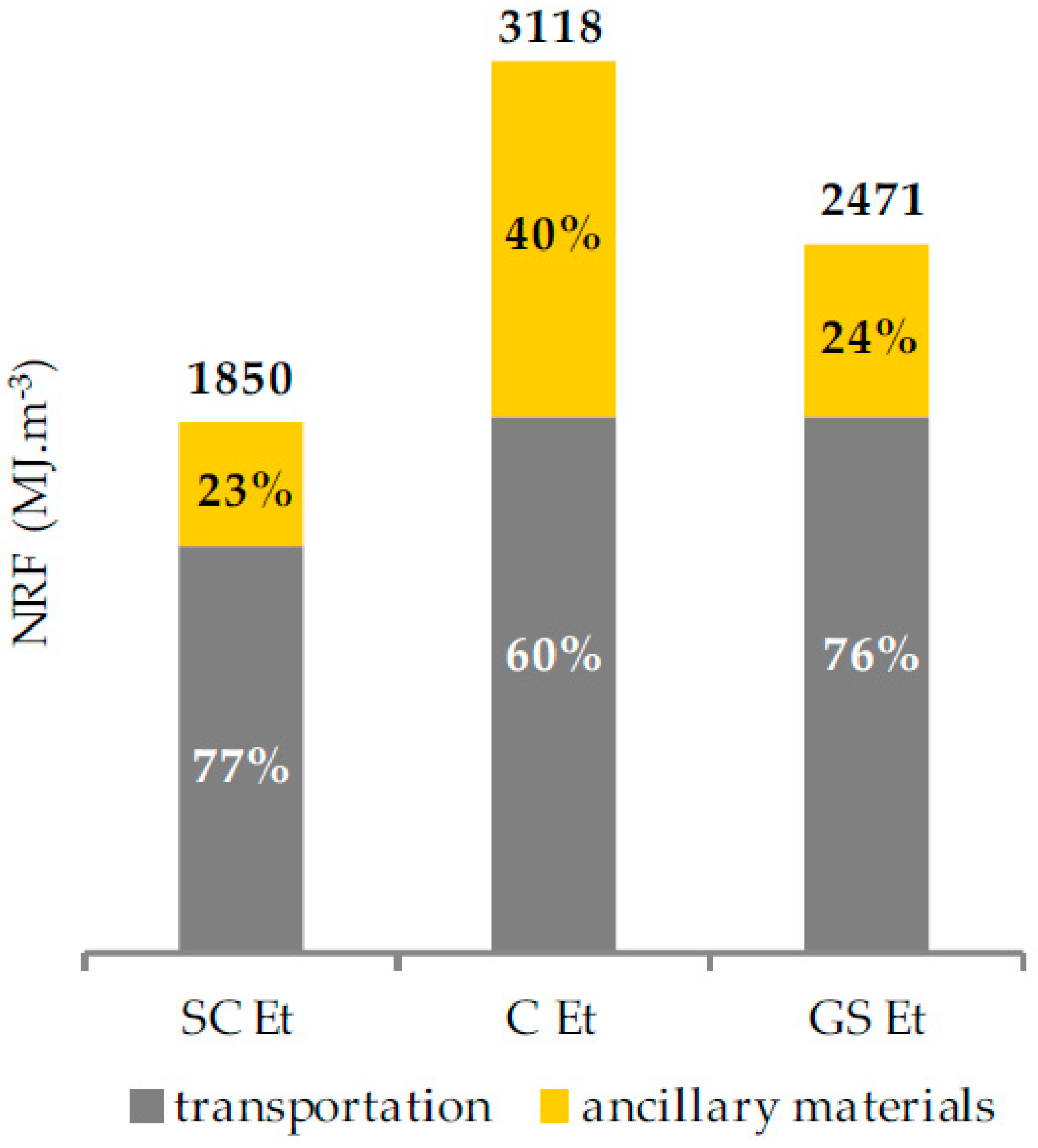

5.1.1. Energy Assessment: EROI

5.1.2. Climate Change

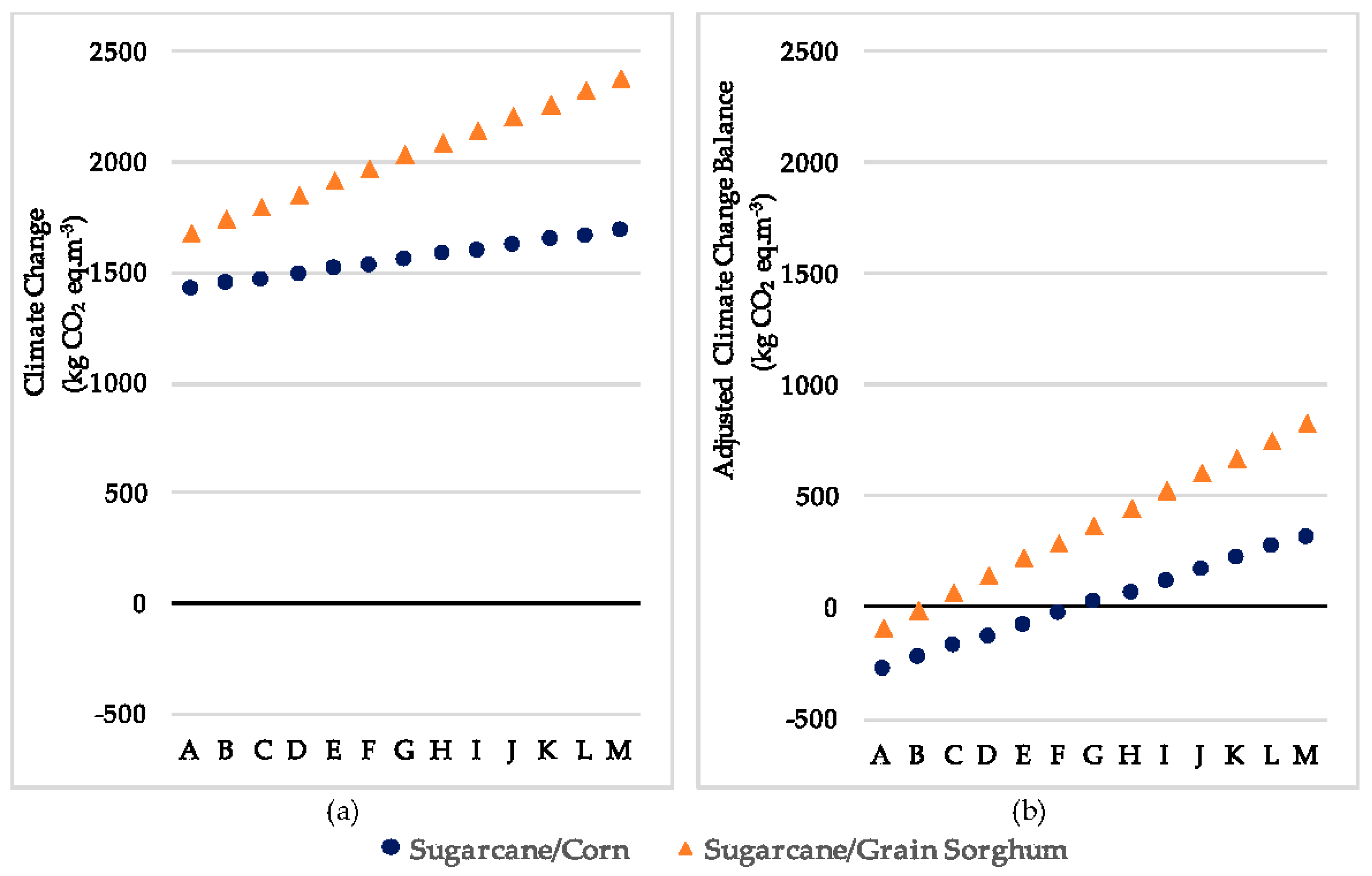

Considerations about the Carbon Balance

5.1.3. Agricultural Land Occupation

5.1.4. Terrestrial Acidification

5.1.5. Photochemical Oxidants Formation

5.1.6. Human Toxicity (Carcinogenic) and Ecotoxicity

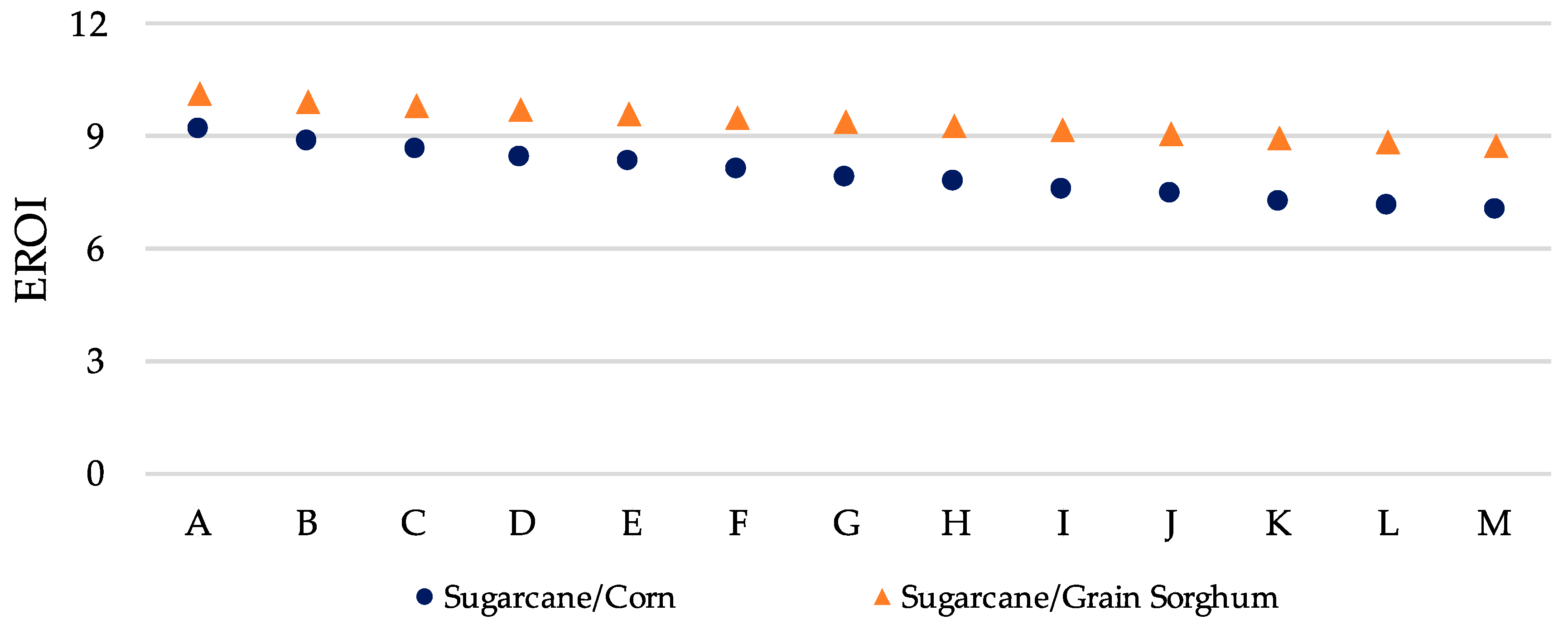

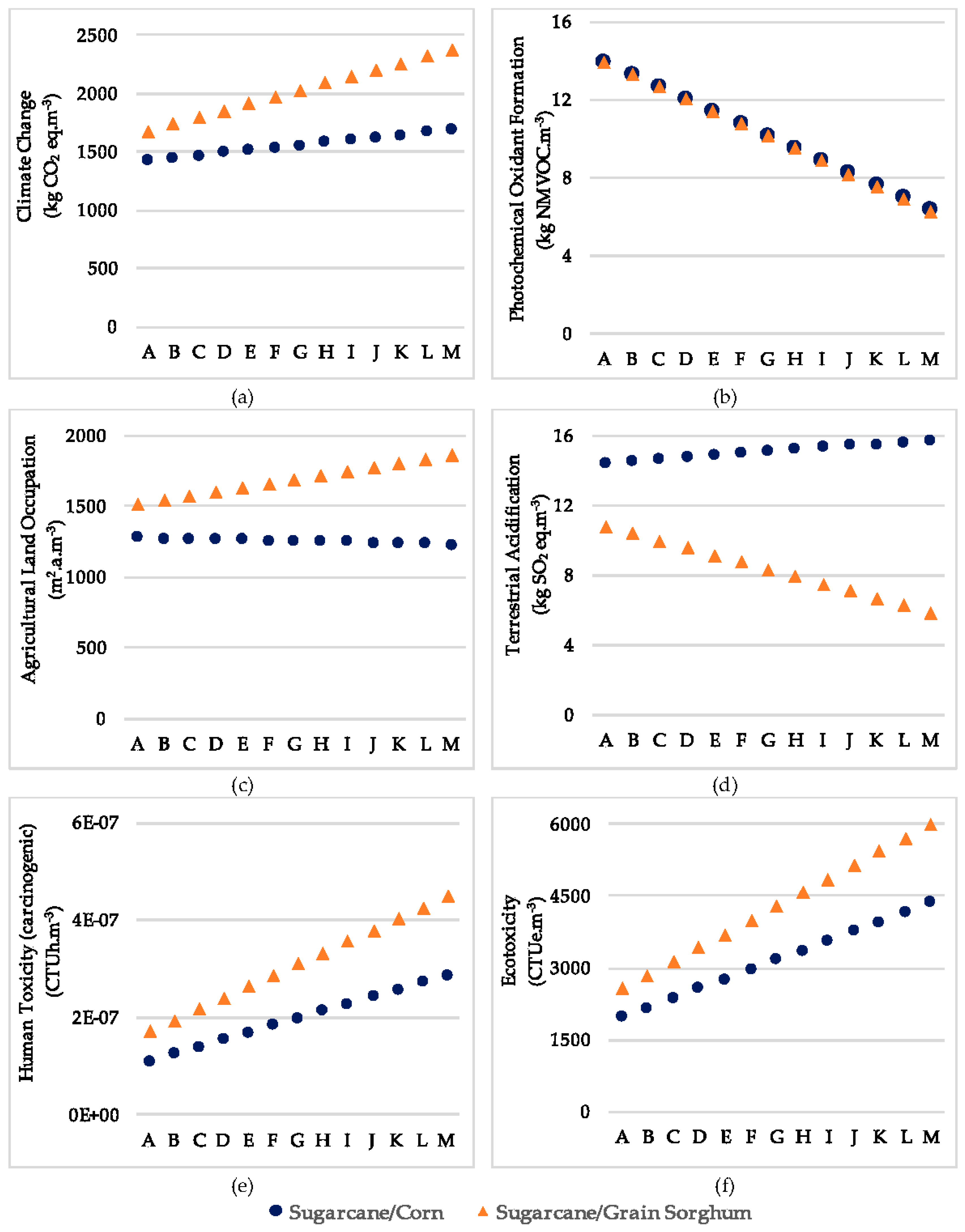

5.2. Evaluation of Process Integration Scenarios in the Multipurpose Plant

6. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- ANP—Agencia Nacional de Petroleo, Gas Natural e Biocombustiveis. Anuario Estatistico Brasileiro do Petroleo, Gas Natural e Biocombustiveis 2016. Available online: http://www.anp.gov.br/?pg=82260 (accessed on 9 August 2016).

- EPE—Empresa Brasileira de Pesquisa Energetica. Balanco Energetico Nacional 2016: Relatorio Sintese ano Base 2015. Available online: https://ben.epe.gov.br/default.aspx?anoColeta=2016 (accessed on 9 August 2016).

- Iglesias, C.; Sesmero, J.P. Economic Analysis of Supplementing Sugarcane with Corn for Ethanol Production in Brazil: A Case Study in Uberaba. Bioenergy Res. 2015, 8, 627–643. [Google Scholar] [CrossRef]

- Menezes, T.J.D.B. Etanol, O Combustível do Brasil; Editora Agronômica Ceres: São Paulo, Brasil, 1980. [Google Scholar]

- Souza, W.A.R.; Goldsmith, P.; Martines Filho, J.G.; Rasmussen, R.L. Bioenergy Efficiency and a Flex-Mill Simulation in Mato Grosso. In Proceedings of the 48° Congresso SOBER Sociedade Brasileira de Economia Administracao e Sociologia Rural, Campo Grande, Brasil, 25–28 July 2010.

- Wang, D.; Bean, S.; McLaren, J.; Seib, P.; Madl, R.; Tuinstra, M.; Shi, Y.; Lenz, M.; Wu, X.; Zhao, R. Grain sorghum is a viable feedstock for ethanol production. J. Ind. Microbiol. Biotechnol. 2008, 35, 313–320. [Google Scholar] [CrossRef] [PubMed]

- Goldsmith, P.D.; Rasmussen, R.; Signorini, G.; Martines, J.; Guimaraes, C. The Capital Efficiency Challenge of Bioenergy Models: The Case of Flex Mills in Brazil. In Handbook of Bioenergy Economics and Policy; Khanna, M., Scheffran, J., Zilberman, D., Eds.; Springer: New York, NY, USA, 2010; pp. 175–192. [Google Scholar]

- Milanez, A.Y.; Nyko, D.; Valente, M.S.; Xavier, C.E.O.; Kulay, L.A.; Donke, A.C.G.; Matsuura, M.I.S.F.; Ramos, N.P.; Morandi, M.A.B.; Bonomi, A.M.F.L.J.; et al. A produção de etanol pela integracao do milho-safrinha as usinas de cana-de-acucar: Avaliacao ambiental, economica e sugestoes de politica. Rev. BNDES 2014, 41, 147–207. [Google Scholar]

- Nogueira, A.R.; Donke, A.C.G.; Matsuura, M.I.S.F.; Matai, P.H.S.; Kulay, L. Use of Environmental and Thermodynamic Indicators to Assess the Performance of an Integrated Process for Ethanol Production. Environ. Nat. Resour. Res. 2014, 4, 59–74. [Google Scholar] [CrossRef]

- Susmozas, A.; Irribarren, D.; Dufour, J. Assessing the Life-Cycle Performance of Hydrogen Production via Biofuel Reforminng in Europe. Resources 2015, 4, 398–411. [Google Scholar] [CrossRef]

- Triana, C.A.R. Energetics of Brazilian ethanol: Comparison between assessment approaches. Energy Policy 2011, 39, 4605–4613. [Google Scholar] [CrossRef]

- Macedo, I.C.; Seabra, J.E.A.; Silva, J.E.A.R. Greenhouse gases emissions in the production and use of ethanol from sugarcane in Brazil: The 2005/2006 averages and a prediction for 2020. Biomass Bioenergy 2008, 32, 582–595. [Google Scholar] [CrossRef]

- Boddey, R.M.; Soares, L.H.B.; Alves, B.J.R.; Urquiaga, S. Bio-Ethanol Production in Brazil. In Biofuels, Solar and Wind as Renewable Energy Systems; Pimentel, D., Ed.; Springer: New York, NY, USA, 2008; pp. 321–356. [Google Scholar]

- Pimentel, D.; Patzek, T.W. Ethanol Production: Energy and Economic Issues Related to U.S. and Brazilian Sugarcane. In Biofuels, Solar and Wind as Renewable Energy Systems; Pimentel, D., Ed.; Springer: New York, NY, USA, 2008; pp. 357–371. [Google Scholar]

- Shapouri, H.; Duffield, J.A.; Wang, M. The Energy Balance of Corn Ethanol: An Update; United States Department of Agriculture: Washington, DC, USA, 2002.

- Kim, S.; Dale, B.E. Life cycle assessment of various cropping systems utilized for producing biofuels: Bioethanol and biodiesel. Biomass Bioenergy 2005, 29, 426–439. [Google Scholar] [CrossRef]

- Pimentel, D.; Patzek, T.W. Ethanol Production Using Corn, Switchgrass, and Wood; Biodiesel Production Using Soybean and Sunflower. Nat. Resour. Res. 2005, 14, 65–76. [Google Scholar] [CrossRef]

- Cai, H.; Dunn, J.B.; Wang, Z.; Han, J.; Wang, M.Q. Life-cycle energy use and greenhouse gas emissions of production of bioethanol from sorghum in the United States. Biotechnol. Biofuels 2013, 6, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Munoz, I.; Flury, K.; Jungbluth, N.; Rigarlsford, G.; Canals, L.M.; King, H. Life cycle assessment of bio-based ethanol produced from different agricultural feedstocks. Int. J. Life Cyle Assess. 2014, 19, 109–119. [Google Scholar] [CrossRef]

- Guerra, J.P.M.; Colete, J.R., Jr.; Arruda, L.C.M.; Silva, G.A.; Kulay, L. Comparative analysis of electricity cogeneration scenarios in sugarcane production by LCA. Int. J. Life Cyle Assess. 2014, 19, 814–825. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; Willey; Scrivener: Cincinnati, OH, USA, 2012. [Google Scholar]

- Guinee, J.B.; Haes, H.A.U.; Huppes, G. Quantitative life cycle assessment of products 1: Goal definition and inventory. J. Clean. Prod. 1993, 1, 3–13. [Google Scholar] [CrossRef]

- Hellweg, S.; Canals, L.M. Emerging approaches, challenges and opportunities in life cycle assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef] [PubMed]

- UNEP—United Nations Environment Programme. Why Take a Life Cycle Approach? United Nations Environment Programme: Nairobi, Kenya, 2004. [Google Scholar]

- Heijungs, R.; Guinee, J.B. An overview of the Life Cycle Assessment Method—Past, Present, and Future. In Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; Curran, M.A., Ed.; Willey; Scrivener: Cincinnati, OH, USA, 2012. [Google Scholar]

- ISO—International Organization for Standardization. ISO 14044. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- CONAB—Companhia Brasileira de Abastecimento. Acompanhamento da Safra Brasileira de Graos. V3. Safra 2015/16. N. 12. 2016. Available online: http://www.conab.gov.br (accessed on 10 August 2016). [Google Scholar]

- IBGE—Instituto Brasileiro de Geografia e Estatistica. Indicadores Sociais Municipais: Uma Analise dos Resultados do Universo do Censo Demográfico, 2010. Available online: http://biblioteca.ibge.gov.br/visualizacao/livros/liv54598.pdf (accessed on 7 December 2016).

- UNDP—United Nations Development Programme. Atlas do Desenvolvimento Humano no Brasil; Fundação João Pinheiro; Instituto de Pesquisa Econômica Aplicada (IPEA): Belo Horizonte, Brasil, 2013.

- Domingues, M.S.; Bermann, C. O arco de desflorestamento na Amazonia: Da pecuaria a soja. Ambiente Soc. 2012, 15, 1–22. [Google Scholar] [CrossRef]

- IBAMA—Instituto Brasileiro de Meio Ambiente e dos Recursos Naturais Renovaveis. Relatorios de Comercializacao de Agrotoxicos. Available online: http://www.ibama.gov.br/areas-tematicas-qa/relatorios-de-comercializacao-de-agrotoxicos/tudo (accessed on 14 July 2016).

- UNEP—United Nations Environment Programme. Global Guidance Principles for Life Cycle Assessment Databases: A Basis for Greener Processes and Products; United Nations Environment Programme: Nairobi, Kenya, 2011. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.J.; Doka, G.; Dones, R.; Hischier, R.; Hellweg, S.; Humbert, S.; Margni, M.; Nemecek, T.; et al. Implementation of Life Cycle Impact Assessment Methods: Data v2.0.; Ecoinvent Report No. 3; Swiss Centre for Life Cycle Inventories: Dubendorf, Switzerland, 2007. [Google Scholar]

- Hammerschlag, R. Ethanol’s Energy Return on Investment: A Survey of the Literature 1990-Present. Environ. Sci. Technol. 2006, 40, 1744–1750. [Google Scholar] [CrossRef] [PubMed]

- CONAB—Companhia Brasileira de Abastecimento. Series Historicas. Series Historicas de Area Plantada, Produtividade e Producao, Relativas as Safras 2005/06 a 2014/15 de Cana-de-Acucar. Available online: http://www.conab.gov.br (accessed on 14 July 2016).

- Borghi, E.; Crusciol, C.A.C.; Nascente, A.S.; Sousa, V.V.; Martins, P.O.; Mateus, G.P.; Costa, C. Sorghum grain yield, forage biomass production and revenue as affected by intercropping time. Eur. J. Agron. 2013, 51, 130–139. [Google Scholar] [CrossRef]

- Rodigheri, H.R.; Pinto, A.F.; Dhlson, J.C. Custo de Producao, Produtividade e Renda do Eucalipto Conduzido para uso Multiplo no Norte Pioneiro do Estado do Parana; Circular Tecnica 51 Embrapa: Colombo, Sri Lanka, 2001. [Google Scholar]

- Granda, C.B.; Zhu, L.; Holtzapple, M.T. Sustainable Liquid Biofuels and Their Environmental Impact. Environ. Prog. 2007, 26, 233–250. [Google Scholar] [CrossRef]

- Nemecek, T.; Kagi, T. Life Cycle Inventories of Agricultural Production Systems; Ecoinvent Report v.2.0, n.15; Swiss Centre for Life Cycle Inventories: Dubendorf, Switzerland, 2007. [Google Scholar]

- Nemecek, T.; Schnetzer, J.; Reinhard, J. Updated and harmonized greenhouse gas emissions for crop inventories. Int. J. Life Cycle Assess. 2016, 21, 1361–1378. [Google Scholar] [CrossRef]

- Kim, Y.; Mosier, N.S.; Hendrickson, R.; Ezeji, T.; Blaschek, H.; Dien, B.; Cotta, M.; Dale, B.; Ladisch, M.R. Composition of corn dry-grind ethanol by-products: DDGS, wet cake, and thin stillage. Bioresour. Technol. 2008, 99, 5165–5176. [Google Scholar] [CrossRef] [PubMed]

- Perez, E.R.; Cardozo, D.R.; Franco, D.W. Analise dos alcoois, esteres e compostos carbonilicos em amostras de oleo fusel. Quim. Nova 2001, 15, 10–12. [Google Scholar] [CrossRef]

- Cortez, L.A.B.; Brossard Perez, L.E. Experiences on vinasse disposal—Part III: Combustion of vinasse-# 6 fuel oil emulsions. Braz. J. Chem. Eng. 1997, 14. [Google Scholar] [CrossRef]

- Matsuura, M.I.S.F.; Dias, F.R.T.; Picoli, J.F.; Lucas, K.R.G.L.; Castro, C.; Hirakuri, M.H. Life-cycle assessment of the soybean-sunflower production system in the Brazilian Cerrado. Int. J. Life Cycle Assess. 2016. [Google Scholar] [CrossRef]

- Canals, L.M. Contributions to LCA Methodology for Agricultural Systems. Site-Dependency and Soil Degradation Impact Assessment. Doctoral Thesis, Universitat Autonoma de Barcelona, Barcelona, Brazail, 2003. [Google Scholar]

- Sugawara, E.T. Comparacao dos Desempenhos Ambientais do B5 Etilico de Soja e do Oleo Diesel, por meio da Avaliacao do Ciclo de Vida (ACV). Master Thesis, Universidade de Sao Paulo, Sao Paulo, Brazil, 2012. [Google Scholar]

- Garcia, J.C.C.; Sperling, E.V. Emissao de gases de efeito estufa no ciclo de vida do etanol: Estimativa nas fases de agricultura e industrializacao em Minas Gerais. Eng. Sanit. Ambient. 2010, 15, 217–222. [Google Scholar] [CrossRef]

- IPCC. Guidelines for National Greenhouse Gas Inventories, Prepared by the National Greenhouse Gas Inventories Programme. Hayana, Japan: IGES. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/ (accessed on 13 July 2016).

- CE—Comissao Europeia. Decisao da Comissao de 10 de Junho de 2010 Relativa a Directrizes para o Calculo das Reservas de Carbono nos Solos para Efeitos do Anexo V da Directiva 2009/28/CE; CE: Brussels, Belgium, 2010. [Google Scholar]

- Novaes, R.M.L.; Pazianotto, R.A.A.; Luiz, A.J.B.; May, A.; Bento, D.F.; Dias, F.R.T.; Matsuura, M.I.S.F. Parametros para estimative de emissoes decorrentes de mudanca de uso da terra para inventarios de ciclo de vida de produtos agropecuarios. In Proceedings of the V Congresso Brasileiro em Gestao do Ciclo de Vida, Gestao de Ciclo de Vida nos Tropicos, Fortaleza, Brasil, 19–22 September 2016; pp. 514–520.

- IBGE—Instituto Brasileiro de Geografia e Estatistica. Sistema IBGE de Recuperação Automática. Available online: www.sidra.ibge.gov.br (accessed on 15 July 2016).

- IBA—Industria Brasileira de Arvores. Relatorio Iba 2015. Available online: http://iba.org/pt/biblioteca-iba/publicacoes (accessed on 15 July2016).

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J. Description of the ReCiPe Methodology for Life Assessment Impact Assessment; ReCiPe Main Report Revised 13 July 2012. Available online: http://www.lcia-recipe.net (accessed on 28 July 2016).

- Huijbreagts, M.; Hauschild, M.; Jolliet, O.; Margni, M.; McKone, T.; Rosenbaum, R.K.; Meent, D. USEtox User Manual, February 2010. Available online: http://www.usetox.org (accessed on 27 July 2016).

| Feature | Sugarcane Ethanol | Corn Ethanol | Sorghum Ethanol |

|---|---|---|---|

| Agricultural productivity (t·ha−1) | 82.0 | 7.54 | 3.83 |

| Harvesting | 75% manual (preceded by straw burning) + 25% mechanized | 100% mechanized | |

| Industrial yield (L·t−1) * | 77.0 | 362 | 354 |

| Raw material crushing capacity (t·day−1) | 4000 | 900 | |

| Maximum operation (days) | 218 | 330 | |

| Fuel for cogeneration system | sugarcane bagasse | wood chips | |

| Vinasse coproduction (t·t−1) * | 1.80 | 2.77 | |

| Water consumption (t·t−1) * | 1.65 | 5.20 | |

| Coproduct | Sugarcane Ethanol | Corn Ethanol | Grain Sorghum Ethanol |

|---|---|---|---|

| Ethanol | 38.7% | 31.8% | 31.0% |

| Fusel oil | 1.20% | 1.30% | 1.00% |

| Vinasse | 60.1% | 29.1% | 29.6% |

| DDGS | n.a. 1 | 37.8% | 38.4% |

| Impact Category | Sugarcane Ethanol | Corn Ethanol | Grain Sorghum Ethanol |

|---|---|---|---|

| EROI 1 | 11.5 | 6.85 | 8.64 |

| Contributions for CC Impact | Unit | Sugarcane Ethanol | Corn Ethanol | Grain Sorghum Ethanol |

|---|---|---|---|---|

| Accumulated value (ReCiPe) | kg CO2 eq | 1256 | 1709 | 2436 |

| CO2,fix | kg CO2 eq | (–) 5407 | (–) 2973 | (–) 3138 |

| CO2,b | kg CO2 eq | 3426 | 1632 | 1600 |

| Adjusted CC balance | kg CO2 eq | (–) 725 | 368 | 898 |

| Scenarios | Composition | Consumption of Renewable Fuel for Cogeneration | ||

|---|---|---|---|---|

| Sugarcane Ethanol | Corn/Sorghum Ethanol | Bagasse | Wood Chips | |

| % | t·m−3 Ethanol | |||

| A | 65 | 35 | 1.03 | 0.95 |

| B | 60 | 40 | 0.84 | 1.06 |

| C | 55 | 45 | 0.69 | 1.15 |

| D | 50 | 50 | 0.56 | 1.22 |

| E | 45 | 55 | 0.46 | 1.28 |

| F | 40 | 60 | 0.37 | 1.32 |

| G | 35 | 65 | 0.30 | 1.36 |

| H | 30 | 70 | 0.24 | 1.40 |

| I | 25 | 75 | 0.19 | 1.43 |

| J | 20 | 80 | 0.14 | 1.46 |

| K | 15 | 85 | 0.10 | 1.48 |

| L | 10 | 90 | 0.06 | 1.50 |

| M | 5 | 95 | 0.03 | 1.52 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Donke, A.; Nogueira, A.; Matai, P.; Kulay, L. Environmental and Energy Performance of Ethanol Production from the Integration of Sugarcane, Corn, and Grain Sorghum in a Multipurpose Plant. Resources 2017, 6, 1. https://doi.org/10.3390/resources6010001

Donke A, Nogueira A, Matai P, Kulay L. Environmental and Energy Performance of Ethanol Production from the Integration of Sugarcane, Corn, and Grain Sorghum in a Multipurpose Plant. Resources. 2017; 6(1):1. https://doi.org/10.3390/resources6010001

Chicago/Turabian StyleDonke, Ana, Alex Nogueira, Patricia Matai, and Luiz Kulay. 2017. "Environmental and Energy Performance of Ethanol Production from the Integration of Sugarcane, Corn, and Grain Sorghum in a Multipurpose Plant" Resources 6, no. 1: 1. https://doi.org/10.3390/resources6010001