Side-Detecting Optical Fiber Doped with Tb3+ for Ultraviolet Sensor Application

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

| Parameter | Value |

|---|---|

| Refractive index ncore (@ 632.8 nm) | 1.529 |

| Refractive index ncladding (@ 632.8 nm) | 1.623 |

| Mass density ρ [g/cm3] | 2.98 |

Thermal expansion coefficient  [10−7 1/K] [10−7 1/K] | 55.9 |

| Dilatometric softening point Ts [°C] | 482 |

| Transformation temperature Tg [°C] (DSC) | 500 |

| Crystallisation temperature Tx [°C] (DSC) | 868 |

| Maximum of phonon energy hωmaax [cm−1] | 1280 |

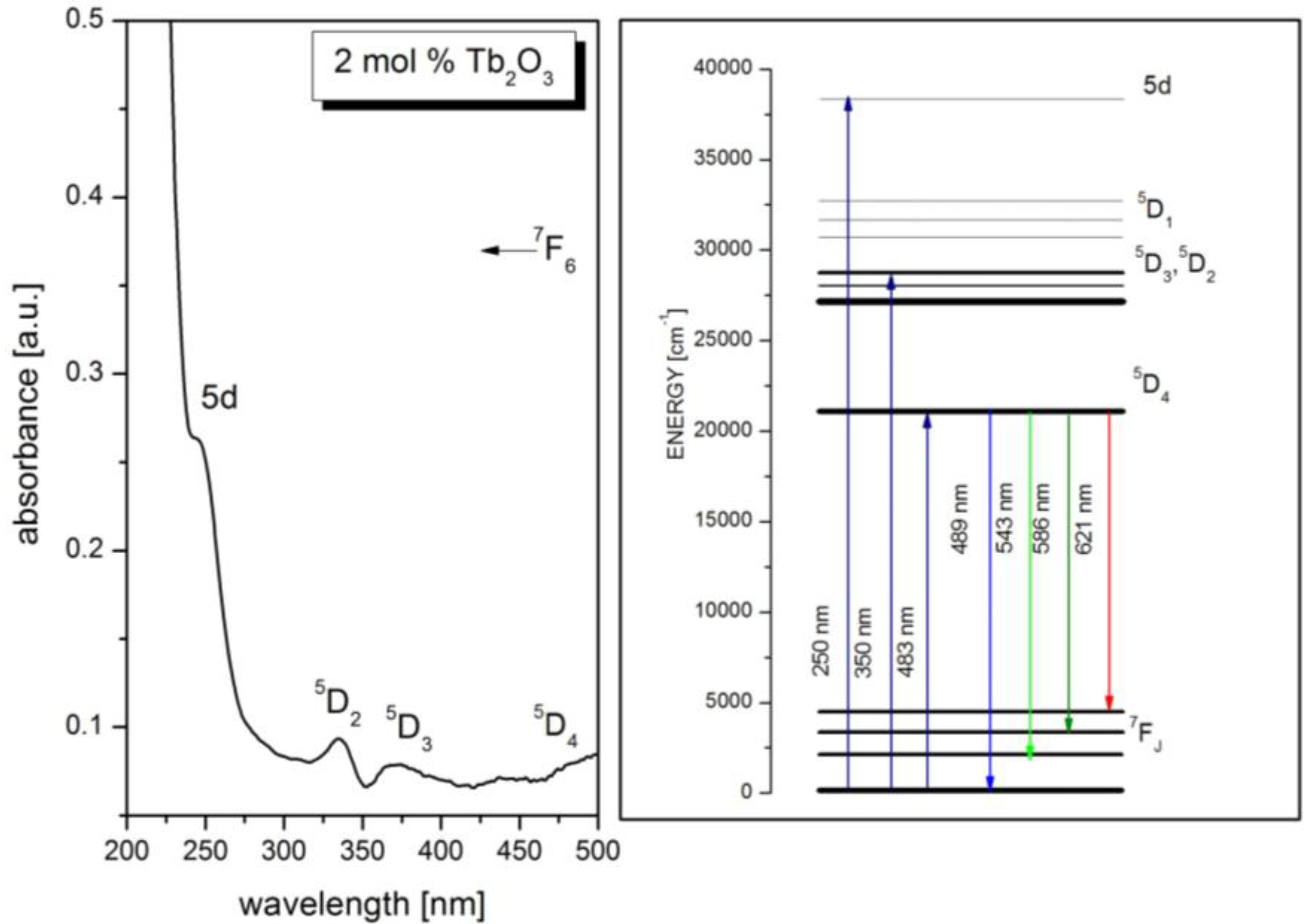

3.1. The Absorption Spectrum and the Energy Diagram

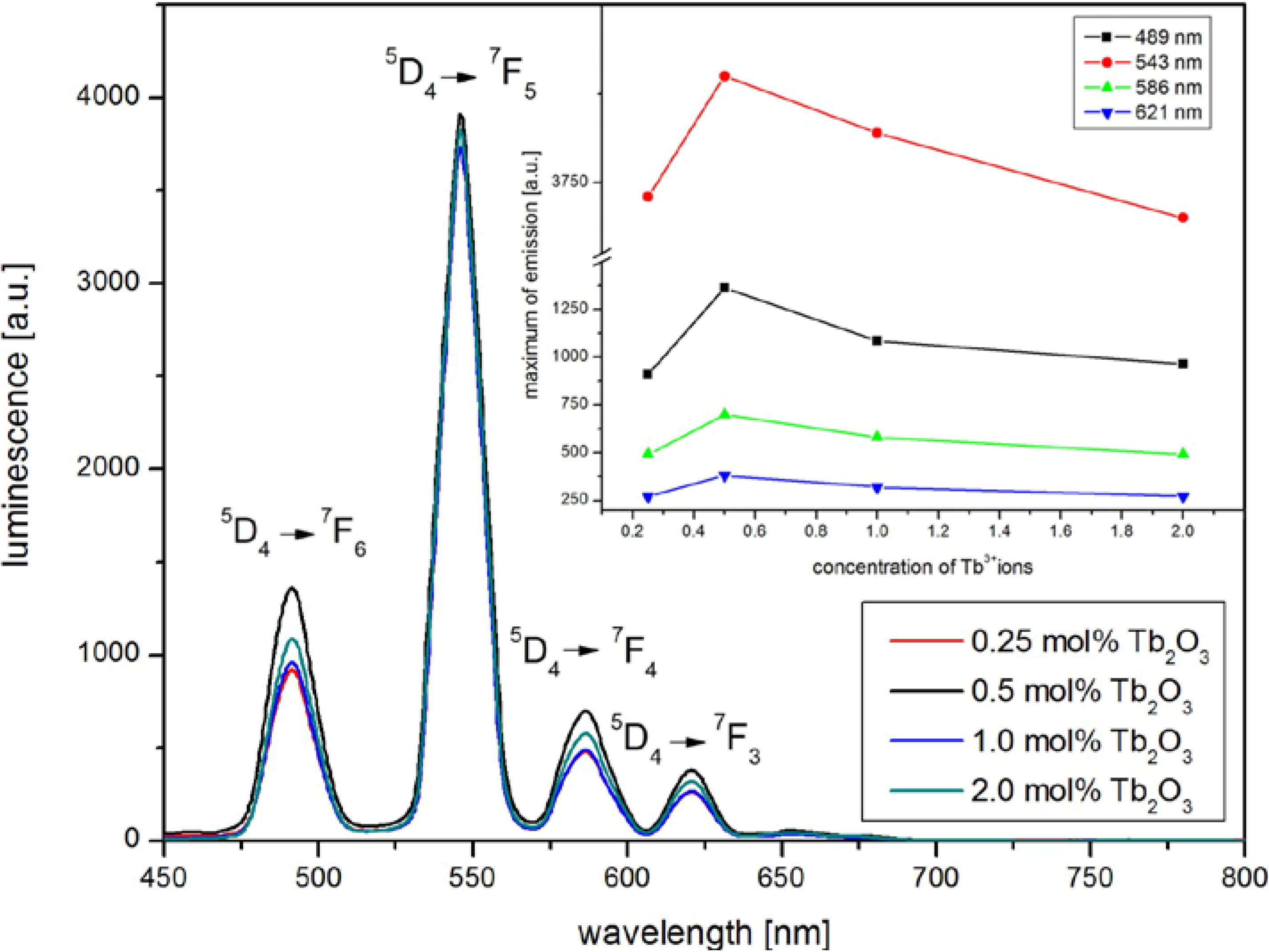

3.2. The Analysis of the Luminescence Spectrum

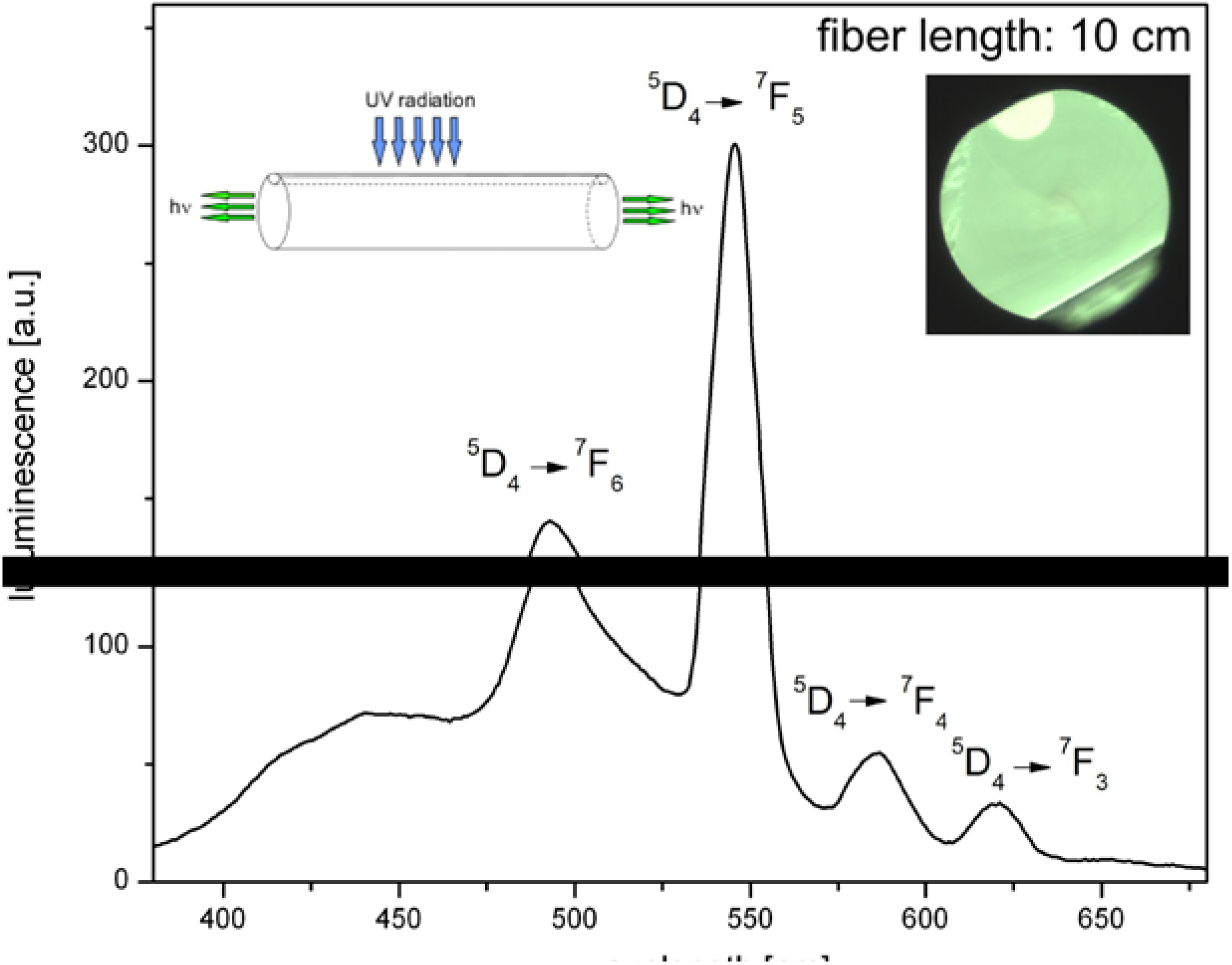

3.3. The Side-Detecting Optical Fiber Doped with Tb3+

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Grattan, K.T.V.; Sun, T. Fibre optic sensor technology: An overview. Sens. Actuators A 2000, 82, 40–61. [Google Scholar] [CrossRef]

- Fitzpatrick, C.; O’Donoghue, C.; Lewis, E. A novel multi-point ultraviolet optical fibre sensor based on cladding luminescence. Meas. Sci. Technol. 2003, 14, 1477–1483. [Google Scholar] [CrossRef]

- Jong-Kuk, Y.; Gyoo-Won, S.; Kang-Min, C.; Eung-Soo, K.; Sung-Hoon, K.; Shin-Won, K. Controllable in-line UV sensor using a side-polished fiber coupler with photofunctional polymer. IEEE Photonics Technol. Lett. 2003, 15, 837–839. [Google Scholar] [CrossRef]

- Lyons, W.B.; Fitzpatrick, C.; Flanagan, C.; Lewis, E. A novel multipoint luminescent coated ultra violet fibre sensor utilising artificial neural network pattern recognition techniques. Sens. Actuators A 2004, 115, 267–272. [Google Scholar]

- Joža, A.V.; Bajić, J.S.; Stupar, D.Z.; Slankamenac, M.P.; Jelić, M.; Živanov, M.B. Simple and low-cost fiber-optic sensors for detection of UV radiation. Telfor J. 2012, 4, 133–137. [Google Scholar]

- Brow, R.K. Review: The structure of simple phosphate glasses. J. Non-Cryst. Solids 2000, 263–264, 1–28. [Google Scholar] [CrossRef]

- Zhu, C.; Yang, Y.; Liang, X.; Yuan, S.; Chen, G. Rare earth ions doped full-color luminescence glasses for white LED. J. Lumin. 2007, 126, 707–710. [Google Scholar] [CrossRef]

- Zhang, L.; Peng, M.; Dong, G.; Qiu, J. An investigation of the optical properties of Tb3+-doped phosphate glasses for green fiber laser. Opt. Mater. 2012, 34, 1202–1207. [Google Scholar] [CrossRef]

- Mura, E.; Lousteau, J.; Milanese, D.; Abrate, S.; Sglavo, V.M. Phosphate glasses for optical fibers: Synthesis, characterization and mechanical properties. J. Non-Cryst. Solids 2013, 362, 147–151. [Google Scholar] [CrossRef]

- Vallés, J.A. Concentration-dependent optimization of Yb3+/Er3+ highly-doped phosphate glass waveguide amplifiers and lasers using a microscopic statistical formalism. Opt. Mater. 2013, 35, 397–401. [Google Scholar] [CrossRef]

- Pisarska, J.; Żur, L.; Goryczka, T.; Pisarski, W.A. Local structure and luminescent properties of lead phosphate glasses containing rare earth ions. J. Rare Earths 2011, 29, 1157–1160. [Google Scholar] [CrossRef]

- Raju, K.V.; Sailaja, S.; Raju, C.N.; Reddy, B.S. Optical characterization of Eu3+ and Tb3+ ions doped cadmium lithium alumino fluoro boro tellurite glasses. Spectrochim. Acta Part A 2011, 79, 87–91. [Google Scholar] [CrossRef]

- Zhu, C.; Liang, X.; Yang, Y.; Chen, G. Luminescence properties of Tb doped and Tm/Tb/Sm co-doped glasses for LED applications. J. Lumin. 2010, 130, 74–77. [Google Scholar] [CrossRef]

- Kochanowicz, M.; Dorosz, D.; Zmojda, J.; Dorosz, J. Cooperative energy transfer in Yb3+/Tb3+ doped germanate glasses. Acta Phys. Pol. A 2012, 122, 837–845. [Google Scholar]

- Lin, H.; Liu, K.; Lin, L.; Hou, Y.; Yang, D.; Ma, T.; Pun, E.Y.B.; An, Q.; Yu, J.; Tanabe, S. Optical parameters and upconversion fluorescence in Tm3+/Yb3+-doped alkali-barium-bismuth-tellurite glasses. Spectrochim. Acta Part A 2006, 65, 702–707. [Google Scholar] [CrossRef]

- Wang, G.; Dai, S.; Zhang, J.; Yang, J.; Jiang, Z. Upconversion emissions in Yb3+–Tm3+-doped tellurite glasses excited at 976 nm. J. Mater. Sci. 2007, 42, 747–751. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Zmojda, J.; Kochanowicz, M.; Miluski, P.; Dorosz, D. Side-Detecting Optical Fiber Doped with Tb3+ for Ultraviolet Sensor Application. Fibers 2014, 2, 150-157. https://doi.org/10.3390/fib2020150

Zmojda J, Kochanowicz M, Miluski P, Dorosz D. Side-Detecting Optical Fiber Doped with Tb3+ for Ultraviolet Sensor Application. Fibers. 2014; 2(2):150-157. https://doi.org/10.3390/fib2020150

Chicago/Turabian StyleZmojda, Jacek, Marcin Kochanowicz, Piotr Miluski, and Dominik Dorosz. 2014. "Side-Detecting Optical Fiber Doped with Tb3+ for Ultraviolet Sensor Application" Fibers 2, no. 2: 150-157. https://doi.org/10.3390/fib2020150