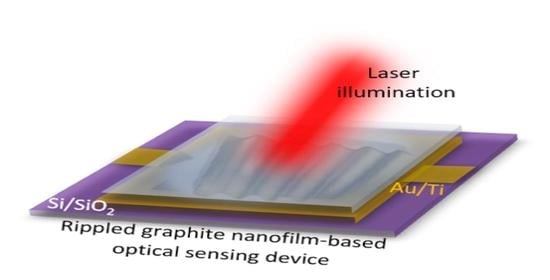

The Ripple Effect of Graphite Nanofilm on Stretchable Polydimethylsiloxane for Optical Sensing

Abstract

:1. Introduction

2. Materials and Methods

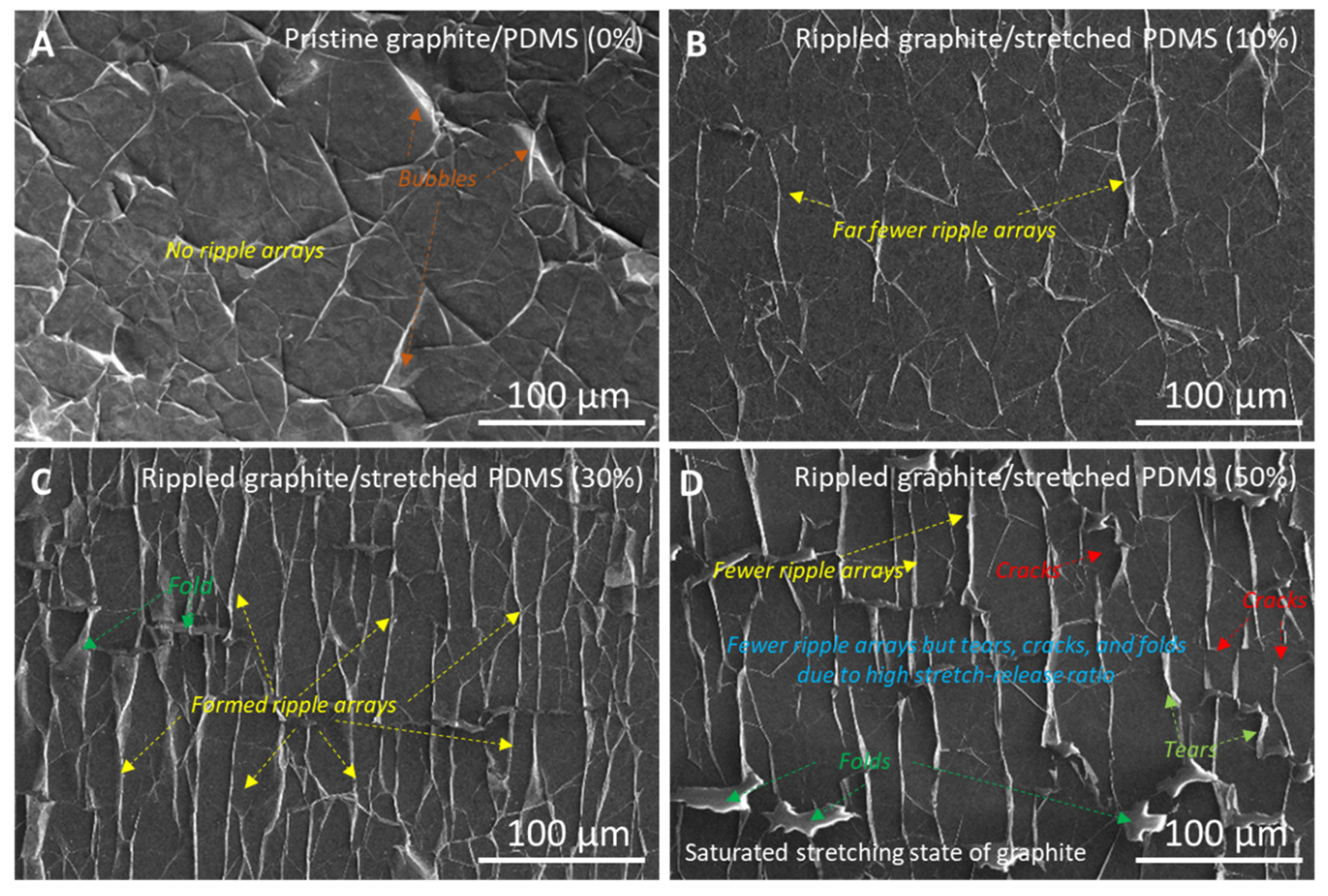

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.V.; Dubonos, S.V.; Firsov, A.A. Two-dimensional gas of massless dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef] [PubMed]

- Geim, A.K.; Grigorieva, I.V. Van der Waals heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Koppens, F.; Mueller, T.; Avouris, P.; Ferrari, A.C.; Vitiello, M.S.; Polini, M. Photodetectors based on graphene, other two-dimensional materials and hybrid systems. Nat. Nanotechnol. 2014, 9, 780–793. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.-P.; Ren, W.; Cheng, H.-M. Transfer methods of graphene from metal substrates: A review. Small Methods 2019, 3, 1900049. [Google Scholar] [CrossRef]

- Abdalrheem, R.; Yam, F.K.; Ibrahim, A.R.; Lim, H.S.; Beh, K.P.; Ahmed, A.A.; Oglat, A.A.; Chahrour, K.M.; Farhat, O.F.; Afzal, N.; et al. Improvement in photodetection characteristics of graphene/p-Silicon heterojunction photodetector by PMMA/graphene cladding layer. J. Electron. Mater. 2019, 48, 4064–4072. [Google Scholar] [CrossRef]

- Zaretski, A.V.; Moetazedi, H.; Kong, C.; Sawyer, E.J.; Savagattrup, S.; Valle, E.; O’Connor, T.F.; Printz, A.D.; Lipomi, D.J. Metal-assisted exfoliation (MAE): Green, roll-to-roll compatible method for transferring graphene to flexible substrates. Nanotechnology 2005, 26, 045301. [Google Scholar] [CrossRef]

- Kim, Y.; Cruz, S.S.; Lee, K.; Alawode, B.O.; Choi, C.; Song, Y.; Johnson, J.M.; Heidelberger, C.; Kong, W.; Choi, S.; et al. Remote epitaxy through graphene enables two-dimensional material-based layer transfer. Nature 2017, 544, 340–343. [Google Scholar] [CrossRef]

- Pham, V.P.; Jang, H.S.; Whang, D.; Choi, J.Y. Direct growth of graphene on rigid and flexible substrates: Progress, applications, and challenges. Chem. Soc. Rev. 2017, 46, 6276–6300. [Google Scholar] [CrossRef]

- Pham, V.P. Atmosphere Pressure Chemical Vapor Deposition of Graphene; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef] [Green Version]

- Pham, V.P. Direct Growth of Graphene on Flexible Substrates toward Flexible Electronics: A Promising Perspective; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Pham, P.V. Hexagon flower quantum dot-like cu pattern formation during low-pressure chemical vapor deposited graphene growth on a liquid Cu/W Substrate. ACS Omega 2018, 3, 8036–8041. [Google Scholar] [CrossRef]

- Schedin, F.; Geim, A.K.; Morozov, S.V.; Hill, E.W.; Blake, P.; Katsnelson, M.I.; Novoselov, K.S. Detection of individual gas molecules adsorbed on graphene. Nat. Mater. 2007, 6, 652–655. [Google Scholar] [CrossRef]

- Lv, R.; Chen, G.; Li, Q.; McCreary, A.; Méndez, A.R.B.; Morozov, S.; Liang, L.; Declerck, X.; Perea-Lopez, N.; Cullen, D.; et al. Ultrasensitive gas detection of large-area boron-doped graphene. Proc. Natl. Acad. Sci. USA 2015, 112, 14527–14532. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pham, V.P.; Nguyen, M.T.; Park, J.W.; Kwak, S.S.; Nguyen, D.H.T.; Mun, M.K.; Phan, H.D.; Kim, D.S.; Kim, K.H.; Lee, N.-E.; et al. Chlorine-trapped CVD bilayer graphene for resistive pressure sensor with high detection limit and high sensitivity. 2D Mater. 2017, 4, 025049. [Google Scholar] [CrossRef] [Green Version]

- Sorkin, V.; Zhang, Y.W. Graphene-based pressure nano-sensors. J. Mol. Model. 2011, 17, 2825–2830. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.H.; Chang, Y.C.; Norris, T.B.; Zhong, Z. Graphene photodetectors with ultra-broadband and high responsivity at room temperature. Nat. Nanotechnol. 2014, 9, 273–278. [Google Scholar] [CrossRef]

- Luongo, G.; Bartolomeo, A.D.; Giubileo, F.; Chavarin, C.A.; Wenger, C. Electronic properties of graphene/p-silicon Schottky junction. J. Phys. D Appl. Phys. 2018, 51, 255305. [Google Scholar] [CrossRef]

- Bartolomeo, A.D.; Luongo, G.; Giobileo, F.; Funicello, N.; Niu, G.; Schroeder, T.; Lisker, M.; Lupina, G. Hybrid graphene/silicon Schottky photodiode with intrinsic gating effect. 2D Mater. 2017, 4, 025075. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.J.; Sohn, I.Y.; Jung, J.H.; Yoon, O.J.; Lee, N.E.; Park, J.S. Reduced graphene oxide field-effect transistor for label-free femtomolar protein detection. Biosens. Bioelectron. 2013, 41, 621–626. [Google Scholar] [CrossRef]

- Hempel, M.; Nezich, D.; Kong, J.; Hofmann, M. A novel class of strain gauges based on layered percolative films of 2D materials. Nano Lett. 2012, 12, 5714–5718. [Google Scholar] [CrossRef]

- Sahoo, S.; Barik, S.K.; Sharma, G.L.; Khurana, G.; Scott, J.F.; Katiyar, R.S. Reduced graphene oxide as ultra-fast temperature sensor. arXiv 2012, arXiv:1204.1928. [Google Scholar]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Finite structure constant defines visual transparency of graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miller, J.R.; Outlaw, R.A.; Holloway, B.C. Graphene double-layer capacitor with ac line-filtering performance. Science 2010, 329, 16371639. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Stoller, M.D.; Ganesh, K.J.; Cai, W.; Ferreira, P.J.; Pirkle, A.; Wallace, R.M.; Cychosz, K.A.; Thommes, M.; et al. Carbon-based supercapacitors produced by activation of graphene. Science 2011, 332, 1537–1541. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.B.T.; Rouff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef]

- Ramanathan, T.; Abdala, A.A.; Stankovich, S.; Dikin, D.A.; Herrera-Alonso, M.; Piner, R.D.; Adamson, D.H.; Schniepp, H.C.; Rouff, R.S.; Nguyen, S.T.; et al. Functionalized graphene sheets for polymer nanocomposites. Nat. Nanotechnol. 2008, 3, 327331. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, F.; Jachak, A.; Kim, S.-P.; Datta, D.; Liu, J.; Kulaots, I.; Vaslet, C.; Jang, H.D.; Huang, J.; et al. Aerosol synthesis of cargo-filled graphene nanosacks. Nano Lett. 2012, 12, 19962002. [Google Scholar] [CrossRef] [Green Version]

- Luo, J.; Jang, H.D.; Sun, T.; Xiao, L.; He, Z.; Katsoulidis, A.P.; Kanatzidis, M.G.; Gibson, J.M.; Huang, J. Compression and aggregation-resistant particles of crumpled soft sheets. ACS Nano 2011, 5, 8943–8949. [Google Scholar] [CrossRef]

- Pereira, V.M.; Neto, A.H.C.; Liang, H.Y.; Mahadevan, L. Geometry, mechanics, and electronics of singular structures and wrinkles in graphene. Phys. Rev. Lett. 2010, 105, 156603. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zang, J.; Ryu, S.; Pugno, N.; Wang, Q.; Tu, Q.; Buehler, M.J.; Zhao, X. Multifunctionality and control of the crumpling and unfolding of large-area graphene. Nat. Mater. 2013, 12, 321–325. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kang, P.; Wang, M.C.; Knapp, P.M.; Nam, S. Crumpled graphene photodetector with enhanced, strain-tunable, and wavelength-selective photoresponsivity. Adv. Mater. 2016, 28, 4639–4645. [Google Scholar] [CrossRef]

- Unsuree, N.; Selvi, H.; Crabb, M.G.; Alains, J.; Parkinson, A.; Echtermeyer, P.T.J. Visible and infrared photocurrent enhancement in a graphene-silicon schottky photodetector through surface-states and electric field engineering. 2D Mater. 2019, 6, 041004. [Google Scholar] [CrossRef] [Green Version]

- Sone, J.; Murakami, M.; Tatami, A. Fundamental study for a graphite-based microelectromechanical system. Micromachines 2018, 9, 64. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Min-Dianey, K.A.A.; Le, T.K.; Choi, J.R.; Pham, P.V. Advanced optical detection through the use of a deformably transferred nanofilm. Nanomaterials 2021, 11, 816. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Ferraro, D.; Zaltron, A.; Galvanetto, N.; Martucci, A.; Sun, L.; Yang, P.; Zhang, Y.; Wang, Y.; Liu, Z.; et al. Optical detection of the susceptibility tensor in two-dimensional crystals. Commun. Phys. 2021, 4, 215. [Google Scholar] [CrossRef]

- Min-Dianey, K.A.A.; Zhang, H.C.; M’Bouana, N.L.P.; Kougblenou, K.; Xia, X. Limitation of optical properties through porous silicon photonic crystals influenced by porosity and lattice dynamic. Opt. Mater. 2018, 75, 150–165. [Google Scholar] [CrossRef]

- Tsang, L.; Gu, X.; Braunisch, H. Effects of random rough surface on absorption by conductors at microwave frequencies. IEEE Microw. Wirel. Compon. Lett. 2006, 16, 221–223. [Google Scholar] [CrossRef]

| Stretch–Release Ratio of Graphite/PDMS | 0% | 10% | 30% | 50% |

|---|---|---|---|---|

| Photoresponsivity at the lowest power (100 nW) | 20 mA/W | 120 mA/W | 260 mA/W | 13 mA/W |

| Noise–equivalent power (NEP) | 15.74 × 10−9 W/(Hz)1/2 | 9.65 × 10−9 W/(Hz)1/2 | 7.54 × 10−9 W/(Hz)1/2 | 10.21 × 10−9 W/(Hz)1/2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min-Dianey, K.A.A.; Le, T.K.; Qadir, A.; M’Bouana, N.L.P.; Malik, M.; Kim, S.W.; Choi, J.R.; Pham, P.V. The Ripple Effect of Graphite Nanofilm on Stretchable Polydimethylsiloxane for Optical Sensing. Nanomaterials 2021, 11, 2934. https://doi.org/10.3390/nano11112934

Min-Dianey KAA, Le TK, Qadir A, M’Bouana NLP, Malik M, Kim SW, Choi JR, Pham PV. The Ripple Effect of Graphite Nanofilm on Stretchable Polydimethylsiloxane for Optical Sensing. Nanomaterials. 2021; 11(11):2934. https://doi.org/10.3390/nano11112934

Chicago/Turabian StyleMin-Dianey, Kossi A. A., Top Khac Le, Akeel Qadir, Noé Landry Privace M’Bouana, Muhammad Malik, Sok Won Kim, Jeong Ryeol Choi, and Phuong V. Pham. 2021. "The Ripple Effect of Graphite Nanofilm on Stretchable Polydimethylsiloxane for Optical Sensing" Nanomaterials 11, no. 11: 2934. https://doi.org/10.3390/nano11112934