Optimization on Emergency Materials Dispatching Considering the Characteristics of Integrated Emergency Response for Large-Scale Marine Oil Spills

Abstract

:1. Introduction

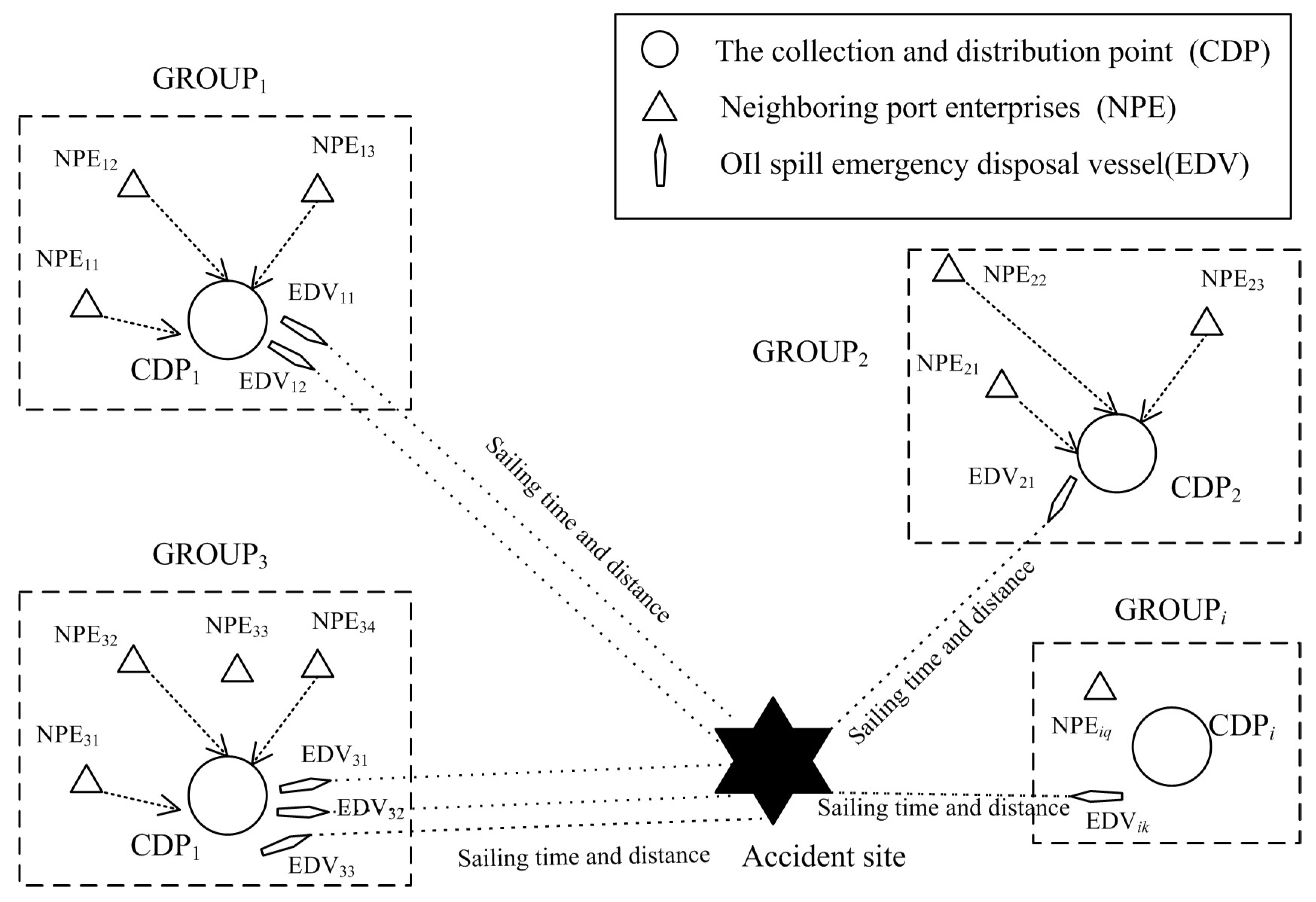

2. Model-Related Descriptions and Assumptions

2.1. Model Related Descriptions

2.2. Model Assumptions

3. Model Building

3.1. Decision Variables

3.2. Model Parameter

3.3. Objective Function

3.4. Constraints

4. Model Implementation

4.1. Estimation of the Demand Equivalent of Emergency Materials for Large Oil Spills

4.2. Model Key Code

5. Case Study Implementation and Analysis

5.1. Known Parameters

V5 = [18,100;12,100]; V6 = [18,200;12,100]; V7 = [18,200;12,100]; V8 = [22,200;15,100;10,800;12,100];

V9 = [18,100;12,100]; V10 = [12,100]; V11 = [18,200;12,200]; V12 = [18,200;12,200]

5.2. Case Test Results

5.3. Analysis of Results

6. Final Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Díez, S.; Sabaté, J.; Viñas, M.; Bayona, J.M.; Solanas, A.M.; Albaigés, J. Prestige Oil Spill. I. Biodegradation of a Heavy Fuel Oil Under Simulated Conditions. Environ. Toxicol. Chem. 2005, 24, 2203–2217. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Zhang, Y. Identification of the Limitation of Liability for Oil Pollution Claims—A Case Study of Sanchi. J. SUIBE 2018, 25, 70–71. [Google Scholar] [CrossRef]

- Li, S.; Yu, F. Study on China’s Emergency Response Ability Construction for Marine Environment Pollution by Ships. J. Zhejiang Inst. Commun. 2015, 16, 27–31. [Google Scholar] [CrossRef]

- Wilhelm, W.E.; Srinivasa, A.V. Prescribing tactical response for oil spill clean up operations. Manag. Sci. 1997, 43, 386–402. [Google Scholar] [CrossRef]

- Mariano, A.J.; Kourafalou, V.H.; Srinivasan, A.; Kang, H.; Halliwell, G.R.; Ryan, E.H.; Roffer, M. On the modeling of the 2010 Gulf of Mexico Oil Spill. Dyn. Atmos. Oceans 2011, 52, 323–340. [Google Scholar] [CrossRef]

- Ventikos, N.P.; Vergetis, E.; Psaraftis, H.N.; Triantafyllou, G. A high-level synthesis of oil spill response equipment and counter measures. J. Hazard Mater. 2004, 107, 51–58. [Google Scholar] [CrossRef] [PubMed]

- LI, S.; Zhang, Y. Study on the Soft Power Construction of National Marine Oil Spill Emergency Equipment Libraryin Zhejiang Province. J. Zhejiang Int. Martime Coll. 2015, 11, 22–25. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Pan, F. On the Emergency Resource Dispatch Process and Mechanism for Major Marine Oil Spill. J. Ship Ocean Eng. 2018, 47, 51–53. [Google Scholar] [CrossRef]

- ZHI, G. Issue the National serious marine oil spill emergency response capacity building plan, achieve the top level design for our country’s marine oil spill emergency response capacity building. China Marit. Saf. 2016, 8, 24–26. [Google Scholar] [CrossRef]

- Ju, G.; Liu, J.; Li, D.; Cheng, M.; Shi, F. Chemical and Equipment-Free Strategy to Fabricate Water/Oil Separating Materials for Emergent Oil Spill Accidents. Langmuir. 2017, 33, 2664–2670. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Yuan, F.; Mikkelsen, J.D.; Ohm, C.; Stange, E.; Holand, M. Modelling the transport of oil after a proposed oil spill accident in Barents Sea and its environmental impact on Alke species. IOP Conf. Ser. Earth Environ. Sci. 2017, 82, 012010. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.Y.; Li, C.; Liang, H.W.; Zhang, Y.N.; Wang, X.; Chen, J.F.; Yu, S.H. Carbon nanofiber aerogels for emergent cleanup of oil spillage and chemical leakage under harsh conditions. Sci. Rep. 2014, 4, 4079. [Google Scholar] [CrossRef] [PubMed]

- Moroni, D.; Pieri, G.; Tampucci, M. Environmental Decision Support Systems for Monitoring Small Scale Oil Spills: Existing Solutions, Best Practices and Current Challenges. J. Mar. Sci. Eng. 2019, 7, 19. [Google Scholar] [CrossRef]

- Liubartseva, S.; Coppini, G.; Pinardi, N.; Dominicis, M.D.; Lecci, R.; Turrisi, G.; Cretì, S.; Martinelli, S.; Agostini, P.; Marra, P.; et al. Decision support system for emergency management of oil spill accidents in the Mediterranean Sea. Nat. Hazards Earth Syst. Sci. 2016, 16, 2009–2020. [Google Scholar] [CrossRef] [Green Version]

- Hammoud, B.; Ndagijimana, F.; Faour, G.; Ayad, H.; Jomaah, J. Bayesian Statistics of Wide-Band Radar Reflections for Oil Spill Detection on Rough Ocean Surface. J. Mar. Sci. Eng. 2019, 7, 12. [Google Scholar] [CrossRef]

- Ribotti, A.; Antognarelli, F.; Cucco, A.; Falcieri, M.; Fazioli, L.; Ferrarin, C.; Olita, A.; Oliva, G.; Pes, A.; Quattrocchi, G.; et al. An Operational Marine Oil Spill Forecasting Tool for the Management of Emergencies in the Italian Seas. J. Mar. Sci. Eng. 2019, 7, 1. [Google Scholar] [CrossRef]

- Li, Z.; Johnson, W. An Improved Method to Estimate the Probability of Oil Spill Contact to Environmental Resources in the Gulf of Mexico. J. Mar. Sci. Eng. 2019, 7, 41. [Google Scholar] [CrossRef]

- Aboim Costa, L.R.; Ferreira Filho, V.J.; de Andrade, F.N.; Antoun, A.R. Strategic Optimization and Contingency Planning Model for Oil Spill Response. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Rio de Janeiro, Brazil, 20–23 June 2005; pp. 1–12. [Google Scholar]

- Wang, J.; Wang, M.; Wang, Y.; Song, X. Collaboratively Scheduling Method of Sar Resources for Drifting Objective in Distress at Sea Based on Greedy Algorithm. Oper. Res. Manag. Sci. 2014, 23, 116–123. [Google Scholar]

- Verma, M.; Gendreau, M.; Laporte, G. Optimal location and capability of oil-spill response facilities for the south coast of Newfoundland. Omega 2013, 41, 856–867. [Google Scholar] [CrossRef]

- Meshkati, N.; Tabibzadeh, M. An Integrated System-Oriented Model for the Interoperability of Multiple Emergency Response Agencies in Large-Scale Disasters: Implications for the Persian Gulf. Int. J. Disaster Risk Sci. 2016, 7, 227–244. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Guo, L.; Jiang, J.; Jiang, D.; Wang, P. Emergency material allocation and scheduling for the application to chemical contingency spills under multiple scenarios. Environ. Sci. Pollut. Res. 2017, 24, 956–968. [Google Scholar] [CrossRef] [PubMed]

- Spezio, T. The Santa Barbara Oil Spill and Its Effect on United States Environmental Policy. Sustainability 2018, 10, 2750. [Google Scholar] [CrossRef]

- Łazuga, K.; Gucma, L.; Perkovic, M. The Model of Optimal Allocation of Maritime Oil Spill Combat Ships. Sustainability 2018, 10, 2321. [Google Scholar] [CrossRef]

- JT/T 1144. Oil Spill Emergency Response Ship Emergency Equipment Supplies Requirements; Ministry of Transport of China: BeiJing, China, 2017. [Google Scholar]

- Sheu, J.B. Dynamic relief-demand management for emergency logistics operations under large-scale disasters. Transp. Res. Part E. 2010, 46, 1–17. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y. Emergency Resources Allocation among Multiple Disaster Places under Fair Priority Principle. Oper. Res. Manag. Sci. 2008, 17, 16–21. [Google Scholar]

- Integrated Planning Division. The National Offshore Oil Spill Emergency Equipment Warehouse Management; Regulations (For trial Implementation); Ministry of Transport of China: BeiJing, China, 2009.

- Zhang, Y.; Li, S.; Guo, Z. The Evolution of the Coastal Economy: The Role of Working Waterfronts in the Alabama Gulf Coast. Sustainability 2015, 7, 4310–4322. [Google Scholar] [CrossRef] [Green Version]

| Kinds | Stowage Factor | 20,000 tons | 10,000 tons | 5000 tons | 1000 tons | 500 tons | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Num | Equivalent Volume m3 | Num | Equivalent Volume m3 | Num | Equivalent Volume m3 | Num | Equivalent Volume m3 | Num | Equivalent Volume m3 | ||

| E1/Containment booms | 45 m3/100 m | 8000 m | 3600 | 6000 | 2700 | 4000 | 1800 | 2200 | 990 | 1600 | 720 |

| E2/unloading pump | 10 m3/set | 12 | 120 | 9 | 90 | 7 | 70 | 5 | 50 | 4 | 40 |

| E3/Oil skimmer | 10 m3/set | 15 | 150 | 9 | 90 | 7 | 70 | 5 | 50 | 4 | 40 |

| E4/Spill dispersant | 1.5 m3/t | 2000 t | 3000 | 1400 | 2100 | 800 | 1200 | 200 | 300 | 100 | 150 |

| E5/Absorption material | 5 m3/t | 800 t | 4000 | 500 | 2500 | 320 | 1600 | 80 | 400 | 40 | 200 |

| E6/Oilwastewater storage | —— | 20,000 t | —— | 16,000 | —— | 8000 | —— | 2000 | —— | 1000 | —— |

| Input Parameters: Di, Ej, Fij, vik, Sik |

| Output Value: OptimalSolutionfij, yik, tik Optimal Value T |

| Di= ;Ej= ; Fij= ; vik = ; Sik = %Input known value |

| F = intvar(i,j); y = intvar(i,k); % Decision variables |

| T = 2∗D./S; % Round trip time ofevery vessel |

| TB = y.∗T; % The sailing time of every vessel |

| MTB = max(max(TB)); % The largest sailing time |

| TC = abs(TB(1,1)−TB(1,2)−…)+… % The sum of the differences sailing time |

| C = [sum(f)> = E,f< = F,sum(y.∗v,2)<=sum(F,2),sum(y.∗v,2)==sum(f,2),f >= 0, y >= 0]; % Constraints |

| Mu = TC+MTB % Objective functions |

| ops =sdpsettings(‘solver’,’cplex’,’verbose’,2); % Solver parameter configuration |

| Result = solvesdp(C,Mu,ops); % Find the minimum |

| TB = double(TB); f= double(f); y = double(y); MTB = double(MTB); |

| disp(TB); disp(x); disp(y); disp(MTB) % Output optimal solution |

| 20,000 tons of Oil Spills | 10,000 tons of Oil Spills | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Point | Emergency Material (m3) | Voyage Times and Sailing Time (h) | Emergency Material (m3) | Voyage Times and Sailing Time (h) | ||||||||||||||||

| F1 | F2 | F3 | F4 | F5 | Y1/TB1 | Y2/TB2 | Y3/TB3 | Y4/TB4 | Max Sailing Time (h) | F1 | F2 | F3 | F4 | F5 | Y1/TB1 | Y2/TB2 | Y3/TB3 | Y4/TB4 | Max Sailing Time (h) | |

| 1 | 110 | 0 | 0 | 210 | 180 | 5/100 | — | — | — | 100 | 0 | 20 | 0 | 210 | 170 | 4/80 | — | — | — | 80 |

| 2 | 745 | 0 | 0 | 255 | 300 | 4/54 | 5/54 | — | — | 54 | 745 | 0 | 0 | 255 | 300 | 4/54 | 5/54 | — | — | 54 |

| 3 | 525 | 0 | 0 | 275 | 500 | 4/55 | 3/60 | 2/60 | — | 60 | 348 | 0 | 0 | 582 | 370 | 4/55 | 3/60 | 2/60 | — | 60 |

| 4 | 470 | 40 | 40 | 150 | 200 | 3/47 | 2/38 | 2/47 | — | 47 | 10 | 40 | 0 | 150 | 200 | 1/16 | 1/19 | 1/24 | — | 24 |

| 5 | 240 | 30 | 30 | 120 | 80 | 3/20 | 2/20 | — | — | 20 | 240 | 30 | 30 | 120 | 80 | 3/20 | 2/20 | — | — | 20 |

| 6 | 390 | 30 | 0 | 180 | 200 | 3/33 | 2/33 | — | — | 33 | 420 | 0 | 0 | 180 | 200 | 3/33 | 2/33 | — | — | 33 |

| 7 | 410 | 20 | 50 | 120 | 200 | 3/37 | 2/37 | — | — | 37 | 430 | 0 | 50 | 120 | 200 | 3/37 | 2/37 | — | — | 37 |

| 8 | 430 | 0 | 0 | 570 | 400 | 2/37 | 1/27 | 1/40 | 1/34 | 40 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | 0/0 | 0/0 | 0 |

| 9 | 280 | 30 | 30 | 360 | 300 | 6/20 | 4/20 | — | — | 20 | 340 | 0 | 0 | 360 | 300 | 6/20 | 4/20 | — | — | 20 |

| 10 | 0 | 0 | 0 | 0 | 400 | 4/107 | — | — | — | 107 | 0 | 0 | 0 | 0 | 0 | 0/0 | — | — | — | 0 |

| 11 | 0 | 0 | 0 | 460 | 540 | 3/107 | 2/107 | — | — | 107 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | — | — | 0 |

| 12 | 0 | 0 | 0 | 300 | 700 | 3/87 | 2/87 | — | — | 87 | 167 | 0 | 10 | 123 | 700 | 3/87 | 2/87 | — | — | 87 |

| Subtotal | 3600 | 150 | 150 | 3000 | 4000 | Max time | 107 | 2700 | 90 | 90 | 2100 | 2520 | Max time | 87 | ||||||

| 5000 tons of Oil Spills | 1000 tons of Oil Spills | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Point | Emergency Material (m3) | Voyage Times and Sailing Time (h) | Emergency Material (m3) | Voyage Times and Sailing Time (h) | ||||||||||||||||

| F1 | F2 | F3 | F4 | F5 | Y1/TB1 | Y2/TB2 | Y3/TB3 | Y4/TB4 | Max Sailing Time (h) | F1 | F2 | F3 | F4 | F5 | Y1/TB1 | Y2/TB2 | Y3/TB3 | Y4/TB4 | Max Sailing Time (h) | |

| 1 | 0 | 0 | 0 | 0 | 100 | 1/20 | — | — | — | 20 | 0 | 0 | 0 | 0 | 0 | 0/0 | — | — | — | 0 |

| 2 | 80 | 20 | 40 | 260 | 300 | 2/27 | 3/32 | — | — | 32 | 0 | 0 | 0 | 0 | 300 | 1/14 | 1/11 | — | — | 14 |

| 3 | 0 | 0 | 0 | 180 | 420 | 2/28 | 1/20 | 1/30 | — | 30 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | 0/0 | — | 0 |

| 4 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | 0/0 | — | 0 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | 0/0 | — | 0 |

| 5 | 540 | 30 | 30 | 120 | 80 | 5/34 | 3/30 | — | — | 30 | 460 | 20 | 20 | 120 | 80 | 3/20 | 2/20 | — | — | 20 |

| 6 | 420 | 0 | 0 | 180 | 200 | 3/33 | 2/33 | — | — | 33 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | — | — | 0 |

| 7 | 450 | 30 | 0 | 120 | 200 | 3/37 | 2/37 | — | — | 37 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | — | — | 0 |

| 8 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | 0/0 | 0/0 | 0 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | 0/0 | 0/0 | 0 |

| 9 | 310 | 0 | 30 | 360 | 300 | 6/20 | 4/20 | — | — | 20 | 540 | 30 | 30 | 300 | 100 | 6/20 | 4/20 | — | — | 20 |

| 10 | 0 | 0 | 0 | 0 | 0 | 0/0 | — | — | — | 0 | 0 | 0 | 0 | 0 | 0 | 0/0 | — | — | — | 0 |

| 11 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | — | — | 0 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | — | — | 0 |

| 12 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | — | — | 0 | 0 | 0 | 0 | 0 | 0 | 0/0 | 0/0 | — | — | 0 |

| Subtotal | 1800 | 80 | 100 | 1220 | 1600 | MAX time | 37 | 1000 | 50 | 50 | 420 | 480 | MAX time | 20 | ||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Grifoll, M.; Estrada, M.; Zheng, P.; Feng, H. Optimization on Emergency Materials Dispatching Considering the Characteristics of Integrated Emergency Response for Large-Scale Marine Oil Spills. J. Mar. Sci. Eng. 2019, 7, 214. https://doi.org/10.3390/jmse7070214

Li S, Grifoll M, Estrada M, Zheng P, Feng H. Optimization on Emergency Materials Dispatching Considering the Characteristics of Integrated Emergency Response for Large-Scale Marine Oil Spills. Journal of Marine Science and Engineering. 2019; 7(7):214. https://doi.org/10.3390/jmse7070214

Chicago/Turabian StyleLi, Song, Manel Grifoll, Miquel Estrada, Pengjun Zheng, and Hongxiang Feng. 2019. "Optimization on Emergency Materials Dispatching Considering the Characteristics of Integrated Emergency Response for Large-Scale Marine Oil Spills" Journal of Marine Science and Engineering 7, no. 7: 214. https://doi.org/10.3390/jmse7070214