Quantitative Optical Coherence Elastography for Robust Stiffness Assessment

Abstract

:Featured Application

Abstract

1. Introduction

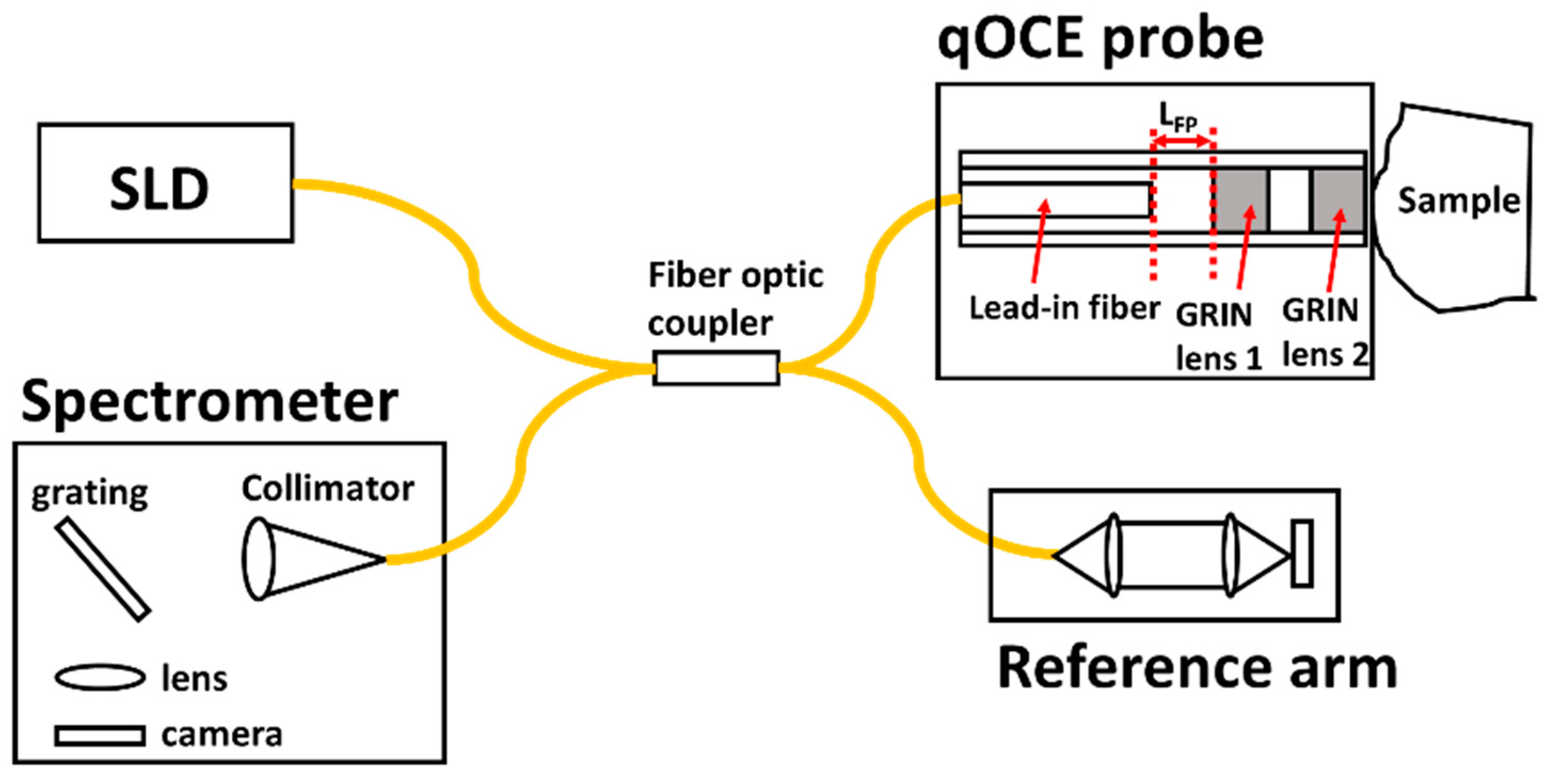

2. qOCE System

3. Sample Preparation

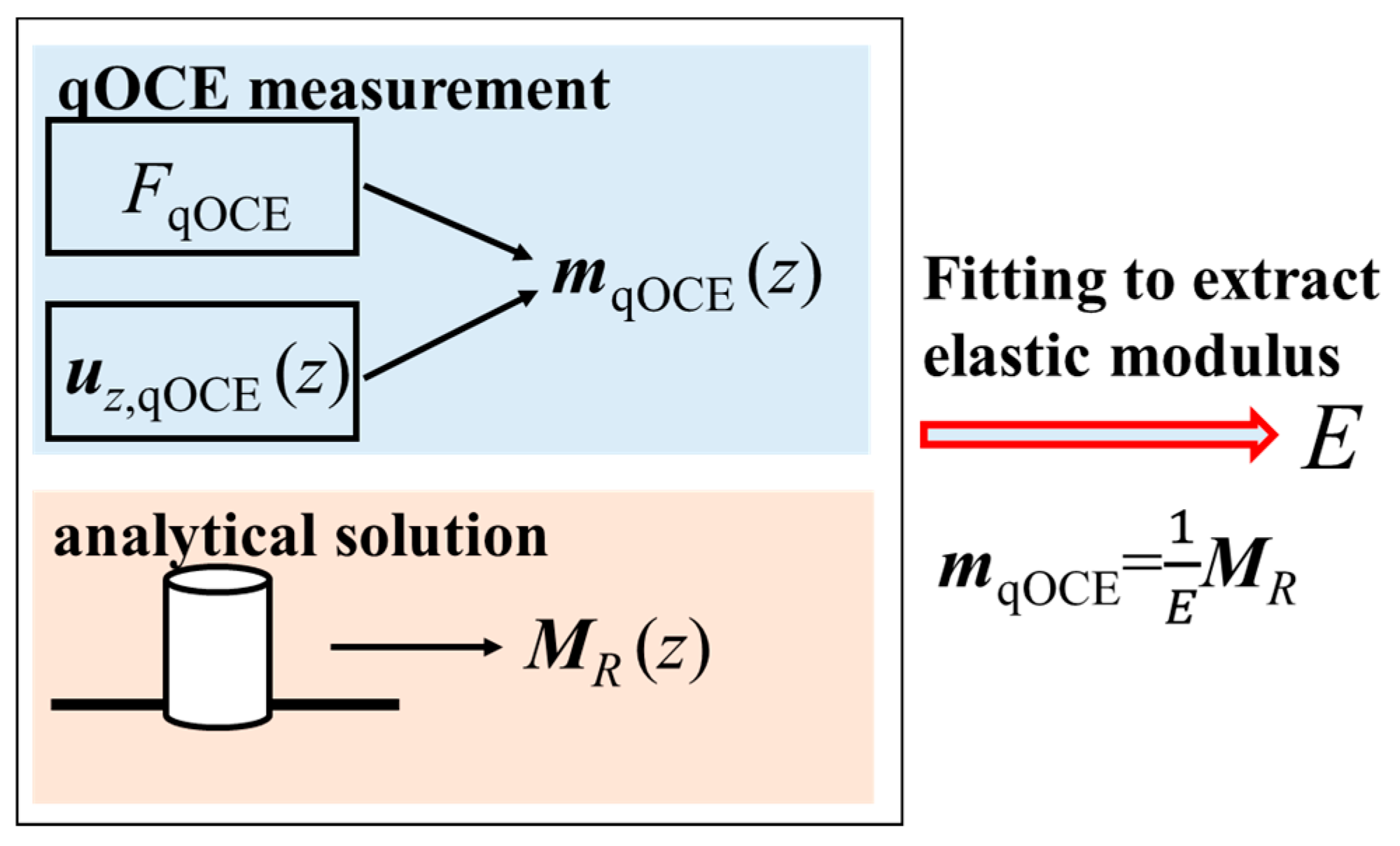

4. Robust Stiffness Characterization Based on qOCE Measurement

5. Results

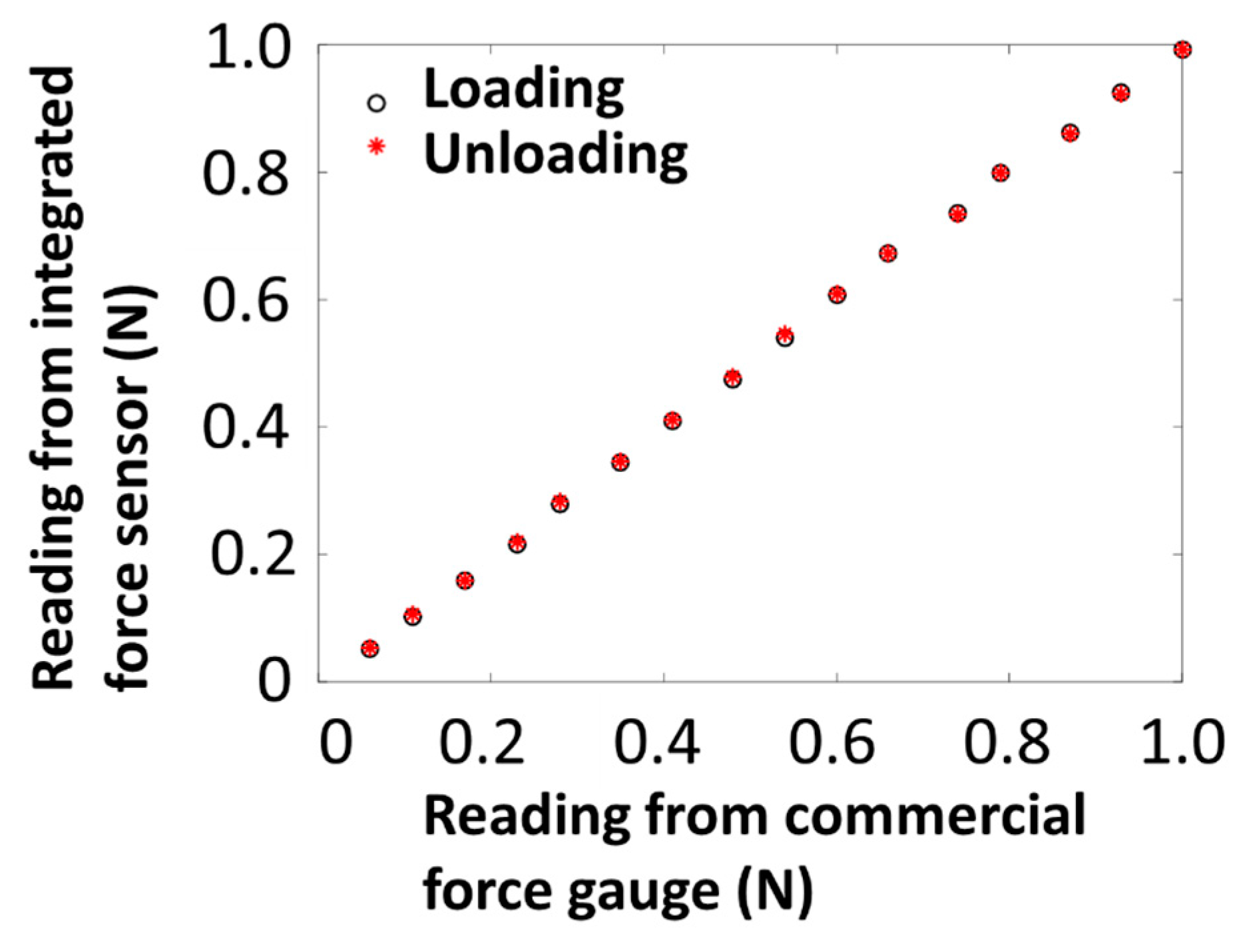

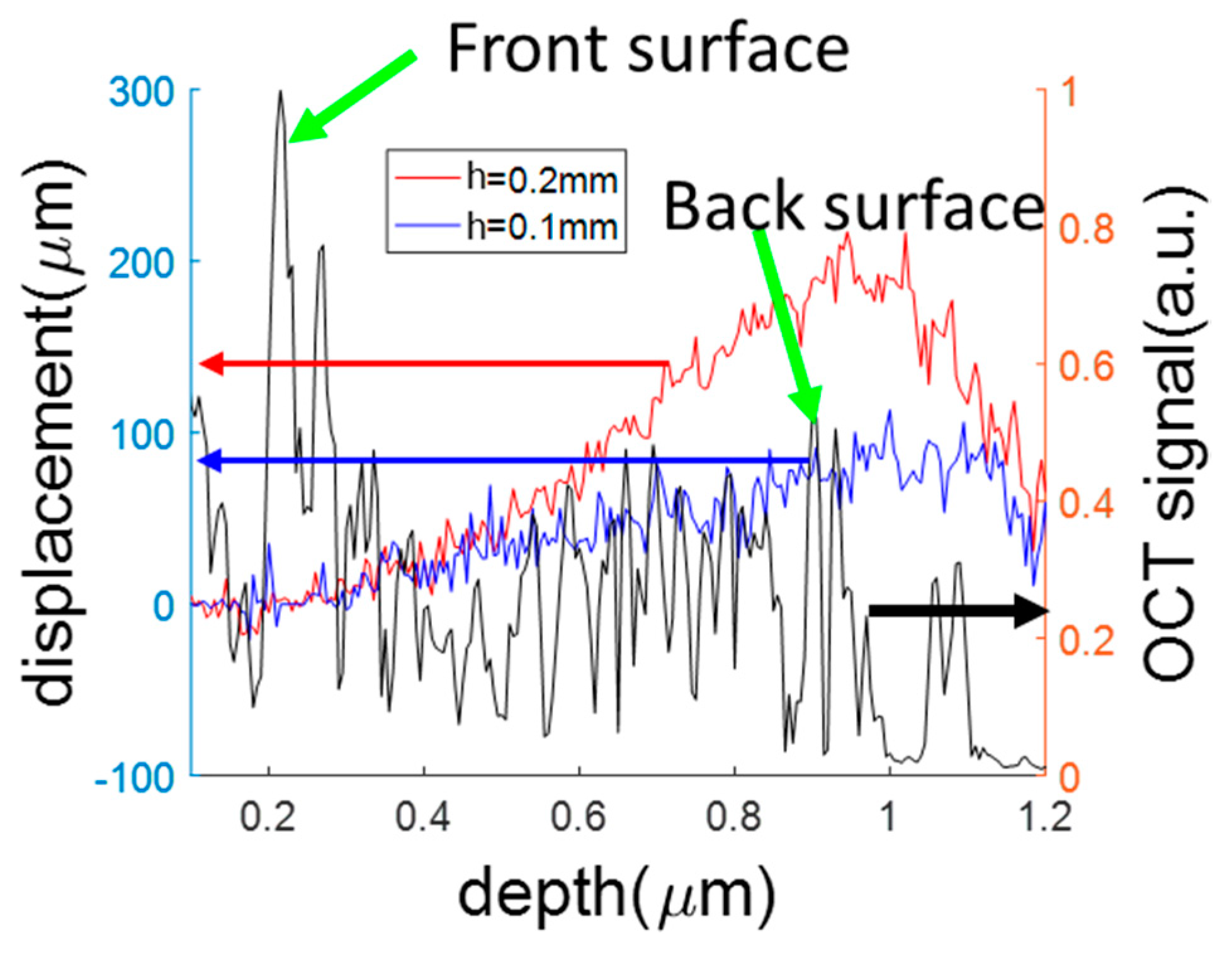

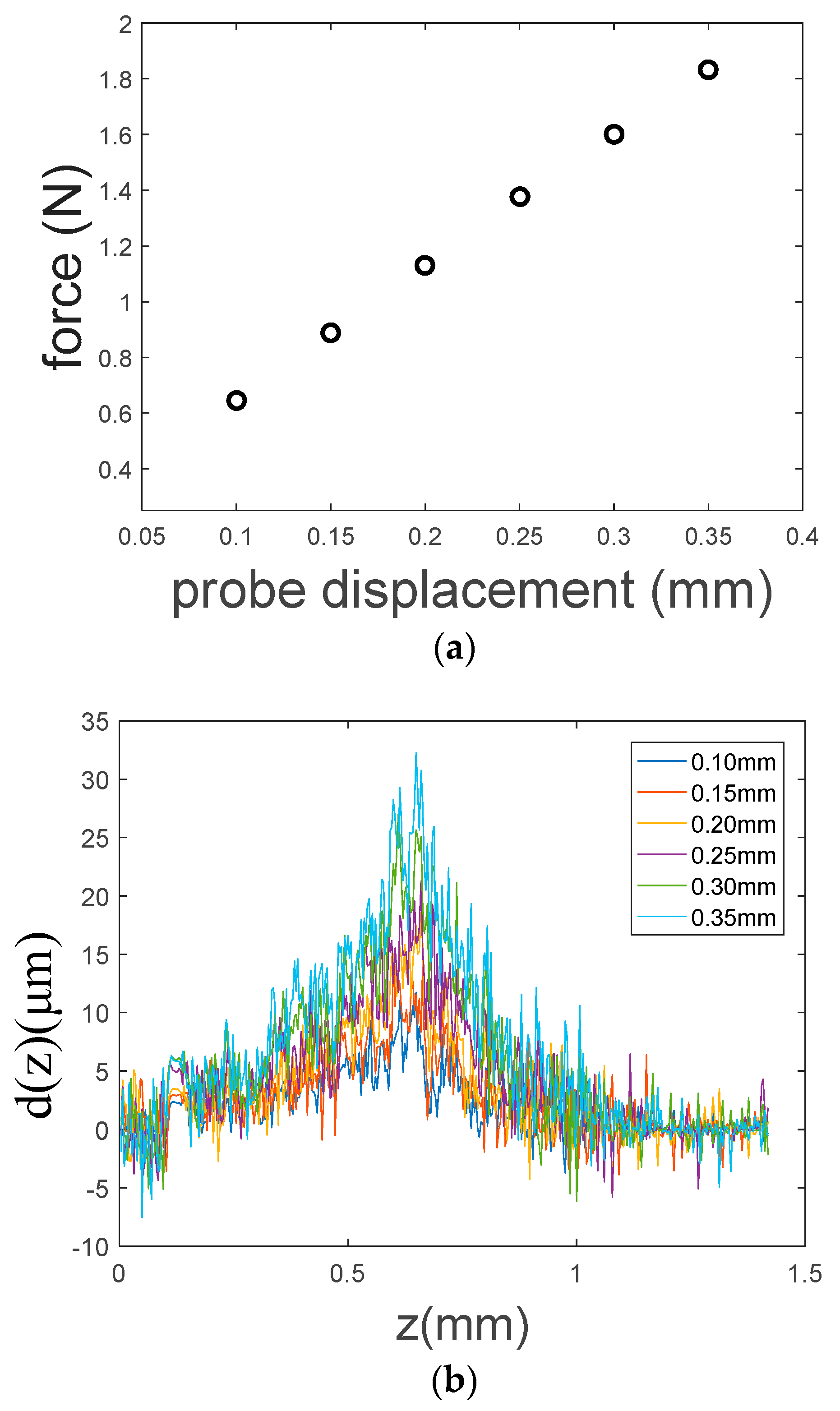

5.1. Measurement Capabilities of qOCE

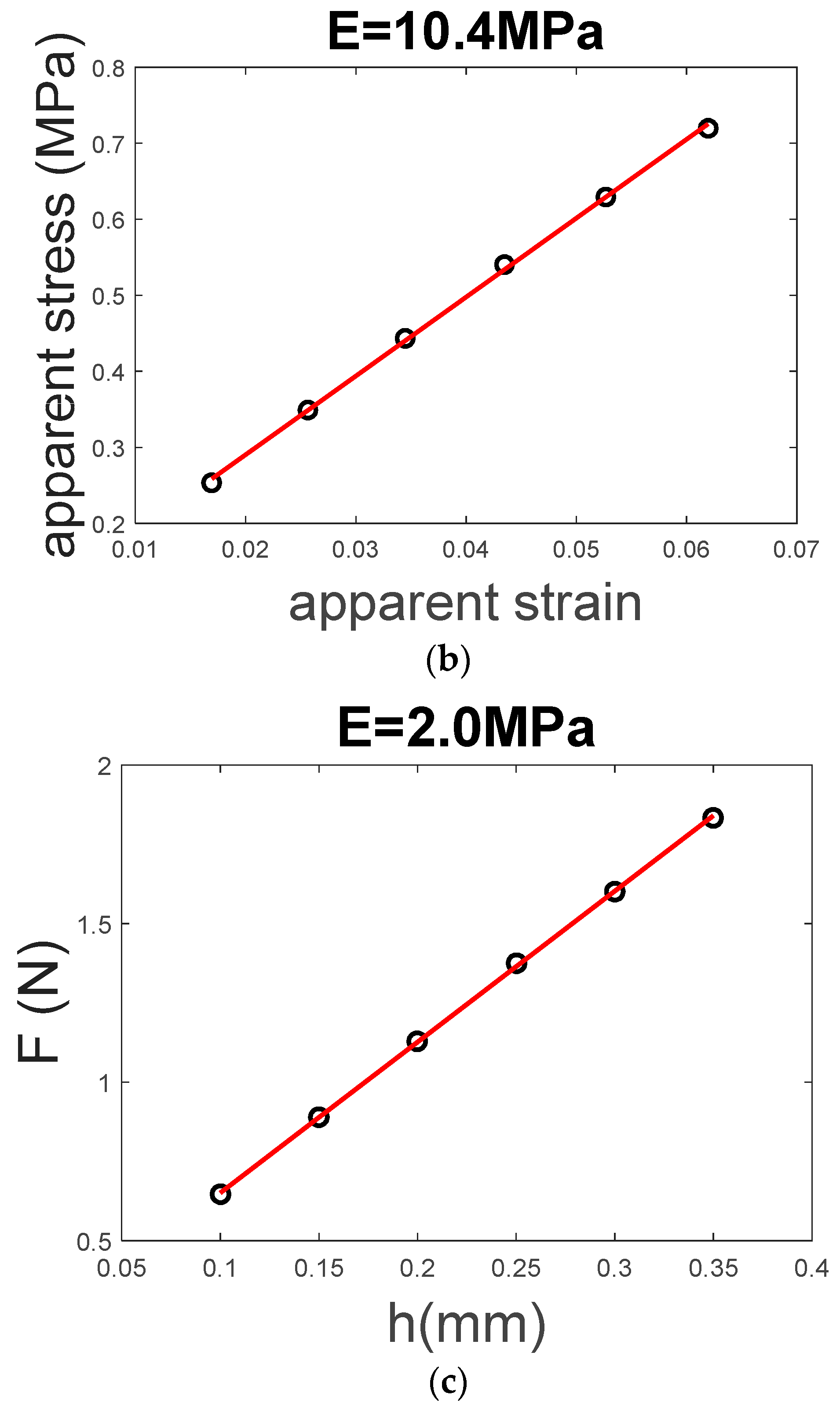

5.2. Quantification of Elastic Modulus Using qOCE Data

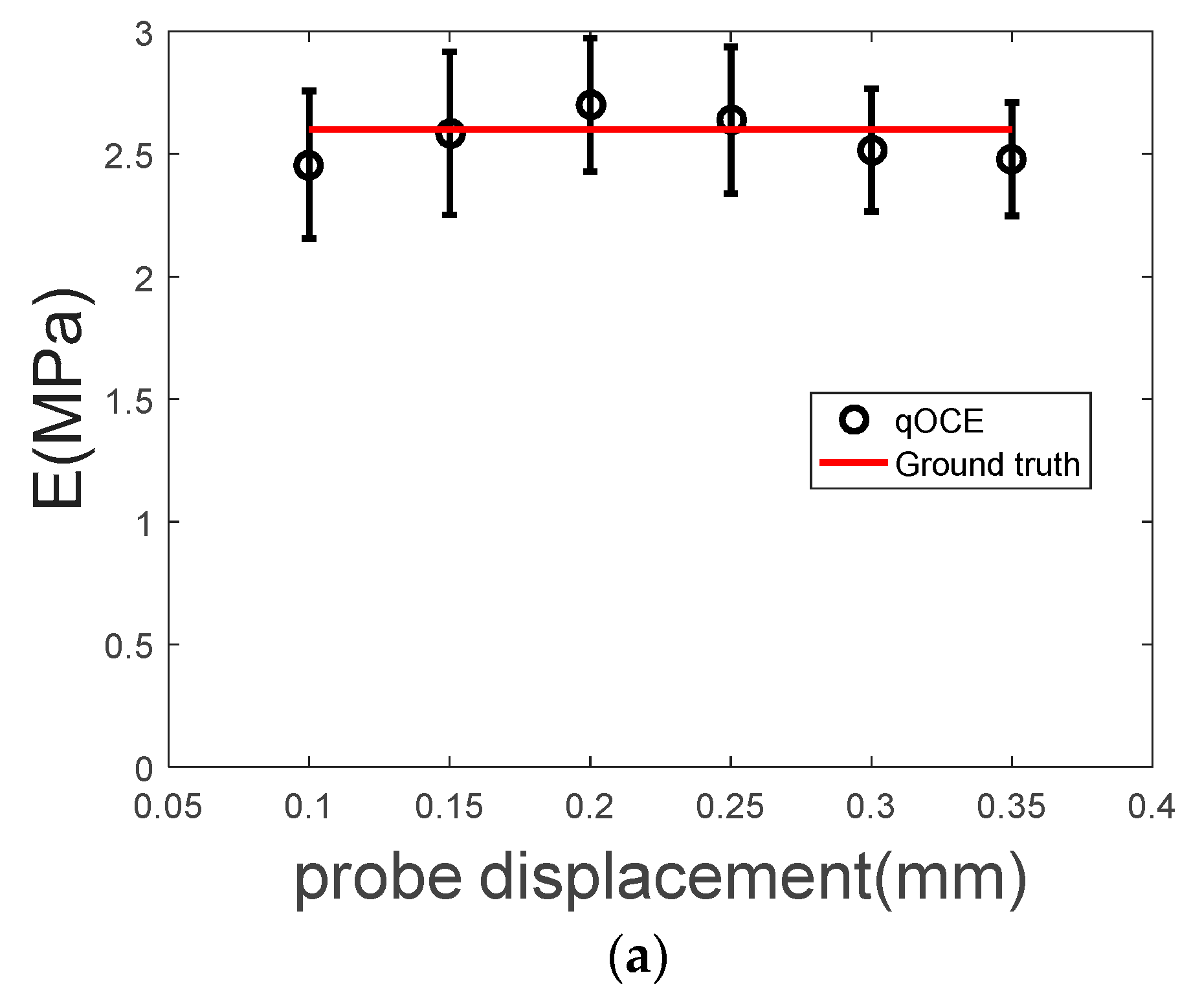

5.3. qOCE Assessment of Stiffness on PDMS Samples with Different Thicknesses

6. Conclusions and Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Voogd, A.C.; Nielsen, M.; Peterse, J.L.; Blichert-Toft, M.; Bartelink, H.; Overgaard, M.; van Tienhoven, G.; Andersen, K.W.; Sylvester, R.J.; van Dongen, J.A. Differences in risk factors for local and distant recurrence after breast-conserving therapy or mastectomy for stage I and II breast cancer: Pooled results of two large European randomized trials. J. Clin. Oncol. 2001, 19, 1688–1697. [Google Scholar] [CrossRef] [PubMed]

- Samani, A.; Zubovits, J.; Plewes, D. Elastic moduli of normal and pathological human breast tissues: An inversion-technique-based investigation of 169 samples. Phys. Med. Biol. 2007, 52, 1565. [Google Scholar] [CrossRef] [PubMed]

- Ophir, J.; Cespedes, I.; Ponnekanti, H.; Yazdi, Y.; Li, X. Elastography: A quantitative method for imaging the elasticity of biological tissues. Ultrason. Imaging 1991, 13, 111–134. [Google Scholar] [CrossRef] [PubMed]

- Muthupillai, R.; Lomas, D.J.; Rossman, P.J.; Greenleaf, J.F.; Manduca, A.; Ehman, R.L. Magnetic resonance elastography by direct visualization of propagating acoustic strain waves. Science 1995, 269, 1854–1857. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.; Swanson, E.A.; Lin, C.P.; Schuman, J.S.; Stinson, W.G.; Chang, W.; Hee, M.R.; Flotte, T.; Gregory, K.; Puliafito, C.A.; et al. Optical coherence tomography. Science 1991, 254, 1178–1181. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boppart, S.A.; Luo, W.; Marks, D.L.; Singletary, K.W. Optical coherence tomography: Feasibility for basic research and image-guided surgery of breast cancer. Breast Cancer Res. Treat. 2004, 84, 85–97. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, F.T.; Zysk, A.M.; Chaney, E.J.; Kotynek, J.G.; Oliphant, U.J.; Bellafiore, F.J.; Rowland, K.M.; Johnson, P.A.; Boppart, S.A. Intraoperative evaluation of breast tumor margins with optical coherence tomography. Cancer Res. 2009, 69, 8790–8796. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, K.M.; McLaughlin, R.A.; Kennedy, B.F.; Tien, A.; Latham, B.; Saunders, C.M.; Sampson, D.D. Needle optical coherence elastography for the measurement of microscale mechanical contrast deep within human breast tissues. J. Biomed. Opt. 2013, 18, 121510. [Google Scholar] [CrossRef] [PubMed]

- Schmitt, J. OCT elastography: Imaging microscopic deformation and strain of tissue. Opt. Express 1998, 3, 199–211. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, B.F.; Kennedy, K.M.; Sampson, D.D. A Review of Optical Coherence Elastography: Fundamentals, Techniques and Prospects. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 1–17. [Google Scholar] [CrossRef]

- Kennedy, M.K.; Kennedy, F.B.; McLaughlin, R.A.; Sampson, D.D. Needle optical coherence elastography for tissue boundary detection. Opt. Lett. 2012, 37, 2310–2312. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zaki, F.R.; Wu, H.; Wang, C.; Wang, Y. Temporally and spatially adaptive Doppler analysis for robust handheld optical coherence elastography. Biomed. Opt. Express 2018, 9, 3335–3353. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Wang, Y.; Xu, Y.; Chandra, N.; Haorah, J.; Hubbi, B.; Pfister, B.J.; Liu, X. Quantitative optical coherence elastography based on fiber-optic probe for in situ measurement of tissue mechanical properties. Biomed. Opt. Express 2016, 7, 688–700. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Zaki, F.; Chandra, N.; Chester, S.; Liu, X. Nonlinear characterization of elasticity using quantitative optical coherence elastography. Biomed. Opt. Express 2016, 11, 4702–4710. [Google Scholar] [CrossRef] [PubMed]

- Sadd, M.H. Elasticity: Theory, Applications, and Numerics; Academic Press: Cambridge, MA, USA, 2009. [Google Scholar]

- Fung, Y.-C. Biomechanics: Mechanical Properties of Living Tissues; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Wang, Z.; Volinsky, A.A.; Gallant, N.D. Crosslinking effect on polydimethylsiloxane elastic modulus measured by custom-built compression instrument. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef] [Green Version]

- Elkin, B.S.; Ilankovan, A.I.; Morrison, B., III. A detailed viscoelastic characterization of the P17 and adult rat brain. J. Neurotrauma 2011, 28, 2235–2244. [Google Scholar] [CrossRef] [PubMed]

- Hayes, W.; Keer, L.; Herrmann, G.; Mockros, L. A mathematical analysis for indentation tests of articular cartilage. J. Biomech. 1972, 5, 541–551. [Google Scholar] [CrossRef]

- Bower, A.F. Applied Mechanics of Solids; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zaki, F.; Wang, Y. Quantitative Optical Coherence Elastography for Robust Stiffness Assessment. Appl. Sci. 2018, 8, 1255. https://doi.org/10.3390/app8081255

Liu X, Zaki F, Wang Y. Quantitative Optical Coherence Elastography for Robust Stiffness Assessment. Applied Sciences. 2018; 8(8):1255. https://doi.org/10.3390/app8081255

Chicago/Turabian StyleLiu, Xuan, Farzana Zaki, and Yahui Wang. 2018. "Quantitative Optical Coherence Elastography for Robust Stiffness Assessment" Applied Sciences 8, no. 8: 1255. https://doi.org/10.3390/app8081255