Advanced Machining Technologies for CVD-SiC: Hybrid Approaches and AI-Enhanced Control for Ultra-Precision

Abstract

1. Introduction

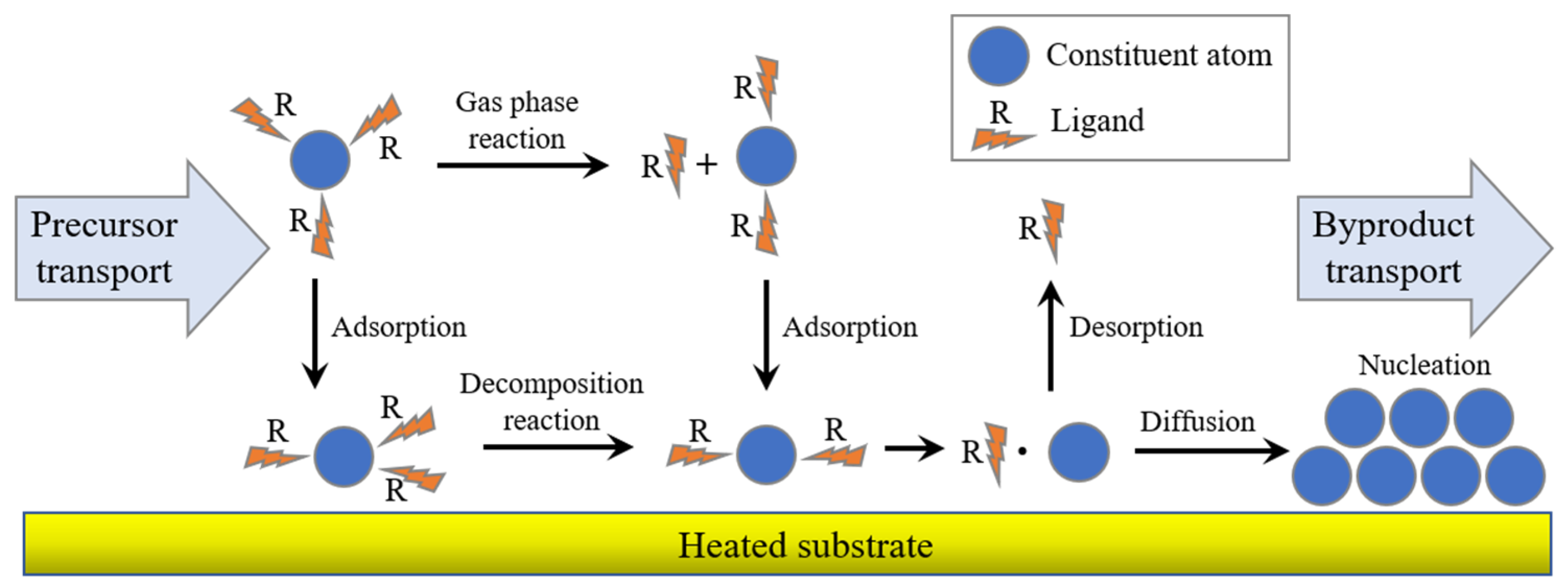

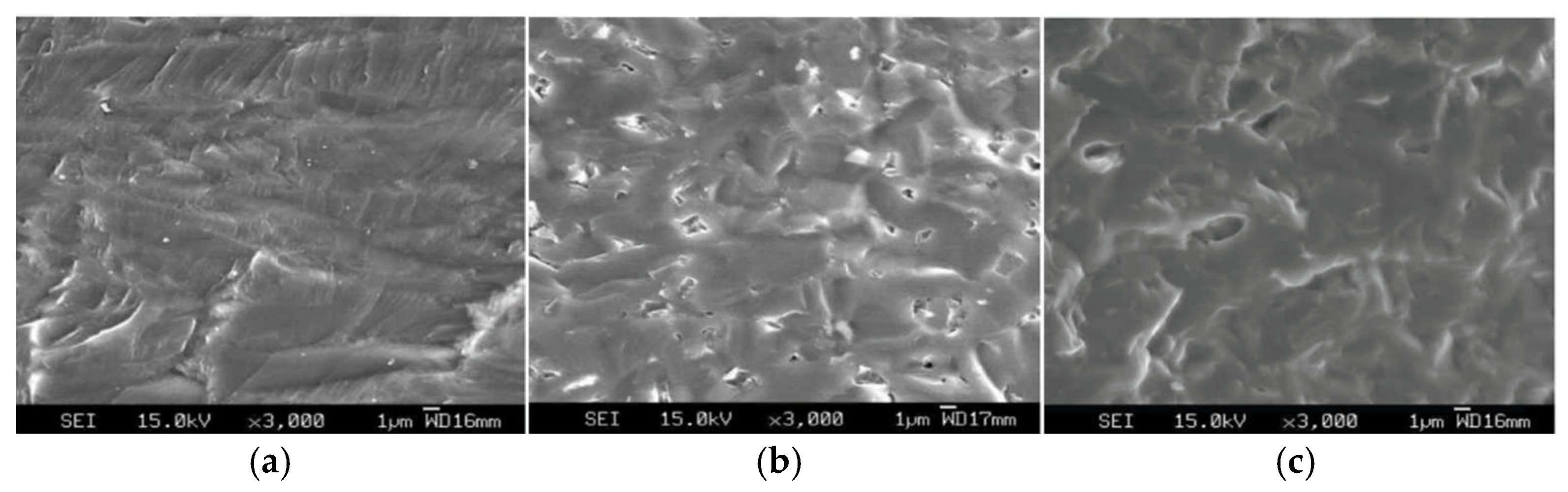

2. Characteristics of CVD-SiC

3. Mechanical Machining Methods for CVD-SiC

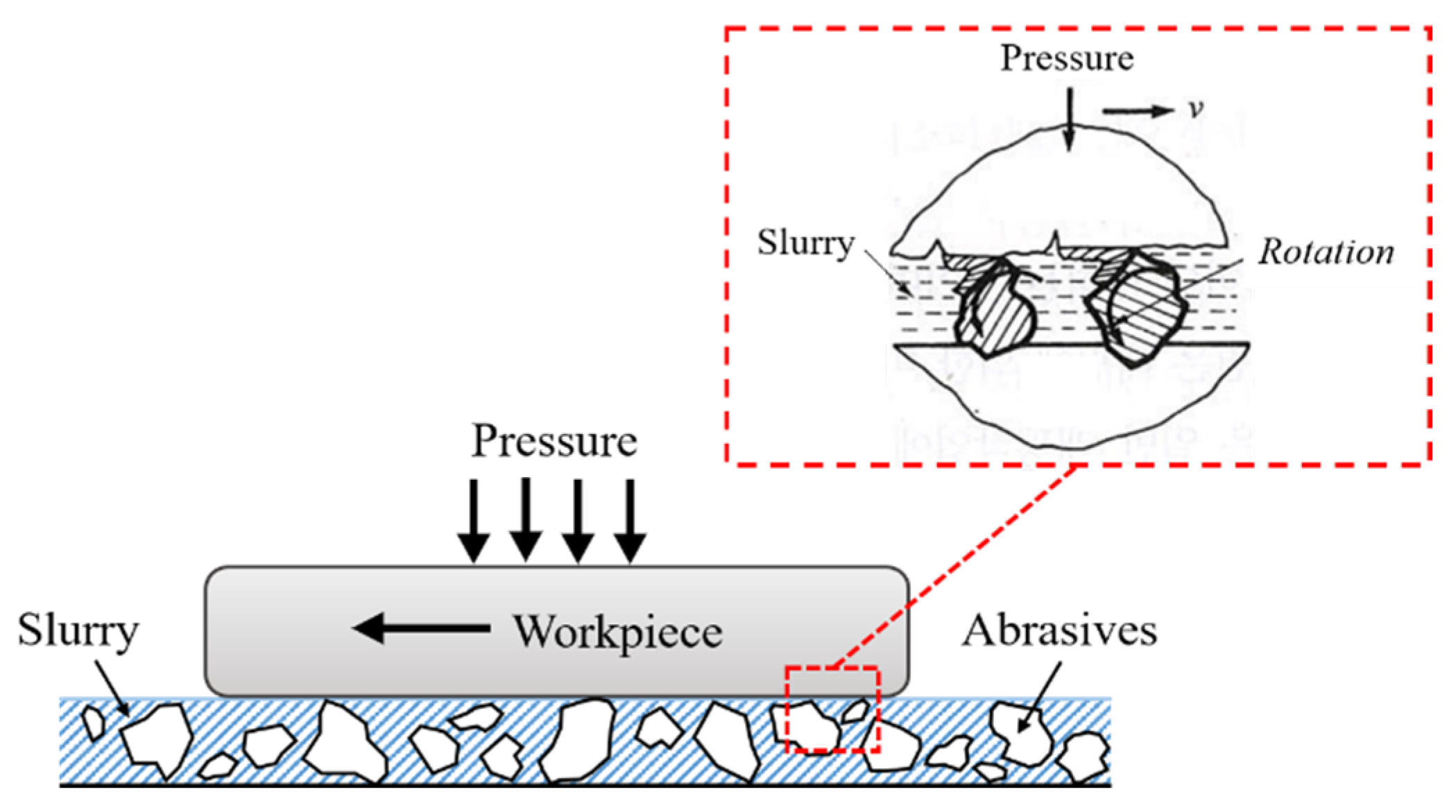

3.1. Loose Abrasive Machining

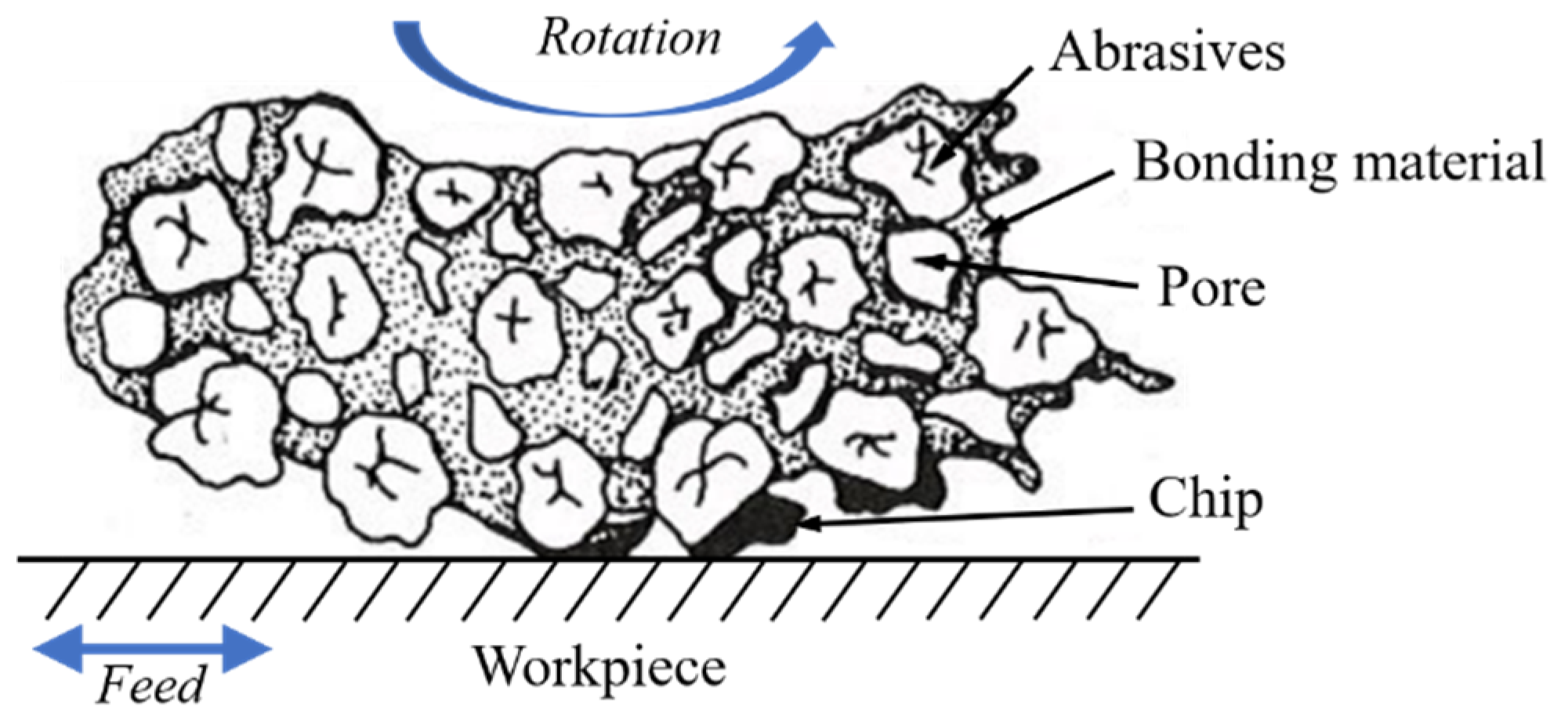

3.2. Fixed Abrasive Machining

4. High-Energy Machining Methods

5. AI-Based Ultra-Precision Control Technology

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goela, J.S.; Pickering, M.A.; Taylor, R.L.; Murray, B.W.; Lompado, A. Properties of chemical-vapor-deposited silicon carbide for optics applications in severe environments. Appl. Opt. 1991, 30, 3166–3175. [Google Scholar] [CrossRef]

- Mubina, S.; Khanra, A.K.; Saha, B.P. Enhancement of oxidation resistance of CVD SiC coated Cf/C-SiC hybrid composite tubes processed through Si-infiltration. J. Alloys Compd. 2020, 826, 154107. [Google Scholar] [CrossRef]

- Seshadri, A.; Phillips, B.; Shirvan, K. Impact of nuclear environment on hydrothermal corrosion and silica transport for CVD SiC in light water reactors. J. Nucl. Mater. 2021, 556, 153155. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, H.; Wang, X.; Luo, X.; Zhang, G.; Zhao, W.; Wang, X.; Liu, Z.; Xiong, L.; Qi, E.; et al. Challenges and strategies in high-accuracy manufacture of the world’s largest SiC aspheric mirror. Light Sci. Appl. 2022, 11, 310. [Google Scholar] [CrossRef] [PubMed]

- Tayaramma, D.P.V.J.; Rao, B.V.; Rudraswamy, B.; Venkateswaran, B.; Sriram, K.V. Optical polishing and characterization of chemical vapour deposited silicon carbide mirrors for space applications. J. Opt. 2022, 52, 969–983. [Google Scholar] [CrossRef]

- Bae, J.I.; Lee, H.B.; Kim, J.W.; Lee, K.M.; Kim, M.W. Development of a Silicon Carbide Large-aperture Optical Telescope for a Satellite. Korean J. Opt. Photonics 2022, 33, 74–83. [Google Scholar]

- Park, H.K. A Study on the Deposition and Grinding Characteristics of CVD-SiC for Semiconductor Process. Ph.D. Thesis, Kumoh National Institute of Technology, Gumi, Republic of Korea, 2017. [Google Scholar]

- Cheng, D.J.; Shyy, W.J.; Kuo, D.H.; Hon, M.H. Growth characteristics of CVD beta—Silicon carbide. J. Electrochem. Soc. 1987, 134, 3145. [Google Scholar] [CrossRef]

- Pickering, M.A.; Taylor, R.L.; Keeley, J.T.; Graves, G.A. Chemically vapor—Deposited silicon carbide (SiC) for optical applications. Nucl. Instrum. Methods Phys. Res. A 1990, 291, 95–100. [Google Scholar] [CrossRef]

- Zhou, J.; Lin, B.; Xue, J.; Li, S.; Liao, Y.; Zhao, P.; Sui, T. Damage characteristics and material removal mechanisms of CVD—iC in nanotests: A comparative with sintered SiC. Int. J. Refract. Met. Hard Mater. 2023, 118, 106460. [Google Scholar] [CrossRef]

- Shimada, K.; Fujita, T.; Oka, H.; Kamiyama, S.; Akagami, Y. Hydrodynamic and magnetized characteristics of MCF (magnetic compound fluid). Trans. Jpn. Soc. Mech. Eng. Ser. B 2001, 67, 3034–3040. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Fujimoto, M.; Nomura, M. Nano-precision polishing of CVD SiC using MCF (magnetic compound fluid) slurry. J. Korean Soc. Manuf. Technol. Eng. 2014, 23, 547–554. [Google Scholar] [CrossRef]

- Hur, C. A Study on Drilling Technology for Silicon Carbide. Master’s Thesis, Kumoh National Institute of Technology, Gumi, Republic of Korea, 2007. [Google Scholar]

- Seo, H.; Han, J.Y.; Kim, S.W.; Seong, S.; Yoon, S.; Lee, K.; Lee, H. Material removal characteristics of orthogonal velocity polishing tool for efficient fabrication of CVD SiC mirror surfaces. In Optical Manufacturing and Testing XI; SPIE: Bellingham, WA, USA, 2015; Volume 9575, pp. 115–124. [Google Scholar]

- Seo, H.; Han, J.Y.; Kim, S.W.; Seong, S.; Yoon, S.; Lee, K.; Hong, J.; Lee, H.; Bok, M. Novel orthogonal velocity polishing tool and its material removal characteristics from CVD SiC mirror surfaces. Opt. Express 2016, 24, 12349–12366. [Google Scholar] [CrossRef]

- Bifano, T.; Yi, Y.; Kahl, K. Fixed abrasive grinding of CVD SiC mirrors. Precis. Eng. 1994, 16, 109–116. [Google Scholar] [CrossRef]

- Bhattacharya, B.; Patten, J.A.; Jacob, J. Single point diamond turning of CVD coated silicon carbide. In Proceedings of the 2006 ASME International Conference on Manufacturing Science and Engineering, Ypsilanti, MI, USA, 8–11 October 2006. [Google Scholar]

- Ravindra, D.; Patten, J. Ductile regime single point diamond turning of CVD-SiC resulting in an improved and damage-free surface. In Proceedings of the 4th International Conference on Recent Advances in Materials, Minerals & Environment and 2nd Asian Symposium on Materials & Processing, Penang, Malaysia, 1–3 June 2009. [Google Scholar]

- Ravindra, D.; Patten, J. Improving the Surface Roughness of a CVD Coated Silicon Carbide Disk by Performing Ductile Regime Single Point Diamond Turning. In Proceedings of the 2008 International Manufacturing Science and Engineering Conference, Evanston, IL, USA, 7–10 October 2008. [Google Scholar]

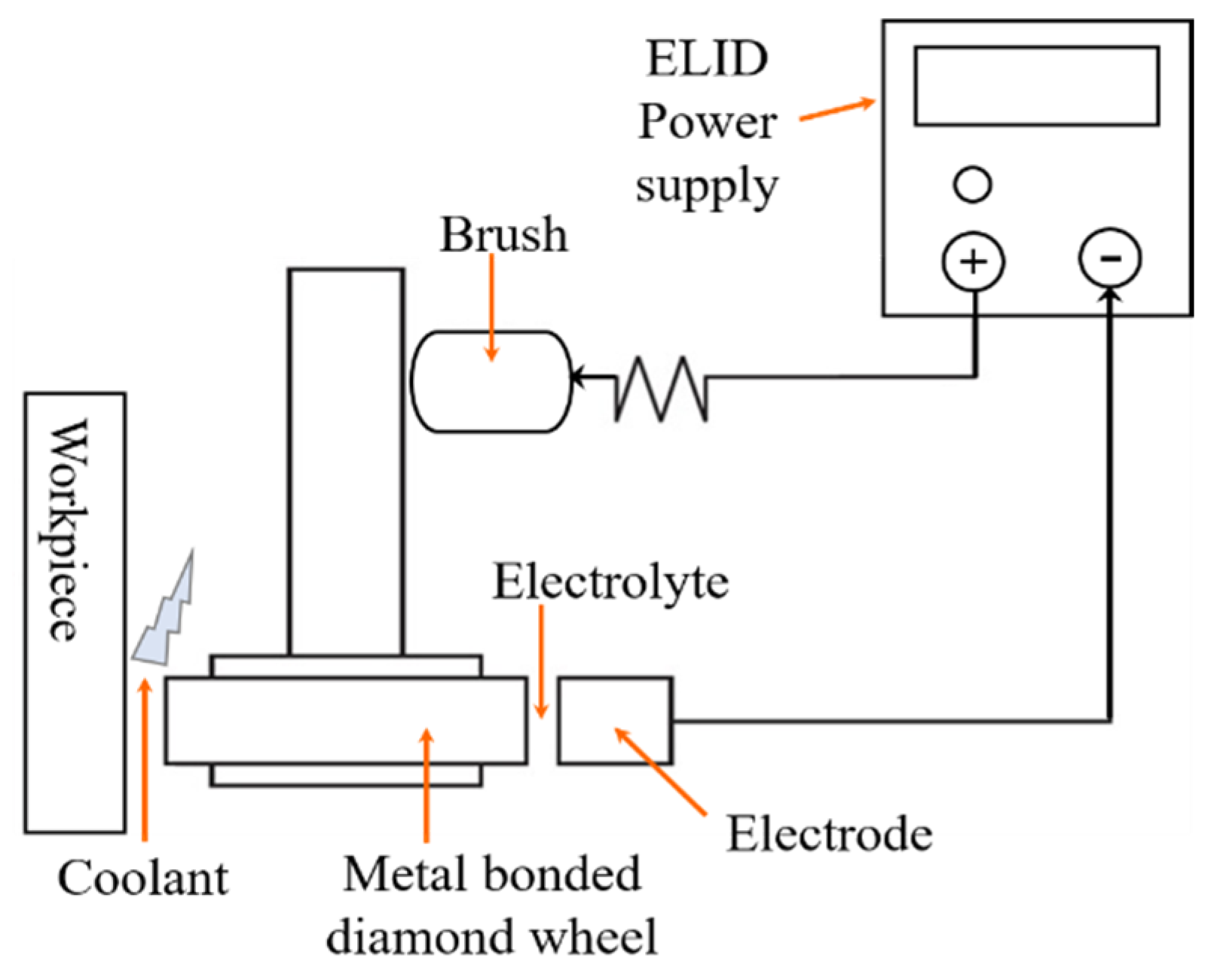

- Ohmori, S.; Moriyasu, S.; Uehara, Y.; Yamagata, Y.; Hayashi, W.; Makinouchi, A. CVD-SiC X-ray Mirror of Ultraprecision Grinding with ELID (Electrolytic In-Process Dressing). J. Jpn. Soc. Mech. Eng. 2000, 504, 123–134. [Google Scholar]

- Zhang, C.; Kato, T.; Li, W.; Ohmori, H. A Comparative Study: Surface Characteristics of CVD-SiC Ground with Cast Iron Bond Diamond Wheel. Int. J. Mach. Tools Manuf. 2000, 40, 527–537. [Google Scholar] [CrossRef]

- Zhang, C.; Ohmori, H.; Kato, T.; Morita, N. Evaluation of surface characteristics of ground CVD-SiC using cast iron bond diamond wheels. Precis. Eng. 2001, 25, 56–62. [Google Scholar] [CrossRef]

- Ao, X.; Kurokawa, S.; Hayashi, T.; Ohmori, H.; Jia, C. Super-smooth processing of CVD-SiC using combined electrolytic in-process dressing grinding and fixed softer-than-diamond abrasive grinding. Int. J. Adv. Manuf. Technol. 2025, 139, 2803–2821. [Google Scholar] [CrossRef]

- Suzuki, A.; Okada, M.; Suzuki, H.; Fujii, K.; Itoh, Y.; Fukuda, T. Ultraprecision cutting of CVD-SiC by micro milling tool of diamond. In Proceedings of the 2019 JSPE Fall Conference, Nagoya, Japan, 9–11 September 2019. [Google Scholar]

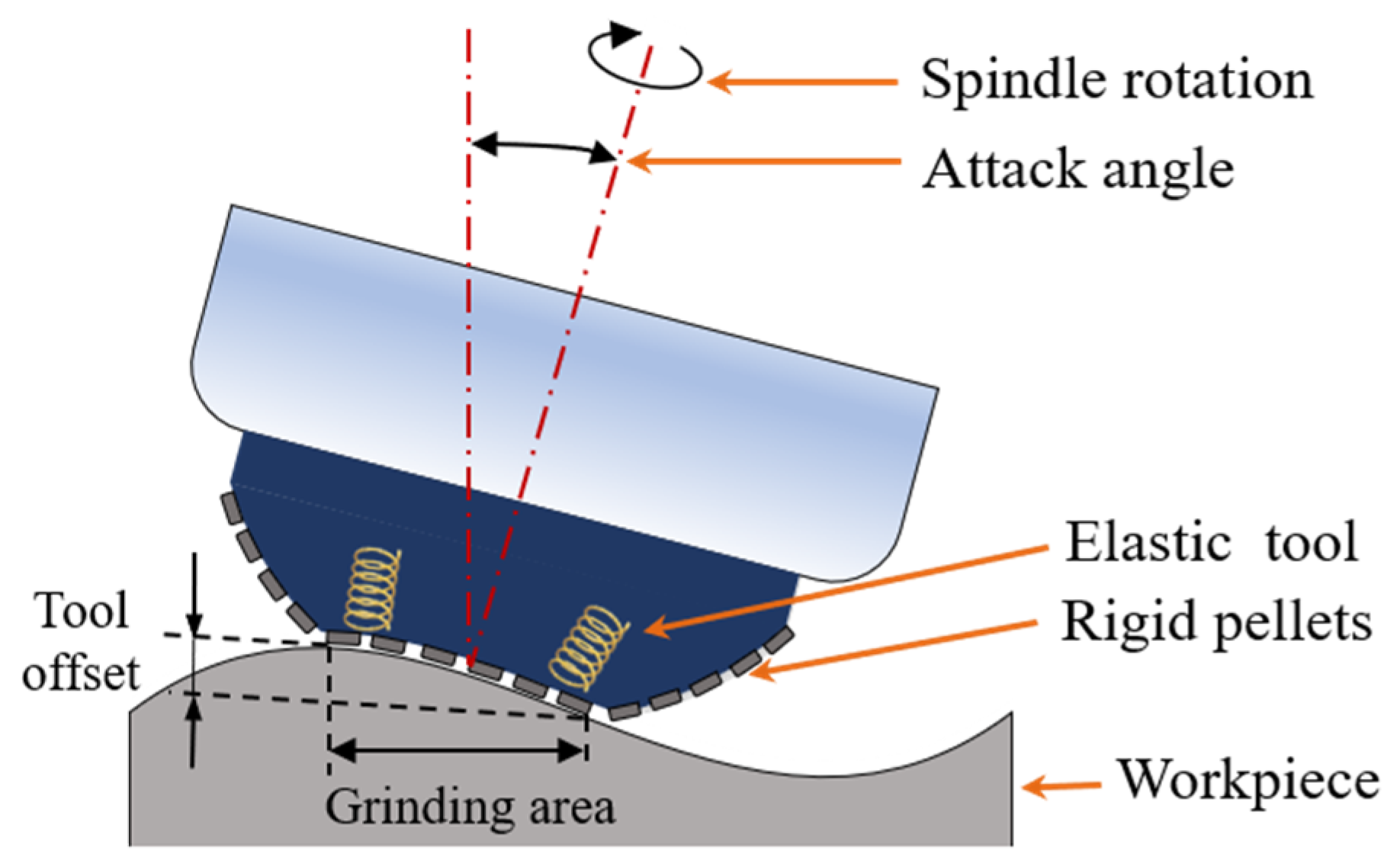

- Beaucamp, A.; Namba, Y.; Combrinck, H.; Freeman, R. Shape Adaptive Grinding of CVD Silicon Carbide. CIRP Ann. 2014, 63, 317–320. [Google Scholar] [CrossRef]

- Namba, Y.; Suzuki, H. Surface-figuring CVD-SiC mirrors with a five-axis-control ultraprecision grinding machine. In Materials, Manufacturing, and Measurement for Synchrotron Radiation Mirrors; SPIE: Bellingham, WA, USA, 1997; Volume 3152, pp. 27–34. [Google Scholar]

- Namba, Y.; Kobayashi, H.; Suzuki, H.; Yamashita, K.; Taniguchi, N. Ultraprecision surface grinding of chemical vapor deposited silicon carbide for X-ray mirrors using resinoid-bonded diamond wheels. CIRP Ann. 1999, 48, 277–280. [Google Scholar] [CrossRef]

- Fawcett, S.C.; Drueding, T.W.; Bifano, T.G. Neutral ion figuring of chemical vapor deposited SiC. Opt. Eng. 1994, 33, 967–974. [Google Scholar] [CrossRef]

- Gailly, P.; Collette, J.P.; Fleury-Frenette, K.; Jamar, C. Ion beam figuring of CVD silicon carbide mirrors. In Proceedings of the International Conference on Space Optics 2004, Toulouse, France, 30 March–2 April 2004. [Google Scholar]

- Gailly, P.; Fleury-Frenette, K.; Lecat, J.H.; Collette, J.P.; Defise, J.M. Ion beam figuring for precision optics. SPIE Newsroom 2008, 10, 1106. [Google Scholar] [CrossRef]

- Nianhui, K.; Shengyi, L.; Ziwen, Z.; Yifan, D. High-precision and Super-smooth Fabrication of CVD SiC Flat Reflecting Mirror. China Mech. Eng. 2009, 20, 69–73. [Google Scholar]

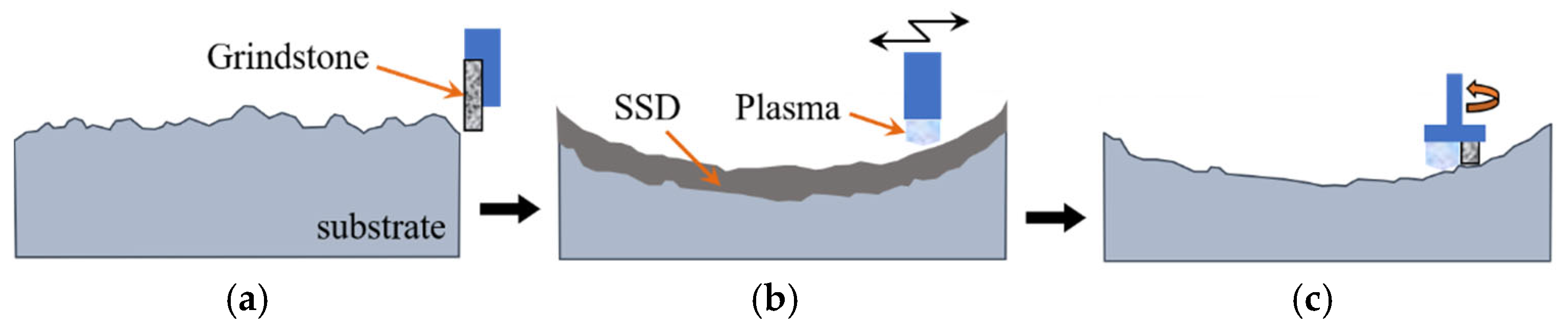

- Deng, H.; Endo, K.; Yamamura, K. Damage-free finishing of CVD-SiC by a combination of dry plasma etching and plasma-assisted polishing. Int. J. Mach. Tools Manuf. 2017, 115, 38–46. [Google Scholar] [CrossRef]

- Sun, R.; Yang, X.; Ohkubo, Y.; Endo, K.; Yamamura, K. Optimization of Gas Composition Used in Plasma Chemical Vaporization Machining for Figuring of Reaction-Sintered Silicon Carbide with Low Surface Roughness. Sci. Rep. 2018, 8, 2505. [Google Scholar] [CrossRef] [PubMed]

- Ravindra, D.; Patten, J.; Jacobsen, R. Hybrid laser ablation-single point diamond turning machining process for CVD-silicon carbide ceramics. Int. J. Manuf. Res. 2013, 8, 227–249. [Google Scholar] [CrossRef]

- Park, K.S.; Kim, S.H. Artificial intelligence approaches to determination of CNC machining parameters in manufacturing: A review. Artif. Intell. Eng. 1998, 12, 121–134. [Google Scholar] [CrossRef]

- Yang, H.; Zheng, H.; Zhang, T. A review of artificial intelligent methods for machined surface roughness prediction. Tribol. Int. 2024, 199, 109935. [Google Scholar] [CrossRef]

- Abdullah, H.; Ramli, R.; Wahab, D.A.; Qudeiri, J.A. Simulation approach of cutting tool movement using artificial intelligence method. J. Eng. Sci. Technol. 2015, 10, 35–44. [Google Scholar]

- Markopoulos, A.P.; Kundrák, J. FEM/AI Models for the Simulation of Precision Grinding. Manuf. Technol. 2016, 16, 384–390. [Google Scholar] [CrossRef]

- Pawanr, S.; Gupta, K. A Review on Recent Advances in the Energy Efficiency of Machining Processes for Sustainability. Energies 2024, 17, 3659. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Machine learning and artificial intelligence in CNC machine tools, A review. Sustain. Manuf. Serv. Econ. 2023, 2, 100009. [Google Scholar] [CrossRef]

- Li, A.; Zhou, J.; Niu, X.; Liu, Z.; Ma, Q.; Song, S.; Wang, M.; Hu, B. Advances and challenges in chemical mechanical polishing of silicon carbide: Materials, mechanisms, and future directions. J. Mater. Chem. C 2025, 13, 22921. [Google Scholar] [CrossRef]

- Ullrich, K.; von Elling, M.; Gutzeit, K.; Dix, M.; Weigold, M.; Aurich, J.C.; Wertheim, R.; Jawahir, I.S.; Ghadbeigi, H. AI-based optimisation of total machining performance: A review. CIRP J. Manuf. Sci. Technol. 2024, 50, 40–54. [Google Scholar] [CrossRef]

- Ji, W.; Wang, L. Industrial robotic machining: A review. Int. J. Adv. Manuf. Technol. 2019, 103, 1239–1255. [Google Scholar] [CrossRef]

- Knittel, D.; Makich, H.; Nouari, M. Milling diagnosis using artificial intelligence approaches. Mech. Ind. 2019, 20, 809. [Google Scholar] [CrossRef]

- Razak, N.H.; Rahman, M.M.; Noor, M.M.; Kadirgama, K. Artificial Intelligence Techniques for Machining Performance: A Review. In Proceedings of the 2nd National Conference in Mechanical Engineering Research and Postgraduate Studies (NCMER 2010), Kuantan, Malaysia, 3–4 December 2010. [Google Scholar]

| Property | Unit | CVD-SiC | S-SiC | RB-SiC |

|---|---|---|---|---|

| Density | g/cm3 | 3.20 | 3.10 | 2.90 |

| Hardness | GPa | 30.0 | 27.5 | 24.5 |

| Flexural strength (3-point) | MPa | 582 | 428 | 274 |

| Young’s modulus | GPa | 466 | 430 | 393 |

| Poisson’s ratio | - | 0.21 | 0.14 | 0.22 |

| Fracture toughness | MPa·m1/2 | 2.94 | 4.00 | 4.50 |

| Machining Method | Removal Mechanism | Benefits(O) and Limitations(X) |

|---|---|---|

| IBF | Accelerated inert gas ions are directed onto the material surface to physically sputter and remove atoms in a controlled manner. This non-contact process eliminates tool wear and mechanical stress. |

|

| PCVM | This is purely chemical, non-contact process. A reactive plasma gas chemically reacts with the surface atoms to form volatile compounds that are subsequently removed. |

|

| PAP | A hybrid process that integrates the chemical activation of plasma with the mechanical action of fine abrasives. Plasma exposure weakens atomic bonds and promotes oxide layer formation, while abrasives remove the softened layer. |

|

| Laser ablation | Rapid and localized temperature rises caused by high-energy laser pulses vaporize surface atoms or induce plasma transitions through bond dissociation. This enables high-precision, high-speed material removal. |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.-Y.; Lee, S.-M.; Jang, M.-S.; Yang, H.-S.; Kwak, T.-S. Advanced Machining Technologies for CVD-SiC: Hybrid Approaches and AI-Enhanced Control for Ultra-Precision. Appl. Sci. 2025, 15, 12892. https://doi.org/10.3390/app152412892

Han S-Y, Lee S-M, Jang M-S, Yang H-S, Kwak T-S. Advanced Machining Technologies for CVD-SiC: Hybrid Approaches and AI-Enhanced Control for Ultra-Precision. Applied Sciences. 2025; 15(24):12892. https://doi.org/10.3390/app152412892

Chicago/Turabian StyleHan, Su-Yeon, Seung-Min Lee, Min-Su Jang, Ho-Soon Yang, and Tae-Soo Kwak. 2025. "Advanced Machining Technologies for CVD-SiC: Hybrid Approaches and AI-Enhanced Control for Ultra-Precision" Applied Sciences 15, no. 24: 12892. https://doi.org/10.3390/app152412892

APA StyleHan, S.-Y., Lee, S.-M., Jang, M.-S., Yang, H.-S., & Kwak, T.-S. (2025). Advanced Machining Technologies for CVD-SiC: Hybrid Approaches and AI-Enhanced Control for Ultra-Precision. Applied Sciences, 15(24), 12892. https://doi.org/10.3390/app152412892