Particle Shape-Driven Stiffness Anisotropy in Calcareous Sand and the Underlying Mechanism

Abstract

1. Introduction

2. Details of Numerical Simulation

2.1. Initial Parameters and Procedure

2.2. Particle Shape

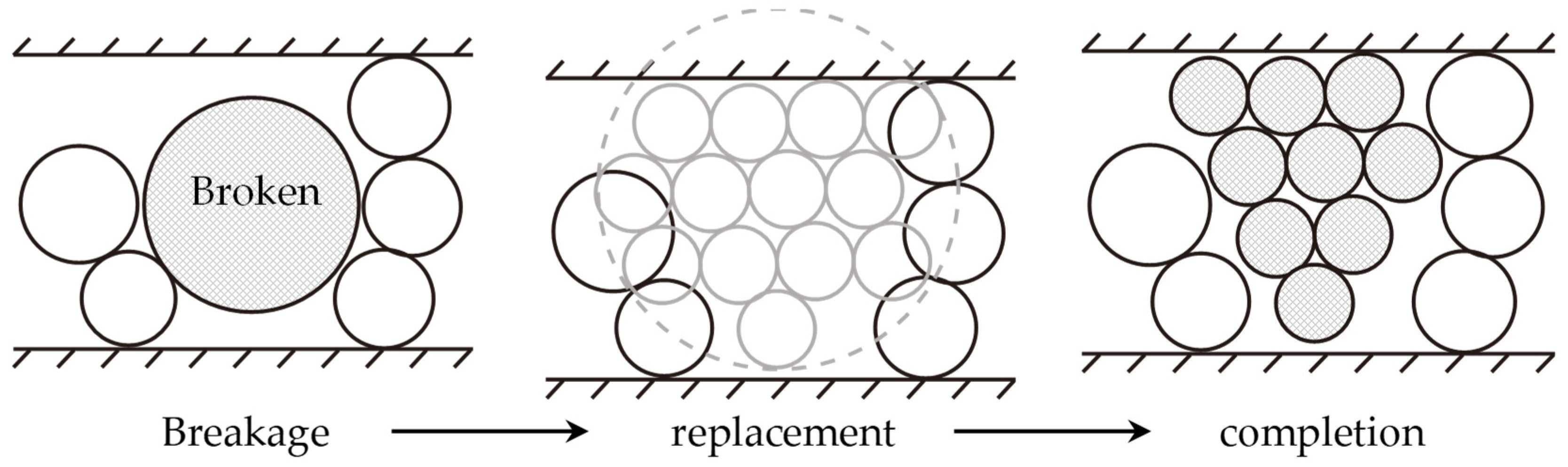

2.3. Algorithm for Particle Breakage

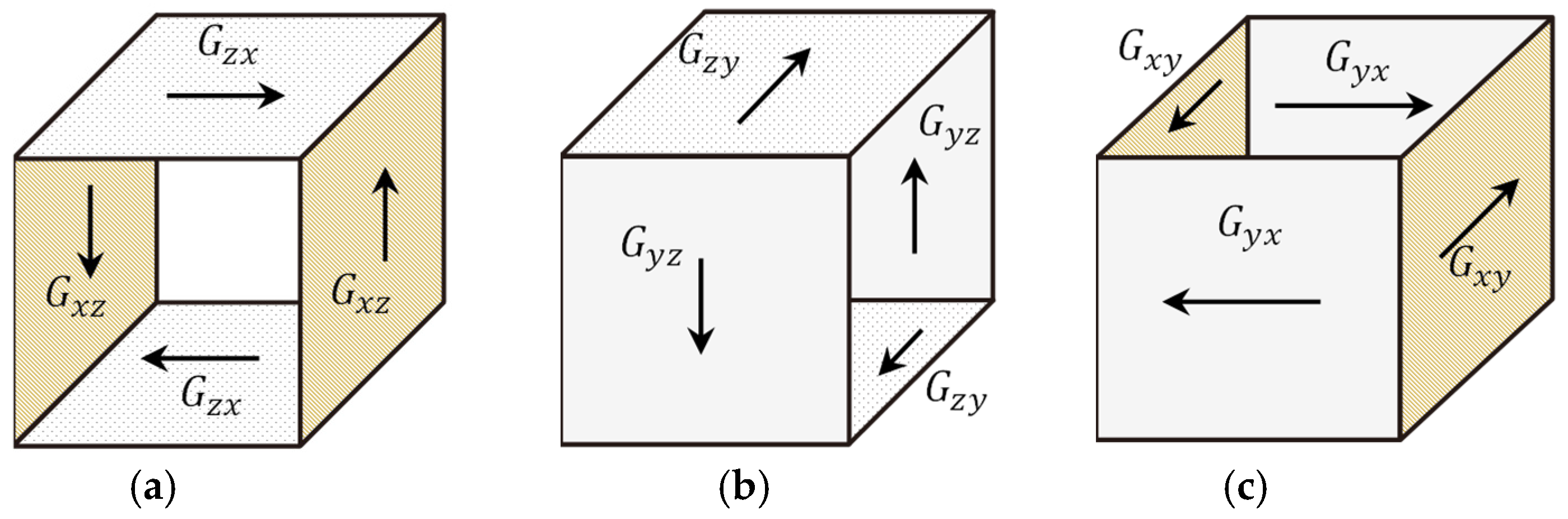

2.4. Algorithm for Small-Strain Shear Modulus

2.5. Characterization of Microscopic Anisotropy

3. Stiffness Anisotropy of Calcareous Sands with Different Particle Shapes During Isotropic Stress Compression

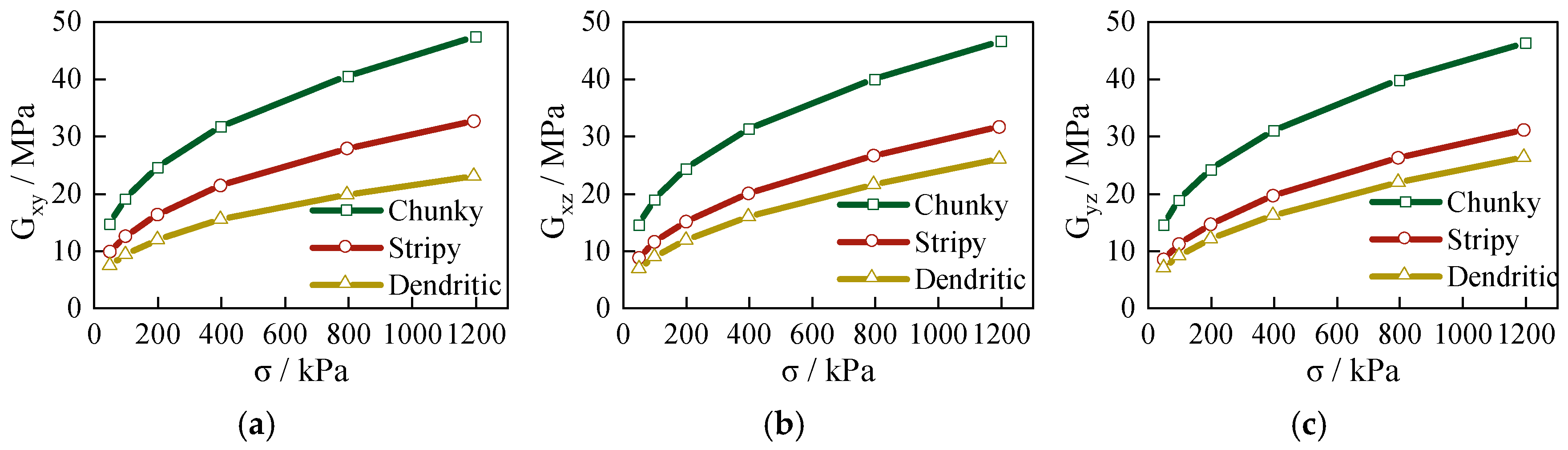

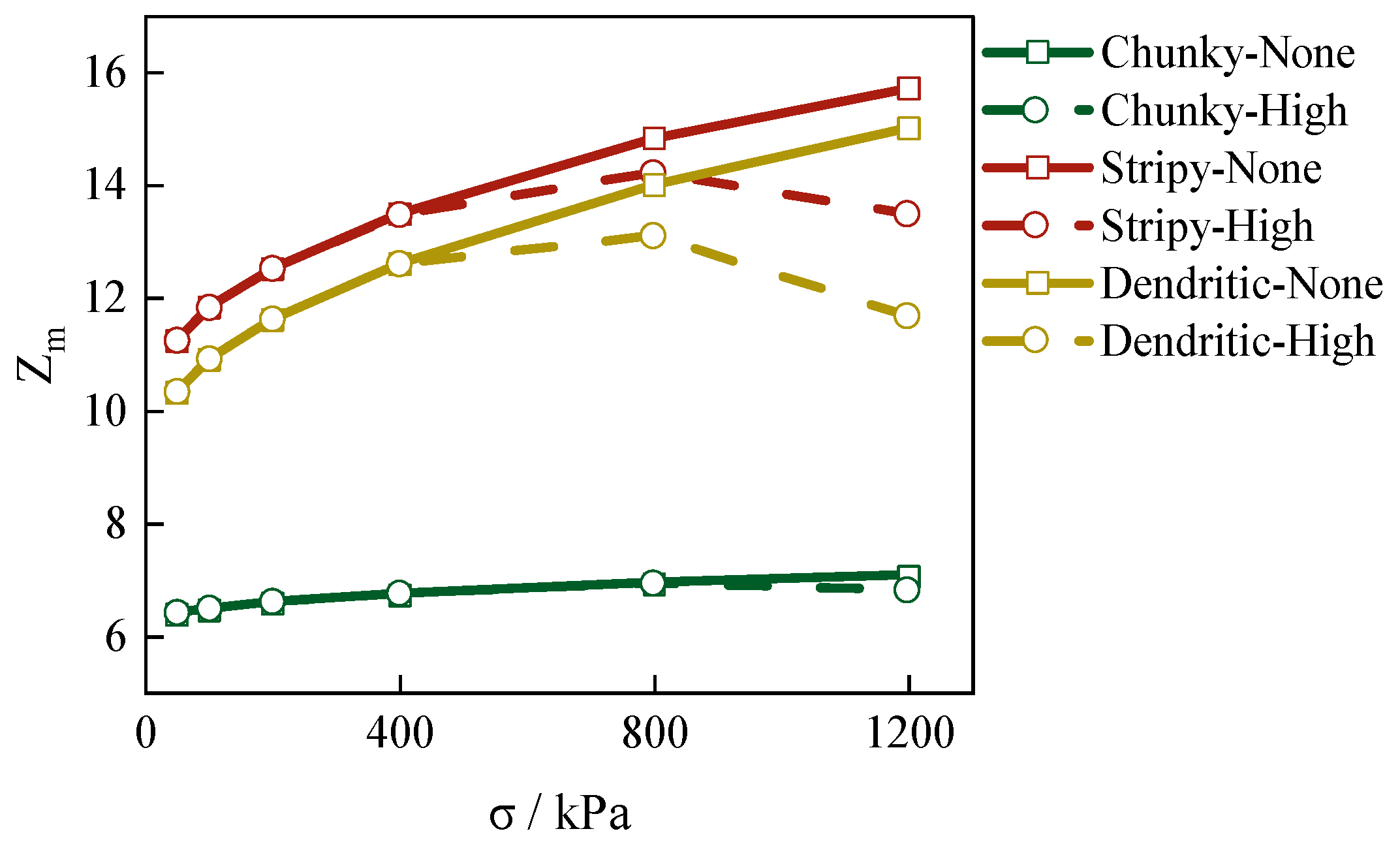

3.1. The Variation in Small-Strain Shear Modulus with Isotropic Stress

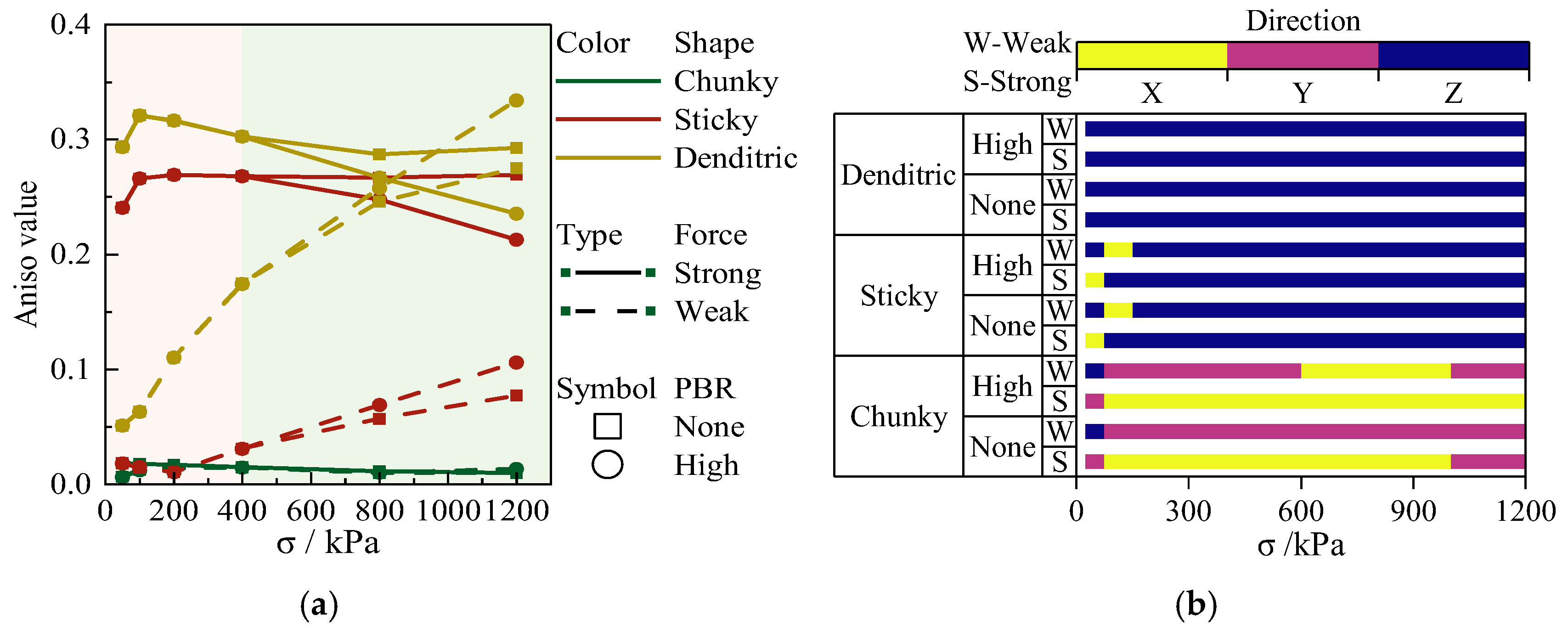

3.2. Anisotropy of the Small-Strain Shear Modulus

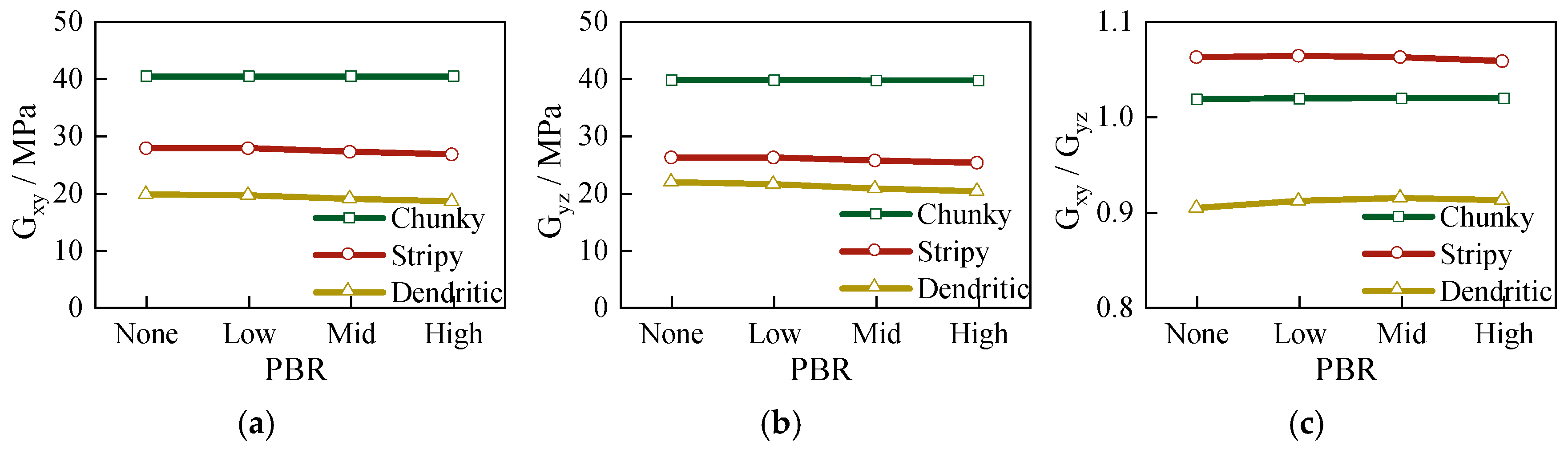

3.3. The Impact of Particle Breakage on the Anisotropy of Small-Strain Shear Modulus

4. The Intrinsic Mechanism of Stiffness Anisotropy Induced by the Particle Shape for Calcareous Sand

4.1. The Influence of Particle Shapes on the Coordination Number

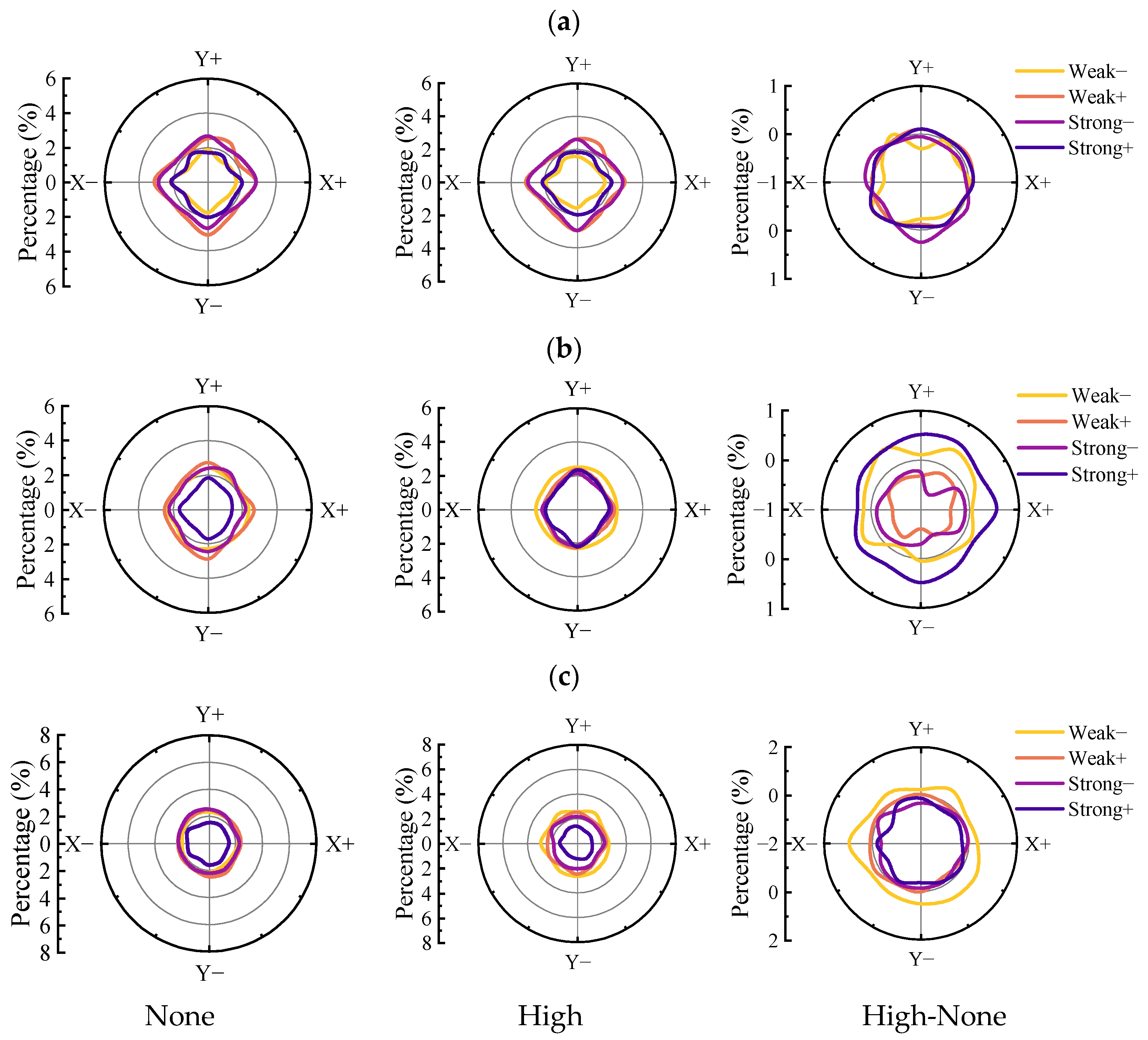

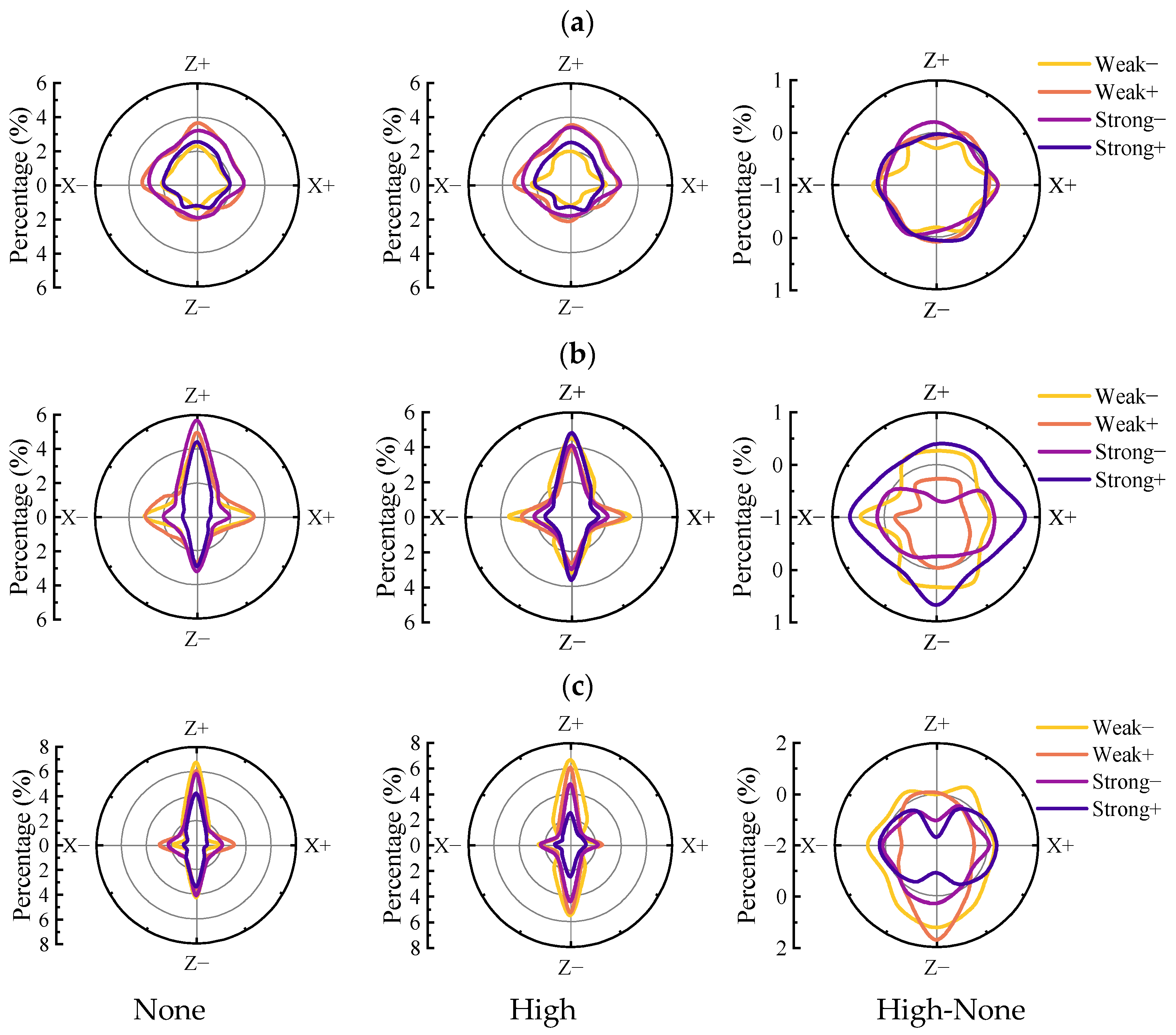

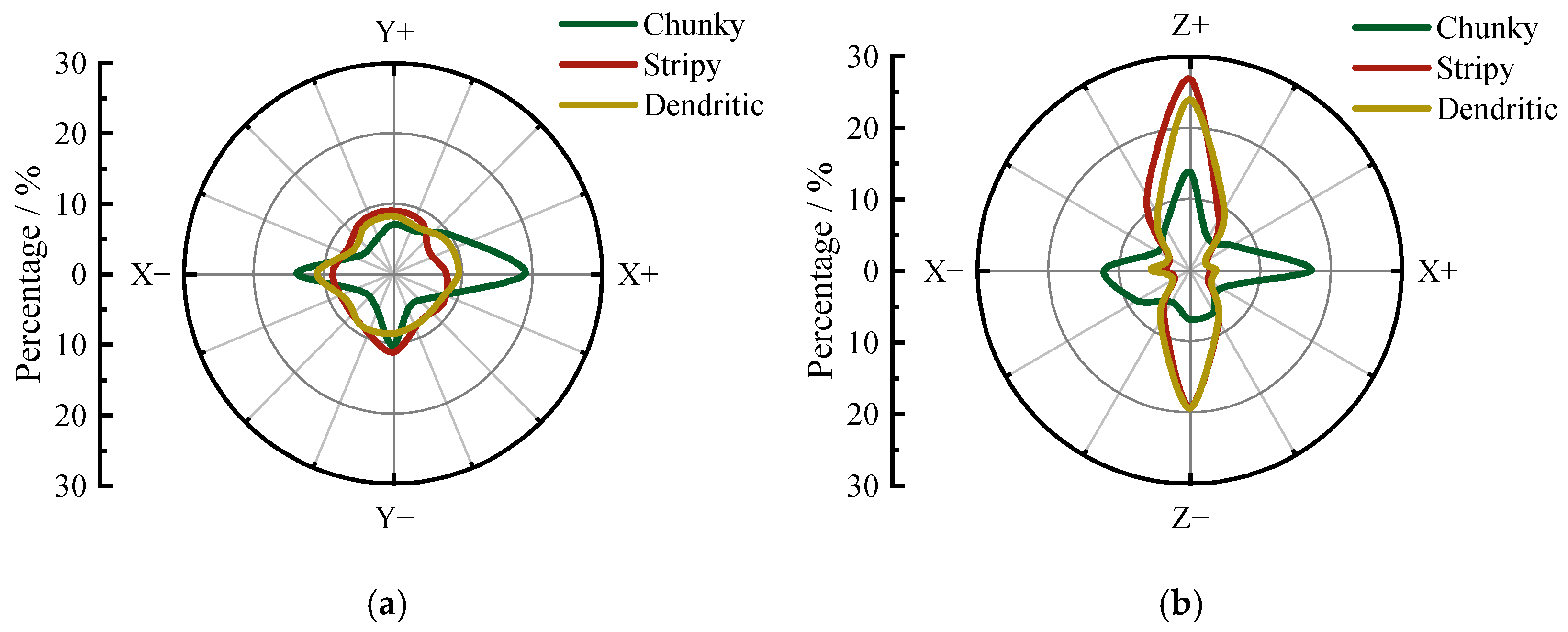

4.2. The Internal Anisotropic Characteristics of Calcareous Sand Induced by Particle Shapes

4.2.1. Magnitude of Contact Force

4.2.2. Direction of Contact Force

5. Discussion

5.1. Factors Influencing the Anisotropy of Calcareous Sand

5.1.1. Particle Shape

5.1.2. Confining Pressure

5.1.3. Particle Breakage

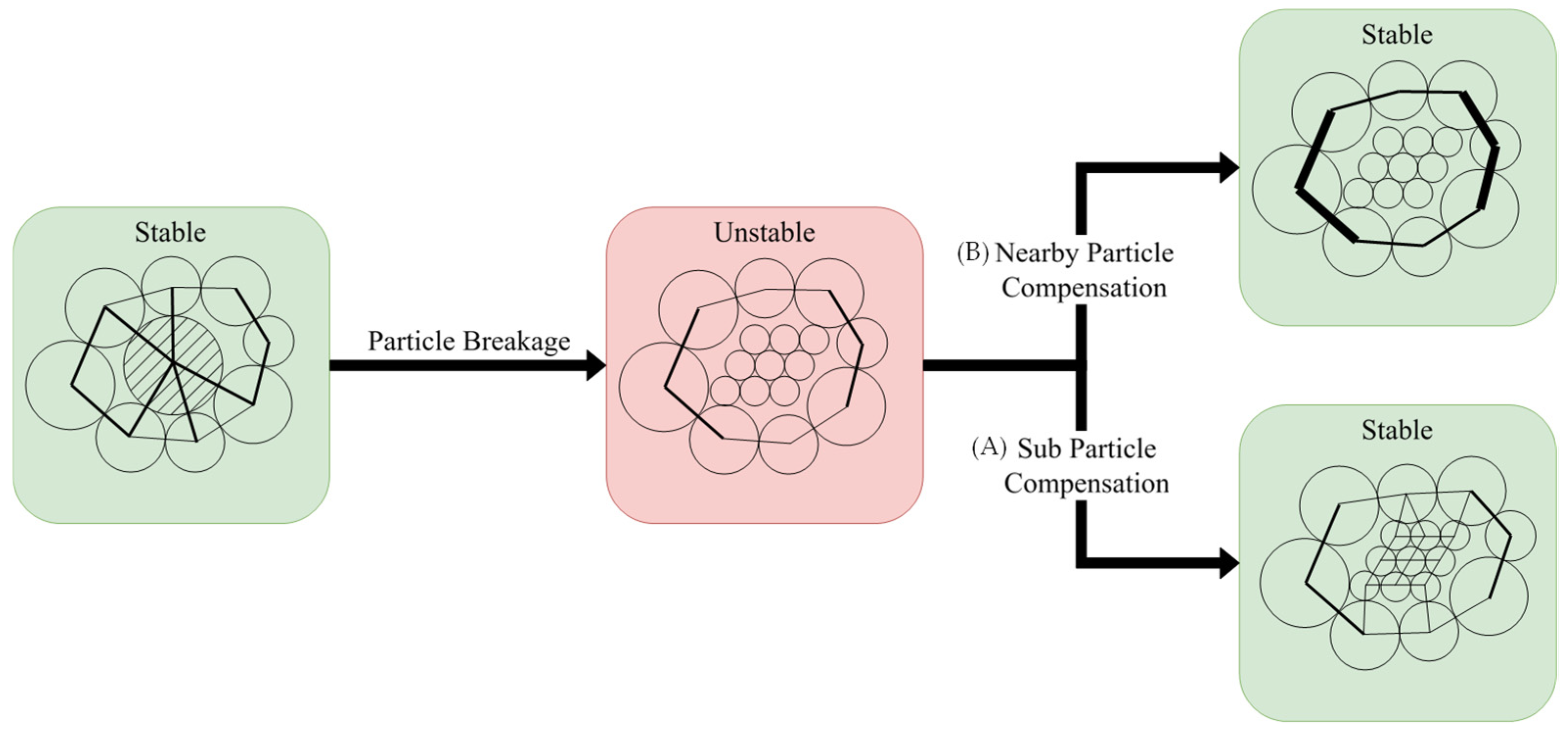

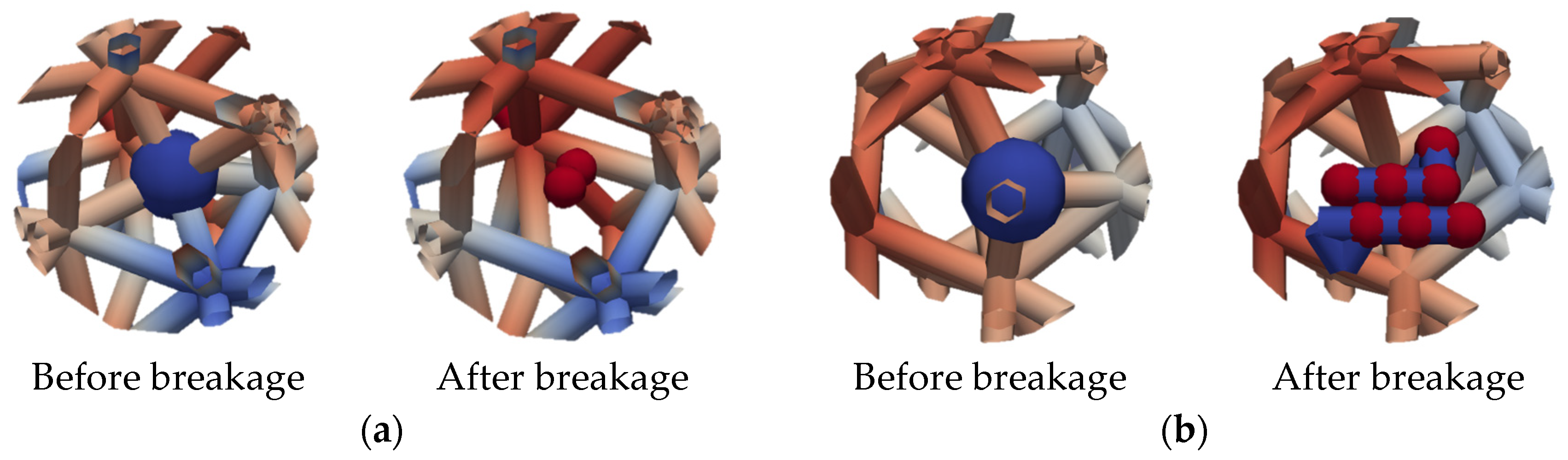

5.2. Increased Contact Forces Within the Strong + Range

6. Conclusions

- The irregular particle shape is the fundamental cause of stiffness anisotropy in calcareous sand under isotropic compression. Under gravitational deposition, stripy and dendritic calcareous sand particles exhibit directional alignment, resulting in significant spatial anisotropy in the distribution of interparticle contact normal. This leads to pronounced anisotropy in shear modulus, with the horizontal shear modulus being greater than the vertical shear modulus. The contact directions of stripy and dendritic particles exhibit a spindle-shaped distribution, with strong contact forces concentrated in the vertical direction. The dominant contact direction aligns closely with the gravitational deposition direction, confirming that the geometric arrangement of particles is the structural origin of anisotropy.

- As the confining pressure increases, the shear modulus of calcareous sand increases, while the stiffness anisotropy induced by irregular particle shapes decreases. However, the degree of anisotropy varies for different particle shapes. Notably, dendritic calcareous sand undergoes a polarity reversal in anisotropy at high confining pressures, transitioning from a larger horizontal shear modulus to a larger vertical shear modulus. Confining pressure exerts a dual effect on the degree of anisotropy. On one hand, it increases the coordination number of particles, enhancing interlocking and overall stiffness; on the other hand, it increases the rolling resistance around the vertical axis. The polarity reversal in dendritic particles at confining pressures above 200 kPa arises from the pronounced vertical interlocking provided by their multi-branch structure under high pressure, causing the vertical shear stiffness to exceed the horizontal shear stiffness and resulting in a 90° shift in the dominant contact direction.

- Particle breakage reduces both the shear modulus and the degree of anisotropy in calcareous sand. At high confining pressures, particle breakage significantly weakens structural integrity by disrupting existing strong contact forces, thereby reducing overall shear stiffness. Additionally, due to the spatial anisotropy of contact normals, particle breakage predominantly disrupts strong contact forces in the vertical direction, leading to stress redistribution. This process homogenizes the distribution of contact normal, which in turn reduces the stiffness of anisotropy.

- After particle breakage, the original system of strong contact forces is disrupted, and stress redistribution compensates for the lost contact forces. Two compensation mechanisms are observed: sub-particle compensation, where broken sub-particles establish weak contacts with other particles, and surrounding particle compensation, where under isotropic confining pressure with minimal strain, the fragments fail to fill the voids and cannot bear the contact forces, leading to increased contact forces in the surrounding particles. The dominant surrounding particle compensation mechanism leads to an increase in microscopic strong+ contact forces, while strong− and weak+ contact forces decrease. This behavior is not limited to the calcareous sand examined in this study; it may also occur in other particle breakage systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.Z.; Jiao, Y.Y.; Wang, R.; Hu, M.J.; Meng, Q.S.; Tan, F.Y. Engineering characteristics of the calcareous sand in Nansha Islands, South China Sea. Eng. Geol. 2011, 120, 40–47. [Google Scholar] [CrossRef]

- Brandes, H.G. Simple Shear Behavior of Calcareous and Quartz Sands. Geotech. Geol. Eng. 2011, 29, 113–126. [Google Scholar] [CrossRef]

- Sharma, S.S.; Ismail, M.A. Monotonic and cyclic behavior of two calcareous soils of different origins. J. Geotech. Geoenvironmental Eng. 2006, 132, 1581–1591. [Google Scholar] [CrossRef]

- He, S.H.; Zhang, Q.F.; Ding, Z.; Xia, T.D.; Gan, X.L. Experimental and Estimation Studies of Resilient Modulus of Marine Coral Sand under Cyclic Loading. J. Mar. Sci. Eng. 2020, 8, 287. [Google Scholar] [CrossRef]

- Salem, M.; Elmamlouk, H.; Agaiby, S. Static and cyclic behavior of North Coast calcareous sand in Egypt. Soil Dyn. Earthq. Eng. 2013, 55, 83–91. [Google Scholar] [CrossRef]

- Rui, S.; Wang, L.; Guo, Z.; Cheng, X.; Wu, B. Monotonic behavior of interface shear between carbonate sands and steel. Acta Geotech. 2021, 16, 167–187. [Google Scholar] [CrossRef]

- Hu, C.; Long, Z.L.; Kuang, D.M.; Gong, Z.M.; Yu, P.Y.; Xu, G.B. Approach to 3D reconstruction of calcareous sand using 2D images of multi-view. Rock Soil Mech. 2022, 43, 761–768. [Google Scholar] [CrossRef]

- Wang, Z.B.; Sun, G.; Liu, J.M.; Zou, Y.S.; Yu, J.T. Structural Characteristics and Correlation Analysis of Calcareous Sand Based on 3D Reconstruction. Sci. Technol. Eng. 2022, 22, 4090–4097. [Google Scholar]

- Li, X.; Lv, Y.; Su, Y.; Zou, K.; Wang, Y.; Huang, W. Coupling effects of morphology and inner pore distribution on the mechanical response of calcareous sand particles. J. Rock Mech. Geotech. Eng. 2023, 15, 1565–1579. [Google Scholar] [CrossRef]

- Li, P.; Chai, S. Test on Lateral Earth Pressure Coefficient of Coral Sand with Some Shapes and Contents. J. Tianjin Chengjian Univ. 2020, 26, 404–408. [Google Scholar] [CrossRef]

- Rui, S.; Guo, Z.; Si, T.; Li, Y. Effect of particle shape on the liquefaction resistance of calcareous sands. Soil Dyn. Earthq. Eng. 2020, 137, 106302. [Google Scholar] [CrossRef]

- Wu, Y.; Li, N.; Wang, X.; Cui, J.; Chen, Y.; Wu, Y.; Yamamoto, H. Experimental investigation on mechanical behavior and particle crushing of calcareous sand retrieved from South China Sea. Eng. Geol. 2021, 280, 105932. [Google Scholar] [CrossRef]

- Cheng, Z.; Hou, M.; Wang, J. Discrete element simulation study on mechanical behavior of cemented calcareous sand considering particle shape and breakage. Chin. J. Comput. Mech. 2022, 39, 315–323. [Google Scholar]

- Hu, J.; Wu, H.; Gu, X.; Zhou, Q. Particle shape effects on dynamic properties of granular soils: A DEM study. Comput. Geotech. 2023, 161, 105578. [Google Scholar] [CrossRef]

- Liu, F.; Tang, H.; Shahin, M.A.; Zhao, H.; Karrech, A.; Zhu, F.; Zhou, H. Multiscale simulation study for mechanical characteristics of coral sand influenced by particle breakage. Powder Technol. 2025, 449, 120387. [Google Scholar] [CrossRef]

- Shi, J.; Haegeman, W.; Cnudde, V. Anisotropic small-strain stiffness of calcareous sand affected by sample preparation, particle characteristic and gradation. Géotechnique 2021, 71, 305–319. [Google Scholar] [CrossRef]

- Gao, Y.; Sun, K.; Yuan, Q.; Shi, T. Stiffness Anisotropy and Micro-Mechanism of Calcareous Sand with Different Particle Breakage Ratios Subjected to Shearing Based on DEM Simulations. J. Mar. Sci. Eng. 2024, 12, 702. [Google Scholar] [CrossRef]

- Varadarajan, A.; Sharma, K.G.; Venkatachalam, K.; Gupta, A.K. Testing and modeling two rockfill materials. J. Geotech. Geoenviron. Eng. 2003, 129, 206–218. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Ding, X.; Chen, Y.; Jiang, J.; Zhang, W. Influence of Particle Breakage on Critical State Line of Rockfill Material. Int. J. Geomech. 2016, 16, 04015031. [Google Scholar] [CrossRef]

- Konrad, J.M.; Salami, Y. Particle breakage in granular materials—A conceptual framework. Can. Geotech. J. 2018, 55, 710–719. [Google Scholar] [CrossRef]

- Lade, P.V.; Yamamuro, J.A.; Bopp, P.A. Significance of particle crushing in granular materials. J. Geotech. Eng. 1996, 122, 309–316. [Google Scholar] [CrossRef]

- Wang, Y.; Santosh, M.; Luo, Z.; Hao, J. Large igneous provinces linked to supercontinent assembly. J. Geodyn. 2015, 85, 1–10. [Google Scholar] [CrossRef]

- Jia, Y.F.; Wang, B.S.; Chi, S.C. Particle breakage of rockfill during triaxial tests. Chinese J. Geotech. Eng. 2015, 37, 1692–1697. [Google Scholar] [CrossRef]

- Yu, F. Characteristics of particle breakage of sand in triaxial shear. Powder Technol. 2017, 320, 656–667. [Google Scholar] [CrossRef]

- Liu, S.; Mao, H.; Wang, Y.; Weng, L. Experimental study on crushable coarse granular materials during monotonic simple shear tests. Geomech. Eng. 2018, 15, 687–694. [Google Scholar] [CrossRef]

- Wu, Y.; Tahmasebi, P.; Lin, C.; Zahid, M.A.; Dong, C.; Golab, A.N.; Ren, L. A comprehensive study on geometric, topological and fractal characterizations of pore systems in low-permeability reservoirs based on SEM, MICP, NMR, and X-ray CT experiments. Mar. Pet. Geol. 2019, 103, 12–28. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Wang, G.; Yang, J.J.; Wang, Z.N. Evolution of critical state of calcareous sand during particle breakage. Chin. J. Geotech. Eng. 2021, 43, 1511–1517. [Google Scholar]

- Ueda, T.; Matsushima, T.; Yamada, Y. DEM simulation on the one-dimensional compression behavior of various shaped crushable granular materials. Granul. Matter 2013, 15, 675–684. [Google Scholar] [CrossRef]

- McDowell, G.R.; Harireche, O. Discrete element modelling of soil particle fracture. Geotech. 2002, 52, 131–135. [Google Scholar] [CrossRef]

- Smilauer, V.; Angelidakis, V.; Catalano, E.; Caulk, R.; Chareyre, B.; Chevremont, W.; Yuan, C. Yade Documentation. arXiv 2023, arXiv:2301.00611. [Google Scholar] [CrossRef]

- Jin, G.; Zhou, Z.; Liu, Y.; Gao, C.; Ma, H.; Yang, Z.; Jing, Y.; Tu, H. A novel coarse-grained discrete element method for simulating failure process of strongly bonded particle materials. Powder Technol. 2025, 464, 121212. [Google Scholar] [CrossRef]

- Gladkyy, A.; Kuna, M. DEM simulation of polyhedral particle cracking using a combined Mohr–Coulomb–Weibull failure criterion. Granul. Matter 2017, 19, 41. [Google Scholar] [CrossRef]

- Brzeziński, K.; Gladky, A. Clump breakage algorithm for DEM simulation of crushable aggregates. Tribol. Int. 2022, 173, 107661. [Google Scholar] [CrossRef]

- Gao, Y.; Shi, T.; Yuan, Q.; Sun, K. The creep characteristics and related evolution of particle morphology for calcareous sand. Powder Technol. 2024, 431, 119077. [Google Scholar] [CrossRef]

- Stokoe, K.; Lee, S.; Knox, D.P. Shear Moduli Measurements under True Triaxial Stresses. In Proceedings of the Advances in the Art of Testing Soils Under Cyclic Conditions: Proceedings of a Session/Sponsored by the Geotechnical Engineering Division in Conjunction with the ASCE Convention, Detroit, MI, USA, 24 October 1985; ASCE: Reston, VA, USA, 1985. [Google Scholar]

- STOKOE, K.H.I.; Hwang, S.K.; Lee, J.K.; Andrus, R.D. Effects of various parameters on the stiffness and damping of soils at small to medium strains. In Proceedings of the Pre-Failure Deformation of Geomaterials: Proceedings of the International Symposium on Pre-Failure Deformation Characteristics of Geomaterials, Sapporo, Japan, 12–14 September 1994; CRC Press: Boca Raton, FL, USA, 1994; pp. 785–816. [Google Scholar]

- Stokoe, K.H.I.; Lee, J.N.K.; Lee, S.H.H. Characterization of soil in calibration chambers with seismic waves. In Proceedings of the Calibration Chamber Testing: Proceedings of the First International Symposium on Calibration Chamber Testing/ISOCCT1, Potsdam, NY, USA, 28–29 June 1991; pp. 363–376. [Google Scholar]

- Ismail, M.; Sharma, S.; Fahey, M. A Small True Triaxial Apparatus with Wave Velocity Measurement. Geotech. Test. J. 2005, 28, 113–122. [Google Scholar] [CrossRef]

- Chaney, R.; Demars, K.; Fioravante, V.; Capoferri, R. On the Use of Multi-directional Piezoelectric Transducers in Triaxial Testing. Geotech. Test. J. 2001, 24, 243. [Google Scholar] [CrossRef]

- Satake, M. Fabric tensor in granular materials. In Proceedings of the Deformation and Failure of Granular Materials, Delft, The Netherlands, 31 August–3 September 1982; IUTAM Symposium: Delft, The Netherlands, 1982; pp. 63–68. [Google Scholar]

- Hardin, B.O. Crushing of Soil Particles. J. Geotech. Eng. 1985, 111, 1177–1192. [Google Scholar] [CrossRef]

- Thornton, C. Numerical simulations of deviatoric shear deformation of granular media. Geotechnique 2000, 50, 43–53. [Google Scholar] [CrossRef]

- Radjai, F.; Wolf, D.E.; Jean, M.; Moreau, J.J. Bimodal Character of Stress Transmission in Granular Packings. Phys. Rev. Lett. 1998, 80, 61–64. [Google Scholar] [CrossRef]

- Russell, A.R.; Wood, D.M. Point load tests and strength measurements for brittle spheres. Int. J. Rock Mech. Min. Sci. 2009, 46, 272–280. [Google Scholar] [CrossRef]

- Chen, Q.; Gao, Y.; Yuan, Q.; Yu, J.Y. Microstructural response during shearing process of dense sand. Water Resour. Hydropower Eng. 2021, 52, 178–187. [Google Scholar] [CrossRef]

- Sun, K.; Gao, Y. Particle Crushing and Anisotropy of Calcareous Sand During Triaxial Shearing. In Proceedings of the 2023 9th International Conference on Architectural, Civil and Hydraulic Engineering (ICACHE 2023), Online, 14 October 2023; Atlantis Press International BV: Dordrecht, The Netherlands, 2023; Volume 228, pp. 354–360. [Google Scholar] [CrossRef]

- Wu, D.; Guo, W.; Luo, F.; Li, M. Simulation experimental investigations on particle breakage mechanism and fractal characteristics of mixed size gangue backfill materials. J. Mater. Res. Technol. 2023, 24, 125–142. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, W.; Li, C.; Ma, L.; Shi, X.; Li, H.; Zhu, H. Randomly generating realistic calcareous sand for directional seepage simulation using deep convolutional generative adversarial networks. J. Rock Mech. Geotech. Eng. 2025, 17, 7297–7312. [Google Scholar] [CrossRef]

| Parameters | Values | ||||

|---|---|---|---|---|---|

| Particles | Number | 3000 | |||

| Effective radius | 0.24–0.48 mm | ||||

| Density | 2810 kg/m3 | ||||

| Young’s modulus | 800 MPa | ||||

| Poisson’s ratio | 0.3 | ||||

| Friction angle | Making sample: 0° Compression: 30° | ||||

| Degree of particle breakage | None | Low | Mid | High | |

| Particle breakage rate (800 kPa) | 0% | 1% | 5% | 10% | |

| Walls | Young’s modulus | 800 MPa | |||

| Poisson’s ratio | 0.3 | ||||

| Friction angle | Making sample: 0° | ||||

| Compression: 30° | |||||

| Chunky Shape | Stripy Shape | Dendritic Shape |

|---|---|---|

|  |  |

|  |  |

| None | Low | Mid | High | |

|---|---|---|---|---|

| Chunky particle | 0% | 1.00% | 4.84% | 9.98% |

| Stripy particle | 0% | 1.01% | 5.09% | 10.06% |

| Dendritic particle | 0% | 0.98% | 5.04% | 10.25% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Sun, K.; Yuan, Q.; Sun, L.; Tang, X. Particle Shape-Driven Stiffness Anisotropy in Calcareous Sand and the Underlying Mechanism. Appl. Sci. 2025, 15, 12682. https://doi.org/10.3390/app152312682

Gao Y, Sun K, Yuan Q, Sun L, Tang X. Particle Shape-Driven Stiffness Anisotropy in Calcareous Sand and the Underlying Mechanism. Applied Sciences. 2025; 15(23):12682. https://doi.org/10.3390/app152312682

Chicago/Turabian StyleGao, Yan, Ketian Sun, Quan Yuan, Le Sun, and Xudong Tang. 2025. "Particle Shape-Driven Stiffness Anisotropy in Calcareous Sand and the Underlying Mechanism" Applied Sciences 15, no. 23: 12682. https://doi.org/10.3390/app152312682

APA StyleGao, Y., Sun, K., Yuan, Q., Sun, L., & Tang, X. (2025). Particle Shape-Driven Stiffness Anisotropy in Calcareous Sand and the Underlying Mechanism. Applied Sciences, 15(23), 12682. https://doi.org/10.3390/app152312682