Synchronous Grouting Analysis of Shield Tunneling through High Water Pressure Fault Fracture Zone

Abstract

:1. Introduction

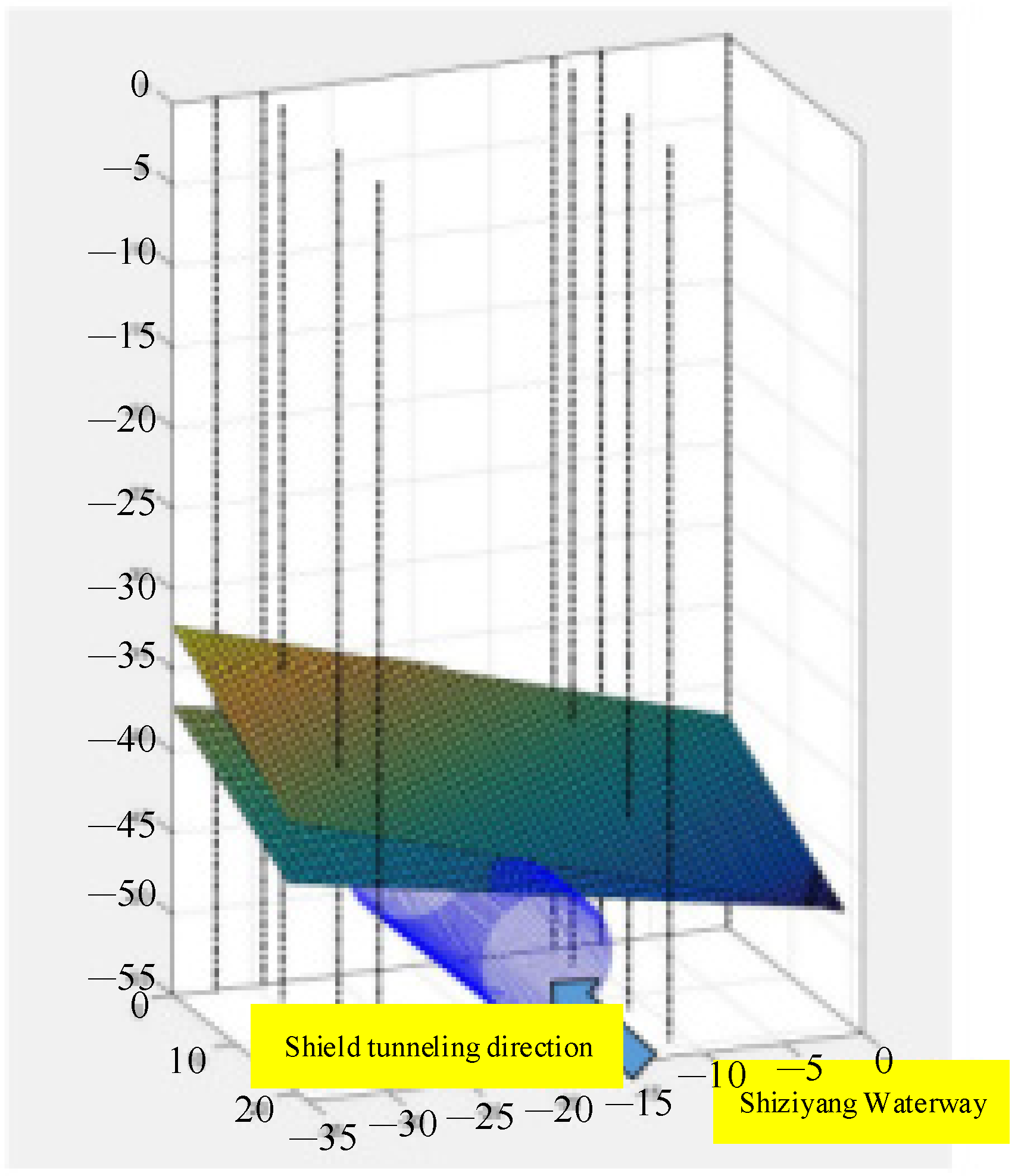

2. Fault Fracture Zone Model

2.1. Project Overview

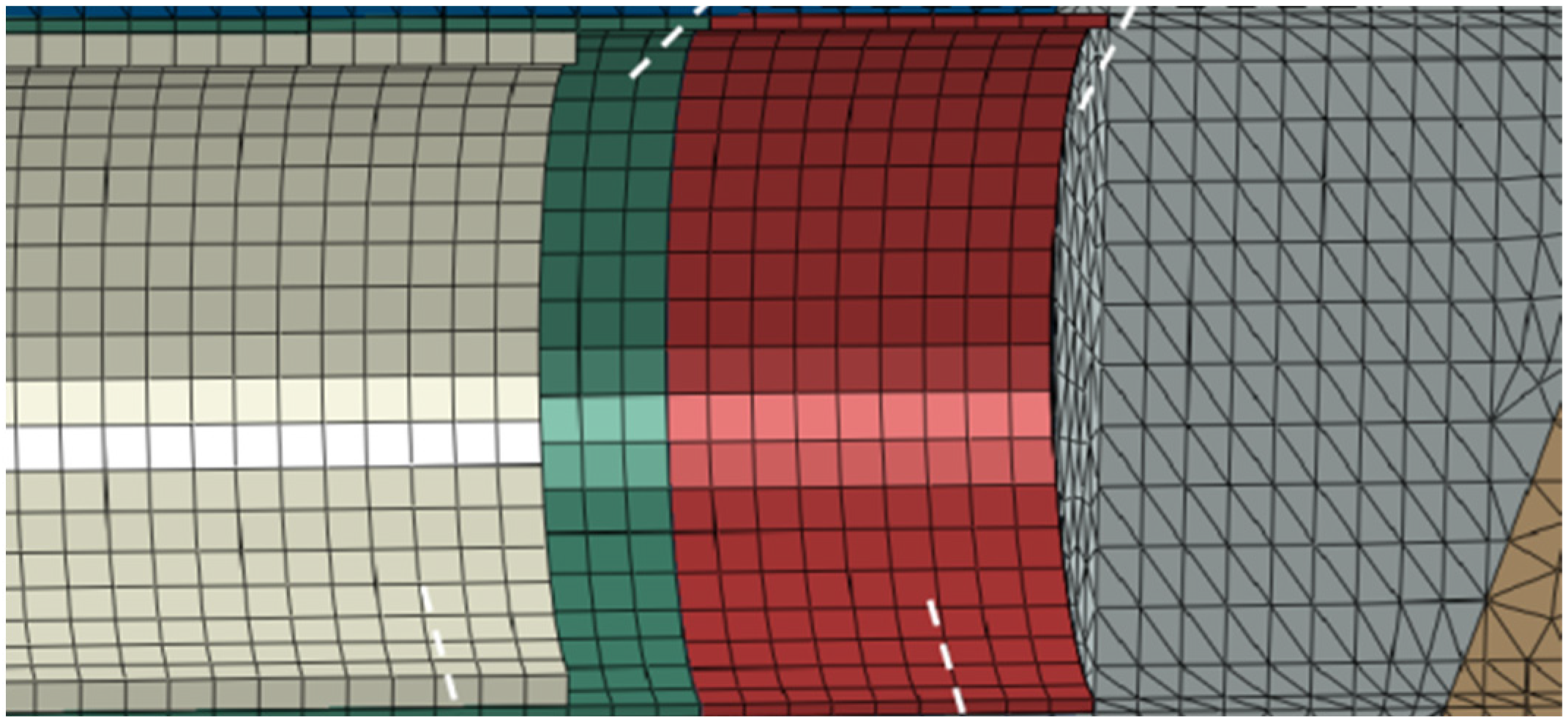

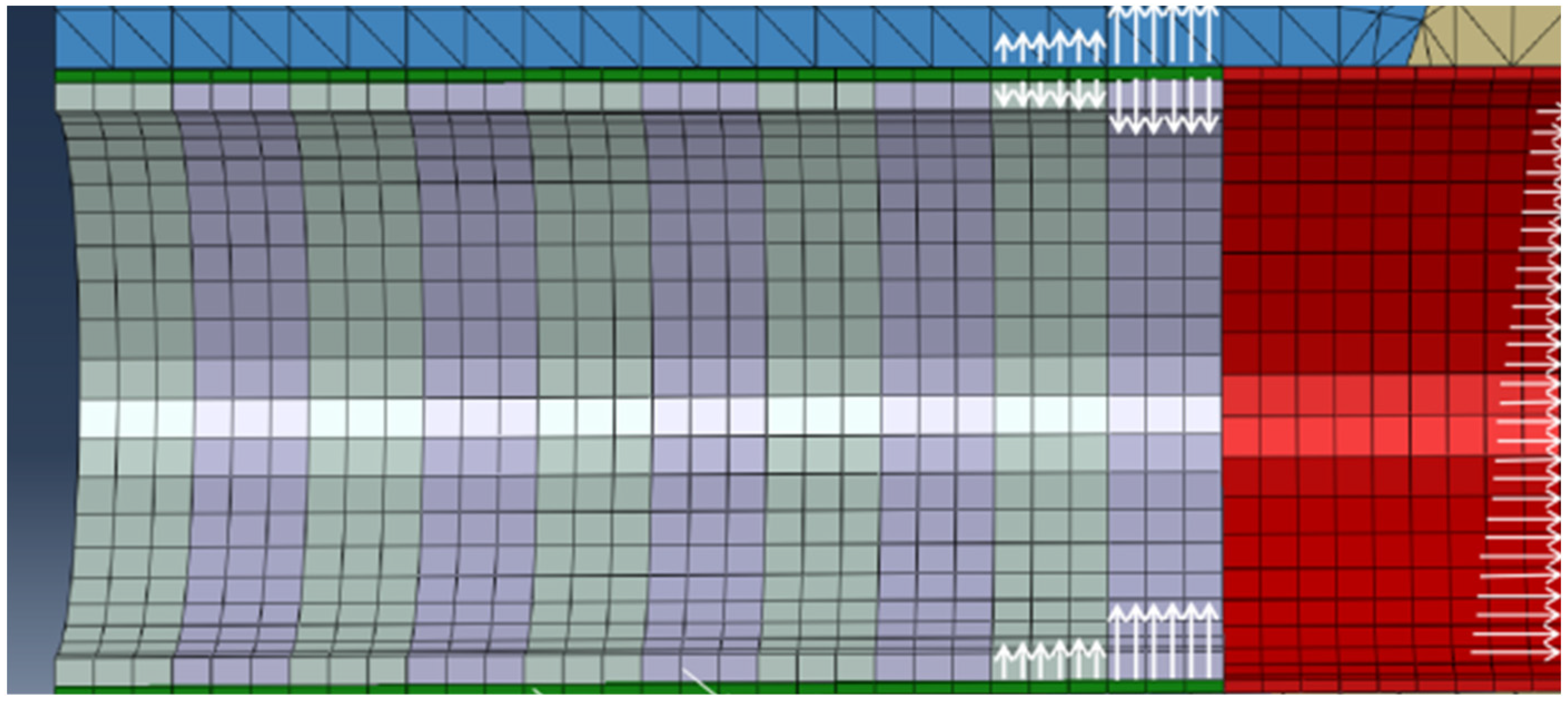

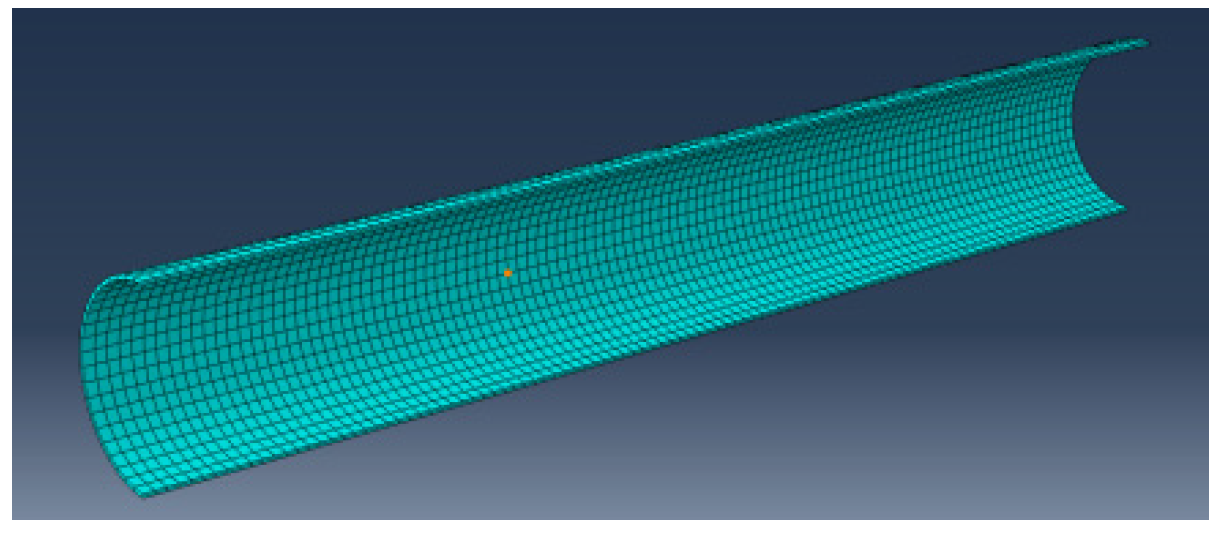

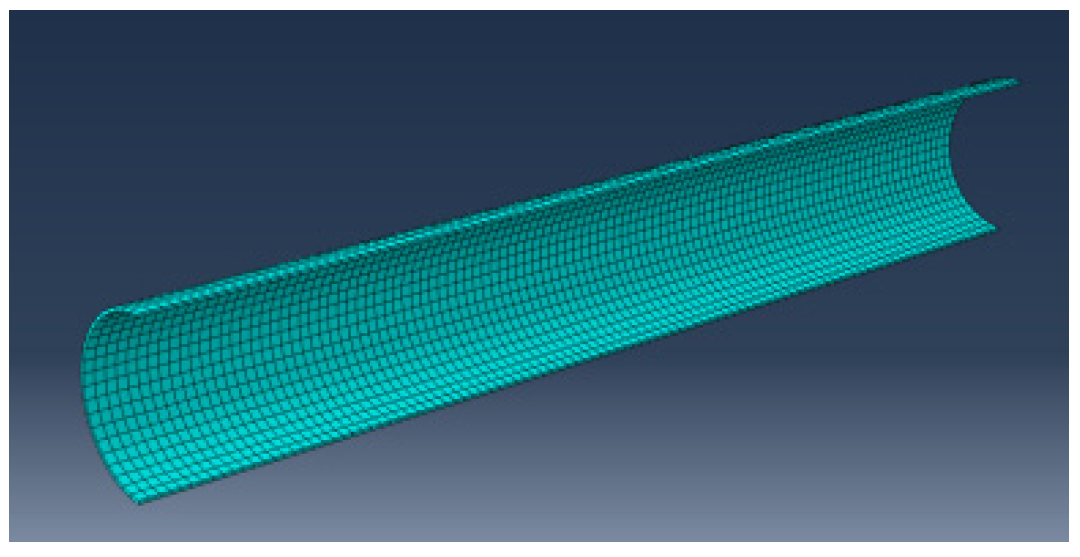

2.2. Establishment of Fault Fracture Zone Model

2.3. Model Parameter Selection

3. Analysis of Synchronous Grouting Results in Fault Fracture Zones

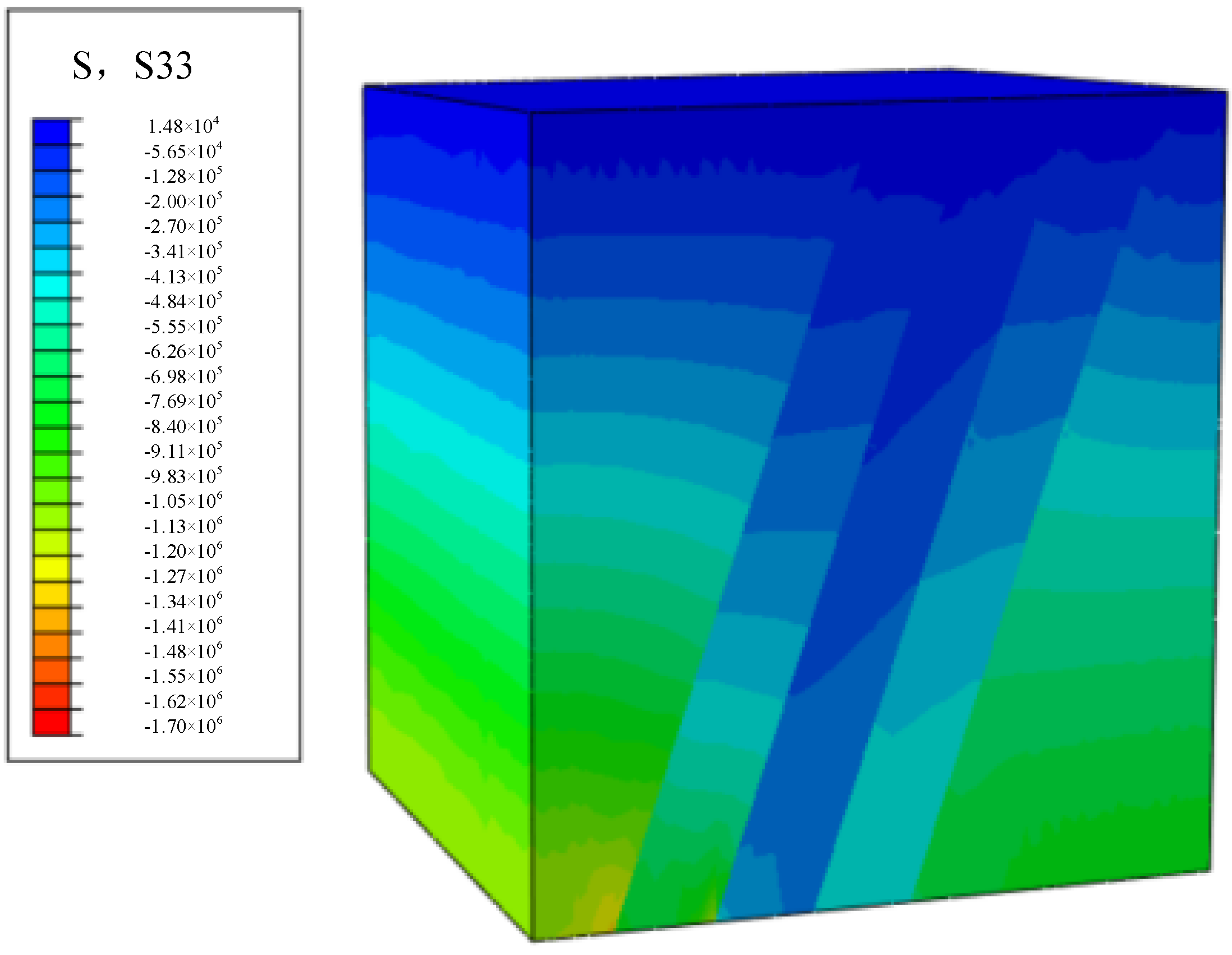

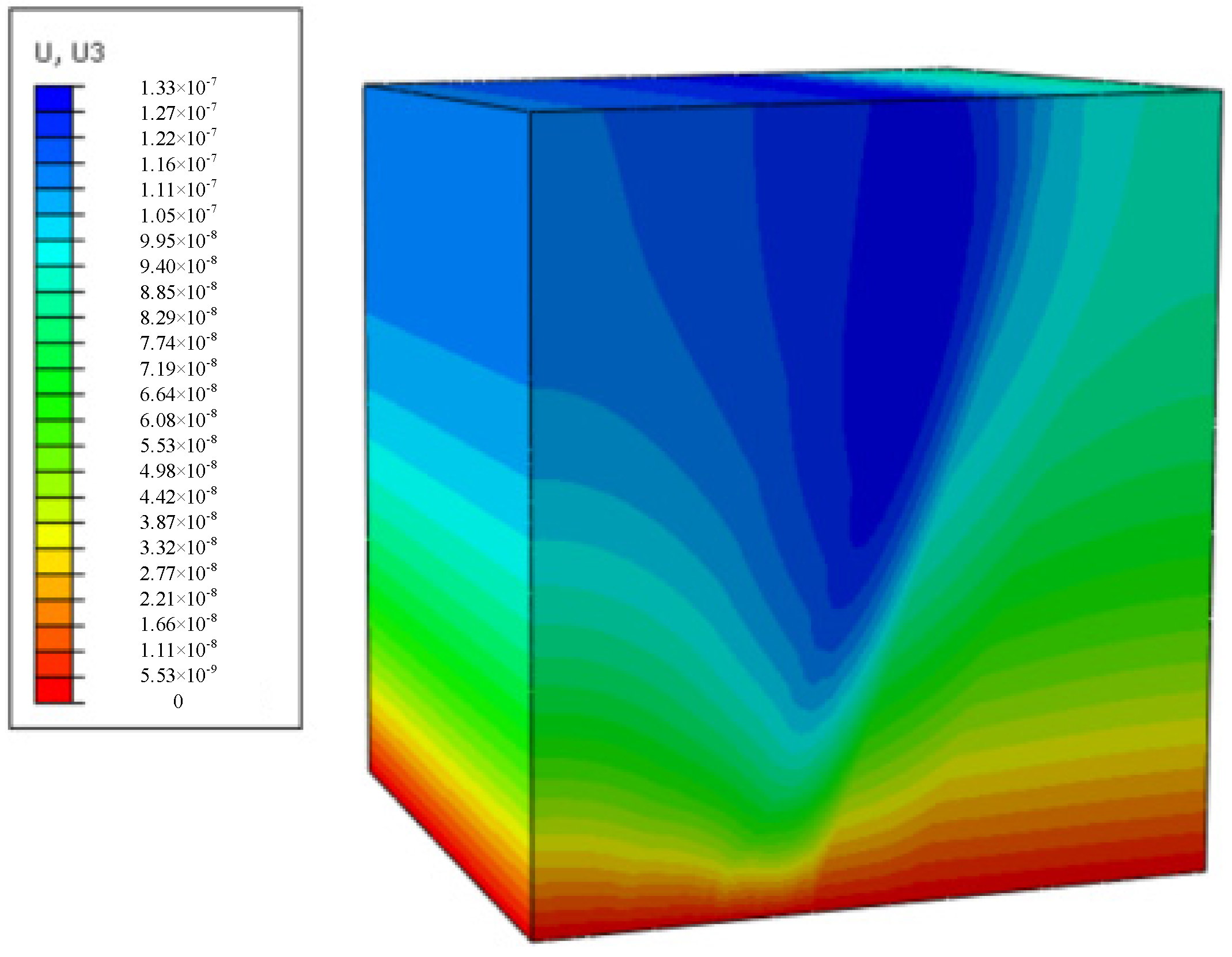

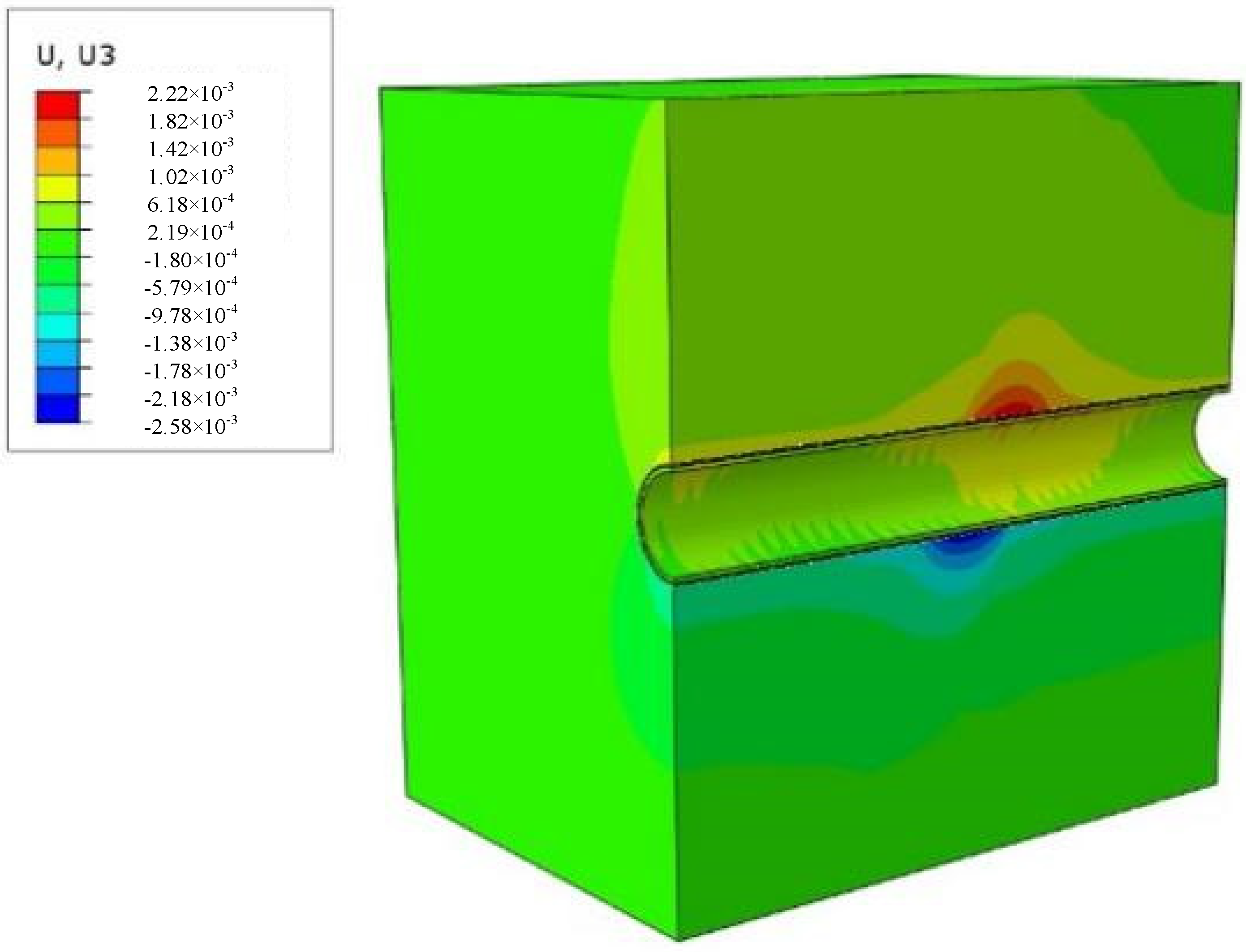

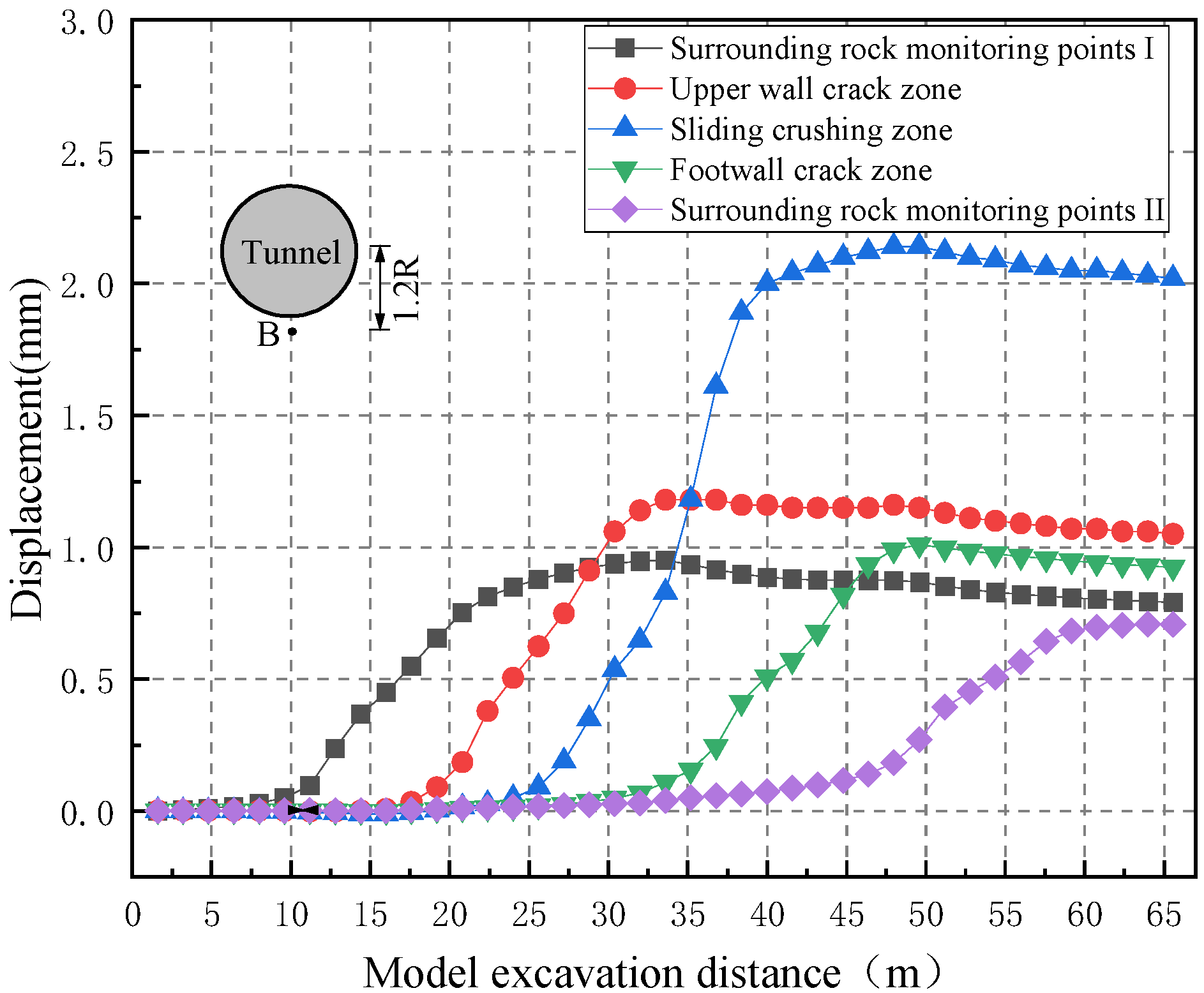

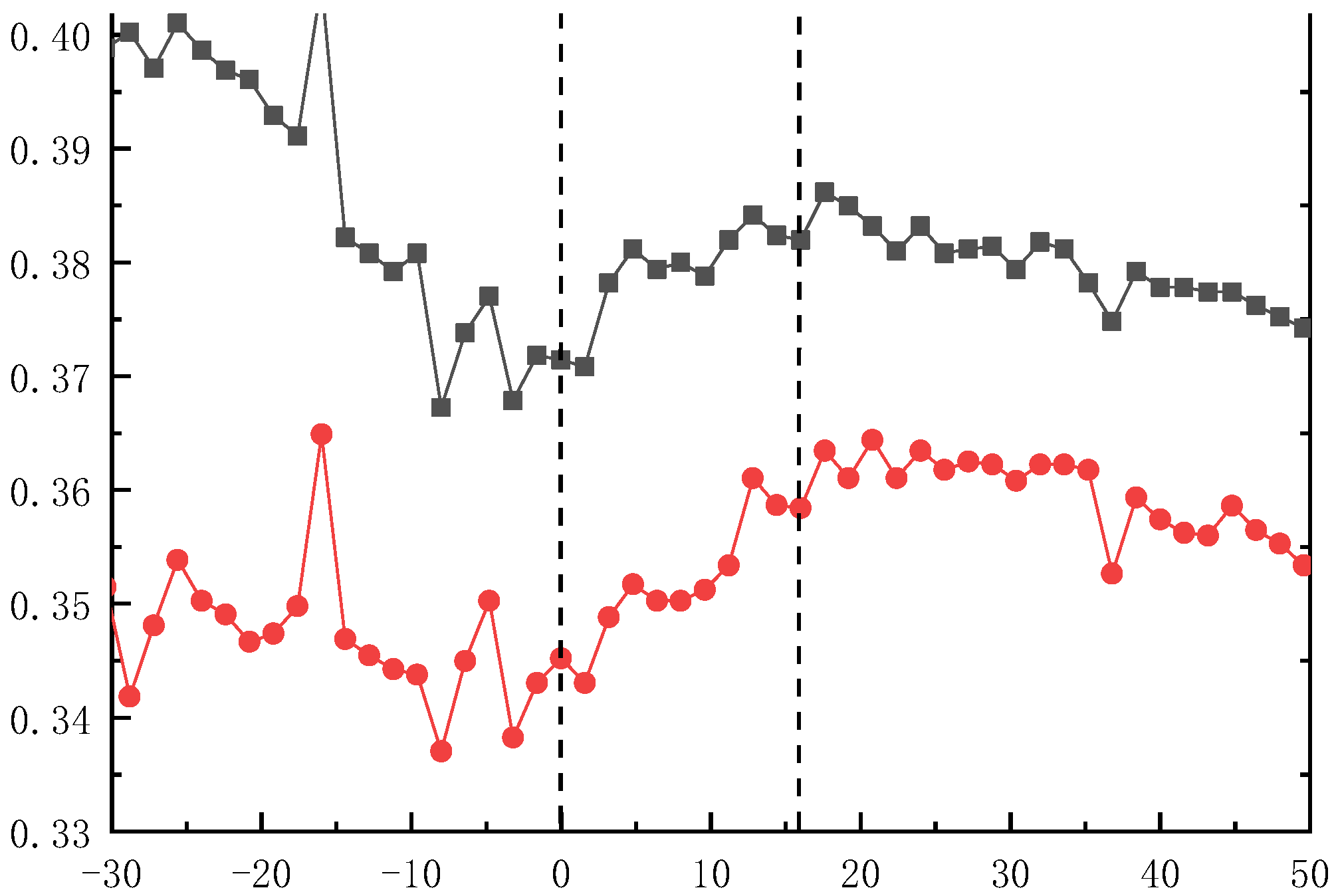

3.1. Analysis of Settlement and Deformation of Surrounding Rock

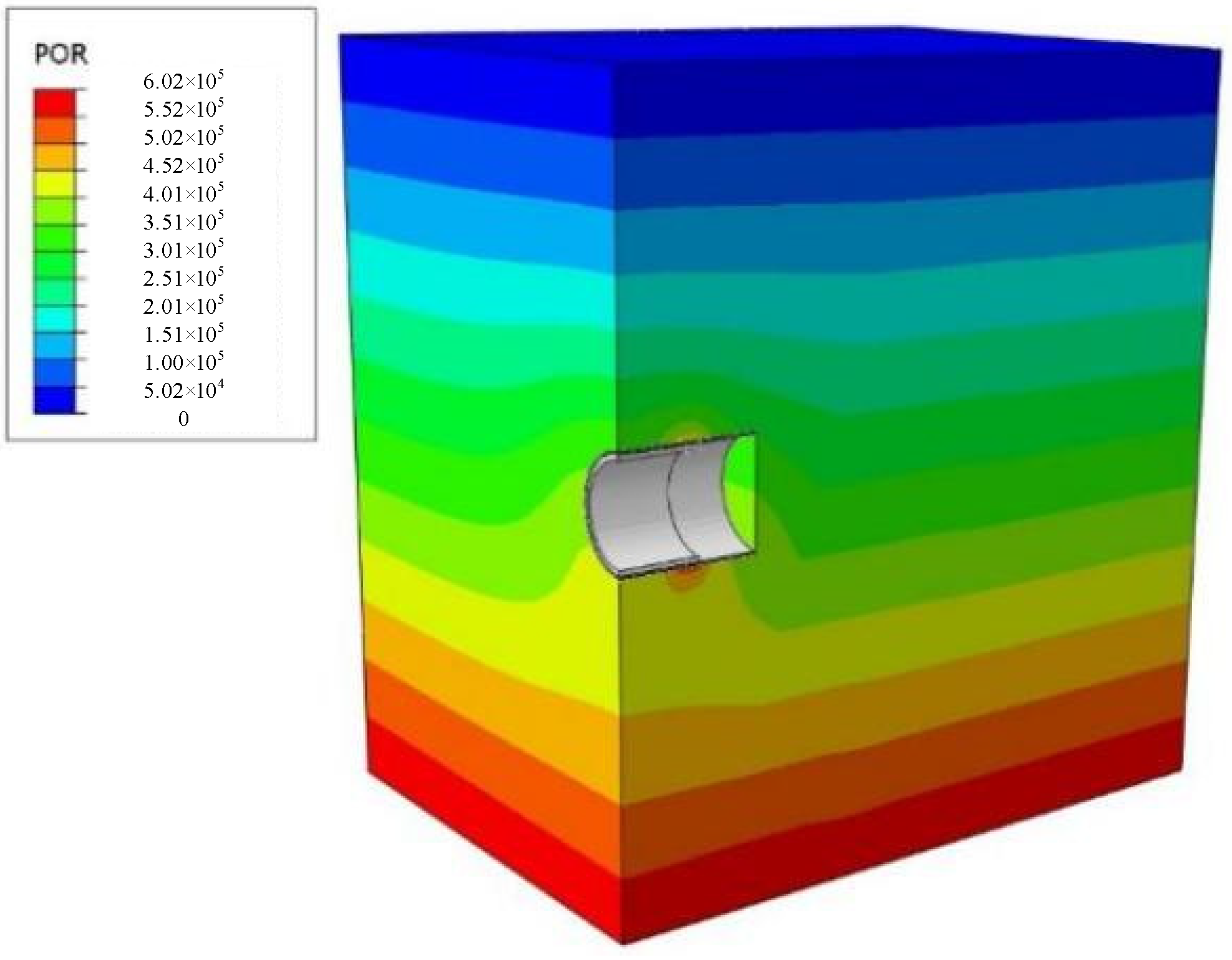

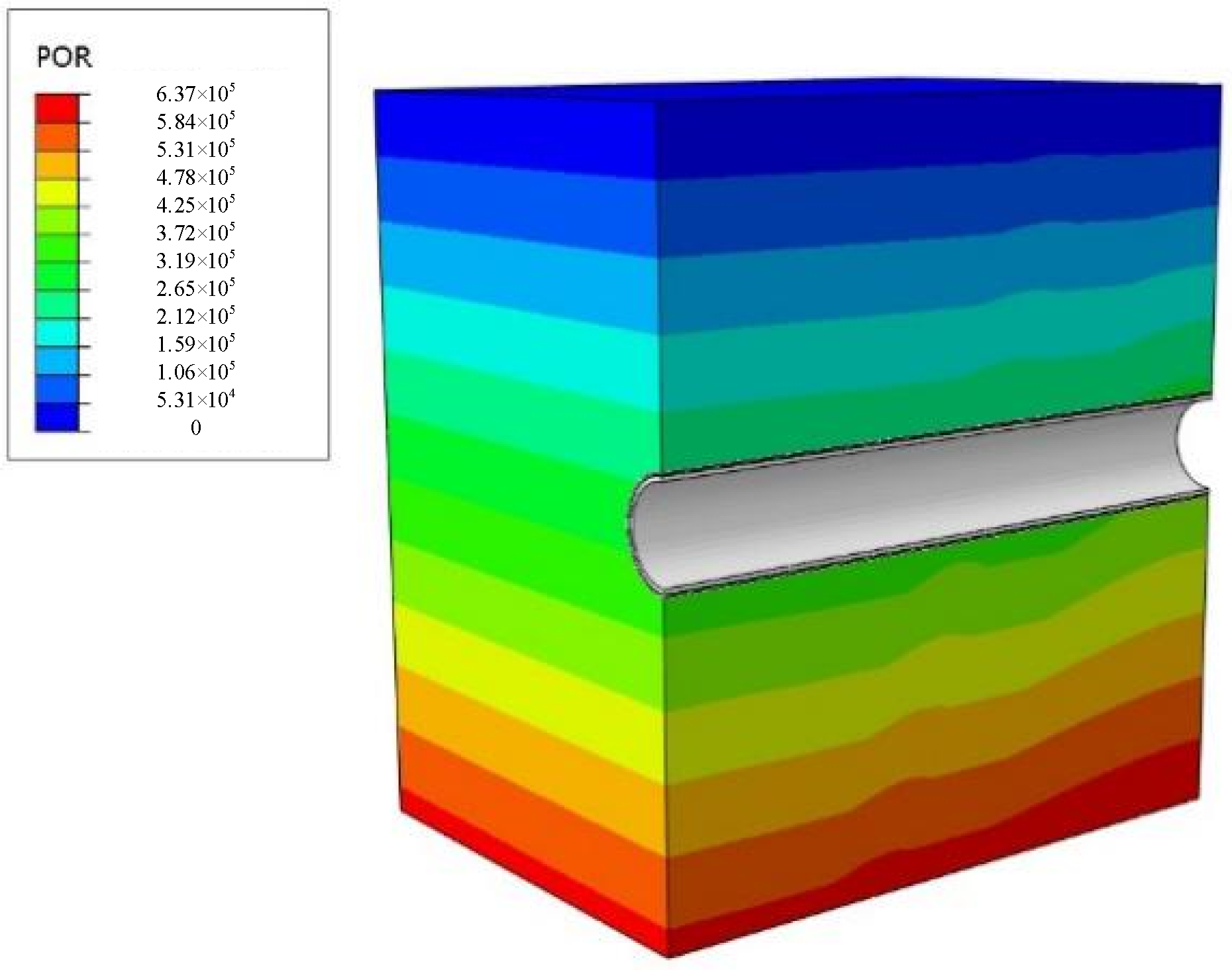

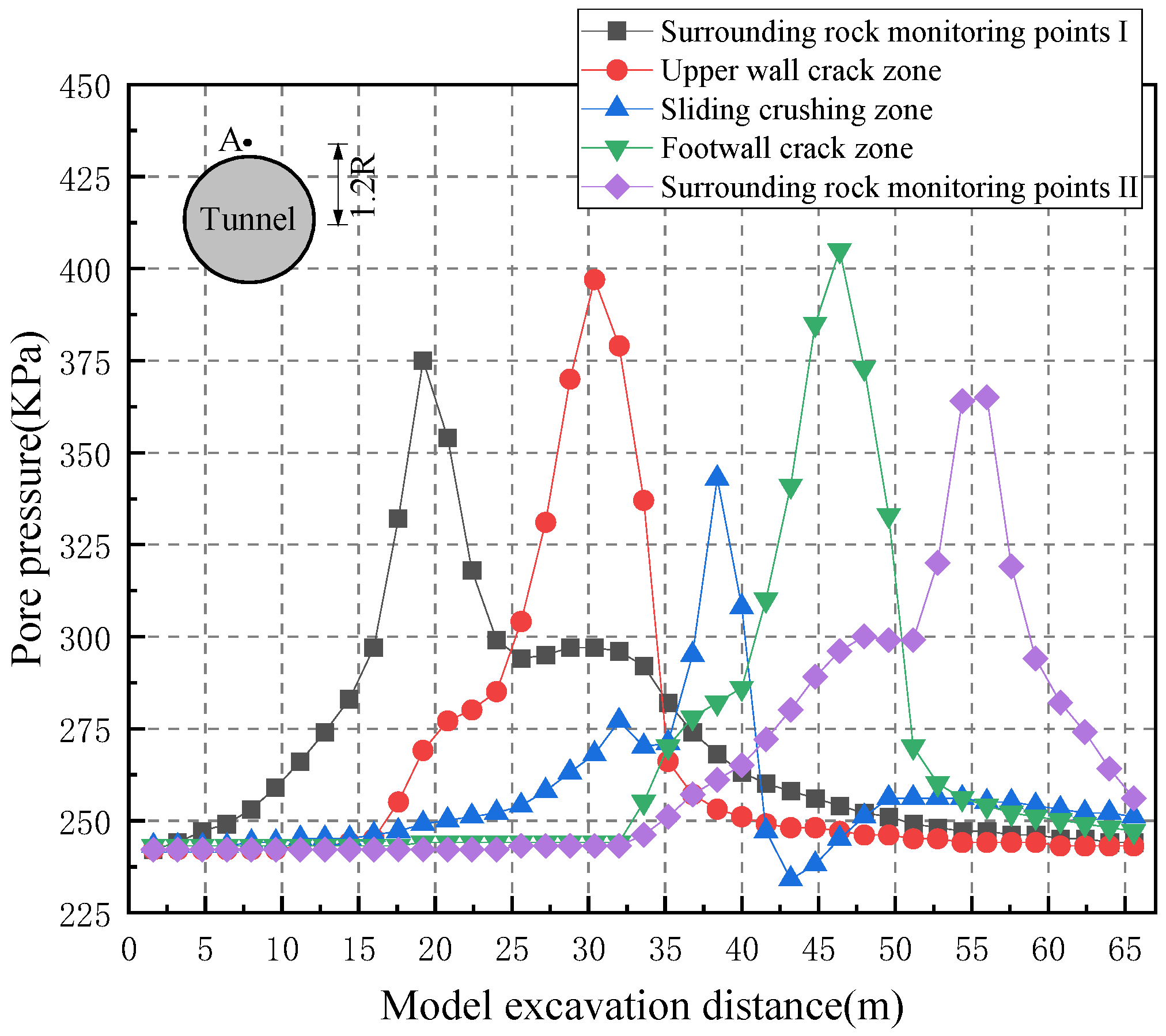

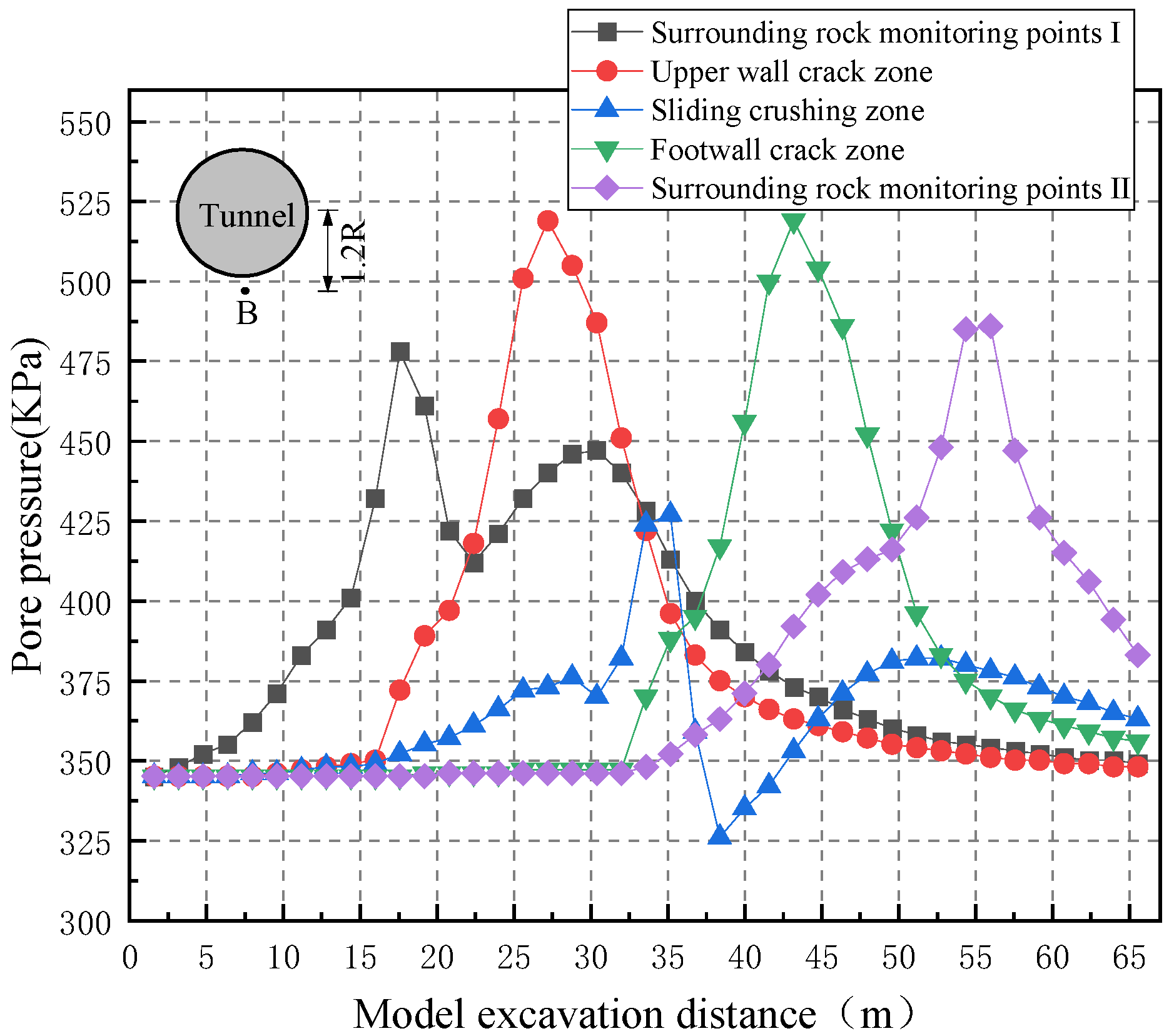

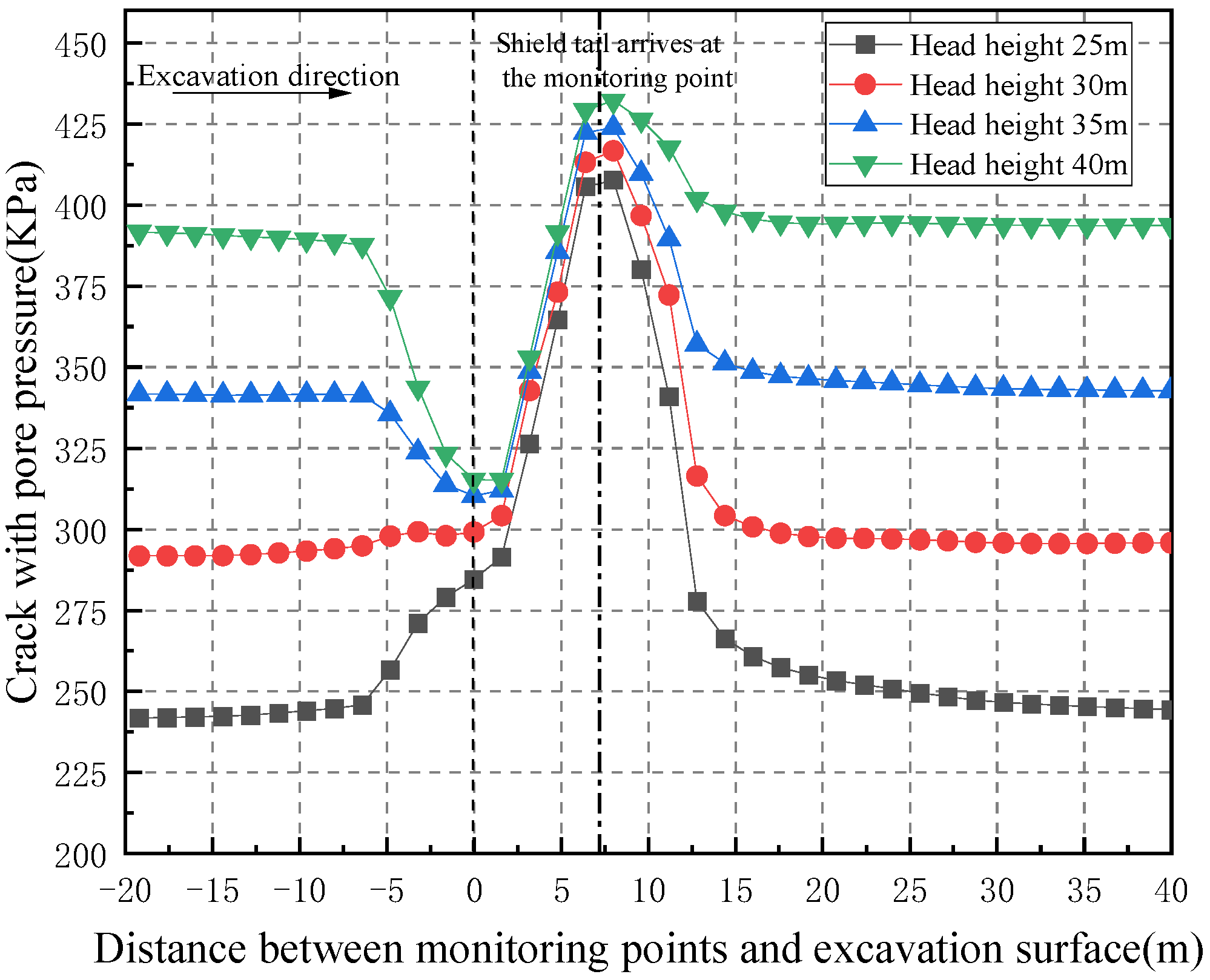

3.2. Analysis of Changes in Pore Water Pressure

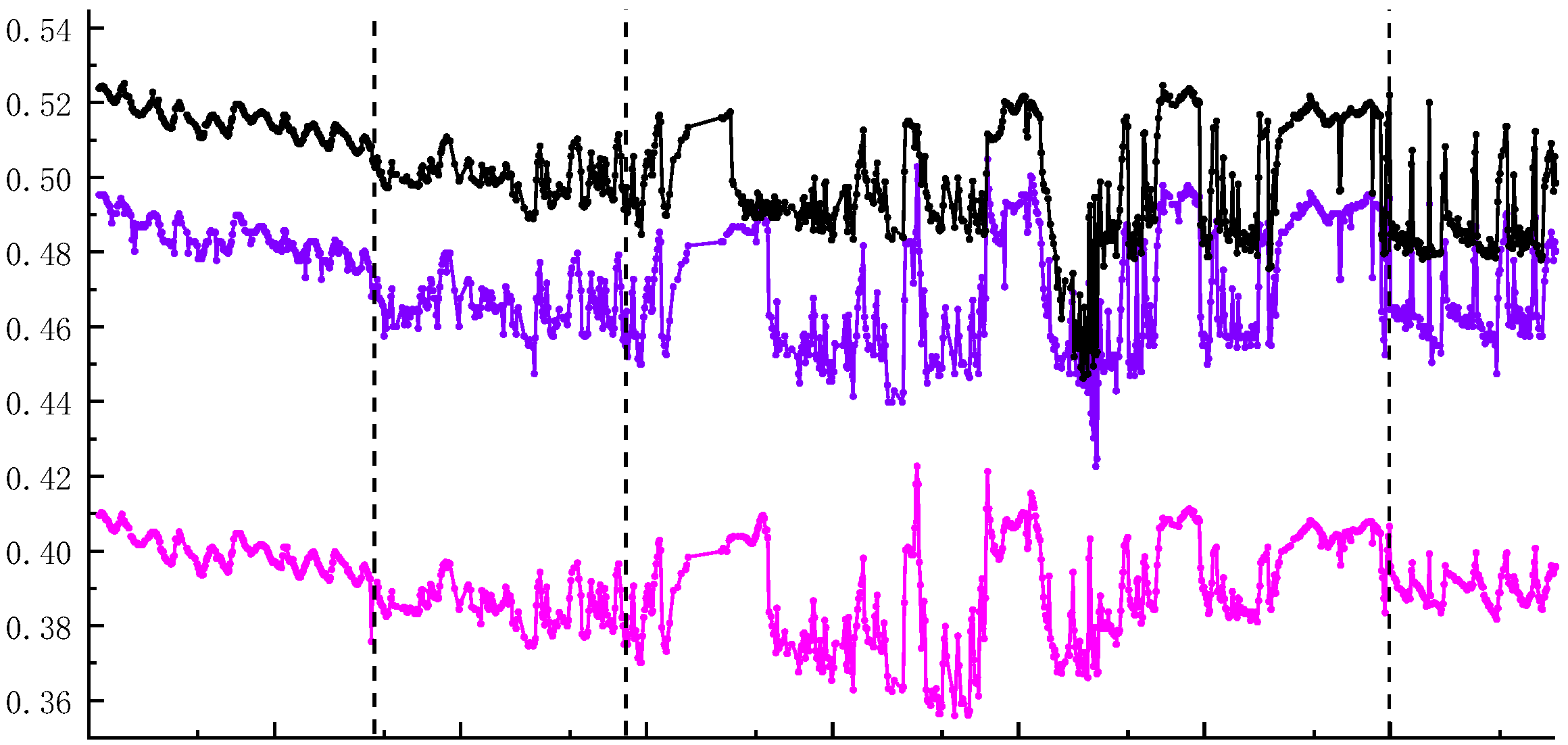

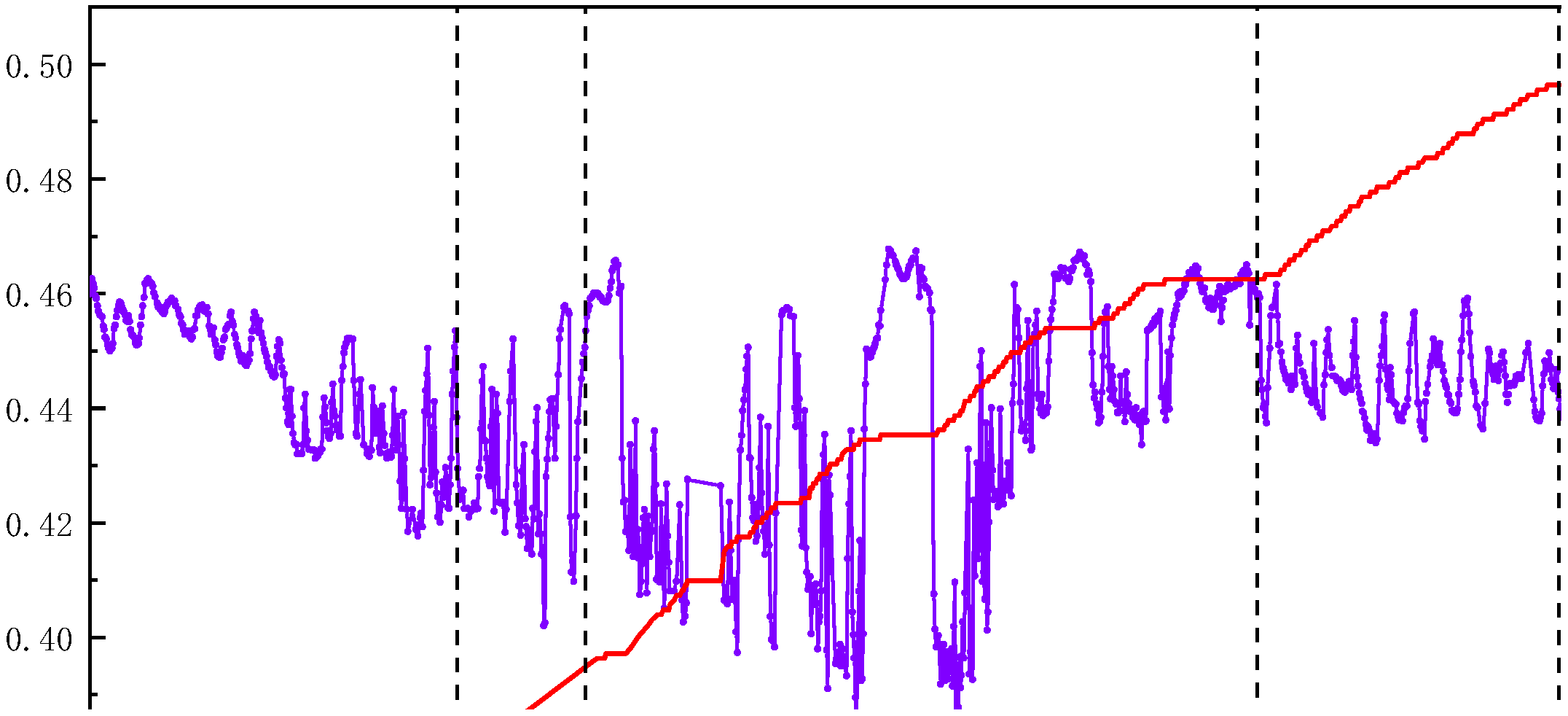

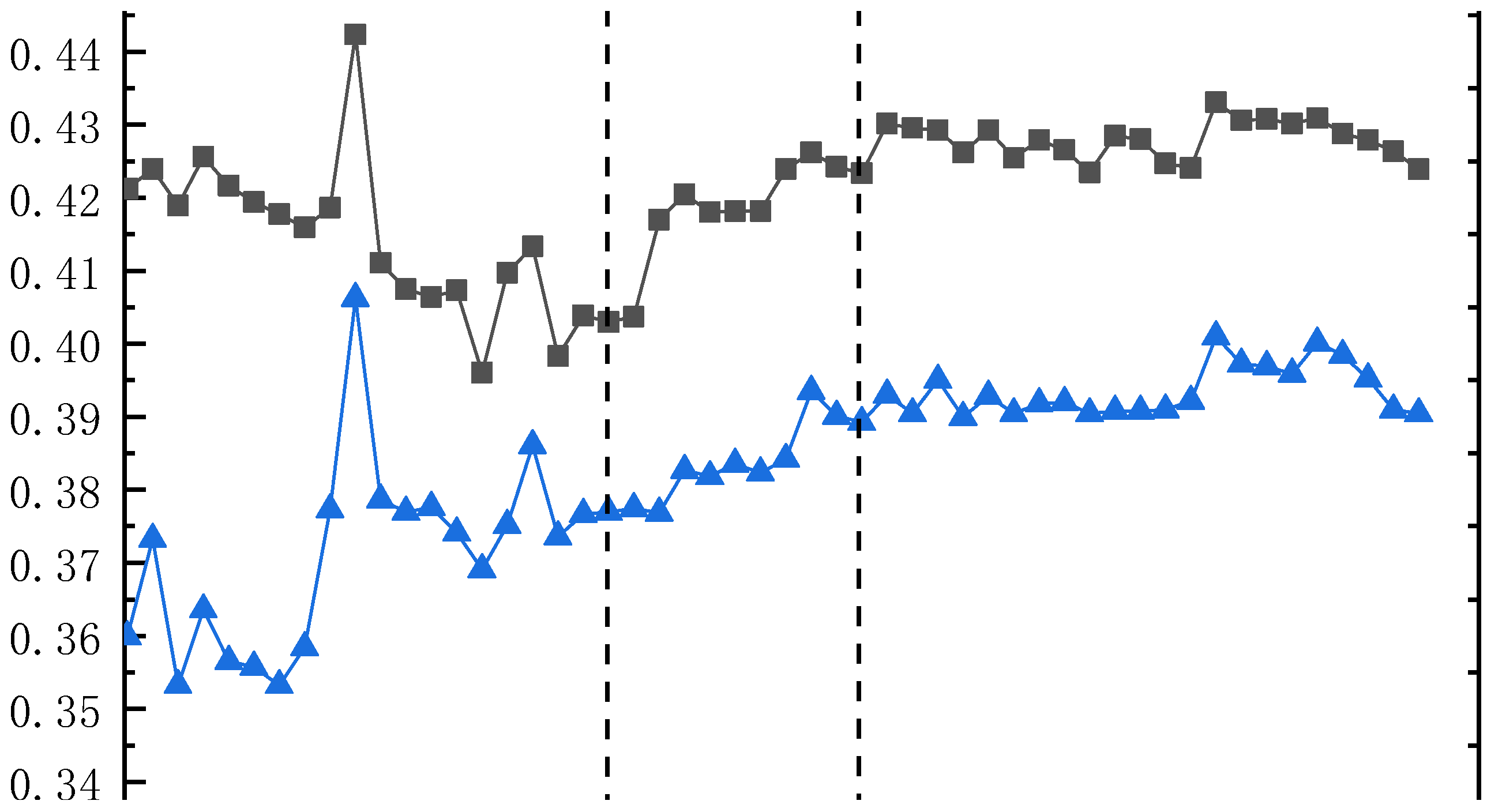

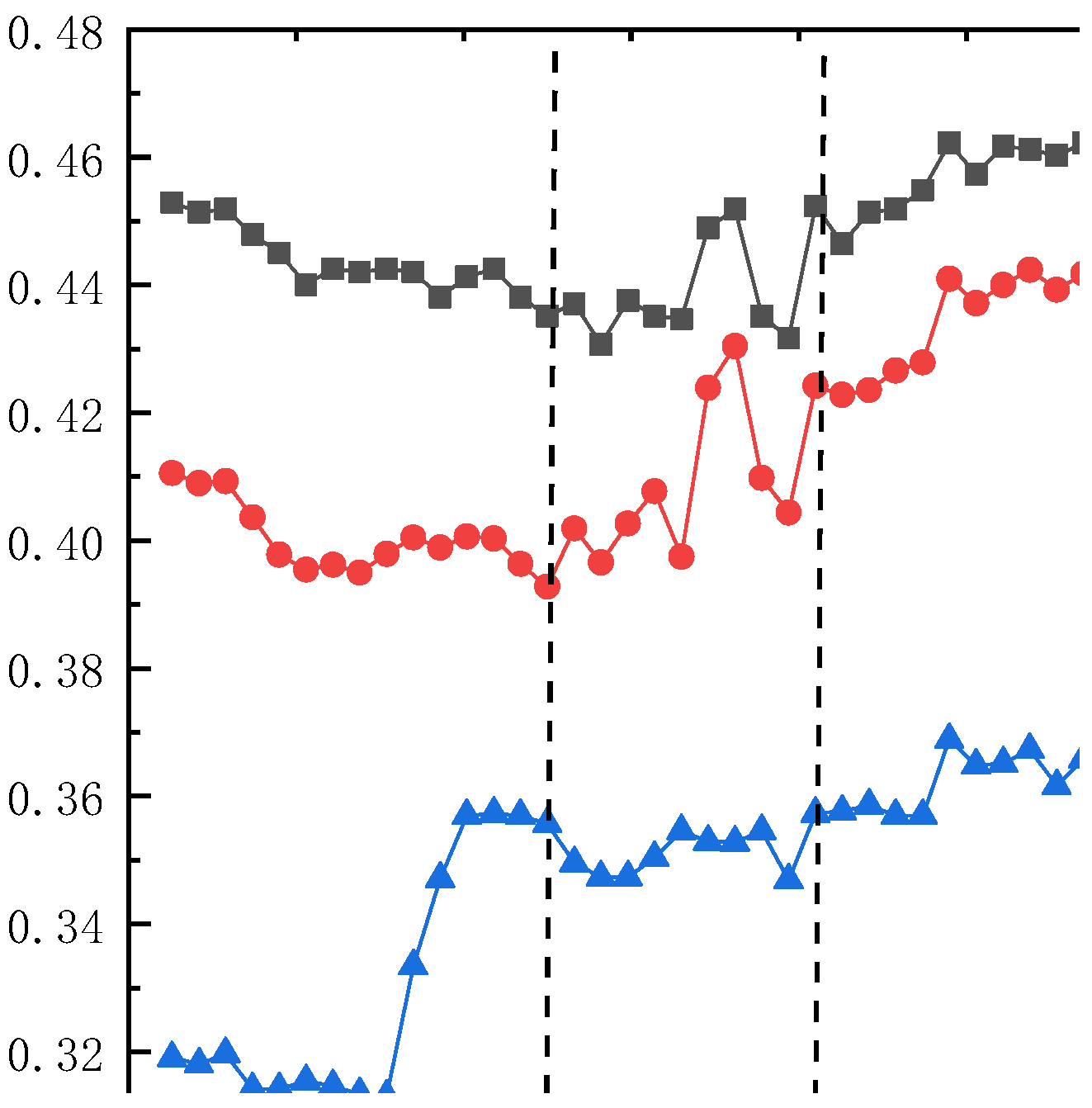

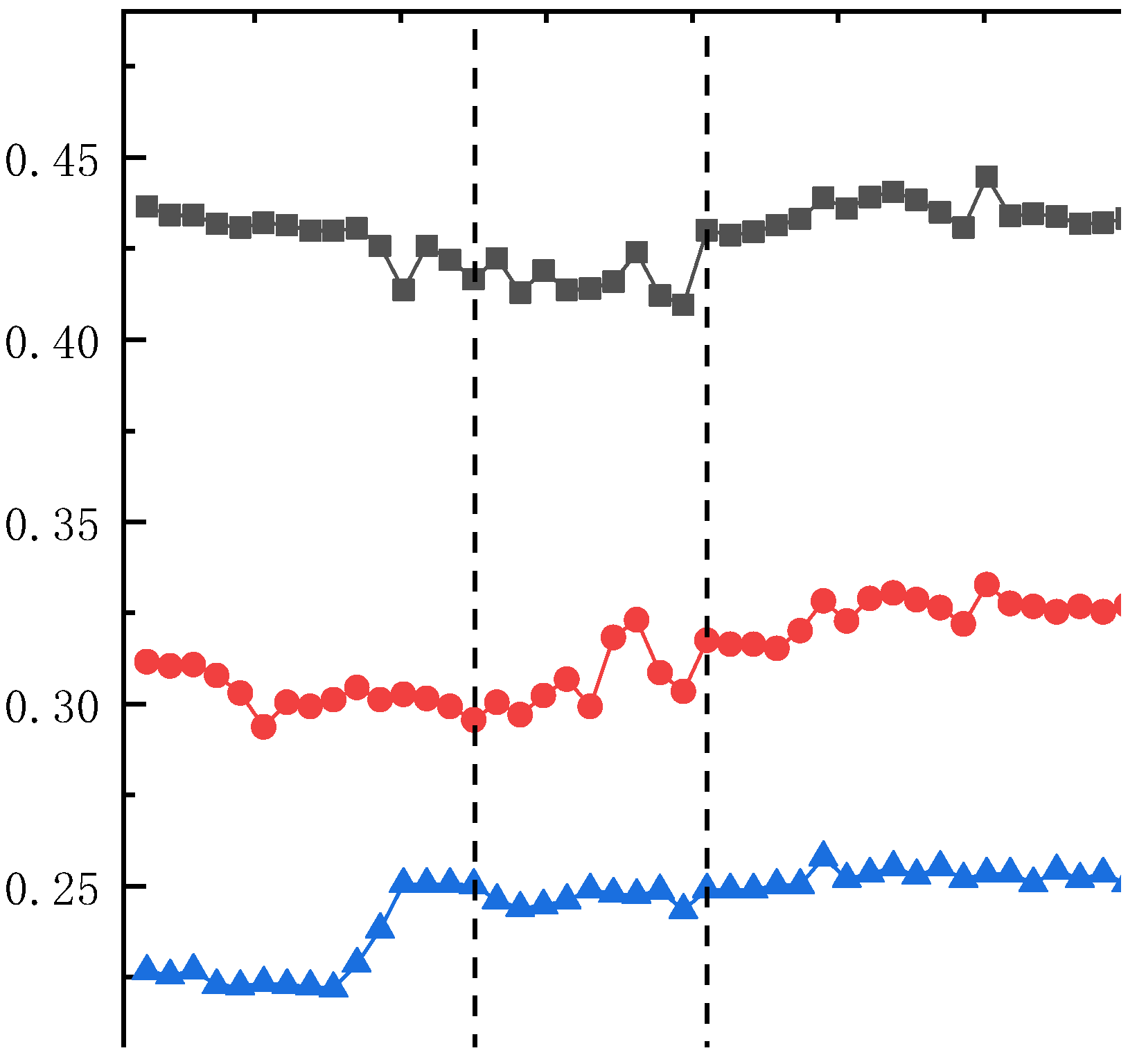

4. Analysis of Synchronous Grouting Parameters

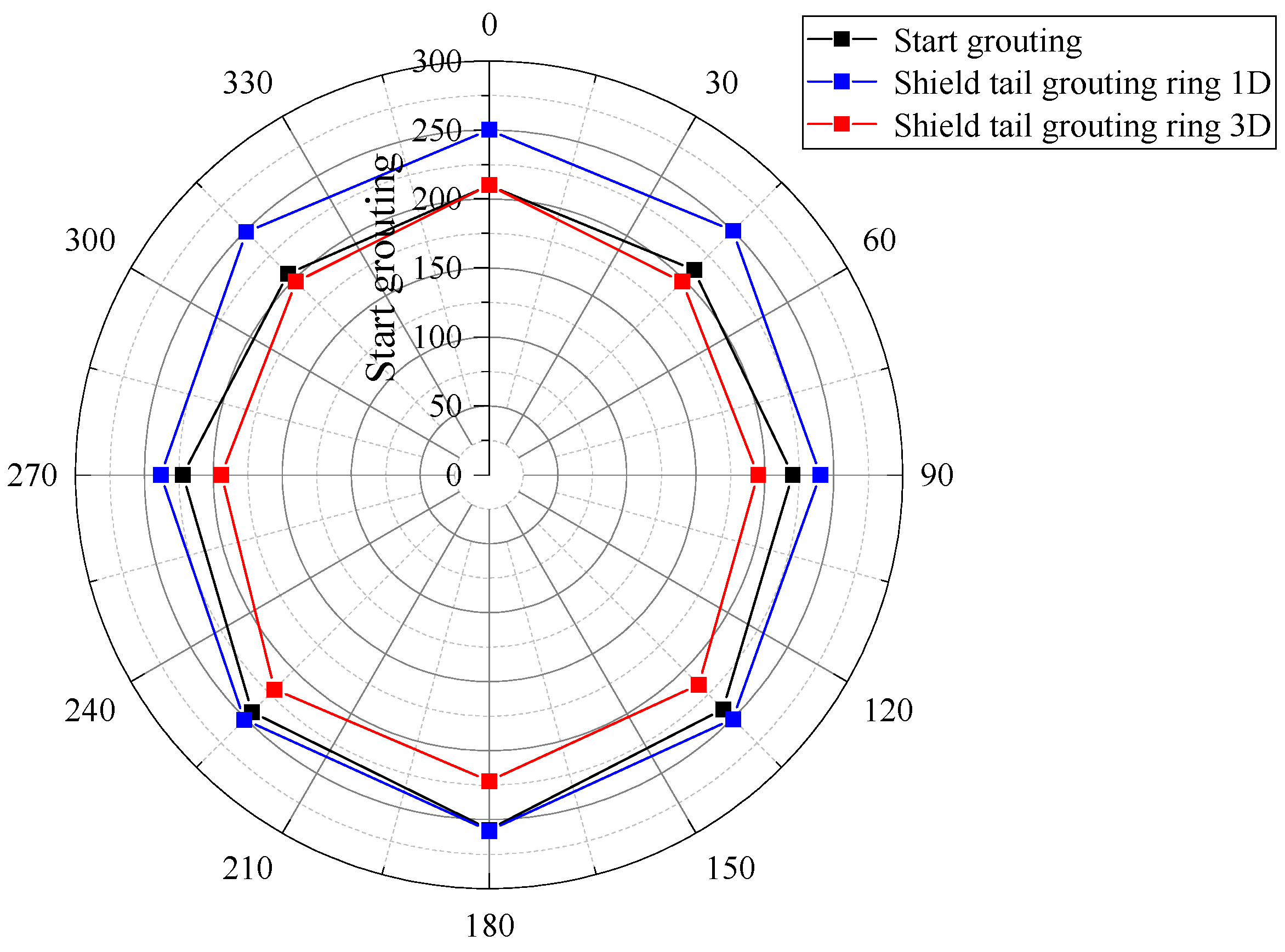

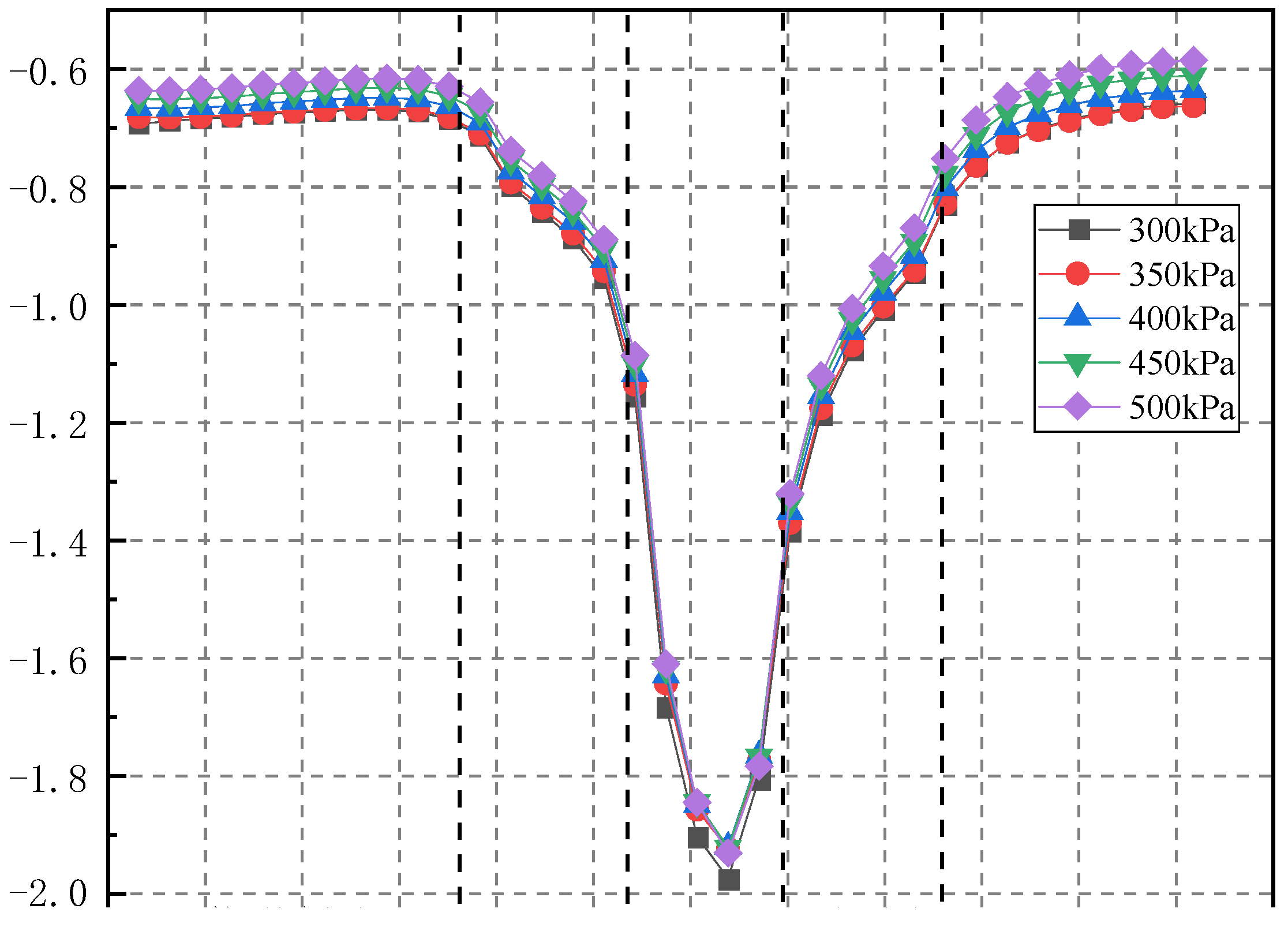

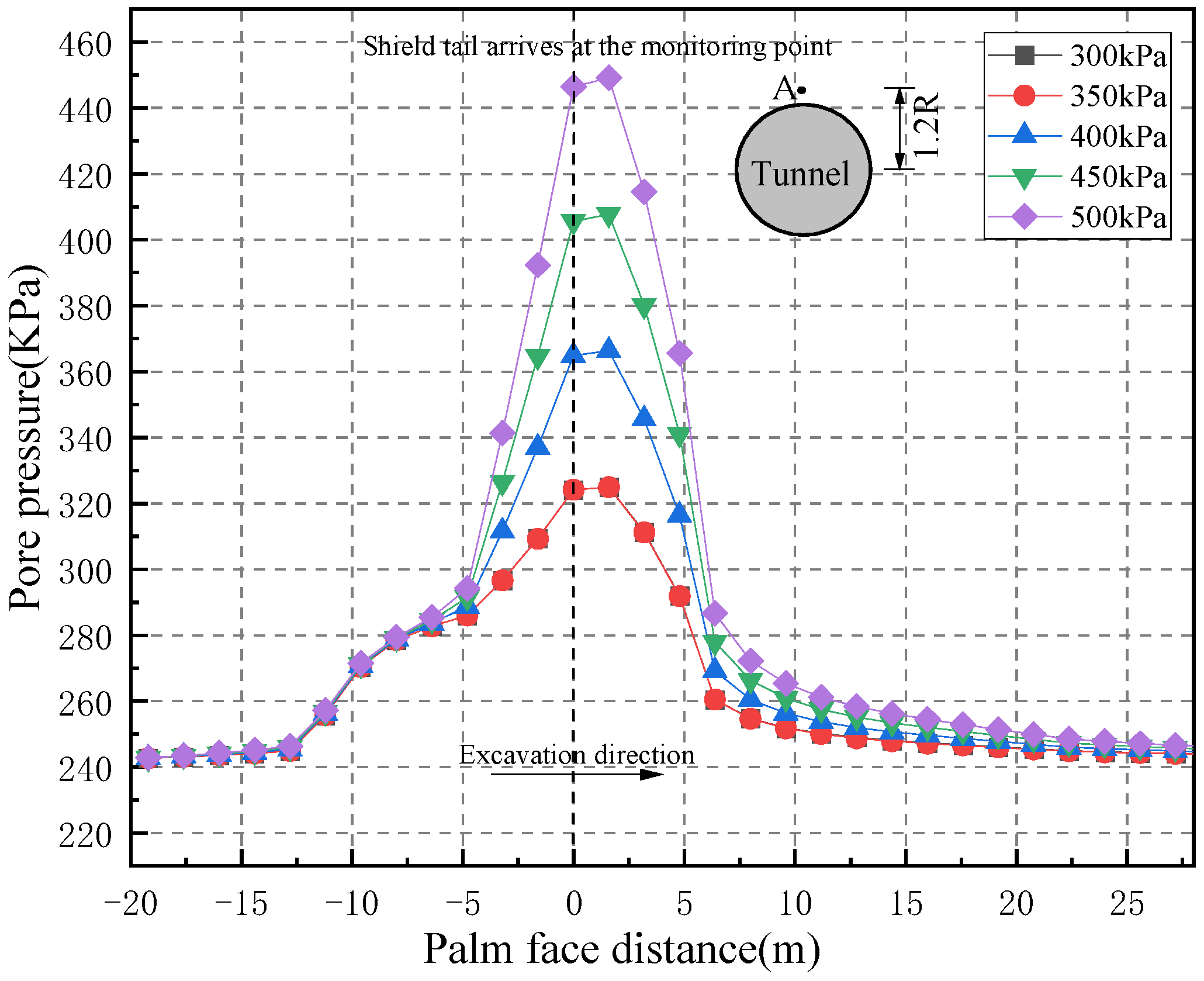

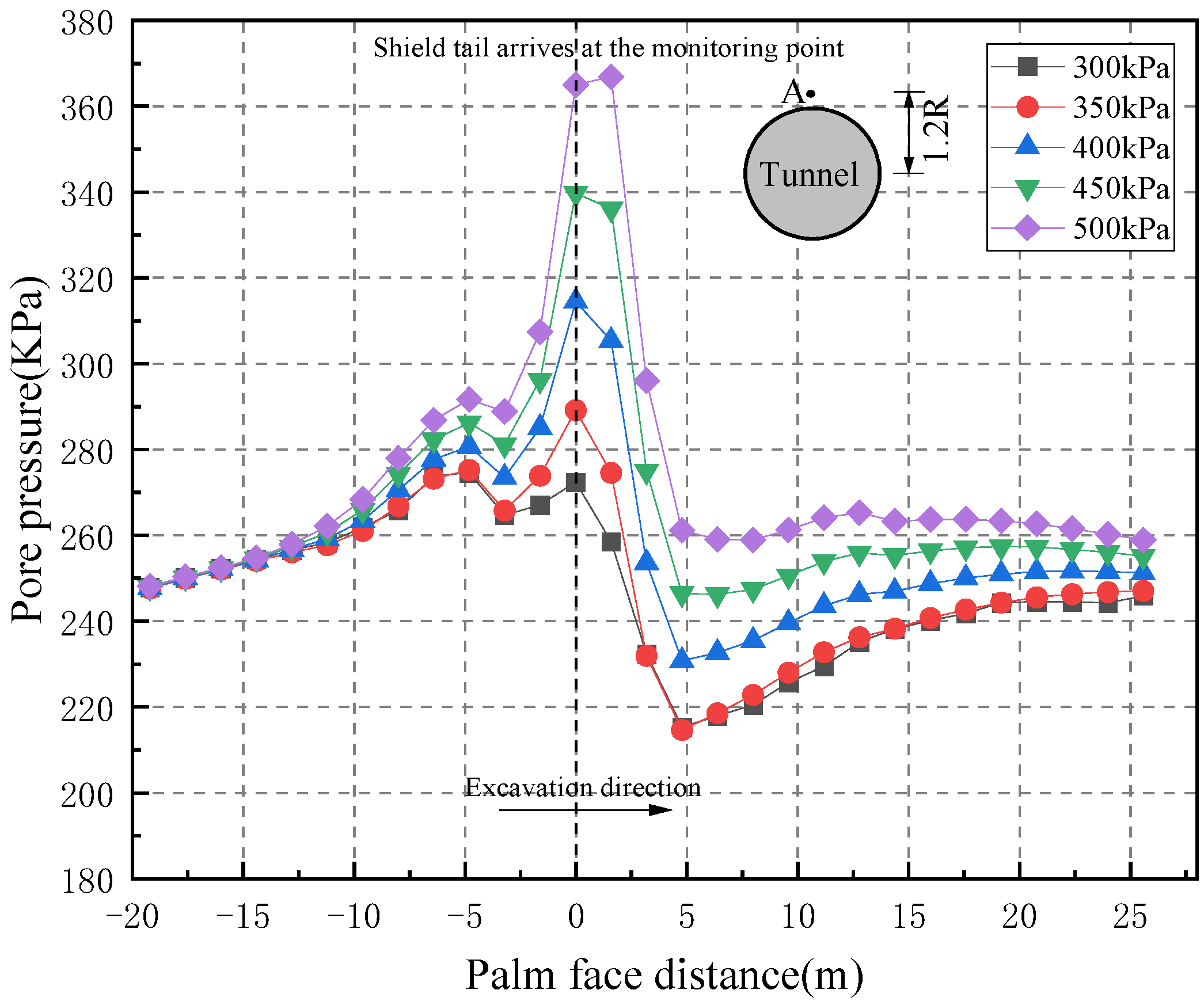

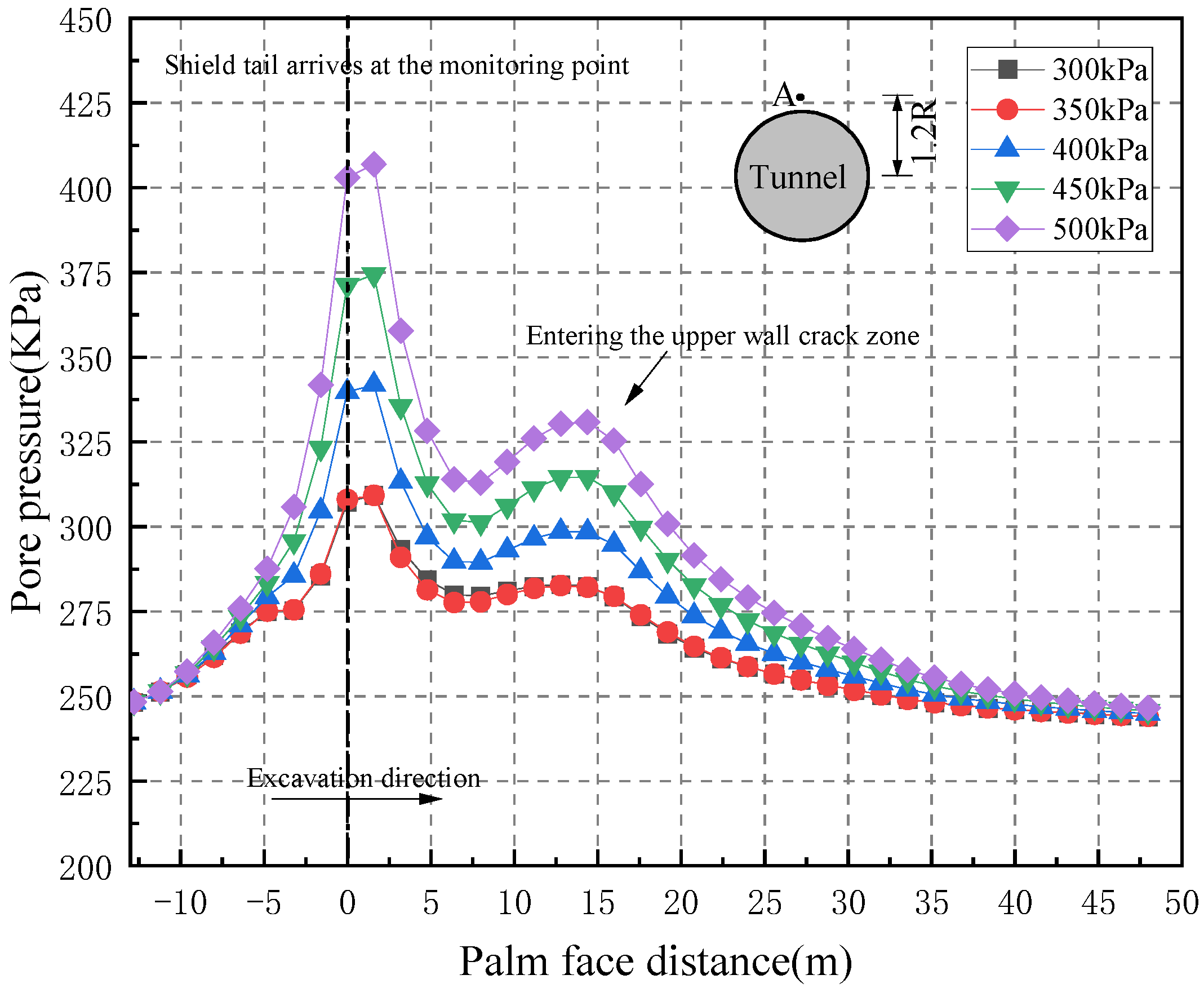

4.1. Grouting Pressure

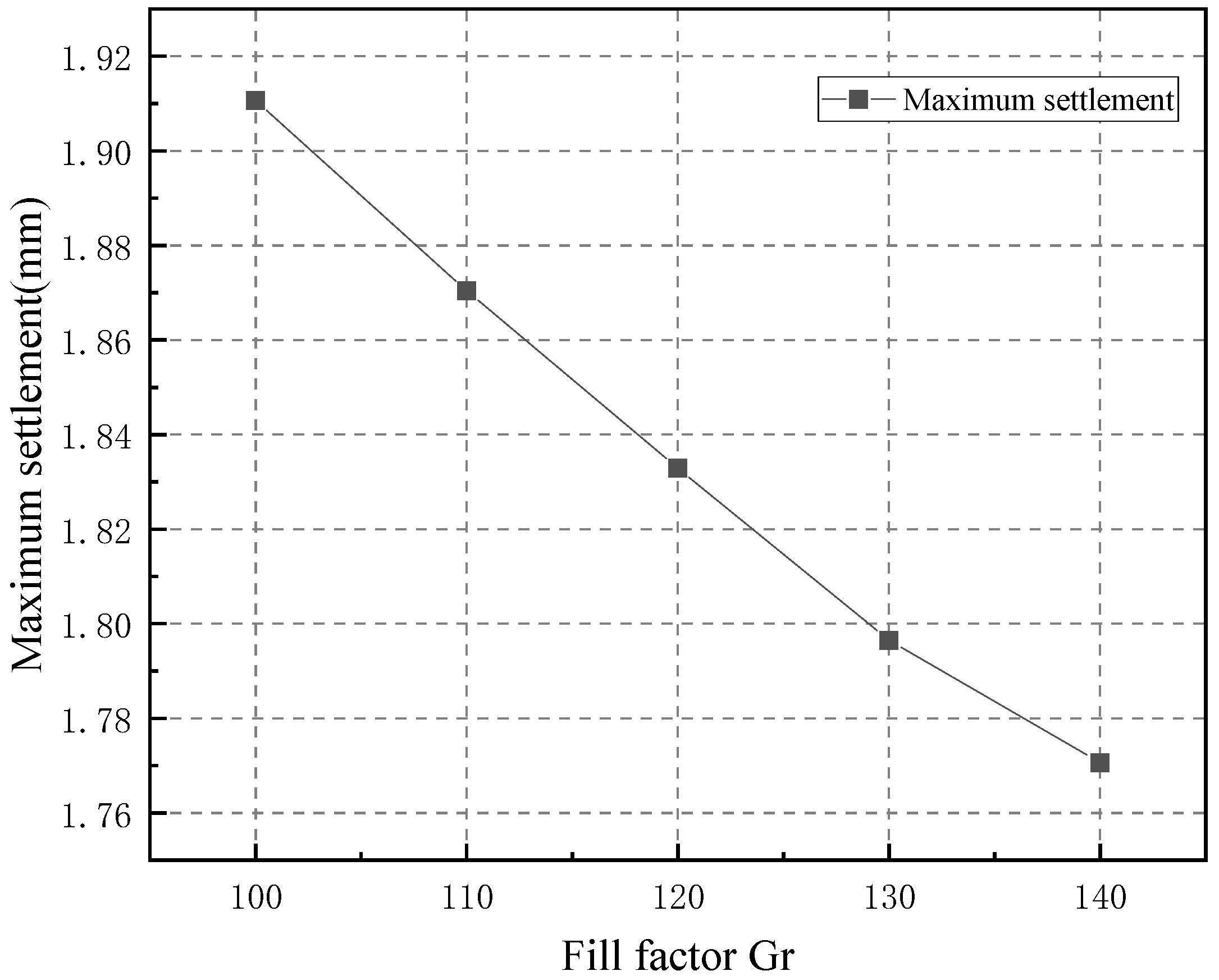

4.2. Grouting Volume

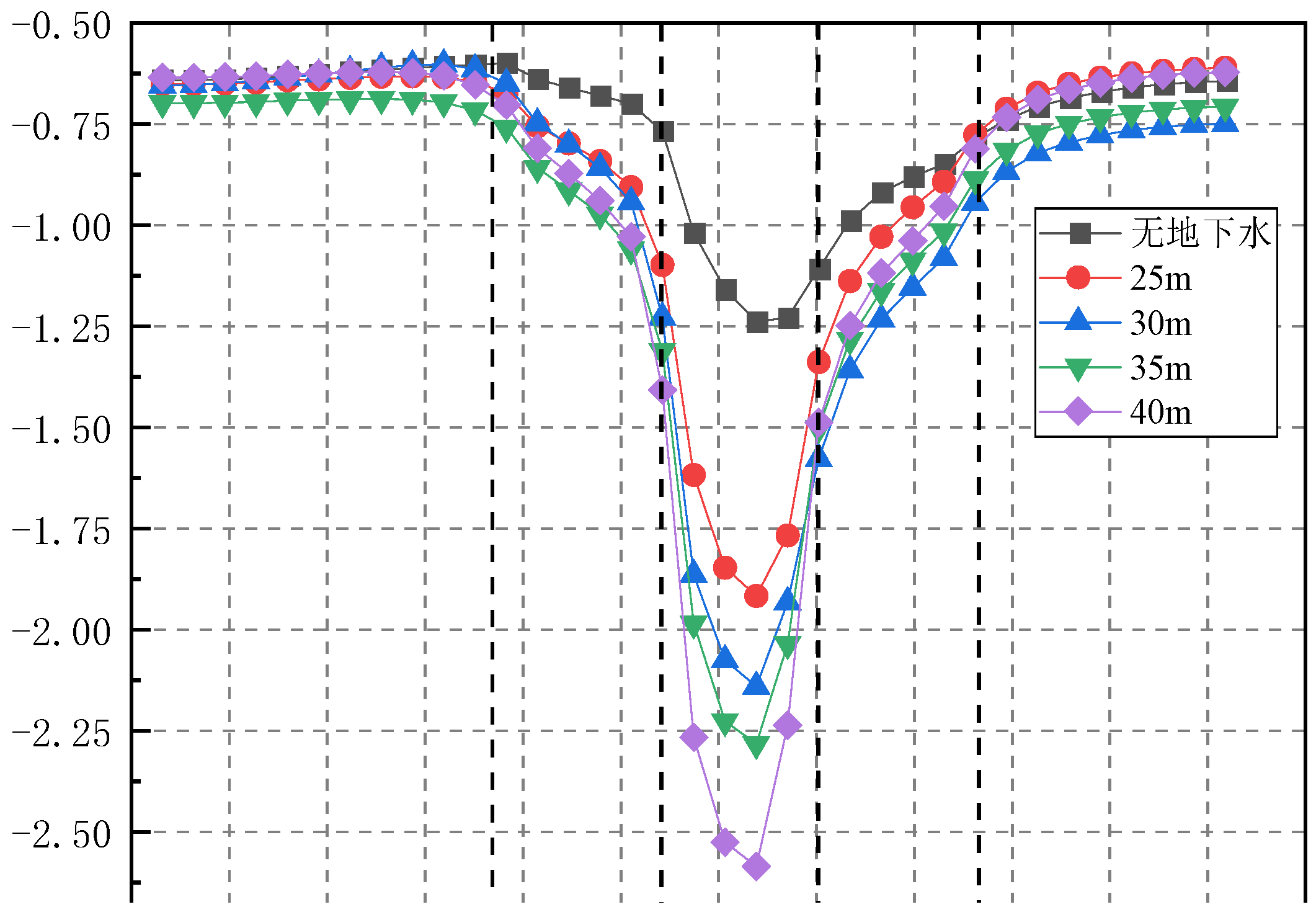

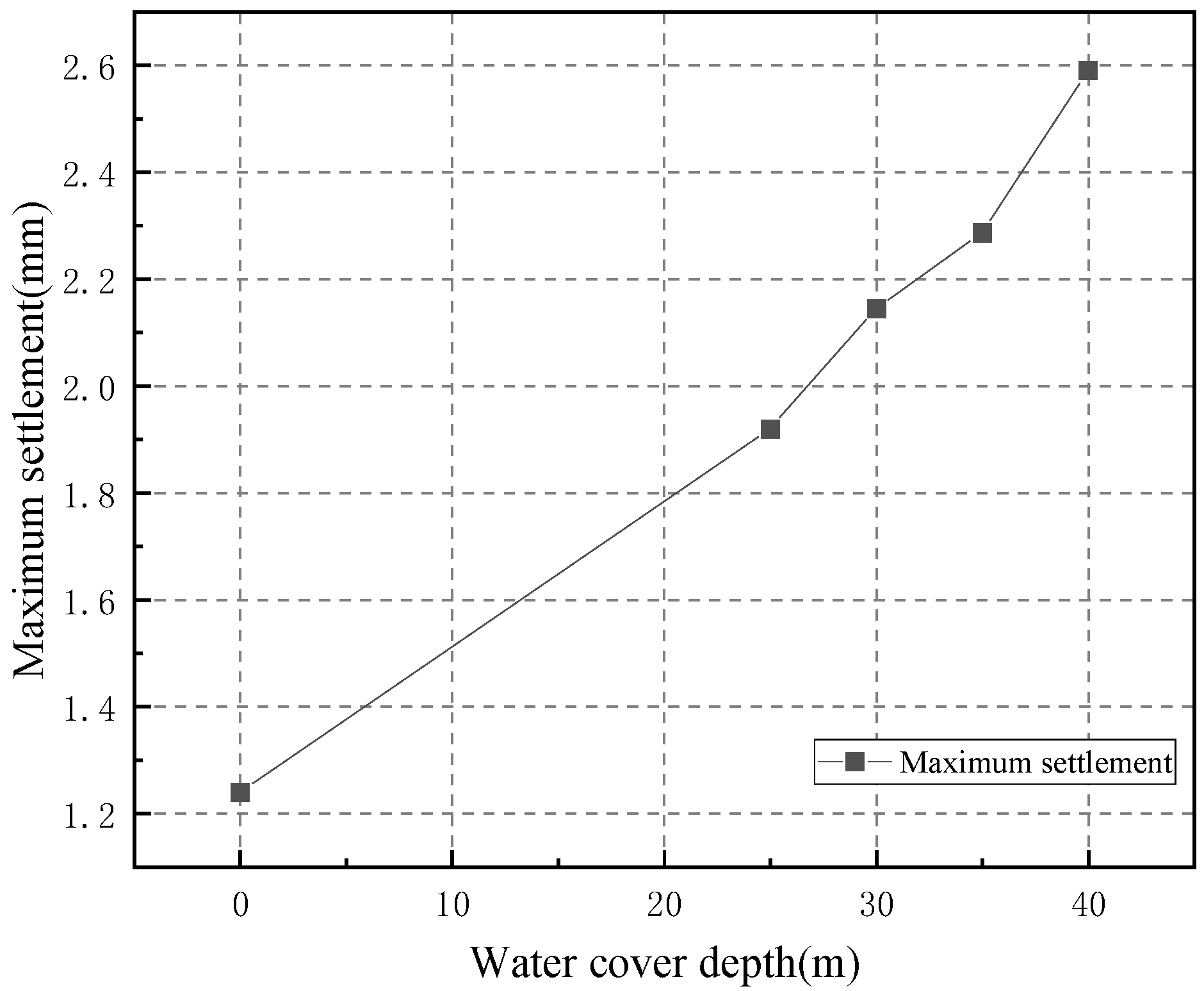

4.3. Water Cover Height

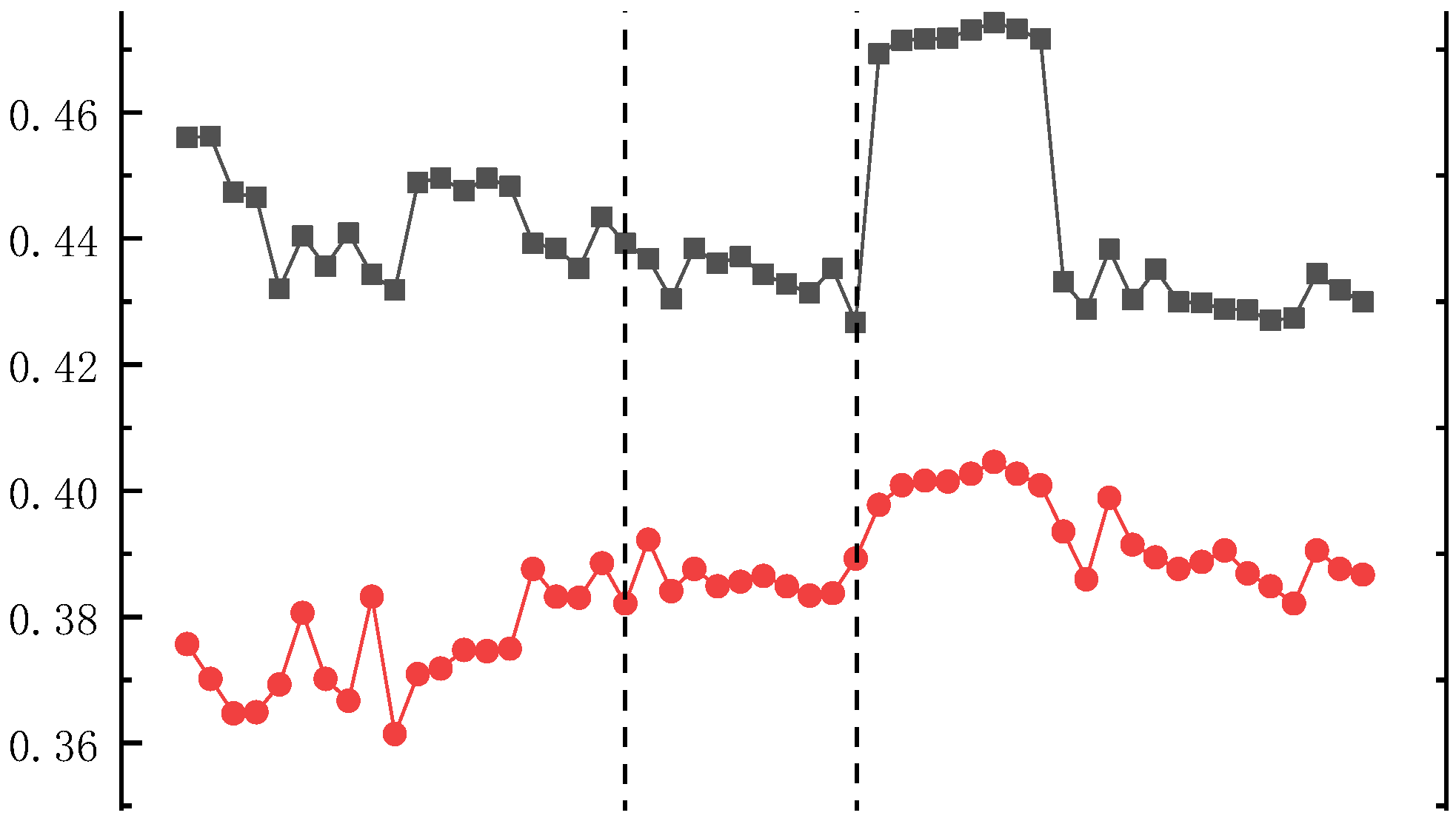

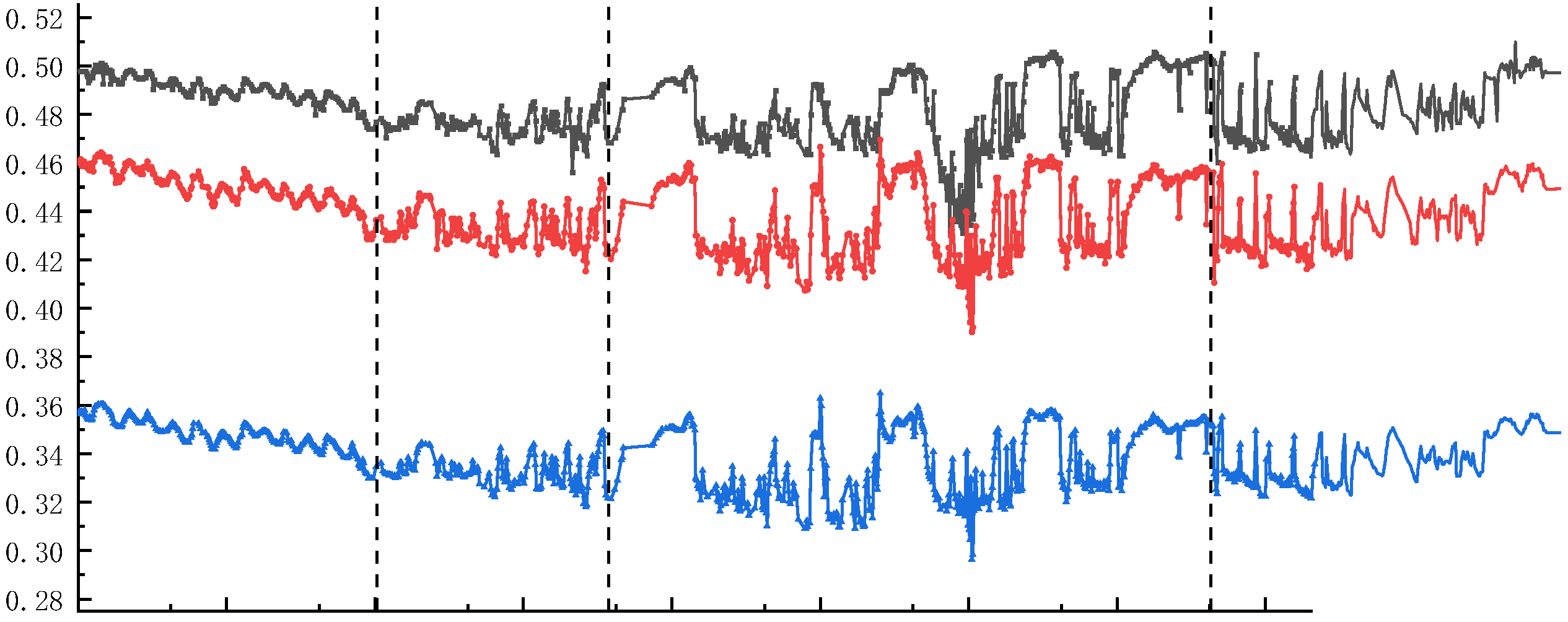

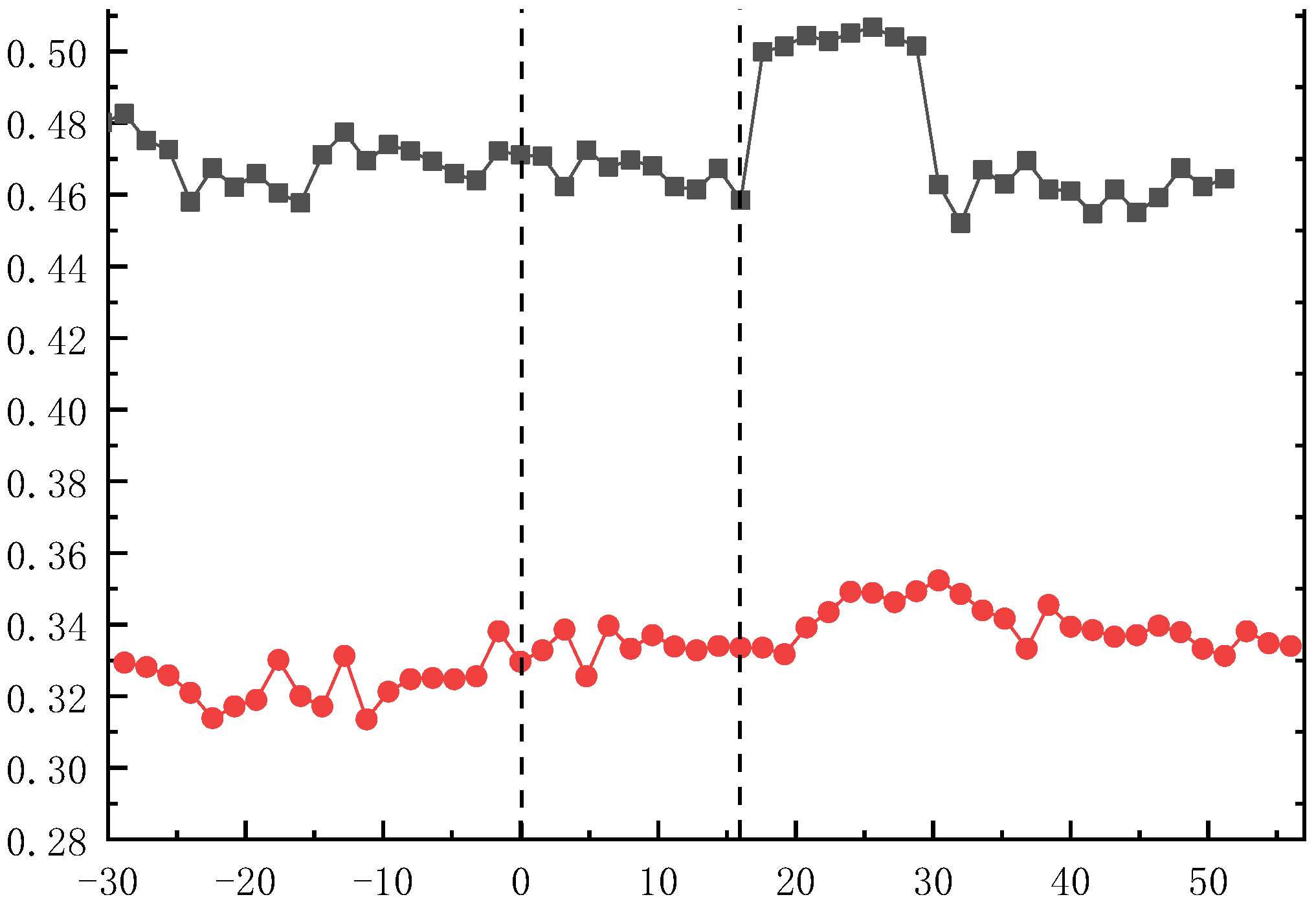

5. On Site Monitoring of Soil and Water Pressure

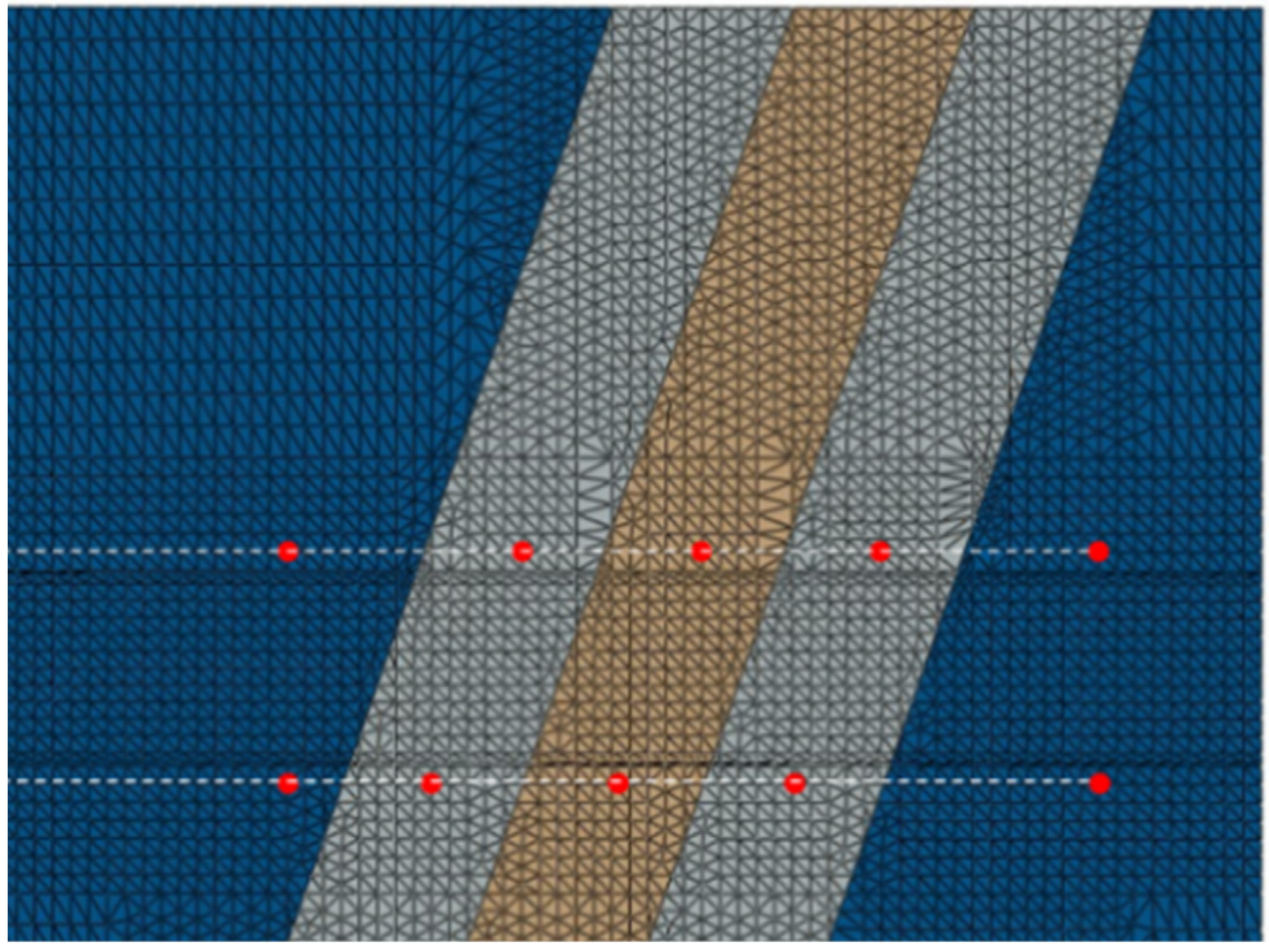

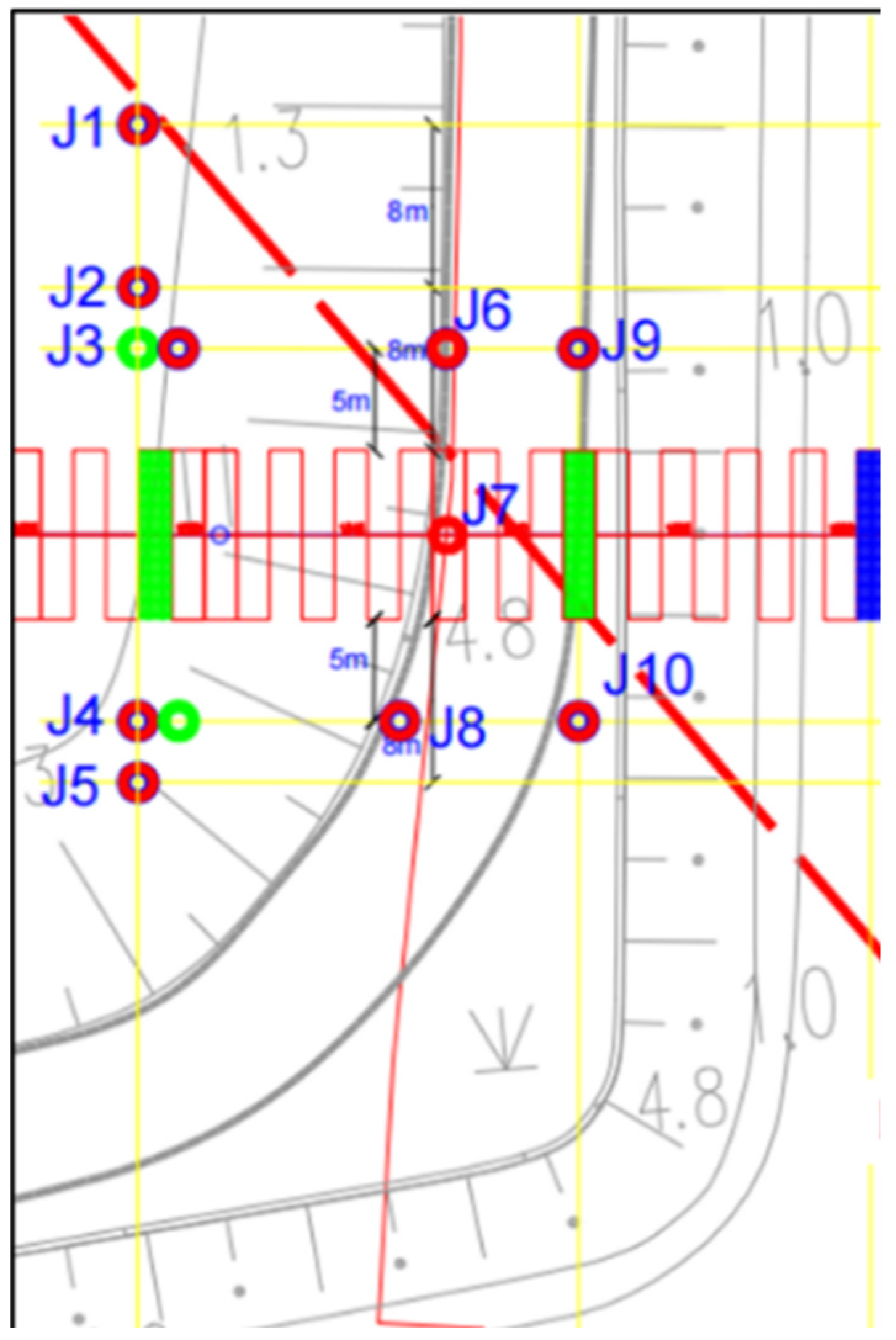

5.1. Monitoring Layout

5.2. Analysis of Monitoring Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, T.; Zhou, S.; Xu, R. The mechanism of synchronous grouting at the tail of shield tunnel and the determination of grouting parameters. J. Undergr. Space Eng. 2008, 4, 130–133. [Google Scholar]

- Ye, F.; Mao, J.; Ji, M.; Sun, C.; Chen, Z. Research status and development trend of grouting behind shield tunnel walls. Tunn. Constr. 2015, 35, 739–752. [Google Scholar]

- Zhang, N.; Shen, J.S.; Zhou, A.; Arulrajah, A. Tunneling induced geohazards in mylonitic rock faults with rich groundwater: A case study in Guangzhou. Tunn. Undergr. Space Technol. 2017, 74, 262–272. [Google Scholar] [CrossRef]

- Huang, L.; Ma, J.; Lei, M.; Liu, L.; Lin, Y.; Zhang, Z. Soil-water inrush induced shield tunnel lining damage and its stabilization: A case study. Tunn. Undergr. Space Technol. 2020, 97, 103290.1–103290.15. [Google Scholar] [CrossRef]

- Ye, F.; Zhu, H.; He, C. Analysis of the diffusion mode of grouting behind the shield tunnel wall and the pressure on the segment. Geotech. Mech. 2009, 30, 1307–1312. [Google Scholar]

- Bai, Y.; Dai, Z.; Zhang, S.; Peng, F. Research on the Pressure Diffusion Mode of Synchronous Grouting in Shield Tunnels. China Railw. Sci. 2011, 32, 38–45. [Google Scholar]

- Hu, C.; Guo, J.; Mei, Y.; Wang, Z.; Yuan, Y. The influencing factors and diffusion mechanism of synchronous grouting slurry pressure in shield tunneling. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2020, 52, 617–625. [Google Scholar]

- Ye, F.; Guo, H.; Duan, Z.; Liang, X.; Wang, S.; Wang, B. Research on the disturbance dynamics of synchronous grouting construction in deep buried shield tunnels. J. Geotech. Eng. 2019, 41, 855–863. [Google Scholar]

- Zhang, W. Research on the Mechanism and Application of Grouting Reinforcement in the Fractured Zone of Water Rich Faults in Tunnel Engineering. Ph.D. Thesis, Shandong University, Jinan, China, 2014. [Google Scholar]

- Li, P. Research on Mechanical Behavior of Tunnel Construction in Fault Fractured Zone Sections. Master’s Thesis, Chang’an University, Xi’an, China, 2013. [Google Scholar]

- Jiang, K.; Liu, B.; Qin, K.; Zhou, T. Research on Optimization of Excavation Parameters for Slurry Shield Tunneling in Fault Fractured Zones. Transp. Sci. Eng. 2020, 36, 43–49. [Google Scholar]

- Zhao, K.; Janutolo, M.; Barla, G. 3D simulation of TBM excavation in brittle rock associated with fault zones: The Brenner Exploratory Tunnel case. Eng. Geol. 2014, 181, 93–111. [Google Scholar] [CrossRef]

- Wan, D.; Zhu, D.; Xia, Y. Numerical simulation study on the influence of grouting behind the shield tunnel wall on surface settlement. J. Hebei Univ. Technol. 2011, 40, 110–113. [Google Scholar]

- Yu, L. Study on the Changes in Seepage Field and Formation Deformation Caused by Synchronous Grouting at the Tail of a Large Diameter Shield Tunnel. Master’s Thesis, South China University of Technology, Guangzhou, China, 2018. [Google Scholar]

- Faulkner, D.R.; Lewis, A.C.; Rutter, E.H. On the internal structure and mechanics of large strike-slip fault zones: Field observations of the Carboneras fault in southeastern Spain. Tectonophysics 2003, 367, 235–251. [Google Scholar] [CrossRef]

- Bezuijen, A.; Talmon, A.M.; Kaalberg, F.J.; Plugge, R. Field measurements of grout pressures during tunnelling of the sophia rail tunnel. J. Jpn. Geotech. Soc. 2008, 44, 39–48. [Google Scholar] [CrossRef]

- Zhang, D.; Ran, L.; Yan, J. The influence of water leakage under grouting on tunnel and ground settlement. J. Tongji Univ. (Nat. Sci. Ed.) 2017, 45, 497–503. [Google Scholar]

- Yu, W. The Mechanism and Engineering Application of Splitting Grouting Diffusion in Tunnel Muddy Filling Fault Fracture Zone. Ph.D. Thesis, Changsha University of Technology, Changsha, China, 2015. [Google Scholar]

- Li, P. Research on the Mechanical Mechanism and Control Method of the Whole Process of Mud Fault Splitting Grouting. Ph.D. Thesis, Shandong University, Jinan, China, 2017. [Google Scholar]

- Zhang, S.; Dai, Z.; Bai, Y. Model experimental study on the pressure distribution law of synchronous grouting slurry in shield tunnel. China Railw. Sci. 2015, 36, 43–53. [Google Scholar]

- Xu, Y. Stability Analysis of Surrounding Rock in Fault Fractured Zone during Construction of Qingdao Metro. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 2017. [Google Scholar]

| Location | Pile Bearing Layer | Relativeness | Spacing |

|---|---|---|---|

| Hongling Interchange | Moderately weathered granite | Passing through the middle | Plane spacing of 4.3 m and 2.4 m |

| Hongling Ramp Bridge | Moderately weathered granite | Passing through the middle | Plane spacing of 6.6 m and 1.3 m |

| Bao’an Interchange | Strongly weathered fragmented rock | Vertically underpass | Vertical distance 3.7 m |

| Bujihe Bridge | Strong~weathered fractured rock | Vertically underpass | Vertical distance 3.8~9.3 m |

| Chunfeng Viaduct | Strongly weathered tuffaceous sandstone | Vertically underpass | Vertical distance 8.7~9.0 m |

| Cutter Disc Excavation Diameter | Outer Diameter of Pipe Segment | Inner Diameter of Pipe Segment | Tail Gap of Shield |

|---|---|---|---|

| 8.65 m | 8.3 m | 7.5 m | 0.35 m |

| Rock and Soil Mass | C (kPa) | φ (°) | γ (kN/m3) | Elastic Modulus (MPa) | Poisson’s Ratio | Permeability Coefficient (cm/s) |

|---|---|---|---|---|---|---|

| Ordinary surrounding rock | 1000 | 40 | 24 | 6140 | 0.24 | 1.1 × 10−6 |

| Induced crack zone | 500 | 33 | 22.8 | 3200 | 0.27 | 6.4 × 10−5 |

| Sliding crushing zone | 200 | 25 | 21 | 800 | 0.35 | 1.3 × 10−7 |

| Title | Time | Thickness (mm) | γ (kN/m3) | Poisson’s Ratio | Elastic Modulus (MPa) |

|---|---|---|---|---|---|

| TBM | —— | 175 | 76 | 0.2 | 200 × 103 |

| Segment | —— | 400 | 25 | 0.2 | 2880 |

| Grout | <24 h | 175 | 24 | 0.34 | 4.8 |

| 24~48 h | 175 | 24 | 0.34 | 4.8 | |

| >48 h | 175 | 24 | 0.2 | 10.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Y.; Wang, S.; Zhang, X.; Luo, M.; Zhu, J.; Bian, Y.; Gong, C.; Fu, Y.; Lv, Q.; Liang, N.; et al. Synchronous Grouting Analysis of Shield Tunneling through High Water Pressure Fault Fracture Zone. Appl. Sci. 2023, 13, 12972. https://doi.org/10.3390/app132412972

Zeng Y, Wang S, Zhang X, Luo M, Zhu J, Bian Y, Gong C, Fu Y, Lv Q, Liang N, et al. Synchronous Grouting Analysis of Shield Tunneling through High Water Pressure Fault Fracture Zone. Applied Sciences. 2023; 13(24):12972. https://doi.org/10.3390/app132412972

Chicago/Turabian StyleZeng, Yi, Shun Wang, Xiaolong Zhang, Miaotong Luo, Junzhou Zhu, Yuewei Bian, Chenjie Gong, Yanbin Fu, Qi Lv, Ning Liang, and et al. 2023. "Synchronous Grouting Analysis of Shield Tunneling through High Water Pressure Fault Fracture Zone" Applied Sciences 13, no. 24: 12972. https://doi.org/10.3390/app132412972

APA StyleZeng, Y., Wang, S., Zhang, X., Luo, M., Zhu, J., Bian, Y., Gong, C., Fu, Y., Lv, Q., Liang, N., & Yu, Z. (2023). Synchronous Grouting Analysis of Shield Tunneling through High Water Pressure Fault Fracture Zone. Applied Sciences, 13(24), 12972. https://doi.org/10.3390/app132412972