1. Introduction

The industry directly depends on customers and their experiences about the product quality. Thus, the quality of the product is the most important factor in making the product more demanding to the customers by manufacturing units. To provide consumers a positive impression of product quality, a manufacturer or wholesaler selects the highest-quality product from a lot and distributes it to customers.. For the selection of best quality product, one may use 100 percent inspection, but 100 percent inspection is not possible due to time, money, labor, etc., constraints. In addition to 100 percent inspection, we have a path between 100 percent inspection and no inspection that is known as acceptance sampling inspection plan (ASIP). Various types of ASIPs are presented in the literature; namely; attribute ASIP and variable ASIP, Single ASIP (SASIP), double ASIP (DASIP), multiple ASIP (MASIP), sequential ASIP (SeASIP), group ASIP (GASIP), and skip-lot ASIP (SkASIP) are included in attribute ASIP, while sampling plans are based on variables using perfect measurements of quality characteristics.

Some of the authors who have developed several ASIPs for different probability distributions include the following: Ref. [

1] for gamma distribution, Ref. [

2] for for normal and lognormal distributions, Ref. [

3] for Birnbaum Saunders model, Ref. [

4] for inverse Rayleigh distribution, Ref. [

5] for generalized Rayleigh distribution, Ref. [

6] for generalized Birnbaum Saunders model, Ref. [

7] for generalized exponential distribution, Ref. [

8] for generalized inverted exponential distribution, Ref. [

9] for for SASIP based on generalized half-normal distribution and [

10] for SASIP and DASIP to the transmuted Rayleigh distribution, Ref. [

11] for chain sampling plan for variables inspection, Ref. [

12] for selection of chain sampling plans ChSP-1 and ChSP-(0,1). Moreover, see [

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30] for other works in ASP.

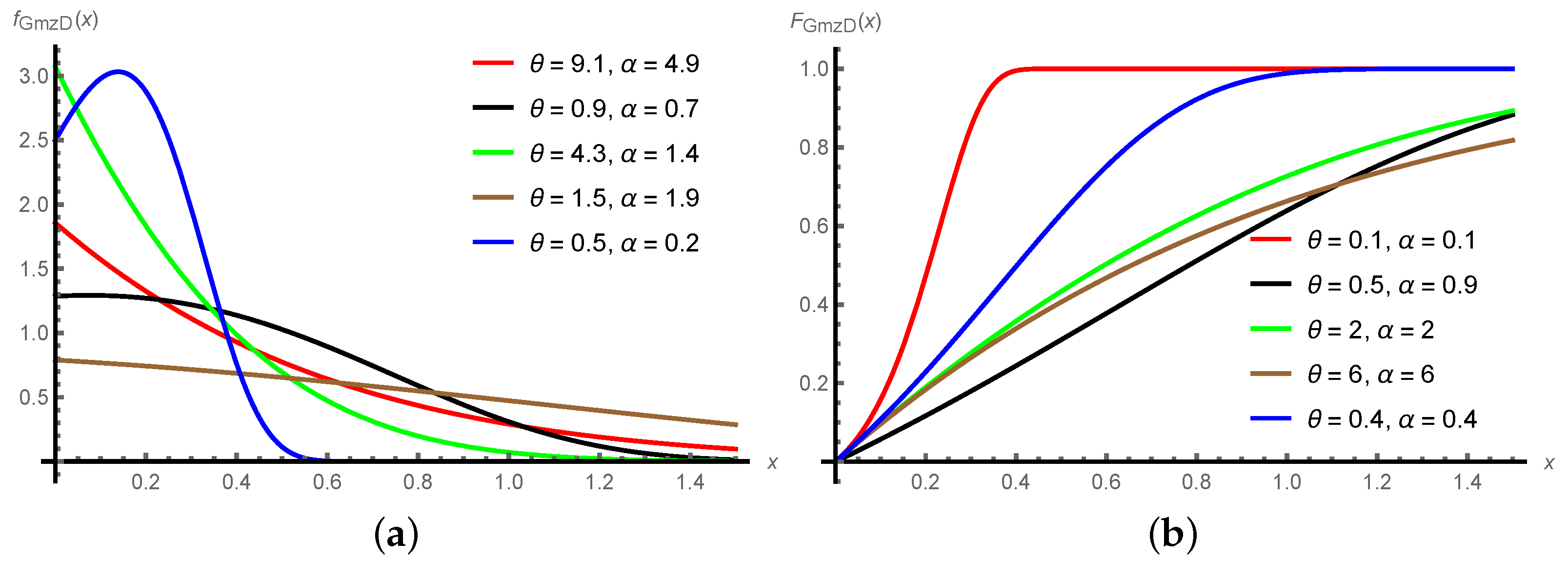

We explored the literature of SQC and found that this is the first study developing SkSP-R under the GmzD. In addition, we placed a strong emphasis on the suggested plan’s real implementation, and we employed two data sets to accomplish this goal. The structure of this paper is classified as follows: In

Section 2, GmzD is presented with its main properties. The design of the offered SkSP-R plan for GmzD is placed in

Section 3 along with illustration. The description of tables is provided in

Section 4. Real data set examples for application purposes are presented in

Section 5.

Section 6 summarizes the main finding and concludes the paper.

5. Real Life Examples

In this part, two real data sets were chosen for the illustration purpose of the proposed SkSP-R plan. To begin, we examine whether data sets have been fitted to the GmzD or not. To accomplish this purpose, several criteria such as Akaike information criterion (AIC), Bayesian information criterion (BIC), and Kolmogorov–Smirnov statistic (KS) goodness-of-fit test value were used. Moreover, the

p-value associated with the KS test were considered to support the presented results based on the real data sets. Descriptive statistics summary and model fitting results of both data sets are presented in

Table 5 and

Table 6, respectively.

Data I: The data include 30 observations of the times of failures and running times for samples of devices from an eld-tracking study of a larger system. Previously, these data were studied by [

32]. The data are as follows: 0.02, 0.10, 0.13, 0.23, 0.23, 0.28, 0.30, 0.65, 0.80, 0.88, 1.06, 1.43, 1.47, 1.73, 1.81, 2.12, 2.45, 2.47, 2.61, 2.66, 2.75, 2.93, 3.00, 3.00, 3.00, 3.00, 3.00, 3.00, 3.00, and 3.00.

Figure 3 shows the histogram density, empirical CDF and P-P plot of the GmzD for the first data set.

The estimated parameters and values are and , respectively, based on Data I. Suppose that a researcher likes to set the mean life as unit and termination ratio = ; then, based on these values, termination time is . For the considered setup, , , and ; the plan parameters of suggested SkSP-R plan are ; and the process is described follows:

- 1.

Start normal inspection and put items on test for prefixed time . Detect and count the number of sample items that failed before the experiment duration, say, , and . Hence, accept the lot.

- 2.

When , consecutive lots are not rejected under normal inspection based on time truncated life test; end the normal inspection and follow SI.

- 3.

Throughout SI, test only a fraction of lots chosen at random. SI is continued up to a point where a sampled lot is rejected.

- 4.

After , where a lot is rejected, consecutively sampled lots are accepted; hence, utilize the resampling method for the immediate next lot as in Step 5.

- 5.

In the resampling technique, perform the inspection based on a reference plan. If the lot is not rejected, then keep SI. If the lot is not accepted, resampling is formed for times and the lot is rejected if it is not accepted on st resubmission.

- 6.

If a lot is not accepted on resampling scheme, then immediately proceed to the normal inspection provided in Step 1.

- 7.

Remove or correct all the nonconforming items found with asserting units in the rejected lots.

The ASN value is . When the quality ratio is , the probability of acceptance of the lot is .

Data II: The data set was obtained by [

33]. It consists of 63 observations the strengths of

cm glass fibers, measured by the National Physical Laboratory, England. The data include the following: 0.77, 0.81, 0.84, 0.93, 1.04, 0.55, 0.74, 1.11, 1.13, 1.24, 1.25, 1.27, 1.28, 1.29, 1.30, 1.36, 1.39, 1.42, 1.48, 1.52, 1.53, 1.54, 1.55, 1.55, 1.48, 1.49, 1.49, 1.50, 1.76, 1.76, 1.77, 1.78, 1.81, 1.82, 1.84, 1.50, 1.51, 1.73, 1.84, 1.89, 2.00, 1.58, 1.59, 1.60, 1.61, 1.61, 1.61, 1.68, 1.68, 1.69, 1.70, 1.70, 1.61, 1.62, 1.62, 1.63, 1.64, 1.66, 1.66, 1.66, 1.67, 2.01, and 2.24.

Figure 4 illustrates the histogram density, empirical CDF and P-P plot of the GmzD for the second data set.

The estimated values of parameters and are and , respectively, for the Data II. Suppose that the researcher wants to set the mean life to be unit and termination ratio as ; then, by using this information, termination time is . For the considered setup, , , and the plan parameters of proposed SkSP-R plan are ; moreover, the process is as follows:

- 1.

Start normal inspection and put items on the test for prefixed time . Detect and count the number of sample items which failed before the experiment duration, say, , and . Thus, we accept the lot.

- 2.

When , consecutive lots are accepted under normal inspection based on time truncated life test, and the normal inspection is discontinued. A switch to the skipping inspection is made.

- 3.

During the skipping inspection, inspect only a fraction of lots selected at random. The skipping inspection is continued until a sampled lot is rejected.

- 4.

If the lot is rejected after , consecutively sampled lots are accepted; then, proceed to the resampling procedure for the immediate next lot as in Step 5 provided below.

- 5.

During resampling procedure, perform the inspection using the reference plan. If the lot is accepted, then continue the skipping inspection. Upon the non-acceptance of the lot, resampling is performed for times and the lot is rejected if it has not been accepted on st resubmission.

- 6.

If a lot is rejected on resampling scheme, then immediately revert to the normal inspection in Step 1.

- 7.

Remove or correct all nonconforming units found with conforming units in the rejected lots.

The ASN value is . When the quality ratio is , then probability of acceptance of lot is .

The above explained real life examples show the superiority of the proposed SkSP-R plan and how one can use it in real life situations.