Defining a Non-Destructive In Situ Approach for the Determination of Historical Mortar Strength Using the Equotip Hardness Tester

Abstract

:1. Introduction

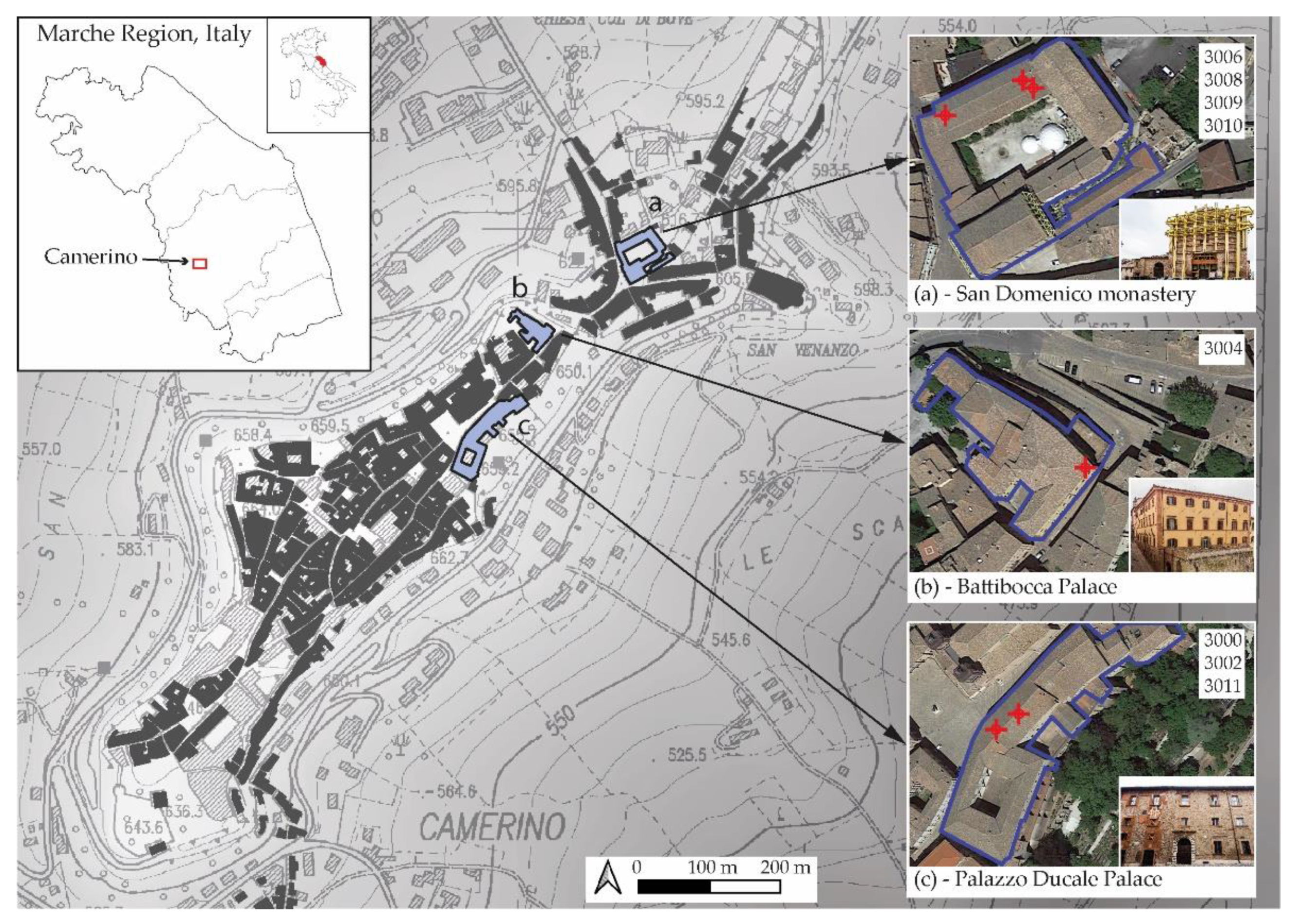

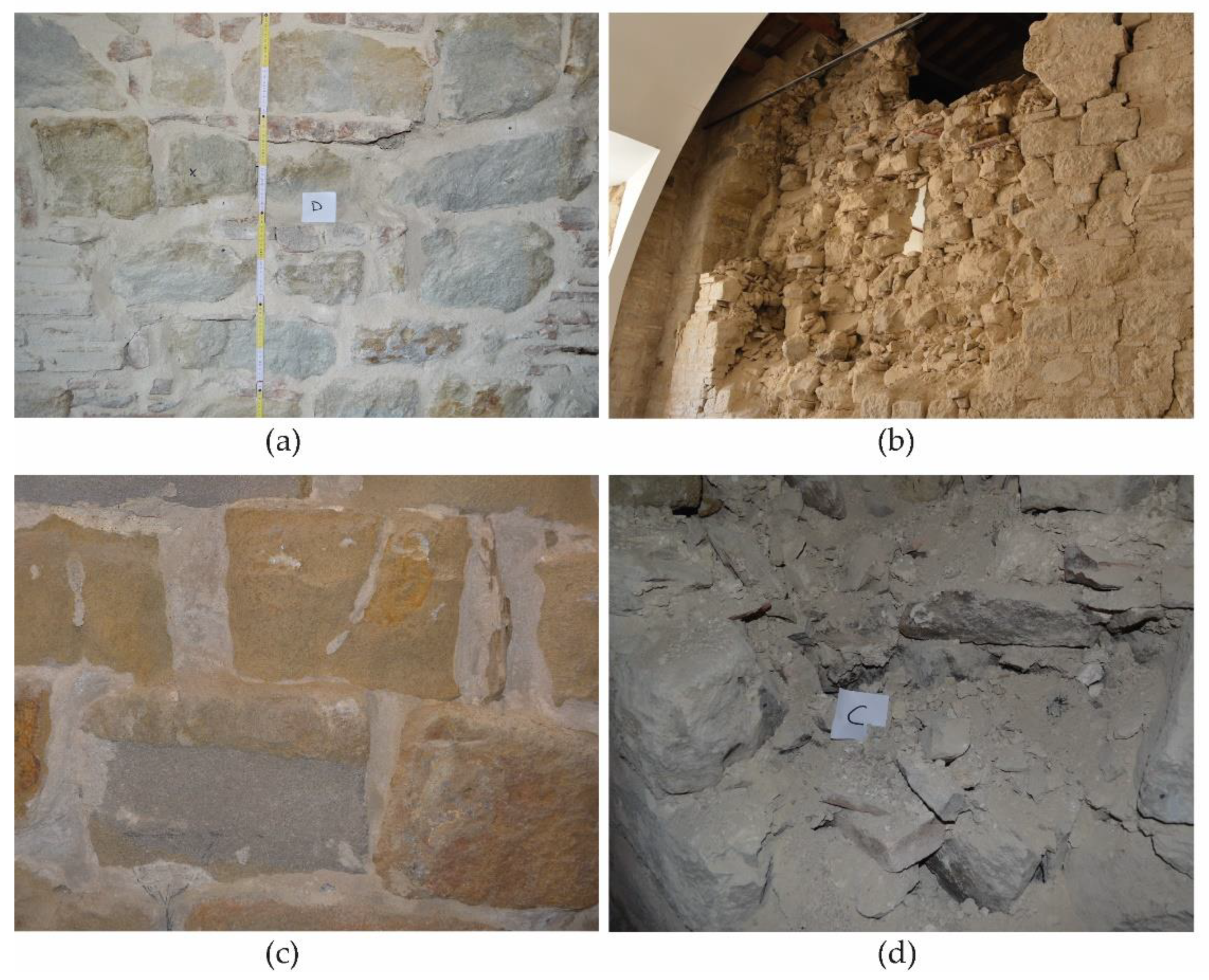

2. The Historical Masonry Mortars of Camerino Town

3. Materials and Methods

3.1. Data Collection Strategy Using the Equotip Hardness Tester

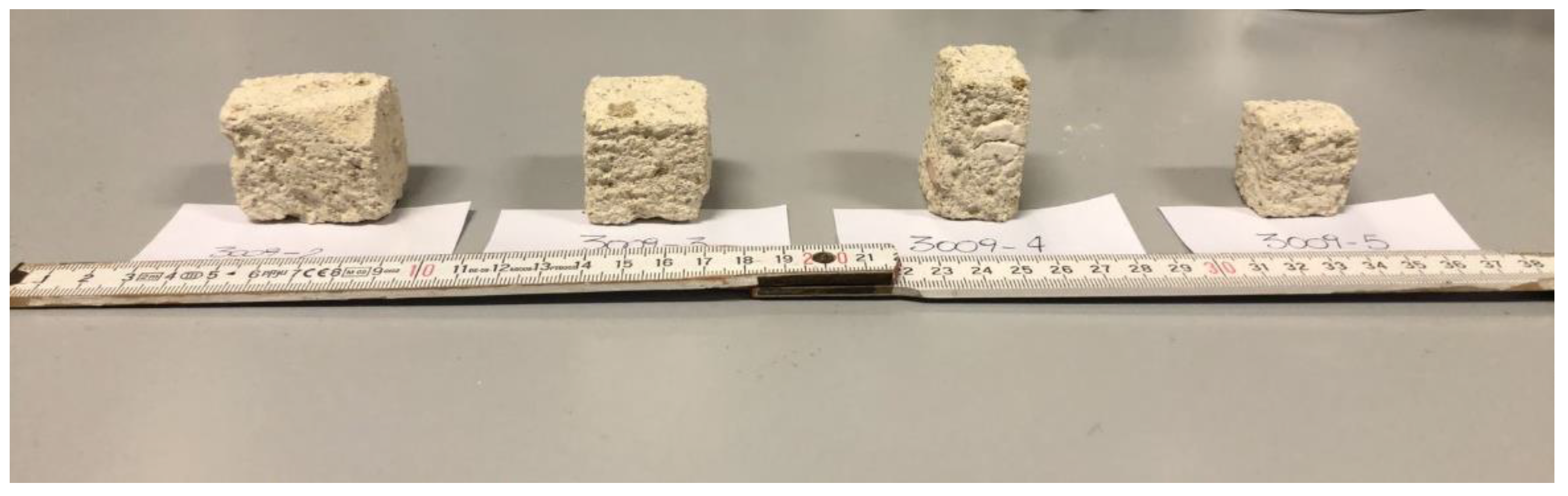

3.2. The Uniaxial Compressive Tests

4. Results and Discussion

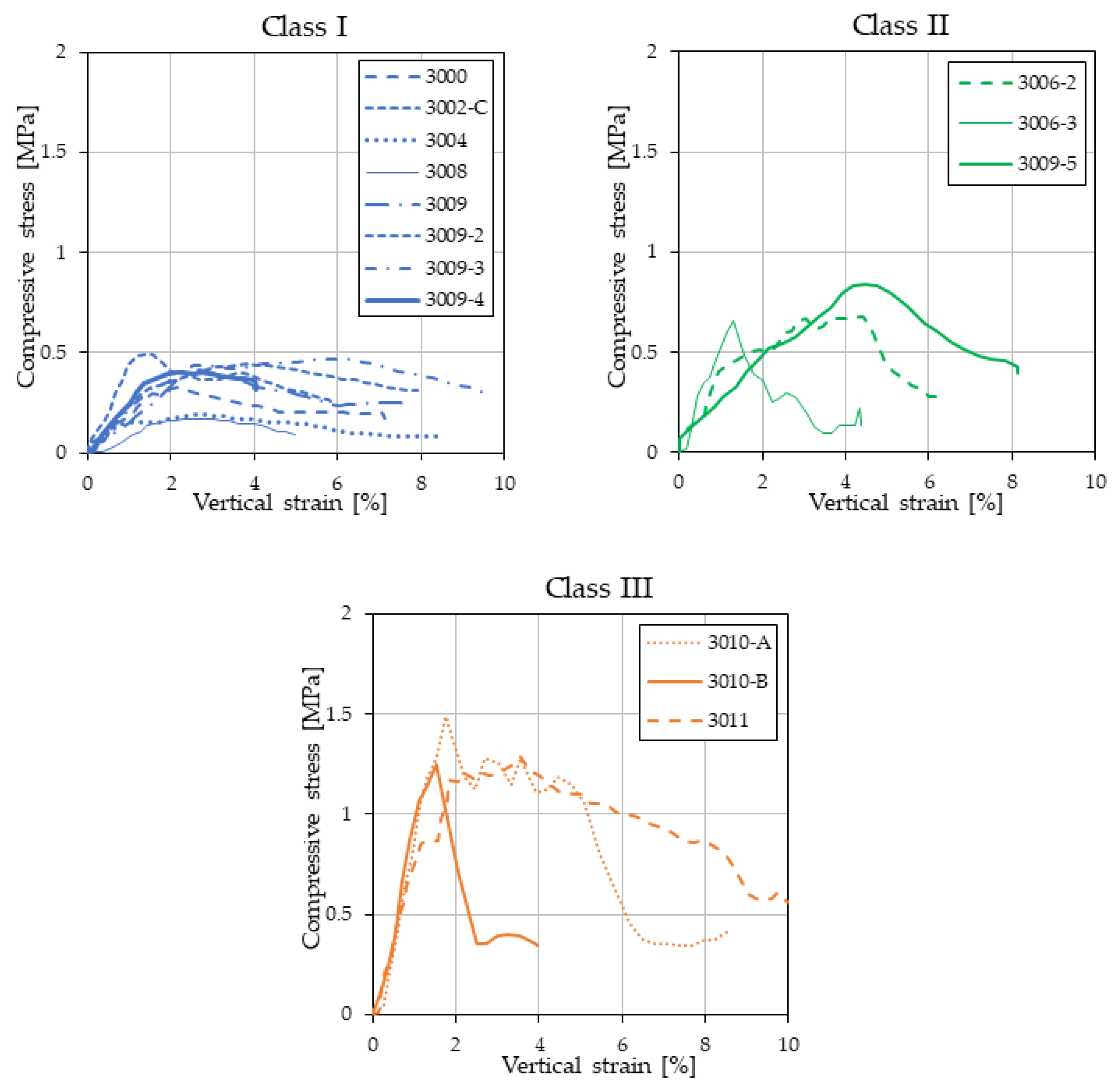

4.1. Uniaxial Compressive Strength of Mortar

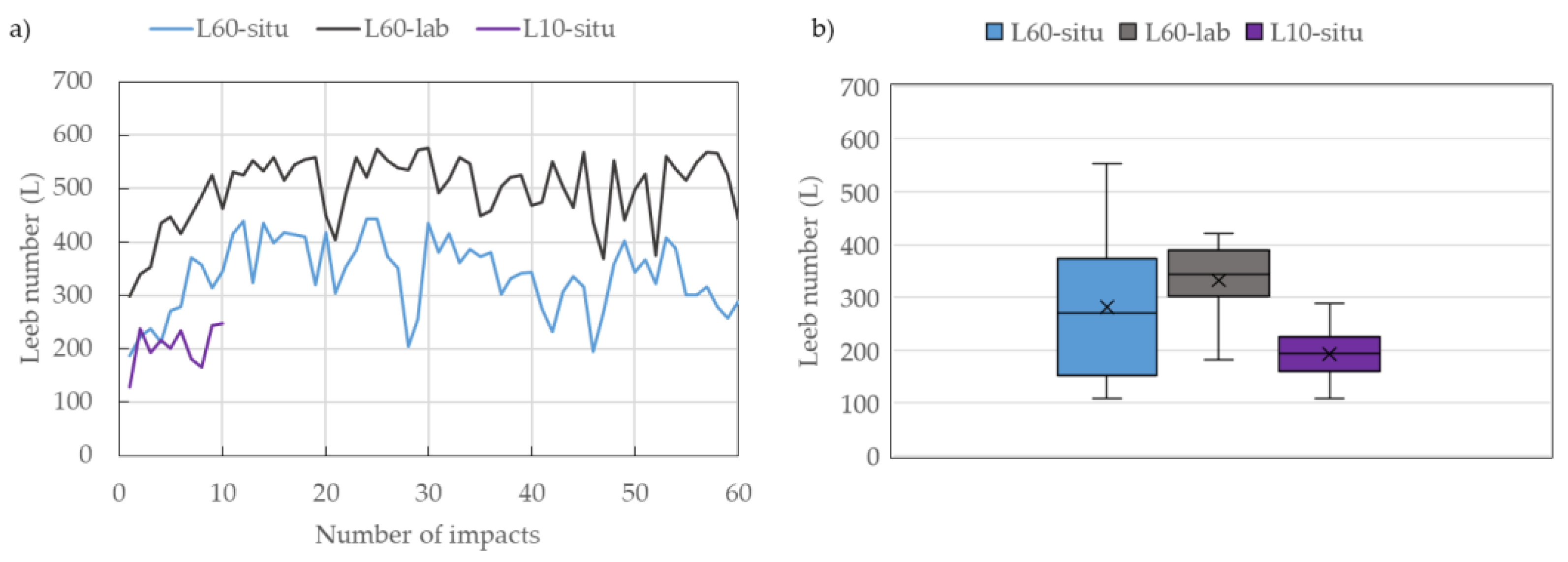

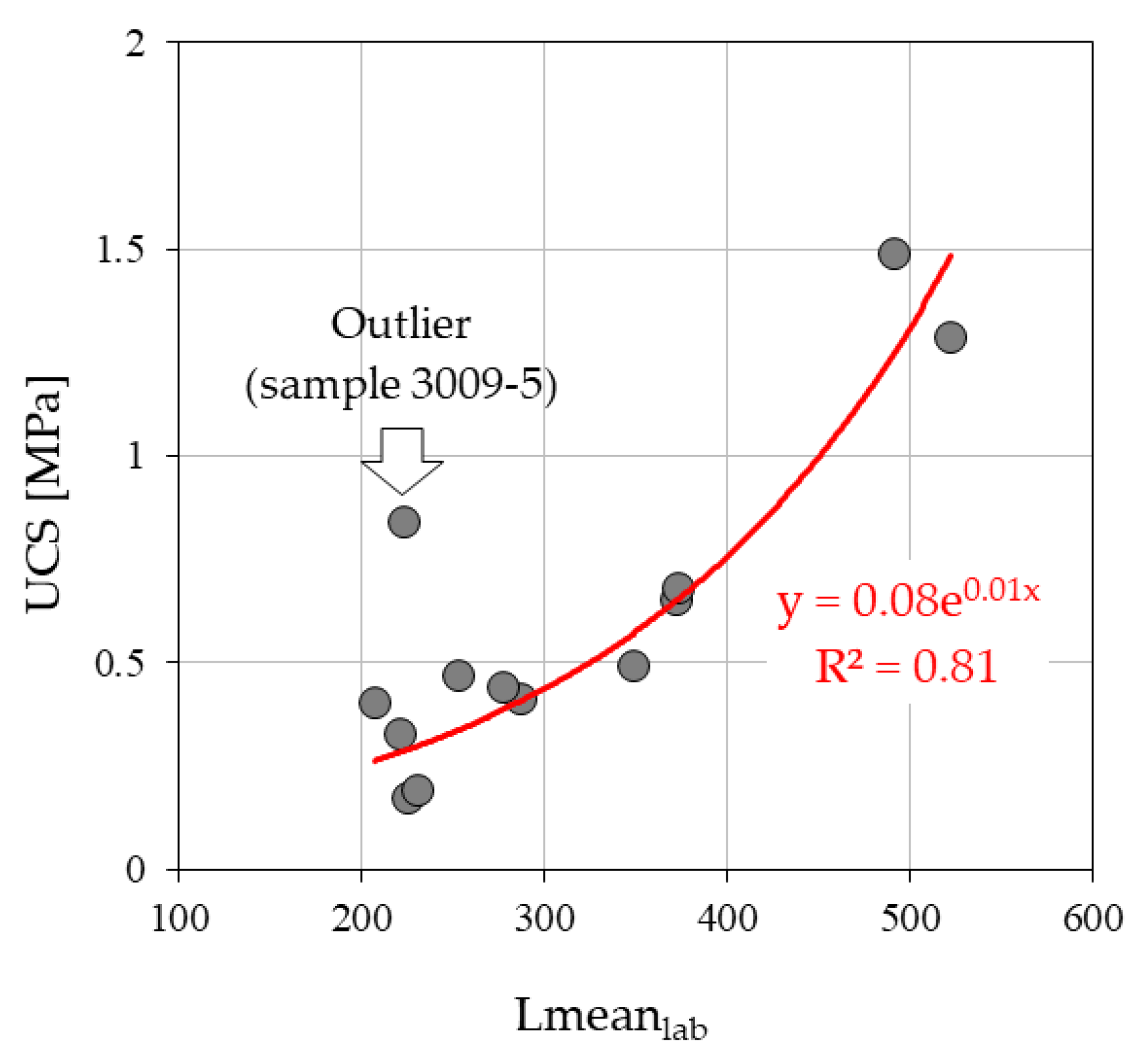

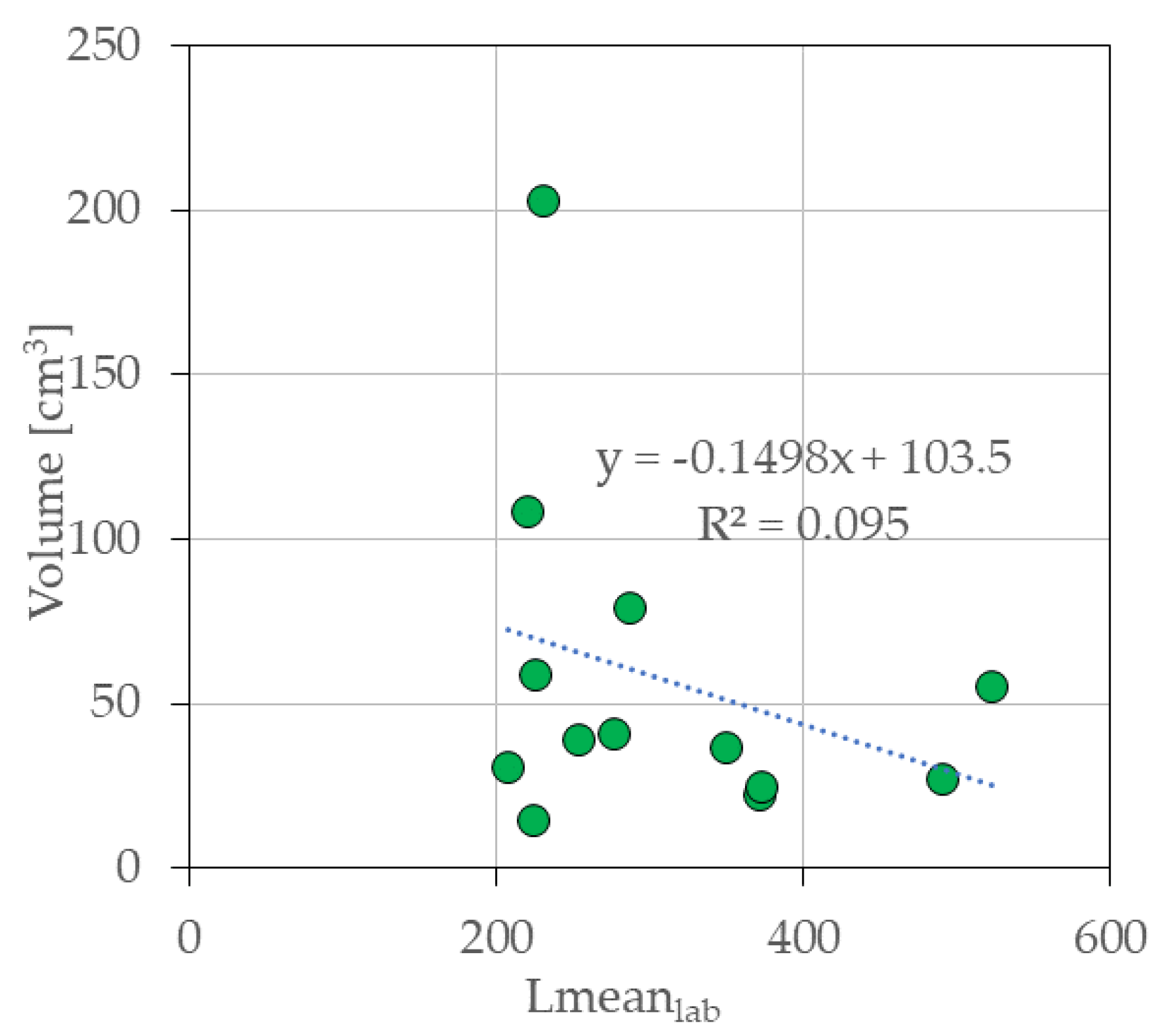

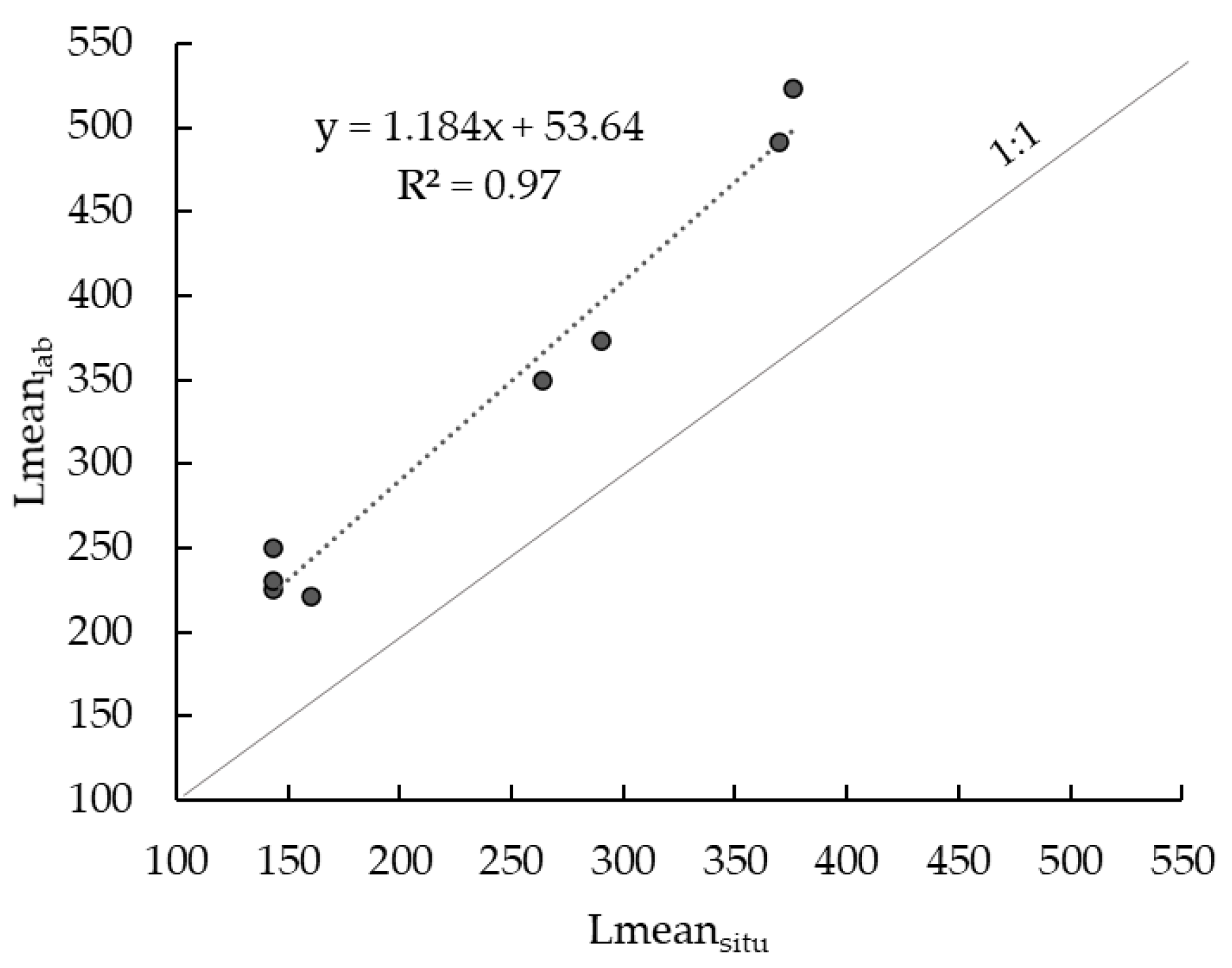

4.2. Results of the In Situ and Laboratory Tests

5. Conclusions

- the Equotip device, due to its low impact energy, is able to evaluate the mechanical properties of ancient mortars, characterized by low strength. In particular, the low dimension of the impact tip of the Equotip device investigates the mechanical properties of the first millimeters of the mortars;

- the data collected by using both the ‘single impact test’ and ‘repeated impact test’ methods; results indicate that the first one is strongly affected by the device settling, underestimating the real mechanical properties of the mortar differently;

- the “repeated impact test” method used in this paper allows monitoring of material behavior following repeated impacts and thus discarding initial values affected by settling and final values affected by artificial micro-fracturing of the material because of the impacts. For this reason, the collecting methodology is fundamental to obtain reliable results;

- the comparison between EQ results and UCS laboratory test allowed the calibration of a relationship between the two parameters;

- the investigated mortars are characterized by low values of UCS, ranging from 0.17 MPa to 1.49 MPa, values largely lower than the strength currently required for new structural mortar; they were classified into three groups based on the UCS values and their different stress-strain response to the compression test; in particular, a brittle behavior has been observed for mortars with a higher UCS whereas a ductile behavior was noticed for mortars with lower UCS values; an evidently different mechanical behavior has also been observed between the mortar samples coming from the core of the masonry and the ones coming from the face. In particular, the mortar in the core of walls is generally weaker than the one coming from the wall face. The reasons for the lower strength of the masonry core can be related to a number of aspects such as the different ages of the mortars, their mineralogical composition, the manufacturing, and application method. Such aspects, not so documented in the literature, are of relevant importance in quantifying more realistically the structural behavior of historical masonry structures;

- the EQ data collected in situ always have a lower mean value comparing to the ones measured on the specimens in the laboratory. This is an important observation to consider in order to give a correct estimation of the real UCS. This aspect has been previously evidenced by [15], pointing out that the NDT may allow a superficial evaluation of the mortar properties and, more so of other materials [21,22,23]. In fact, natural environmental processes, with time, cause decay mostly at the most superficial portion of the mortar, in this study evidenced by the reduction in strength derived from the δ parameter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hughes, J.J.; Van Balen, K.; Bicer-Simsir, B.; Binda, L.; Elsen, J.; van Hees, R.; von Konow, T.; Lindqvist, J.E.; Maurenbrecher, P.; Papayanni, I.; et al. RILEM TC 203-RHM Repair mortars for historic masonry: The role of mortar in masonry: An introduction to requirements for the design of repair mortars. Mater. Struct. 2012, 45, 1287–1294. [Google Scholar]

- Kirca, Ö. Ancient binding materials, mortars and concrete technology: History and durability aspects. In Structural Analysis of Historical Constructions; Modena, C., Lourenço, P.B., Roca, P., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 87–95. [Google Scholar]

- Moropoulou, A.; Labropoulos, K.; Moundoulas, P.; Bakolas, A. The contribution of historic mortars on the earthquake resistance of Byzantine monuments. In Measuring, Monitoring and Modeling Concrete Properties; Springer: Berlin/Heidelberg, Germany, 2006; pp. 643–652. [Google Scholar]

- Rodríguez-Pascua, M.A.; Pérez-López, R.; Giner-Robles, J.L.; Silva, P.G.; Garduño-Monroy, V.H.; Reicherter, K. A comprehensive classification of Earthquake Archaeological Effects (EAE) in archaeoseismology: Application to ancient remains of Roman and Mesoamerican cultures. Quat. Int. 2011, 242, 20–30. [Google Scholar] [CrossRef]

- Penna, A.; Morandi, P.; Rota, M.; Manzini, C.F.; Da Porto, F.; Magenes, G. Performance of masonry buildings during the Emilia 2012 earthquake. Bull. Earthq. Eng. 2014, 12, 2255–2273. [Google Scholar] [CrossRef]

- Binici, H.; Kapur, S. The physical, chemical, and microscopic properties of masonry mortars from Alhambra Palace (Spain) in reference to their earthquake resistance. Front. Archit. Res. 2016, 5, 101–110. [Google Scholar] [CrossRef] [Green Version]

- Clementi, F.; Ferrante, A.; Giordano, E.; Dubois, F.; Lenci, S. Damage assessment of ancient masonry churches stroked by the Central Italy earthquakes of 2016 by the non-smooth contact dynamics method. Bull. Earthq. Eng. 2020, 18, 455–486. [Google Scholar] [CrossRef] [Green Version]

- Liberatore, D.; Doglioni, C.; AlShawa, O.; Atzori, S.; Sorrentino, L. Effects of coseismic ground vertical motion on masonry constructions damage during the 2016 Amatrice-Norcia (Central Italy) earthquakes. Soil Dyn. Earthq. Eng. 2019, 120, 423–435. [Google Scholar] [CrossRef]

- Cattari, S.; Degli Abbati, S.; Ferretti, D.; Lagomarsino, S.; Ottonelli, D.; Tralli, A. Damage assessment of fortresses after the 2012 Emilia earthquake (Italy). Bull. Earthq. Eng. 2014, 12, 2333–2365. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Moundoulas, P.; Cakmak, A.S. Compatible restoration mortars for Hagia Sophia earthquake protection. WIT Trans. Built Environ. 1970, 38, 521–531. [Google Scholar] [CrossRef]

- Moropoulou, A.; Apostolopoulou, M.; Moundoulas, P.; Aggelakopoulou, E.; Siouta, L.; Bakolas, A.; Douvika, M.; Karakitsios, P.; Asteris, P.G. The role of Restoration Mortars in the Earthquake Protection of the Kaisariani Monastery. In Proceedings of the VII European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2016), Crete Island, Greece, 5–10 June 2016; pp. 5–10. [Google Scholar]

- Apostolopoulou, M.; Aggelakopoulou, E.; Siouta, L.; Bakolas, A.; Douvika, M.; Asteris, P.G.; Moropoulou, A. A methodological approach for the selection of compatible and performable restoration mortars in seismic hazard areas. Construct. Build. Mater. 2017, 155, 1–14. [Google Scholar] [CrossRef]

- EN, UNI. Methods of Test for Mortar for Masonry–Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; European Parliament: Kirchberg, Luxembourg, 2007. [Google Scholar]

- Drdácký, M. Non-standard testing of mechanical characteristics of historic mortars. Int. J. Archit. Herit. 2011, 5, 383–394. [Google Scholar] [CrossRef]

- Pelà, L.; Roca, P.; Aprile, A. Combined in-situ and laboratory minor destructive testing of historical mortars. Int. J. Archit. Herit. 2018, 12, 334–349. [Google Scholar] [CrossRef]

- Anzani, A.; Binda, L.; Carpinteri, A.; Invernizzi, S.; Lacidogna, G. A multilevel approach for the damage assessment of Historic masonry towers. J. Cult. Herit. 2010, 11, 459–470. [Google Scholar] [CrossRef]

- Schuller, M.P. Nondestructive testing and damage assessment of masonry structures. Progress Struct. Eng. Mater. 2003, 5, 239–251. [Google Scholar] [CrossRef]

- Mammoliti, E. A New Approach for Engineering Geological Mapping of Subsurface Rock Masses by Means of Fieldwork-Based Rebound Hardness Indexes and Non-Parametric Bayesian Networks. Ph.D. Thesis, University of Pisa, Pisa, Italy, 5 June 2020. [Google Scholar]

- Aydin, A. ISRM suggested method for determination of the Schmidt hammer rebound hardness: Revised version. In The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Springer: Cham, Switzerland, 2008; pp. 25–33. [Google Scholar]

- Kompatscher, M. Equotip-rebound hardness testing after D. Leeb. In Proceedings of the Conference on Hardness Measurements Theory and Application in Laboratories and Industries, Washington, DC, USA, 11–12 November 2004; Volume 1, pp. 1–12. [Google Scholar]

- Kawasaki, S.; Tanimoto, C.; Koizumi, K.; Ishikawa, M. An attempt to estimate mechanical properties of rocks using the Equotip hardness tester. J. Jpn. Soc. Eng. Geol. 2002, 43, 244–248. [Google Scholar] [CrossRef]

- Aoki, H.; Matsukura, Y. A new technique for non-destructive field measurement of rock-surface strength: An application of the Equotip hardness tester to weathering studies. Earth Surface Process. Landforms J. Br. Geomorphol. Res. Group 2007, 32, 1759–1769. [Google Scholar] [CrossRef] [Green Version]

- Viles, H.; Goudie, A.; Grab, S.; Lalley, J. The use of the Schmidt Hammer and Equotip for rock hardness assessment in geomorphology and heritage science: A comparative analysis. Earth Surface Process. Landforms 2011, 36, 320–333. [Google Scholar] [CrossRef]

- Karpuz, C.; Pa, A.G. Field characterisation of weathered Ankara andesites. Eng. Geol. 1997, 46, 1–17. [Google Scholar] [CrossRef]

- Ballantyne, C.K.; McCarroll, D.; Nesje, A.; Dahl, S.O. Periglacial trimlines, former nunataks and the altitude of the last ice sheet in Wester Ross, northwest Scotland. J. Quat. Sci. 1997, 12, 225–238. [Google Scholar] [CrossRef]

- Anderson, E.; Harrison, S.; Passmore, D.G.; Mighall, T.M. Geomorphic evidence of Younger Dryas glaciation in the Macgillycuddy’s Reeks, south west Ireland. J. Quat. Sci. 1998, 13, 75–90. [Google Scholar]

- Rae, A.C.; Harrison, S.; Mighall, T.; Dawson, A.G. Periglacial trimlines and nunataks of the last glacial maximum: The gap of Dunloe, southwest Ireland. J. Quat. Sci. 2004, 19, 87–97. [Google Scholar] [CrossRef]

- Galli, P.; Castenetto, S.; Peronace, E. The macroseismic intensity distribution of the 30 October 2016 earthquake in central Italy (Mw 6.6): Seismotectonic implications. Tectonics 2017, 36, 2179–2191. [Google Scholar] [CrossRef]

- Scisciani, V.; Calamita, F.; Tavarnelli, E.; Rusciadelli, G.; Ori, G.G.; Paltrinieri, W. Foreland-dipping normal faults in the inner edges of syn-orogenic basins: A case from the Central Apennines, Italy. Tectonophysics 2001, 330, 211–224. [Google Scholar] [CrossRef]

- Vintzileou, E.; Miltiadou-Fezans, A. Mechanical properties of three-leaf stone masonry grouted with ternary or hydraulic lime-based grouts. Eng. Struct. 2008, 30, 2265–2276. [Google Scholar] [CrossRef]

- Valluzzi, M.R.; Da Porto, F.; Modena, C. Behaviour of multi-leaf stone masonry walls strengthened by different intervention techniques. Hist. Construct. 2001, 1023–1032. [Google Scholar]

- Verwaal, W.; Mulder, A. Estimating rock strength with the Equotip hardness tester. Int. J. Rock Mech. Min. Sci. Geomech. Abstracts 1993, 30, 659–662. [Google Scholar] [CrossRef]

- Proceq, S.A. Equotip Application Booklet. Portable Hardness Testing Leeb, Portable Rockwell and UCI. 2019. Available online: https://www.proceq.com/compare/equotip-portable-hardness-testing/ (accessed on 1 December 2019).

- Autiero, F.; De Martino, G.; Di Ludovico, M.; Prota, A. Mechanical behavior of ancient mortar specimens from Pompeii site. In COMPDYN 2019, Proceedings of the 7th ECCOMAS Thematic Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, Crete, Greece, 24–26 June 2019; Papadrakakis, M., Fragiadakis, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Drdácký, M.; Masin, D.; Mekonone, M.D. Compression tests on non-standard historic mortar specimens. In Proceedings of the 1st Historical Mortars Conference (HMCO8), Lisbon, Spain, 24–26 September 2008. [Google Scholar]

| Building | Sampling Location | Site ID |

|---|---|---|

| Palazzo Ducale Palace | masonry core | 3000 |

| Battibocca Palace | masonry core | 3004 |

| San Domenico Monastery | masonry core | 3008 |

| San Domenico Monastery | masonry core | 3009 |

| Palazzo Ducale Palace | masonry face | 3011 |

| Palazzo Ducale Palace | masonry core | 3002 |

| San Domenico Monastery | masonry face | 3006 |

| San Domenico Monastery | masonry core | 3009 |

| San Domenico Monastery | masonry face | 3010 |

| San Domenico Monastery | masonry face | 3011 |

| Site | Sample | h | lmax | lmin | h/d |

|---|---|---|---|---|---|

| ID | Name | [cm] | [cm] | [cm] | [-] |

| 3000 | 3000 | 5.83 | 4.65 | 4 | 1.2 |

| 3004 | 3004 | 6.9 | 6 | 4.9 | 1.13 |

| 3008 | 3008 | 4.8 | 3.6 | 3.4 | 1.22 |

| 3011 | 3011 | 4.7 | 4.5 | 2.6 | 1.22 |

| 3002 | 3002-C | 4.2 | 3.05 | 2.88 | 1.26 |

| 3006 | 3006-2 | 4.4 | 2.55 | 2.2 | 1.65 |

| 3006-3 | 4.55 | 2.25 | 2.2 | 1.81 | |

| 3009 | 3009 3009-2 | 4.86 3.6 | 2.85 4.2 | 3.35 2.7 | 1.07 0.95 |

| 3009-3 | 3.3 | 3.5 | 3.4 | 0.85 | |

| 3009-4 | 4.3 | 3.1 | 2.3 | 1.43 | |

| 3009-5 | 2.8 | 2.4 | 2.2 | 1.08 | |

| 3010 | 3010-A | 4.6 | 2.47 | 2.4 | 1.67 |

| 3010-B | 4.75 | 2.6 | 2.48 | 1.66 |

| Sample Name | Sampling Location | UCS [MPa] |

|---|---|---|

| 3008 | masonry core | 0.17 |

| 3004 | masonry core | 0.19 |

| 3000 | masonry core | 0.33 |

| 3009-4 | masonry core | 0.4 |

| 3009 | masonry core | 0.41 |

| 3009-2 | masonry core | 0.44 |

| 3009-3 | masonry core | 0.47 |

| 3002-C | masonry core | 0.49 |

| 3006-3 | masonry face | 0.65 |

| 3006-2 | masonry face | 0.68 |

| 3009-5 | masonry core | 0.84 |

| 3010-B | masonry face | 1.25 |

| 3011 | masonry face | 1.29 |

| 3010-A | masonry face | 1.49 |

| Sampling Location | Site ID | Number of Specimens (pcs.) | Lmeansitu | Lmeanlab * | δ | UCS * [MPa] | ||

|---|---|---|---|---|---|---|---|---|

| mean | std | mean | std | |||||

| masonry core | 3000 | 1 | 160 | 15 | 221 | 42.1 | 0.72 | 0.33 |

| masonry core | 3002 | 1 | 263.5 | 91.2 | 349.5 | 30.9 | 0.75 | 0.3 |

| masonry core | 3004 | 1 | 143 | 23.5 | 230.6 | 20.5 | 0.62 | 0.19 |

| masonry face | 3006 | 2 | 290 | 54.9 | 372.7 * | 34.5 | 0.78 | 0.67 * |

| masonry core | 3008 | 1 | 143 | 71.3 | 225.3 | 63.3 | 0.63 | 0.17 |

| masonry core | 3009 | 5 | 143.2 | 74.2 | 250.0 * | 107.1 | 0.57 | 0.51 * |

| masonry face | 3010 | 1 | 369.6 | 46.5 | 491.4 * | 55 | 0.75 | 1.37 * |

| masonry face | 3011 | 1 | 375.6 | 37.9 | 523 | 43.8 | 0.72 | 1.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mammoliti, E.; Ferretti, A.; Malavolta, M.; Teloni, R.; Ruggeri, P.; Roselli, G. Defining a Non-Destructive In Situ Approach for the Determination of Historical Mortar Strength Using the Equotip Hardness Tester. Appl. Sci. 2021, 11, 4788. https://doi.org/10.3390/app11114788

Mammoliti E, Ferretti A, Malavolta M, Teloni R, Ruggeri P, Roselli G. Defining a Non-Destructive In Situ Approach for the Determination of Historical Mortar Strength Using the Equotip Hardness Tester. Applied Sciences. 2021; 11(11):4788. https://doi.org/10.3390/app11114788

Chicago/Turabian StyleMammoliti, Elisa, Antonio Ferretti, Michele Malavolta, Riccardo Teloni, Paolo Ruggeri, and Graziella Roselli. 2021. "Defining a Non-Destructive In Situ Approach for the Determination of Historical Mortar Strength Using the Equotip Hardness Tester" Applied Sciences 11, no. 11: 4788. https://doi.org/10.3390/app11114788