A New Design of an Integrated Solar Absorption Cooling System Driven by an Evacuated Tube Collector: A Case Study for Baghdad, Iraq

Abstract

:1. Introduction

2. Design Aspects

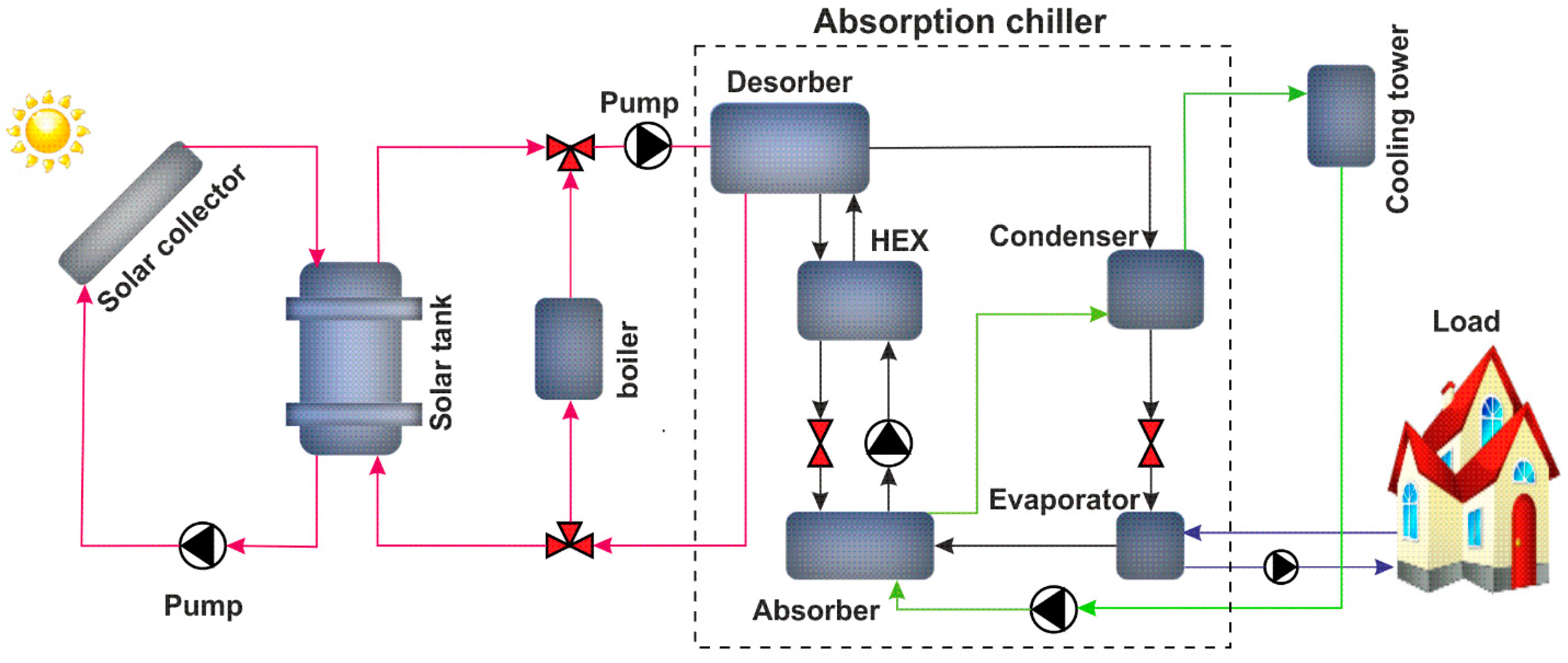

2.1. Thermal Solar Cooling System Description

2.1.1. Solar Collector

2.1.2. Solar Tank

2.1.3. Auxiliary Boiler

2.1.4. Heat Rejection System: Cooling Tower

2.1.5. Cooling Cycle: Absorption

- →

- COP nominal. COPnom. (0.7 for Yazaki WFC-10, Yazaki Energy Systems Inc., Plano, TX, USA)

- →

- Nominal evaporator power . (35 kW for Yazaki WFC-10, Yazaki Energy Systems Inc., Plano, TX, USA)

- →

- Fraction capacity fcapacity: is the ratio of the evaporator’s output power to the nominal power of the chiller. With the manufacturer’s data for each of the established operating points, the quotient between the output power it has in each of these conditions and the nominal power of the evaporator is evaluated.where is the output power under the particular conditions;

- →

- Energy input fraction fEnergyinput: is the ratio of the generator power to the nominal generator power necessary to satisfy the evaporator power. Similarly, it is obtained from the operation curves as:where and COP are the values for the particular evaluation conditions obtained from the manufacture’s curves. The maximum output power that the chiller will be able to offer on the evaporator for each of the conditions evaluated is calculated from Equation (10).

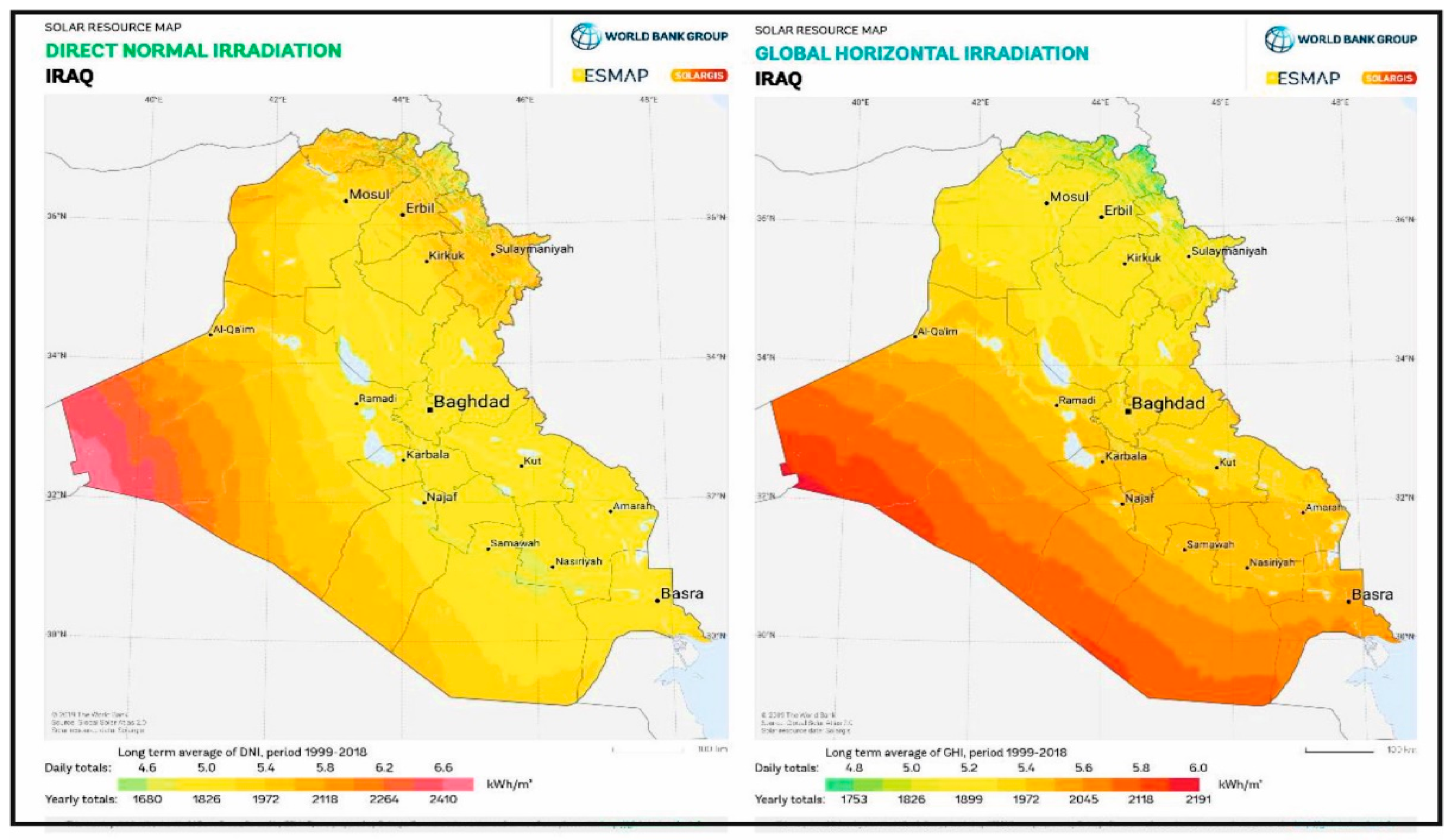

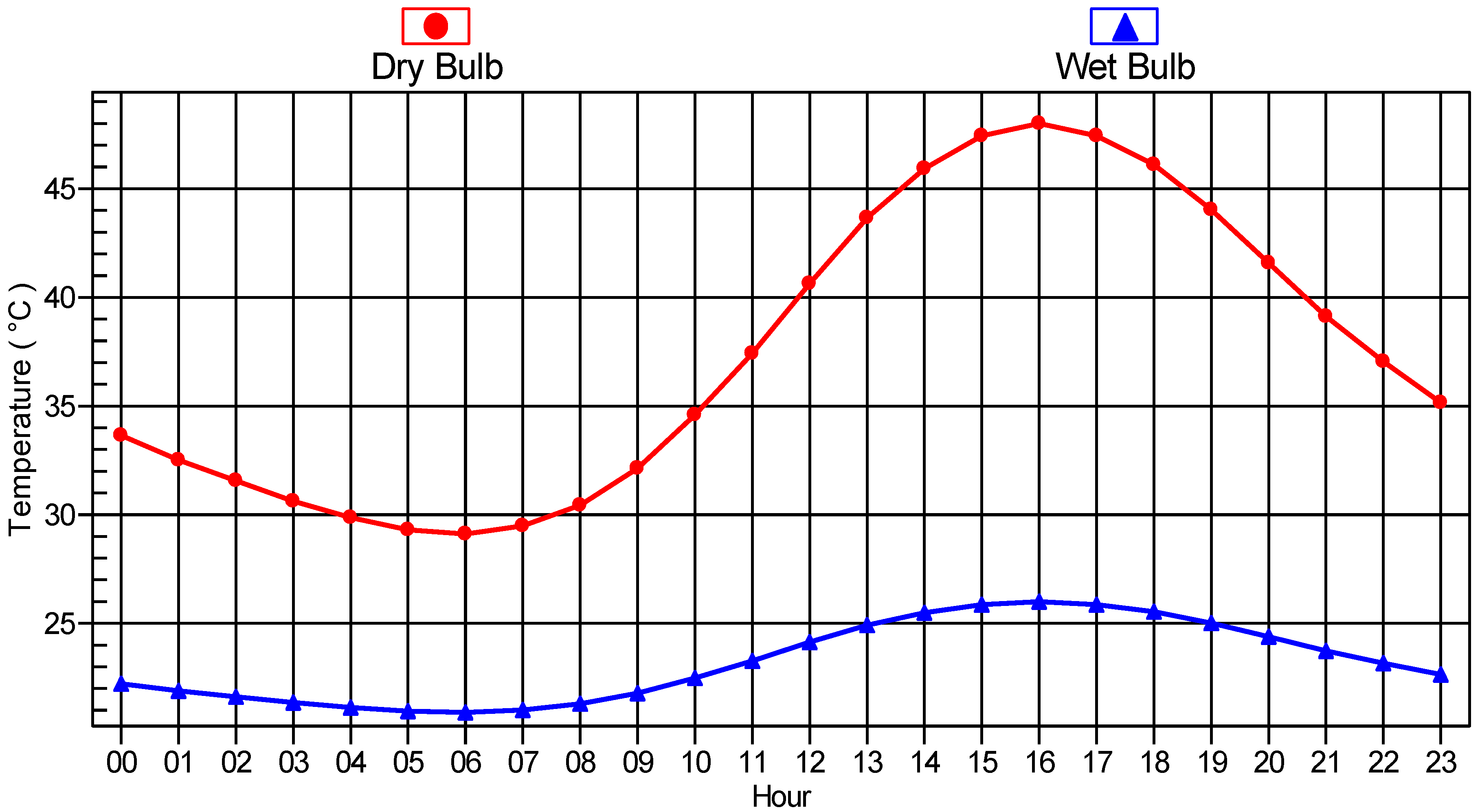

2.2. Meteorological Data

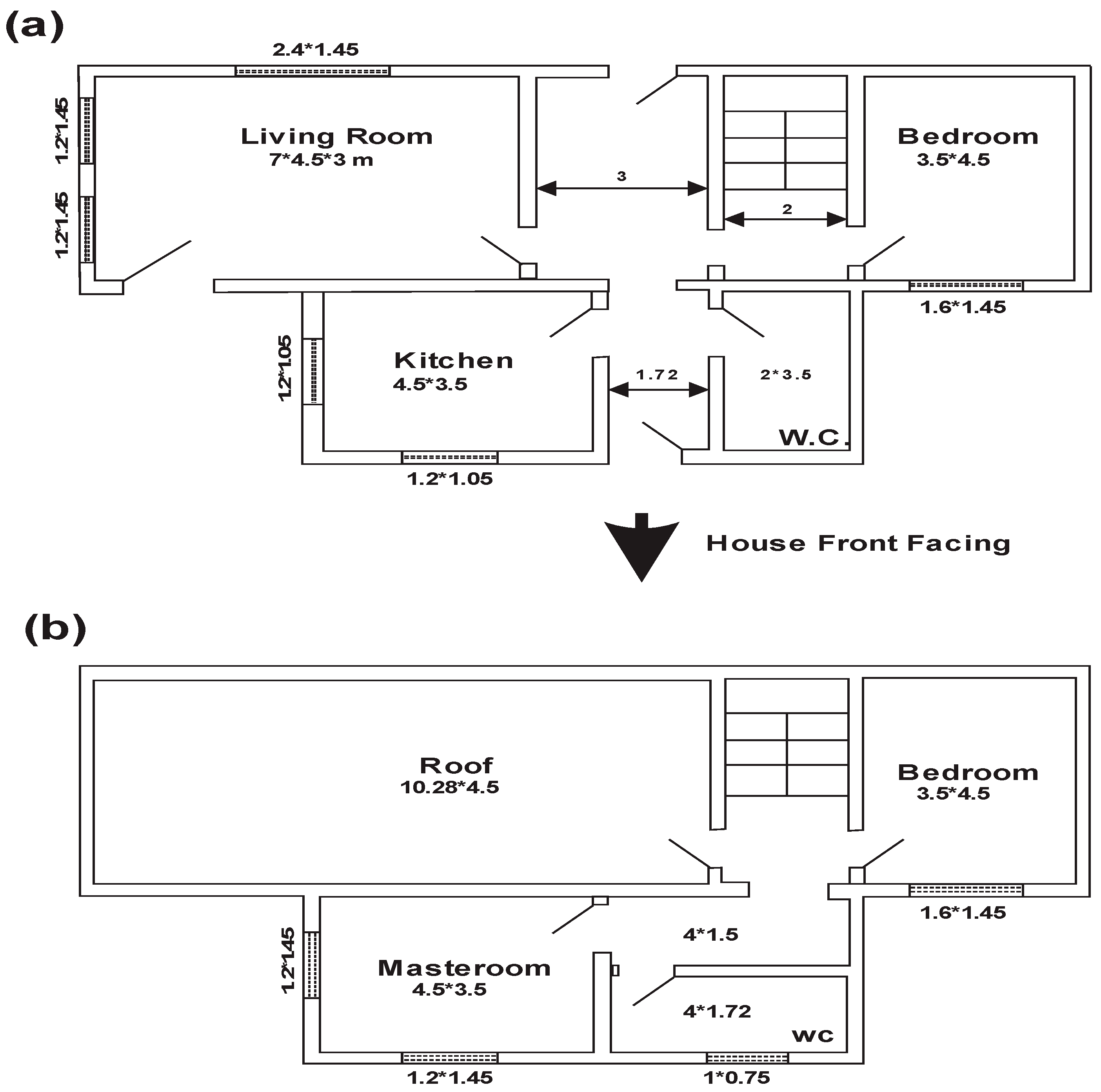

2.3. House Profile and Cooling Loads

- The window-to-gross-wall area should not be greater than 35%.

- Overhangs should be placed on the east, west, and south windows of the building with a projection factor (overhang depth/window height) of greater than 0.5.

- Lighting devices should have an efficiency of 60 lumens/W.

- Specific lighting, 15 W/m2.

- Specific gain (equipment and people), 15 W/m2.

- Occupation rate 0.05 occupants/m2.

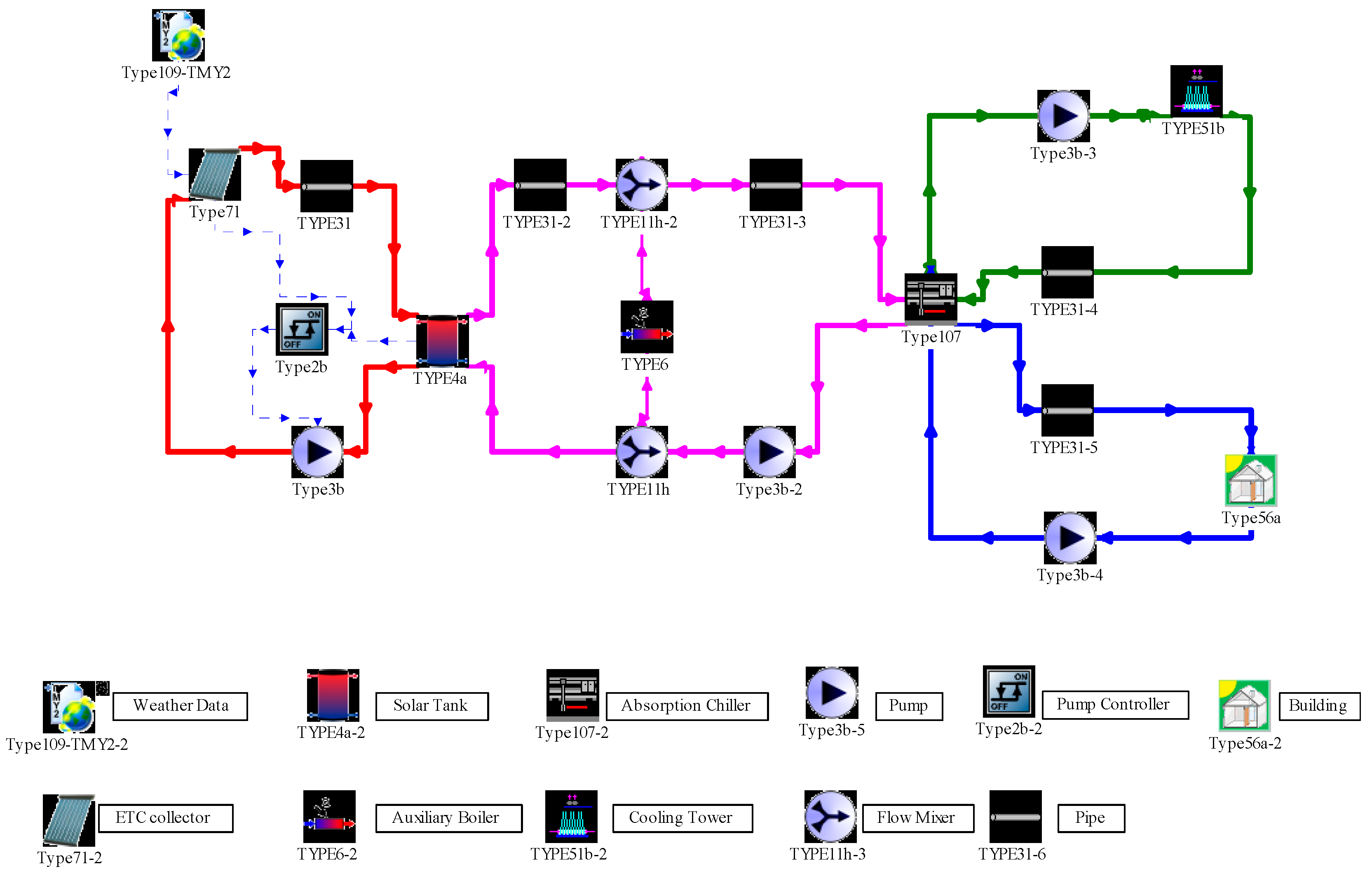

2.4. System Modeling

- The electrical energy consumed by the pumps is neglected.

- Pumps are not supposed to transmit thermal energy to the fluid.

- When the pumps are running the mass, flows remain constant.

- The limit capacity of the chiller is assumed to correspond to a cooling water temperature of 27 °C.

3. Performance Analysis

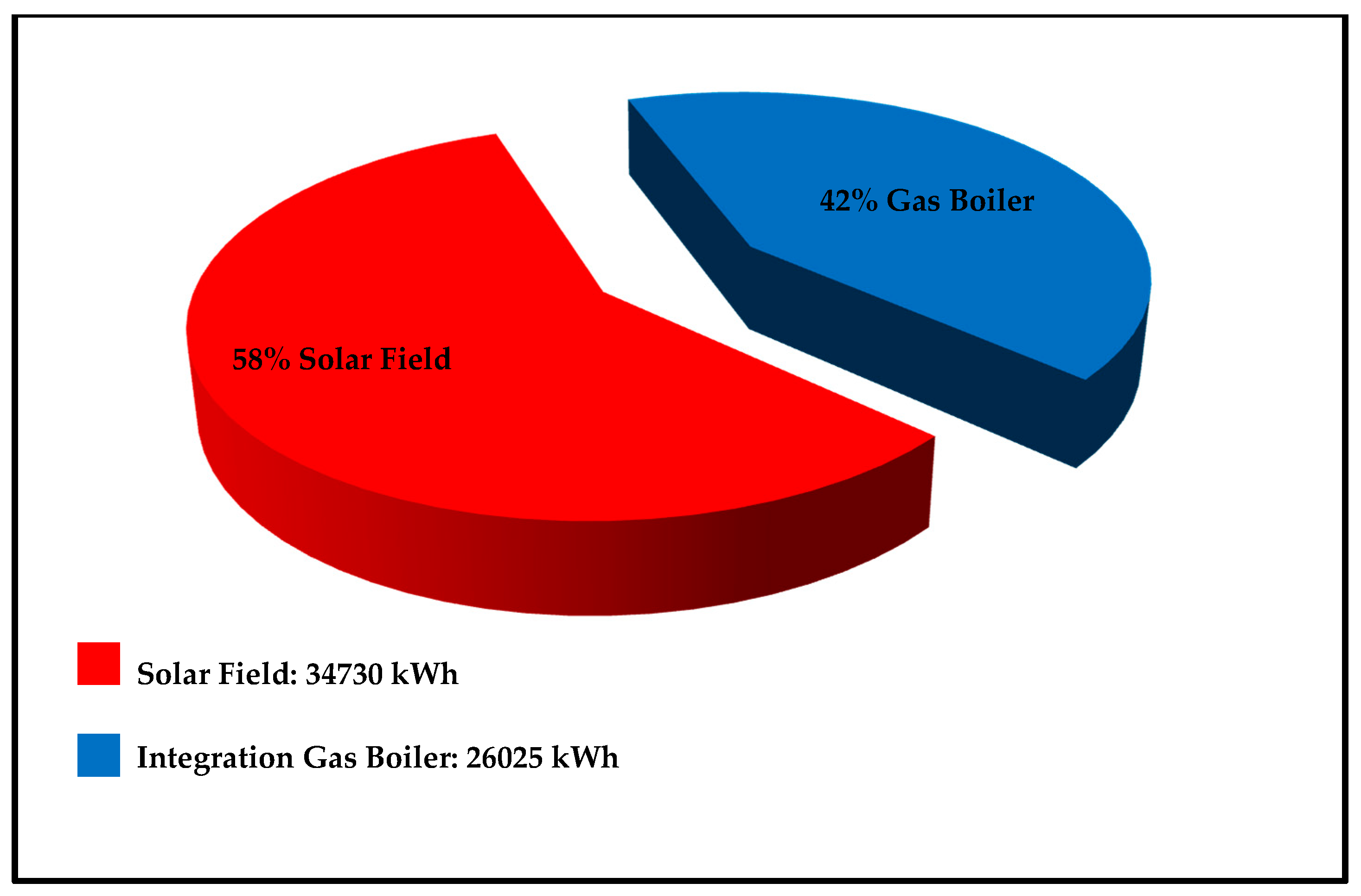

3.1. Solar Fraction

3.2. Primary Energy Saving

- is the efficiency of auxiliary boiler 0.9;

- is required heat for both space heating and DHW (Domestic Hot Water) in the conventional system (kWh).

- is the produced energy by auxiliary heater (kWh).

- , are the primary energy conversion factors for heat and electricity from fossil fuel, 0.95 kWhheat,fossil/kWhPE and 0.5 kWhelec,fossil/kWhPE.

3.3. Electric Efficiency of the Total System

- is the consumed electricity by a pump that feeds the chiller (kWh).

- is the consumed electricity by cooling water loop pump (kWh).

- is the consumed electricity by the chiller (kWh).

- is the electrical power of fan cooling tower (kWh).

- is the consumed electricity by solar loops pumps (kWh).

- is the consumed electricity by boiler (kWh).

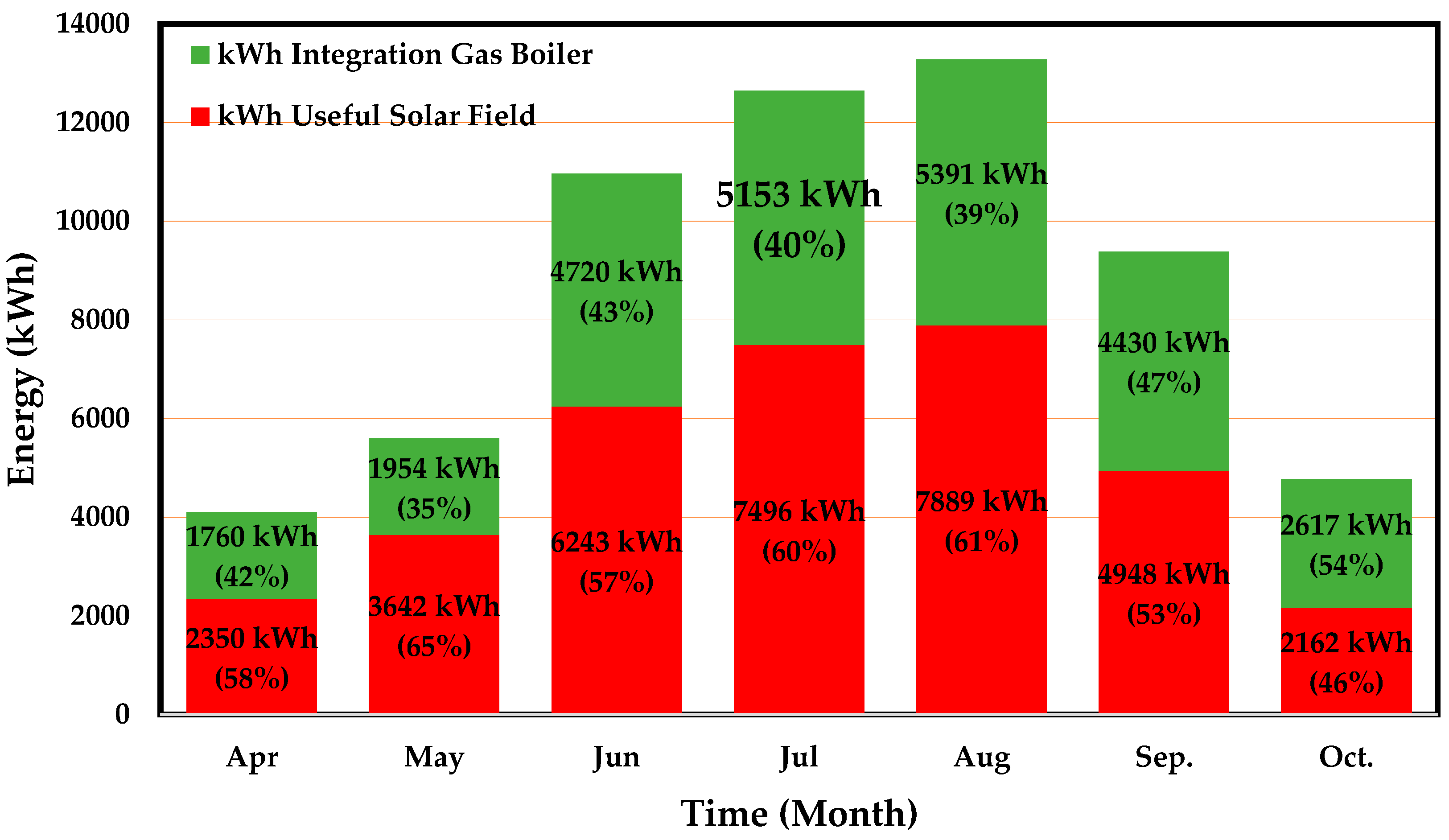

4. Results and Discussion

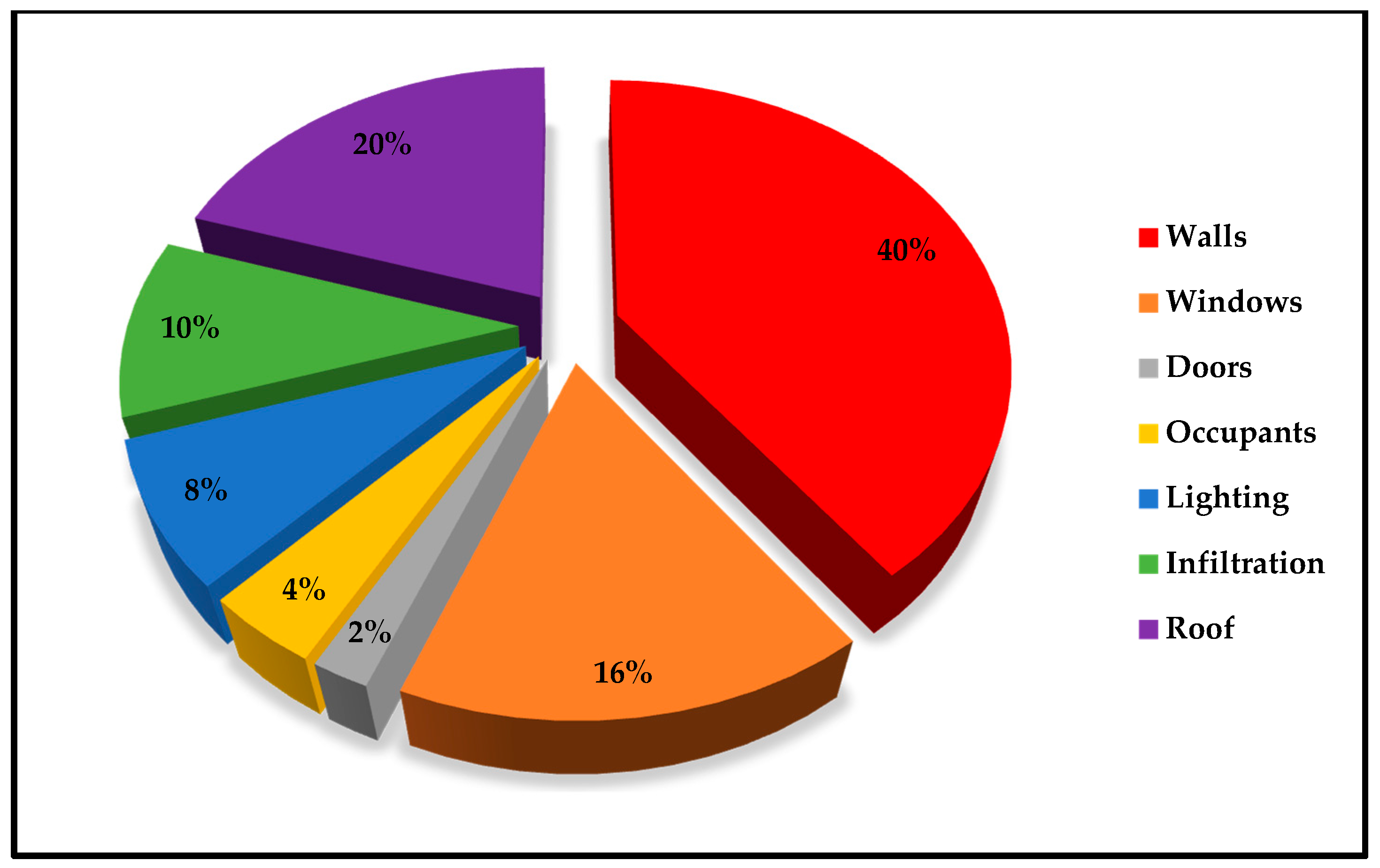

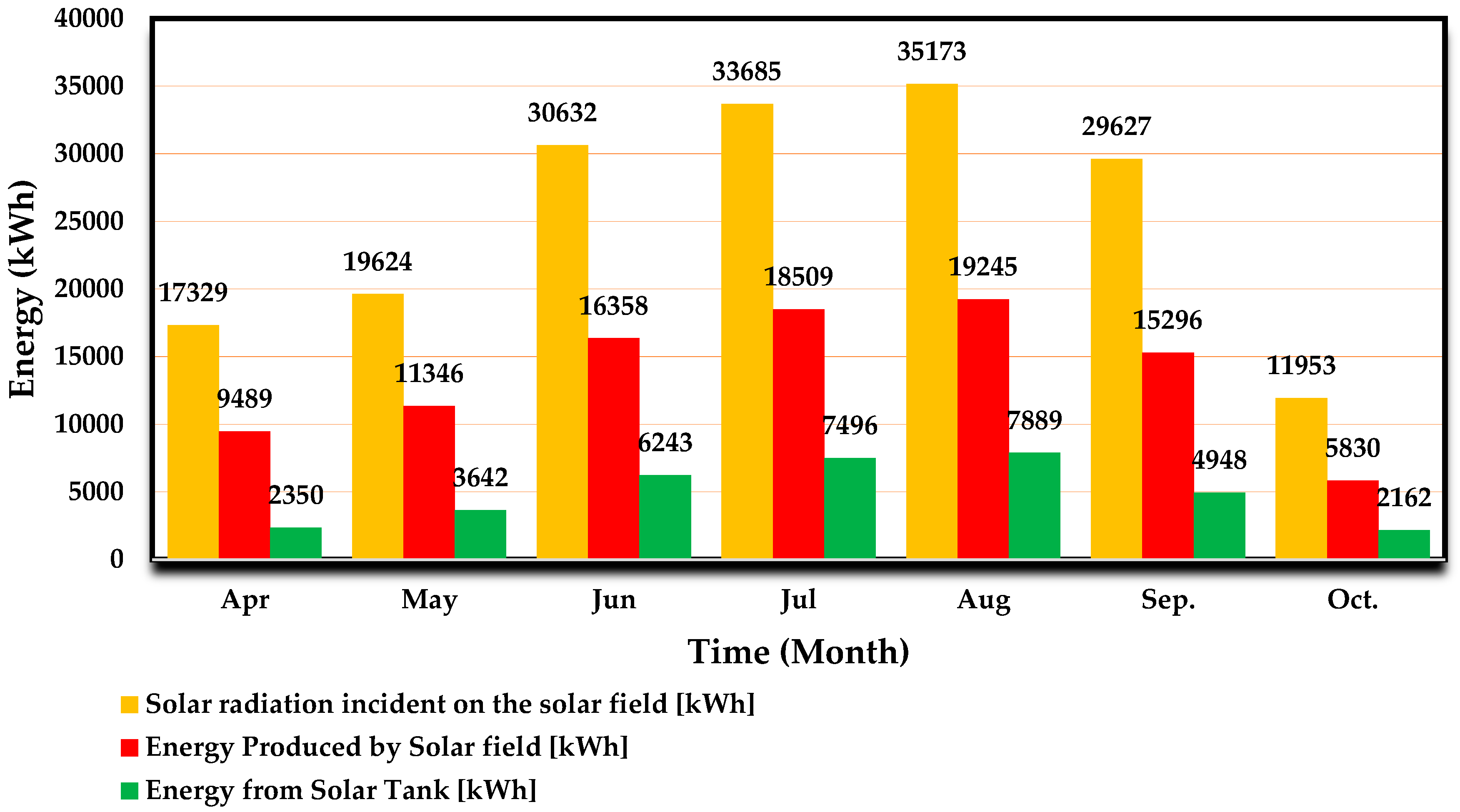

4.1. House Energy Balance Analysis

4.2. Primary Energy Analysis

4.3. Parametric Analysis

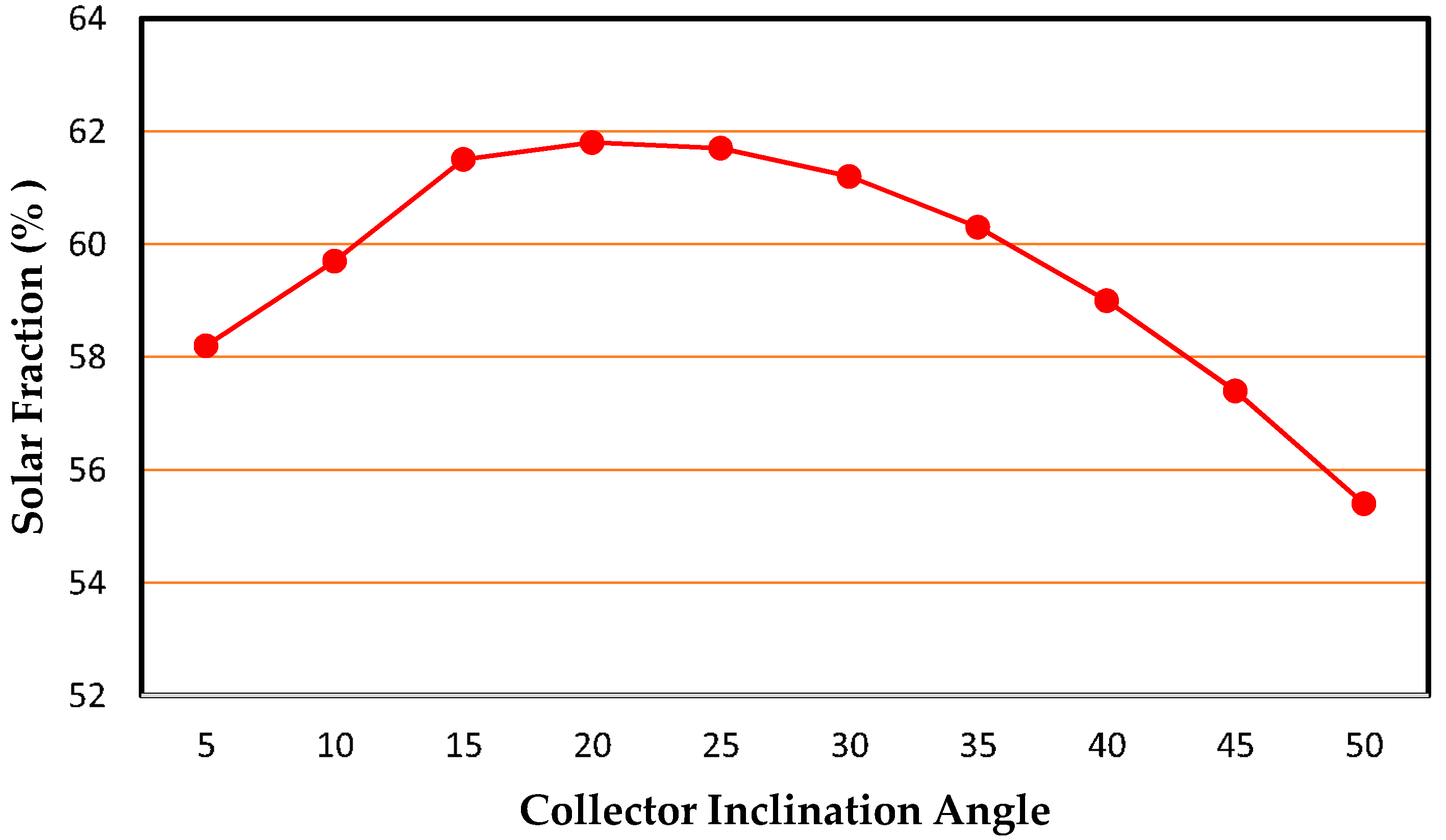

4.3.1. Effect of Collector Slope

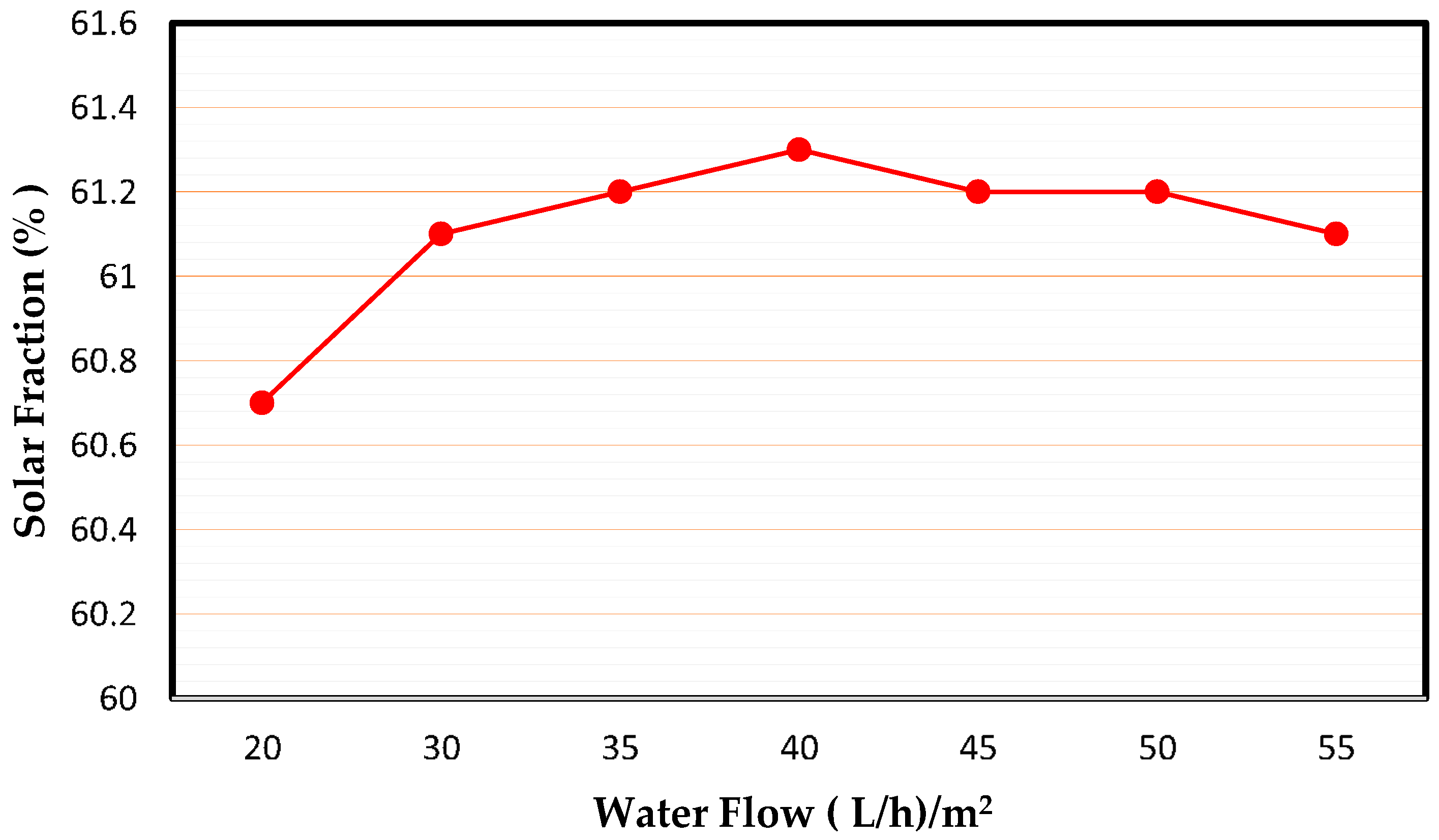

4.3.2. Effect of Water Flow Rate

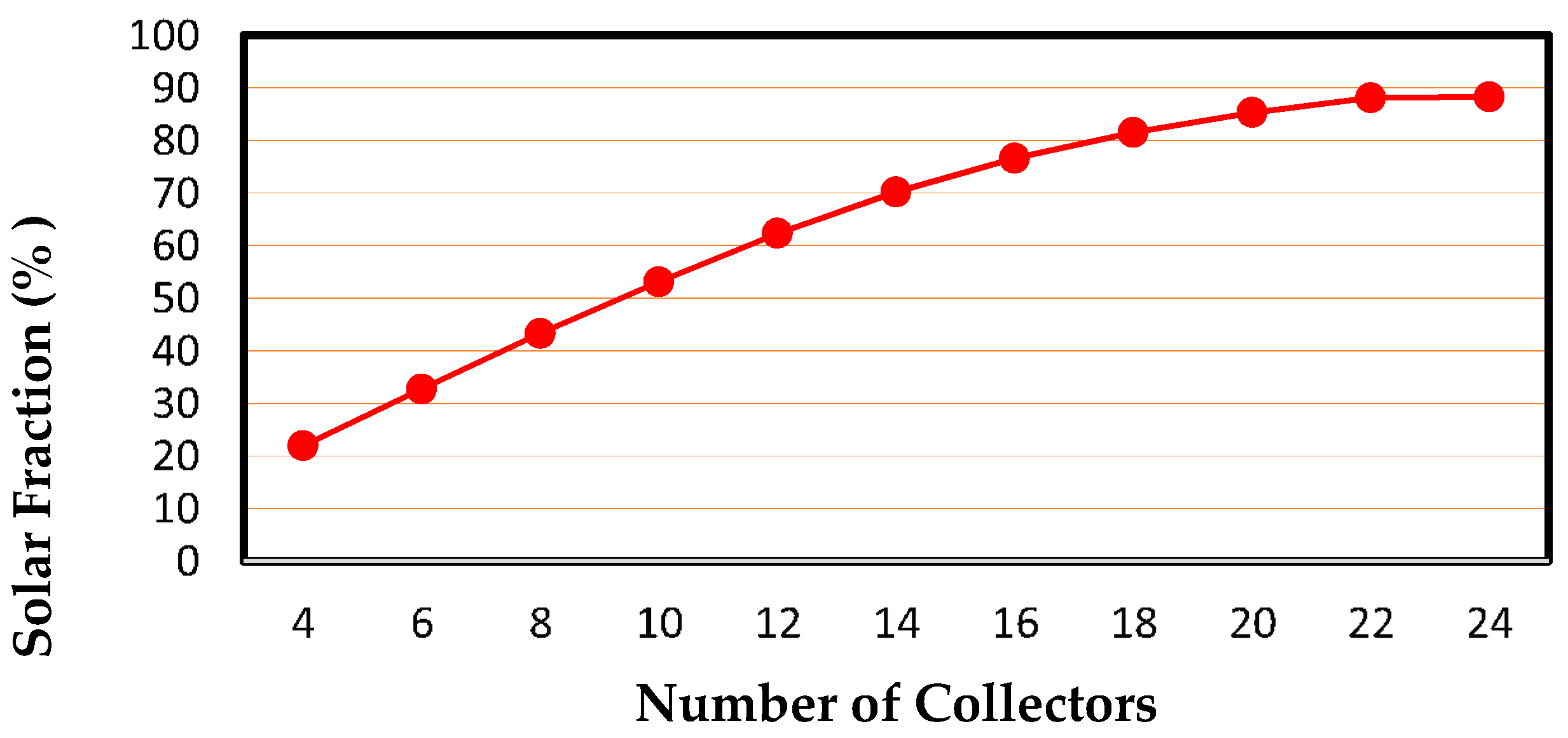

4.3.3. Effect of Solar Field Area

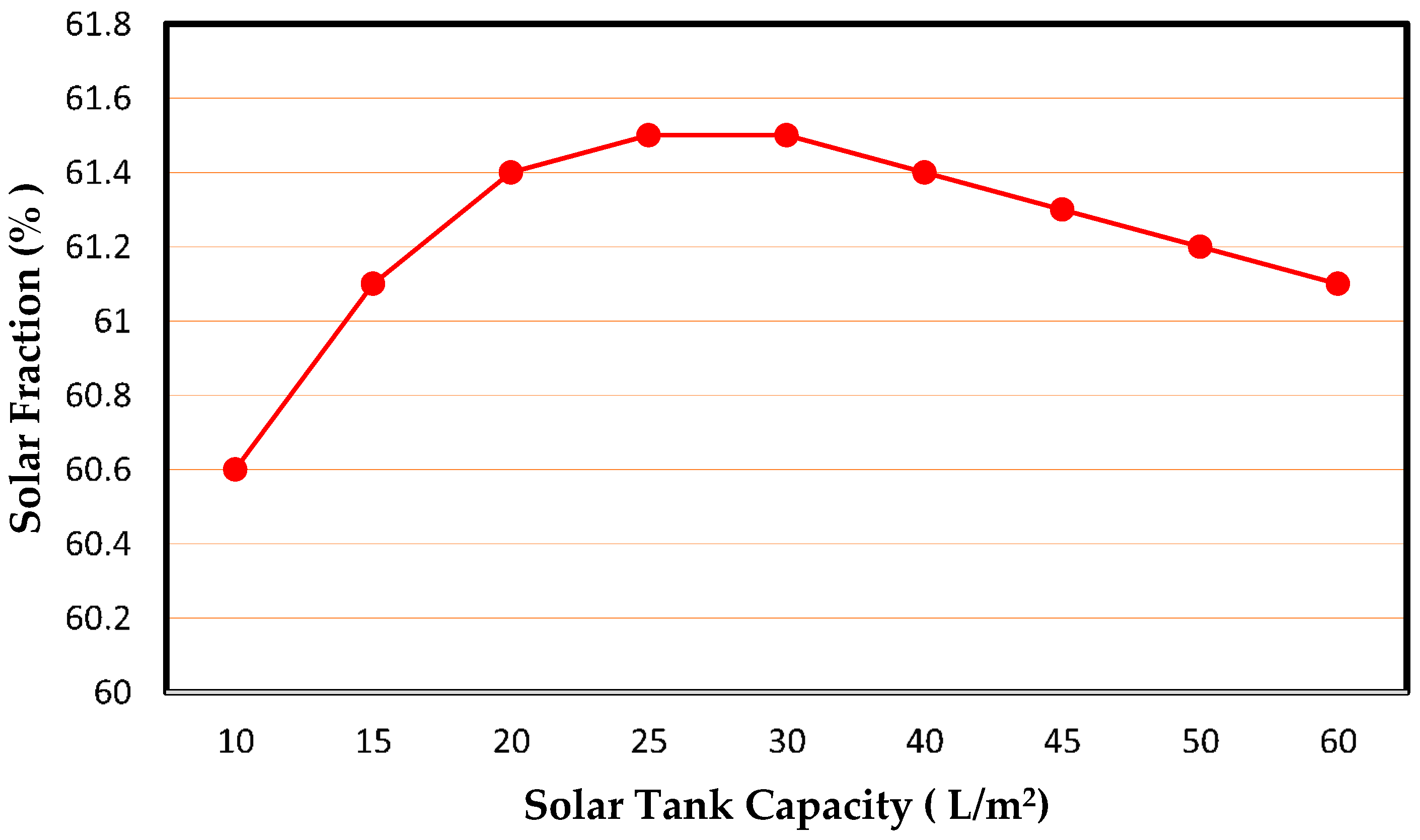

4.3.4. Effect of Solar Tank Capacity

4.3.5. Effect of Solar Tank Temperature

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclatures, Subscripts and Abbreviations

| Nomenclatures | |

| area (m2) | |

| loss coefficient | |

| efficiency | |

| radiation incident (W/m2) | |

| mass flow rate (kg/s) | |

| specific heat (kPa) | |

| heat transfer rate (kW) | |

| temperature (°C) | |

| overall heat transfer coefficient (kW/m2·K) | |

| power (kW) | |

| Subscripts | |

| a | Ambient |

| Auxiliary | |

| Condense | |

| Evaporator | |

| Fraction | |

| Generator | |

| i | Node |

| Load | |

| Nominal | |

| Minimum | |

| Maximum | |

| Outlet | |

| Source | |

| Set | |

| Water | |

| Abbreviations | |

| COP | Coefficient of performance |

| DHW | Domestic hot water |

| EES | Engineering Equation Solver |

| ETC | Evacuated tube collector |

| HVAC | Heating, ventilation, and air conditioning |

| IEA | International Energy Agency |

| IAM | Incidence angle modifier |

| NTU | Number of transfer unit |

| PE | Primary energy |

| SACS | Solar absorption cooling system |

| SF | Solar fraction |

| TMY | Typical meteorological year |

| TRNSYS | Transient System Simulation Program |

Appendix A

The House under Study

| Wall Details Outside Surface Color Dark Absorptivity 0.900 Overall U-Value 0.415 W/(m2·K) | |||||

|---|---|---|---|---|---|

| Wall Layers Details (Inside to Outside) | |||||

| Layers | Thickness mm | Density kg/m3 | Specific Ht·kJ/(kg·K) | R-Value (m2·K)/W | Weight kg/m2 |

| Inside surface resistance | 0.000 | 0.0 | 0.00 | 0.00200 | 0.0 |

| Cement bounded | 12.000 | 1600.0 | 1.34 | 0.04200 | 19.2 |

| Insulation | 50.000 | 32.0 | 0.90 | 1.66600 | 1.6 |

| Hollow block | 200.000 | 1922.0 | 0.84 | 0.40000 | 384.4 |

| 13 mm gypsum board | 12.700 | 800.9 | 1.09 | 0.07890 | 10.2 |

| Outside surface resistance | 0.000 | 0.0 | 0.00 | 0.00200 | 0.0 |

| Air space | 0.000 | 0.0 | 0.00 | 0.16026 | 0.0 |

| Outside surface resistance | 0.000 | 0.0 | 0.00 | 0.05864 | 0.0 |

| Totals | 274.700 | - | - | 2.40980 | 415.4 |

| Component | Exterior Roof | Exterior Glass | Exterior Wooden Door | Exterior Steel Door |

|---|---|---|---|---|

| U value (W/m2 °C) | 1.670388 | 5.888993 | 2.087049 | 6.07040 |

References

- Allouhi, A.; El Fouih, Y.; Kousksou, T.; Jamil, A.; Zeraouli, Y.; Mourad, Y. Energy consumption and efficiency in buildings: Current status and future trends. J. Clean. Prod. 2015, 109, 118–130. [Google Scholar] [CrossRef]

- Dahl, R. Cooling concepts: Alternatives to air conditioning for a warm world. Environ. Health Perspect. 2013, 121, a18–a25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rashid, S.; Peters, I.; Wickel, M.; Magazowski, C. Electricity Problem in Iraq. In Economics and Planning of Technical Urban Infrastructure Systems; HafenCity Universität Hamburg: Hamburg, Germany, 2012. [Google Scholar]

- Allouhi, A.; Kousksou, T.; Jamil, A.; El Rhafiki, T.; Mourad, Y.; Zeraouli, Y. Economic and environmental assessment of solar air-conditioning systems in Morocco. Renew. Sustain. Energy Rev. 2015, 50, 770–781. [Google Scholar] [CrossRef]

- Petela, K.; Szlęk, A. Assesment of Passive Cooling in Residential Application under Moderate Climate Conditions. Ecol. Chem. Eng. A 2016, 23, 211–225. [Google Scholar]

- Baniyounes, A.M.; Rasul, M.G.; Khan, M.M.K. Assessment of solar assisted air conditioning in Central Queensland’s subtropical climate, Australia. Renew. Energy 2013, 50, 334–341. [Google Scholar] [CrossRef]

- Balghouthi, M.; Chahbani, M.H.; Guizani, A. Feasibility of solar absorption air conditioning in Tunisia. Build. Environ. 2008, 43, 1459–1470. [Google Scholar] [CrossRef]

- Martínez, P.J.; Martínez, J.C.; Lucas, M. Design and test results of a low-capacity solar cooling system in Alicante (Spain). Sol. Energy 2012, 86, 2950–2960. [Google Scholar] [CrossRef]

- Burckhart, H.J.; Audinet, F.; Gabassi, M.-L.; Martel, C. Application of a novel, vacuum-insulated solar collector for heating and cooling. Energy Procedia 2014, 48, 790–795. [Google Scholar] [CrossRef] [Green Version]

- Ketjoy, N.; Rawipa, Y.; Mansiri, K. Performance evaluation of 35 kW LiBr H2O solar absorption cooling system in Thailand. Energy Procedia 2013, 34, 198–210. [Google Scholar] [CrossRef] [Green Version]

- Leiva-Illanes, R.; Escobar, R.; Cardemil, J.M.; Alarcón-Padilla, D.-C. Comparison of the levelized cost and thermoeconomic methodologies—Cost allocation in a solar polygeneration plant to produce power, desalted water, cooling and process heat. Energy Convers. Manag. 2018, 168, 215–229. [Google Scholar] [CrossRef]

- Jenkins, P.; Elmnifi, M.; Younis, A.; Emhamed, A.; Alshilmany, M. Design of a Solar Absorption Cooling System: Case Study. J. Power Energy Eng. 2020, 8, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; He, Y.; Kan, A.; Yu, W.; Wang, D.; Zhang, L.; Zhu, G.; Xie, H.; She, X. Significant photothermal conversion enhancement of nanofluids induced by Rayleigh-Bénard convection for direct absorption solar collectors. Appl. Energy 2019, 254, 113706. [Google Scholar] [CrossRef]

- Mukhtar, H.K.; Said, S.A.; El-Sharaawi, M.I. Dynamic performance of solar powered vapor absorption cooling system in dhahran—Saudi Arabia. In Proceedings of the 2018 5th International Conference on Renewable Energy: Generation and Applications (ICREGA), Al Ain, United Arab Emirates, 26–28 February 2018. [Google Scholar]

- Elahi, R.; Nagassou, D.; Trelles, J.; Mohsenian, S.; Trelles, J. Enhanced solar absorption by CO2 in thermodynamic noneq. Sol. Energy 2019, 195, 369–381. [Google Scholar] [CrossRef]

- Behi, M.; Mirmohammadi, S.A.; Ghanbarpour, M.; Behi, H.; Palm, B. Evaluation of a novel solar driven sorption cooling/heating system integrated with PCM storage compartment. Energy 2018, 164, 449–464. [Google Scholar] [CrossRef]

- Salehi, S.; Yari, M.; Rosen, M.A. Exergoeconomic comparison of solar-assisted absorption heat pumps, solar heaters and gas boiler systems for district heating in Sarein Town, Iran. Appl. Therm. Eng. 2019, 153, 409–425. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Dentice D’accadia, M.; Ferruzzi, G.; Frascogna, S.; Palombo, A.; Russo, R.; Scarpellino, M. Experimental analysis and dynamic simulation of a novel high-temperature solar cooling system. Energy Convers. Manag. 2016, 109, 19–39. [Google Scholar] [CrossRef]

- Mateus, T.; Oliveira, A.C. Energy and economic analysis of an integrated solar absorption cooling and heating system in different building types and climates. Appl. Energy 2009, 86, 949–957. [Google Scholar] [CrossRef]

- Fedrizzi, R.; Franchini, G.; Mugnier, D.; Melograno, P.N.; Theofilidi, M.; Thuer, A.; Nienborg, B.; Koch, L.; Fernandez, R.; Troi, A.; et al. Assessment of Standard Small-Scale Solar Cooling Configurations within the SolarCombi+ Project. In Proceedings of the 3rd International Conference Solar Air-Conditioning, Palermo, Italy, 30 September–2 October 2009. [Google Scholar]

- Shirazi, A.; Taylor, R.A.; White, S.D.; Morrison, G.L. Transient simulation and parametric study of solar-assisted heating and cooling absorption systems: An energetic, economic and environmental (3E) assessment. Renew. Energy 2016, 86, 955–971. [Google Scholar] [CrossRef]

- Vasta, S.; Palomba, V.; Frazzica, A.; Costa, F.; Freni, A. Dynamic simulation and performance analysis of solar cooling systems in Italy. Energy Procedia 2015, 81, 1171–1183. [Google Scholar] [CrossRef] [Green Version]

- Calise, F.; d’Accadia, M.D.; Palombo, A. Transient analysis and energy optimization of solar heating and cooling systems in various configurations. Sol. Energy 2010, 84, 432–449. [Google Scholar] [CrossRef]

- Djelloul, A.; Draoui, B.; Moummi, N. Simulation of a solar driven air conditioning system for a house in dry and hot climate of algeria. Courr. Savoir 2013, 15, 31–39. [Google Scholar]

- Hassan, L.; Moghavvemi, M.; Mohamed, H.A.F. Impact of UPFC-based damping controller on dynamic stability of Iraqi power network. Sci. Res. Essays 2011, 6, 136–145. [Google Scholar]

- The World Bank. Available online: https://solargis.com/maps-and-gis-data/download/iraq (accessed on 5 December 2019).

- Nafey, A.S.; Sharaf, M.A.; García-Rodríguez, L. A new visual library for design and simulation of solar desalination systems (SDS). Desalination 2010, 259, 197–207. [Google Scholar] [CrossRef]

- Sharaf Eldean, M.A.; Soliman, A.M. A new visual library for modeling and simulation of renewable energy desalination systems (REDS). Desalin. Water Treat. 2013, 51, 6905–6920. [Google Scholar] [CrossRef]

- Available online: http://www.apricus.com/en/america/products/solar-collectors/ap-30/ (accessed on 6 December 2019).

- Peuser, F.; Remmers, K.; Schnauss, M. Solar Thermal Systems: Successful Planning and Construction; Routledge: Abingdon, UK, 2013. [Google Scholar]

- Balghouthi, M.; Chahbani, M.H.; Guizani, A. Solar powered air conditioning as a solution to reduce environmental pollution in Tunisia. Desalination 2005, 185, 105–110. [Google Scholar] [CrossRef]

- Available online: http://www.BaltimoreAircoil.com (accessed on 16 December 2019).

- ASHRAE. Heating, Ventilating, and Air-Conditioning Systems and Equipment, SI ed.; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2012. [Google Scholar]

- Available online: http://www.yazakienergy.com (accessed on 31 January 2020).

- Rodríguez-Hidalgo, M.D.C.; Rodríguez-Aumente, P.A.; Lecuona, A.; Legrand, M.; Ventas, R. Domestic hot water consumption vs. solar thermal energy storage: The optimum size of the storage tank. Appl. Energy 2012, 97, 897–906. [Google Scholar]

- Allouhi, A.; Kousksou, T.; Jamil, A.; Bruel, P.; Mourad, Y.; Zeraouli, Y. Solar driven cooling systems: An updated review. Renew. Sustain. Energy Rev. 2015, 44, 159–181. [Google Scholar] [CrossRef]

- Joudi, K.A.; Dhaidan, N.S. Application of solar assisted heating and desiccant cooling systems for a domestic building. Energy Convers. Manag. 2001, 42, 995–1022. [Google Scholar] [CrossRef]

- Shariah, A.; Al-Akhras, M.A.; Al-Omari, I.A. Optimizing the tilt angle of solar collectors. Renew. Energy 2002, 26, 587–598. [Google Scholar] [CrossRef]

- Elminir, H.K.; Ghitas, A.E.; El-Hussainy, F.; Hamid, R.; Beheary, M.M.; Abdel-Moneim, K.M.; Elminir, H.K. Optimum solar flat-plate collector slope: Case study for Helwan, Egypt. Energy Convers. Manag. 2005, 47, 624–637. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley & Sons: Hoboken, NJ, USA, 1991. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Bahria, S.; Amirat, M.; Hamidat, A.; El Ganaoui, M.; Slimani, M.E.A. Parametric study of solar heating and cooling systems in different climates of Algeria–A comparison between conventional and high-energy-performance buildings. Energy 2016, 113, 521–535. [Google Scholar] [CrossRef]

- Assilzadeh, F.; Kalogirou, S.A.; Ali, Y.; Sopian, K. Simulation and optimization of a LiBr solar absorption cooling system with evacuated tube collectors. Renew. Energy 2005, 30, 1143–1159. [Google Scholar] [CrossRef]

| Variable | Units | Value |

|---|---|---|

| Absorber area | m2 | 2.4 |

| Optical performance () | - | 0.845 |

| Loss coefficient () | W/(m2·K) | 1.47 |

| Loss coefficient () | W/(m2·K) | 0.01 |

| Characteristics | Value | Units |

|---|---|---|

| Cooling tower capacity | 105 | kW |

| Wet temperature | 25 | °C |

| Cooling water temperature | 35-30 | °C |

| Airflow rate | 16 | m3/h |

| Electrical power | 0.75 | kW |

| Characteristic | Unit | Value |

|---|---|---|

| Cooling capacity | kW | 35 |

| Chilled water outlet /inlet temp. | °C | 7/12.5 |

| Cooling water outlet /inlet temp. | °C | 35/31 |

| Heating water outlet /inlet temp. | °C | 88/83 |

| Chilled water flowrate | m3/h | 11 |

| Cooling water flow rate | m3/h | 36.7 |

| Heating water flow rate | m3/h | 17.3 |

| Electric power consumption | kW | 0.21 |

| Component | Type TRNSYS | Parameters (Base Design Values) |

|---|---|---|

| Solar Collector | TYPE 71a | Apricus ETC-30 (Table 3) Number of collectors (12) Inclination (30°) |

| Hot water tank | TYPE 4a | Volume (50 L/m2 collector) |

| Auxiliary boiler | TYPE 6 | Efficiency (90%) |

| Absorption chiller | TYPE 107 | YAZAKI WFC SC10 (Table 5) |

| Cooling tower | TYPE 51b | B.A.C. FXT-26 (Table 4) |

| Weather data | TYPE 109—TMY2 | Location: Baghdad, Iraq |

| Collector pump | TYPE 3b | Flow rate 50 (L/h)/m2 of collector |

| Collector pump control | TYPE 2b | Maximum accumulator temperature (90 °C) Minimum collector gain (5 °C) |

| Pipe | TYPE 31 | |

| Flow mixer | TYPE 11h | |

| Building | TYPE 56a |

| Month | Incident Energy | Collected Energy | Solar Tank Energy | Aux. Boiler Energy | Load Energy | Collector Efficiency (%) | COP | Solar Fraction (%) |

|---|---|---|---|---|---|---|---|---|

| April | 17,329 | 9489 | 2350 | 1760 | 4110 | 54.75 | 0.39 | 57.17 |

| May | 19,624 | 11,346 | 3642 | 1954 | 5596 | 57.81 | 0.41 | 65.08 |

| June | 30,632 | 16,358 | 6243 | 4720 | 10,963 | 53.40 | 0.45 | 56.94 |

| July | 33,685 | 18,509 | 7496 | 5153 | 12,649 | 54.94 | 0.51 | 59.26 |

| August | 35,173 | 19,245 | 7889 | 5391 | 13,280 | 54.71 | 0.52 | 59.40 |

| September | 29,627 | 15,296 | 4948 | 4430 | 9378 | 51.62 | 0.40 | 52.76 |

| Oct. | 11,953 | 5830 | 2162 | 2617 | 4779 | 48.77 | 0.40 | 45.23 |

| Total | 178,023 | 96,073 | 34,730 | 26,025 | 60,755 | 53.96 | 0.44 | 57.16 |

| Number of Collectors | Solar Tank Volume L | ||||||

|---|---|---|---|---|---|---|---|

| 10 (25 m2) | 12 (30 m2) | 14(35 m2) | 1000 | 1500 | 2000 | ||

| Solar Fraction% | 53.1 | 62.3 | 70.2 | 61.5 | 62.3 | 63.9 | |

| ηele,total | 11.2 | 11.5 | 11.9 | 11.6 | 11.9 | 12.1 | |

| PE save | PEsave kWhPE | 1361 | 3759 | 5661 | 4669 | 5761 | 6342 |

| PEref (Primary Energy References) kWhPE | 15,469 | 15,545 | 15,666 | 15,628 | 15,666 | 15,306 | |

| Relative % | 8.8 | 24.8 | 36.8 | 29.9 | 36.8 | 40.6 | |

| Temperature °C | 70 | 72.5 | 75 | 77.5 | 80 |

|---|---|---|---|---|---|

| Solar Fraction% | 63.1 | 62.2 | 61.2 | 59.9 | 57.9 |

| Temperature °C | 85 | 87.5 | 90 | 92.5 | 95 |

|---|---|---|---|---|---|

| Solar Fraction% | 60.7 | 61.0 | 61.2 | 61.3 | 60.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Falahi, A.; Alobaid, F.; Epple, B. A New Design of an Integrated Solar Absorption Cooling System Driven by an Evacuated Tube Collector: A Case Study for Baghdad, Iraq. Appl. Sci. 2020, 10, 3622. https://doi.org/10.3390/app10103622

Al-Falahi A, Alobaid F, Epple B. A New Design of an Integrated Solar Absorption Cooling System Driven by an Evacuated Tube Collector: A Case Study for Baghdad, Iraq. Applied Sciences. 2020; 10(10):3622. https://doi.org/10.3390/app10103622

Chicago/Turabian StyleAl-Falahi, Adil, Falah Alobaid, and Bernd Epple. 2020. "A New Design of an Integrated Solar Absorption Cooling System Driven by an Evacuated Tube Collector: A Case Study for Baghdad, Iraq" Applied Sciences 10, no. 10: 3622. https://doi.org/10.3390/app10103622