Recent Developments in Pneumatic Artificial Muscle Actuators

Abstract

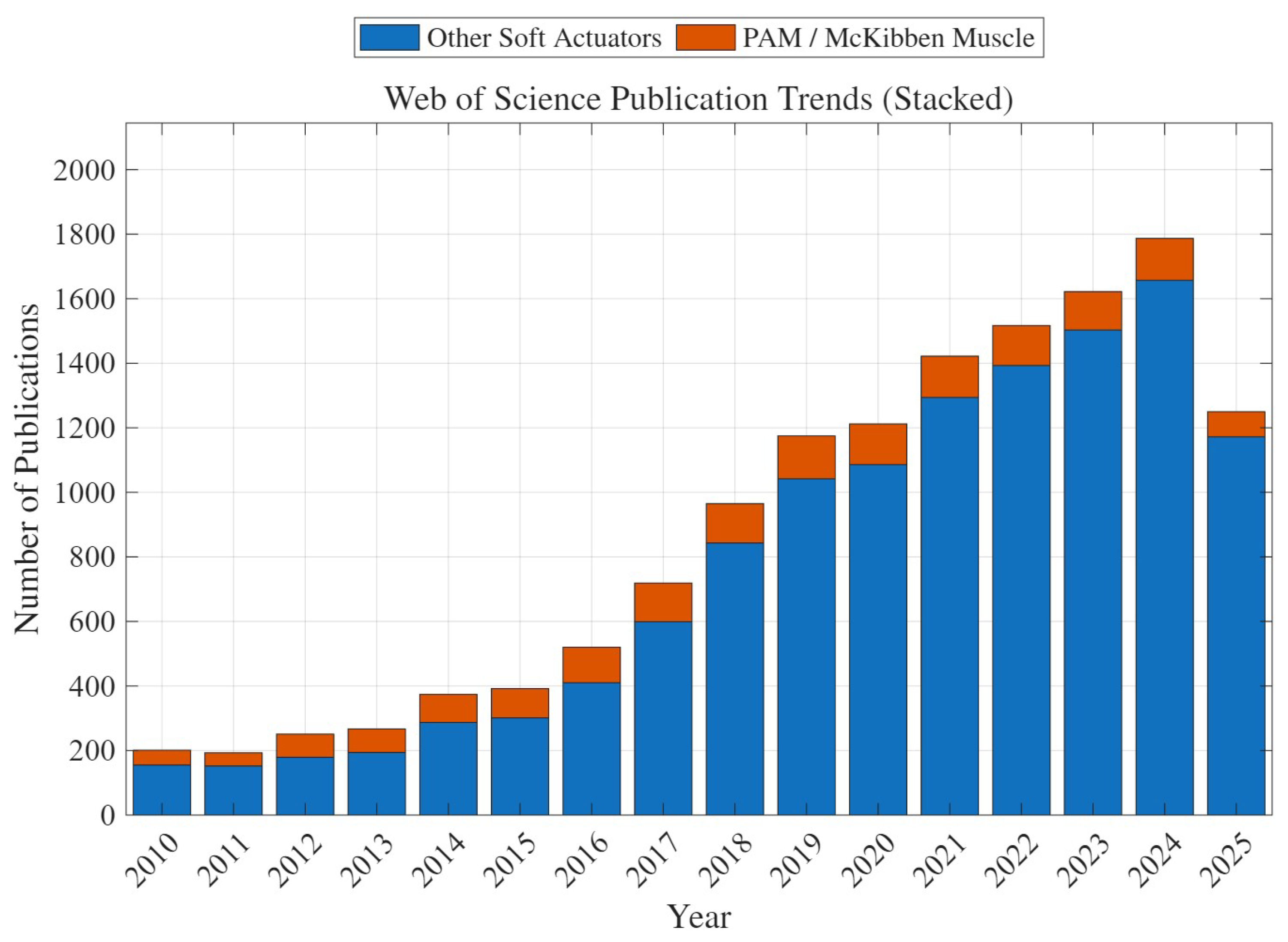

1. Introduction

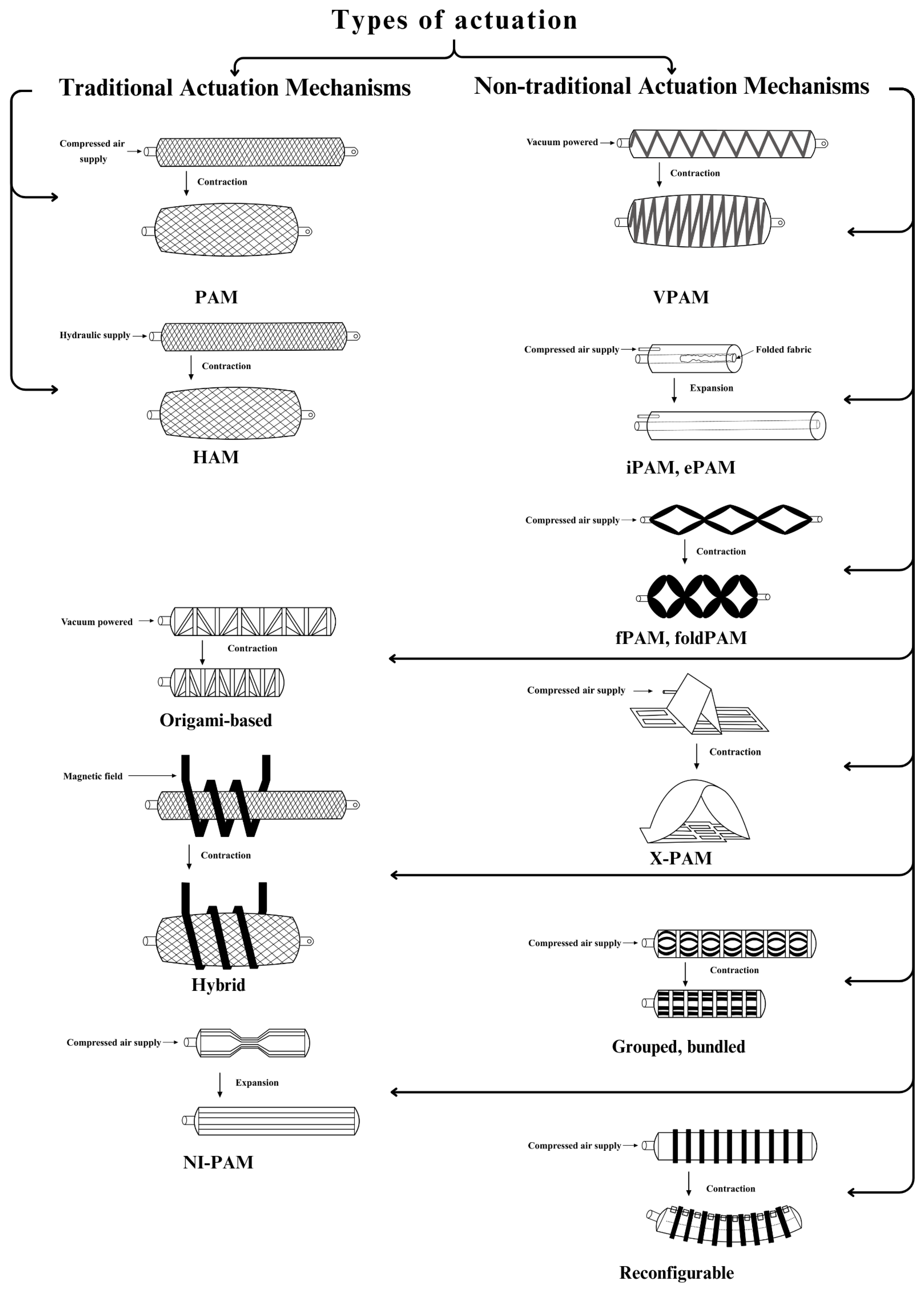

2. Actuation Mechanisms

2.1. Traditional Actuation Mechanisms

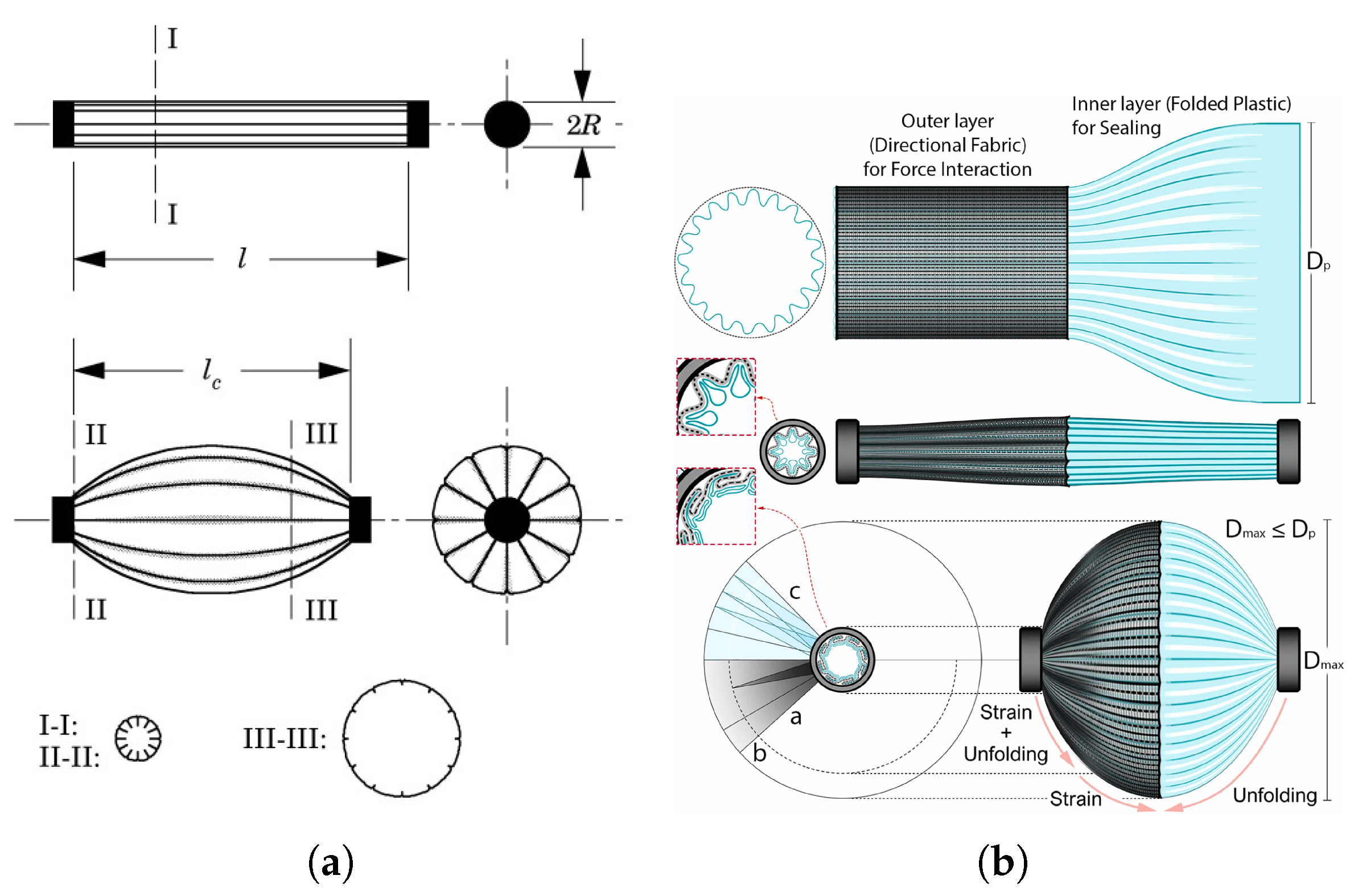

2.1.1. Pneumatic Artificial Muscles (PAMs)

2.1.2. Hydraulic Artificial Muscles (HAMs)

2.2. Non-Traditional Actuation Mechanisms

2.2.1. Vacuum-Powered PAMs

2.2.2. Inverse PAMs

2.2.3. Foldable and Fabric-Based PAMs

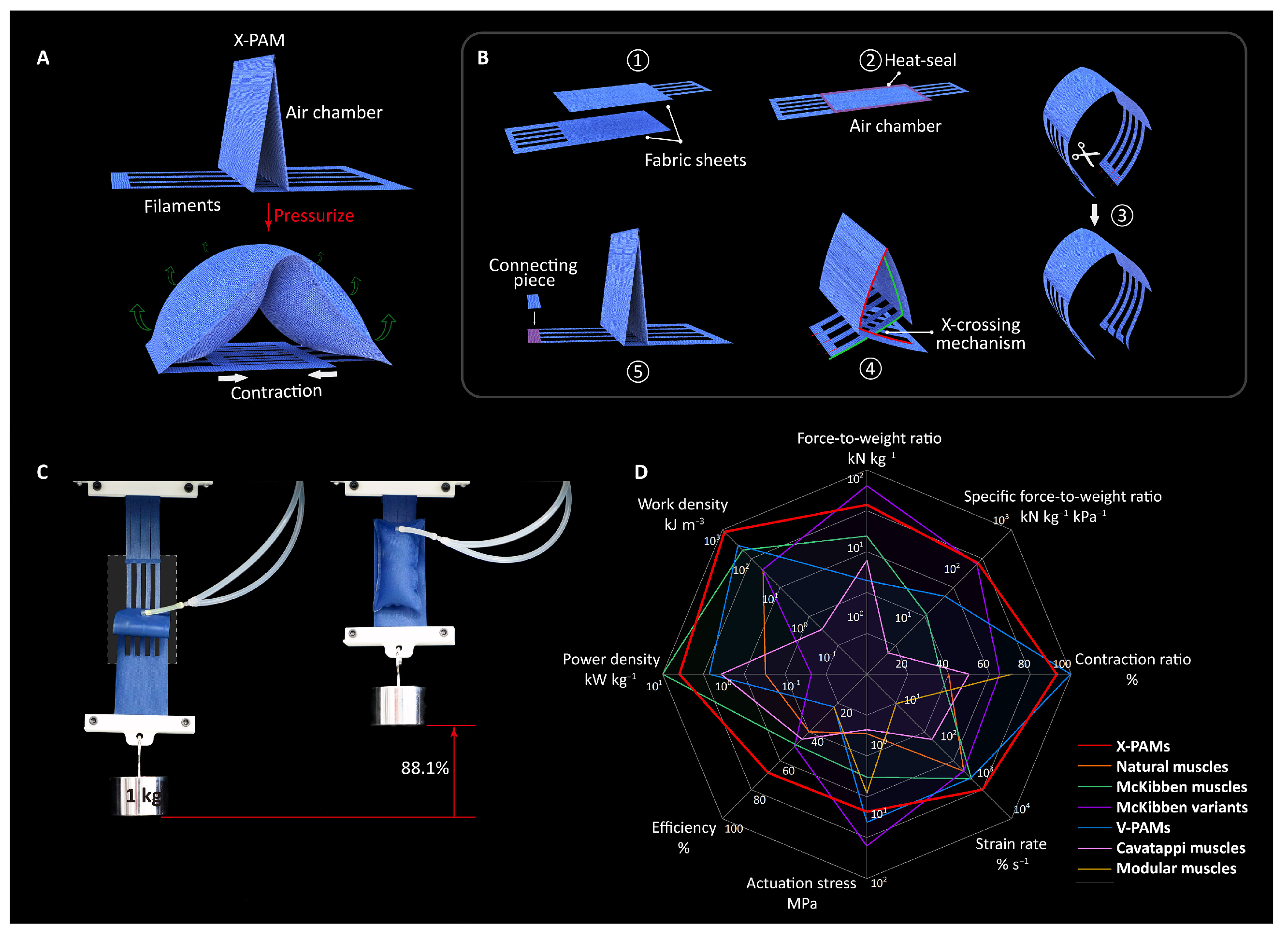

2.2.4. X-PAMs

2.2.5. Grouped and Bundled PAMs

2.2.6. Reconfigurable PAMs

2.2.7. Origami-Based PAMs

2.2.8. Hybrid PAMs

Thermo-Pneumatic Actuation

Pneumatic-Electric Hybrids

Chemically Driven Hybrids

Magnetically Induced Phase-Change Hybrids

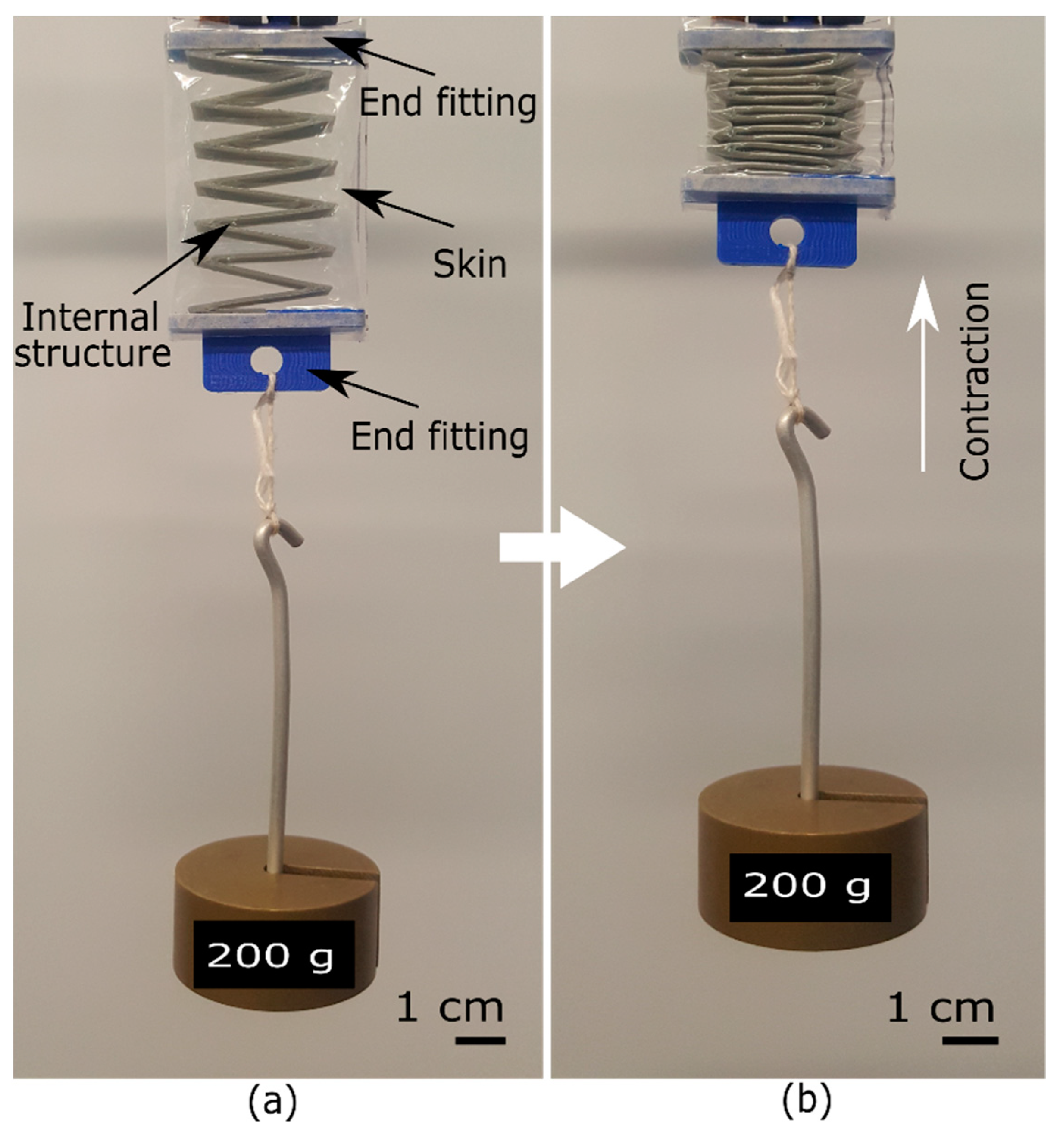

2.2.9. Compact, Flat, and Non-Inflatable PAMs

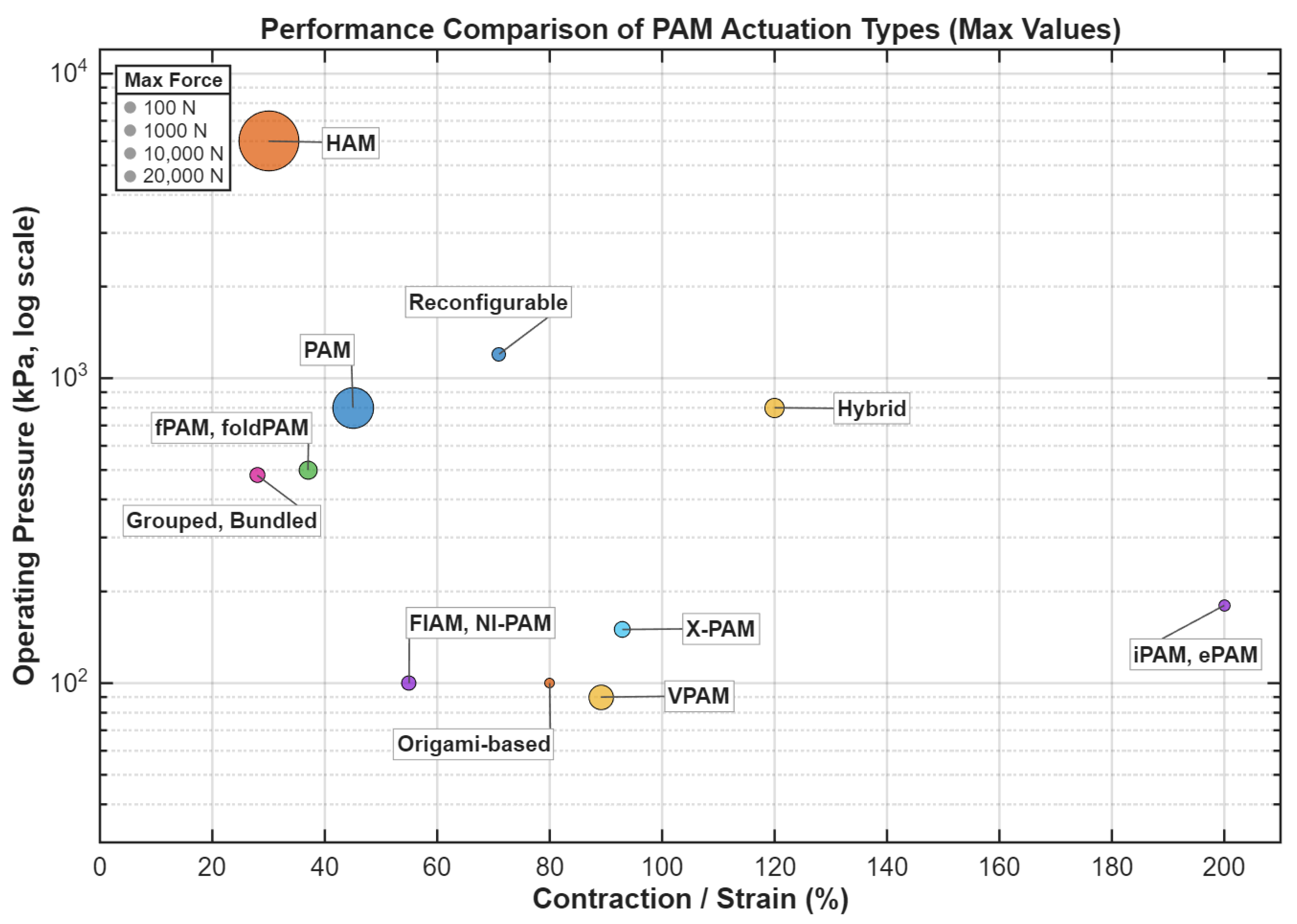

2.2.10. Overall PAM Classification and Comparison

3. Applications

3.1. Traditional Applications

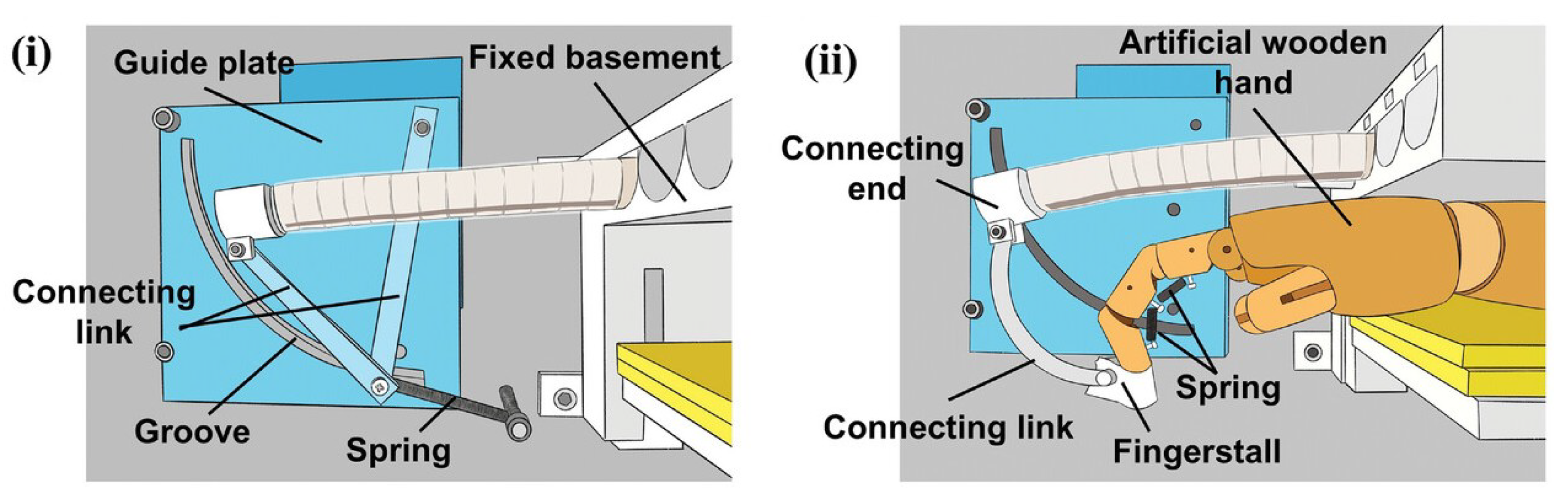

3.1.1. Biomechanics and Rehabilitation

3.1.2. Human-Machine Interactions

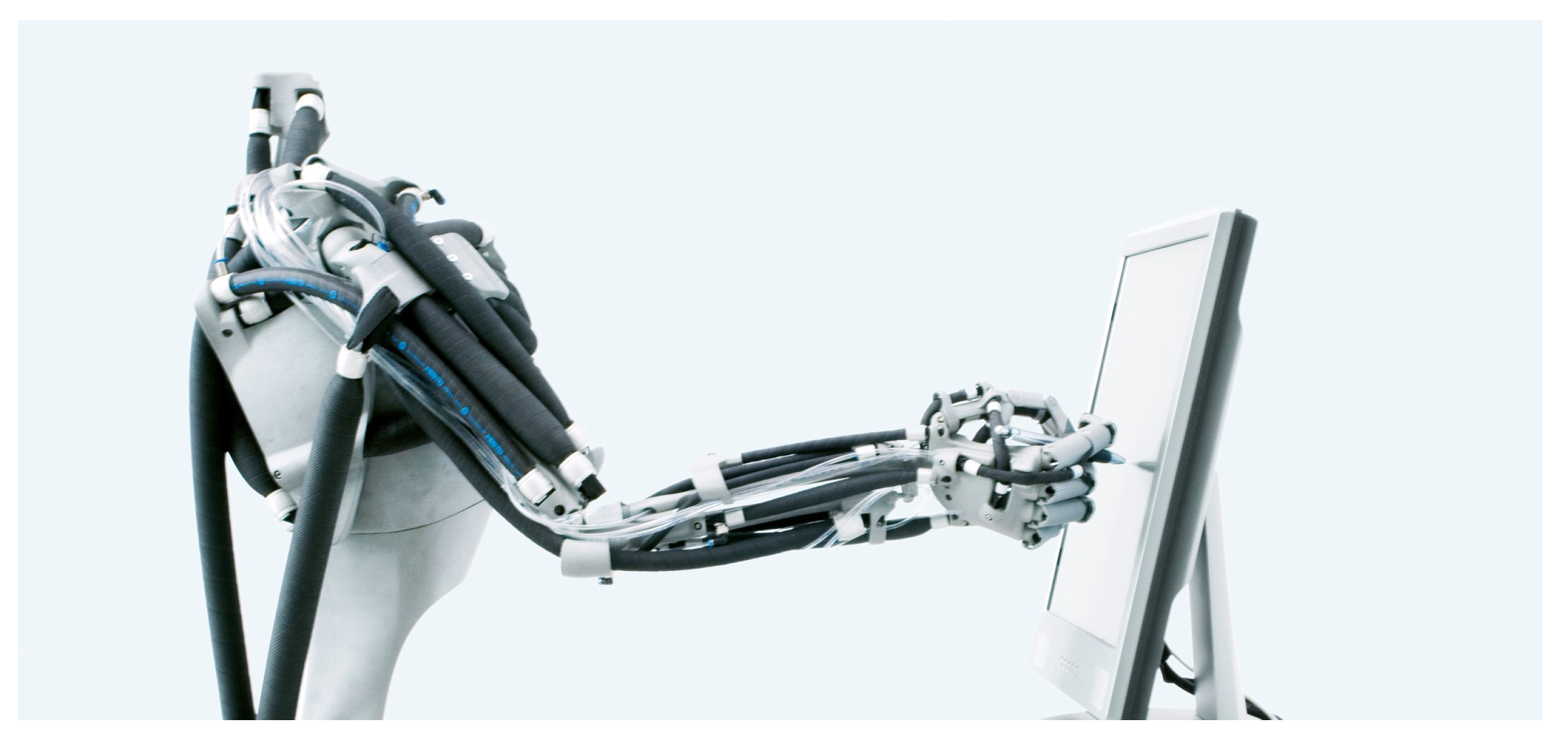

3.1.3. Soft Robotics

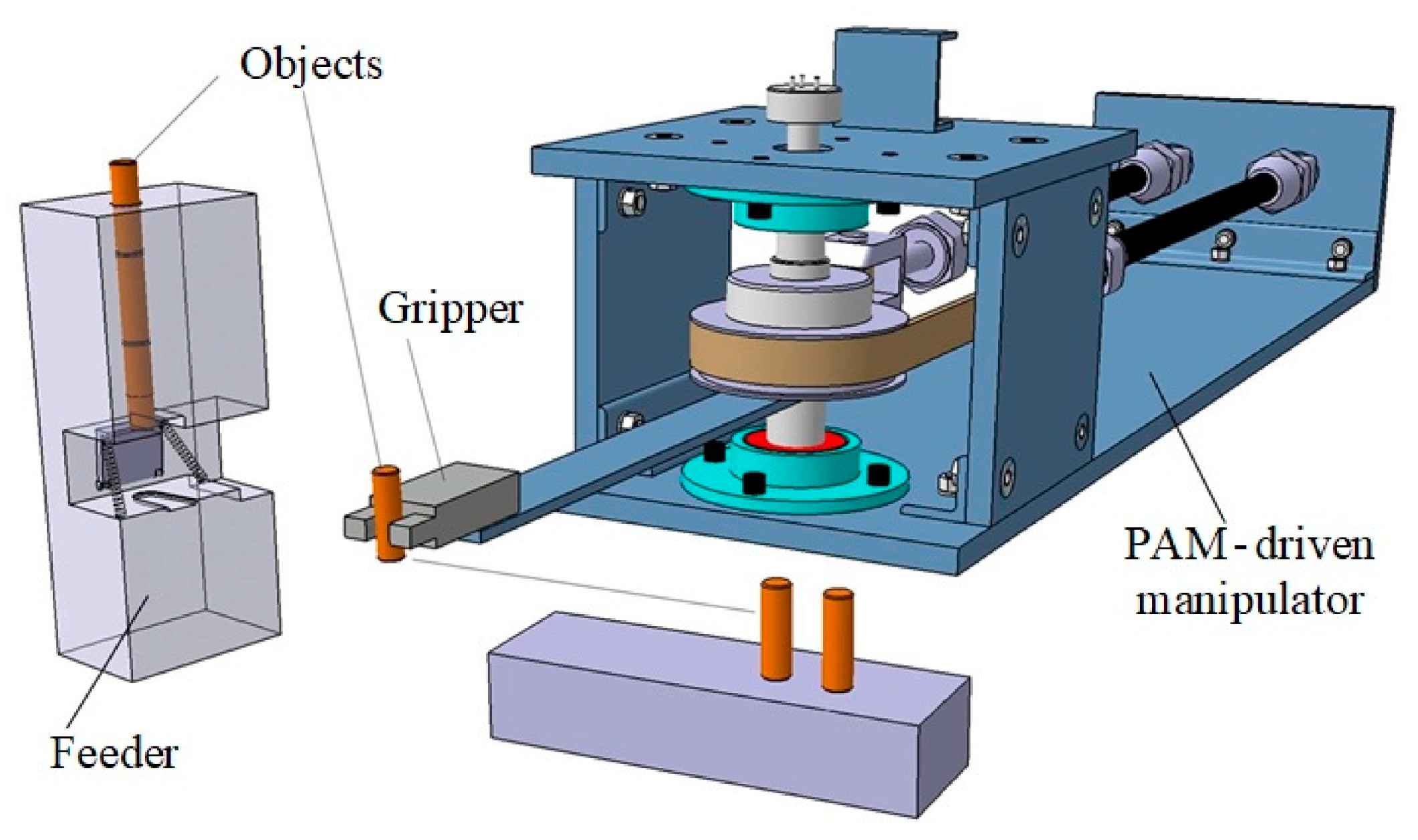

3.1.4. Industrial Automation

3.2. Non-Traditional Applications

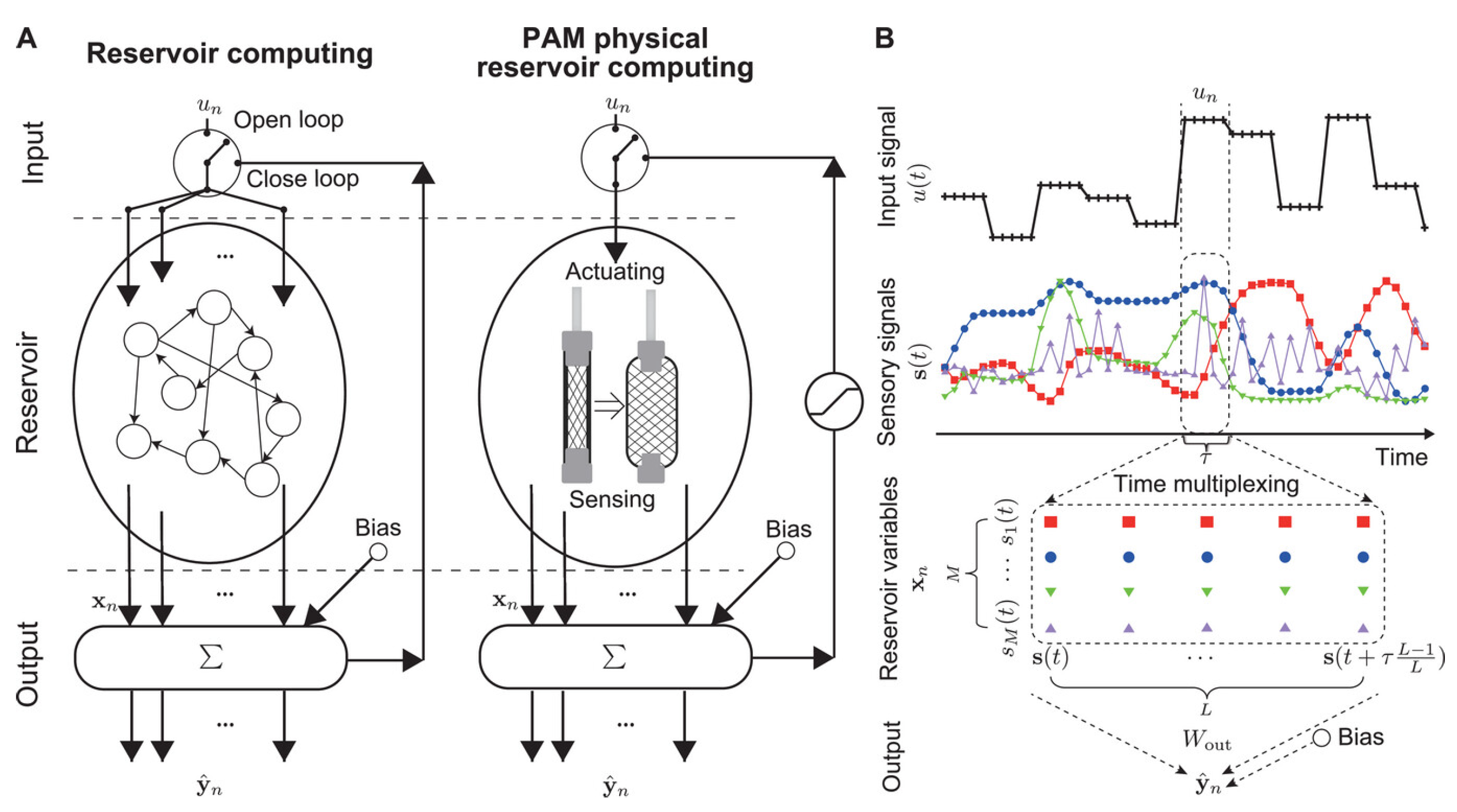

3.2.1. Embodied Computation

3.2.2. Aerospace and Space Exploration

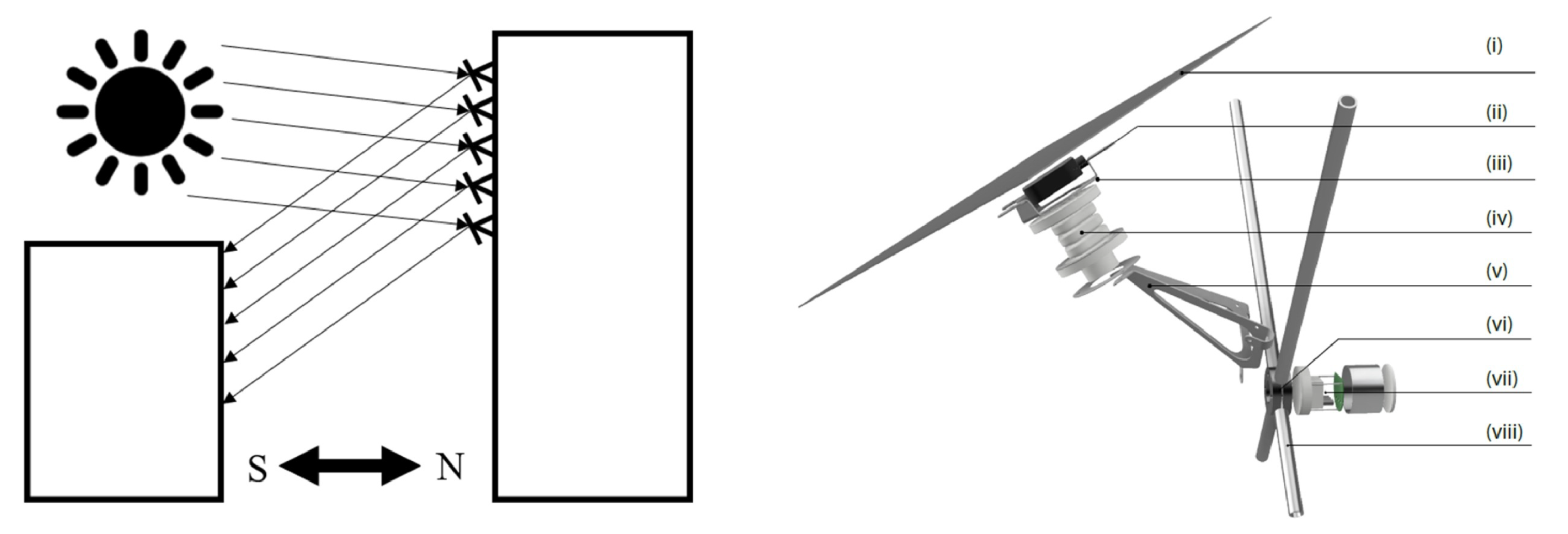

3.2.3. Adaptive Architecture

3.2.4. Art, Education, and Entertainment

4. Future Work

- Integrated control and sensing. One of the major limitations of PAMs is their nonlinear and hysteretic response, which complicates precise control. Future work should emphasize embedding self-sensing elements, such as conductive threads, capacitive layers, or microfluidic channels, to provide real-time feedback for closed-loop control without reliance on external sensors. Recent developments in proprioceptive PAMs and sensorized skins (Section 2.2.9) provide a strong foundation for this direction.

- Miniaturization and portability. Most PAM systems continue to rely on bulky air or hydraulic supply units, limiting their portability. Developing compact, integrated, or on-demand pressure sources, such as electrolysis-based micropumps, phase-change media, or thermo-pneumatic modules, will be critical for enabling untethered and wearable applications, particularly in biomedical devices and soft assistive technologies.

- Durability and long-term reliability. Actuators operating under repeated cyclic loading or environmental exposure (e.g., UV, moisture, temperature variation) remain prone to fatigue or leakage. Future materials research should prioritize high-endurance elastomers, self-healing polymers, and fatigue-resistant architectures. Lessons from adaptive architectural systems (Section 3.2.3) and space robotics (Section 3.2.2) underscore the importance of achieving long operational lifetimes under harsh conditions.

- Multifunctional and reconfigurable systems. The integration of modular and reconfigurable PAM units, capable of dynamically changing length, stiffness, or orientation, can enhance adaptability in robotics, architecture, and aerospace. Advances in origami-based designs (Section 2.2.7), reconfigurable PAMs (Section 2.2.6), and hybrid actuation architectures (Section 2.2.8) provide a roadmap for actuators that also serve structural or computational functions, supporting the broader vision of morphological intelligence.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Daerden, F.; Lefeber, D. Pneumatic Artificial Muscles: Actuators for Robotics and Automation. Eur. J. Mech. Environ. Eng. 2002, 47, 11–21. [Google Scholar]

- Kelasidi, E.; Andrikopoulos, G.; Nikolakopoulos, G.; Manesis, S. A Survey on Pneumatic Muscle Actuators Modeling. In Proceedings of the 2011 IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011; pp. 1263–1269. [Google Scholar] [CrossRef]

- Daerden, F. Conception and Realization of Pleated Pneumatic Artificial Muscles and Their Use as Compliant Actuation Elements. Ph.D. Thesis, Vrije Universiteit Brussel, Brussels, Belgium, 1999. Available online: https://researchportal.vub.be/en/publications/conception-and-realization-of-pleated-pneumatic-artificial-muscle (accessed on 1 June 2025).

- Daerden, F.; Lefeber, D. The Concept and Design of Pleated Pneumatic Artificial Muscles. Int. J. Fluid Power 2001, 2, 41–50. Available online: https://journals.riverpublishers.com/index.php/IJFP/article/view/635 (accessed on 11 November 2025). [CrossRef]

- Mori, M.; Suzumori, K.; Takahashi, M.; Hosoya, T. Very High Force Hydraulic McKibben Artificial Muscle with a p-Phenylene-2,6-benzobisoxazole Cord Sleeve. Adv. Robot. 2010, 24, 233–254. [Google Scholar] [CrossRef]

- Morin, A.H. Elastic Diaphragm. U.S. Patent 2,642,091, 16 June 1953. [Google Scholar]

- Oros, D.; Penčić, M.; Čavić, M.; Orošnjak, M.; Čavić, D.; Lu, Z. PAM Actuators Applications in Robotics: Rapid Review. In Proceedings of the 2023 10th International Conference on Electrical, Electronic and Computing Engineering (IcETRAN), East Sarajevo, Bosnia and Herzegovina, 5–8 June 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Chen, L.; Li, Y.; Han, L.; Yuan, L.; Sun, Y.; Tang, X. Comparative Analysis of Soft Kinematics of Hand Rehabilitation Robot Powered by Pneumatic Muscles. In Elderly Health Services and Remote Health Monitoring; SpringerBriefs in Applied Sciences and Technology; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, A.; Meng, W.; Ai, Q.; Xie, S.Q. Hierarchical Compliance Control of a Soft Ankle Rehabilitation Robot Actuated by Pneumatic Muscles. Front. Neurorobot. 2017, 11, 64. [Google Scholar] [CrossRef] [PubMed]

- Pitel’, J.; Líška, O.; Janáčová, D. Pneumatic Muscle-Based Actuator for Industrial Robotic Applications. In Proceedings of the 7th International Workshop on Computer Science and Engineering (WCSE 2017), Beijing, China, 25–27 June 2017; pp. 1218–1223, ISBN 978-981-11-3671-9. [Google Scholar] [CrossRef]

- Wereley, N.M.; Kothera, C.; Bubert, E.; Woods, B.; Gentry, M.; Vocke, R. Pneumatic Artificial Muscles for Aerospace Applications. In Proceedings of the 50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Palm Springs, CA, USA, 4–7 May 2009; American Institute of Aeronautics and Astronautics (AIAA): Reston, VA, USA, 2009. [Google Scholar] [CrossRef]

- Woods, B.; Gentry, M.F.; Kothera, C.S.; Wereley, N.M. Fatigue Life Testing of Swaged Pneumatic Artificial Muscles for Aerospace Morphing Applications. In Proceedings of the 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Orlando, FL, USA, 12–15 April 2010; American Institute of Aeronautics and Astronautics (AIAA): Reston, VA, USA, 2010. [Google Scholar] [CrossRef]

- Soylak, M.; Bakır, M. Development of a New System for Reducing the Temperature Increase During the Positioning of Spoilers Using Pneumatic Artificial Muscle (PAM). Aircr. Eng. Aerosp. Technol. 2020, 92, 1257–1261. [Google Scholar] [CrossRef]

- Akashi, N.; Kuniyoshi, Y.; Jo, T.; Nishida, M.; Sakurai, R.; Wakao, Y.; Nakajima, K. Embedding Bifurcations into Pneumatic Artificial Muscle. Adv. Sci. 2024, 11, 2304402. [Google Scholar] [CrossRef]

- Walters, P.; Ieropoulos, I.; McGoran, D. Digital Fabrication of a Novel Bio-Actuator for Bio-Robotic Art and Design. NIP Digit. Fabr. Conf. 2011, 27, 496–499. [Google Scholar] [CrossRef]

- Web of Science. Available online: https://www.webofscience.com (accessed on 9 October 2025).

- Iwata, K.; Suzumori, K.; Wakimoto, S. A Method of Designing and Fabricating McKibben Muscles Driven by 7 MPa Hydraulics. Int. J. Autom. Technol. 2012, 6, 482–487. [Google Scholar] [CrossRef]

- Doi, T.; Wakimoto, S.; Suzumori, K.; Mori, K. Proposal of Flexible Robotic Arm with Thin McKibben Actuators Mimicking Octopus Arm Structure. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; pp. 5503–5508. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Peng, Y.; Zhong, S.; Liu, N.; Pu, H. A Light Soft Manipulator With Continuously Controllable Stiffness Actuated by a Thin McKibben Pneumatic Artificial Muscle. IEEE/ASME Trans. Mechatronics 2020, 25, 1944–1952. [Google Scholar] [CrossRef]

- Mendoza, M.J.; Gollob, S.D.; Lavado, D.; Koo, B.H.B.; Cruz, S.; Roche, E.T.; Vela, E.A. A Vacuum-Powered Artificial Muscle Designed for Infant Rehabilitation. Micromachines 2021, 12, 971. [Google Scholar] [CrossRef]

- Mendoza, M.J.; Cancán, S.; Surichaqui, S.; Centeno, E.; Vilchez, R.; Bertoldi, K.; Vela, E.A. Versatile Vacuum-Powered Artificial Muscles through Replaceable External Reinforcements. Front. Robot. AI 2023, 10, 1289074. [Google Scholar] [CrossRef]

- Ye, M.; Qian, X. High Load-to-Weight Ratio and Large-Deformation Vacuum Pneumatic Actuator. In Proceedings of the 2024 7th International Conference on Robotics, Control and Automation Engineering (RCAE), Wuhu, China, 20–22 December 2024; pp. 357–361. [Google Scholar] [CrossRef]

- Caiyang, E.; Wang, B.; Guo, Z.; Zhang, H.; Xu, Q.; Chen, J. An Origami-Inspired 3D-Printed Soft Foldable Actuator with Large Contraction Deformation and Strong Actuation Capability. Smart Mater. Struct. 2025, 34, 045019. [Google Scholar] [CrossRef]

- Lee, J.; Rodrigue, H. Origami-Based Vacuum Pneumatic Artificial Muscles with Large Contraction Ratios. Soft Robot. 2019, 6, 109–117. [Google Scholar] [CrossRef] [PubMed]

- Naclerio, N.D.; Hawkes, E.W. Simple, Low-Hysteresis, Foldable, Fabric Pneumatic Artificial Muscle. IEEE Robot. Autom. Lett. 2020, 5, 3406–3413. [Google Scholar] [CrossRef]

- Wang, S.; Frias Miranda, E.; Blumenschein, L.H. The Folded Pneumatic Artificial Muscle (FoldPAM): Towards Programmability and Control via End Geometry. IEEE Robot. Autom. Lett. 2023, 8, 1383–1390. [Google Scholar] [CrossRef]

- Lee, J.G.; Rodrigue, H. Efficiency of Origami-Based Vacuum Pneumatic Artificial Muscle for Off-Grid Operation. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 789–797. [Google Scholar] [CrossRef]

- Prakongpak, N.; Chanthasopeephan, T. Hybrid PI-Neural Network Control for Fluid-Driven Origami-Inspired Artificial Muscle. In Proceedings of the 2024 IEEE 20th International Conference on Automation Science and Engineering (CASE), Bari, Italy, 28–31 August 2024; pp. 3767–3772. [Google Scholar] [CrossRef]

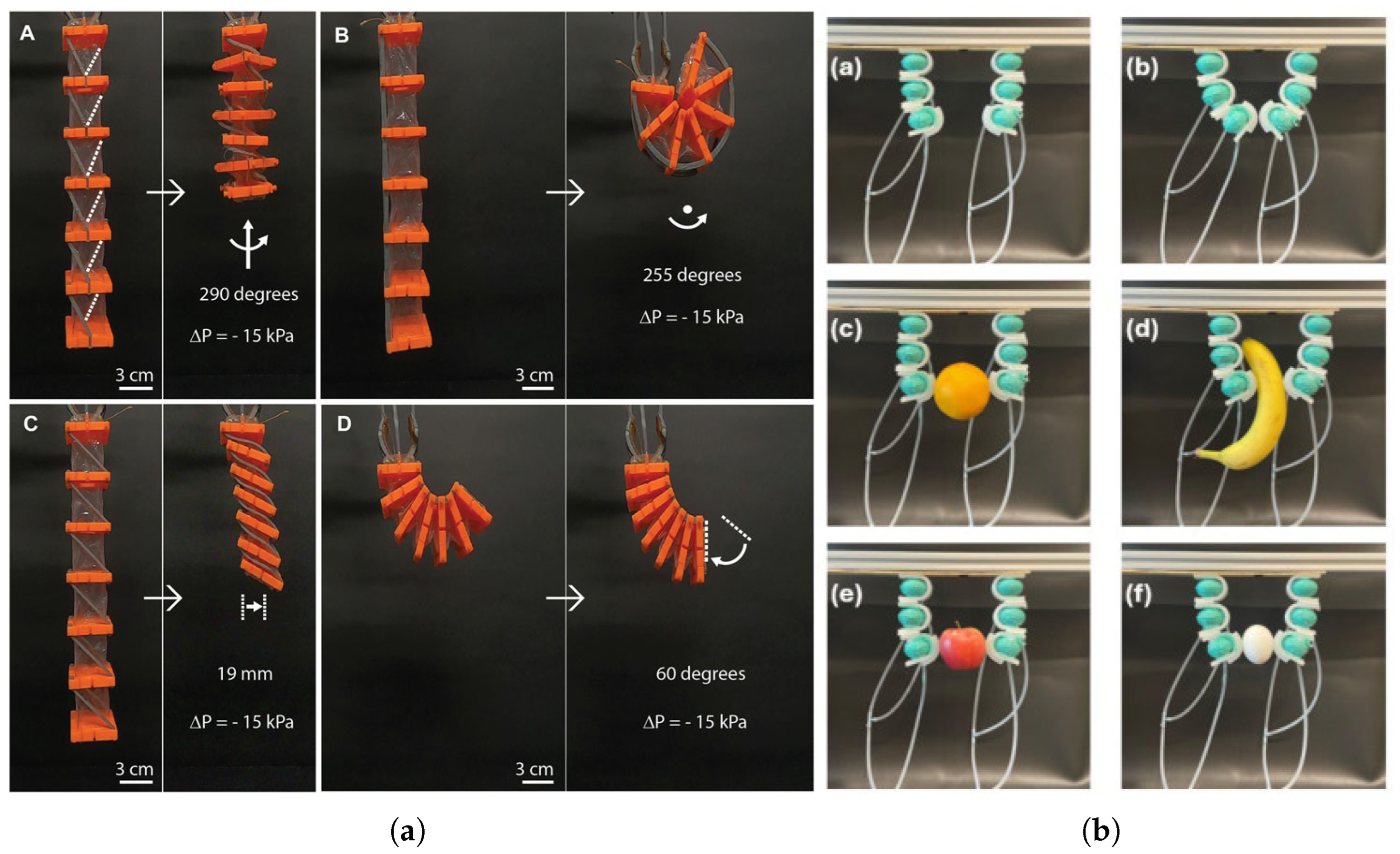

- Lee, J.; Rodrigue, H. Design and Analysis of Reconfigurable Origami-Based Vacuum Pneumatic Artificial Muscles for Versatile Robotic System. Soft Robot. 2024, 11, 984–993. [Google Scholar] [CrossRef]

- Lorenzon, L.; Beccali, G.; Maselli, M.; Cianchetti, M. A Self-Sensing Inverse Pneumatic Artificial Muscle. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022; pp. 817–822. [Google Scholar] [CrossRef]

- Abrar, T.; Putzu, F.; Konstantinova, J.; Althoefer, K. EPAM: Eversive Pneumatic Artificial Muscle. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Republic of Korea, 14–18 April 2019; pp. 19–24. [Google Scholar] [CrossRef]

- Shin, D.; Yeh, X.; Khatib, O. A New Hybrid Actuation Scheme with Artificial Pneumatic Muscles and a Magnetic Particle Brake for Safe Human-Robot Collaboration. Int. J. Robot. Res. 2014, 33, 507–518. [Google Scholar] [CrossRef]

- Michelson, R.C.; Helmick, D.; Reece, S.; Amarena, C. A Reciprocating Chemical Muscle (RCM) for Micro Air Vehicle “Entomopter” Flight. In Georgia Tech Research Institute Technical Report; Georgia Tech Research Institute: Atlanta, GA, USA, 1998. [Google Scholar]

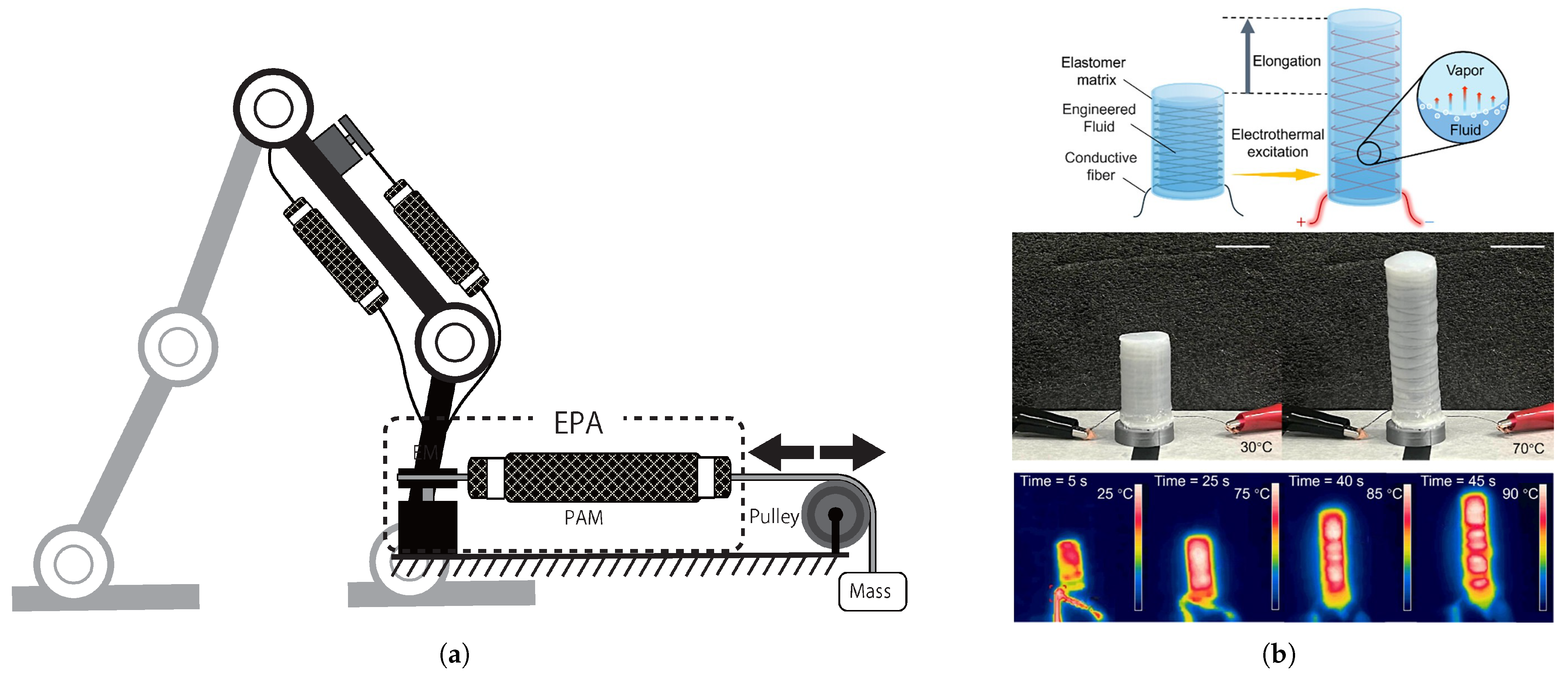

- Sharbafi, M.A.; Shin, H.; Zhao, G.; Hosoda, K.; Seyfarth, A. Electric-Pneumatic Actuator: A New Muscle for Locomotion. Actuators 2017, 6, 30. [Google Scholar] [CrossRef]

- Kalita, B.; Leonessa, A.; Dwivedy, S.K. A Review on the Development of Pneumatic Artificial Muscle Actuators: Force Model and Application. Actuators 2022, 11, 288. [Google Scholar] [CrossRef]

- Jamil, B.; Oh, N.; Lee, J.G.; Rodrigue, H. A Review and Comparison of Linear Pneumatic Artificial Muscles. Int. J. Precis. Eng. Manuf.-Technol. 2024, 11, 277–289. [Google Scholar] [CrossRef]

- Tang, D.; Zhu, Z.; Zhang, Y. Pneumatic Soft Actuator: A Review of Design, Modeling and Applications. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2025, 239, 9658–9686. [Google Scholar] [CrossRef]

- Šitum, Ž.; Benić, J.; Cipek, M. Mechatronic and Robotic Systems Utilizing Pneumatic Artificial Muscles as Actuators. Inventions 2025, 10, 44. [Google Scholar] [CrossRef]

- Brown, D.F.; Xie, S.Q. A Piecewise Particle Swarm Optimisation Modelling Method for Pneumatic Artificial Muscle Actuators. Actuators 2024, 13, 286. [Google Scholar] [CrossRef]

- Jing, Y.; Su, F.; Yu, X.; Fang, H.; Wan, Y. Advances in Artificial Muscles: A Brief Literature and Patent Review. Front. Bioeng. Biotechnol. 2023, 11, 1083857. [Google Scholar] [CrossRef]

- Caldwell, D.G.; Medrano-Cerda, G.A.; Goodwin, M.J. Braided Pneumatic Actuator Control of a Multi-Jointed Manipulator. In Proceedings of the IEEE Systems, Man and Cybernetics Conference (SMC), Le Touquet, France, 17–20 October 1993; Volume 1, pp. 423–428. [Google Scholar] [CrossRef]

- Chou, C.-P.; Hannaford, B. Measurement and Modeling of McKibben Pneumatic Artificial Muscles. IEEE Trans. Robot. Autom. 1996, 12, 90–102. [Google Scholar] [CrossRef]

- Tsagarakis, N.; Caldwell, D.G. Improved Modelling and Assessment of Pneumatic Muscle Actuators. In Proceedings of the 2000 IEEE International Conference on Robotics and Automation (ICRA), San Francisco, CA, USA, 24–28 April 2000; Volume 4, pp. 3641–3646. [Google Scholar] [CrossRef]

- Tondu, B.; Lopez, P. Modeling and Control of McKibben Artificial Muscle Robot Actuators. IEEE Control Syst. Mag. 2000, 20, 15–38. [Google Scholar] [CrossRef]

- Kang, B.-S.; Kothera, C.S.; Woods, B.K.S.; Wereley, N.M. Dynamic Modeling of McKibben Pneumatic Artificial Muscles for Antagonistic Actuation. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation (ICRA), Kobe, Japan, 12–17 May 2009; pp. 182–187. [Google Scholar] [CrossRef]

- Vo-Minh, T.; Tjahjowidodo, T.; Ramon, H.; Van Brussel, H. A New Approach to Modeling Hysteresis in a Pneumatic Artificial Muscle Using the Maxwell-Slip Model. IEEE/ASME Trans. Mechatron. 2011, 16, 177–186. [Google Scholar] [CrossRef]

- Caldwell, D.G.; Medrano-Cerda, G.A.; Goodwin, M. Control of Pneumatic Muscle Actuators. IEEE Control Syst. Mag. 1995, 15, 40–48. [Google Scholar] [CrossRef]

- Yarlott, J.M. Fluid Actuator. U.S. Patent 3,645,173, 29 February 1972. [Google Scholar]

- Kukolj, M. Axially Contractable Actuator. U.S. Patent 4,819,547, 11 April 1989. [Google Scholar]

- Babaei Banyarani, P.; Tarvirdizadeh, B.; Hadi, A. Design and fabrication of a soft wearable robot using a novel pleated fabric pneumatic artificial muscle (pfPAM) to assist walking. Sens. Actuators A Phys. 2024, 370, 115278. [Google Scholar] [CrossRef]

- Baldwin, H.A. Realizable Models of Muscle Function. In Biomechanics; Bootzin, D., Muffley, H.C., Eds.; Springer: New York, NY, USA, 1969; pp. 139–148. [Google Scholar] [CrossRef]

- Paynter, H.M. Hyperboloid of Revolution Fluid-Driven Tension Actuators and Method of Making. U.S. Patent 4,721,030, 26 January 1988. [Google Scholar]

- Gaylord, R.H. Fluid Actuated Motor System and Stroking Device. U.S. Patent 2,844,126, 22 July 1958. [Google Scholar]

- Festo. Fluidic Muscle DMSP Product Page. Festo US. 2025. Available online: https://www.festo.com/us/en/p/fluidic-muscle-id_DMSP/ (accessed on 15 June 2025).

- Martens, M.; Boblan, I. Modeling the Static Force of a Festo Pneumatic Muscle Actuator: A New Approach and a Comparison to Existing Models. Actuators 2017, 6, 33. [Google Scholar] [CrossRef]

- Watanabe, K.; Tanaka, S.; Nagai, T.; Yoshida, K.; Kuramochi, A.; Kanda, T. Hyperboloidal Pneumatic Artificial Muscle with Braided Straight Fibers. IEEE Robot. Autom. Lett. 2024, 9, 6272–6279. [Google Scholar] [CrossRef]

- Mori, M.; Suzumori, K.; Seita, S.; Takahashi, M.; Hosoya, T.; Kusumoto, K. Development of very high force hydraulic McKibben artificial muscle and its application to shape-adaptable power hand. In Proceedings of the 2009 IEEE International Conference on Robotics and Biomimetics (ROBIO), Guilin, China, 19–23 December 2009; pp. 1457–1462. [Google Scholar] [CrossRef]

- Morita, R.; Nabae, H.; Endo, G.; Suzumori, K. A proposal of a new rotational-compliant joint with oil-hydraulic McKibben artificial muscles. Adv. Robot. 2018, 32, 511–523. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, W.; Chen, G.; Luo, J.; Lu, Q.; Wang, H. A 3D Printable Origami Vacuum Pneumatic Artificial Muscle with Fast and Powerful Motion. In Proceedings of the 2021 IEEE 4th International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 12–16 April 2021; pp. 551–554. [Google Scholar] [CrossRef]

- Coutinho, A.; Park, J.H.; Jamil, B.; Choi, H.R.; Rodrigue, H. Hyperbaric Vacuum-Based Artificial Muscles for High-Performance Actuation. Adv. Intell. Syst. 2023, 5, 2200090. [Google Scholar] [CrossRef]

- Joe, S.; Totaro, M.; Wang, H.; Beccai, L. Development of the Ultralight Hybrid Pneumatic Artificial Muscle: Modelling and optimization. PLoS ONE 2021, 16, e0250325. [Google Scholar] [CrossRef]

- Skorina, E.H.; Luo, M.; Oo, W.Y.; Tao, W.; Chen, F.; Youssefian, S.; Rahbar, N.; Onal, C.D. Reverse Pneumatic Artificial Muscles (rPAMs): Modeling, Integration, and Control. PLoS ONE 2018, 13, e0204637. [Google Scholar] [CrossRef]

- Lorenzon, L.; Zrinscak, D.; Maselli, M.; Cianchetti, M. Modelling and characterization of a Soft Inverse Pneumatic Artificial Muscle. In Proceedings of the ACTUATOR 2021; International Conference and Exhibition on New Actuator Systems and Applications, Online, 17–19 February 2021; pp. 1–4. [Google Scholar]

- Feng, M.; Yang, D.; Ren, L.; Wei, G.; Gu, G. X-crossing pneumatic artificial muscles. Sci. Adv. 2023, 9, eadi7133. [Google Scholar] [CrossRef]

- Irshaidat, M.; Soufian, M.; Al-Ibadi, A.; Nefti-Meziani, S. A Novel Elbow Pneumatic Muscle Actuator for Exoskeleton Arm in Post-Stroke Rehabilitation. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Republic of Korea, 14–18 April 2019; pp. 630–635. [Google Scholar] [CrossRef]

- Zhang, S.; Gong, D.; Yu, J. Design of a Multi-connection Pneumatic Artificial Muscle. In Proceedings of the 2022 12th International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Baishan, China, 27–31 July 2022; pp. 301–306. [Google Scholar] [CrossRef]

- Jamil, B.; Rodrigue, H.; Choi, Y. Design of a Novel Sensing Method for a Pneumatic Artificial Muscle Actuator-Driven 2-Degrees of Freedom Parallel Joint. Soft Robot. 2023, 10, 187–196. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Fei, Y. A High-torque Bidirectional Curl Pneumatic Artificial Muscle. In Proceedings of the 2022 28th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Nanjing, China, 16–18 November 2022; pp. 1–6. [Google Scholar] [CrossRef]

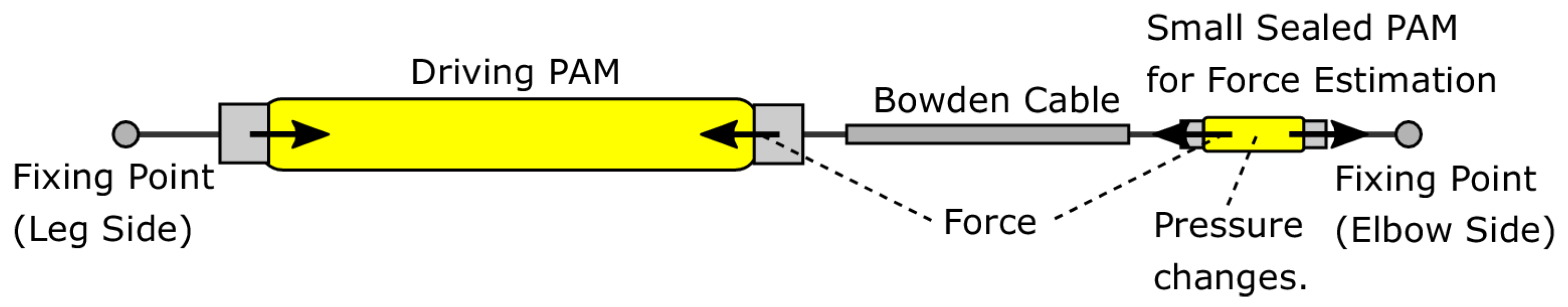

- Miyazaki, T.; Tomita, Y.; Kawashima, K. Force control of motion teaching suit using serial-connected pneumatic artificial muscles for actuation and estimation. Wearable Technol. 2025, 6, e10. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Blumenschein, L.H. Refined Modeling for Serial Pneumatic Artificial Muscles Enables Model-Based Actuation Design. In Proceedings of the 2024 IEEE 7th International Conference on Soft Robotics (RoboSoft), San Diego, CA, USA, 14–17 April 2024; pp. 800–807. [Google Scholar] [CrossRef]

- Pagliocca, N.; Gupta, A.; Knospler, J.; Singh, N.K.; Trkov, M. Modular reconfigurable rotary style soft pneumatic actuators. Sens. Actuators A Phys. 2024, 378, 115830. [Google Scholar] [CrossRef]

- Liu, J.; Ma, Z.; Wang, Y.; Zuo, S. Reconfigurable Self-Sensing Pneumatic Artificial Muscle With Locking Ability Based on Modular Multi-Chamber Soft Actuator. IEEE Robot. Autom. Lett. 2022, 7, 8635–8642. [Google Scholar] [CrossRef]

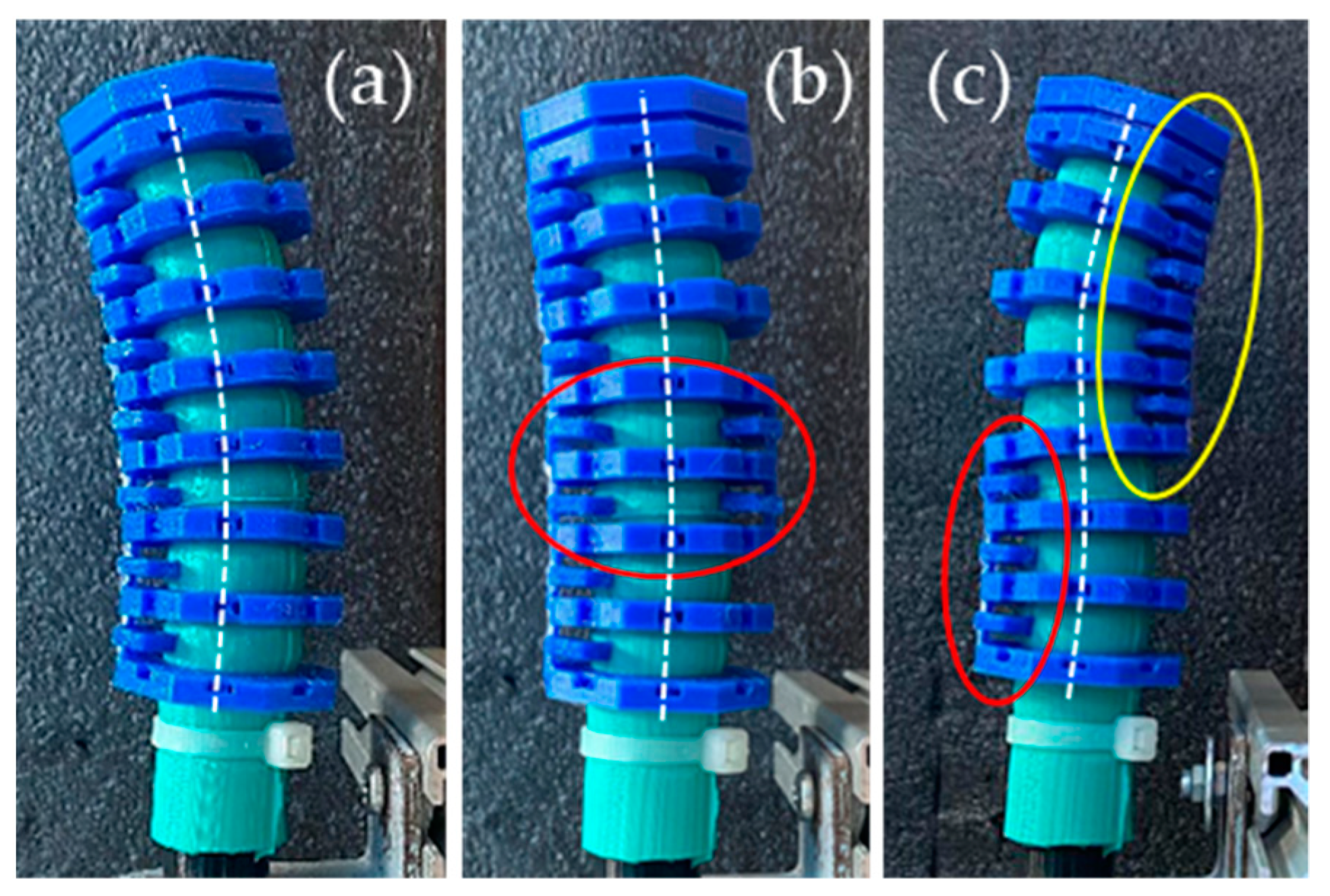

- Antonelli, M.G.; Beomonte Zobel, P.; Mattei, E.; Stampone, N. Mechanical Design, Manufacturing, and Testing of a Soft Pneumatic Actuator with a Reconfigurable Modular Reinforcement. Robotics 2024, 13, 165. [Google Scholar] [CrossRef]

- Kosaka, S.; Kimura, K.; Yamamoto, S.; Ishizuka, H.; Masuda, Y.; Punpongsanon, P.; Ikeda, S.; Oshiro, O. Reconfigurable Soft Pneumatic Actuators Using Multi-Material Self-Healing Polymers. IEEE Robot. Autom. Lett. 2025, 10, 4938–4945. [Google Scholar] [CrossRef]

- Shin, J.; Jamil, B.; Moon, H.; Koo, J.C.; Choi, H.R.; Rodrigue, H. Thermo-Pneumatic Artificial Muscle: Air-Based Thermo-Pneumatic Artificial Muscles for Pumpless Pneumatic Actuation. Soft Robot. 2024, 11, 187–197. [Google Scholar] [CrossRef]

- Yuan, Z.; Li, J.; Liu, L.; Zhu, X.; Wang, W.; Dickey, M.D.; Lum, G.Z.; Chirarattananon, P.; Luo, J.; Chen, R. Ultrarobust and Lightweight Electro-Pneumatic Actuators for Soft Robotics. IEEE Trans. Robot. 2025, 41, 2894–2910. [Google Scholar] [CrossRef]

- Liu, H.; Wu, C.; Lin, S.; Li, Y.; Yang, Y.; Lam, J.; Xi, N.; Chen, Y. Embedded Conductive Fiber for Pumpless Liquid-Gas Phase Transition Soft Actuation. ACS Appl. Mater. Interfaces 2025, 17, 28682–28692. [Google Scholar] [CrossRef]

- Zakeri, R.; Zakeri, R. Bio inspired general artificial muscle using hybrid of mixed electrolysis and fluids chemical reaction (HEFR). Sci. Rep. 2022, 12, 3627. [Google Scholar] [CrossRef]

- Michelson, R.C. Entomopter and Method for Using Same. U.S. Patent 6,082,671, 4 July 2000. [Google Scholar]

- Mirvakili, S.M.; Sim, D.; Hunter, I.W.; Langer, R. Actuation of untethered pneumatic artificial muscles and soft robots using magnetically induced liquid-to-gas phase transitions. Sci. Robot. 2020, 5, eaaz4239. [Google Scholar] [CrossRef] [PubMed]

- Wirekoh, J.; Valle, L.; Pol, N.; Park, Y.-L. Sensorized, Flat, Pneumatic Artificial Muscle Embedded with Biomimetic Microfluidic Sensors for Proprioceptive Feedback. Soft Robot. 2019, 6, 760–767. [Google Scholar] [CrossRef]

- Kwon, J.; Yoon, S.J.; Park, Y.-L. Flat Inflatable Artificial Muscles With Large Stroke and Adjustable Force-Length Relations. IEEE Trans. Robot. 2020, 36, 743–756. [Google Scholar] [CrossRef]

- Hong, T.; Lee, C.; Chang, S.; Choi, E.; Kim, B.; Ahn, J.; Park, Y.L. Design of a Fully-Soft Lift-Assist Wearable Suit Powered by Flat Inflatable Artificial Muscles. IEEE Robot. Autom. Lett. 2025, 10, 4428–4435. [Google Scholar] [CrossRef]

- Okui, M.; Ito, F.; Kojima, A.; Nakamura, T. Noninflatable Pneumatic Artificial Muscle Requiring Low Space and Consumption Flow Rate. In Proceedings of the 2020 IEEE/SICE International Symposium on System Integration (SII), Honolulu, HI, USA, 12–15 January 2020; pp. 495–499. [Google Scholar] [CrossRef]

- Martens, M.; Zawatzki, J.; Seel, T.; Boblan, I. A Pneumatic-Muscle-Actuator-Driven Knee Rehabilitation Device for CAM Therapy. In Proceedings of the 2019 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Berlin, Germany, 23–27 July 2019; pp. 6237–6242. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Y.; Qin, Y.; Yu, N.; Wang, H.; Han, J. Dynamic Surface Impedance Control of an Upper Limb Rehabilitation Exoskeleton Robot Driven by Pneumatic Artificial Muscles. In Proceedings of the 2024 IEEE 14th International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Copenhagen, Denmark, 16–19 July 2024; pp. 674–679. [Google Scholar] [CrossRef]

- Shiota, K.; Tarvainen, T.V.J.; Sekine, M.; Kita, K.; Yu, W. Development of a Robotic Thumb Rehabilitation System Using a Soft Pneumatic Actuator and a Pneumatic Artificial Muscles-Based Parallel Link Mechanism. In Intelligent Autonomous Systems 14 (IAS 2016); Chen, W., Hosoda, K., Menegatti, E., Shimizu, M., Wang, H., Eds.; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2017; Volume 531, pp. 525–537. [Google Scholar] [CrossRef]

- Enyan, M.; Bing, Z.; Amu-Darko, J.N.O.; Issaka, E.; Otoo, S.L.; Agyemang, M.F. Advances in Smart Materials Soft Actuators on Mechanisms, Fabrication, Materials, and Multifaceted Applications: A Review. J. Thermoplast. Compos. Mater. 2024, 38, 302–370. [Google Scholar] [CrossRef]

- Li, W.; Luo, F.; Liu, Y.; Zou, Y.; Mo, L.; He, Q.; Lin, P.-J.; Xu, Q.; Liu, A.; Zhang, C.; et al. Bioinspired Smart Triboelectric Soft Pneumatic Actuator-Enabled Hand Rehabilitation Robot. Adv. Mater. 2025, 37, 2419059. [Google Scholar] [CrossRef]

- Doumit, M.; Murillo, J.; Lawrynczyk, A.; Baddour, N. Design and Evaluation of Pneumatic Artificial Muscle for Powered Transfemoral Prostheses. J. Med. Biol. Eng. 2014, 34, 439–447. [Google Scholar] [CrossRef]

- Markus, A.T.; Sobczyk, M.R.; Perondi, E.A. Modeling, Control, and Simulation of a 3-Degrees of Freedom Mechanism Actuated by Pneumatic Artificial Muscles for Upper Limb Prosthesis Application. J. Mech. Robot. 2023, 15, 011002. [Google Scholar] [CrossRef]

- Tian, J.; Wei, B.; Luo, S.; Yang, C.; Chen, C.; Liu, Y.; Feng, J.; Li, P.; Zhu, H.; Yi, C. A Systematic Review of Occupational Shoulder Exoskeletons for Industrial Use: Mechanism Design, Actuators, Control, and Evaluation Aspects. Actuators 2024, 13, 501. [Google Scholar] [CrossRef]

- Taylor, S.J.G.; Walker, P.S.; Perry, J.S.; Cannon, S.R.; Woledge, R. The Forces in the Distal Femur and the Knee During Walking and Other Activities Measured by Telemetry. J. Arthroplast. 1998, 13, 428–437. [Google Scholar] [CrossRef] [PubMed]

- D’Lima, D.D.; Fregly, B.J.; Patil, S.; Steklov, N.; Colwell, C.W., Jr. Knee Joint Forces: Prediction, Measurement, and Significance. Proc. Inst. Mech. Eng. H 2012, 226, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Takosoglu, J. Static Characteristics of the New Artificial Pneumatic Muscle. EPJ Web Conf. 2022, 269, 01061. [Google Scholar] [CrossRef]

- Kumar, V.; Xu, Z.; Todorov, E. Fast, Strong and Compliant Pneumatic Actuation for Dexterous Tendon-Driven Hands. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation (ICRA), Karlsruhe, Germany, 6–10 May 2013; pp. 1512–1519. [Google Scholar] [CrossRef]

- Shadow Robot. Shadow Dexterous Hand Series-Technical Specifications and Overview. 2025. Available online: https://shadowrobot.com/ (accessed on 9 October 2025).

- Gaiser, I.N.; Pylatiuk, C.; Schulz, S.; Kargov, A.; Oberle, R.; Werner, T. The FLUIDHAND III: A Multifunctional Prosthetic Hand. J. Prosthet. Orthot. 2009, 21, 91–96. [Google Scholar] [CrossRef]

- Zhao, Z.; Hao, L.; Liu, M.; Gao, H.; Li, X. Prescribed Performance Model-Free Adaptive Terminal Sliding Mode Control for the Pneumatic Artificial Muscles Elbow Exoskeleton. J. Mech. Sci. Technol. 2021, 35, 3183–3197. [Google Scholar] [CrossRef]

- Carvalho, A.D.D.R.; Karanth, P.N.; Desai, V. Characterization of Pneumatic Muscle Actuators and Their Implementation on an Elbow Exoskeleton with a Novel Hinge Design. Sens. Actuators Rep. 2022, 4, 100109. [Google Scholar] [CrossRef]

- Feng, Y.; Ide, T.; Nabae, H.; Endo, G.; Suzumori, K. Safety-enhanced control strategy of a power soft robot driven by hydraulic artificial muscles. Robomech J. 2021, 8, 10. [Google Scholar] [CrossRef]

- Hocking, E.; Wereley, N. Fabrication and Characterization of Small-Scale Pneumatic Artificial Muscles for a Bio-Inspired Robotic Hand. In Proceedings of the 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013; American Institute of Aeronautics and Astronautics: Grapevine, TX, USA, 2013. [Google Scholar] [CrossRef]

- Ohta, P.; Valle, L.; King, J.; Low, K.; Yi, J.; Atkeson, C.G.; Park, Y.-L. Design of a Lightweight Soft Robotic Arm Using Pneumatic Artificial Muscles and Inflatable Sleeves. Soft Robot. 2018, 5, 204–215. [Google Scholar] [CrossRef]

- Sokolov, O.; Hošovský, A.; Trojanová, M. Design, Modelling, and Control of Continuum Arms with Pneumatic Artificial Muscles: A Review. Machines 2023, 11, 936. [Google Scholar] [CrossRef]

- Wang, J.X.; Gao, D.; Lee, P.S. Recent Progress in Artificial Muscles for Interactive Soft Robotics. Adv. Mater. 2021, 33, 2003088. [Google Scholar] [CrossRef] [PubMed]

- Zhong, W.; Wu, Y.; Li, L.; Shao, J.; Gu, X. A Tortoise-Inspired Quadrupedal Pneumatic Soft Robot That Adapts to Environments through Shape Change. Bioinspir. Biomim. 2025, 20, 036002. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Ni, X.; Gao, W.; Shen, H.; Sun, M.; Guo, G.; Wu, H.; Jiang, S. Pneumatically Controlled Reconfigurable Bistable Bionic Flower for Robotic Gripper. Soft Robot. 2022, 9, 657–668. [Google Scholar] [CrossRef]

- Tinsley, B.; Caponi, S.; McAteer, L.; Nebesnyy, G.; Sammanthan, D.; Keza, E.S.; Alam, P. Peristaltic Motion Enabled by Pneumatic Artificial Muscles (PAMs) as Structural “Soft–Stiff” Actuators in a Modular Worm-Inspired Robot. Biomimetics 2024, 9, 447. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Liang, J.; Zhou, Y. Manta Ray-Inspired Soft Robotic Swimmer for High-Speed and Multi-Modal Swimming. In Proceedings of the 2024 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Abu Dhabi, United Arab Emirates, 14–18 October 2024; pp. 235–240. [Google Scholar] [CrossRef]

- Sayahkarajy, M.; Witte, H. Empirical Data-Driven Linear Model of a Swimming Robot Using the Complex Delay-Embedding DMD Technique. Biomimetics 2025, 10, 60. [Google Scholar] [CrossRef]

- Niikura, A.; Nabae, H.; Endo, G.; Gunji, M.; Mori, K.; Niiyama, R.; Suzumori, K. Giraffe Neck Robot: First Step Toward a Powerful and Flexible Robot Prototyping Based on Giraffe Anatomy. IEEE Robot. Autom. Lett. 2022, 7, 3539–3546. [Google Scholar] [CrossRef]

- Shin, T.; Teranishi, K.; Kogiso, K. Cyber-Secure Pneumatic Actuator System Equipped with Encrypted Controller and Attack Detectors. Adv. Robot. 2022, 36, 438–449. [Google Scholar] [CrossRef]

- Festo. Fluidic Muscle DMSP/MAS Series: Technical Information; Product Brochure, Festo AG & Co. KG: Esslingen, Germany, 2019; Available online: https://www.festo.com/rep/en_corp/assets/pdf/info_501_en.pdf (accessed on 5 November 2025).

- Kotkas, L.; Zhurkin, N.; Donskoy, A.; Zharkovskij, A. Design and Mathematical Modeling of a Pneumatic Artificial Muscle-Actuated System for Industrial Manipulators. Machines 2022, 10, 885. [Google Scholar] [CrossRef]

- SMuscle Co., Ltd. Technical Data of Thin McKibben Muscles (EM-Series). Available online: https://www.s-muscle.com/ (accessed on 7 November 2025).

- Kobayashi, R.; Nabae, H.; Mao, Z.; Endo, G.; Suzumori, K. Enhancement of Thin McKibben Muscle Durability Under Repetitive Actuation in a Bent State. IEEE Robot. Autom. Lett. 2024, 9, 9685–9692. [Google Scholar] [CrossRef]

- Šitum, Ž.; Herceg, S.; Bolf, N.; Ujević Andrijić, Ž. Design, Construction and Control of a Manipulator Driven by Pneumatic Artificial Muscles. Sensors 2023, 23, 776. [Google Scholar] [CrossRef]

- Ye, X.; Zhu, S.; Qian, X.; Zhang, M.; Wang, X. V-Shape Pneumatic Torsional Actuator: A Building Block for Soft Grasper and Manipulator. Soft Robot. 2022, 9, 562–576. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Xu, Y.-X.; Juang, J.-Y. Single-Actuator Soft Robot for In-Pipe Crawling. Soft Robot. 2023, 10, 174–186. [Google Scholar] [CrossRef] [PubMed]

- Tawk, C.; in het Panhuis, M.; Spinks, G.M.; Alici, G. Bioinspired 3D Printable Soft Vacuum Actuators for Locomotion Robots, Grippers and Artificial Muscles. Soft Robot. 2018, 5, 685–694. [Google Scholar] [CrossRef] [PubMed]

- Arquimea Ingeniería, S.L. Final Report Summary-STAMAS (Smart Technology for Artificial Muscle Applications in Space); Arquimea Ingeniería S.L.: Madrid, Spain, 2015. [Google Scholar]

- Netwall, C.J.; Thomas, J.P.; Kubista, M.S.; Griffith, K.A.; Kindle, C.; Schlater, J.; Hays, J.T.; Feerst, P.A.; Wereley, N.M. Pneumatic Artificial Muscle Actuators With Integrated Controls for Space Flight Applications. In Proceedings of the ASME 2019 Conference on Smart Materials, Adaptive Structures and Intelligent Systems (SMASIS), Louisville, KY, USA, 9–11 September 2019. [Google Scholar] [CrossRef]

- Sun, Y.; Guo, J.; Miller-Jackson, T.M.; Liang, X.; Ang, M.H.; Yeow, R.C.H. Design and Fabrication of a Shape-Morphing Soft Pneumatic Actuator: Soft Robotic Pad. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 6214–6220. [Google Scholar] [CrossRef]

- Powell, D.; Hischier, I.; Jayathissa, P.; Svetozarevic, B.; Schlüter, A. A Reflective Adaptive Solar Façade for Multi-Building Energy and Comfort Management. Energy Build. 2018, 177, 303–315. [Google Scholar] [CrossRef]

- Svetozarevic, B.; Begle, M.; Jayathissa, P.; Caranovic, S.; Shepherd, R.F.; Nagy, Z.; Hischier, I.; Hofer, J.; Schlueter, A. Dynamic Photovoltaic Building Envelopes for Adaptive Energy and Comfort Management. Nat. Energy 2019, 4, 671–682. [Google Scholar] [CrossRef]

- Festo. AirJelly: First Indoor Flying Object with Peristaltic Propulsion. Research & Development—Bionic Flying Objects. 2025. Available online: https://www.festo.com/us/en/e/about-festo/research-and-development/bionic-learning-network/bionic-flying-objects/airjelly-id_33841/ (accessed on 23 June 2025).

- Festo. AirPenguins-Bionic Flying Objects: Autonomous Flying Penguins with Collective Behavior. Research & Development—Bionic Learning Network. 2025. Available online: https://www.festo.com/us/en/e/about-festo/research-and-development/bionic-learning-network/bionic-flying-objects/airpenguins-id_33788/ (accessed on 23 June 2025).

- Festo. Airic’s Arm: Robot Arm with Fluidic Muscles. Bionic Grippers and Soft Robots, Bionic Learning Network. 2025. Available online: https://www.festo.com/us/en/e/about-festo/research-and-development/bionic-learning-network/bionic-grippers-and-soft-robots/airic-s-arm-id_33870/ (accessed on 23 June 2025).

| Type | Contraction Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| Braided [1,42,46,47] | 20–30 | 200–600 | 50–1200 | ∼10–15 |

| Pleated [3,4,50] | 20–45 | 10–300 | <3500 | <10 |

| Netted [3,48,49] | 20–30 | 1.7–300 | 10–300 | N/A |

| Embedded [1,54,55,56] | 15–25 | 50–800 | 184–6000 | <10 |

| Type | Contraction Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| PAM [1,42,46,47] | 15–45 | 10–800 | 50–6000 | ∼10–15 |

| HAM [5,57,58] | 25–30 | 4000–6000 | 8000–28,000 | <5 |

| Type | Contraction Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| Origami VPAM [59] | ∼62 | <−80 | 29 | N/A |

| LP-VPAM [20] | ∼61 | <−40 | 26.4 | N/A |

| Modular VPAM [22] | ∼80 | −80 | 39 | N/A |

| Hyper-VAM [60] | 89.1 | −90/+60 | 784 | N/A |

| UH-PAM [61] | ∼50 | −80 | 29 | 11.5 |

| Type | Extension Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| rPAM [62] | ∼50 | <190 | ∼3 | N/A |

| SIPAM [63] | ∼200 | <180 | ∼15 | 24–38 |

| Self-sensing IPAM [30] | ∼40 | <180 | 13.6 | ∼20–30 |

| EPAM [31] | ∼100 | <83 | 34.4 | N/A |

| Type | Contraction Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| fPAM [25] | ∼30 | 100 | 230 | <1 |

| foldPAM [26] | 2–37 | <12.4 | ∼1 | N/A |

| X-PAM [64] | 62.6–92.9 | <150 | 23.3–134.7 | ∼20–25 |

| Type | Contraction Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| MPAM [66] | 28 | <480 | 108 | N/A |

| Bundled [19] | 21–23 (ind.)/∼19 (sys.) | <400 | 14–20 (ind.)/1 (sys.) | N/A |

| BCPAM [68] | bend 82.7° | 400 | 34.1 Nm (torque) | ∼10–15 |

| Serial PAM [70] | 30–40 | 3.4–27.6 (<40) | 20–60 | N/A |

| Type | Contraction Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| Reinforced VPAM [21] | <30 (linear); twist 290°, bend 255° | −21 | 5 | N/A |

| Modular Rotary [71] | <40 | 77 | <60 | N/A |

| RSPAM [72] | 71 | 300 | 70.14 | N/A |

| SPA [73] | bend 31° | 150 | 1.28 | N/A |

| Self-Healing SPA [74] | <15 | 24 | 3 | N/A |

| Type | Contraction Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| OV-PAM [27] | ∼80 | −80 | ∼98 | N/A |

| ROV-PAM [29] | 47.1 (ind)/75.7 (sys.) | −20 | ∼9.8 | N/A |

| SFA [23] | 62 | −99.8 | ∼19 | N/A |

| Type/Design | Contraction Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| Thermal PAM [75] | ∼10 | −10–30 | <196 | N/A |

| EPA [34] | <20 | <800 | ∼300 | N/A |

| Macro–Mini Hybrid [32] | N/A | ∼300 | <250 | small |

| EHA [76] | bend 11°–104° | N/A (sealed) | 0.1–0.5 (gripper) | N/A |

| E-FPTA [77] | 120 | ∼60 | <16 | N/A |

| HEFR [78] | ∼30 | N/A | ∼2.5 | N/A |

| MITPAM [80] | <20 | ∼0.44 | <20 | N/A |

| Type/Design | Contraction Ratio (%) | Operating Pressure (kPa) | Max Force (N) | Hysteresis (%) |

|---|---|---|---|---|

| sFPAM [81] | 19.8 | 89.7 | 24 | N/A |

| FIAM [82,83] | <55.3 | 10–50 | 25–43 | ∼10 |

| NI-PAM [84] | 4 | −0.05–0.1 | 40–90 | ∼20 |

| Actuation Type | Working Principle | Contraction/Strain (%) | Operating Pressure (kPa) | Max Force (N) |

|---|---|---|---|---|

| PAM | Inner bladder inflates; braid expands radially causing axial contraction | 15–45 | 10–800 | 50–6000 |

| HAM | Incompressible fluid expands elastomeric tube against braided sleeve | 25–30 | 4000–6000 | 8000–28,000 |

| VPAM | Negative pressure collapses flexible origami or fabric structure | 50–89.1 | −40 to −90 | 26–784 |

| iPAM, ePAM | Positive-pressure elongation or eversion produces extension | 40–100 (EPAM), up to 200 (SIPAM) | ≤180 | 13–34 |

| fPAM, foldPAM | folded geometry and anisotropic fabric converts inflation to contraction | ∼30 (fPAM), 2–37 (foldPAM) | 12–500 | ∼230 (fPAM); ∼1 (foldPAM) |

| X-PAM | X-crossing sliding filaments yield high strain without radial expansion | 62.6–92.9 | ≤150 | 23–135 |

| Grouped, Bundled | Multiple PAMs in parallel/series enhance force and compliance | ∼19 (system)/ 28 (MPAM) | ≤480 | 108 N (MPAM); 34.1 Nm (BCPAM) |

| Reconfigurable | Modular chambers and variable reinforcement enable adaptable morphology | up to 71 | −21 to 1200 | 2–70 |

| Origami-based | Folding geometries (e.g., Kresling) convert collapse to motion | 60–80 | −20 to −100 | up to 18 N/∼98 Nm |

| Hybrid | Pneumatic with thermal, electric, magnetic or chemical | 10–120 | 0–800 | 2–300 N (up to 1.5 Nm) |

| FIAM, NI-PAM | Flat (constrained) or non-inflatable fiber-reinforced designs minimize volume | 4–55 | −50 to 100 | 24–90 |

| Actuator Type | Strain (%) | Pressure (kPa) | Max Force (N) | Force Density (kN/kg) | Specific Power (kW/kg) | Actuation Speed (s) |

|---|---|---|---|---|---|---|

| Braided PAM [1,42,46,47] | 20–30 | 200–600 | 50–1200 | ∼0.29–10 | ∼1–1.5 | 0.03–1 |

| Pleated PAM [3,4,50] | 20–45 | 10–600 | <3500 | 4–60 | ∼1 | ∼0.5–1 |

| Netted PAM [3,48,49] | 20–30 | 1.7–300 | 10–300 | ∼1–10 | N/A | N/A |

| Embedded-fiber PAM [1,54,55,56] | 20–25 | 600–800 | 184–6000 | ∼4–18 | ∼0.2–1 | 0.05–1 |

| Hydraulic PAM (HAM) [5,57,58] | 25–30 | 4000–6000 | 8000–28,000 | ∼9.4–17 | ∼1–2.5 | ∼1–1.5 |

| Origami VPAM [59] | ∼62 | >−80 | 29 | ∼1.96 | N/A | ∼0.18 |

| Low-profile VPAM [20] | ∼61 | >−40 | 26.4 | N/A | N/A | N/A |

| Modular origami VPAM [22] | ∼80 | ∼39 | ∼4.5 | N/A | ∼0.96 | |

| Hyper-VAM [60] | 89.1 | /+60 | 784 | ∼5.2 | 0.675 | 0.31 |

| UH-PAM [61] | ∼50 | >−80 | 29 | 1.64 | 0.0663 | 0.5 |

| rPAM (reverse PAM) [62] | ∼50 (ext.) | <190 | ∼3 | N/A | N/A | N/A |

| SIPAM [63] | ∼200 (ext.) | <180 | ∼15 | N/A | N/A | N/A |

| Self-sensing IPAM [30] | ∼40 (ext.) | <180 | 13 | N/A | N/A | N/A |

| EPAM [31] | ∼100 (ext.) | <83 | 34.4 | 1–3.4 | N/A | N/A |

| fPAM [25] | ∼30 | <100 | 230 | 120 | N/A | ∼0.06 |

| foldPAM [26] | 2–37 | <12.4 | ∼1 | N/A | N/A | N/A |

| X-PAM [64] | 62.6–92.9 | <150 | 23–135 | 5.2–31.2 | 2.3–5.7 | ∼0.06 |

| MPAM (6-fiber bundle) [66] | 28 | <480 | 108 | ∼3.1 | N/A | N/A |

| BCPAM (bidirectional) [68] | bend 82.7° | 400 | 34.1 Nm | N/A | N/A | N/A |

| Reinforced VPAM [21] | <30 (lin.); 290° twist | −21 | 5 | N/A | N/A | ∼0.5–2.5 |

| Modular rotary PAM [71] | <40 | 77 | <60 | N/A | N/A | N/A |

| RSPAM [72] | 71 | 300 | 70 | N/A | N/A | 0.51–0.66 |

| Modular SPA finger [73] | bend 31° | 150 | 1.28 | ∼0.05 | N/A | 0.054 |

| Self-healing SPA [74] | <15 | 24 | 3 | N/A | N/A | N/A |

| OV-PAM [27] | ∼80 | −80 | ∼98 | 6.5 | N/A | 1–2 |

| ROV-PAM [29] | 47 (mod)/ 75 (sys) | −20 | ∼9.8 | N/A | N/A | N/A |

| 3D-printed SFA [23] | 62 | −99.8 | ∼19 | ∼1.37 | N/A | N/A |

| Thermo-PAM (sealed) [75] | ∼10 | −10–30 | <196 | N/A | N/A | 3–5 |

| EPA (PAM + motor) [34] | <20 | <800 | ∼300 | N/A | N/A | N/A |

| Macro-mini hybrid [32] | N/A | ∼300 | <250 | N/A | N/A | N/A |

| EHA (electro-HPA) [76] | bend 104° | N/A (6–10 kV) | ∼0.5 | ∼0.5 | ∼0.1 | 0.06–2 |

| E-FPTA (phase-change) [77] | 120 (ext.) | ∼60 | 16 | ∼1–2 | ∼1.2–1.7 | 30–50 |

| HEFR (chem. react.) [78] | ∼30 | N/A | 2.5 | ∼0.074 | ∼0.36 | <1–2 |

| MITPAM (magnetic) [80] | <20 | N/A | <20 | ∼1.5 | ∼40 | 3–10 |

| sFPAM (flat, sens.) [81] | 19.8 | 89.7 | 24 | ∼1.4 | N/A | 0.28–0.82 |

| FIAM (flat inflatable) [82,83] | 55.3 | 10–50 | 43 | N/A | N/A | 3–4 |

| NI-PAM (non-inflatable) [84] | 4 | −50–100 | 40–90 | ∼1.3 | N/A | N/A |

| Domain/Area | Typical PAM Types | Key Requirements | Example Systems/References |

|---|---|---|---|

| Biomechanics & Rehabilitation | Compressed-air, Reconfigurable, Sensorized | Safe interaction, compliance, lightweight, closed-loop control | CAMOped [85], Elbow exoskeletons [86], TENG-SPA [89] |

| Human-Machine Interaction | Compressed-air, Hybrid, High-force | High force-to-weight, compactness, compliance | Transfemoral prosthesis [90], Elbow exoskeleton [100] |

| Soft Robotics | Miniaturized, Hybrid arms, Inverse, Origami-based | Miniaturization, compliance, adaptive morphology | Robotic hands [102], Hybrid arm [103], Octopus arm [18] |

| Aerospace & Space | Compressed-air, Hybrid, Fatigue-resistant | High fatigue life, low mass, adaptability, reliability | NRL 7-DOF arm [122], Morphing wings [11,12], Spoilers [13], Entomopter RCM [33,79] |

| Adaptive Architecture | Origami-based, Flat/Non-inflatable, Reconfigurable | Scalability, energy efficiency, modularity, durability | SRP [123], PV facade [124,125] |

| Art, Education & Entertainment | Reconfigurable, Hybrid, Kinetic structures | Expressive motion, modularity, safe interaction, aesthetics | Bio-robotic art [15], AirPenguin [127], Airic’s arm [128] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhagiparova, A.; Golubev, V.; Kim, D. Recent Developments in Pneumatic Artificial Muscle Actuators. Actuators 2025, 14, 582. https://doi.org/10.3390/act14120582

Zhagiparova A, Golubev V, Kim D. Recent Developments in Pneumatic Artificial Muscle Actuators. Actuators. 2025; 14(12):582. https://doi.org/10.3390/act14120582

Chicago/Turabian StyleZhagiparova, Aliya, Vladimir Golubev, and Daewon Kim. 2025. "Recent Developments in Pneumatic Artificial Muscle Actuators" Actuators 14, no. 12: 582. https://doi.org/10.3390/act14120582

APA StyleZhagiparova, A., Golubev, V., & Kim, D. (2025). Recent Developments in Pneumatic Artificial Muscle Actuators. Actuators, 14(12), 582. https://doi.org/10.3390/act14120582