Development of an Innovative Modular Foam-Filled Panelized System for Rapidly Assembled Postdisaster Housing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Foam-Core

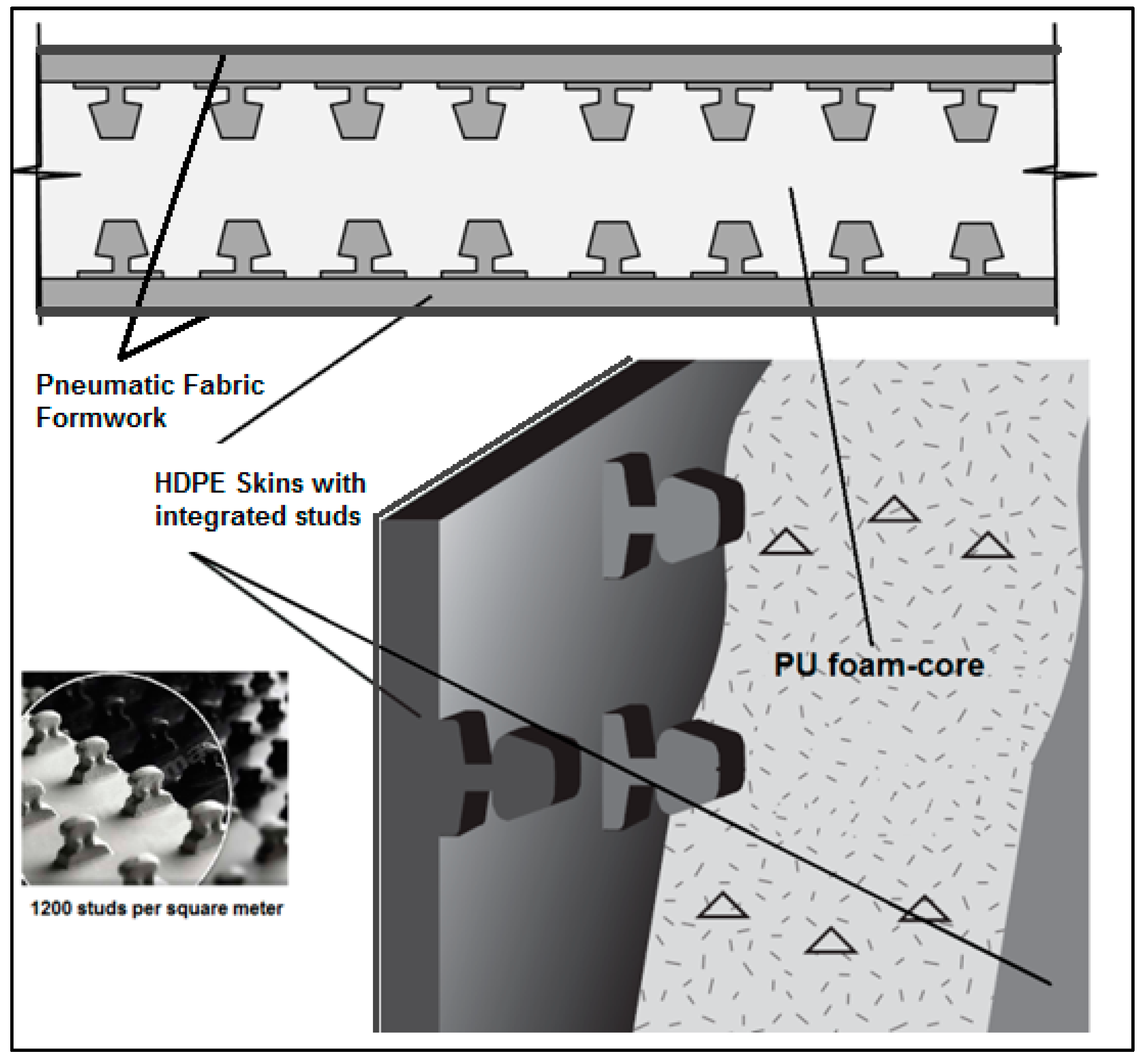

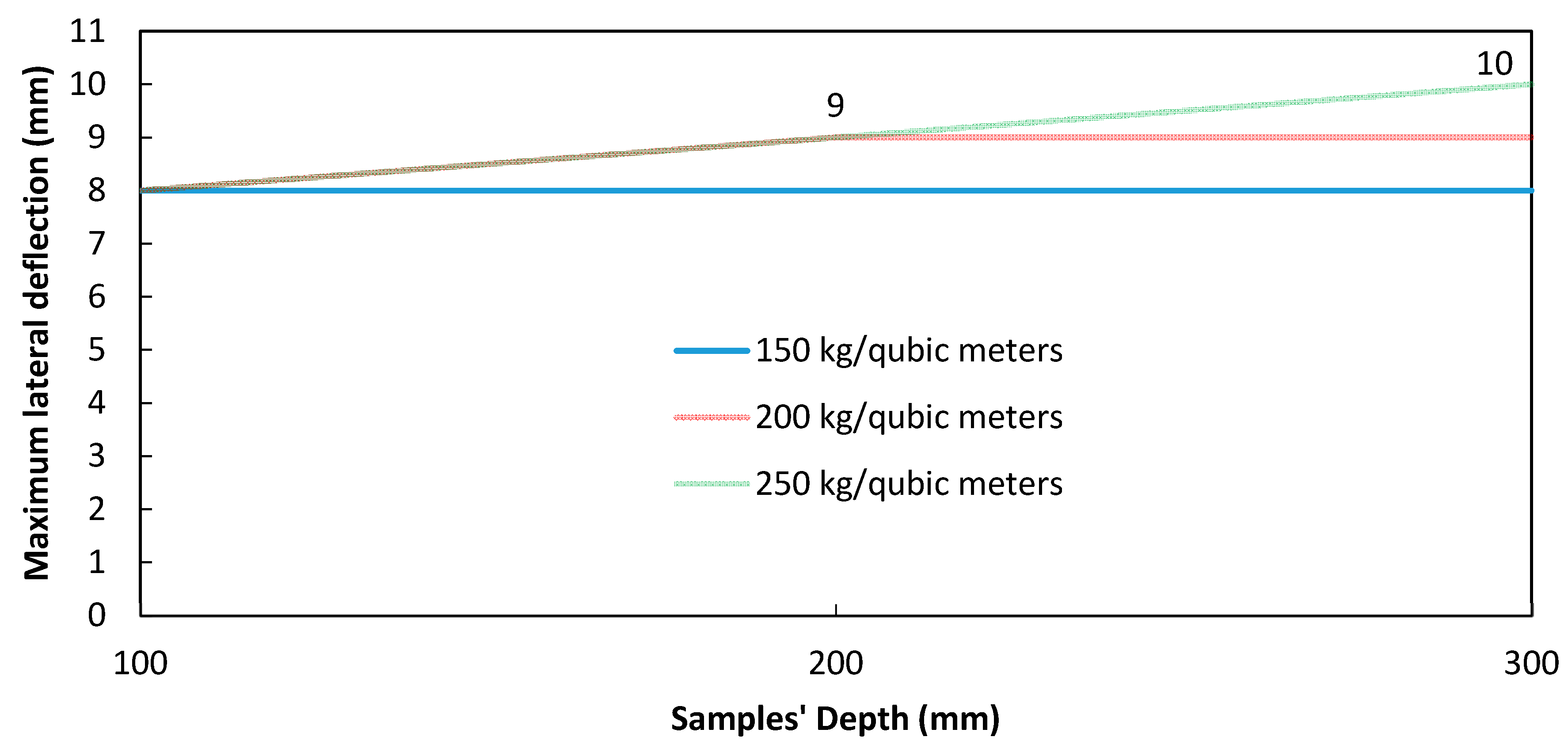

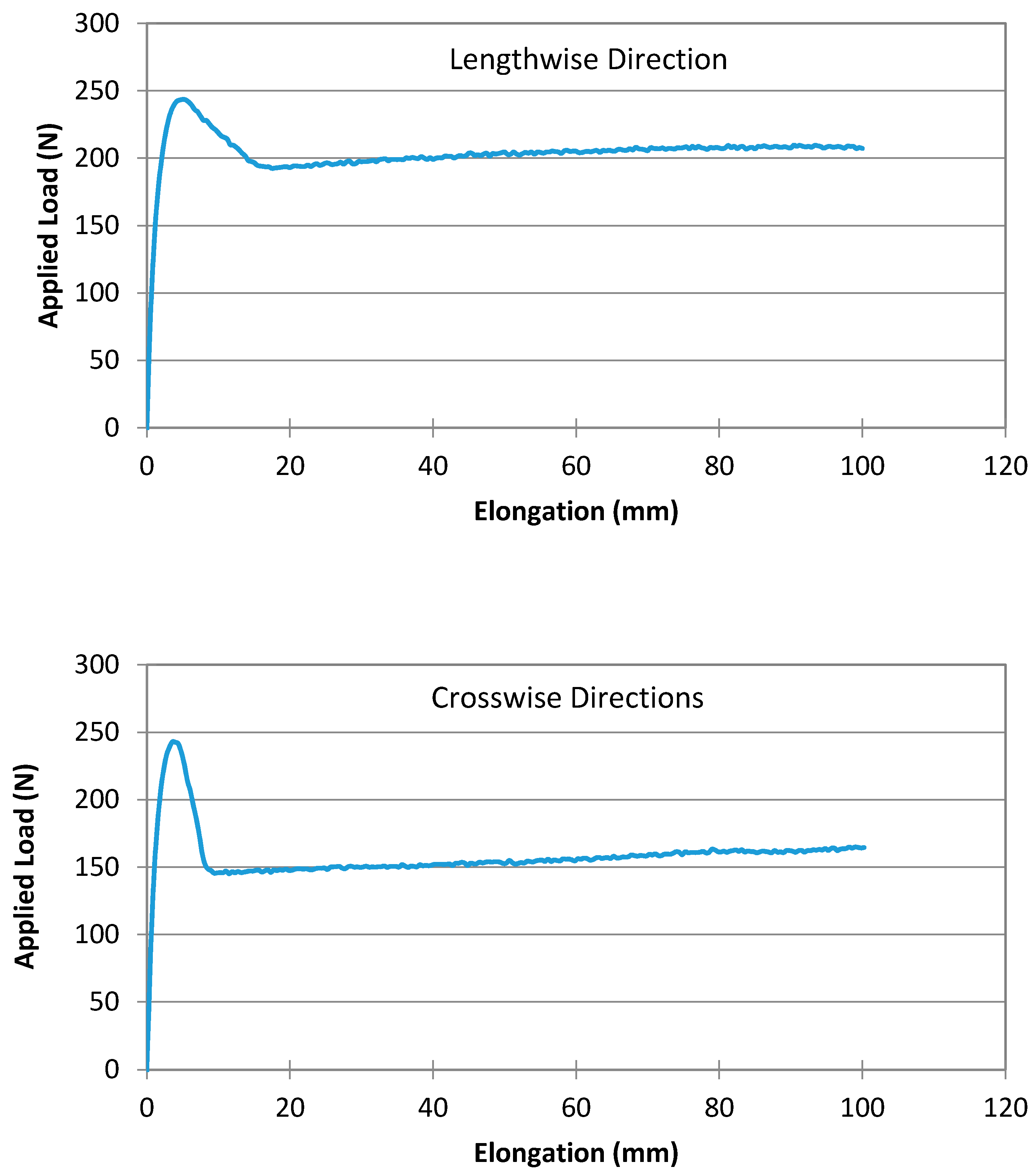

2.2. Fabric Formwork

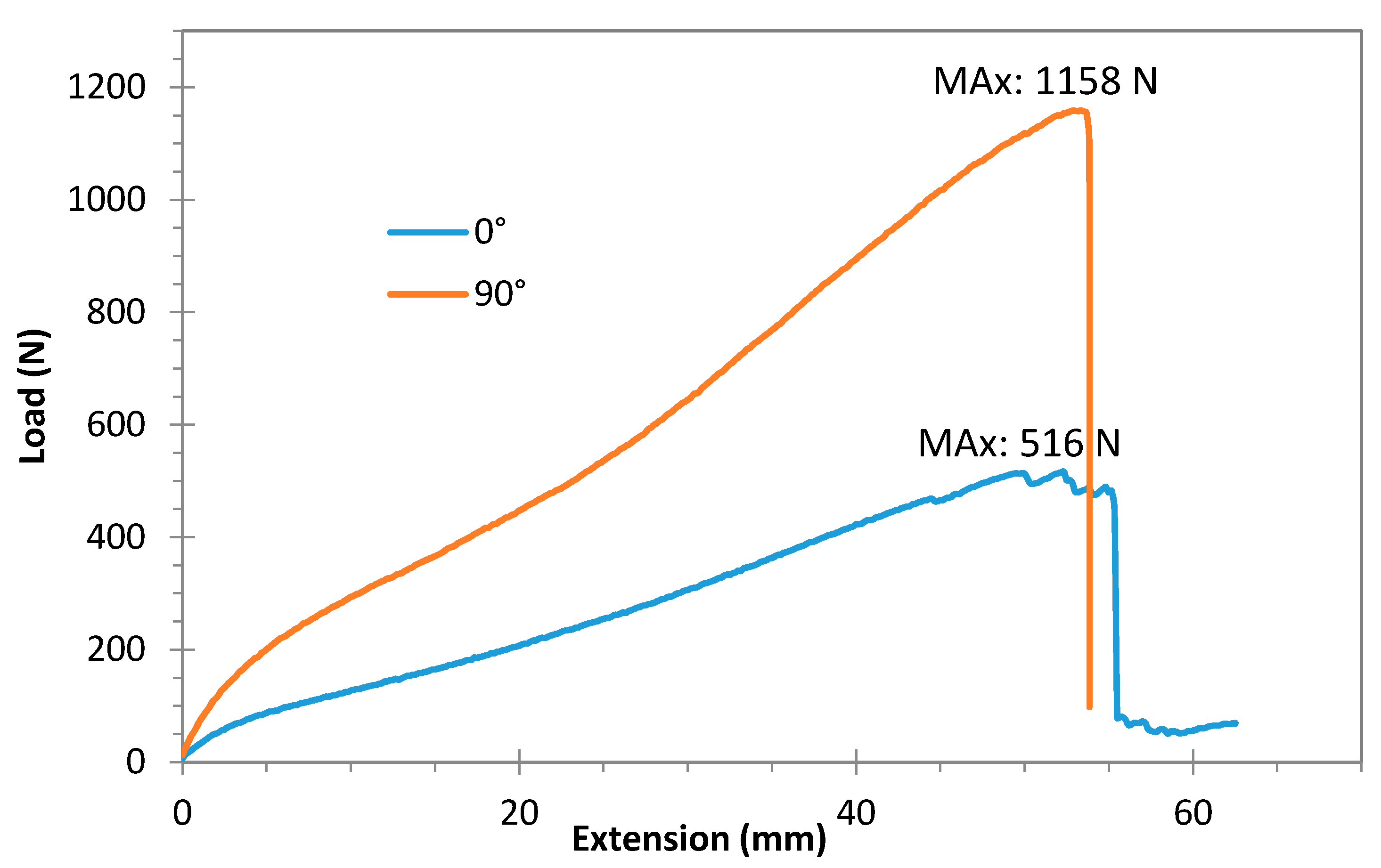

2.3. Skin Sheets

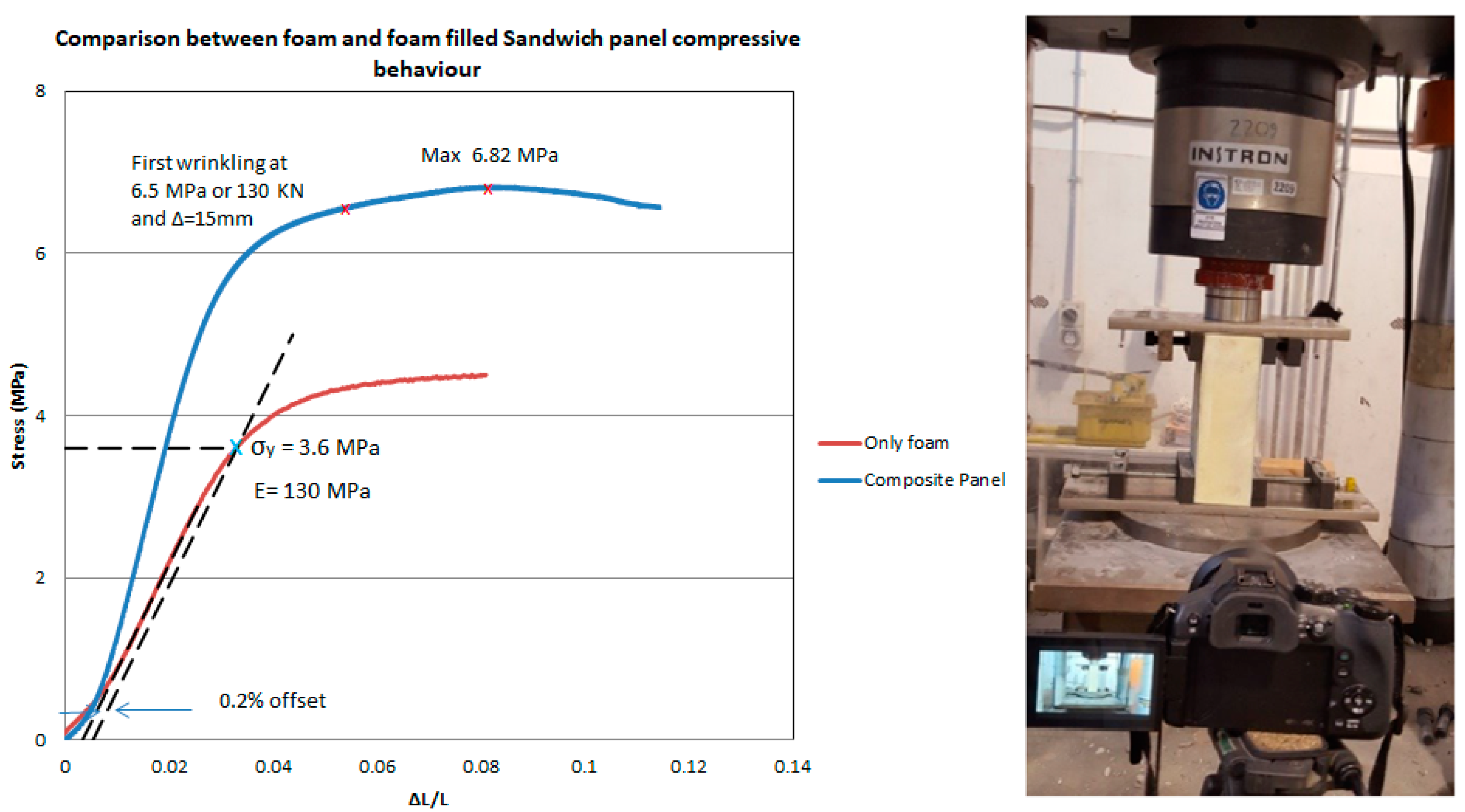

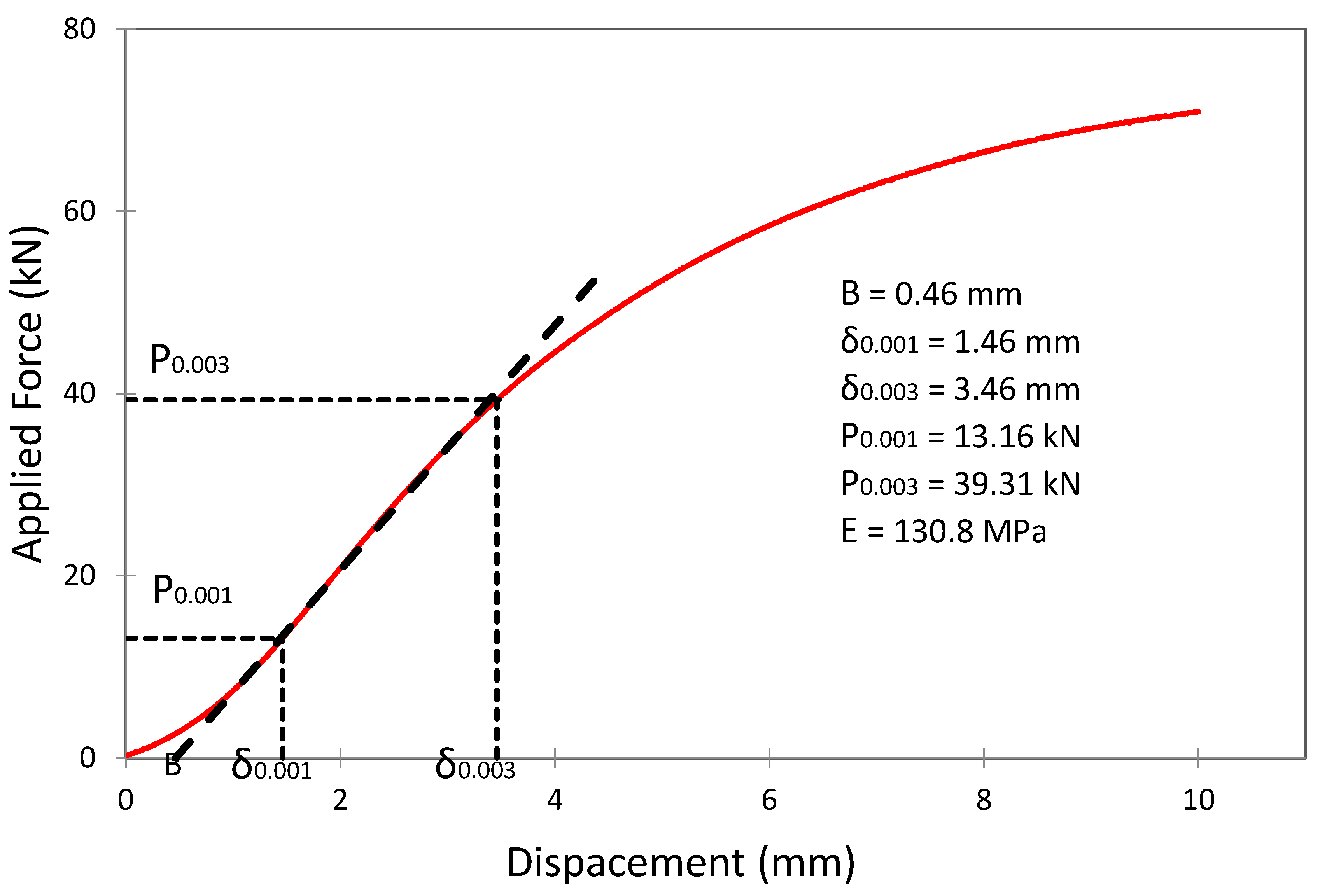

3. Edgewise and Flatwise Compressive Behavior

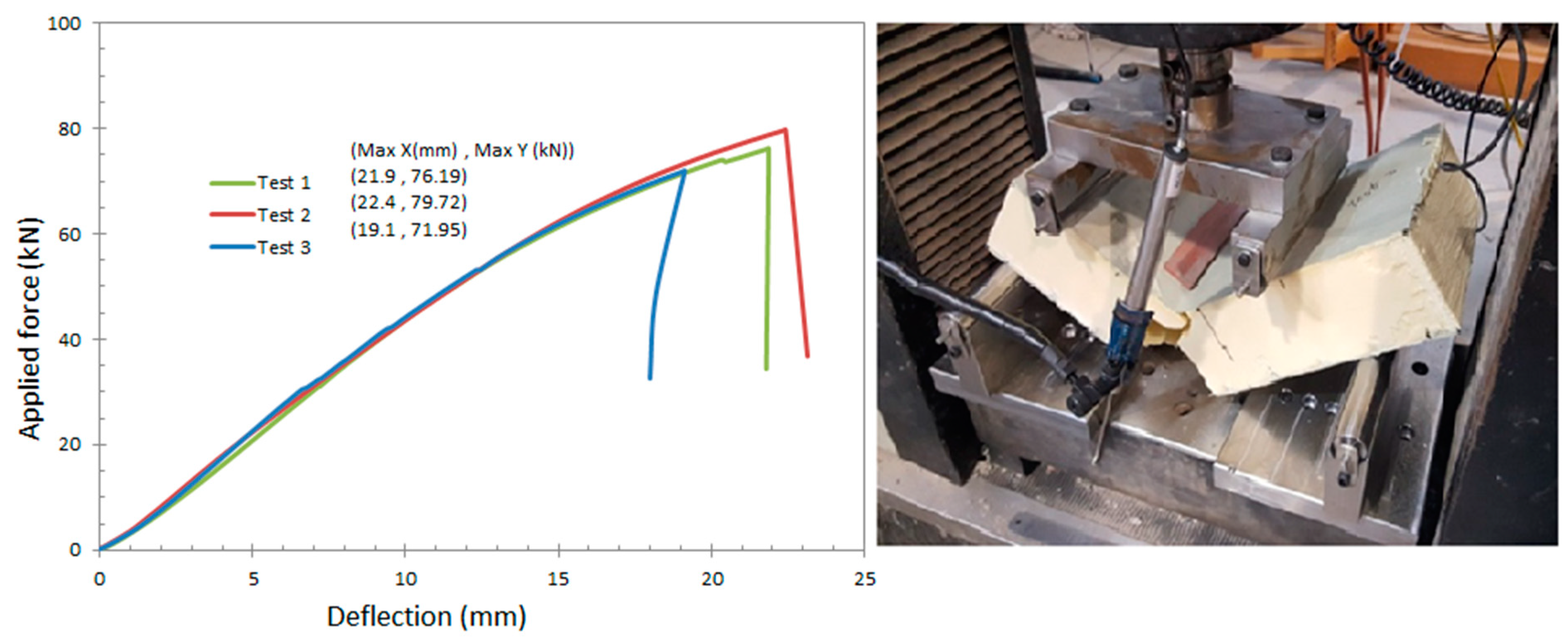

4. Flexural and Shear Behavior

Effects of Cold Joints

5. Integrated Connections

6. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Goodyear, R.K.; Fabian, A. Housing in Auckland: Trends in Housing from the Census of Population and Dwellings 1991 to 2013; Statistics New Zealand: Wellington, New Zealand, 2014. [Google Scholar]

- Goodyear, R. Housing in Greater Christchurch after the Earthquakes: Trends in Housing from the Census of Population and Dwellings 1991–2013; Statistics New Zealand: Wellington, New Zealand, 2014. [Google Scholar]

- Abulnour, A.H. The post-disaster temporary dwelling: Fundamentals of provision, design and construction. HBRC J. 2014, 10, 10–24. [Google Scholar] [CrossRef]

- De Temmerman, N.; Brebbia, C.A. (Eds.) Mobile and Rapidly Assembled Structures IV; WIT Press: Ashurst, UK, 2014. [Google Scholar]

- Preston, S.J.; Bank, L.C. Portals to an architecture: Design of a temporary structure with paper tube arches. Constr. Build. Mater. 2012, 30, 657–666. [Google Scholar] [CrossRef]

- Australian Building Codes Board. National Construction Code Series/Australian Building Codes Board; Australian Building Codes Board: Canberra, Australia, 2011. [Google Scholar]

- Australian Building Codes Board. Temporary Structures Standard; Australian Building Codes Board: Canberra, Australia, 2015. [Google Scholar]

- Mira, L.A.; Thrall, A.P.; De Temmerman, N. Deployable scissor arch for transitional shelters. Autom. Constr. 2014, 43, 123–131. [Google Scholar] [CrossRef]

- Bouhaya, L.; Baverel, O.; Caron, J.-F. Optimization of gridshell bar orientation using a simplified genetic approach. Struct. Multidiscip. Optim. 2014, 50, 839–848. [Google Scholar] [CrossRef] [Green Version]

- Thrall, A.; Quaglia, C. Accordion shelters: A historical review of origami-like deployable shelters developed by the US military. Eng. Struct. 2014, 59, 686–692. [Google Scholar] [CrossRef]

- Sharafi, P.; Mortazavi, M.; Samali, B.; Ronagh, H. Interlocking system for enhancing the integrity of multi-storey modular buildings. Autom. Constr. 2018, 85, 263–272. [Google Scholar] [CrossRef]

- Sharafi, P.; Rashidi, M.; Mortazavi, M.; Samali, B.; Ronagh, H. Identification of Factors and Multi-Criteria Decision Analysis of the Level of Modularization in Building Construction. ASCE J. Archit. Eng. 2018, 24. [Google Scholar] [CrossRef]

- Sharafi, P.; Samali, B.; Ronagh, H.; Ghodrat, M. Automated spatial design of multi-story modular buildings using a unified matrix method. Autom. Constr. 2017, 82, 31–42. [Google Scholar] [CrossRef]

- Defonseka, C. Practical Guide to Flexible Polyurethane Foams; Smithers Rapra Technology: Shawbury, UK, 2013. [Google Scholar]

- Sharafi, P.; Teh, L.H.; Hadi, M.N.S. Conceptual design optimization of rectilinear building frames: A knapsack problem approach. Eng. Optim. 2015, 47, 1303–1323. [Google Scholar] [CrossRef]

- Allen, H.G.; Neal, B.G. Analysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics Division; Elsevier Science: London, UK, 2013. [Google Scholar]

- Correia, J.R.; Garrido, M.; Gonilha, J.A.; Branco, F.A.; Reis, L.G. GFRP sandwich panels with PU foam and PP honeycomb cores for civil engineering structural applications: Effects of introducing strengthening ribs. Int. J. Struct. Integr. 2012, 3, 127–147. [Google Scholar] [CrossRef]

- Potluri, P.; Kusak, E.; Reddy, T.Y. Novel stitch-bonded sandwich composite structures. Compos. Struct. 2003, 59, 251–259. [Google Scholar] [CrossRef]

- Dawood, M.; Taylor, E.; Rizkalla, S. Two-way bending behavior of 3-D GFRP sandwich panels with through-thickness fiber insertions. Compos. Struct. 2010, 92, 950–963. [Google Scholar] [CrossRef]

- Company, D.P. How to Reduce Energy Costs in Your Building; Diane Publishing Company: Collingdale, PA, USA, 1983. [Google Scholar]

- Nemati, S.; Sharafi, P.; Samali, B.; Aliabadizadeh, Y.; Saadati, S. Non-reinforced foam filled modules for rapidly assembled post disaster housing. Int. J. GEOMATE 2018, 14, 151–161. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Rigid Foam for Use in Structural Sandwich Panel Cores, ASTM-E1730; ASTM International: West Conshohocken, PA, USA, 2015.

- West, M.; Araya, R. Fabric formwork for concrete structures and architecture. In Proceedings of the International Conference on Textile Composites and Inflatable Structures, Stuttgart, Germany, 5–7 October 2009; CIMNE: Barcelona, Spain; pp. 5–7. [Google Scholar]

- Veenendaal, D.; West, M.; Block, P. History and overview of fabric formwork: Using fabrics for concrete casting. Struct. Concr. 2011, 12, 164–177. [Google Scholar] [CrossRef]

- Orr, M.J.; Darby, A.; Ibell, T.; Evernden, M. Fabric formwork for ultra high performance fibre reinforced concrete structures. In Proceedings of the FIB Symposium: Concrete Structures for Sustainable Community, Stockholm, Sweden, 11–14 June 2012. [Google Scholar]

- Orr, J.J.; Darby, A.P.; Ibell, T.J.; Evernden, M.; Otlet, M. Concrete structures using fabric formwork. Struct. Eng. 2011, 89, 20–26. [Google Scholar]

- West, M. The Fabric Formwork Book: Methods for Building New Architectural and Structural Forms in Concrete; Taylor & Francis: London, UK, 2016. [Google Scholar]

- Nemati, S.; Rashidi, M.; Samali, B. Decision making on the optimised choice of pneumatic formwork textile for foam-filled structural composite panels. Int. J. GEOMATE 2017, 13, 220–228. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test); ASTM D5034-09; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- McCarthy, M.J.; Dhir, R.K.; Caliskan, S.; Ashraf, M.K. Influence of self-compacting concrete on the lateral pressure on formwork. Proc. Inst. Civ. Eng. Struct. Build. 2012, 165, 127–138. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Determining Tensile Properties of Nonreinforced Polyethylene and Nonreinforced Flexible Polypropylene Geomembranes; ASTM-D6693; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Sharafi, P.; Nemati, S.; Samali, B.; Mousavi, A.; Khakpour, S.; Aliabadizadeh, Y. Edgewise and flatwise compressive behaviour of foam-filled sandwich panels with 3-D high density polyethylene skins. Eng. Solid Mech. 2018, 6, 285–298. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Edgewise Compressive Strength of Sandwich Constructions; ASTM-C364; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Abdi, B.; Azwan, S.; Abdullah, M.R.; Ayob, A.; Yahya, Y.; Xin, L. Flatwise compression and flexural behavior of foam core and polymer pin-reinforced foam core composite sandwich panels. Int. J. Mech. Sci. 2014, 88, 138–144. [Google Scholar] [CrossRef]

- Norouzi, H.; Rostamiyan, Y. Experimental and numerical study of flatwise compression behavior of carbon fiber composite sandwich panels with new lattice cores. Constr. Build. Mater. 2015, 100, 22–30. [Google Scholar] [CrossRef]

- Carlsson, L.A.; Kardomateas, G.A. Structural and Failure Mechanics of Sandwich Composites; Springer: Dordrecht, The Netherlands, 2011; Volume 121. [Google Scholar]

- Kaveh, A.; Sharafi, P. Nodal ordering for bandwidth reduction using ant system algorithm. Eng. Comput. 2009, 26, 313–323. [Google Scholar] [CrossRef]

- Kaveh, A.; Sharafi, P. A simple ant algorithm for profile optimization of sparse matrices. Asian J. Civ. Eng. (Build. Hous.) 2007, 9, 35–46. [Google Scholar]

- Kaveh, A.; Sharafi, P. Charged System Search Algorithm for Minimax and Minisum Facility Layout Problems. Asian J. Civ. Eng. 2011, 12, 703–718. [Google Scholar]

- Hayes, M.D. Structural Analysis of a Pultruded Composite Beam: Shear Stiffness Determination and Strength and Fatigue Life Predictions. Ph.D. Dissertation, Faculty of the Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, November 2003. [Google Scholar]

- Sharafi, P.; Nemati, S.; Samali, B.; Bahmani, A.; Khakpour, S.; Aliabadizadeh, Y. Flexural and shear performance of an innovative foam-filled sandwich panel with 3-D high density polyethylene skins. Eng. Solid Mech. 2018, 6, 113–128. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure; ASTM-C393/C393M; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM International. Standard Practice for Determining Sandwich Beam Flexural and Shear Stiffness; ASTM-D7250/D7250M; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

| Mechanical Properties of the PU Foam | |||

|---|---|---|---|

| Density (kg/m3) | Compressive yield strength (MPa) | Tensile yield strength (MPa) | Shear yield strength (MPa) |

| 192 | 3.51 | 1.896 | 1.034 |

| Manufacturing properties of AUW763 | |||

| Cream time | Gel time | Track free time | Free rise density |

| 35-40 s | 94 ± 4 s | 115 ± 5 s | 280–300 kg/m3 |

| Tests | 4-Point Quarter | Span Loading | 3-Point Mid Span | Loading |

|---|---|---|---|---|

| Pmax (kN) | ∆midspan (mm) | Pmax (kN) | ∆midspan (mm) | |

| Specimen 1 | 76.19 | 21.9 | 56.23 | 24.9 |

| Specimen 2 | 79.72 | 22.4 | 52.54 (minimum) | 23.8 |

| Specimen 3 | 71.95 (minimum) | 19.1 | 53.98 | 24.2 |

| Average | 75.95 | 21.1 | 54.25 | 24.3 |

| Standard deviation | 3.89 | 1.8 | 1.86 | 0.56 |

| CV (%) | 5.12 | 8.42 | 3.5 | 2.3 |

| Test Details | Ultimate Load (N) | Ultimate Displacement (mm) | Ultimate Rotation (Degree) | |

|---|---|---|---|---|

| Foam-only Specimens | Specimen 1 | 7991 | 42.0 | 5.0 |

| Specimen 2 | 7172 | 44.0 | 6.0 | |

| Specimen 3 | 7870 | 52.0 | 8.0 | |

| Average | 7678 | 46.0 | 6.3 | |

| CV (%) | 5.8 | 11.5 | 1.8 | |

| Composite Specimens | Specimen 1 | 9299 | 44.0 | 4.0 |

| Specimen 2 | 9602 | 41.0 | 6.0 | |

| Specimen 3 | 9926 | 38.0 | 3.0 | |

| Average | 9609 | 41.0 | 4.3 | |

| CV (%) | 3.3 | 7.3 | 1.8 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharafi, P.; Nemati, S.; Samali, B.; Ghodrat, M. Development of an Innovative Modular Foam-Filled Panelized System for Rapidly Assembled Postdisaster Housing. Buildings 2018, 8, 97. https://doi.org/10.3390/buildings8080097

Sharafi P, Nemati S, Samali B, Ghodrat M. Development of an Innovative Modular Foam-Filled Panelized System for Rapidly Assembled Postdisaster Housing. Buildings. 2018; 8(8):97. https://doi.org/10.3390/buildings8080097

Chicago/Turabian StyleSharafi, P., S. Nemati, B. Samali, and M. Ghodrat. 2018. "Development of an Innovative Modular Foam-Filled Panelized System for Rapidly Assembled Postdisaster Housing" Buildings 8, no. 8: 97. https://doi.org/10.3390/buildings8080097