Near-Surface-Mounted CFRP Ropes as External Shear Reinforcement for the Rehabilitation of Substandard RC Joints

Abstract

1. Introduction

2. Materials and Methods

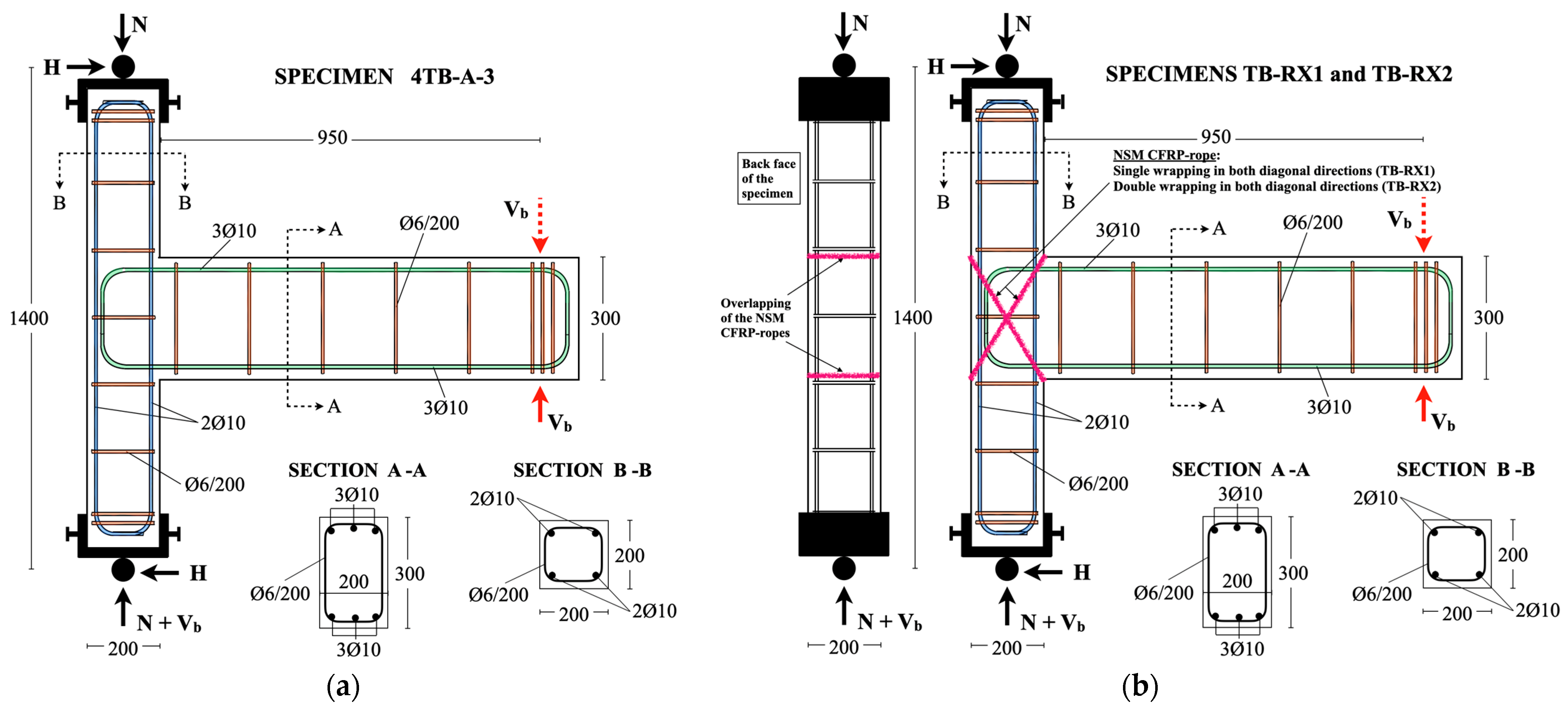

2.1. Construction of the Beam–Column Joint Subassemblages

| Specimen | Retrofit Technique | Column and Beam Rebars | Anchorage of Beam Rebars in the Joint | ||||

|---|---|---|---|---|---|---|---|

| * 4TB-A | - | Column: 4Ø10 Beam: 3Ø10 (top) 3Ø10 (bottom) | 90° hook + 2Ø10 plain steel bars welded transversely | 7.0 | 374 plain steel bars | 263.5 plain steel bars | 1.17 |

| 4TB-A-3 | - | 90° hook | |||||

| TB-RX1 | NSM CFRP rope— single wrapping in both diagonal directions of the joint | ||||||

| TB-RX2 | NSM CFRP rope— double wrapping in both diagonal directions of the joint |

- Using a grinding wheel, a 1 cm deep trench was formed in the surface around the joint region in both diagonal directions and subsequently cleaned with air pressure (see Figure 2a).

- Afterwards, each CFRP rope (SikaWrap® FX-50 C) was impregnated with epoxy resin in two compartments (Sikadur® 52 Injection LP), inserted into the groove and applied to the beam–column joint by wrapping it diagonally one or two times in the case of specimens TB-RX1 and TB-RX2, respectively (see Figure 2b).

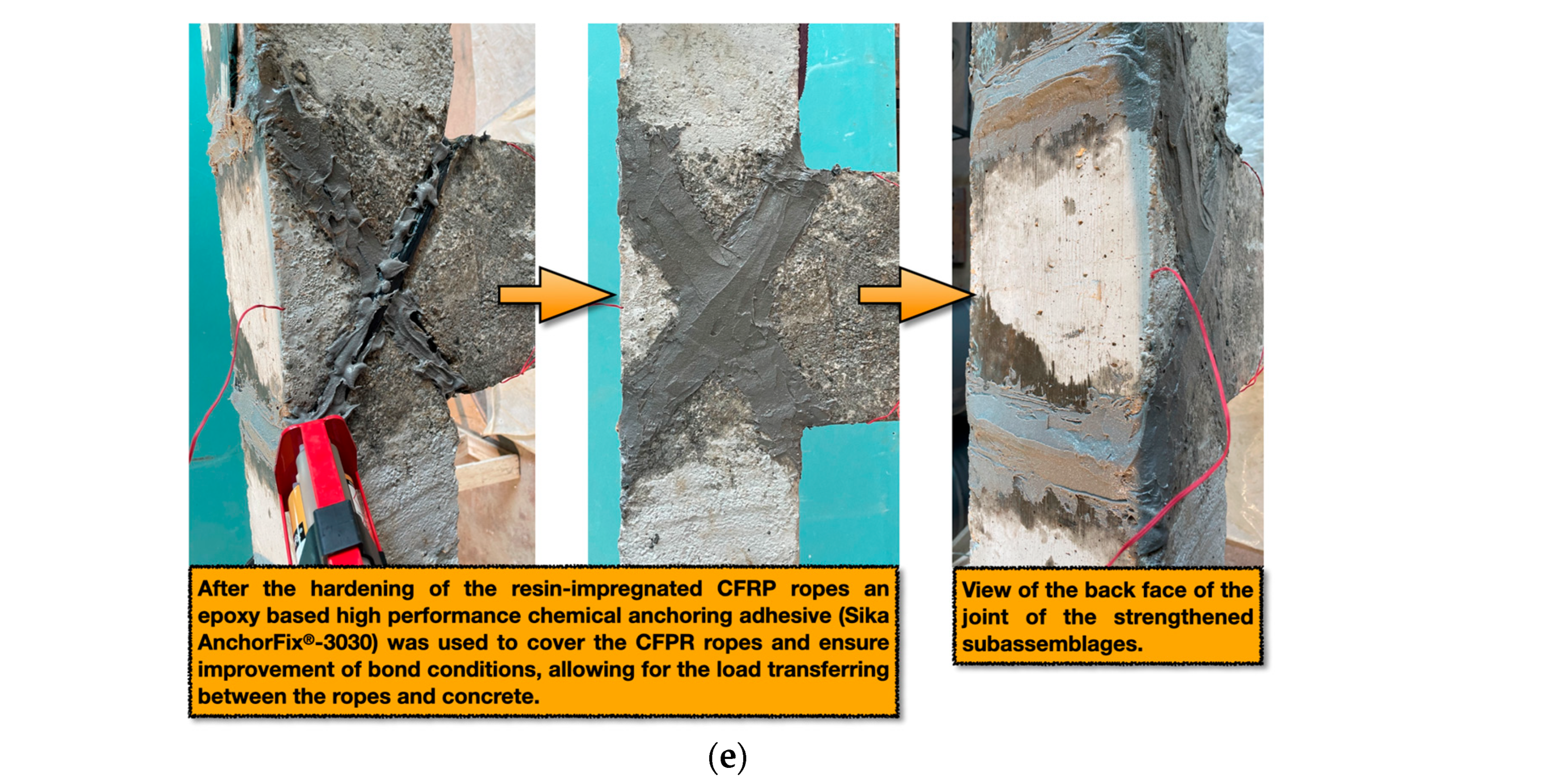

- The anchorage of each CFRP rope was achieved by overlapping at the back face of the specimen, while weights were hung from its free ends to prevent the loose application of the rope and ensure that it is tight enough for actively contributing as shear reinforcement of the joint (see Figure 2c,d).

- After the hardening of the resin-impregnated CFRP ropes, an epoxy-based high-performance chemical anchoring adhesive (Sika AnchorFix®-3030) was used to cover the CFPR ropes and ensure improvement of bond conditions, allowing for the load transferring between the ropes and concrete (see Figure 2e).

2.2. Micro-Tensile Testing Results of the Rope Fibers

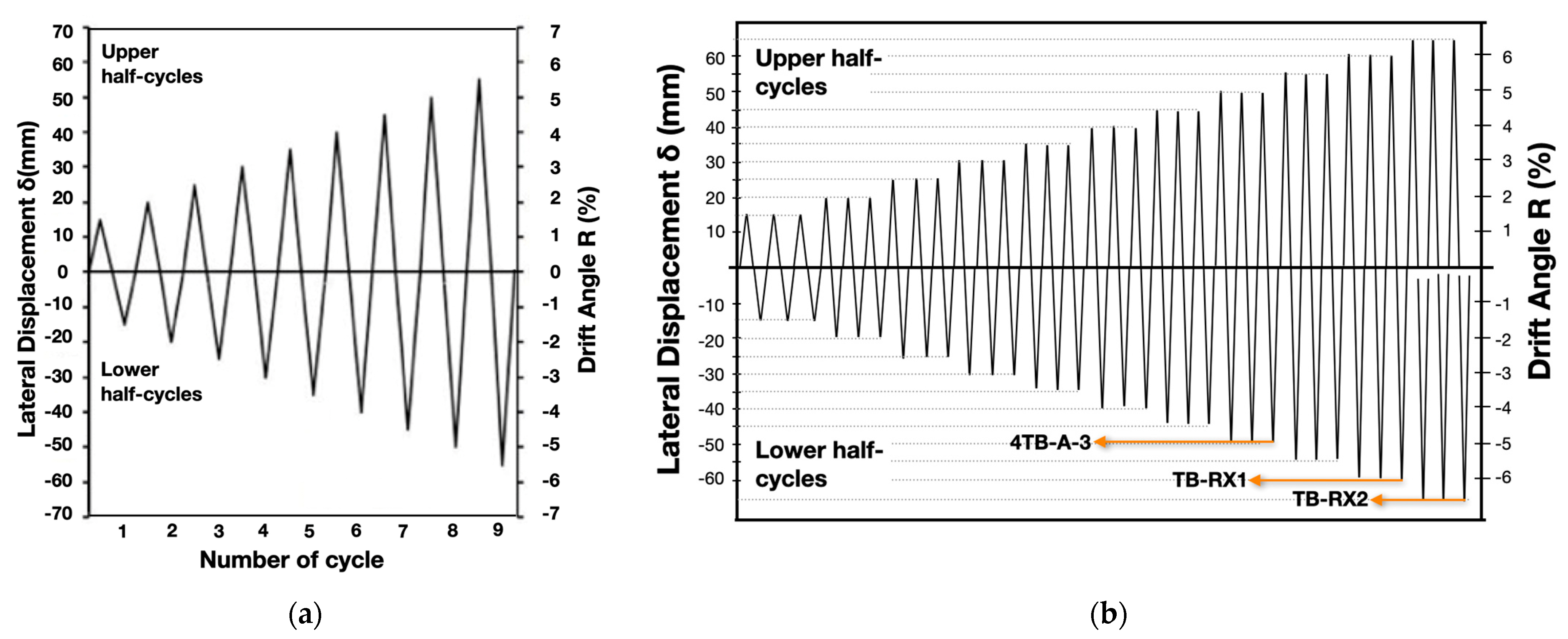

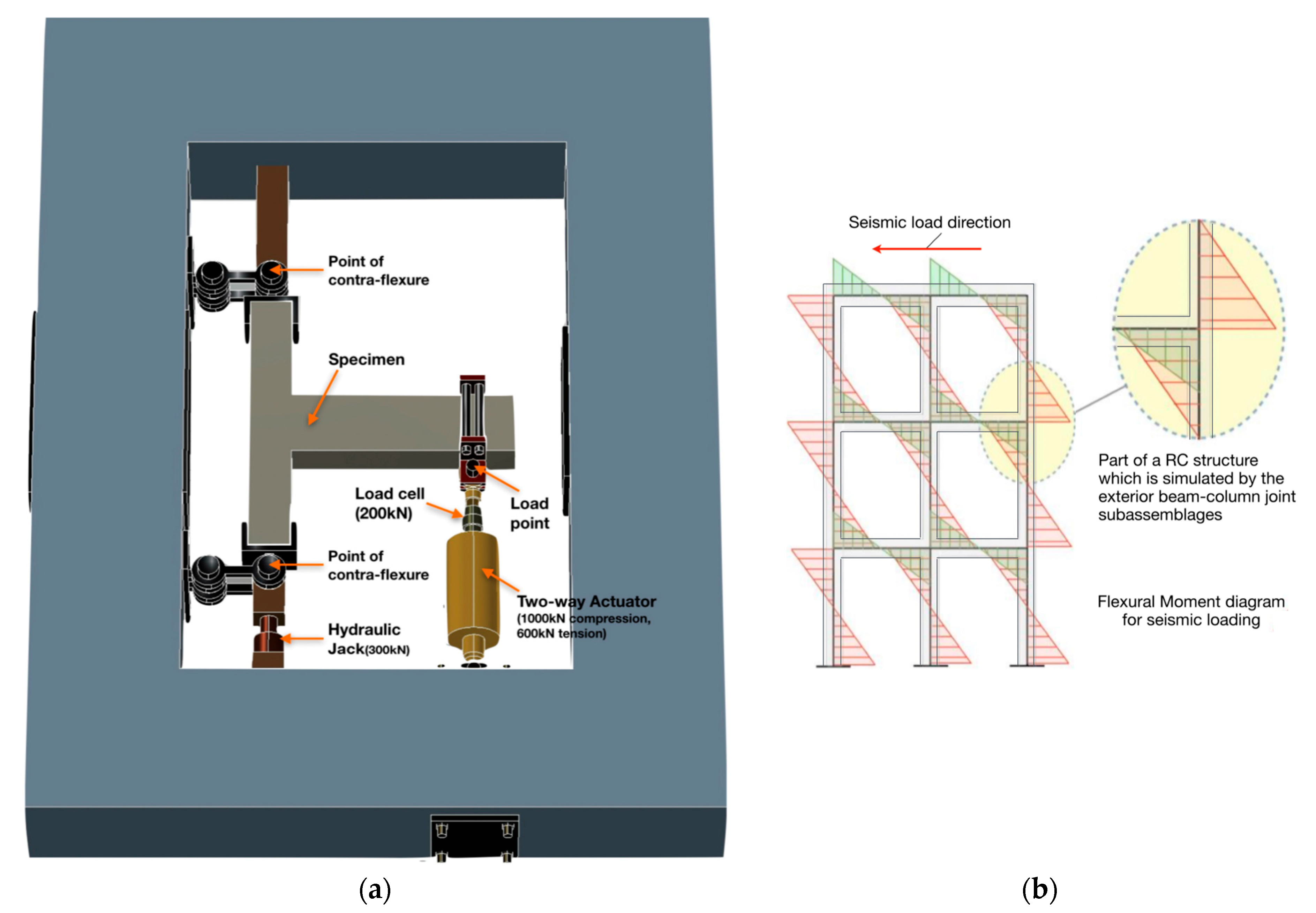

2.3. Seismic Testing of the Beam–Column Joint Subassemblages

3. Experimental Results

3.1. Hysteresis Behavior of the Beam–Column Joint Subassemblages

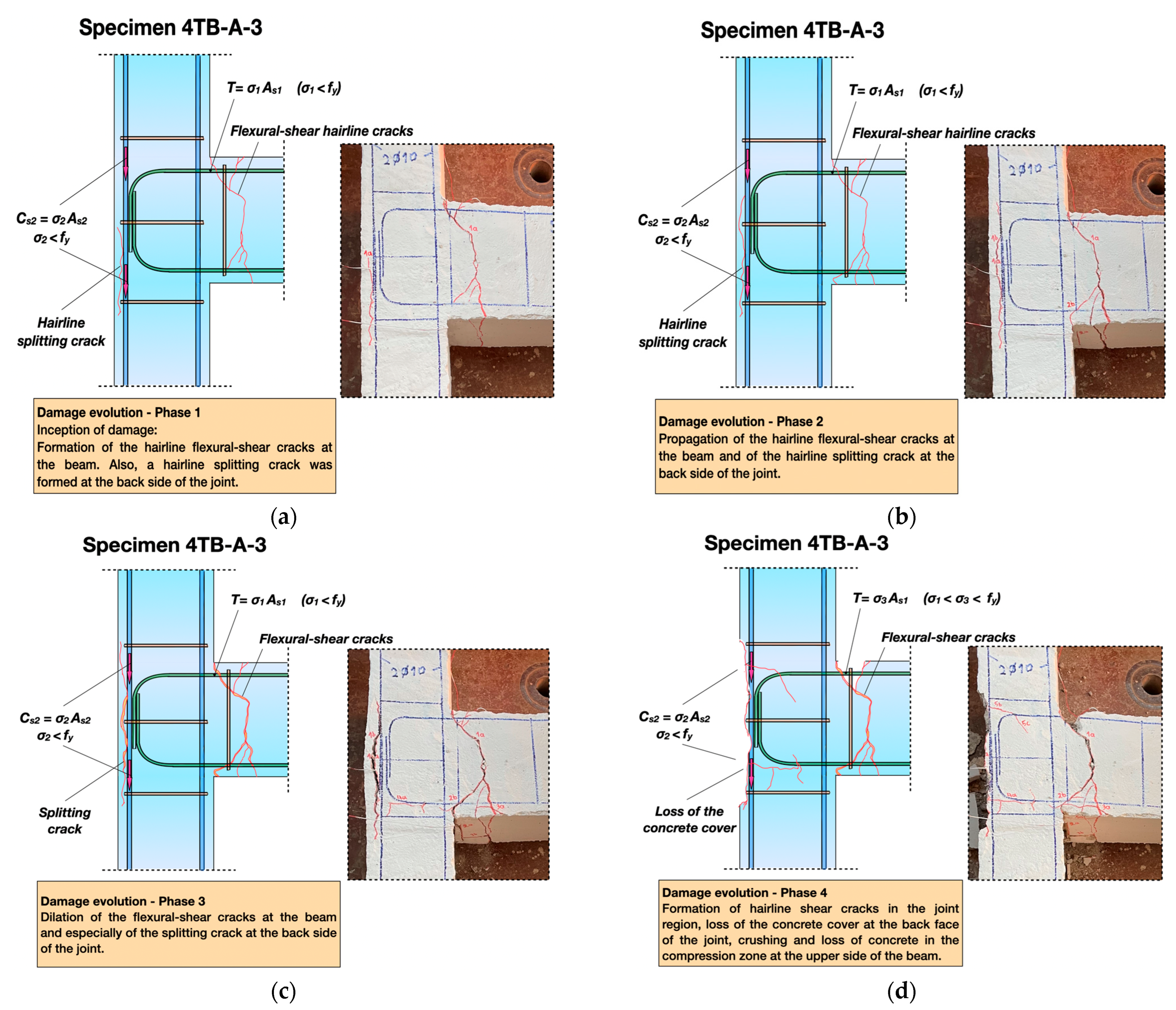

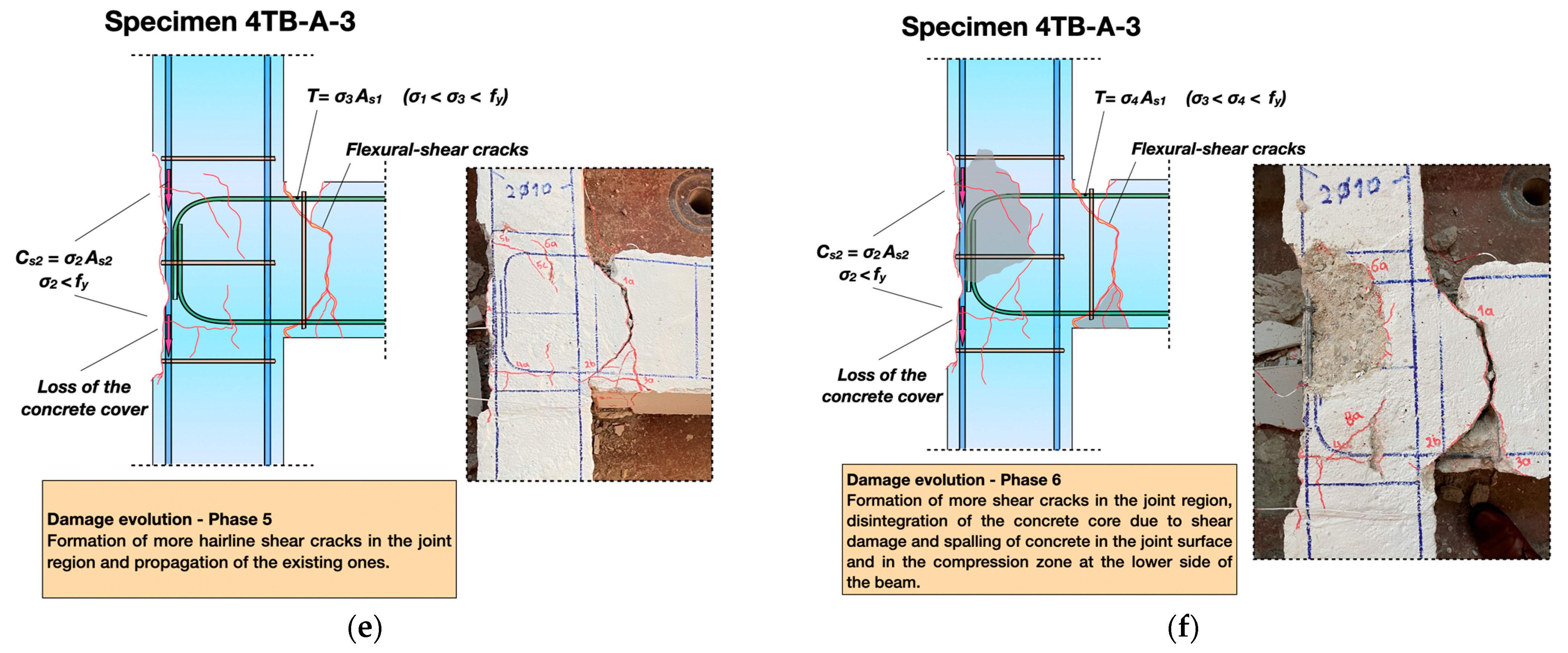

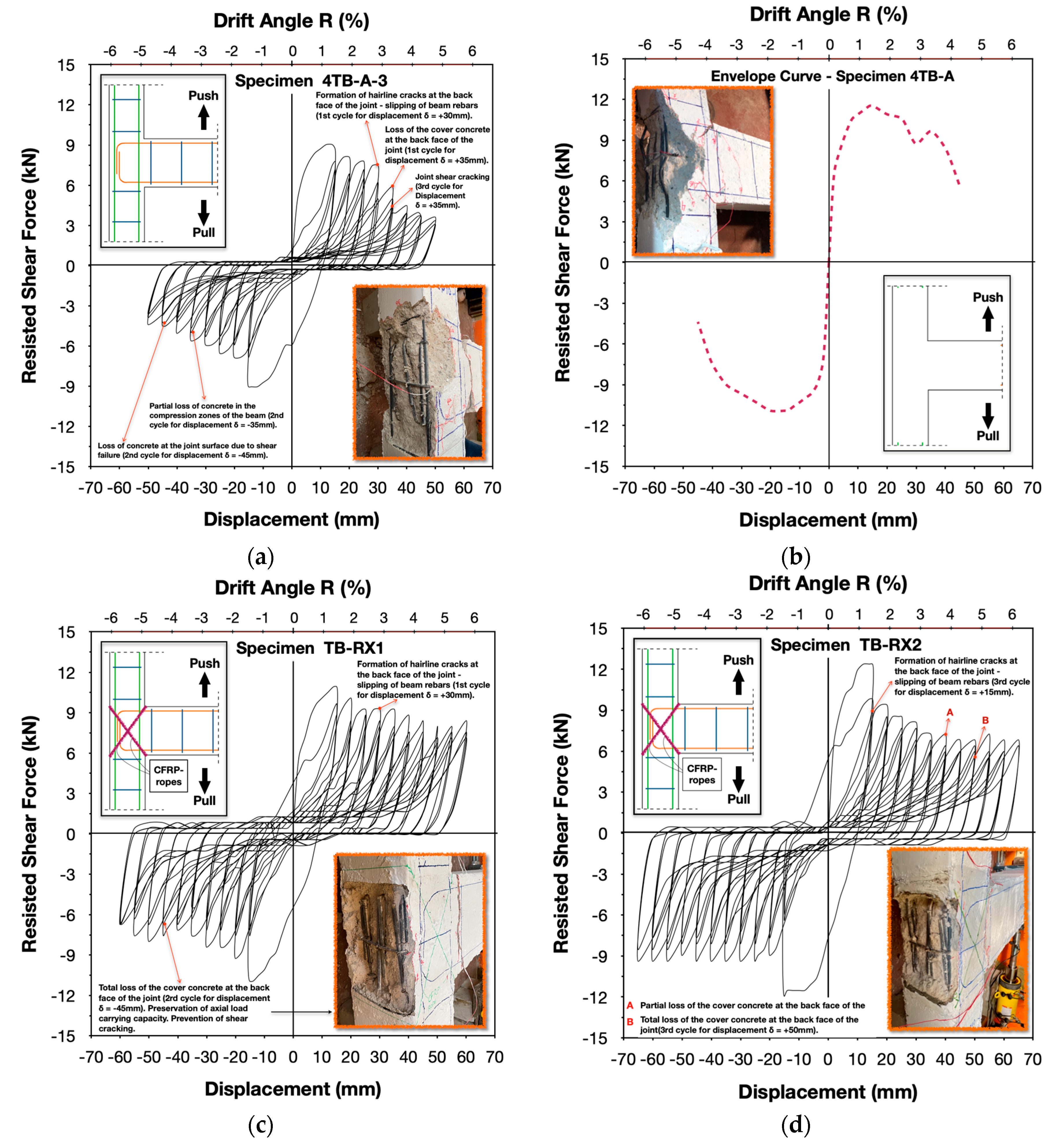

3.1.1. Original Subassemblage 4TB-A-3

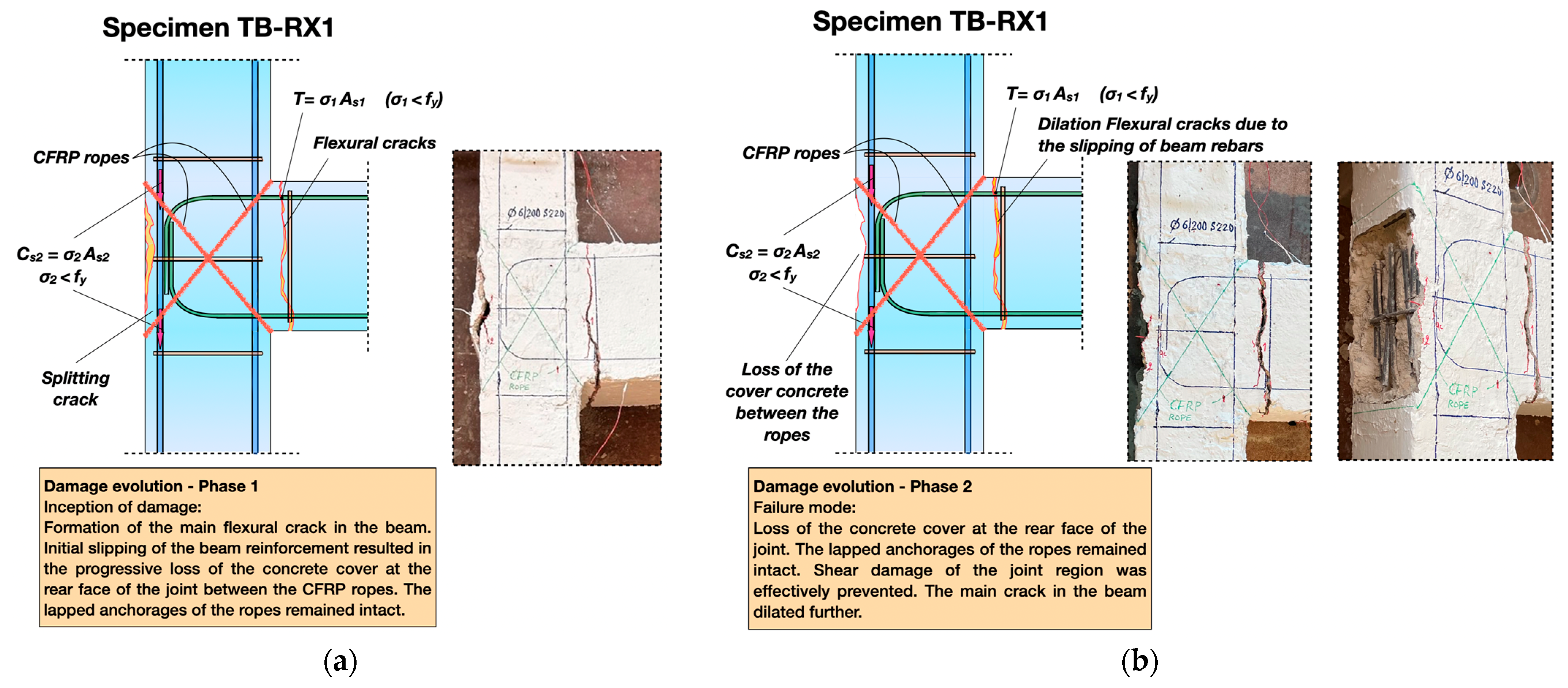

3.1.2. Strengthened Subassemblage TB-RX1

3.1.3. Strengthened Subassemblage TB-RX2

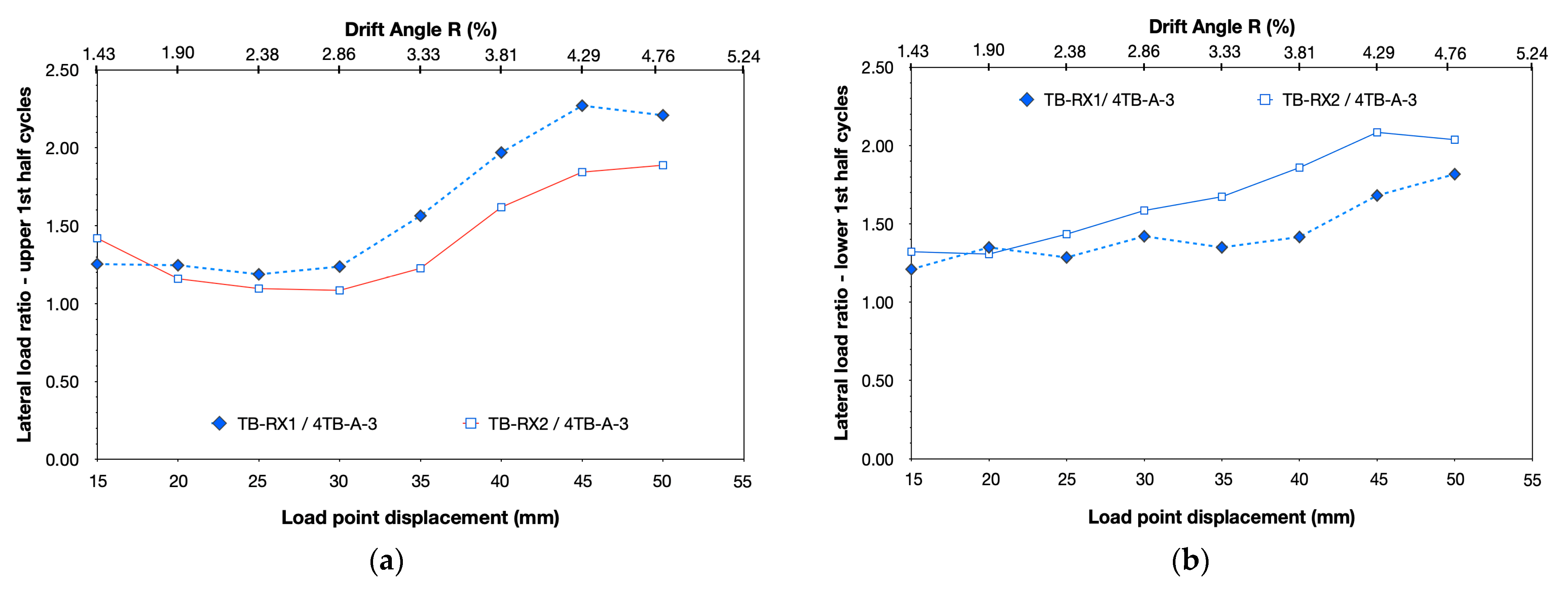

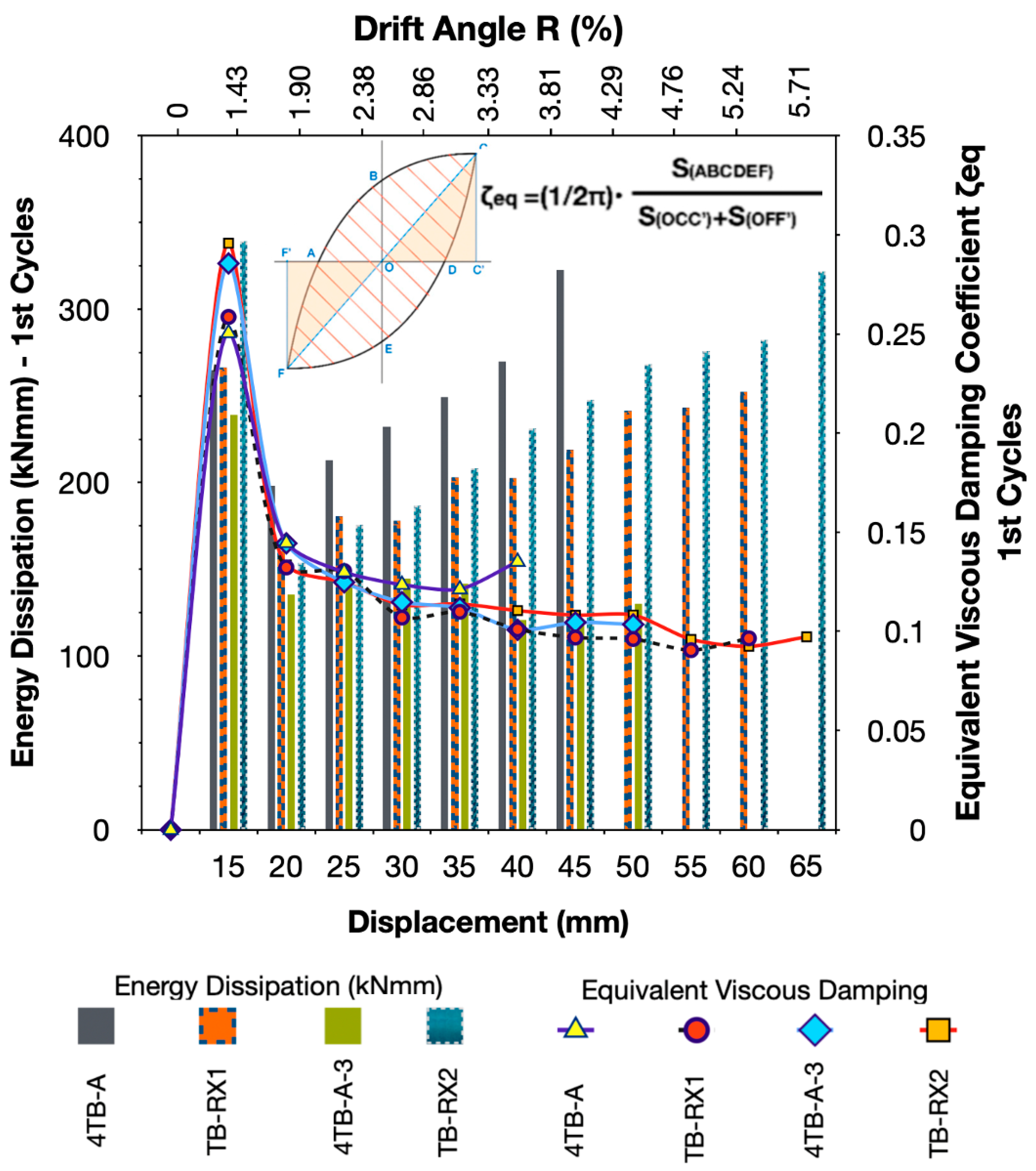

3.2. Comparison of the Seismic Performance of the Subassemblages

4. Conclusions

- The seismic behavior of the original beam–column joint subassemblage 4TB-A-3 was dominated by brittle failure modes including slipping of the beam longitudinal reinforcement and shear cracking of the joint region. As a result, the specimen exhibited poor hysteresis performance with limited energy dissipation capacity, degrading lateral strength and low ductility.

- The excessive shear damage of 4TB-A resulted from the significantly increased forces in the joint region due to the improved anchorage conditions of the beam rebars, achieved by using transversely welded bar segments [24]. These were not provided in the case of subassemblage 4TB-A-3. Hence, slipping of the beam rebars from the joint region of 4TB-A-3 initially occurred, and consequently, shear cracking of the joint was delayed with respect to specimen 4TB-A. Therefore, despite being subjected to multiple (three) cycles of the earthquake-type loading per displacement step (with respect to the similar specimen 4TB-A), the original specimen 4TB-A-3 did not collapse for drift angle R = 4.29% (when specimen 4TB-A collapsed) and retained its axial load carrying capacity for R = 4.76%. Nevertheless, the failure mode of both subassemblages was eventually dominated by shear failure of the beam–column connection.

- The proposed retrofit scheme proved to be very satisfactory in preventing shear damage of the joint region and in shifting the damage mainly in the beam of the strengthened subassemblages, TB-RX1 and TB-RX2. Therefore, the structural integrity of the retrofitted specimens was effectively preserved, while deformation capacity and ductility were significantly improved.

- Partial loss of the concrete cover at the rear face of the exterior beam–column joint specimens TB-RX1 and TB-RX2 occurred due to the initial slipping of the beam reinforcement and the consequential slight push-out of the hook of the bar anchorage from the joint (since only one Ø6mm tie was provided). This loss, however, had no adverse influence at all in axial load-carrying capacity and in lateral strength of the subassemblages, while it was limited solely in the height between the CFRP ropes.

- After loss of the concrete cover, the lateral bearing capacity of TB-RX1 and TB-RX2 increased during the consecutive cycles of the earthquake-type loading, demonstrating that the joint concrete core remained elastic, and shear cracking was effectively prevented.

- The original specimen 4TB-A collapsed due to the loss of axial load-carrying capacity for drift angle R = 4.29%. Also, the original subassemblage 4TB-A-3 retained only 35.55% and 40.15% of its initial strength values during the upper and lower half-cycles for R = 4.71%, respectively. Conversely, the strengthened subassemblages, TB-RX1 and TB-RX2, exhibited a more stable hysteresis performance and maintained 80.70% (for R = 5.71%) and 60.02% (for R = 6.19%) of their initial strength, respectively.

- The significant increase in lateral load ratio values TB-RX1/4TB-A-3 (up to 2.27) and TB-RX2/4TB-A-3 (up to 1.82), especially for drift angle values R greater than 2.86%, was achieved without using additional longitudinal steel reinforcement, but solely by preserving and exploiting the inherent strength of the subassemblages which, due to the retrofitting, performed in a more ductile manner.

- The strengthened subassemblages were subjected to a significant number of inelastic cycles of incremental lateral displacements, showing substantially improved energy dissipation capacity with respect to the original specimens, 4TB-A and 4TB-A-3. For drift angle R = 4.76% (end of testing of 4TB-A-3), the cumulative dissipated energy capacity of the strengthened specimens TB-RX1 and TB-RX2 was increased with respect to the corresponding value for the original specimen 4TB-A-3 by 60.92% and 78.23%, respectively. Furthermore, the joint concrete core of both TB-RX1 and TB-RX2 remained intact until the end of the seismic tests. Ultimately, the proposed retrofit scheme successfully transformed the failure mode of the subassemblages, which was dominated by brittle shear in the case of 4TB-A and 4TB-A-3, to a ductile one with concentration of damage mainly in the beam.

- The proposed retrofit scheme provides additional essential advantages regarding the ease of application, cost-effectiveness, limited labor demands, low disturbance and, primarily, the ability to be used even in the case of interior beam–column joints linking beams in all directions. Thus, it seems particularly competitive and convenient with respect to other strengthening schemes, especially when the primary goal is the improvement of ductility and energy dissipation capacity of the existing substandard RC structures. Given that the proposed retrofit scheme does not change the inertial characteristics of the structure, its application would possibly be more efficient when combined with the addition of RC walls which make the structure more rigid. Also, alternative placement of the CFRP ropes (not in the diagonal directions of the joint region) may also be used to avoid even minor damage and ensure that the joint remains totally intact.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Risi, M.T.; Del Vecchio, C.; Ricci, P.; Ludovico, M.D.; Prota, A.; Verderame, G.M. Light FRP Strengthening of poorly detailed reinforced concrete exterior beam-column joints. J. Compos. Constr. 2020, 24, 04020014. [Google Scholar]

- Karayannis, C.G.; Sirkelis, G.M. Strengthening and rehabilitation of RC beam-column joints using FRP jacketing and epoxy resin injections. J. Earthq. Eng. Struct. Dyn. 2008, 37, 769–790. [Google Scholar]

- Tsonos, A.G. Effectiveness of CFRP jackets in post-earthquake and pre-earthquake retrofitting of beam-column subassemblages. Struct. Eng. Mech. 2007, 27, 393–408. [Google Scholar]

- Tsonos, A.-D. Ultra-high-performance fiber reinforced concrete: An innovative solution for strengthening old R/C structures and for improving the FRP strengthening method. WIT Trans. Eng. Sci. 2008, 64, 273–284. [Google Scholar]

- Tsonos, A.-D. Effectiveness of CFRP-jackets and RC-jackets in post-earthquake and pre-earthquake retrofitting of beam-column subassemblages. Eng. Struct. 2008, 30, 777–793. [Google Scholar]

- Karayannis, C.G.; Golias, E. Full-scale tests of RC joints with minor to moderate damage repaired using C-FRP sheets. Earthq. Struct. 2018, 15, 617–627. [Google Scholar]

- Pohoryles, D.A.; Melo, J.; Rossetto, T.; Varum, H.; Bisby, L. Seismic retrofit schemes with FRP for deficient RC beam-column joints: State-of-the-art review. J. Compos. Constr. 2019, 23, 4. [Google Scholar]

- Murad, Y.; Al Bodur, W.; Ashteyat, A. Seismic retrofitting of severely damaged RC connections made with recycled concrete using CFRP sheets. Front. Struct. Civ. Eng. 2020, 14, 554–568. [Google Scholar]

- Tafsirojjaman, T.; Fawzia, S.; Thambiratnam, D.P. Structural behaviour of CFRP strengthened beam-column connections under monotonic and cyclic loading. Structures 2021, 33, 2689–2699. [Google Scholar]

- Mostofinejad, D.; Akhlaghi, A. Experimental Investigation of the Efficacy of EBROG Method in Seismic Rehabilitation of Deficient Reinforced Concrete Beam–Column Joints Using CFRP Sheets. J. Compos. Constr. 2017, 21, 04016116. [Google Scholar]

- Mostofinejad, D.; Akhlaghi, A. Flexural strengthening of reinforced concrete beam column joints using innovative anchorage system. ACI Struct. J. 2017, 114, 1603–1614. [Google Scholar]

- Dalfre, G.M.; Barros, J.A.O. NSM technique to increase the load carrying capacity of continuous RC slabs. Eng. Struct. 2013, 56, 137–153. [Google Scholar]

- Al-Mahmoud, F.; Castel, A.; François, R.; Tourneur, C. Strengthening of RC members with near-surface mounted CFRP rods. Compos. Struct. 2009, 91, 138–147. [Google Scholar]

- Alwash, D.; Kalfat, R.; Al-Mahaidi, R.; Du, H. Shear strengthening of RC beams using NSM CFRP bonded using cement based adhesive. Constr. Build. Mater. 2021, 301, 124365. [Google Scholar]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R.; Sanjayan, J. A state-of-the-art review: Near-surface mounted FRP composites for reinforced concrete structures. Constr. Build. Mater. 2019, 209, 748–769. [Google Scholar]

- Ercan, E.; Arisoy, B.; Ertem, O.-B. Experimental Assessment of RC Beam-Column Connections with Internal and External Strengthening Techniques. Adv. Civ. Eng. 2019, 2828353. [Google Scholar] [CrossRef]

- Golias, E.; Zapris, A.G.; Kytinou, V.K.; Kalogeropoulos, G.I.; Chalioris, C.E.; Karayannis, C.G. Effectiveness of the novel rehabilitation method of seismically damaged rc joints using c-frp ropes and comparison with widely applied method using c-frp sheets—Experimental investigation. Sustainability 2021, 13, 6454. [Google Scholar]

- Chalioris, C.; Kosmidou, P.-M.; Papadopoulos, N. Investigation of a new strengthening technique for RC deep beams using carbon FRP ropes as transverse reinforcement. Fibers 2018, 6, 52. [Google Scholar] [CrossRef]

- Golias, E.; Vougioukas, E.; Wittemann, K.; Kalogeropoulos, G.; Karayannis, C. Cyclic response of RC beam-column joints setrngthened with transverse steel bars and with CFRP diagonal ties. Acta Polytech. 2022, 62, 274–282. [Google Scholar]

- Karayannis, C.; Golias, E. Full-scale experimental testing of RC beam-column joints strengthened using CFRP ropes as external reinforcement. Eng. Struct. 2022, 250, 113305. [Google Scholar]

- Karayannis, C.; Golias, E. Strengthening of deficient RC joints with diagonally placed C-FRP ropes. Earthq. Struct. 2021, 20, 123–132. [Google Scholar]

- Karayannis, C.; Golias, E.; Kalogeropoulos, G. Influence of Carbon Fiber-Reinforced Ropes Applied as External Diagonal Reinforcement on the Shear Deformation of RC Joints. Fibers 2022, 10, 28. [Google Scholar] [CrossRef]

- Kytinou, V.; Gribniak, V.; Golias, E.; Zapris, A.; Sapidis, G.; Chalioris, C. A novel technique for strengthening reinforced concrete shear-deficient members using fiber-reinforced polymer rope as near Surface Mounted reinforcement. In Olympiad in Engineering Science; Springer Nature: Cham, Switzerland, 2023; pp. 315–326. [Google Scholar]

- Kalogeropoulos, G.; Tsonos, A.-D.; Iakovidis, P. Hysteresis Behavior of RC Beam–Column Joints of Existing Substandard RC Structures Subjected to Seismic Loading–Experimental and Analytical Investigation. Buildings 2024, 14, 1609. [Google Scholar] [CrossRef]

- Herrmann, D. Methods for Determining the Modulus of Elasticity of Wire and Fibre Ropes. innoTRAC 2020, 1, 47–54. [Google Scholar] [CrossRef]

- Sika. Available online: https://grc.sika.com/dam/dms/gr01/r/sikawrap-fx-50-c.pdf (accessed on 6 July 2025).

- Hakuto, S.; Park, R.; Tanaka, H. Seismic load tests on interior and exterior beam-column joints with substandard reinforcing details. ACI Struct. J. 2000, 97, 11–25. [Google Scholar]

- Ehsani, M.R.; Wight, J.K. Effect of transverse and slab on behavior of reinforced concrete beam-to-column connections. ACI J. Proc. 1985, 82, 188–195. [Google Scholar]

- Durrani, A.J.; Wight, J.K. Earthquake resistance of reinforced concrete interior connections including a floor slab. ACI J. Proc. 1987, 84, 400–406. [Google Scholar]

- Soroushian, P.; Sim, J. Axial behavior of reinforced concrete columns under dynamic loads. ACI J. Proc. 1986, 83, 1018–1025. [Google Scholar]

- Scott, B.D.; Park, R.; Priestley, M.J.N. Stress-strain behavior of concrete confined by overlapping hoops at low and high strain rates. ACI J. Proc. 1982, 79, 13–27. [Google Scholar]

- CEB. CEB—FIP Modes Code 1990, Bulletin d’ Information CEB; CEB: Lausanne, Switzerland, 1993; pp. 213–214. [Google Scholar]

- Ehsani, M.R.; Wight, J.K. Exterior reinforced concrete beam-to-column connections subjected to earthquake-type loading. ACI J. Proc. 1985, 82, 492–499. [Google Scholar]

| Displacement Step (mm) | ±15 | ±20 | ±25 | ±30 | ±35 | ±40 | ±45 | ±50 | ±55 | ±60 | ±65 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maximum lateral load (kN) (upper/lower a-half-cycles) | ||||||||||||

| Specimen | 4TB-A * | +11.53 −10.91 | +10.91 −10.91 | +10.60 −10.29 | +10.29 −9.66 | +9.66 −9.03 | +8.42 −7.48 | +5.61 −4.36 | ||||

| 4TB-A-3 | +8.72 −9.04 | +8.10 −6.86 | +7.79 −6.55 | +7.48 −5.93 | +5.92 −5.61 | +4.49 −5.05 | +3.71 −4.51 | +3.62 −4.40 | ||||

| TB-RX1 | +10.94 −10.94 | +10.09 −9.26 | +9.25 −8.42 | +9.25 −8.42 | +9.25 −7.58 | +8.83 −7.16 | +8.41 −7.58 | +7.99 −8.00 | +7.99 −7.58 | +8.41 −6.74 | ||

| TB-RX2 | +12.38 −11.96 | +9.40 −8.97 | +8.54 −9.39 | +8.11 −9.39 | +7.26 −9.39 | +7.26 −9.39 | +6.83 −9.39 | +6.83 −8.97 | +7.26 −9.39 | +6.83 −9.39 | +6.83 −9.39 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalogeropoulos, G.; Nikolopoulou, G.; Gianniki, E.-T.; Konstantinidis, A.; Karayannis, C. Near-Surface-Mounted CFRP Ropes as External Shear Reinforcement for the Rehabilitation of Substandard RC Joints. Buildings 2025, 15, 2409. https://doi.org/10.3390/buildings15142409

Kalogeropoulos G, Nikolopoulou G, Gianniki E-T, Konstantinidis A, Karayannis C. Near-Surface-Mounted CFRP Ropes as External Shear Reinforcement for the Rehabilitation of Substandard RC Joints. Buildings. 2025; 15(14):2409. https://doi.org/10.3390/buildings15142409

Chicago/Turabian StyleKalogeropoulos, George, Georgia Nikolopoulou, Evangelia-Tsampika Gianniki, Avraam Konstantinidis, and Chris Karayannis. 2025. "Near-Surface-Mounted CFRP Ropes as External Shear Reinforcement for the Rehabilitation of Substandard RC Joints" Buildings 15, no. 14: 2409. https://doi.org/10.3390/buildings15142409

APA StyleKalogeropoulos, G., Nikolopoulou, G., Gianniki, E.-T., Konstantinidis, A., & Karayannis, C. (2025). Near-Surface-Mounted CFRP Ropes as External Shear Reinforcement for the Rehabilitation of Substandard RC Joints. Buildings, 15(14), 2409. https://doi.org/10.3390/buildings15142409