Optimal Control Method for HVAC Systems in Offices with a Control Algorithm Based on Thermal Environment

Abstract

:1. Introduction

2. Materials and Method

2.1. Comfort Range of Indoor Thermal Environment Evaluation Index

2.1.1. Temperature and Humidity

2.1.2. Predicted Mean Vote

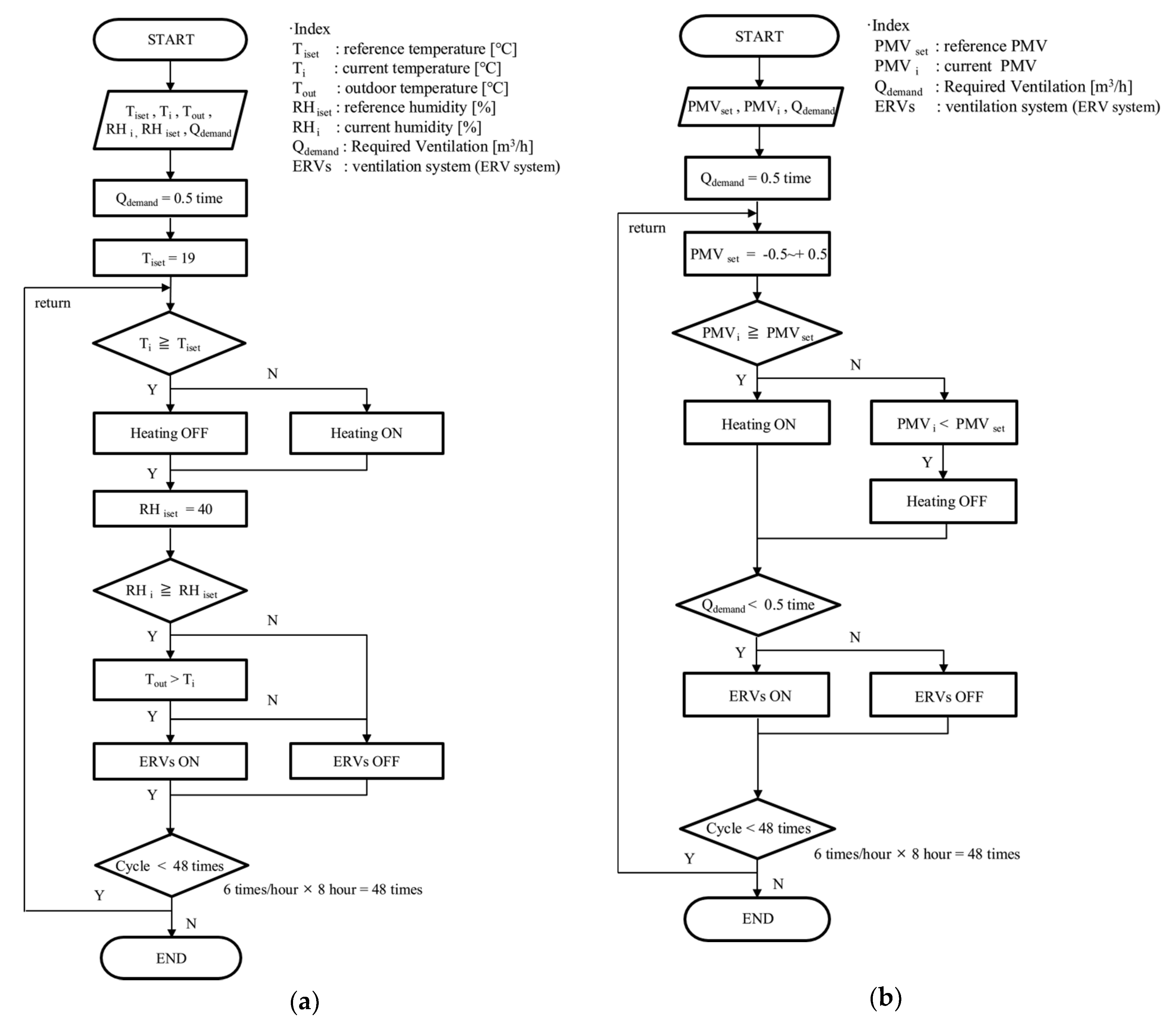

2.2. Indoor Thermal Environment Control Algorithm Following the Control Standards by an Evaluation Indicator

3. Experimental

3.1. Experimental Details

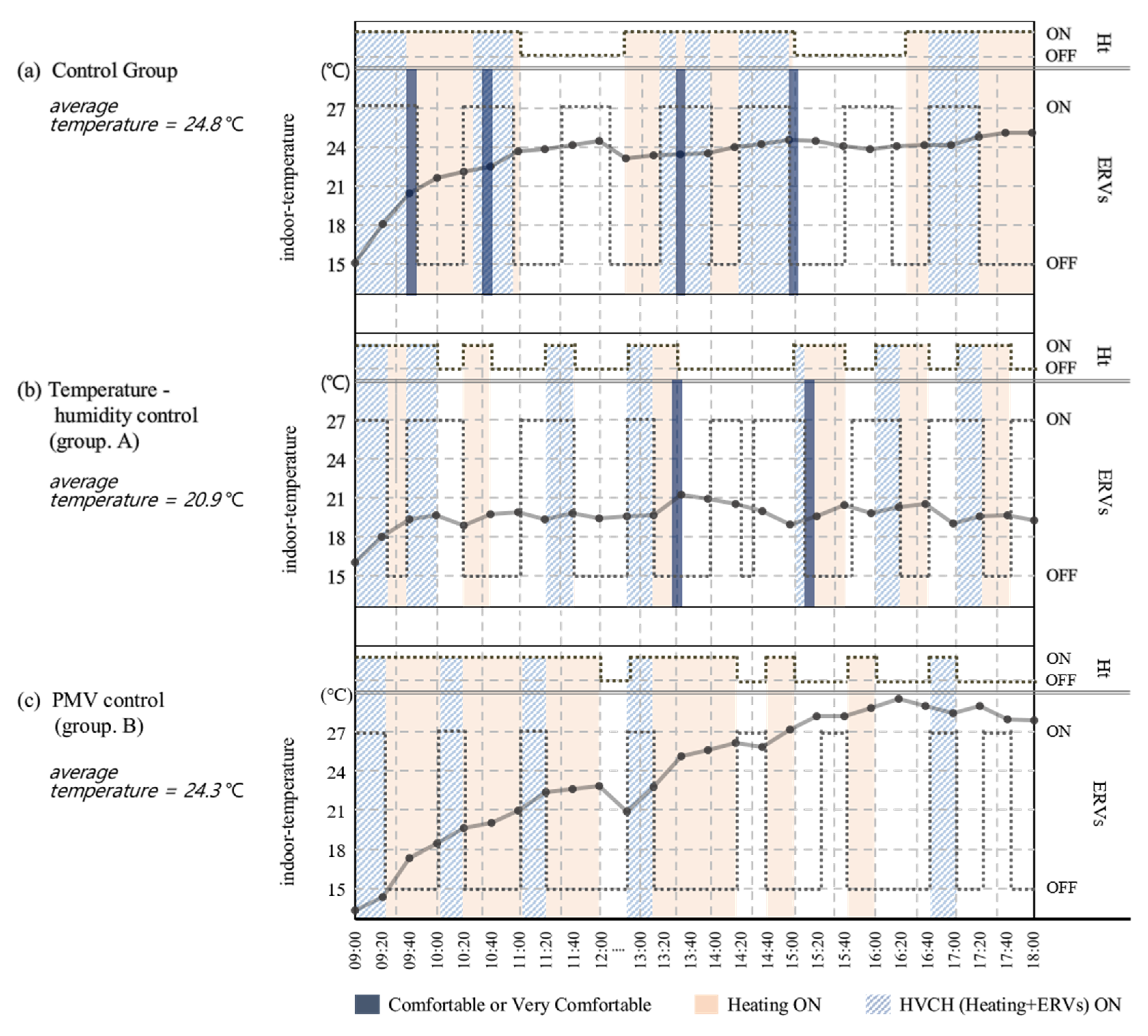

3.2. Heating, Ventilation, and Air Conditioning (HVAC) System’s Operating Pattern Determined by the Control Algorithm

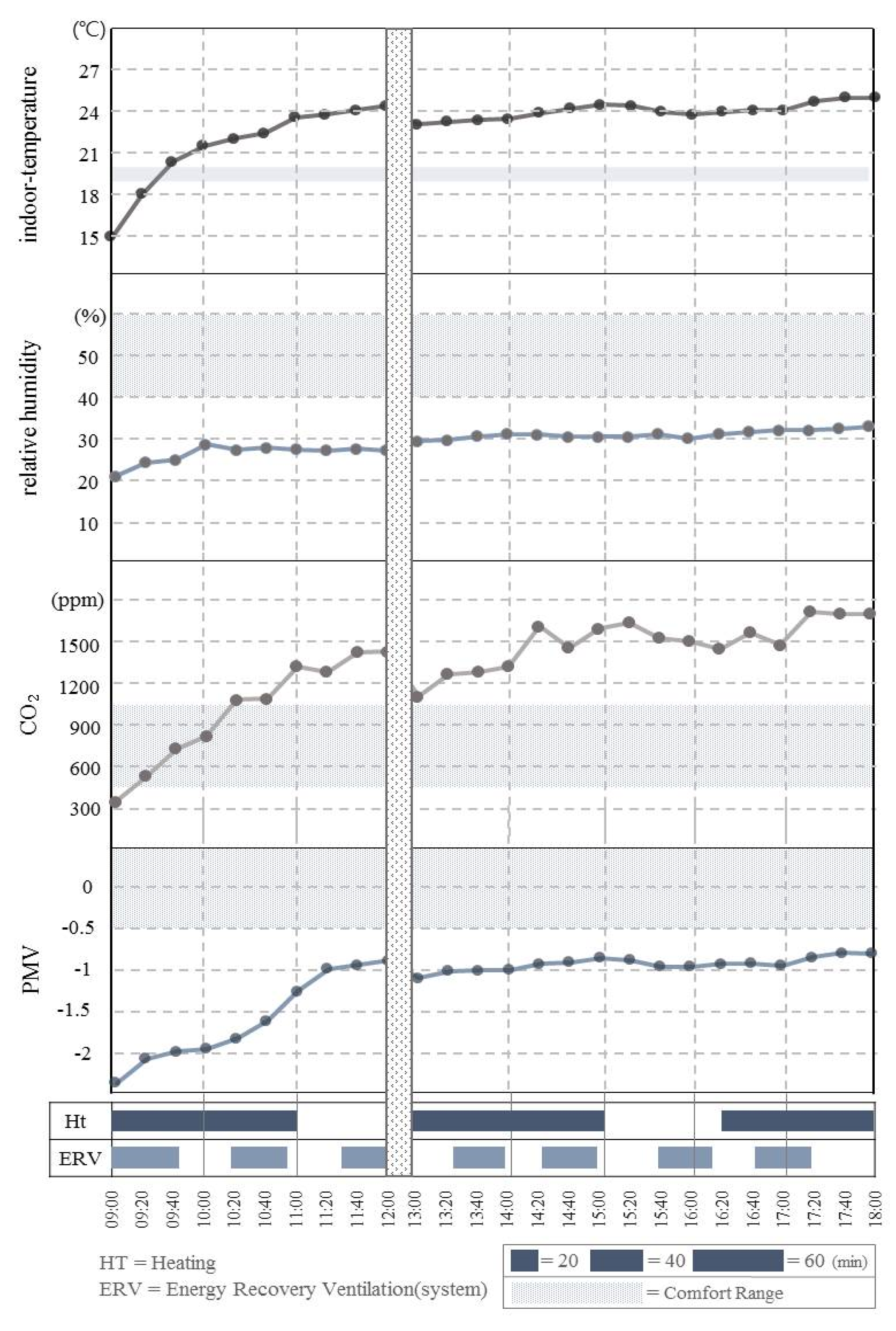

3.2.1. Control Group

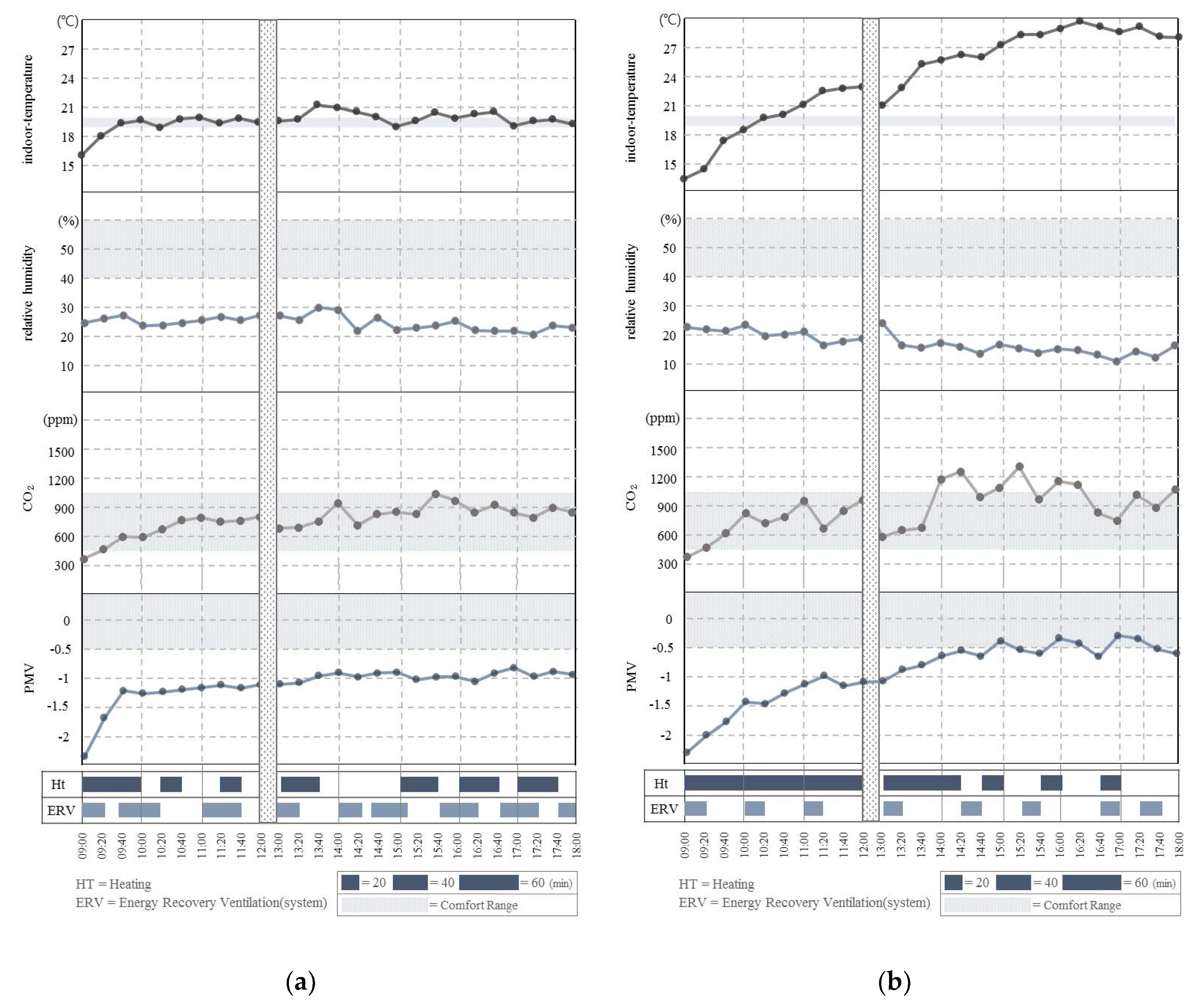

3.2.2. Control According to Temperature and Humidity Index

3.2.3. Control According to PMV Index (B)

4. Results and Discussion

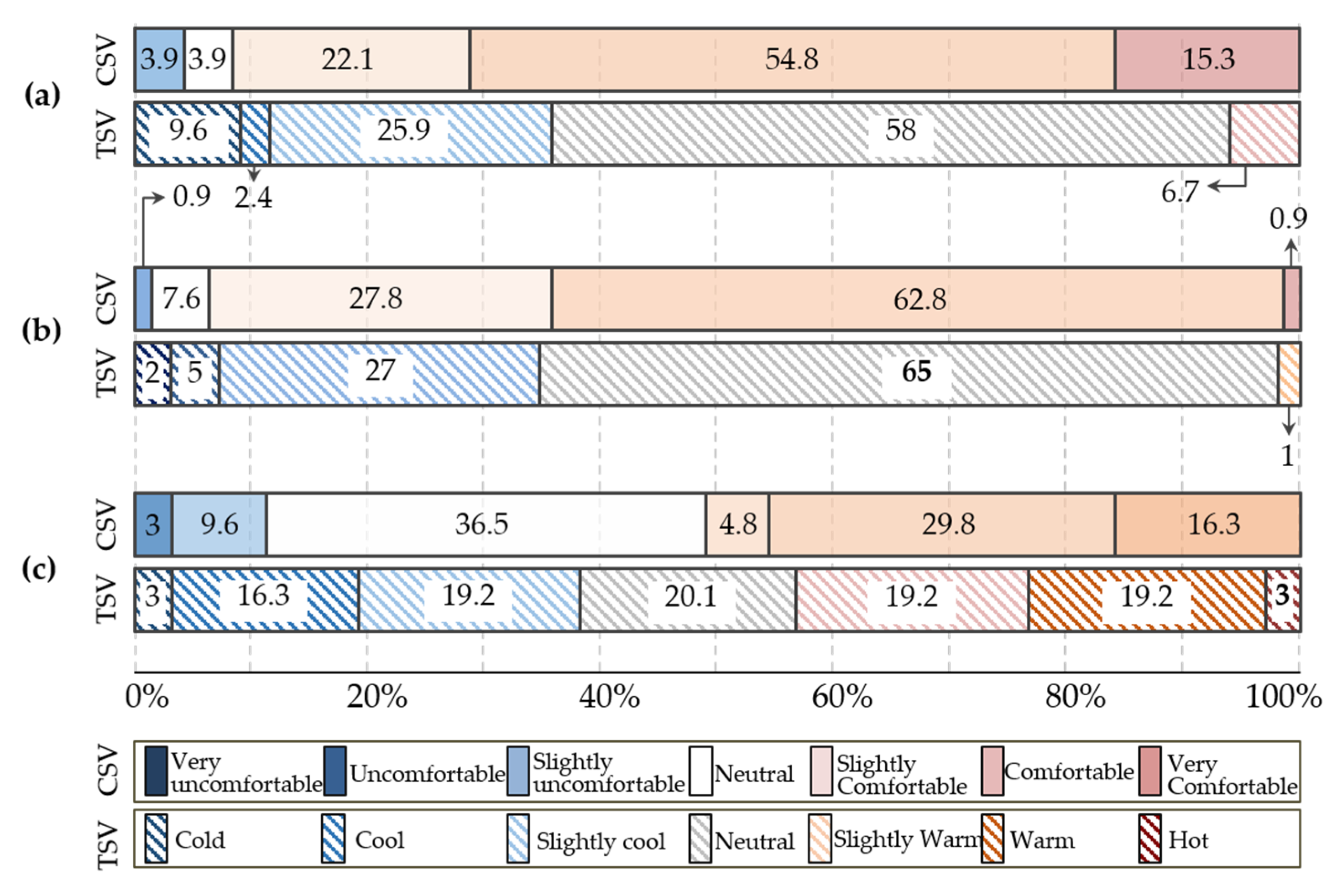

4.1. Indoor Comfort (CSV) and Sense of Heat and Cold (TSV) Based on Control Standards

4.2. Analysis of the Simultaneous Satisfaction of the HVAC System Operation and Resident Comfort According to Control Standards

5. Conclusions

- The CO2 concentration was related to indoor comfort. Outcomes demonstrated that it was more comfortable in group (A) compared with the control group. Moreover, there were limitations in reaching the comfort range of office humidity with ERVs. Furthermore, group (B) demonstrated an increased cumulative consumption of the heating equipment for reaching the comfort range.

- Regarding the comfort levels of the occupants, group (A) yielded results that were similar to those of the control group. Group (B) exhibited small deviations among the provided responses and can be considered as a control method that does not consider the thermal adaptation capability of humans.

- When the HVAC system is controlled based on the temperature and humidity, as implemented in the algorithm of group (A), the use of the HVAC system can be reduced due to the human capability to thermally adapt after reaching the comfort range of temperature.

Author Contributions

Funding

Conflicts of Interest

References

- Directive 2004/8/EC of the European Parliament and of the Council of 11 February 2004 on the promotion of cogeneration based on a useful heat demand in the internal energy market and amending Directive 92/42/EEC. Off. J. Eur. Union 2004, 52, 50–60. Available online: https://www.buildup.eu/en/node/37848 (accessed on 21 April 2013).

- Dincer, I. Renewable and Sustainable Energy Reviews, Renewable energy and sustainable development: A crucial review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Park, H.S.; Lee, M.; Kang, H.; Hong, T.; Jeong, J. Development of a new energybenchmark for improving the operational rating system of office buildingsusing various data-mining techniques. Appl. Energy 2016, 173, 225–237. [Google Scholar] [CrossRef]

- Sibilio, S.; Rosato, A.; Ciampi, G.; Scorpio, M.; Akisawa, A. Renewable and Sustainable Energy Reviews Building-integrated trigeneration system: Energy, environmental and economic dynamic performance assessment for Italian residential applications. Renew. Sustain. Energy Rev. 2017, 68, 920–933. [Google Scholar] [CrossRef]

- Li, C.; Zhou, J.; Cao, Y.; Zhong, J.; Liu, Y.; Kang, C.; Tan, Y. Interaction between urban microclimate and electric air-conditioning energy consumption during high temperature season. Appl. Energy 2014, 117, 149–156. [Google Scholar] [CrossRef]

- Jang, J.; Baek, J.; Leigh, S.-B. Prediction of Optimal Heating Timing with Empirical Data of the Office Building. J. Archit. Inst. Korea Spring Conf. 2017, 37, 537–538. [Google Scholar] [CrossRef]

- Ma, Z.; Li, H.; Sun, Q.; Wang, C.; Yan, A.; Starfelt, F. Statistical analysis of energy consumption patterns on the heat demand of buildings in district heating systems. Energy Build. 2014, 85, 464–472. [Google Scholar] [CrossRef]

- Oh, G.-S.; Jung, G.-J.; Im, Y.-B. Impact of Indoor CO2 Concentration on Work Performance. J. Archit. Inst. Korea 2010, 30, 385–386. [Google Scholar]

- Azar, E.; Menassa, C.C. A comprehensive analysis of the impact of occupancy parameters in energy simulation of office buildings. Energy Build. 2012, 55, 841–853. [Google Scholar] [CrossRef]

- Andersen, P.D.; Iversen, A.; Madsen, H.; Rode, C. Dynamic modeling of presence of occupants using inhomogeneous Markov chains. Energy Build. 2014, 69, 213–223. [Google Scholar] [CrossRef]

- Yang, R.; Wang, L. Development of multi-agent system for building energy and comfort management based on occupant behaviors. Energy Build. 2013, 56, 1–7. [Google Scholar] [CrossRef]

- Widén, J.; Wäckelgård, E. A high-resolution stochastic model of domestic activity patterns and electricity demand. Appl. Energy 2010, 87, 1880–1892. [Google Scholar] [CrossRef]

- Hong, T.; Taylor-Lange, S.C.; D’Oca, S.; Yan, D.; Corgnati, S.P. Advances in research and applications of energy-related occupant behavior in buildings. Energy Build. 2016, 116, 694–702. [Google Scholar] [CrossRef] [Green Version]

- Liang, H.-H.; Lin, T.-P.; Hwang, R.-L. Linking occupants’ thermal perception and building thermal performance in naturally ventilated school buildings. Appl. Energy 2012, 94, 355–363. [Google Scholar] [CrossRef]

- Ma, Z.; Leijon, A. Bayesian Estimation of Beta Mixture Models with Variational Inference. IEEE Trans. Pattern Anal. Mach. Intell. 2011, 33, 2160–2173. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Wang, Q.; Wang, Y.; Liu, Y.; Sun, Q.; Wennersten, R. The energy-saving potential of an office under different pricingmechanisms—Application of an agent-based model. Appl. Energy 2017, 202, 248–258. [Google Scholar] [CrossRef]

- Ministry of Environment of KOREA. Manual for Indoor Indoor Air Quality Management. 2017. Available online: https://www.gov.kr/portal/locgovNews/1994168 (accessed on 27 September 2019).

- Fanger, P.O. (Ed.) Thermal Comfort: Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970; 244p. [Google Scholar]

- ISO 7730. Ergonomics of the Thermal Environment; Ergonomics of the physical environment: Geneva, Switzerland, 2005; Available online: https://www.iso.org/standard/39155.html (accessed on 15 November 2005).

- ASHRAE Standard 55-2010 Thermal Environment Conditions for Human Occupancy. ASHRAE standard ISSN 1041-2336: Atlanta, GA, US. Available online: www.ashrae.org (accessed on 24 July 2013.).

- Kim, S.-K.; Hong, W.-H.; Ryu, J.-H. A Study on the Residents Comfort in the Operation of Air-conditioner by using the Control Criteria of Indoor Thermal Environment in Apartment Buildings. J. Archit. Inst. Korea Struct. Constr. 2017, 33, 43–52. [Google Scholar] [CrossRef]

- Ryu, J.-H.; Hong, W.-H.; Seo, H.-C.; Seo, Y.-K. Determination of an acceptable comfort zone for apartment occupants in South Korea: An empirical analysis of cooling operation. Build. Environ. 2017, 125, 484–501. [Google Scholar] [CrossRef]

- Kim, J.; Hong, T.; Jeong, J.; Koo, C.; Jeong, K. An optimization model for selecting the optimal green systems by considering the thermal comfort and energy, consumption. Appl. Energy 2016, 169, 682–695. [Google Scholar] [CrossRef]

- Cannistraro, G.; Cannistraro, M.; Restivo, R. Smart control of air climatization system in function on the values of mean local radiant temperature. Smart Sci. 2015, 3, 157–163. [Google Scholar] [CrossRef] [Green Version]

- Cannistraro, G.; Cannistraro, M.; Restivo, R. Some observations on the radiative exchanges influence on thermal comfort in rectangular open-space environments. Int. J. Heat Technol. 2015, 33, 79–84. [Google Scholar] [CrossRef] [Green Version]

- Cannistraro, G.; Cannistraro, M.; Restivo, R. The local media radiant temperature for the calculation of comfort in areas characterized by Radiant surfaces. Int. J. Heat Technol. 2015, 33, 115–122. [Google Scholar] [CrossRef]

- Cannistraro, M.; Ponterio, L.; Cao, J. Experimental study of air pollution in the urban centre of the city of Messina. Model. Meas. Control. C 2018, 79, 133–139. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, A.T.; Singh, M.K.; Reiter, S. An Analysis of the Occupant’s Thermal Comfort controlled by System air conditioner under Hot and Humid region. J. Archit. Inst. Korea 2011, 31, 419–420. [Google Scholar] [CrossRef] [Green Version]

- Cannistraro, M.; Trancossi, M. Enhancement of indoor comfort in the presence of large glazed radiant surfaces by a local heat pump system based on Peltier cells. Therm. Sci. Eng. Prog. 2019, 14, 100388. [Google Scholar] [CrossRef]

- Akimoto, T.; Tanabe, S.-I.; Yanai, T.; Sasaki, M. Thermal comfort and productivity evaluation of workplace environment in a task conditioned office. Build. Environ. 2010, 45, 45–50. [Google Scholar] [CrossRef]

- Diakaki, C.; Grigoroudis, E.; Kolokotsa, D. Towards a multi-objective optimization approach for improving energy efficiency in buildings. Energy Build. 2008, 40, 1747–1754. [Google Scholar] [CrossRef]

- Dounis, A.I.; Caraiscos, C. Advanced control systems engineering for energy and comfort management in a building environment—A review. Renew. Sustain. Energy Rev. 2009, 13, 1246–1261. [Google Scholar] [CrossRef]

- Xu, X.; Taylor, J.E.; Pisello, A.L.; Culligan, P.J. The impact of place-based affiliation networks on energy conservation: An holistic model that integrates the influence of buildings, residents and the neighborhood context. Energy Build. 2012, 55, 637–646. [Google Scholar] [CrossRef]

- Karyono, T.H.; Sri, E.; Sulistiawan, J.G.; Triswanti, Y. Thermal Comfort Studies in Naturally Ventilated Buildings in Jakarta, Indonesia. Buildings 2015, 5, 917–932. [Google Scholar] [CrossRef]

| Element Item | Experimental Group 1/Temperature and Humidity (A) | Experimental Group 2/PMV (B) | |

|---|---|---|---|

| common standards for thermal environment | ERV system ≧ 0.5 times/h | ||

| control criteria | T 1 = 19 °C | −0.5 < measurement data < + 0.5 | |

| RH 2 = 40% | |||

| control device | ERVs 3, heating | ||

| control device influence | ERVs | RH | RH |

| heating | T | T, PMV | |

| repetition | 6 times/h × 8 h = 48 times/1 day | ||

| (A) Comfort Sensation Vote (CSV) | ||||||

| very uncomfortable | uncomfortable | slightly uncomfortable | neutral | slightly comfortable | comfortable | very comfortable |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| (B) Thermal Sensation Vote (TSV) | ||||||

| cold | cool | slightly cool | neutral | slightly warm | warm | hot |

| −3 | −2 | −1 | 0 | 1 | 2 | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-K.; Hong, W.-H.; Hwang, J.-H.; Jung, M.-S.; Park, Y.-S. Optimal Control Method for HVAC Systems in Offices with a Control Algorithm Based on Thermal Environment. Buildings 2020, 10, 95. https://doi.org/10.3390/buildings10050095

Kim S-K, Hong W-H, Hwang J-H, Jung M-S, Park Y-S. Optimal Control Method for HVAC Systems in Offices with a Control Algorithm Based on Thermal Environment. Buildings. 2020; 10(5):95. https://doi.org/10.3390/buildings10050095

Chicago/Turabian StyleKim, Sung-Kyung, Won-Hwa Hong, Jung-Ha Hwang, Myung-Sup Jung, and Yong-Seo Park. 2020. "Optimal Control Method for HVAC Systems in Offices with a Control Algorithm Based on Thermal Environment" Buildings 10, no. 5: 95. https://doi.org/10.3390/buildings10050095