Magnetic Field-Induced Reverse Martensitic Transformation and Thermal Transformation Arrest Phenomenon of Ni41Co9Mn39Sb11 Alloy

Abstract

:1. Introduction

2. Results and Discussion

2.1. Metamagnetic Behavior of Ni41Co9Mn39Sb11

2.2. Magnetic Moment and Magnetic Structure of Ni41Co9Mn39Sb11

3. Experimental Procedure

4. Conclusions

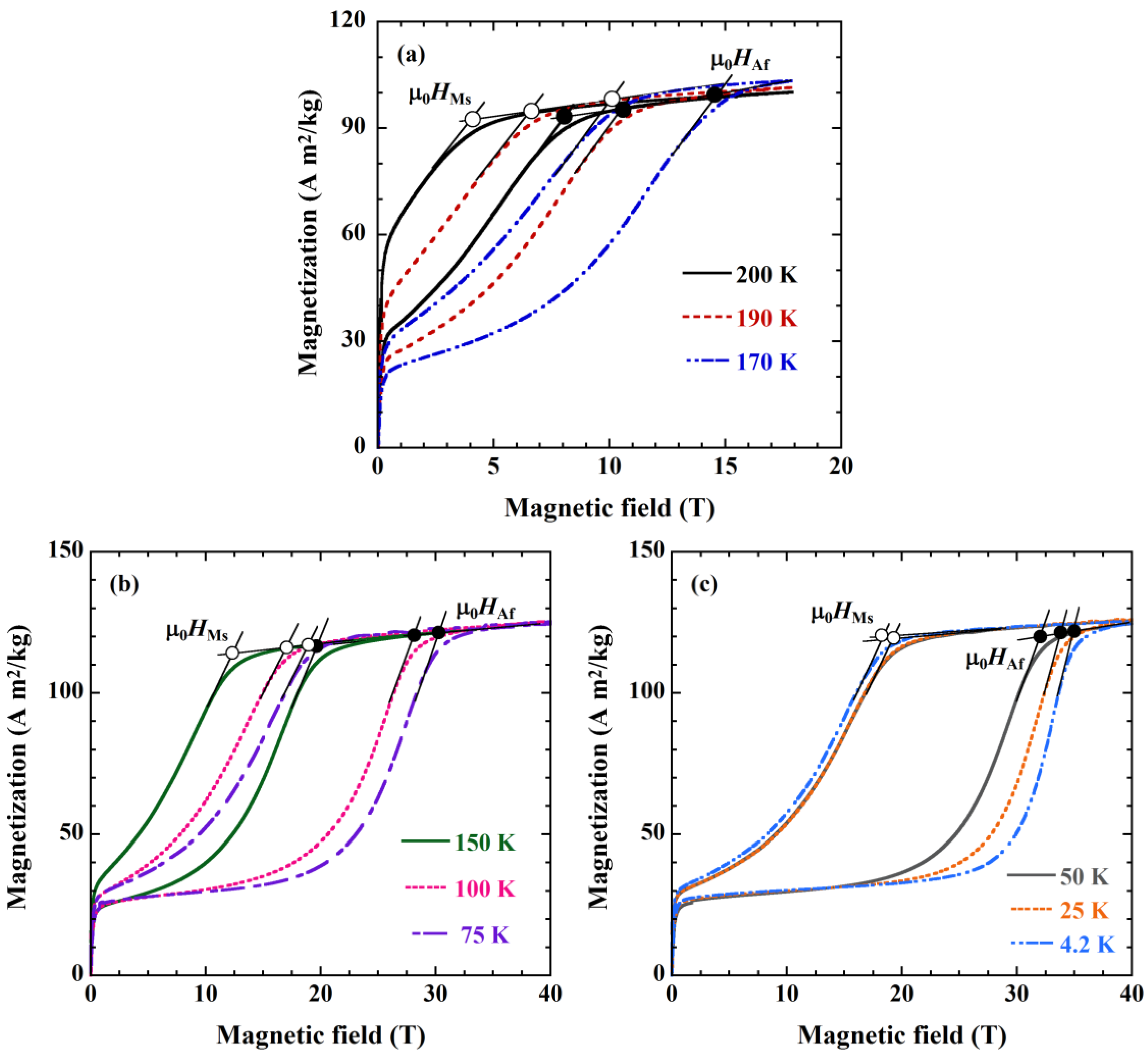

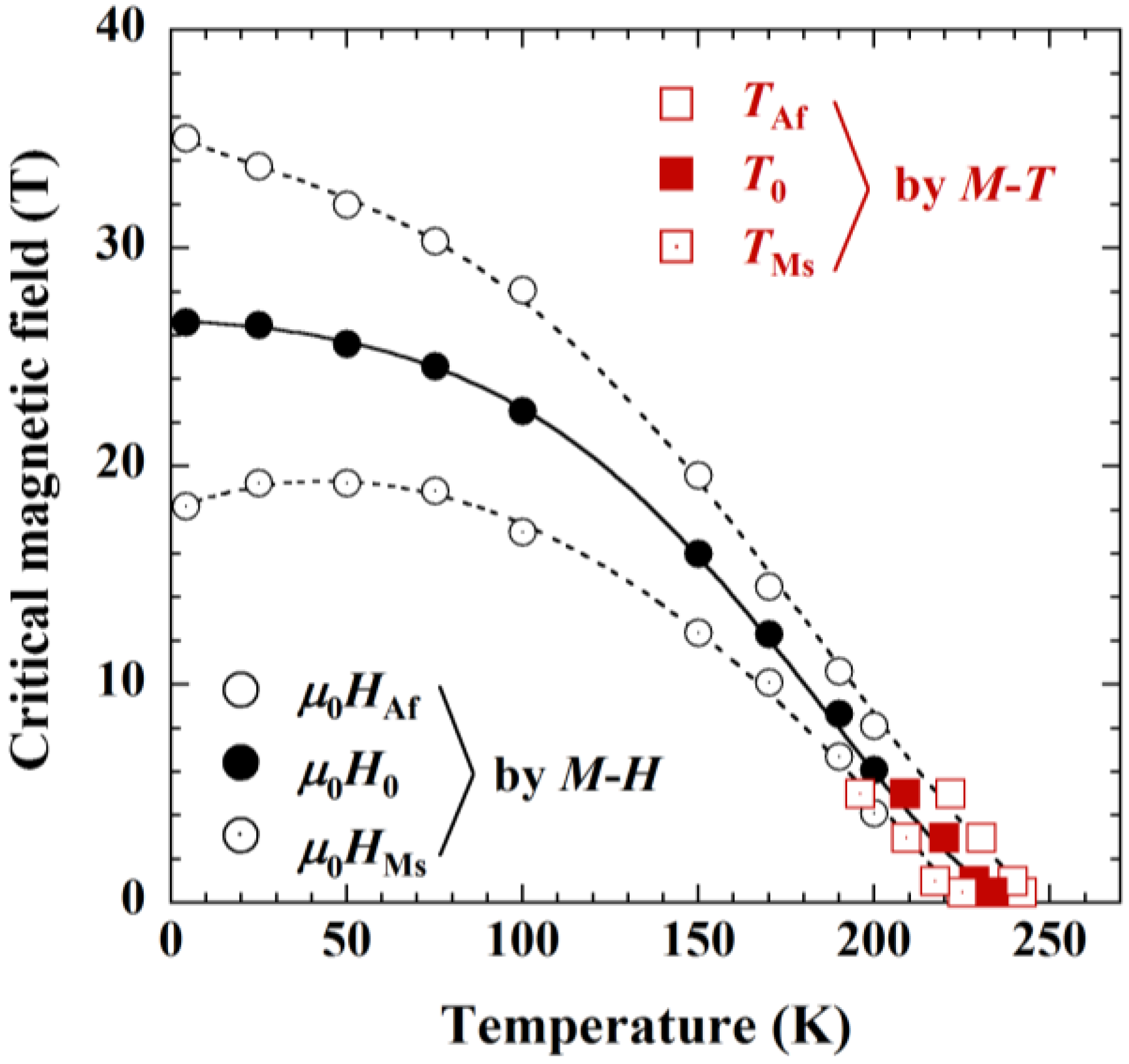

- The equilibrium magnetic field, μ0H0, linearly increases with decreasing temperature just below the martensitic transformation temperature. The value of dμ0H0/dT is about 0.22 T/K and gives the value of the entropy change during the martensitic transformation ΔS = 14.1 J/(K·kg) from the Clausius-Clapeyron relation. The obtained value is in good agreement with the result given by the DSC measurement of 15.2 J/(K·kg).

- The equilibrium magnetic field, μ0H0, tends to become flat in the low temperature region, showing arresting behavior of the martensitic transformation, analogous with what occurs in the Ni(Co)-Mn-Z (Z = In, Sn, Ga, Al) alloys. The thermal transformation arrest temperature of the preset alloy is about 50 K.

- The temperature dependence of the magnetic field hysteresis, μ0Hhys, well follows the fitting curves based on the model for the plastic deformation introduced by the dislocations. The difference of the sweeping rate of the applied magnetic field is reflected in the experimental results and activation energy of around 1.06 eV for Ni41Co9Mn39Sb11 was obtained.

- Spontaneous magnetization at 4.2 K for the magnetically induced parent phase of Ni41Co9Mn39Sb11 is 5.4 μB/f.u. This value deviates from the extrapolation from the concentration dependence of the magnetic moment of Ni-Mn-Sb ternary alloy system. The experimental fact suggests a change of the magnetic configuration between Mn atoms at the 4a site and Mn at the 4b site by Co substitution.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sutou, Y.; Imano, Y.; Koeda, N.; Omori, T.; Kainuma, R.; Ishida, K.; Oikawa, K. Magnetic and martensitic transformations of NiMnX (X = In,Sn,Sb) ferromagnetic shape memory alloys. Appl. Phys. Lett. 2004, 85, 4358–4360. [Google Scholar] [CrossRef]

- Ullakko, K.; Huang, J.K.; Kanter, C.; Kokorin, V.V.; O’Handley, R.C. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- Sozinov, A.; Likhachev, A.A.; Ullakko, K. Crystal structures and magnetic anisotropy properties of Ni-Mn-Ga martensitic phases with giant magnetic-field-induced strain. IEEE Trans. Magn. 2002, 38, 2814–2816. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef] [PubMed]

- Ito, W.; Ito, K.; Umetsu, R.Y.; Kainuma, R.; Koyama, K.; Watanabe, K.; Fujita, T.; Oikawa, K.; Ishida, K.; Kanomata, T. Kinetic arrest of martensitic transformation in the NiCoMnIn metamagnetic shape memory alloy. Appl. Phys. Lett. 2008, 92, 021908. [Google Scholar] [CrossRef]

- Yu, S.Y.; Liu, Z.H.; Liu, G.D.; Chen, J.L.; Cao, Z.X.; Wu, G.H.; Zhan, B.; Zhang, X.X. Large magnetoresistance in single-crystalline Ni50Mn50−xInx alloys (x = 14–16) upon martensitic transformation. Appl. Phys. Lett. 2006, 89, 162503. [Google Scholar] [CrossRef]

- Sharma, V.K.; Chattopadhyay, M.K.; Shaeb, K.H.B.; Chouhan, A.; Roy, S.B. Large magnetoresistance in Ni50Mn34In16 alloy. Appl. Phys. Lett. 2006, 89, 222509. [Google Scholar] [CrossRef]

- Krenke, T.; Duman, E.; Acet, M.; Wassermann, E.F.; Moya, X.; Mañosa, L.; Planes, A. Magnetic superelasticity and inverse magnetocaloric effect in Ni-Mn-In. Phys. Rev. B 2007, 75, 104414. [Google Scholar] [CrossRef]

- Krenke, T.; Duman, E.; Acet, M.; Wassermann, E.F.; Moya, X.; Manosa, L.; Planes, A. Inverse magnetocaloric effect in ferromagnetic Ni-Mn-Sn alloys. Nat. Mater. 2005, 4, 450–454. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.D.; Wang, D.H.; Zhang, C.L.; Tang, S.L.; Gu, B.X.; Du, Y.W. Large magnetic entropy changes in the Ni45.4Mn41.5In13.1 ferromagnetic shape memory alloy. Appl. Phys. Lett. 2006, 89, 182507. [Google Scholar] [CrossRef]

- Yu, S.Y.; Ma, L.; Liu, G.D.; Liu, Z.H.; Chen, J.L.; Cao, Z.X.; Wu, G.H.; Zhang, B.; Zhang, X.X. Magnetic field-induced martensitic transformation and large magnetoresistance in NiCoMnSb alloys. Appl. Phys. Lett. 2007, 90, 242501. [Google Scholar] [CrossRef]

- Liu, J.; Gottschall, T.; Skokov, K.P.; Moore, J.D.; Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 2012, 11, 620–626. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Zhang, X.X.; Yu, S.Y.; Chen, J.L.; Cao, Z.X.; Wu, G.H. Giant magnetothermal conductivity in the Ni-Mn-In ferromagnetic shape memory alloys. Appl. Phys. Lett. 2007, 91, 012510. [Google Scholar] [CrossRef]

- Koyama, K.; Igarashi, T.; Okada, H.; Watanabe, K.; Kanomata, T.; Kainuma, R.; Ito, W.; Oikawa, K.; Ishida, K. Magnetic and thermoelectric properties of Ni50Mn36Sn14 in high-magnetic fields. J. Magn. Magn. Mater. 2007, 310, e994–e995. [Google Scholar] [CrossRef]

- Sharath, L.S.; Chattopadhyay, C.M.K.; Sharma, V.K.; Roy, S.B.; Pandey, S.K. Temperature dependence of thermoelectric power and thermal conductivity in ferromagnetic shape memory alloy Ni50Mn34In16 in magnetic fields. Phys. Rev. B 2010, 81, 195105. [Google Scholar] [CrossRef]

- Umetsu, R.Y.; Ito, W.; Ito, K.; Koyama, K.; Fujita, A.; Oikawa, K.; Kanomata, T.; Kainuma, R.; Ishida, K. Anomaly in entropy change between parent and martensite phases in the Ni50Mn34In16 Heusler alloy. Scr. Mater. 2009, 60, 25–28. [Google Scholar] [CrossRef]

- Umetsu, R.Y.; Endo, K.; Kondo, A.; Kindo, K.; Ito, W.; Xu, X.; Kanomata, T.; Kainuma, R. Magnetoresistance and transformation hysteresis in the Ni50Mn34.4In15.6 metamagnetic shape memory alloy. Mater. Trans. 2013, 54, 291–296. [Google Scholar] [CrossRef]

- Niitsu, K.; Xu, X.; Umetsu, R.Y.; Kainuma, R. Stress-induced transformations at low temperatures in a Ni45Co5Mn36In14 metamagnetic shape memory alloy. Appl. Phys. Lett. 2013, 103, 242406. [Google Scholar] [CrossRef]

- Umetsu, R.Y.; Ito, K.; Ito, W.; Koyama, K.; Kanomata, T.; Ishida, K.; Kainuma, R. Kinetic arrest behavior in martensitic transformation of NiCoMnSn metamagnetic shape memory alloy. J. Alloy. Compd. 2011, 509, 1389–1393. [Google Scholar] [CrossRef]

- Xu, X.; Ito, W.; Umetsu, R.Y.; Koyama, K.; Kainuma, R.; Ishida, K. Kinetic arrest of martensitic transformation in Ni33.0Co13.4Mn39.7Ga13.9 metamagnetic shape memory alloy. Mater. Trans. 2010, 51, 469–471. [Google Scholar] [CrossRef]

- Xu, X.; Ito, W.; Tokunaga, M.; Umetsu, R.Y.; Kainuma, R.; Ishida, K. Kinetic arrest of martensitic transformation in NiCoMnAl metamagnetic shape memory alloy. Mater. Trans. 2010, 51, 1357–1360. [Google Scholar] [CrossRef]

- Xu, X.; Katakura, I.; Kihara, T.; Tokunaga, M.; Ito, W.; Umetsu, R.Y.; Kainuma, R. Optical microscopic study on NiCoMnAl metamagnetic shape memory alloy by in situ observation under a pulsed high magnetic field. Mater. Trans. 2013, 54, 357–362. [Google Scholar] [CrossRef]

- Xu, X.; Ito, W.; Tokunaga, M.; Kihara, T.; Oka, K.; Umetsu, R.Y.; Kanomata, T. The thermal transformation arrest phenomenon in NiCoMnAl Heusler alloys. Metals 2013, 3, 298–311. [Google Scholar] [CrossRef]

- Shinohara, T. Nuclear magnetic resonance in Heusler alloys: Ni2MnSn, Co2MnSn and Ni2MnSb. J. Phys. Soc. Jpn. 1970, 28, 313–317. [Google Scholar] [CrossRef]

- Kanomata, T.; Shirakawa, K.; Kaneko, T. Effect of hydrostatic pressure on the Curie temperature of the Heusler alloys Ni2MnZ (Z = Al, Ga, In, Sn and Sb). J. Magn. Magn. Mater. 1987, 65, 76–82. [Google Scholar] [CrossRef]

- Kaneko, T.; Yoshida, H.; Abe, S.; Kamigaki, K. Pressure effect on the Curie point of the Heusler alloys Ni2MnSn and Ni2MnSb. J. Appl. Phys. 1981, 52, 2046–2048. [Google Scholar] [CrossRef]

- Nayak, A.K.; Suresh, K.G.; Nigam, A.K. Irreversibility of field-induced magnetostructural transition in NiCoMnSb shape memory alloy revealed by magnetization, transport and heat capacity studies. Appl. Phys. Lett. 2010, 96, 112503. [Google Scholar] [CrossRef]

- Nayak, A.K.; Suresh, K.G.; Nigam, A.K. Anomalous effects of repeated martensitic transitions on the transport, magnetic and thermal properties in Ni-Co-Mn-Sb Heusler alloy. Acta Mater. 2011, 59, 3304–3312. [Google Scholar] [CrossRef]

- Nayak, A.K.; Suresh, K.G.; Nigam, A.K.; Coelho, A.A.; Gama, S. Pressure induced magnetic and magnetocaloric properties in NiCoMnSb Heusler alloy. J. Appl. Phys. 2009, 106, 053901. [Google Scholar] [CrossRef]

- Sahoo, R.; Nayak, A.K.; Suresh, K.G.; Nigam, A.K. Effect of Si and Ga substitutions on the magnetocaloric properties of NiCoMnSb quaternary Heusler alloys. J. Appl. Phys. 2011, 109, 07A921. [Google Scholar]

- Du, J.; Zheng, Q.; Ren, W.J.; Feng, W.J.; Liu, X.G.; Zhang, Z.D. Magnetocaloric effect and magnetic-field-induced shape recovery effect at room temperature in ferromagnetic Heusler alloy Ni-Mn-Sb. J. Phys. D Appl. Phys. 2007, 40, 5523–5526. [Google Scholar] [CrossRef]

- Nayak, A.K.; Suresh, K.G.; Nigam, A.K. Observation of enhanced exchange bias behavior in NiCoMnSb Heusler alloys. J. Phys. D Appl. Phys. 2009, 42, 115004. [Google Scholar] [CrossRef]

- Khan, M.; Dubenko, I.; Stadler, S.; Ali, N. Exchange bias behavior in Ni-Mn-Sb Heusler alloys. Appl. Phys. Lett. 2007, 91, 072510. [Google Scholar] [CrossRef]

- Tong, H.C.; Wayman, C.M. Characteristic temperatures and other properties of thermoelastic martensites. Acta Metall. Mater. 1974, 22, 887–896. [Google Scholar] [CrossRef]

- Cesari, E.; Kustov, S.; Salas, D. Entropy changes in ferromagnetic shape memory alloys. Mater. Sci. Forum 2011, 684, 49–60. [Google Scholar] [CrossRef]

- Seeger, A. Dislocations and Mechanical Properties; Fisher, J.C., Johnston, W.G., Thomson, R., Vreeland, T., Jr., Eds.; John Wiley: New York, NY, USA, 1957; p. 271. [Google Scholar]

- Kocks, U.F.; Argon, A.S.; Ashby, M.F. Thermodynamics and Kinetics of Slips, Progress in Materials Science; Chalmers, B.J., Christian, W., Massalski, T.B., Eds.; Pergamon Press: Oxford, UK; New York, NY, USA, 1975; Volume 19. [Google Scholar]

- Mecking, H.; Kocks, U.F. Kinetics of flow and strain-hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Ghosh, G.; Olson, G.B. Kinetics of f.c.c → b.c.c heterogeneous martensitic nucleation-II thermal activation. Acta Metall. Mater. 1994, 42, 3371–3379. [Google Scholar] [CrossRef]

- Niitsu, K.; Omori, T.; Kainuma, R. Stress-induced transformation behaviors at low temperatures in Ti-51.8Ni (at. %) shape memory alloy. Appl. Phys. Lett. 2013, 102, 231915. [Google Scholar] [CrossRef]

- Xu, X.; Kihara, T.; Tokunaga, M.; Matsuo, A.; Ito, W.; Umetsu, R.Y.; Kindo, K.; Kainuma, R. Magnetic field hysteresis under various sweeping rates for Ni-Co-Mn-In metamagnetic shape memory alloys. Appl. Phys. Lett. 2013, 103, 122406. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Söderberg, O.; Bliznuk, V.V.; Glavatska, N.I.; Lindroos, V.K. Martensitic transformations and mobility of twin boundaries in Ni2MnGa alloys studied by using internal friction. Scr. Mater. 2003, 49, 803–809. [Google Scholar] [CrossRef]

- Straka, L.; Hänninen, H.; Heczko, O. Temperature dependence of single twin boundary motion in Ni-Mn-Ga martensite. Appl. Phys. Lett. 2011, 98, 141902. [Google Scholar] [CrossRef]

- Peng, Z.; Jin, X.; Hsu, T.Y.; Pagounis, E. Relaxation of twin boundaries in a Ni2MnGa single crystalline. Mater. Sci. Eng. A 2008, 481–482, 310–313. [Google Scholar] [CrossRef]

- Ito, W.; Xu, X.; Umetsu, R.Y.; Kanomata, T.; Ishida, K.; Kainuma, R. Concentration dependence of magnetic moment in Ni50−xCoxMn50−yZy (Z = In,Sn) Heusler alloys. Appl. Phys. Lett. 2010, 97, 242512. [Google Scholar] [CrossRef]

- Miyamoto, T.; Ito, W.; Umetsu, R.Y.; Kainuma, R.; Kanomata, T.; Ishida, K. Phase stability and magnetic properties of Ni50Mn50−xInx Heusler-type alloys. Scr. Mater. 2010, 62, 151–154. [Google Scholar] [CrossRef]

- Şaşıoğlu, E.; Sandratskii, L.M.; Bruno, P. First-principles calculation of the intersublattice exchange interactions and Curie temperatures of the full Heusler alloys Ni2MnX X = Ga,In,Sn,Sb. Phys. Rev. B 2004, 70, 024427. [Google Scholar] [CrossRef]

- Umetsu, R.Y.; Sheikh, A.; Ito, W.; Ouladdiaf, B.; Ziebeck, K.R.A.; Kanomata, T.; Kainuma, R. The effect of Co substitution on the magnetic properties of the Heusler alloy Ni50Mn33Sn17. Appl. Phys. Lett. 2011, 98, 042507. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Umetsu, R.Y.; Xu, X.; Ito, W.; Kihara, T.; Takahashi, K.; Tokunaga, M.; Kainuma, R. Magnetic Field-Induced Reverse Martensitic Transformation and Thermal Transformation Arrest Phenomenon of Ni41Co9Mn39Sb11 Alloy. Metals 2014, 4, 609-622. https://doi.org/10.3390/met4040609

Umetsu RY, Xu X, Ito W, Kihara T, Takahashi K, Tokunaga M, Kainuma R. Magnetic Field-Induced Reverse Martensitic Transformation and Thermal Transformation Arrest Phenomenon of Ni41Co9Mn39Sb11 Alloy. Metals. 2014; 4(4):609-622. https://doi.org/10.3390/met4040609

Chicago/Turabian StyleUmetsu, Rie Y., Xiao Xu, Wataru Ito, Takumi Kihara, Kohki Takahashi, Masashi Tokunaga, and Ryosuke Kainuma. 2014. "Magnetic Field-Induced Reverse Martensitic Transformation and Thermal Transformation Arrest Phenomenon of Ni41Co9Mn39Sb11 Alloy" Metals 4, no. 4: 609-622. https://doi.org/10.3390/met4040609