Simultaneous Improvement in Mechanical Properties and Fatigue Crack Propagation Resistance of Low Carbon Offshore Structural Steel EH36 by Cu–Cr Microalloying

Abstract

:1. Introduction

2. Materials and Methods

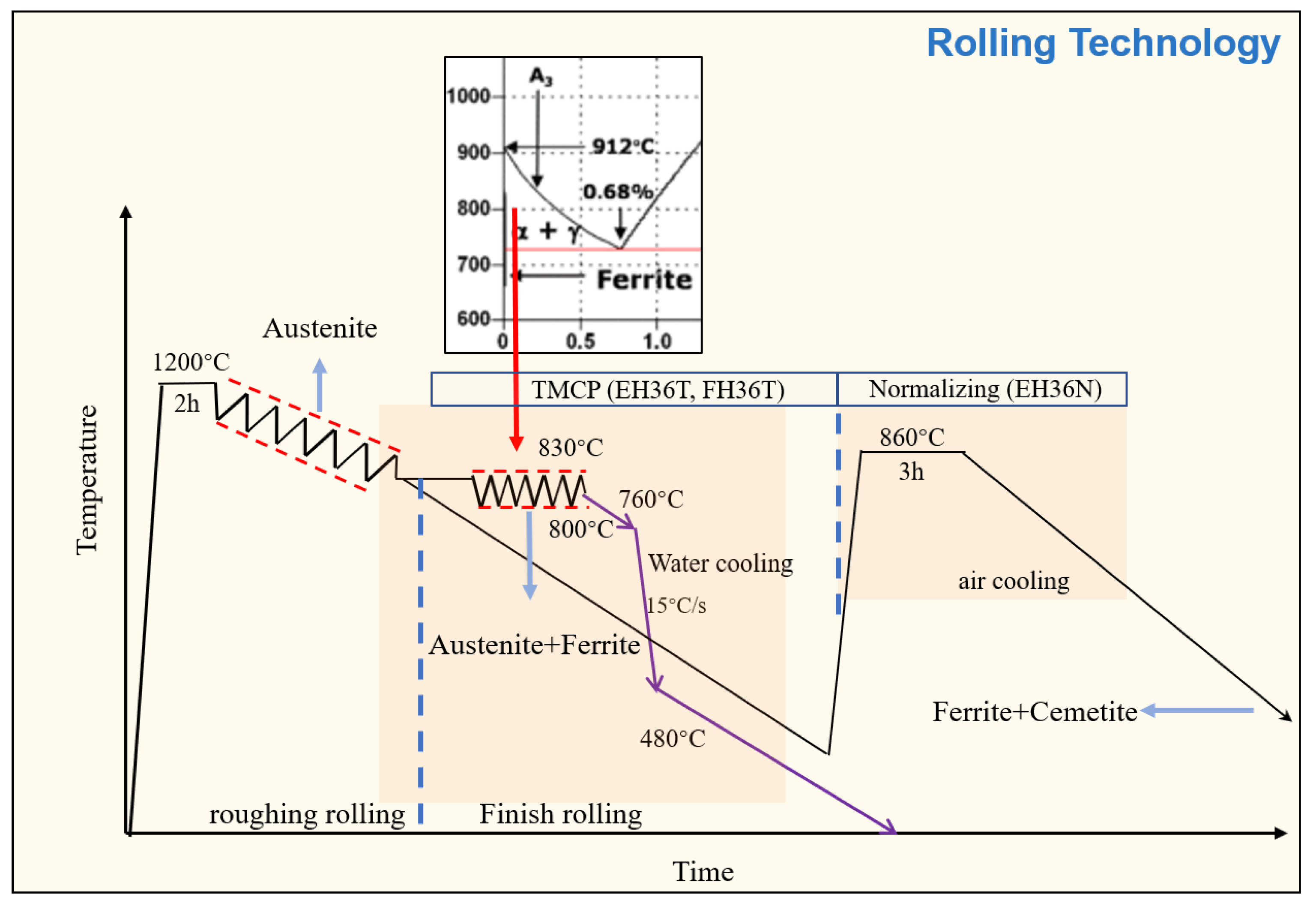

2.1. Process and Materials

2.2. Mechanical Properties Test

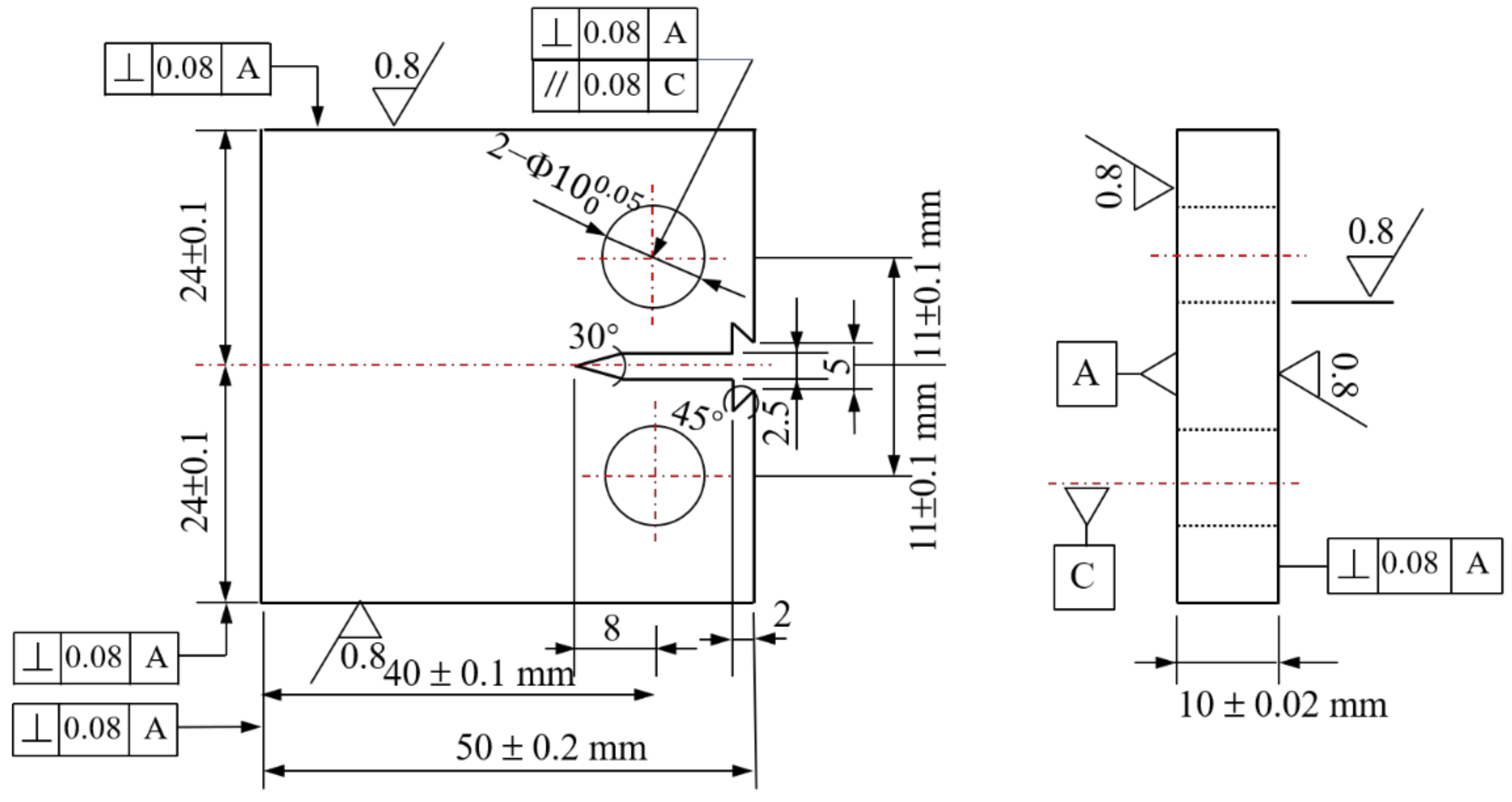

2.3. Fatigue Crack Propagation Test

2.4. Characterization Methods

3. Results and Discussion

3.1. Microstructure Analysis by OM and SEM

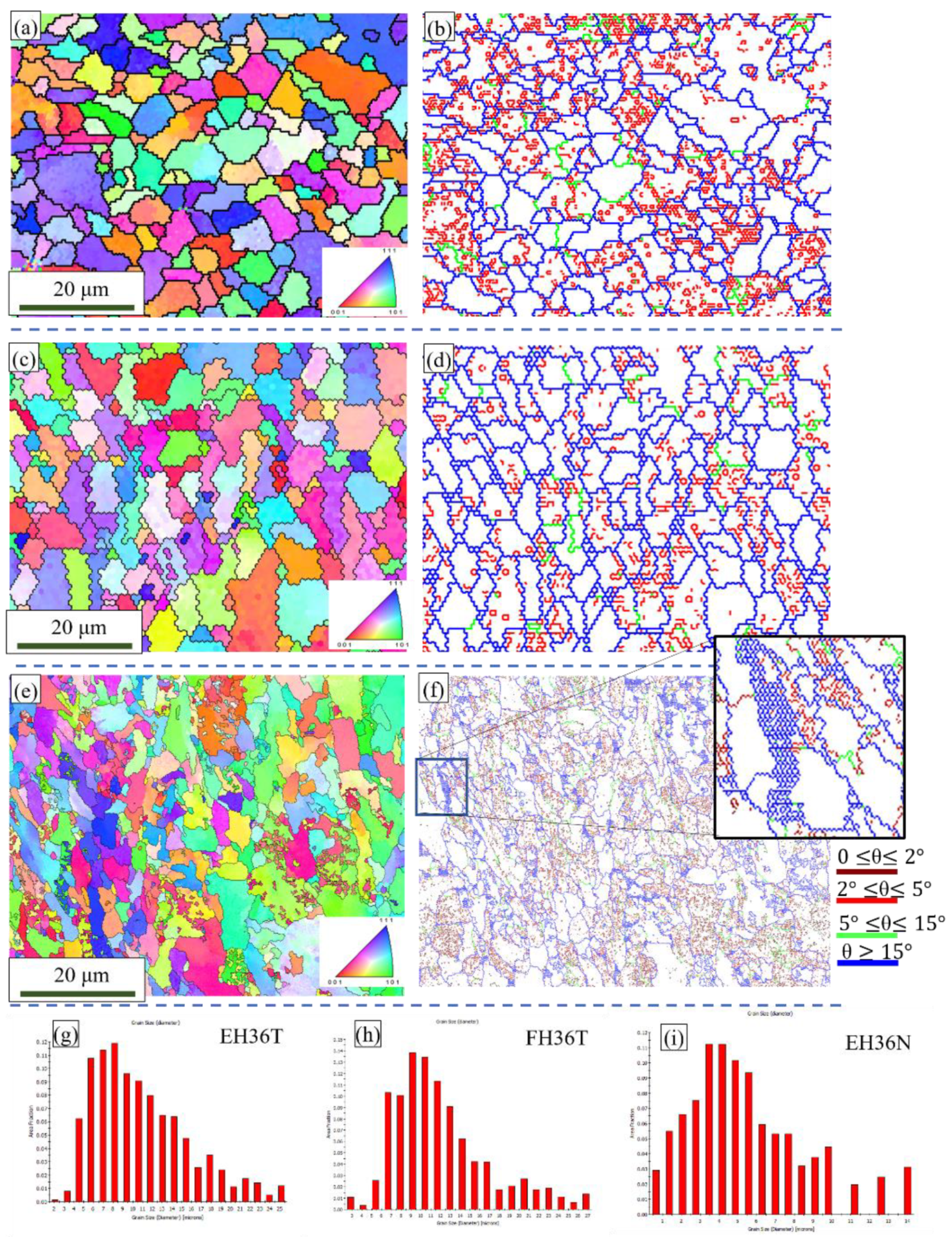

3.2. EBSD Analysis

3.2.1. Microstructure Analysis

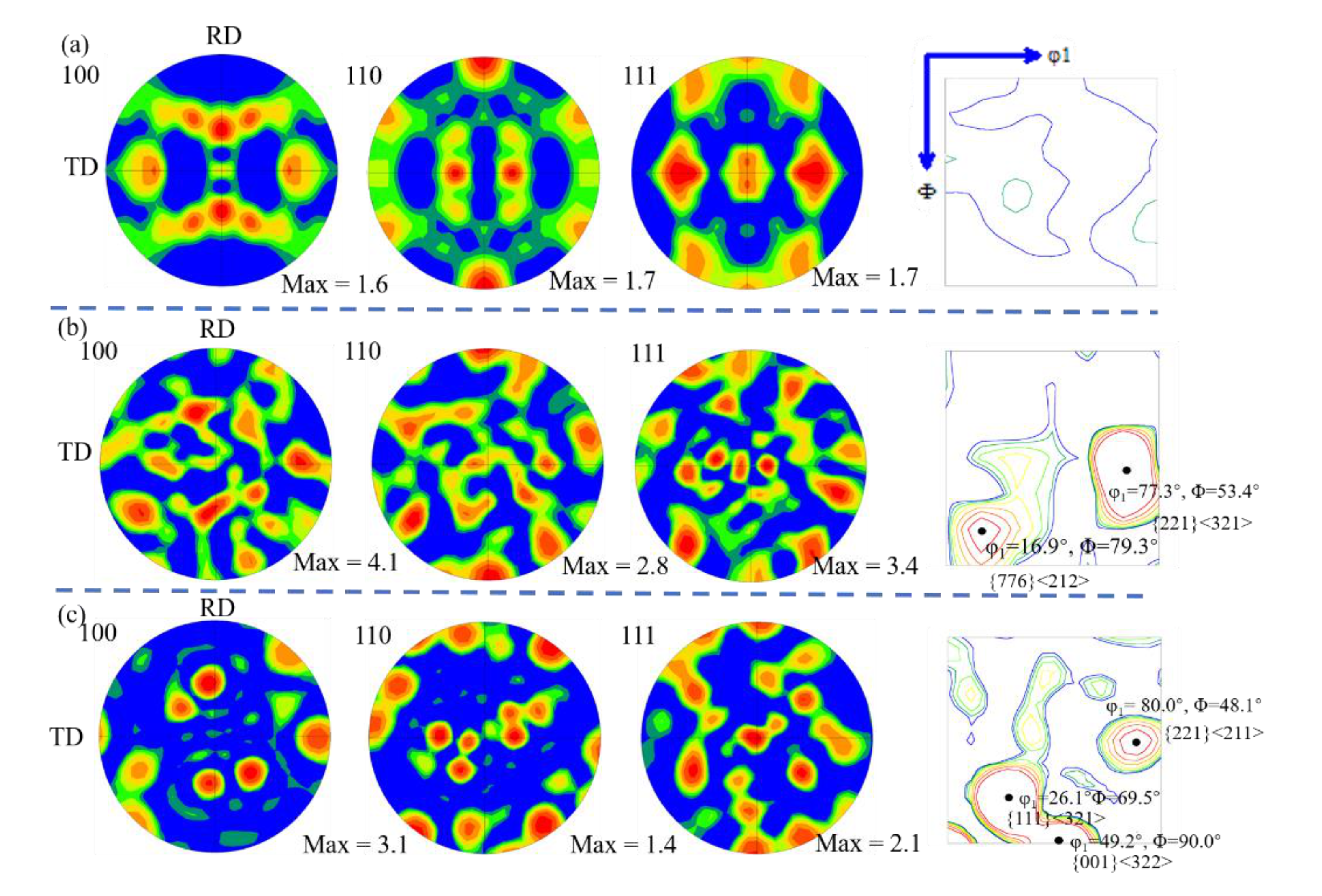

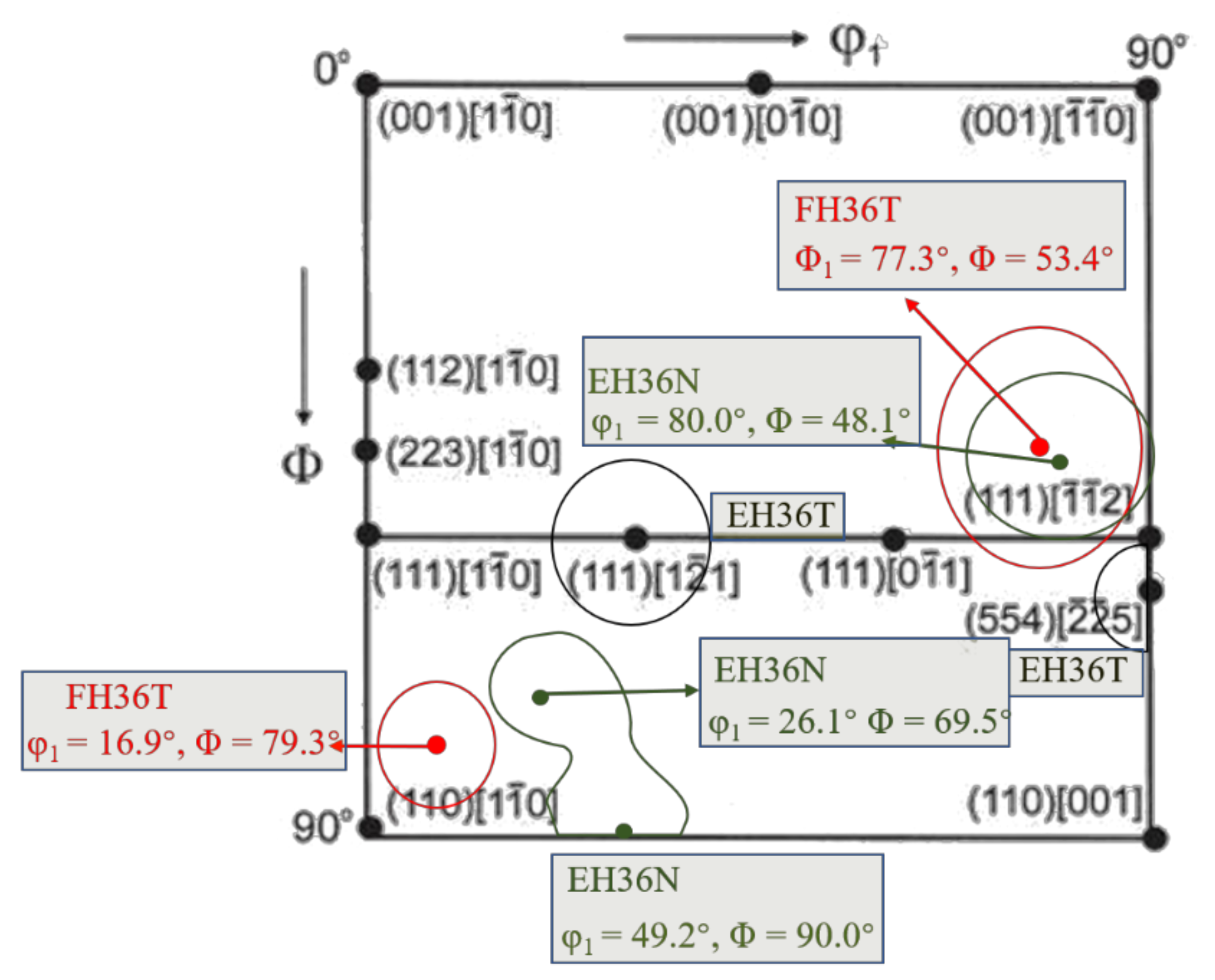

3.2.2. Textural Analysis

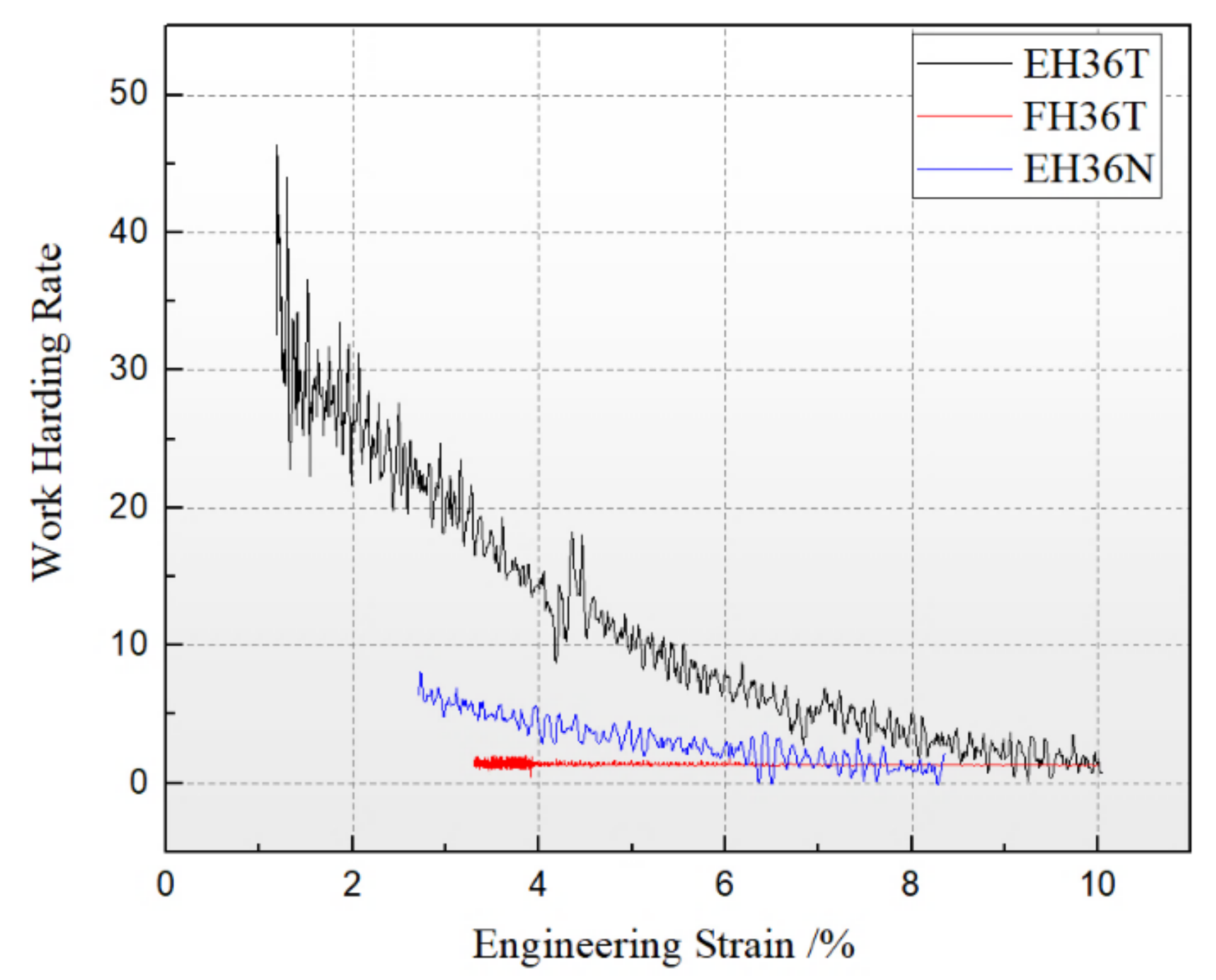

3.3. Mechanical Performance

3.3.1. Mechanical Properties

3.3.2. Strengthening Mechanism

3.3.3. Improvement in Ductility

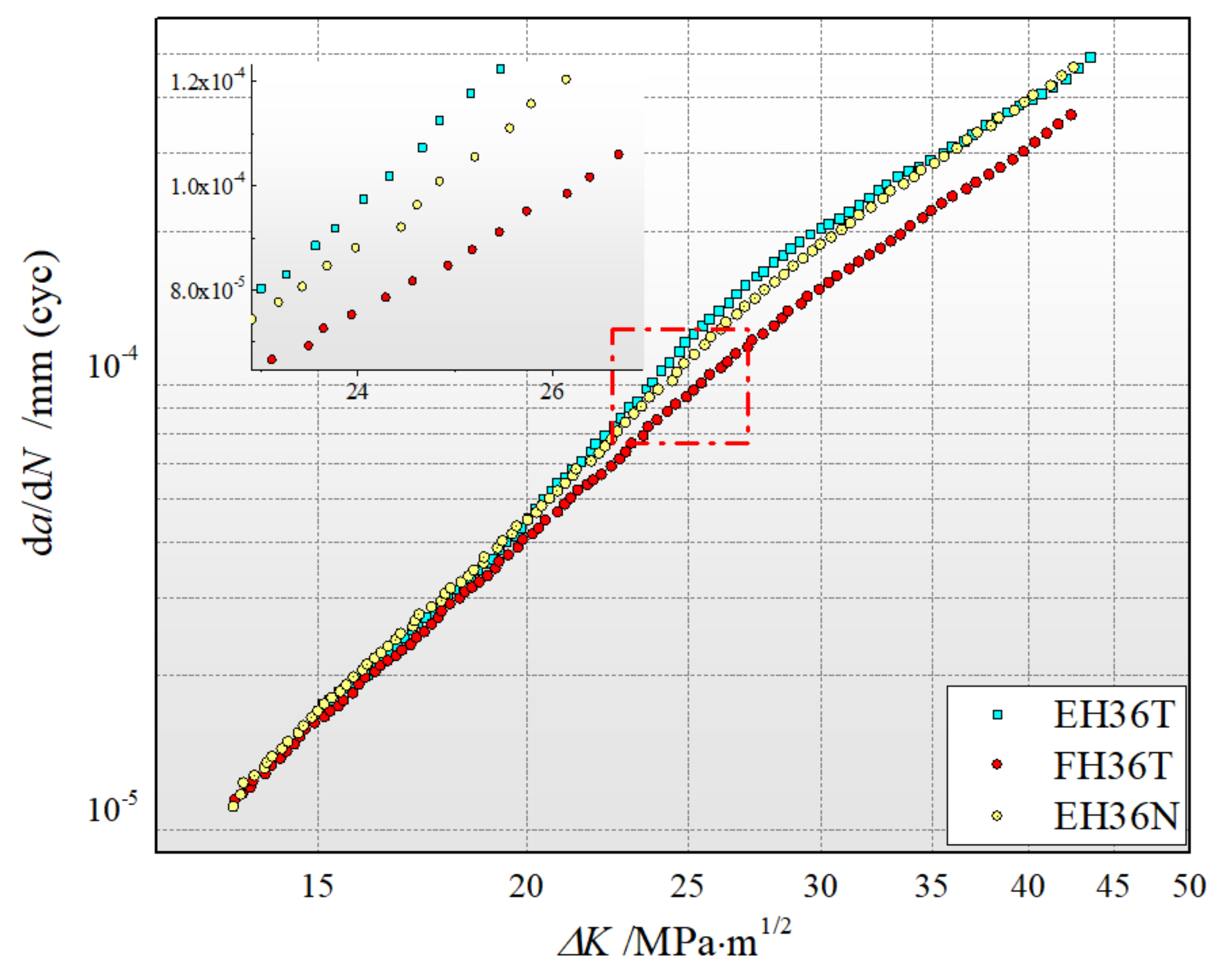

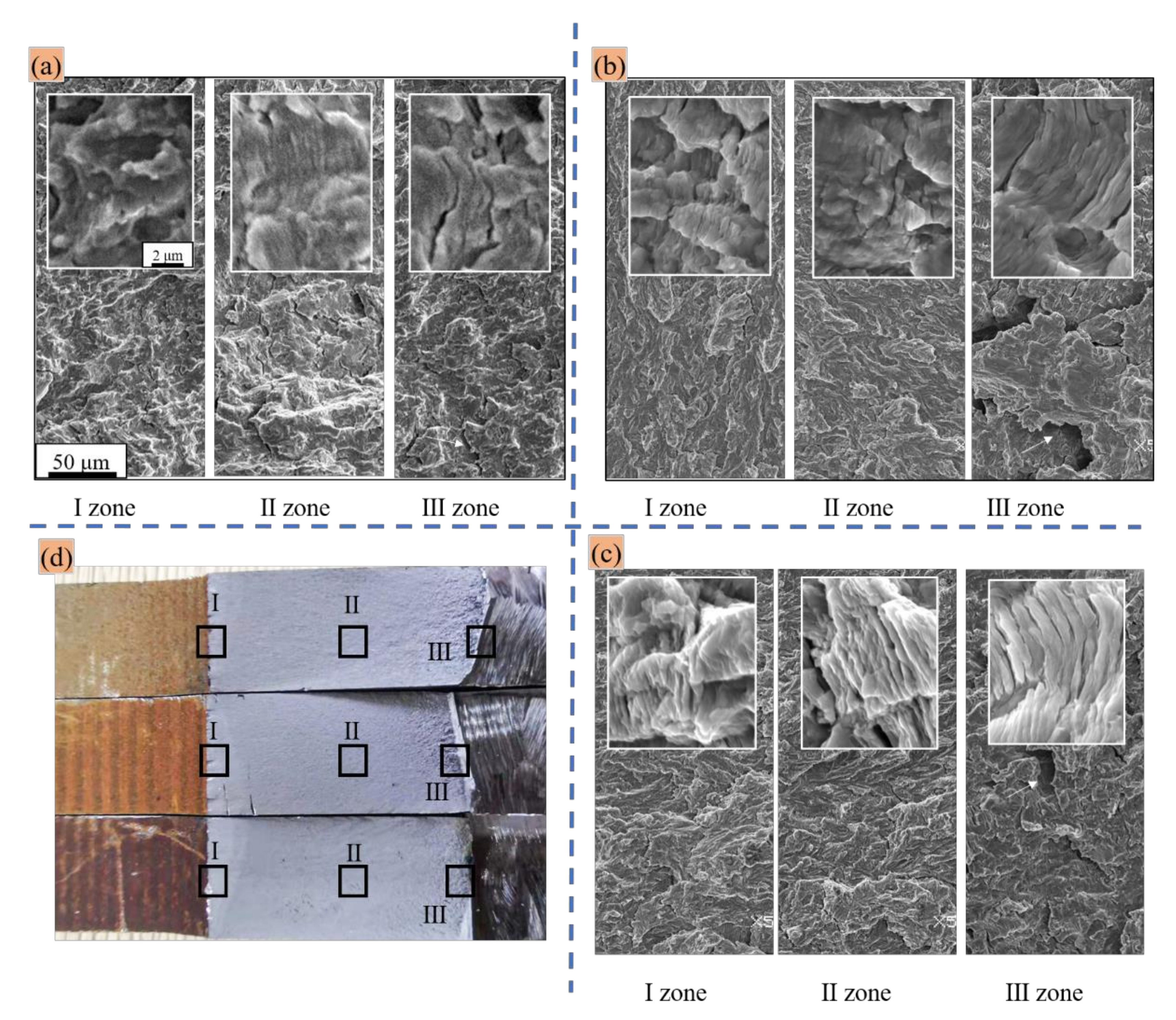

3.4. Fatigue Crack Propagation Analysis

4. Conclusions

- (1)

- The addition of Cu-Cr elements significantly improved the ductility, which increased by 52.2% compared to EH36T, and both yield strength and ultimate strength were enhanced slightly with the values of 438 MPa and 553 MPa, respectively. The serrated shape of the grain boundaries and the precipitation strengthening were the main contributions to the yield stress for the FH36T plate. The normalizing process led to a decrease in yield stress for EH36T, but substantially reduced the yield ratio and increased the ultimate elongation (33%), owing to the sharp decrease of the contribution of precipitation strengthening.

- (2)

- The considerable improvement in elongations of FH36T and EH36N were analyzed by the deformation textures. The results showed that SFs of the deformation texture of FH36T and EH36N in TD and ND were much higher than that of EH36T. This enhances the ability to sacrifice the volume of material in the width and thickness direction to make up for the loss brought by the increase of sample length, thus leading to higher ductility.

- (3)

- FH36T plates showed a better resistance to fatigue crack propagation when was higher than 20 MPa/m1/2 in comparison with the other two offshore steels. This could be attributed to the formation of jagged shape grain boundaries, which decreases the effective stress intensity factor during the fatigue crack propagation process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| TMCP | thermo-mechanical control process |

| FH36 | Cu–Cr microalloyed offshore structural steel based on EH36 |

| FH36T | TMCP treated FH36 |

| EH36N | normalizing treated EH36 |

| EH36T | TMCP treated EH36 |

| TD | transverse direction |

| ND | normal direction |

| SFs | Schmidt factors |

| YS | yield strength |

| UTS | ultimate tensile strength |

| E | elongation to failure |

| YR | yield ratio |

| a | length of fatigue crack |

| ΔK | intensity factor |

| da/dN | fatigue crack growth rate |

| σy | yield strength contributed by different strengthening mechanisms |

| ΔσS | yield strength contributed by solid solute strengthening |

| Δσgs | yield strength contributed by grain boundary strengthening |

| ΔσDis | yield strength contributed by dislocation strengthening |

| Δσppt | yield strength contributed by precipitation strengthening |

| d | average grain size |

| [X] | the weight percent of alloying element X |

| ρ | dislocation density |

| M | Taylor factor |

| G | shear modulus |

| b | Burgers vector |

| s | density of “ridges” |

References

- Tervo, H.; Kaijalainen, A.; Pallaspuro, S.; Anttila, S.; Mehtonen, S.; Porter, D.; Kömi, J. Low-temperature toughness properties of 500 MPa offshore steels and their simulated coarse-grained heat-affected zones. Mater. Sci. Eng. A 2020, 773, 138719. [Google Scholar] [CrossRef]

- Djeumen, E.; Chataigner, S.; Créac’Hcadec, R.; Sourisseau, Q.; Quéméré, M.; Court, J.; Sayed, F. Creep investigations on adhesively bonded fasteners developed for offshore steel structures. Mar. Struct. 2019, 69, 102660. [Google Scholar] [CrossRef]

- Zou, X.; Zhao, D.; Sun, J.; Wang, C.; Matsuura, H. An Integrated Study on the Evolution of Inclusions in EH36 Shipbuilding Steel with Mg Addition: From Casting to Welding. Met. Mater. Trans. A 2018, 49, 481–489. [Google Scholar] [CrossRef]

- Zou, X.-D.; Sun, J.-C.; Zhao, D.-P.; Matsuura, H.; Wang, C. Effects of Zr addition on evolution behavior of inclusions in EH36 shipbuilding steel: From casting to welding. J. Iron Steel Res. Int. 2018, 25, 164–172. [Google Scholar] [CrossRef]

- Ma, Y.T.; Ye, J.J. Application of Nb in Low Temperature High Strength Hull Structural Steel EH36. Wide Heavy Plate. 2002, 8, 18–23. [Google Scholar]

- Zhao, Y.; Tong, X.; Wei, X.; Xu, S.; Lan, S.; Wang, X.-L.; Zhang, Z. Effects of microstructure on crack resistance and low-temperature toughness of ultra-low carbon high strength steel. Int. J. Plast. 2019, 116, 203–215. [Google Scholar] [CrossRef]

- Ueki, S.; Mine, Y.; Takashima, K. Microstructure-sensitive fatigue crack growth in lath martensite of low carbon steel. Mater. Sci. Eng. A 2020, 773, 138830. [Google Scholar] [CrossRef]

- Sung, H.K.; Shin, S.Y.; Hwang, B.; Gil Lee, C.; Kim, N.J.; Lee, S. Effects of carbon equivalent and cooling rate on tensile and Charpy impact properties of high-strength bainitic steels. Mater. Sci. Eng. A 2011, 530, 530–538. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, J.; Xu, Y.; Liu, Z. Effects of Cr, Ni and Cu on the Corrosion Behavior of Low Carbon Microalloying Steel in a Cl− Containing Environment. J. Mater. Sci. Technol. 2013, 29, 168–174. [Google Scholar] [CrossRef]

- Kim, S.-J.; Gil Lee, C.; Lee, T.-H.; Oh, C.-S. Effect of Cu, Cr and Ni on mechanical properties of 0.15 wt.% C TRIP-aided cold rolled steels. Scr. Mater. 2003, 48, 539–544. [Google Scholar] [CrossRef]

- Ruck, A.; Monceau, D.; Grabke, H.J. Effects of tramp elements Cu, P, Pb, Sb and Sn on the kinetics of carburization of case hardening steels. Steel Res. 1996, 67, 240–246. [Google Scholar] [CrossRef]

- Ren, L.; Nan, L.; Yang, K. Study of copper precipitation behavior in a Cu-bearing austenitic antibacterial stainless steel. Mater. Des. 2011, 32, 2374–2379. [Google Scholar] [CrossRef]

- García-León, R.A.; Martínez-Trinidad, J.; Campos-Silva, I. Historical Review on the Boriding Process using Bibliometric Analysis. Trans. Indian Inst. Met. 2021, 74, 541–557. [Google Scholar] [CrossRef]

- Wong-Ángel, W.D.; Martínez-Trinidad, J.; Campos-Silva, I.; Hernandez-Hernandez, V.; Silva-Rivera, U.S.; García-León, R.A. Wear-Corrosion Synergy on Din-16MnCr5 Steel Under Nitriding and Post-Oxidizing Treatments. J. Bio Tribo-Corros. 2021, 7, 83. [Google Scholar] [CrossRef]

- García-León, R.A.; Martínez-Trinidad, J.; Campos-Silva, I.; Figueroa-López, U.; Guevara-Morales, A. Development of tribological maps on borided AISI 316L stainless steel under ball-on-flat wet sliding conditions. Tribol. Int. 2021, 163, 107161. [Google Scholar] [CrossRef]

- García-León, R.A.; Martínez-Trinidad, J.; Zepeda-Bautista, R.; Campos-Silva, I.; Guevara-Morales, A.; Martínez-Londoño, J.; Barbosa-Saldaña, J. Dry sliding wear test on borided AISI 316L stainless steel under ball-on-flat configuration: A statistical analysis. Tribol. Int. 2021, 157, 106885. [Google Scholar] [CrossRef]

- García-León, R.A.; Martínez-Trinidad, J.; Campos-Silva, I.; Figueroa-López, U.; Guevara-Morales, A. Wear maps of borided AISI 316L steel under ball-on-flat dry sliding conditions. Mater. Lett. 2021, 282, 128842. [Google Scholar] [CrossRef]

- Thompson, S. Interrelationships between yield strength, low-temperature impact toughness, and microstructure in low-carbon, copper-precipitation-strengthened, high-strength low-alloy plate steels. Mater. Sci. Eng. A 2018, 711, 424–433. [Google Scholar] [CrossRef]

- Paris, P.; Erdogan, F. A Critical Analysis of Crack Propagation Laws. J. Basic Eng. 1963, 85, 528–533. [Google Scholar] [CrossRef]

- Li, C.; Duan, R.; Fu, W.; Gao, H.; Wang, D.; Di, X. Improvement of mechanical properties for low carbon ultra-high strength steel strengthened by Cu-rich multistructured precipitation via modification to bainite. Mater. Sci. Eng. A 2021, 817, 141337. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Mao, J.H.; Wang, R.P.; Qiao, X.L. Effect of precipitated phase particles on secondary recrystallization in grain oriented silicon steel. Heat Treat. Met. 2009, 34, 29–32. [Google Scholar]

- Raabe, D.; Hantcherli, L. 2D cellular automaton simulation of the recrystallization texture of an IF sheet steel under consideration of Zener pinning. Comput. Mater. Sci. 2005, 34, 299–313. [Google Scholar] [CrossRef]

- Mittemeijer, E.J. Fundamentals of Materials Science: The Microstructure-Property Relationship Using Metals as Model Systems; Springer: Cham, Switzerland, 2011; pp. 527–529. [Google Scholar]

- Luo, X.D.; Zhu, Y.X.; Liu, H.; Li, M.Y. Effect of Normalizing on Microstructure and Mechanical Properties of EH36 Alloy. Appl. Mech. Mater. 2014, 487, 110–113. [Google Scholar] [CrossRef]

- Luo, X.D.; Liu, H.; Zhu, Y.X.; Zheng, C.Y. Effect of Heat Treatment on Microstructure and Mechanical Properties of EH36 Alloy. Appl. Mech. Mater. 2014, 487, 177–180. [Google Scholar] [CrossRef]

- XGao, H.; Qiu, C.L.; Lin-Xiu, D.U. Effect of Rolling Process on Microstructure and Mechanical Properties of EH36 Ship Plate Steel. Mater. Mech. Eng. 2010, 34, 5–8. [Google Scholar]

- Ke, H.; Chunyu, L.; Guojun, X.; Ruizhen, G.; Qichi, L.; Qiyu, L. Effect of extrusion temperature on the microstructure and mechanical properties of low Zn containing wrought Mg alloy micro-alloying with Mn and La-rich misch metal. Mater. Sci. Eng. A 2018, 742, 692–703. [Google Scholar]

- Yen, H.-W.; Chen, P.-Y.; Huang, C.-Y.; Yang, J.-R. Interphase precipitation of nanometer-sized carbides in a titanium–molybdenum-bearing low-carbon steel. Acta Mater. 2011, 59, 6264–6274. [Google Scholar] [CrossRef]

- Syn, C.K.; Lesuer, D.R.; Sherby, O.D. Influence of microstructure on tensile properties of spheroidized ultrahigh-carbon (1.8 Pct C steel. Met. Mater. Trans. A 1994, 25, 1481–1493. [Google Scholar] [CrossRef]

- Weijuanli; Zhang, H.; Wang, G.; Liu, X. Effect of deformed grain boundary on microstructure of mild steel (in Chinese). J. Iron Steel Res. 2000, 13, 27–30. [Google Scholar]

- Jiao, Z.B.; Luan, J.; Zhang, Z.; Miller, M.; Ma, W.; Liu, C. Synergistic effects of Cu and Ni on nanoscale precipitation and mechanical properties of high-strength steels. Acta Mater. 2013, 61, 5996–6005. [Google Scholar] [CrossRef]

- Inoue, T.; Ueji, R. Improvement of strength, toughness and ductility in ultrafine-grained low-carbon steel processed by warm bi-axial rolling. Mater. Sci. Eng. A 2020, 786, 139415. [Google Scholar] [CrossRef]

- Griffiths, D. Understanding Texture Weakening in Magnesium Rare Earth Alloys; Robson, J., Ed.; The School of Materials, The University of Manchester: Manchester, UK, 2015; pp. 16–52. [Google Scholar]

- Hu, K.; Liao, Q.; Li, C.; Le, Q.; Zhou, W.; Cheng, C.; Ning, S.; Chen, X.; Yu, F. High ductility induced by un-DRXed grains in a Mg-Zn-Mn-La-Ce alloy. J. Mater. Sci. 2019, 54, 10902–10917. [Google Scholar] [CrossRef]

- Laird, C.; Krause, A.R. On the temperature effect in the fatigue fracture of copper and Cu-7.9 wt pct Al alloy. Trans. AIME 1968, 242, 2339–2342. [Google Scholar]

- Richter-Trummer, V.; Koch, D.; Witte, A.; dos Santos, J.F.; de Castro, P.M.S.T. Methodology for prediction of distortion of workpieces manufactured by high speed machining based on an accurate through-the-thickness residual stress determination. Int. J. Adv. Manuf. Technol. 2013, 68, 2271–2281. [Google Scholar] [CrossRef]

- Mercer, C.; Soboyejo, A.; Soboyejo, W. Micromechanisms of fatigue crack growth in a forged Inconel 718 nickel-based superalloy. Mater. Sci. Eng. A 1999, 270, 308–322. [Google Scholar] [CrossRef]

- Kim, H.-K.; Choi, M.-I.; Chung, C.-S.; Shin, D.H. Fatigue properties of ultrafine grained low carbon steel produced by equal channel angular pressing. Mater. Sci. Eng. A 2003, 340, 243–250. [Google Scholar] [CrossRef]

- Birkbeck, G.; Inckle, A.E.; Waldron, G. Aspects of Stage II fatigue crack propagation in low-carbon steel. J. Mater. Sci. 1971, 6, 319–323. [Google Scholar] [CrossRef]

- Yakushiji, T.; Goto, M.; Kage, M.; Hashimoto, S. Fatigue, Cyclic Deformation and Microstructure. Effects of Texture on Fatigue Crack Propagation of Low-carbon Steel. ISIJ Int. 1997, 37, 1180–1188. [Google Scholar] [CrossRef] [Green Version]

- Krueger, D.D.; Kissinger, R.D.; Menzies, R.G. Development and Introduction of a Damage Tolerant High Temperature Nickel-Base Disk Alloy, Rene’88DT. In Proceedings of the International Symposium on Superalloys; Springer: Cham, Switzerland, 1992; pp. 277–286. [Google Scholar]

- Schirra, J.J.; Reynolds, P.L.; Huron, E.S.; Bain, K.R.; Mourer, D.P. Effect of Microstructure (and Heat Treatment) on the 649 °C Properties of Advanced P/M Superalloy Disk Materials. In Proceedings of the International Symposium on Superalloys; Springer: Cham, Switzerland, 2004; pp. 341–350. [Google Scholar]

| Elements | C | Si | Mn | Cu | Cr | Ni | V | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| EH36 | 0.18 | 0.15 | 1.45 | - | - | 0.40 | 0.04 | 0.015 | 0.040 |

| FH36 | 0.06 | 0.15 | 1.35 | 0.12 | 0.18 | 0.38 | 0.045 | 0.017 | 0.045 |

| Position | Carbon | Silicon | Aluminum | Nickel | Niobium | Cuprum | Chromium |

|---|---|---|---|---|---|---|---|

| A | 6.5 | 0.35 | 0.21 | 0.51 | 0.10 | - | - |

| B | 3.06 | 0.43 | 0.30 | 0.63 | 021 | - | - |

| C | 6.92 | 0.24 | 0.31 | 0.61 | 0.29 | 0.19 | 0.15 |

| D | 3.92 | 0.30 | 0.22 | 0.70 | 0.35 | 0.27 | 0.32 |

| E | 9.57 | 0.28 | 0.31 | 0.57 | 0.15 | - | - |

| F | 2.29 | 0.28 | 0.13 | 0.64 | 0.15 | - | - |

| Sample | YS/MPa | UTS/MPa | E/% | YR |

|---|---|---|---|---|

| EH36T | 412 | 536 | 19 | 0.77 |

| FH36T | 438 | 553 | 29 | 0.79 |

| EH36N | 338 | 506 | 33 | 0.67 |

| Technological Conditions | Material | YS/MPa | UTS/MPa | Elongation/% | YR | Reference |

|---|---|---|---|---|---|---|

| TMCP | EH36 | 385.2 | 541.1 | 22.7 | 0.71 | [24] |

| 870 °C × 30 min | EH36 | 353.8 | 497.2 | 34.6 | 0.71 | [24] |

| 910 °C × 30 min | EH36 | 372.1 | 494.4 | 35.5 | 0.75 | [24] |

| 950 °C × 30 min | EH36 | 380.6 | 496.3 | 35.2 | 0.77 | [24] |

| 870 °C/30 min + 500 °C/30 min | EH36 | 352.6 | 467.6 | 25.3 | 0.75 | [25] |

| 870 °C/30 min + 550 °C/30 min | EH36 | 371.1 | 493.6 | 27.6 | 0.75 | [25] |

| 950 °C/30 min + 500 °C/30 min | EH36 | 382.6 | 517.2 | 30.6 | 0.74 | [25] |

| 950 °C/30 min + 550 °C/30 min | EH36 | 384.6 | 516.3 | 32.2 | 0.75 | [25] |

| TMCP | EH36 | 420 | 550 | 23 | 0.76 | [26] |

| TMCP (1200 °C × 2 h + 1050–840 °C rolling + 840–440 °C water cooling) | EH36 microalloyed by Mg | 415 | 531 | - | 0.78 | [3] |

| TMCP (1200 °C × 2 h + 1050–840 °C rolling + 840–440 °C water cooling) | EH36 microalloyed by Zr | 445 | 563 | - | 0.79 | [4] |

| Sample | Deformation Texture | SFs | ||

|---|---|---|---|---|

| RD | ND | TD | ||

| EH36T | {112}<110> {554}<225> | 0.41, 0.43 | 0.41, 0.33 | 0.41, 0.41 |

| FH36T | {221}<321> {776}<212> | 0.47, 0.41 | 0.41, 0.32 | 0.48, 0.42 |

| EH36N | {111}<321>,{001}<322> {221}<211> | 0.47, 0.36, 0.41 | 0.27, 0.41, 0.41 | 0.46, 0.41, 0.49 |

| Samples | Paris Formula |

|---|---|

| EH36T | da/dN = 1.97 × 10−9 × (ΔK)3.33 |

| FH36T | da/dN = 3.49 × 10−9 × (ΔK)3.12 |

| EH36N | da/dN = 1.96 × 10−9 × (ΔK)3.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, X.; Zhang, P.; Hu, K.; Yan, L.; Li, G. Simultaneous Improvement in Mechanical Properties and Fatigue Crack Propagation Resistance of Low Carbon Offshore Structural Steel EH36 by Cu–Cr Microalloying. Metals 2021, 11, 1880. https://doi.org/10.3390/met11111880

Peng X, Zhang P, Hu K, Yan L, Li G. Simultaneous Improvement in Mechanical Properties and Fatigue Crack Propagation Resistance of Low Carbon Offshore Structural Steel EH36 by Cu–Cr Microalloying. Metals. 2021; 11(11):1880. https://doi.org/10.3390/met11111880

Chicago/Turabian StylePeng, Xingdong, Peng Zhang, Ke Hu, Ling Yan, and Guanglong Li. 2021. "Simultaneous Improvement in Mechanical Properties and Fatigue Crack Propagation Resistance of Low Carbon Offshore Structural Steel EH36 by Cu–Cr Microalloying" Metals 11, no. 11: 1880. https://doi.org/10.3390/met11111880