Spacecraft Health Status Monitoring Method Based on Multidimensional Data Fusion

Abstract

1. Introduction

2. Related Work

3. Feature Extraction on the Basis of Multidimensional Spacecraft Telemetry Data

3.1. Spacecraft Telemetry Data Characterization and Analysis

- Complexity

- Slow change

- Susceptibility to interference

3.2. Explicit Physical Characteristics

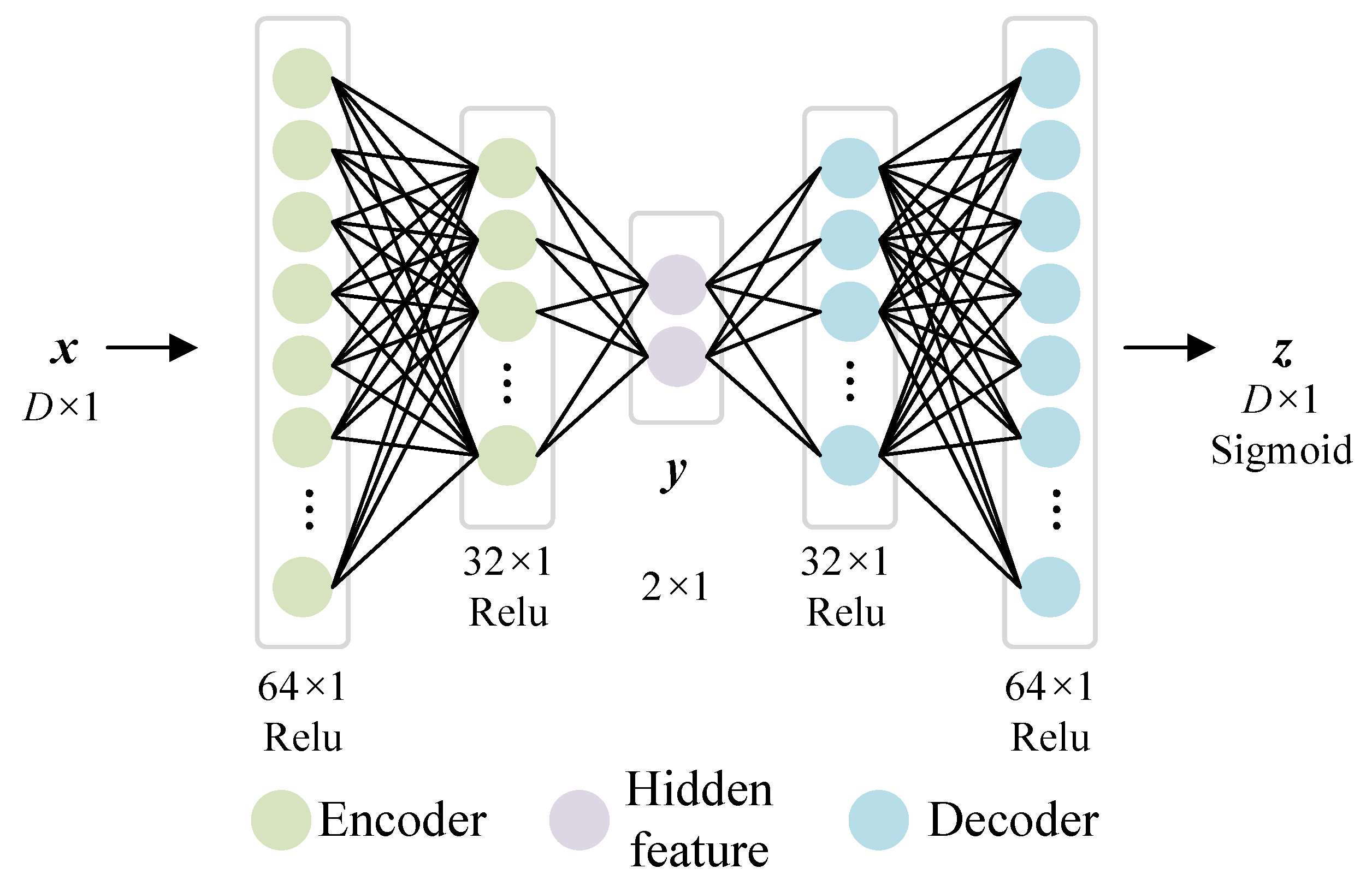

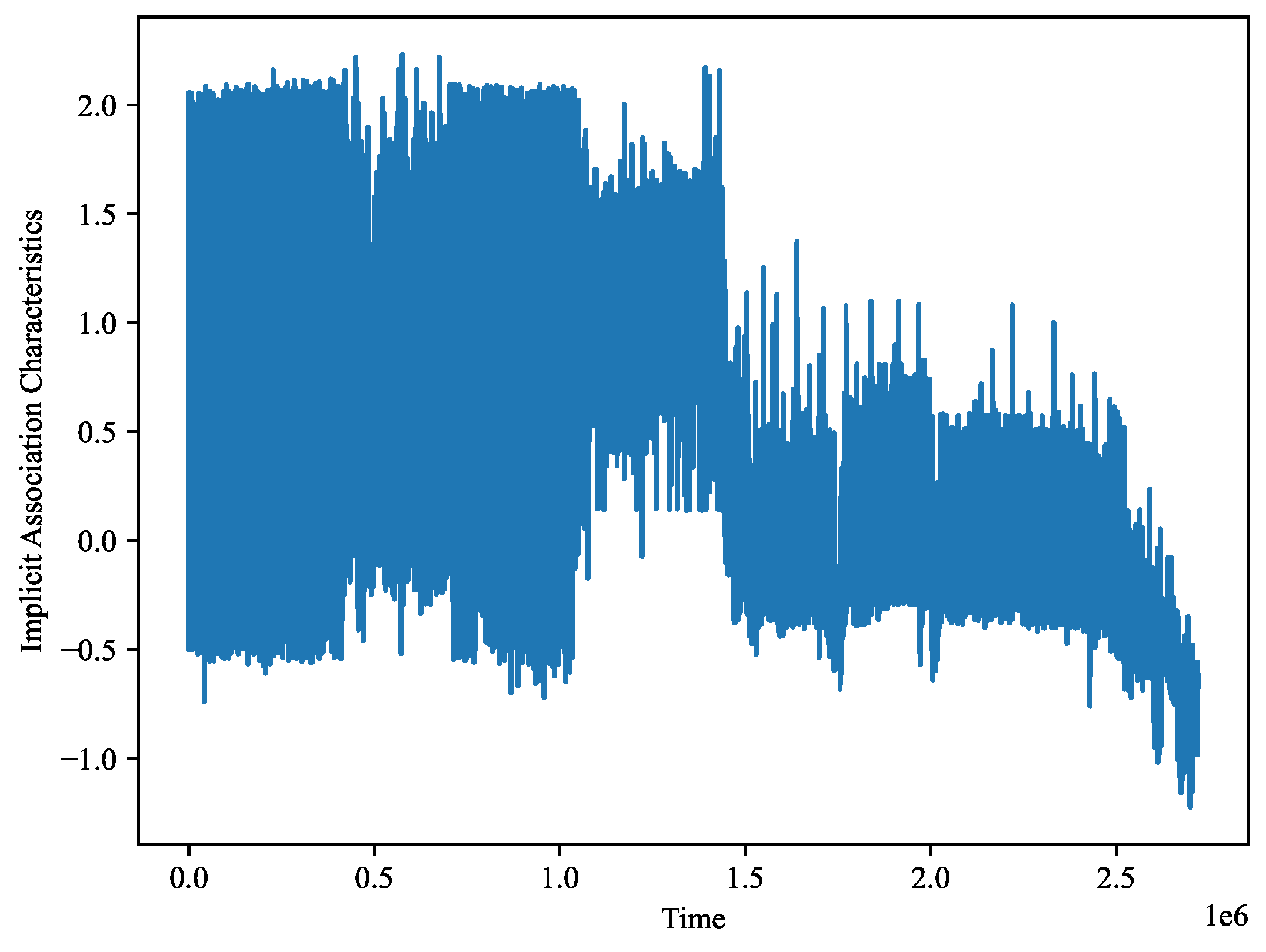

3.3. Implicit Association Characteristics

4. Health Factor Estimation and Performance Degradation Identification

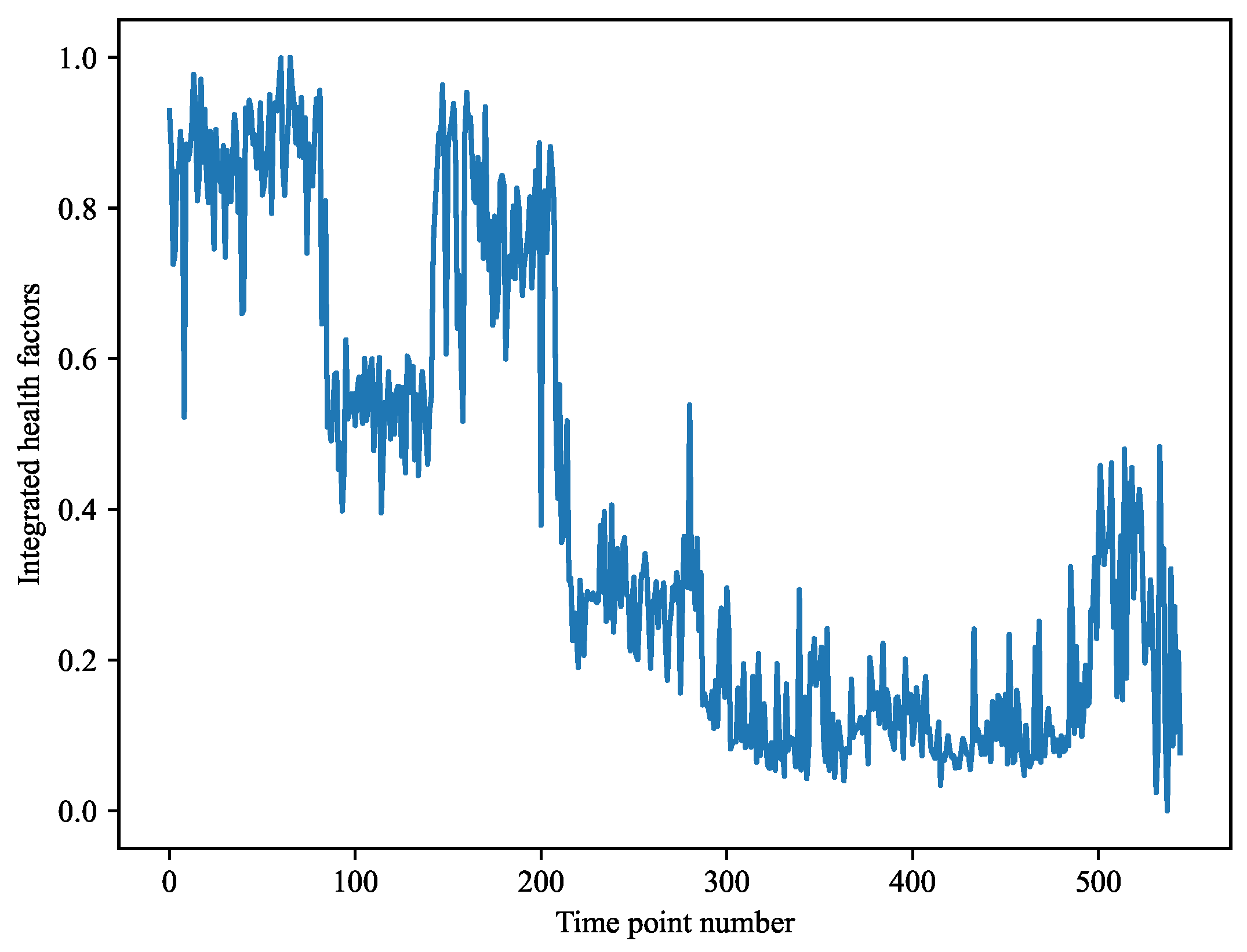

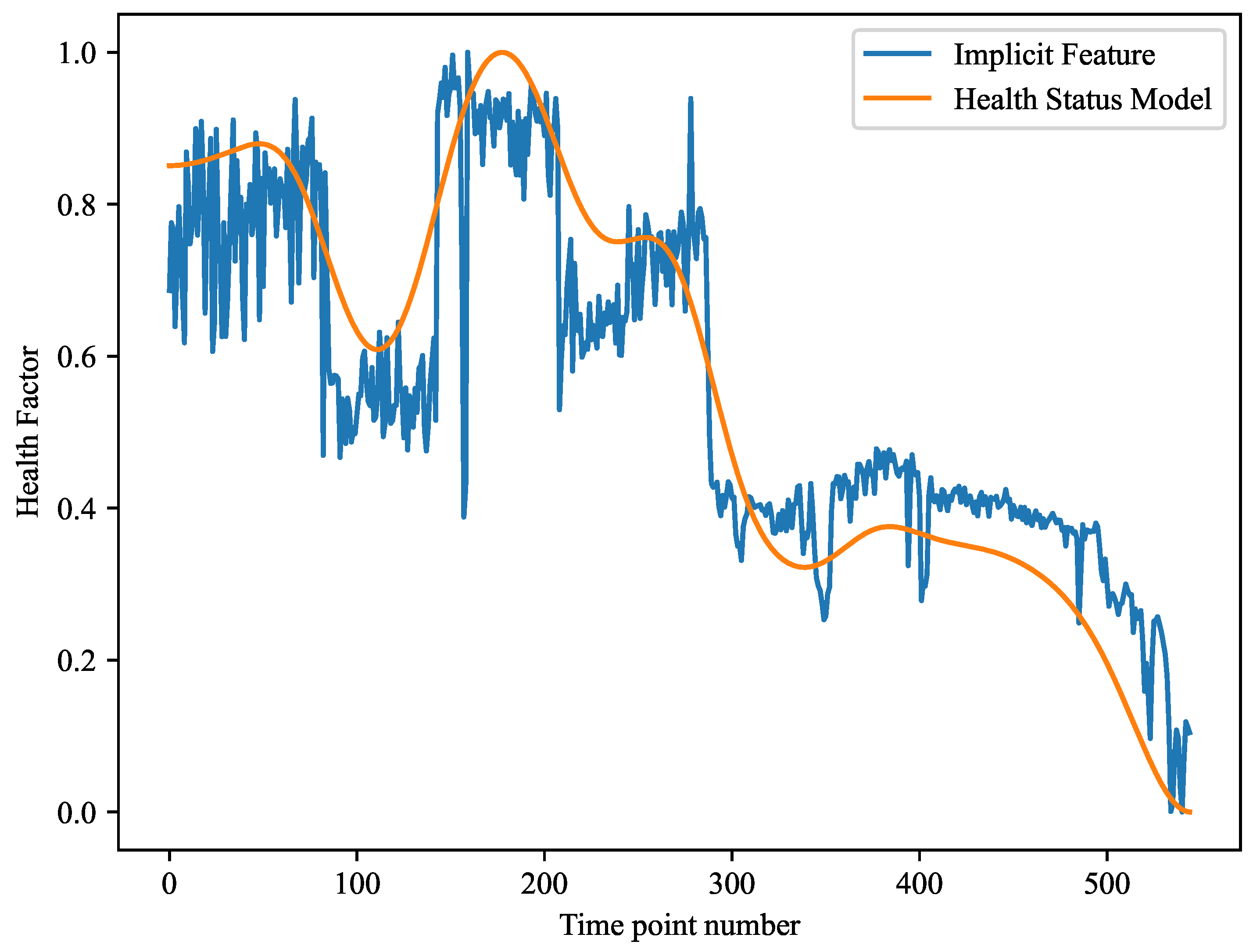

4.1. Health Factor Estimation

4.2. Performance Degradation Identification

5. Health Status Monitoring Method Based on Deep Neural Network

5.1. Health Status Monitoring Model Based on Bi-LSTM

5.2. The Proposed Intelligent Health Status Monitoring Framework

6. Experiment and Results

6.1. Subject (Of an Experiment)

6.2. Data Presentation and Preprocessing

6.3. Experimental Procedure and Analysis of Results

7. Conclusions

- (1)

- In view of the problems of intensive sampling and the large amount of telemetry data of spacecraft in orbit, the method developed in this study can effectively integrate and utilize the massive amount of operation data, fully extract and integrate the explicit and implicit features of the operation data of spacecraft components throughout their whole lifecycle, and synthesize multicharacteristic factors to realize the comprehensive monitoring and assessment of their health status.

- (2)

- To address the difficulty of determining the evolution law of spacecraft performance, the method proposed in this paper can automatically identify the performance degradation stage according to the on-orbit telemetry data, fully consider the evolution mechanism of different degradation stages, greatly simplify the analysis work on the ground, and effectively assist in the intelligent analysis of the on-orbit telemetry data and the identification of performance degradation stages.

- (3)

- Aiming at overcoming the inadequacy of existing spacecraft health monitoring technologies, which are limited to a single threshold, the proposed model fully combines the multidimensional telemetry data and their implied characteristics, reasonably predicts the evolution process of spacecraft component performance degradation, and follows the trend of the health status curve on the basis of the telemetry data to realize effective monitoring and prediction of the health status of the spacecraft components. The validity of the proposed method was verified.

- (4)

- The proposed method has a certain degree of generality and is applicable to key spacecraft electromechanical components such as flywheels and CMGs. However, owing to the differences in the compositions, operating environments, and degradation modes of different components, it is necessary to collect full-lifecycle data and analyze the degradation stages and construct prediction models for different electromechanical components, working conditions, and failure modes using the proposed method to form a single-component health status monitoring model of a spacecraft under specific failure modes, enabling effective ground operations and control management. It should be noted that the current limitations of this study lie in its primary focus on single component prediction for specific failure modes, with room for improvement in transferability and generalization capabilities. Future research may explore integrating physical mechanism models with data-driven methods to establish a hybrid neural network framework. It may hold promise for incorporating domain knowledge and enhancing adaptability to unseen operating conditions or similar components, enabling efficient, transferable health status prediction for a broader range of spacecraft components.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Number | Feature Name | Formula | The Physical Significance of the Features |

|---|---|---|---|

| 1 | Mean Value | Reflect the stable component of the signal | |

| 2 | Rectified Mean Value | Provide some indication of early-stage failures | |

| 3 | Variance | Sensitive to any fault that causes signal changes | |

| 4 | Root Mean Square | Reflect the overall noise level of the mechanical system | |

| 5 | Root Amplitude | Used to distinguish between steady-state faults and transient faults | |

| 6 | Kurtosis | Sensitive to early impact failure characteristics in vibration signals | |

| 7 | Skewness | Sensitive to faults caused by asymmetric impacts such as friction and collisions | |

| 8 | Waveform Factor | Indicate whether mechanical components have experienced wear-related failures | |

| 9 | Peak Factor | Detect impulse components in signals | |

| 10 | Impulse Factor | Sensitive to transient impacts and early failures |

| Number | Feature Name | Formula | The Physical Significance of the Features |

|---|---|---|---|

| 1 | Centre of Gravity Frequency | Sensitive to frequency structure changes caused by faults | |

| 2 | Mean Square Frequency | Highly sensitive to faults triggered by high-frequency resonance or impact | |

| 3 | Root Mean Square Frequency | Same as MSF | |

| 4 | Frequency Variance | Extremely sensitive to impact faults | |

| 5 | Frequency Standard Deviation | Same as VF |

References

- Curzi, G.; Modenini, D.; Tortora, P. Large Constellations of Small Satellites: A Survey of Near Future Challenges and Missions. Aerospace 2020, 7, 133. [Google Scholar] [CrossRef]

- Fang, Z.; Li, W.; Su, L.; Feng, J.K. Prognostics and Health Management Based on Next-Generation Technologies: A Literature Review. Appl. Sci. 2024, 14, 6120. [Google Scholar] [CrossRef]

- Liu, Q. Prediction of the Remaining Life of Satellite Key Components. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2020. [Google Scholar]

- Tang, Y.F.; Dou, L.Q.; Ji, C.H.; Liu, W.J.; Zong, Q. Deep transfer learning-based fault diagnosis of spacecraft attitude system. Aerosp. Control Appl. 2021, 47, 57–63. [Google Scholar]

- Kosova, F.; Altay, Ö.; Ünver, H.Ö. Structural health monitoring in aviation: A comprehensive review and future directions for machine learning. Nondestruct. Test. Eval. 2024, 40, 1–60. [Google Scholar] [CrossRef]

- Ruan, D.W.; Wang, Y.; Qian, Y.L.; Yan, J.P.; Li, Z.R. Deep stacked state-observer based neural network (DSSO-NN): A new network for system dynamics modeling and application in bearing. Adv. Eng. Inform. 2025, 65, 103357. [Google Scholar] [CrossRef]

- Liu, C.; Chen, L.P.; Qu, Y.; Jiang, X.P. Spacecraft health monitoring technology driven by model-data hybrid. Aerosp. Control Appl. 2023, 49, 121–129. [Google Scholar]

- Veresnikov, G.S.; Bazhenov, S.G.; Bashkirov, I.G.; Chernyshev, S.L.; Goncharenko, V.I.; Skryabin, A.V.; Petrov, D.A. Machine learning-based synthesis of diagnostic algorithms for electromechanical actuators to improve the aerospace flight safety. Acta Astronaut. 2025, 226, 239–247. [Google Scholar] [CrossRef]

- Deng, L.F.; Li, W.; Yan, X.H. An intelligent hybrid deep learning model for rolling bearing remaining useful life prediction. Nondestruct. Test. Eval. 2024, 40, 2670–2697. [Google Scholar] [CrossRef]

- Shao, H.D.; Ming, Y.H.; Liu, Y.Y.; Liu, B. Small sample gearbox fault diagnosis based on improved deep forest in noisy environments. Nondestruct. Test. Eval. 2024, 40, 3935–3956. [Google Scholar] [CrossRef]

- You, K.S.; Lian, Z.W.; Chen, R.H.; Gu, Y.K. A novel rolling bearing fault diagnosis method based on time-series fusion transformer with interpretability analysis. Nondestruct. Test. Eval. 2024, 1–27. [Google Scholar] [CrossRef]

- Yang, T.Z.; Dang, J.C.; Zhong, L.; Liu, Y.; Liu, Y.Y. Health assessment technology of lithium-ion battery for spacecraft based on multi-feature fusion. Chin. Space Sci. Technol. 2021, 41, 79–84. [Google Scholar]

- Zhang, F.S.; Zhao, Y.; Zhang, S.M.; Wu, W.T.; Tan, C. Spacecraft Equipment Health Condition Monitoring Based on Augmented Dickey-Fuller Test and Gaussian Mixture Model. In Proceedings of the 2021 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 8–11 August 2021; pp. 1379–1384. [Google Scholar]

- Pang, J.Y.; Liu, D.T.; Peng, Y.; Peng, X.Y. Temporal dependence Mahalanobis distance for anomaly detection in multivariate spacecraft telemetry series. ISA Trans. 2023, 140, 354–367. [Google Scholar] [CrossRef]

- Tang, X.Y.; Jiang, D.Z.; Guo, B.T. Spacecraft hitch detection and health evaluation based on Multivariable Time Series. In Proceedings of the 2022 2nd International Conference on Measurement Control and Instrumentation (MCAI 2022), Guangzhou, China, 22–24 July 2022; p. 2366. [Google Scholar]

- Yash, P.; Gundawar, S.; Kumar, N.; Rajasekaraiah, U.B.; Ganesan, K.P.; Kar, P. Multiforecast-based Early Anomaly Detection for Spacecraft Health Monitoring. In Proceedings of the 7th Joint International Conference on Data Science & Management of Data (11th ACM IKDD CODS and 29th COMAD), New York, NY, USA, 4–7 January 2024; pp. 275–283. [Google Scholar]

- Cuéllar, S.; Santos, M.; Alonso, F.; Fabregas, E.; Farias, G. Explainable anomaly detection in spacecraft telemetry. Eng. Appl. Artif. Intell. 2024, 133, 108083. [Google Scholar] [CrossRef]

- Gu, X.Y. Research on Satellite Telemetry Data Prediction Based on ARIMA-SVR Combination Model. Master’s Thesis, University of Chinese Academy of Sciences, Beijing, China, 2021. [Google Scholar]

- Kumar, P.S.; Oruganti, S.K. Review of GNSS Scintillation Detection Methods with Emphasis on Low-Latitude and Indian Region Challenges. SGS-Eng. Sci. 2025, 1. Available online: https://spast.org/techrep/article/view/5657 (accessed on 19 October 2025).

- Ruan, D.W.; Ma, L.; Yang, Y.Y.; Yan, J.P.; Gühmann, C. Improvement by Monte Carlo for Trajectory Similarity-Based RUL Prediction. IEEE Trans. Instrum. Meas. 2024, 73, 3509811. [Google Scholar] [CrossRef]

- Hou, B.W.; Wang, J.Q.; Zhou, X.Y.; Li, D.; He, Z.M. Analysis on Performance of Ballistic Tracking Data Outlier Elimination Methods. Aerosp. Shanghai 2018, 35, 10. [Google Scholar]

- Berahmand, K.; Daneshfar, F.; Salehi, E.S.; Li, Y.F.; Xu, Y. Autoencoders and their applications in machine learning: A survey. Artif. Intell. Rev. 2024, 57, 28. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, A.; Mallipeddi, R.; Lee, D.G. High-density cluster core-based k-means clustering with an unknown number of clusters. Appl. Soft Comput. 2024, 155, 111419. [Google Scholar] [CrossRef]

- Gao, D.W.; Zhu, Y.S.; Ren, Z.J.; Yan, K.; Kang, W. A novel weak fault diagnosis method for rolling bearings based on LSTM considering quasi-periodicity. Knowl.-Based Syst. 2021, 231, 107413. [Google Scholar] [CrossRef]

- Shi, J.C.; Peng, D.K.; Peng, Z.X.; Zhang, Z.Y.; Goebel, K.; Wu, D.Z. Planetary gearbox fault diagnosis using bidirectional-convolutional LSTM networks. Mech. Syst. Signal Process. 2022, 162, 107996. [Google Scholar] [CrossRef]

- Peng, Y.; Jia, S.Z.; Xie, L.Z.; Shang, J. Accurate Satellite Operation Predictions Using Attention-BiLSTM Model with Telemetry Correlation. Aerospace 2024, 11, 398. [Google Scholar] [CrossRef]

- Zhang, K.; Ma, Z. Prediction of performance degradation of high-speed rotor shafting of control moment gyro based on support vector regression mechanism. Satell. Netw. 2021, 8, 70–74. [Google Scholar]

- Farahani, H.V.; Rahimi, A. Fault Diagnosis of Control Moment Gyroscope Using Optimized Support Vector Machine. In Proceedings of the 2020 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Toronto, ON, Canada, 11–14 October 2020; pp. 3111–3116. [Google Scholar]

- Rakhmanov, A.; Wiseman, Y. Compression of GNSS data with the aim of speeding up communication to autonomous vehicles. Remote Sens. 2023, 15, 2165. [Google Scholar] [CrossRef]

| Number of Layers | Input Data Dimension | Output Data Dimension | Activation Function |

|---|---|---|---|

| Encoder layer 1 | D | 64 | ReLU |

| Encoder layer 2 | 64 | 32 | ReLU |

| Encoder layer 3 | 32 | 2 | / |

| Decoder layer 1 | 2 | 32 | ReLU |

| Decoder layer 2 | 32 | 64 | ReLU |

| Decoder layer 3 | 64 | D | Sigmoid |

| Prediction Stage | Number of LSTM Cells | Number of Layers | Predicted Data Size | Epoch | Learning Rate |

|---|---|---|---|---|---|

| Slow degradation stage | 9 | 2 | 273 × 1 | 1000 | 0.005 |

| Rapid degradation stage | 98 | 1 | 272 × 1 | 1000 | 0.01 |

| Prediction Method | MSE | RMSE | |

|---|---|---|---|

| GRU | 0.000371 | 0.019250 | 0.995110 |

| LSTM | 0.002197 | 0.046871 | 0.971011 |

| The Proposed Method | 0.000029 | 0.005428 | 0.999611 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, H.; Liu, C.; Liu, W.; Li, W.; Zhang, Y. Spacecraft Health Status Monitoring Method Based on Multidimensional Data Fusion. Machines 2025, 13, 1136. https://doi.org/10.3390/machines13121136

Liang H, Liu C, Liu W, Li W, Zhang Y. Spacecraft Health Status Monitoring Method Based on Multidimensional Data Fusion. Machines. 2025; 13(12):1136. https://doi.org/10.3390/machines13121136

Chicago/Turabian StyleLiang, Hanyu, Chengrui Liu, Wenjing Liu, Wenbo Li, and Yan Zhang. 2025. "Spacecraft Health Status Monitoring Method Based on Multidimensional Data Fusion" Machines 13, no. 12: 1136. https://doi.org/10.3390/machines13121136

APA StyleLiang, H., Liu, C., Liu, W., Li, W., & Zhang, Y. (2025). Spacecraft Health Status Monitoring Method Based on Multidimensional Data Fusion. Machines, 13(12), 1136. https://doi.org/10.3390/machines13121136