1. Introduction

The possibility that fractured quartz turns into cristobalite and tridymite poses serious problems in the safe management of industrial milling. In the last twenty years, numerous laboratories have sprung up all over the world conducting experiments on rocks in the conditions of friction typical of technologies utilized in rock grinding. To a large extent, these experiments are carried out trying to correlate the friction coefficient with stress (tangential and normal), the speed and the spaces covered by the simulated fault [

1,

2]. At the same time, attention has grown towards the “dynamometamorphic” phenomena suffered by rocks and linked to stress: heating, gas dissociation, partial or total melting of the friction layers. In the recent past, several working groups have focused their attention on the role of quartz in the sliding phenomena of rocks, and the idea is that the heating of the contact surface by friction produces a partial melting of the material, the formation of a silica layer amorphous which is quickly hydrated by ambient moisture, which thus becomes a lubricating gel that drastically reduces the friction coefficient of the defects [

3,

4]. In a recent publication, we formulated another hypothesis to explain the lowering of the coefficient of friction in experiments on quartz-containing rocks. This hypothesis is based on the progressive formation of nanocrystalline cristobalite, which works as a solid lubricant [

5,

6]. The silica polymorph called cristobalite has the particularity of being an auxetic material, i.e., with a negative Poisson ratio, both in the form of low temperature (alpha) and in that of high temperature (beta). If a layer of cristobalite is found in shear conditions, it can reduce its contact area as a result of the volume contraction and equally reduces the friction coefficient.

The hypothesis is that quartz, subjected to a prolonged reticular distortion over time, tends to take on a structure with ever greater disturbance, but formed by cristobalite nanophases. This phase would be nanocrystalline, not visible by X diffraction but visible by Raman spectroscopy. The accumulation of this phase in the interface between the sliding surfaces would cause the friction coefficient to decay more or less rapidly, depending on the intensity of the dynamometamorphic action [

6]. Furthermore, quartz’s structural decay is marked by the decay of the electromagnetic signals generated by its fracturing, which diminishes over time as fracturing and damage of the original crystalline structure proceed [

5,

6]. A key element is missing in this theory: how and when the patina of cristobalite is generated. The purpose of present work is to contribute to a better understanding of the processes related to quartz tribochemistry.

2. Experimental Procedure

The task of this experimental work is to understand the mechanisms that link the progressive demolition of the crystal structure of quartz and the appearance of polymorphic phases during the application of sliding stresses. In two previous works [

5,

6], the authors of this work reported details on the polymorphic phases of silica that are formed during fracturing and on the correlations between fractures and the amount of very low frequency electromagnetic energy emitted by the crystals during the fracturing.

An innovative “piston cylinder” was used to carry out these studies. It is equipped with two steel pistons which compress the sample and which represent the armatures of a condenser, equipped with an insulating Teflon jacket, which allows the containment of the material. Thanks to Teflon, the pressure distribution exerted is anisotropic, and this is due to the materials that make up the cell itself. The materials that exert the pressure (stainless steel) and the containment material (Teflon) are different in terms of elasticity, coefficient of Poisson and compressive strength. This determines a condition of anisotropy in the exercise of compression: the mineral is not subjected to equal stresses in all directions, but greater according to the direction of the piston and less in the directions perpendicular to it. This anisotropy allows one to create a fracturing system by shear, which generates fractures favoring the development of a network of microcracks. The entire piston cylinder is first evacuated and subsequently subjected to an analytical grade nitrogen flow to ensure an anhydrous atmosphere. The system was created taking into account similar systems published in the past by various authors [

7,

8,

9,

10]. The pressure is applied through a motorized hydraulic press, which develops a maximum load of 4.9 kN.

The quartz-α samples come from natural quartz crystals, purchased at Ward (Ward, West Henrietta, NY, USA;

www.wardsci.com), previously analyzed in optical microscopy to detect any defects, such as inclusions and fractures. The crystals were chosen in the weight range from 0.05 to 1.5 g. Each test generated powders and fragments that were analyzed for shape, size, area and volume, through the new Morphology G3ID image analysis system (Malvern, UK) based on optical scanning microscopy. The automated scanning system allows one to measure and analyze about 1 million particles per hour and to know the values of the perimeter, area and volume of each particle, from 300 μm to 1 μm. This scanning microscope has already been used previously by the authors for investigations on asbestos fibers in soils and recently on quartz crystals [

5,

6]. To determine the morphologies, the particles are dispersed on the surface of the optical plate. Scanning takes place at constant magnification on all particles following an

x-y scanning mechanism; the depth of the particles is reconstructed through the “

z-stacking” mechanism that allows one to shoot the same image of the particle on different focal planes.

In this work, we used the data of the optical scan to estimate the quantities of “new” surfaces generated by the fracture, the statistics on morphologies (equivalent diameter, area for every particle). These data were compared to the entity of the stress rate. The calculation of the real volume deserves special mention. The instrument software measures the volume by the diameter equivalent to the sphere (SE Volume), but this value is very far from reality. Therefore, we used an algorithm that is based on the measurement of the attenuation of the intensity of light transmitted by the particle. For non-scattering media, the Beer–Lambert law (BL, or absorption law) is well recognized to describe the relationship between transmittance and sample thickness as:

where

T is the transmittance,

d is the sample thickness, and

μa is the absorption coefficient (cm

−1). This expression is based on the random nature of stochastic light absorption, characterized by the rate constant

μa. Since the transmitted light intensity is measured for each particle, and since we are always in the presence of quartz, which has an absorption coefficient from 664 cm

−1 at 450 nm to 312 cm

−1 at 650 nm [

10], the thickness “

d” can be derived for all particles.

Figure 1A shows the effect of fracturing on quartz grains; the images have been modified after Zhao, B. et al. [

11]. On the left, we can see the two-dimensional projection of the particles obtained from the compression fracturing of a quartz grain. The perimeter of the granule, obtained from the two-dimensional projection, is expressed in green. The perimeters of the projections of the individual particles obtained from the fracturing are indicated in red. In

Figure 1B, images of the original crystal, a tip weighing 207 mg and some of the particles obtained from the fracturing can be observed.

The surfaces of the “internal” granules are, in fact, the new fracture surfaces, created when the imposed stress exceeds the critical stress level. The sum of the surfaces of the particles will be equivalent to the sum of the new surfaces created by the fractures, Stot, plus the original surface. In this way, it is possible to calculate the total area created by the fractures. By extrapolating this concept, it is also possible to calculate the total length of the fractures. The total perimeter of all particles is correlated with the total length of the fractures, minus the original perimeter of the crystal and the loss of data due to the two-dimensional transposition of the three-dimensional particles. The latter error is reduced if the particles analyzed by microscopy are in very large numbers. For this reason, the analyses in morphology must be carried out on a high number of particles, usually above 100,000 particles.

In order to determine the nature of silica polymorphs, a Raman microprobe inserted in the Morphology G3ID was used, which uses a 785 nm laser with a spot of 2 microns in diameter. The Raman laser power is 40 mW.

To determine the stress to which the crystal is subjected, a measurement method was developed using the image of the shattered crystal printed on a pressure sensitive film (Pressurex Inc., Madison, NJ, USA;

www.sensorprod.com). These films have an ink layer that produces a color, and the intensity of which is proportional to pressure.

Figure 2 shows the pressure marks left on the film by different quartz crystals

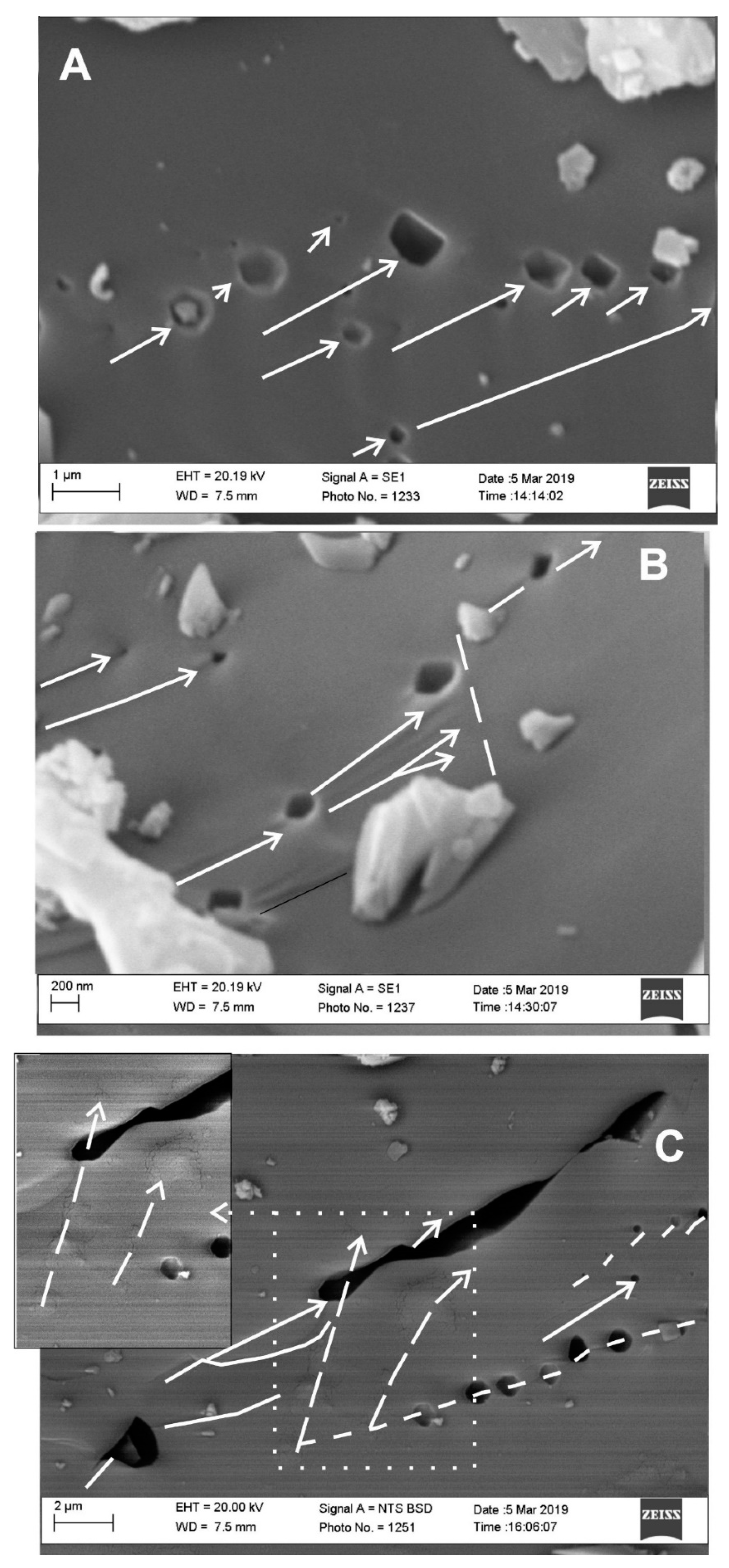

Finally, we used scanning electron microscopy to determine the microscopic characteristics of fractures at different stress levels (Zeiss EVO MA10, Zeiss Gmbh, Ulm, Germany). The samples to be analyzed in the SEM were left in their original condition, without cleaning, since debris on the surfaces of the granules can provide important information.

4. Discussion of Data

The data obtained in this study should be seen in the light of the most recent literature on the effects of shear stress on alpha quartz, literature to which the authors have also contributed [

5,

6]. The fractures we have observed show an evolution which, we believe, depends substantially on the stress rate rather than on the pressure itself. In fact, we have verified that even a pressure of 50 MPa, supplied in times exceeding one minute, generates a more intense fragmentation than a pressure of 100 MPa supplied in times of a few tens of seconds. The most relevant phenomena observed on quartz granules that have undergone increasing stress are as follows:

Formation of craters with euhedral shape at the apex of the fracture;

Coalescence of the craters to form open fractures;

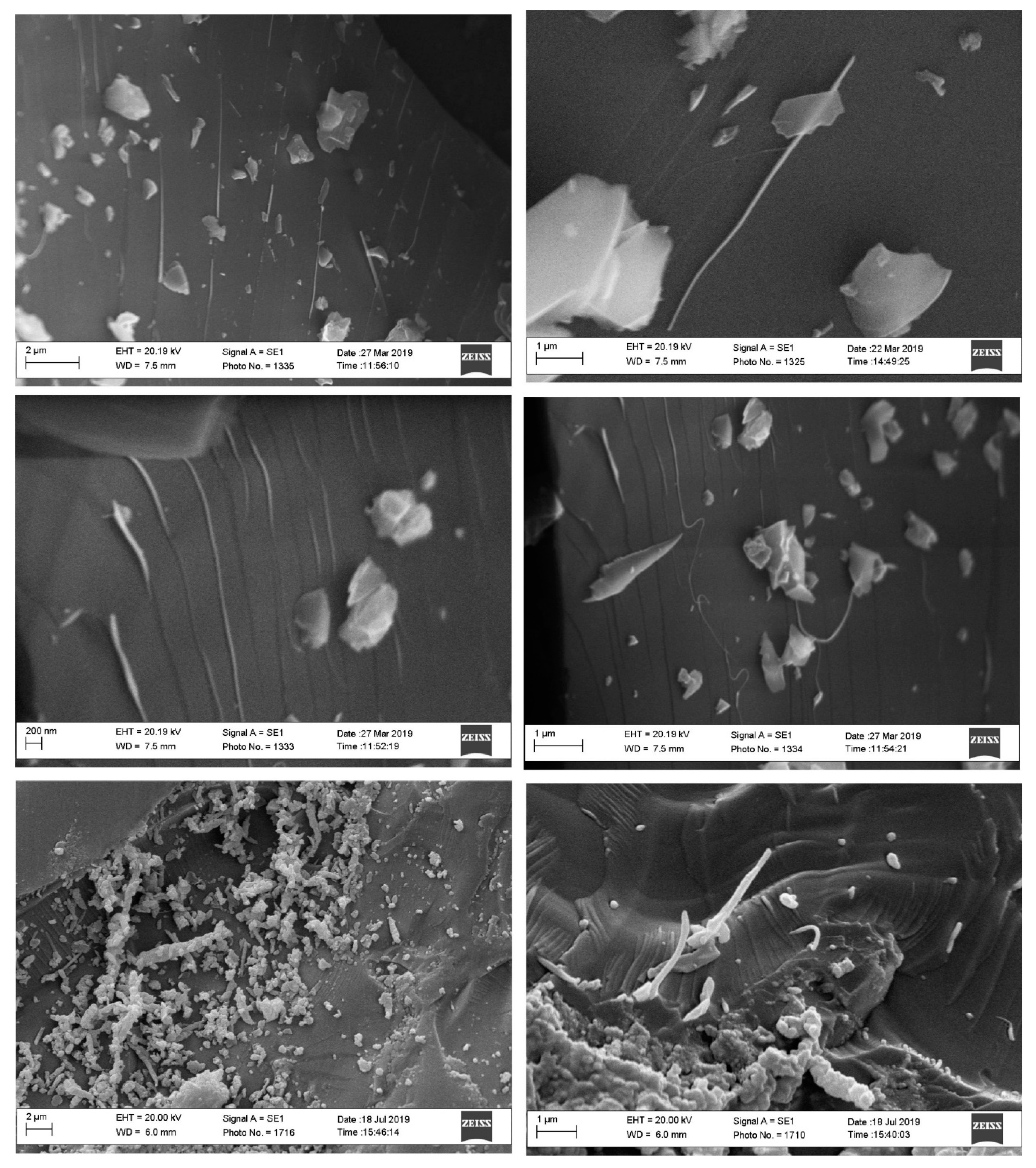

Detachment of apparently amorphous siliceous material, fibrous in shape from the ridges and traces of fractures;

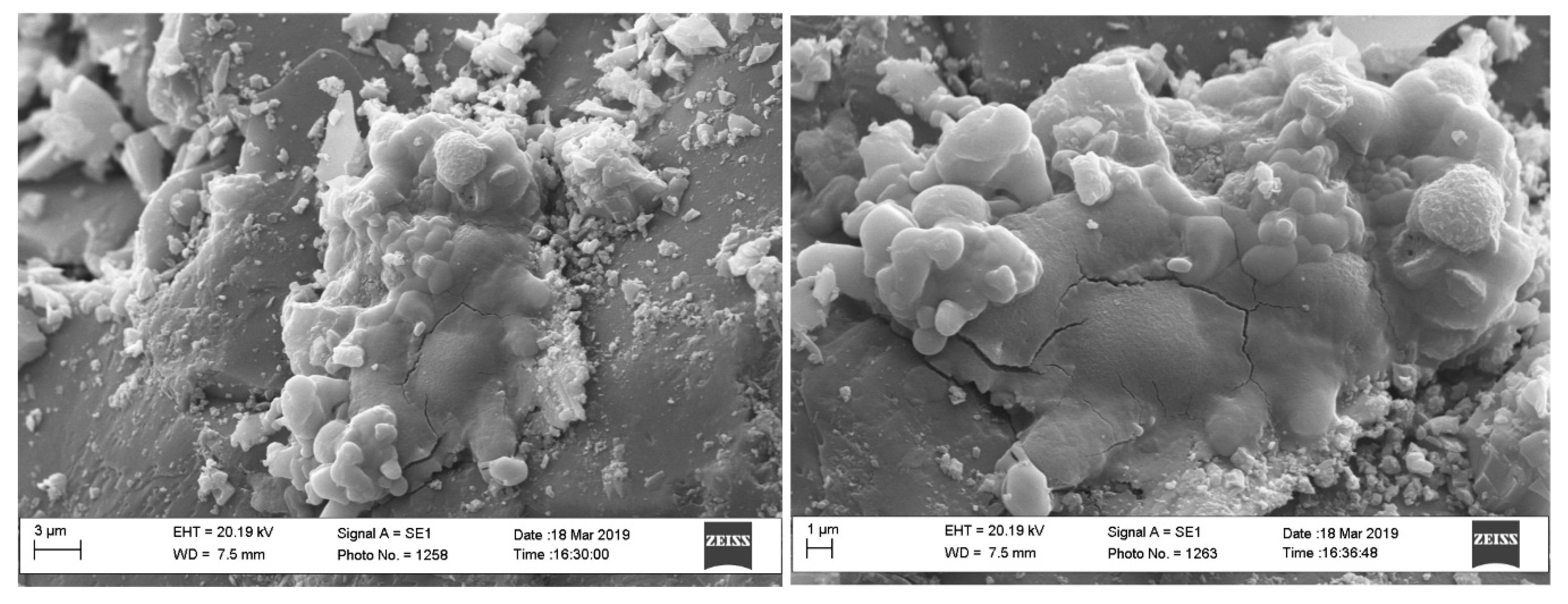

Bubble formation on the surface, some of which show amorphous silica extrusions;

Formation of craters on the surface from which amorphous silica is expelled;

Formation of secondary quartz crystallizations, which radiate from “emission” points, such as craters and open fractures.

From

Figure 4 it can be observed that the fracture length increases exponentially with the increase in the stress rate. This is reasonable, since the total length is related to the number of particles and this to the number of bifurcations of the cracks that are generated during the breaking of the quartz crystals. Cracks that reach critical speed tend to divide into two cracks (bifurcations) with an acute angle between them, as demonstrated by Tromans and Meech [

13,

14,

15]. Consequently, if the stress velocity is greater, the cracks’ opening speed will also be greater, and this will produce more fractures and a greater number of particles.

In

Figure 6, the ridges indicate the presence of fractures under the surface. The crests indicate an increase in volume propagated linearly along the fractures. The fractures separate into two sections with an acute angle of 27°. As is known, the angle of forking varies with the stress state. In particular, the bifurcation angle indicates the relationship between shear stress and normal stress

τ/σn. An angle of 27° corresponds to a ratio from −0.3 to −0.5, which essentially indicates a bending stress (Richter, 2003) [

16]. Both the total length of the fractures and the amplitude of the bifurcation angle are parameters to be framed in a wider context of energy analysis of the fracturing phenomenon, for which the reader is referred to the cited bibliography. In this context, it is sufficient to remember that the fracture length is connected with the fracturing speed [

13,

14,

15]. The cited authors calculate that in alpha quartz, the fractures split in two when the propagation speed reaches the

climit (limit speed of 1990 m/s). At that moment, the ratio between the size of the new fracture,

ai and the initial size,

a, is equal to 2, and the speeds of the two daughter fractures is reduced to 30–50% of

climit. The two fractures thus formed increase their speed and must again fork when they reach

climit and at an

ai/a ratio of 4, according to relation:

It is important to note that an increase in the propagation speed leads to a higher frequency of bifurcations and therefore to a greater fragmentation. This is confirmed by the observations made with the analysis of the morphological image of the particles, where it is evident that a higher stress rate increases the number of particles and the total fracture length (

Figure 4). It is noteworthy that the propagation of fractures in the minerals causes an accumulation of deformation energy, and this energy must dissipate; in mineral mechanics, the ways of disposing of the plastic deformation energy are essentially two: the bifurcation of fractures and, above all, the increase in temperatures in the deformation areas at the fracture tip [

17,

18].

The formation of the craters visible in

Figure 7A–C is consequential to the propagation of fractures. In

Figure 7A,B it is observed that the fractures end with a regular-shaped crater, often mimicking a crystalline form with five to six faces. The volume of matter removed from these craters seems independent of the visible (or superficial) length of the fractures. We believe that the loss of fragments of material with crystalline forms is linked to the presence of fracture lines already existing in the crystal, parallel to crystallographic directions. The reader should also note the correspondence between the apex of the fracture and the corresponding crater. We believe this is due to the undermining of the material by the wave at ultrasonic speed connected to the propagation of the fractures.

Figure 7C shows the presence of surface bubbles that show cracks of about 40 nm width and lengths of about 1 μm. The bubbles also appear aligned, according to directions that lie at 60° with respect to the fractures. We believe that these bubbles are the superficial manifestation of the melting effect at ultrasonic speed that occurs inside the quartz grains during the crack propagation and which produces most of the phenomena we are describing. The same phenomenon is responsible for the formation of the craters aligned with the amorphous silica extrusions, visible in

Figure 8, the silica extrusions in

Figure 9, the recrystallized quartz from silica extrusion in

Figure 10 and, finally, the filamentous fibers in

Figure 11 that are, perhaps, the most interesting part of the discoveries made in this work. The Raman analysis performed on the silica fibers associated with the fractures shows that this silica is organized in the form of α-cristobalite and tridymite (

Figure 12). The presence of cristobalite had already been highlighted by the authors of this work [

5,

6], where the structural changes of quartz in nanocrystalline cristobalite were described when alpha quartz was subjected to shear stresses. In the aforementioned work, we have shown that the action of prolonged shear stress on the quartz crystals determines a reticular distortion so large as to lead the quartz itself to an amorphization; in this “amorphous silica”, the radial distribution function analysis (RDF) has highlighted the formation of short-term clusters with a six-tetrahedron organization, similar to cristobalite and tridymite and no longer to four tetrahedrons [

6]. It has also been shown that, if these amorphous phases are brought to 1200 °C, they tend to transform nano-cristobalite into a well-crystallized cristobalite, well visible in X-ray diffraction analysis [

6]. The same association of minerals had been reported in a paper of Brodie and Rutter (2000) on quartz samples subjected first to tensile stress and then to heating at 1200 °C [

17].

To explain the data collected, we hypothesized a mechanism that can materialize thanks to the speed of propagation of the fractures. The heart of the mechanism is tensile stress, which induces the opening of a large number of fractures in the quartz volume. Fracture propagation occurs at an estimated speed between 50% and 60% of the shear wave, therefore between 650 and 1000 m/s, and for this reason we can speak of ultrasonic speed. At these speeds, the fractures tend to fork after just 25–30 μm, and the crack tip transit times are therefore in the order of 30 ÷ 50ns. In such a short fraction of time, the amount of heat produced by the passage of the crack tip cannot have transferred to the volume outside the fracture. Weichert had already measured temperatures above 2000 K on the fractured quartz, and this has been confirmed by other authors [

18,

19]. These temperature increases generate channels of fused silica, which has a decidedly lower density than quartz (2.2 g/cm

3 against 2.65 g/cm

3). The decrease in density causes an immediate expansion in volume which causes surface fracturing. In actual fact, we can say that during the melting, the molar volume increases from 22.688 cm

3/mol to 27.20 cm

3/mol, with an expansion of 16.5% [

19], more than enough to open the surface over the crack and bring out the fused and clotted silica filament that is inside it.

The events we have described are summarized in the diagrams in

Figure 13. In the first one, we observe the simulation of the silica filaments growth, starting from the fractures;

Figure 13B shows the formation of fractures ending with the euhedral craters and the formation of bullous-shaped growths.

Figure 13C shows the pattern of crater formation (“hot spot”) and silica protrusion from subsurface melted areas. Our data demonstrate that the friction action applied to quartz in totally anhydrous conditions leads to the formation of amorphous silica, which quickly organizes itself into nanostructures of cristobalite and tridymite [

5,

6]. Cristobalite has a structure consisting of rings with 6 tetrahedra, with structural arrangements that show an auxetic behavior, that is, with a negative Poisson’s ratio [

20,

21] (

Table 1). This means that a tangential compression produces a reduction in length in the normal direction and not an expansion, as expected from solids with a positive Poisson’s ratio. The effect is particularly felt by the alpha cristobalite, whose Poisson ratio reaches the considerable negative value of −0.169. In practice, if the tangential contraction is 100 mm, the normal contraction will be 16.9 mm; this reduces the contact surface and correspondingly reduces its friction. It should also be taken into account that the phenomena whose generation we have verified are extremely fast, because they occur in the time interval that elapses during the final phase of propagation of the fractures. The speed of these contractions is linked to the propagation speed of the ultrasonic wave.

If the application of stress is continuous, there is an accumulation of amorphous silica that quickly transforms into cristobalite and tridymite near the fracture and sliding areas. The mechanisms described also explain the so-called “flash melting” which is observed by numerous authors in the shear stress tests on quartz and, above all, the sudden drop in the coefficient of friction that all the authors observe when the quartz is subjected to severe friction conditions [

1]. Various authors support the thesis that the friction, exerted on quartz-rich rocks, generates a sort of silica gel lubricating film, an amorphous material rich in water, deriving from the environment where the test takes place. The concept of the lubricating gel is also taken up by [

4], who had detected the presence of amorphous silica in the flow tracks of experiments by means of tribometric rotating friction apparatuses, such as the “pin-on-disk” on quartz [

3,

4]. Authors detected, via Raman spectroscopy, the peaks attributable to moganite (metastable phase of silica, quickly converted into cristobalite and tridymite) and to amorphous silica, as well as reticular distortions of alpha quartz. In addition, the authors showed spectra in FTIR microspectrophotometry to prove the presence of water in the amorphous silica of these traces of flow. The results obtained, albeit preliminary, do appear interesting. In particular, the fact that amorphous silica has hydrated with atmospheric humidity is possible, but it does not prove that it is the means of sliding the faults that insist on quartz-based rocks. In our tests, carried out under anhydrous conditions, there can be no water presence, but the same amorphous silica and cristobalite and nanocrystalline tridymite are formed, which, as we have said, have the characteristic of reacting to efforts by decreasing the contact area, with relative reduction of the friction coefficient. At the end of this long discussion of data, we would like to summarize the events that, in our opinion, characterize the transformation of quartz into a low friction coefficient material:

the tensile stress field generates fractures that open quickly, spreading over the entire volume of the area subjected to shear stress;

the propagation of the fractures generates the local melting of the quartz, producing the formation of amorphous silica, whose density is lower than that of the quartz; the difference in density and thermal expansion causes the fracture of the surfaces and the dispersion of the silica, which quickly solidifies in the form of nanocrystalline cristobalite (which has a marked auxetic behavior) and sometimes tridymite;

the accumulation of these polymorphs in the rock volumes subject to greater stress leads to a progressive reduction of friction and, easily, to the triggering of the movement.

In none of these events is the presence of water necessary.