Cost-Factor Recognition and Recommendation in Open-Pit Coal Mining via BERT-BiLSTM-CRF and Knowledge Graphs

Abstract

1. Introduction

- A high-precision entity recognition method based on BERT-BiLSTM-CRF for named entity recognition in the cost domain of open-pit coal mining was proposed.

- A knowledge graph-driven cost factor identification framework was established, which analyzes multi-level cascading influences through entity relationship path mining.

- The foundation of cascading relationship inference for cost factors is clarified through an attention weight network, and the relationship weight matrix is used to enhance the interpretability of cost fluctuation attribution.

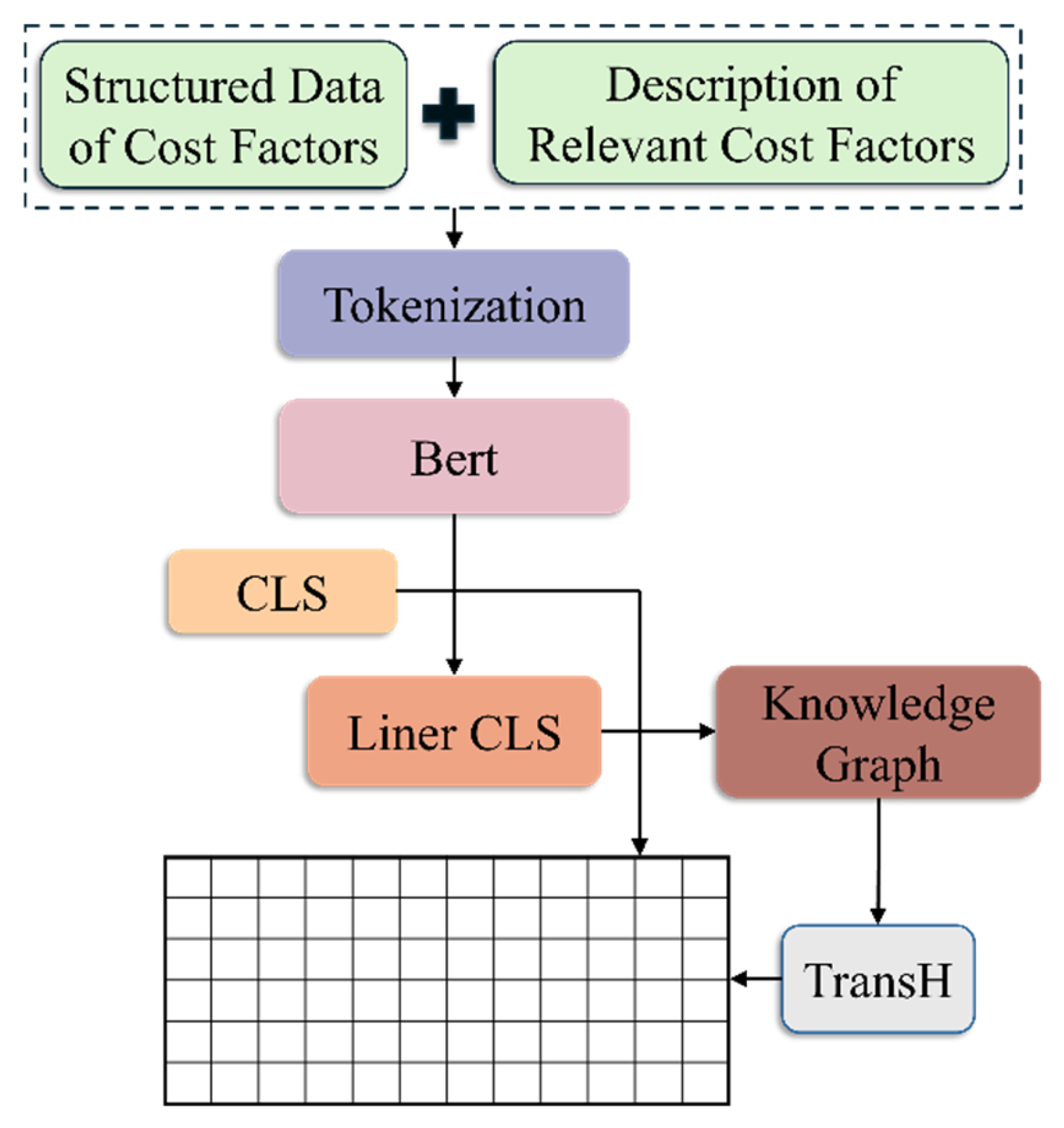

2. Methodology

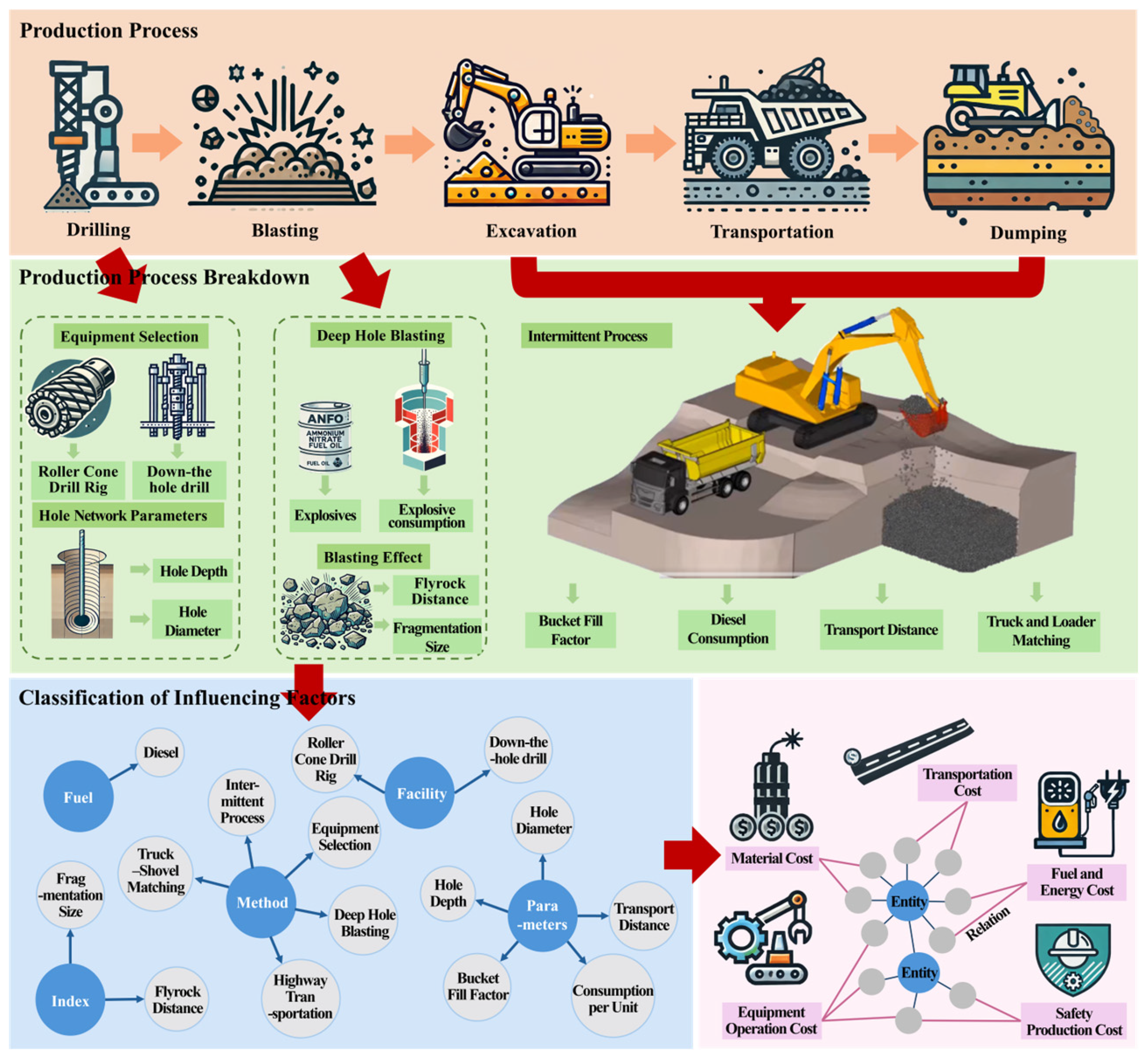

2.1. Research Process

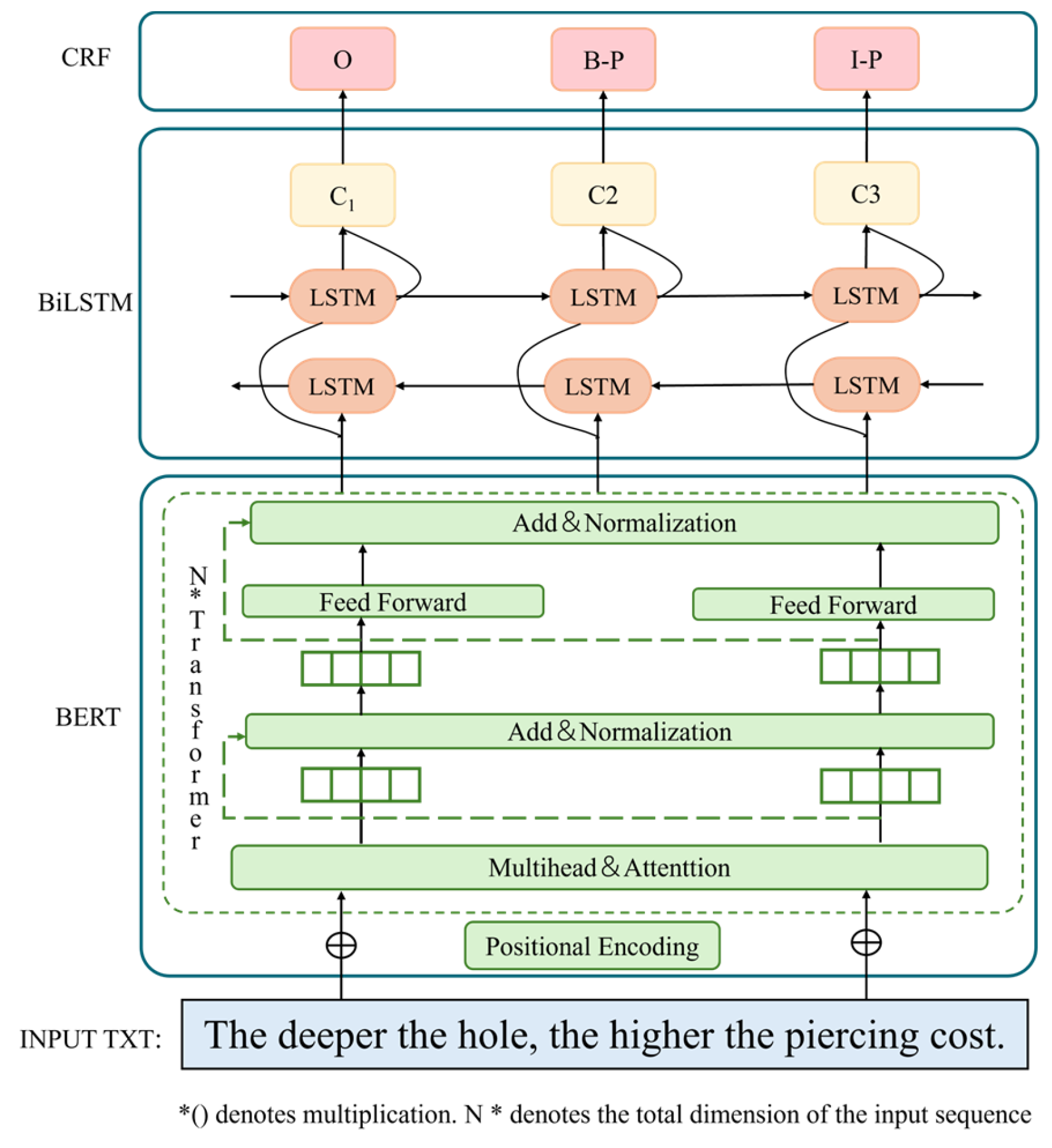

2.2. BERT-BiLSTM-CRF Model

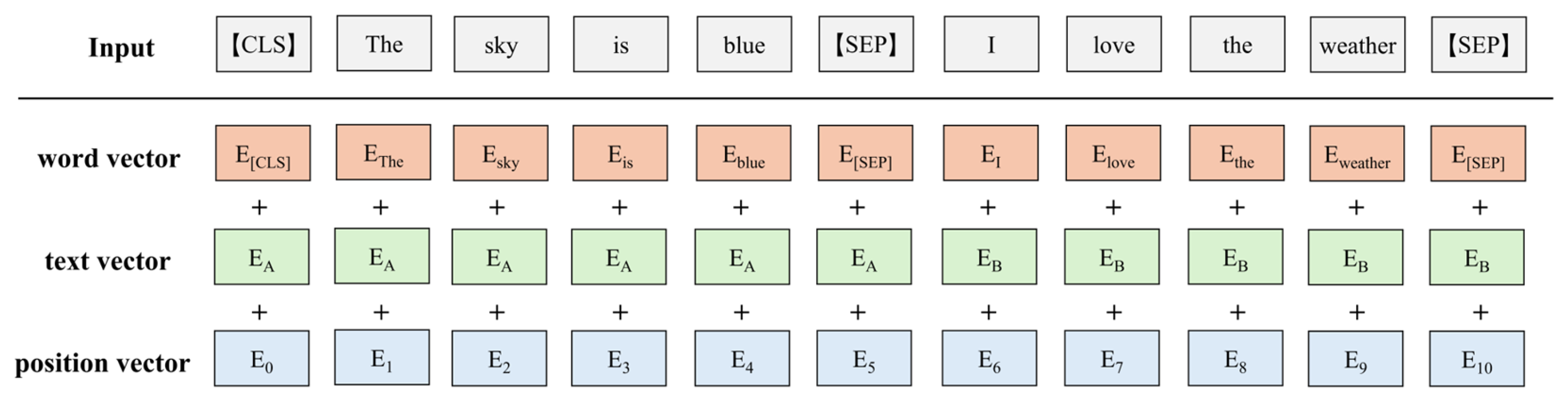

2.2.1. BERT Model

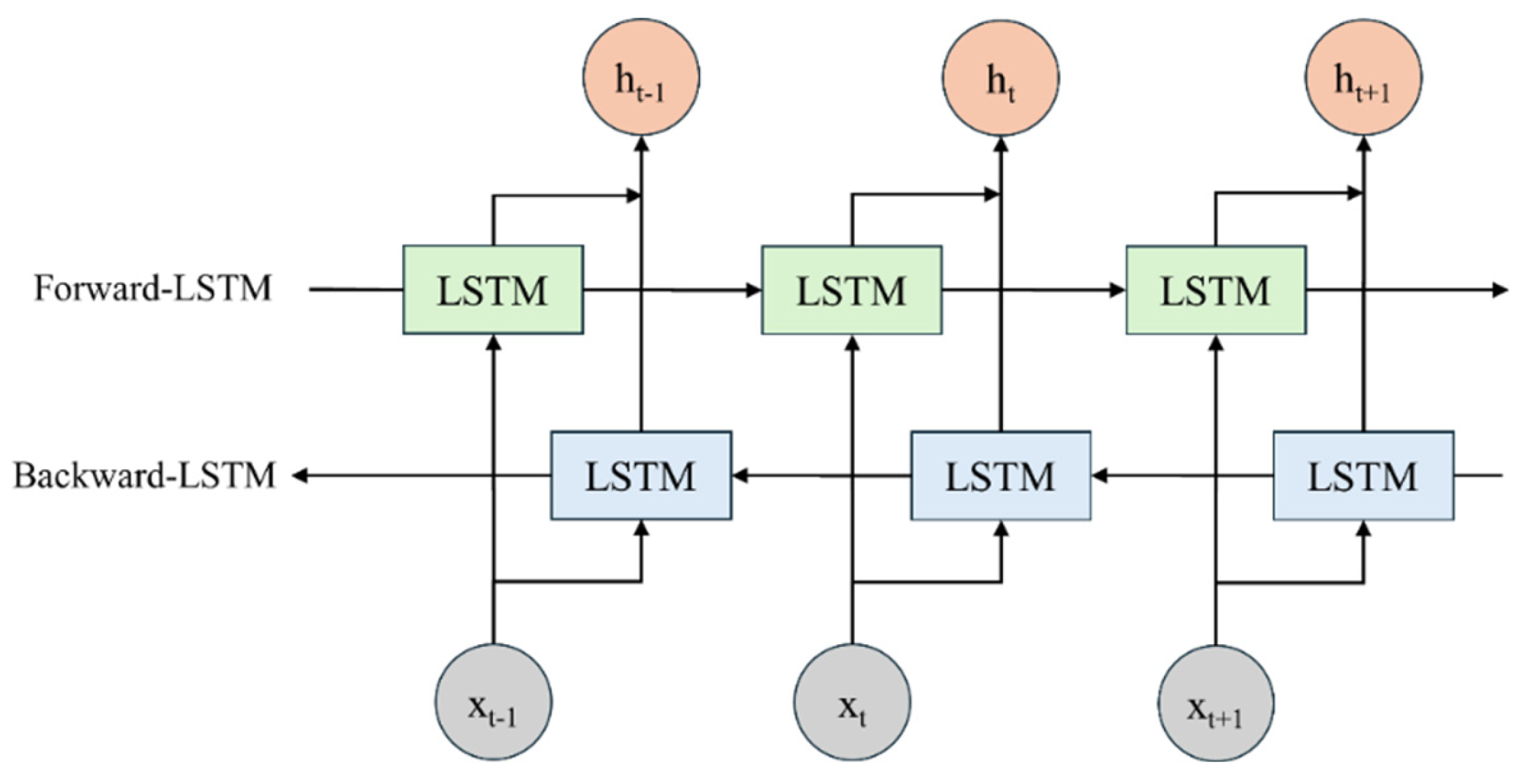

2.2.2. BiLSTM Model

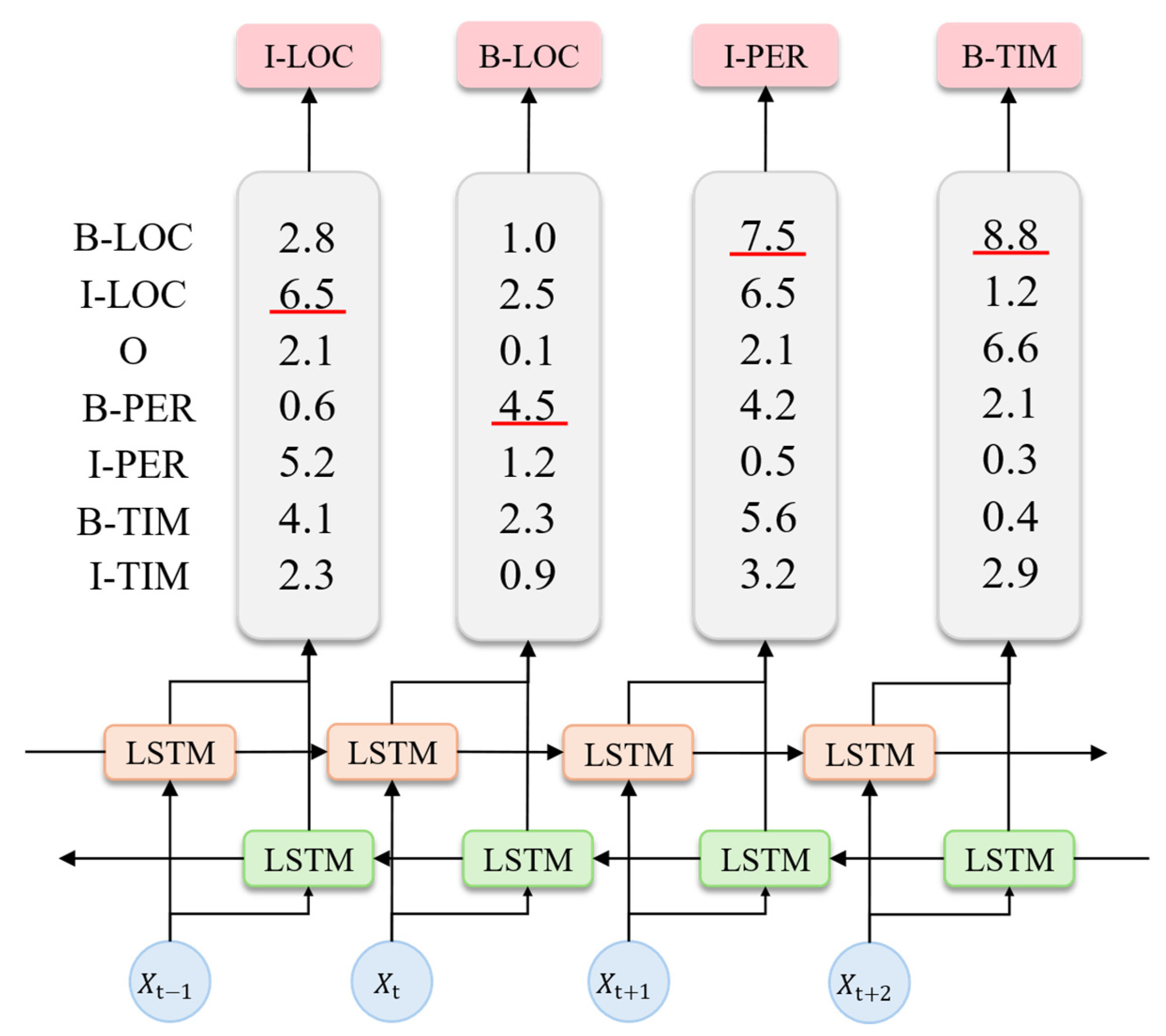

2.2.3. CRF Model

2.3. Evaluation Metrics

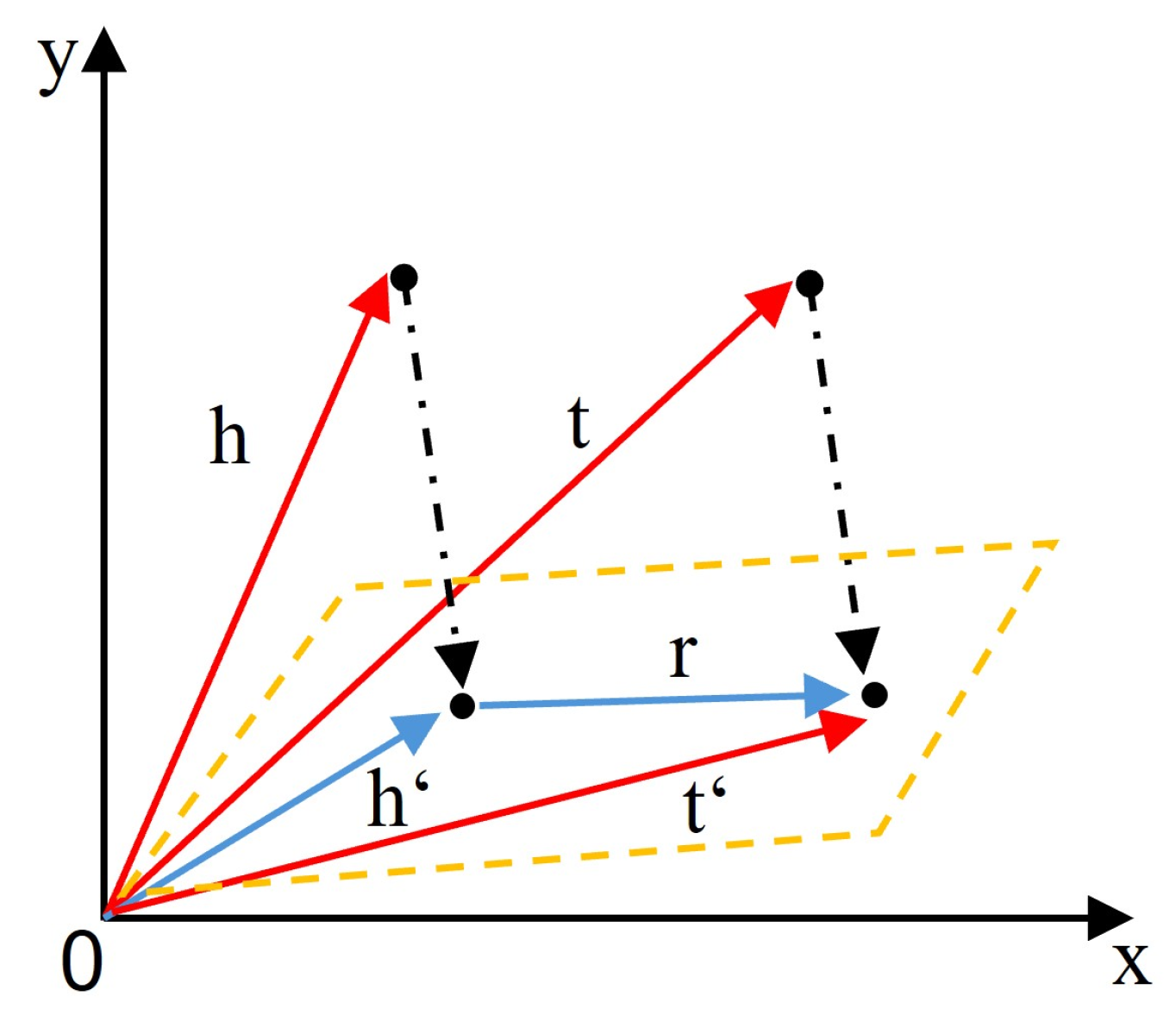

2.4. TransH Inference Model

3. Case Analysis

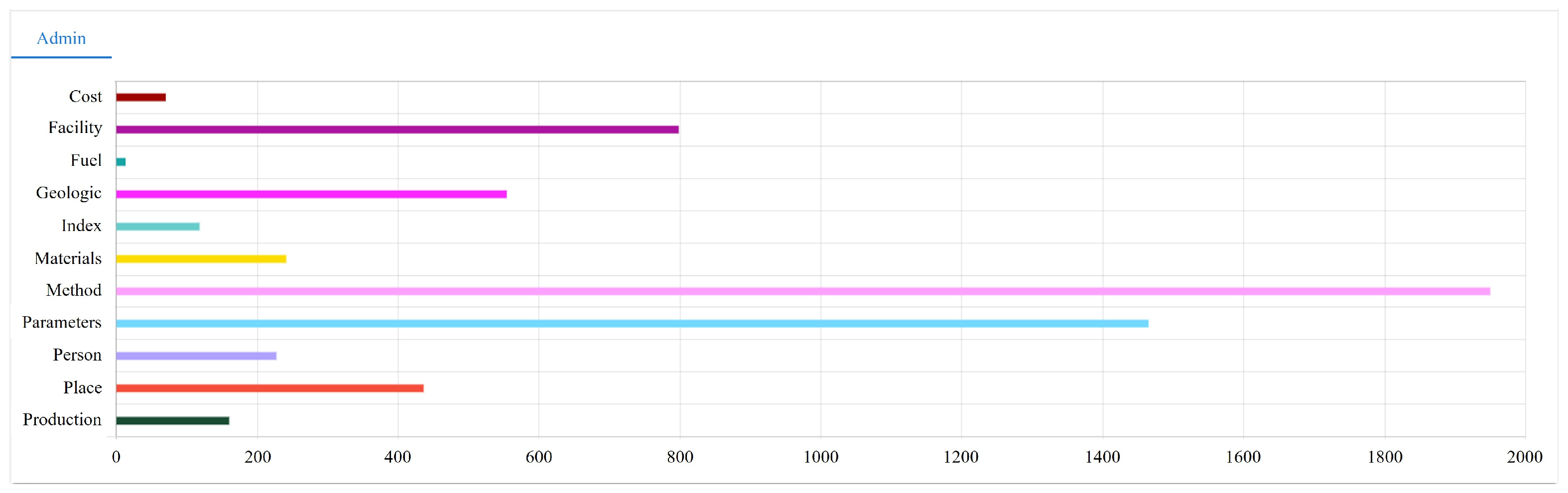

3.1. Dataset Source and Entity Classification

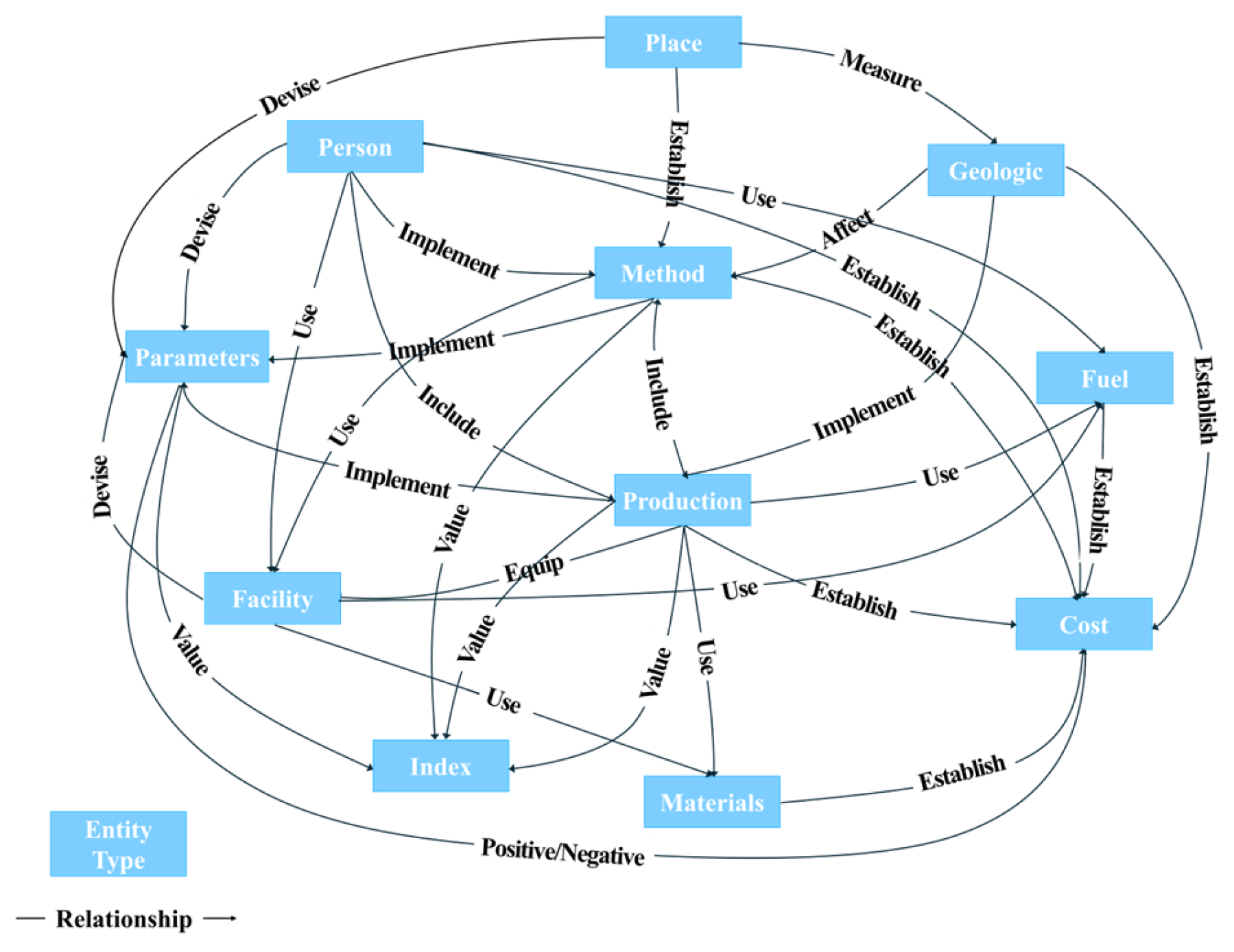

3.2. Knowledge Graph Construction

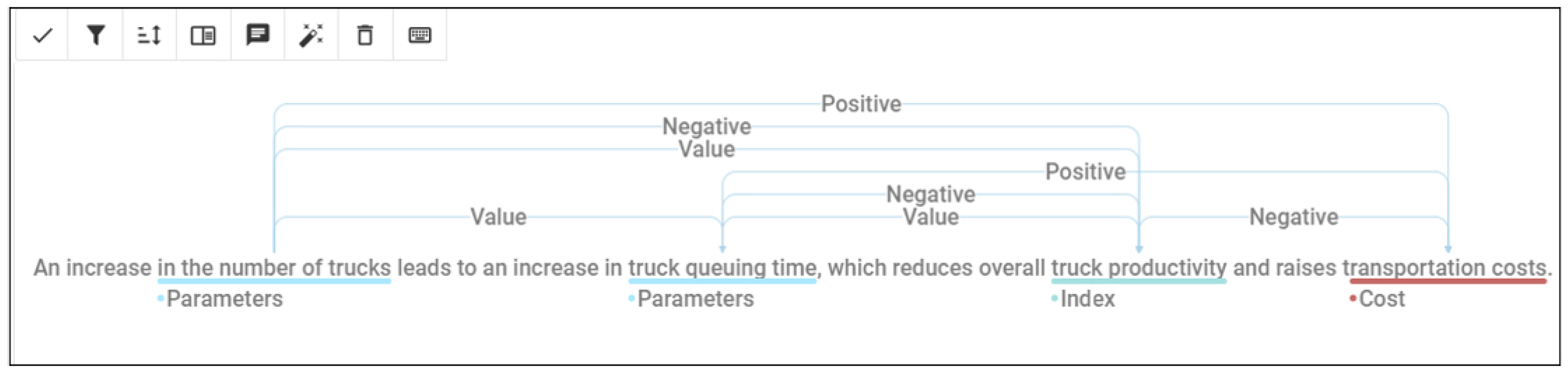

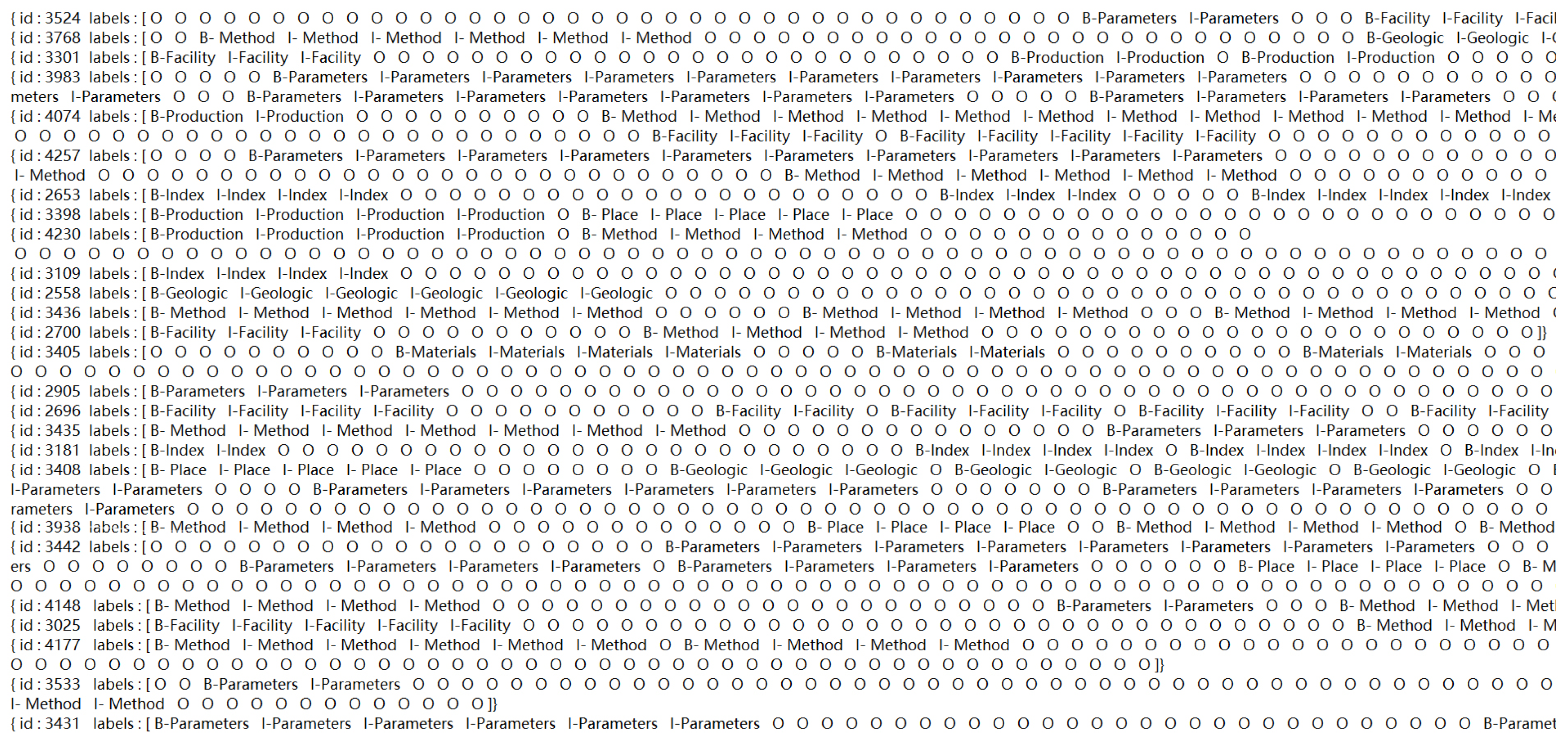

3.2.1. Platform Entity Labeling

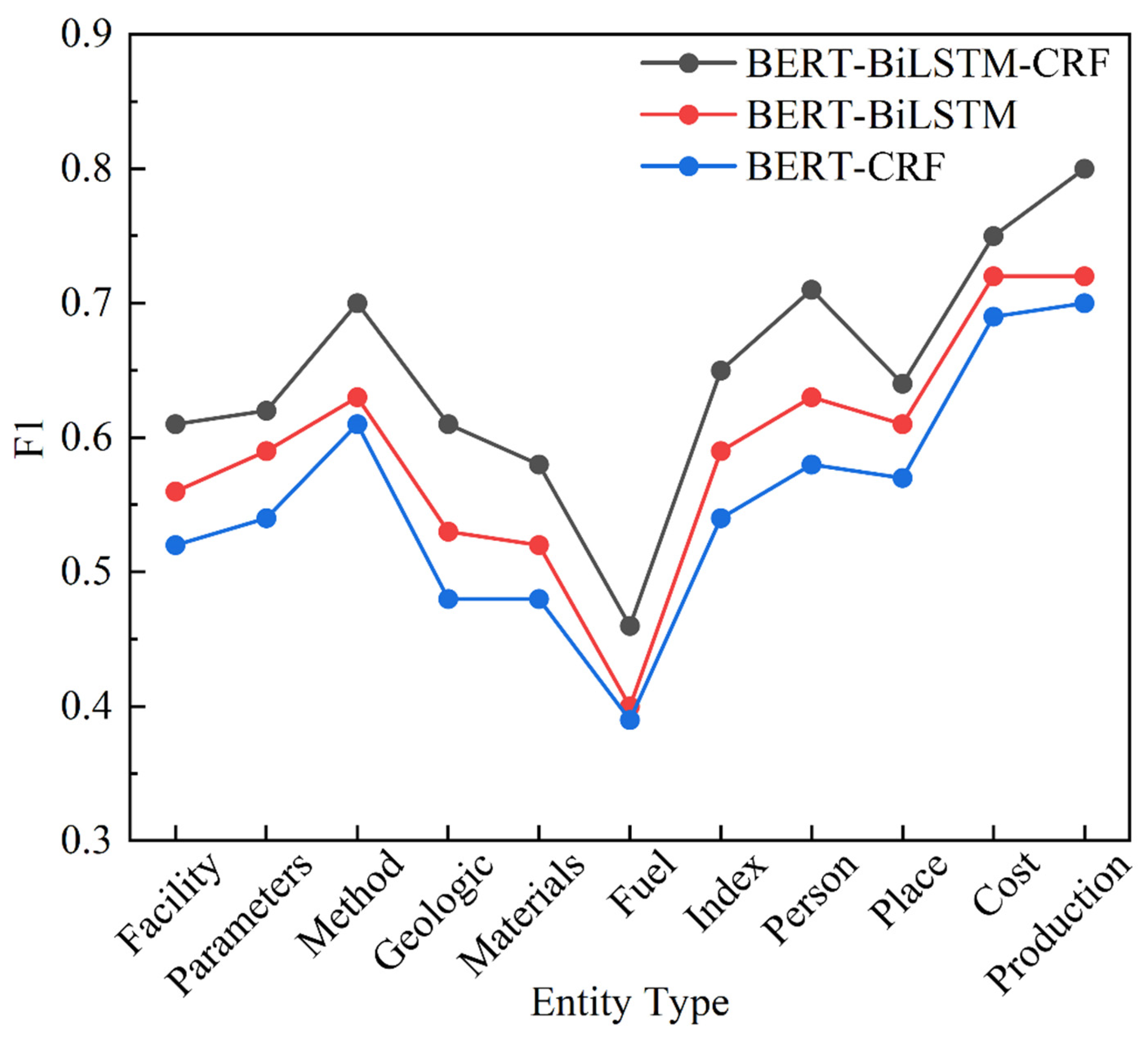

3.2.2. Named Entity Recognition

3.2.3. Entity Relationship Extraction

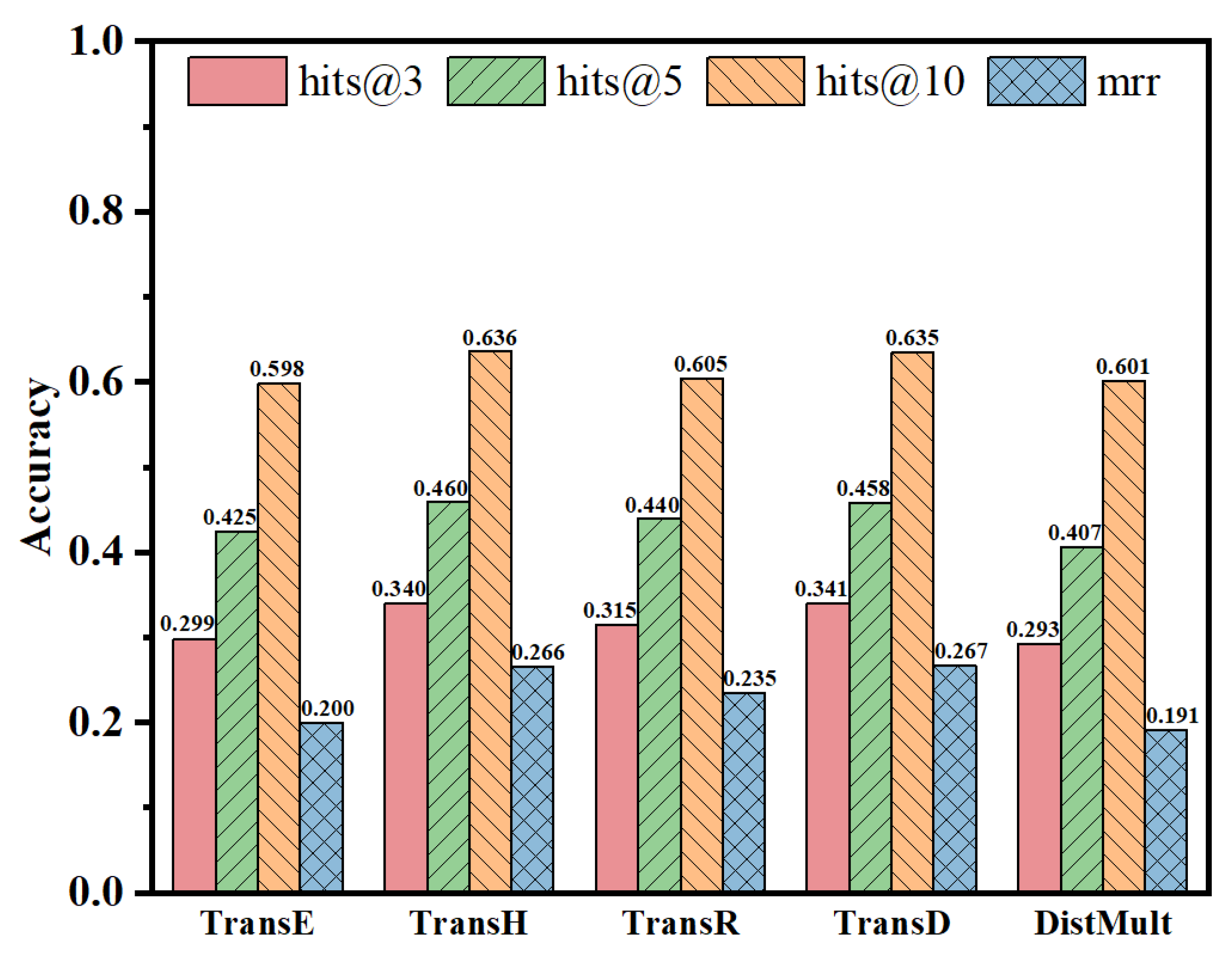

3.2.4. Knowledge Inference

3.3. Knowledge Storage and Representation

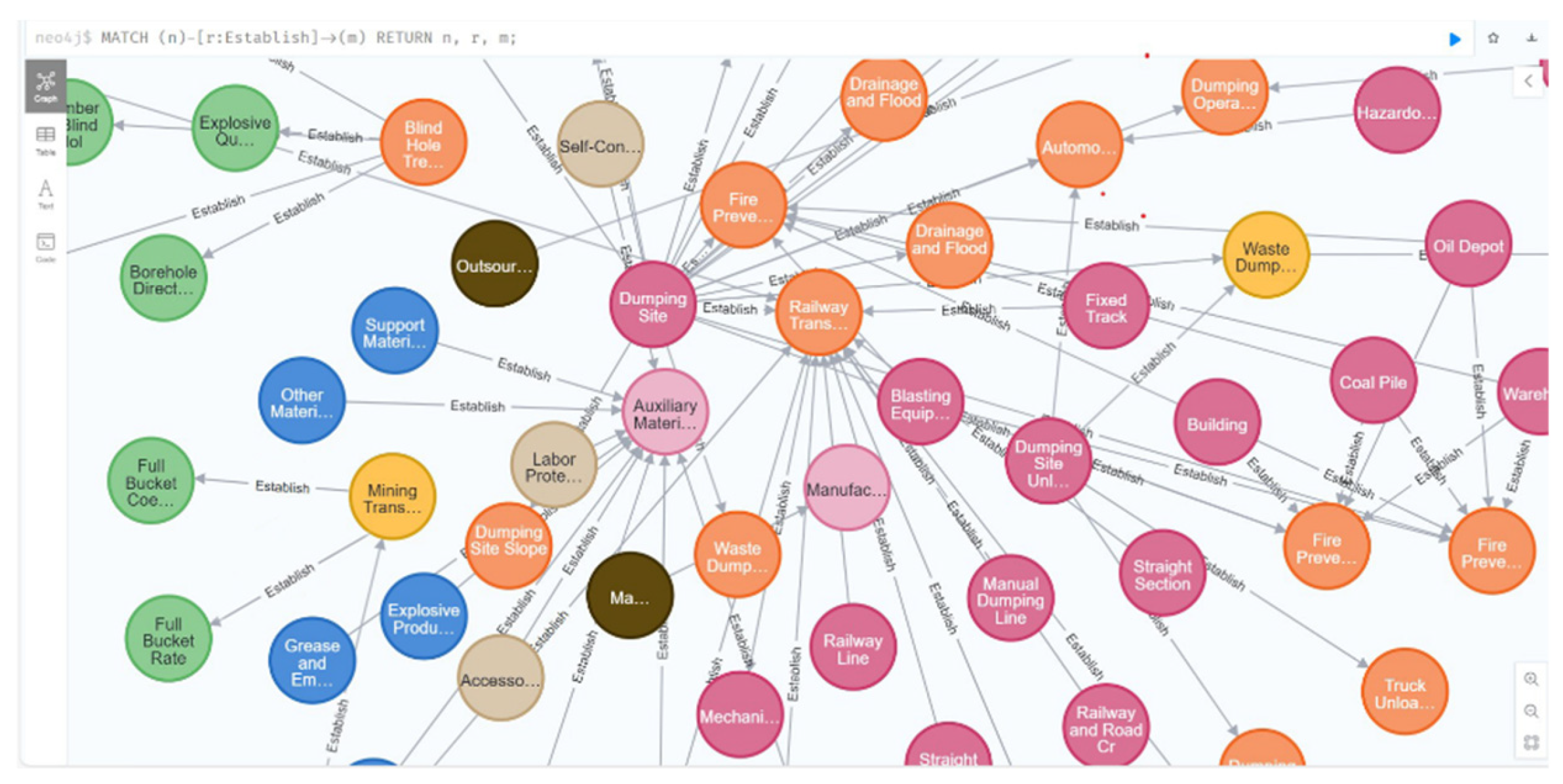

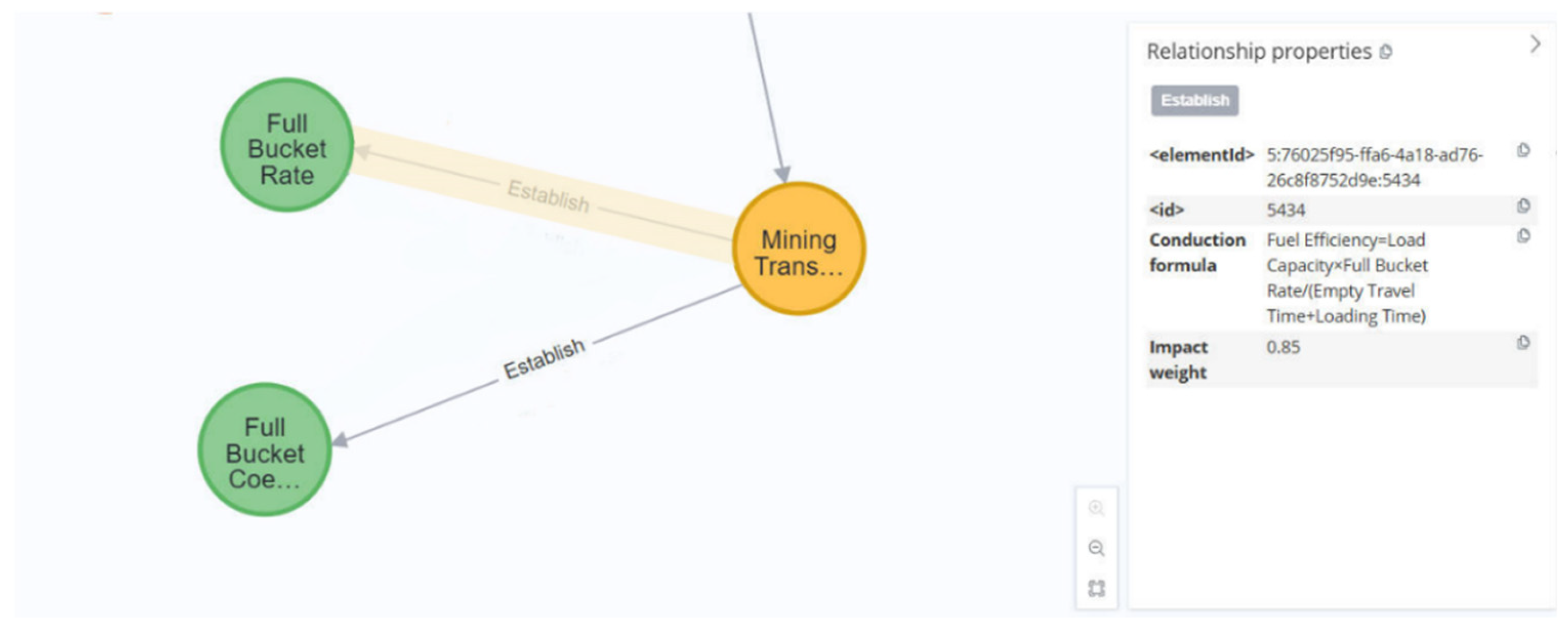

3.3.1. Knowledge Storage Based on Neo4j

3.3.2. Knowledge Graph Visualization

3.4. Knowledge Query

3.5. Validation of Priority Ranking Accuracy for Cost Factors

Accuracy Validation

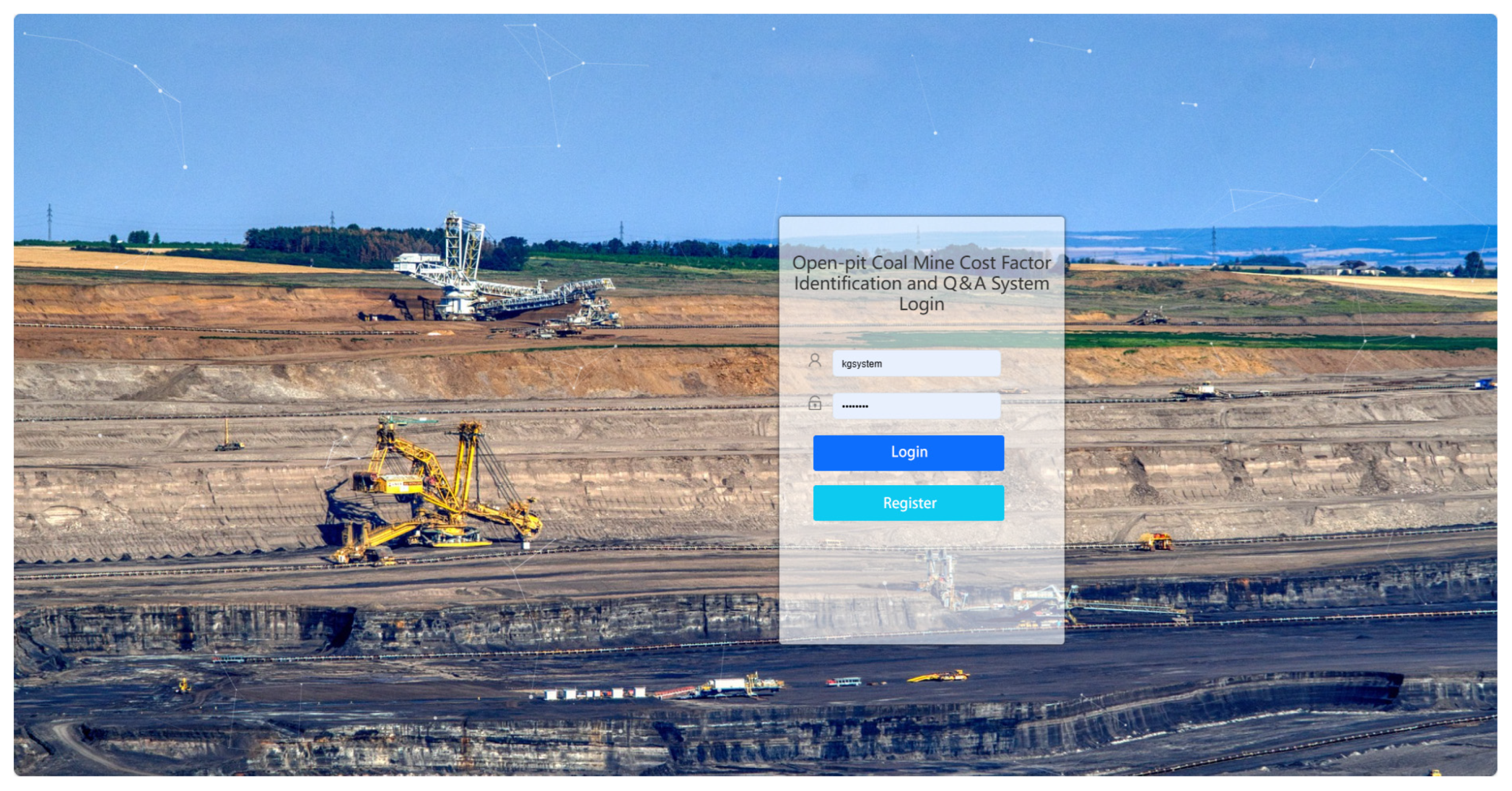

3.6. Cost Influencing Factor Identification and Decision Support System

System: Display

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tan, Z.; Chen, X. Discussion on situation and development countermeasures of coal enterprise informatization construction. J. Mine Autom. 2016, 42, 63–66. [Google Scholar]

- Shim, H.-J.; Ryu, D.-W.; Chung, S.-K.; Synn, J.-H.; Song, J.-J. Optimized blasting Design for Large-scale Quarrying based on a 3-D Spatial Distribution of Rock Factor. Int. J. Rock Mech. Min. Sci. 2009, 46, 326–332. [Google Scholar] [CrossRef]

- Badakhshan, N.; Shahriar, K.; Afraei, S.; Bakhtavar, E. Determining the environmental costs of mining projects: A comprehensive quantitative assessment. Resour. Policy 2023, 82, 103561. [Google Scholar] [CrossRef]

- Akintoye, A. Analysis of factors influencing project cost estimating practice. Constr. Manag. Econ. 2000, 18, 77–89. [Google Scholar] [CrossRef]

- Russell, L.B.; Bhanot, G.; Kim, S.-Y.; Sinha, A. Using cluster analysis to group countries for cost-effectiveness analysis: An application to sub-saharan africa. Med. Decis. Mak. 2018, 38, 139–149. [Google Scholar] [CrossRef]

- Thengane, S.K.; Hoadley, A.; Bhattacharya, S.; Mitra, S.; Bandyopadhyay, S. Cost-benefit analysis of different hydrogen production technologies using AHP and Fuzzy AHP. Int. J. Hydrogen Energy 2014, 39, 15293–15306. [Google Scholar] [CrossRef]

- Nadeau, D.; Sekine, S. A survey of named entity recognition and classification. Lingvisticae Investig. 2007, 30, 3–26. [Google Scholar] [CrossRef]

- Collins, M.; Singer, Y. Unsupervised models for named entity classification. In Proceedings of the 1999 Joint SIGDAT Conference on Empirical Methods in Natural Language Processing and very Large Corpora, College Park, MD, USA, 21–22 June 1999; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Liu, P.; Yuan, W.; Fu, J. Pre-train, prompt, and predict: A systematic survey of prompting methods in natural language processing. ACM Comput. Surv. 2023, 55, 1–35. [Google Scholar] [CrossRef]

- Jahan, M.S.; Khan, H.U.; Akbar, S.; Farooq, M.U.; Gul, S.; Amjad, A. Bidirectional Language Modeling: A Systematic Literature Review. Sci. Program. 2021, 2021, 6641832. [Google Scholar] [CrossRef]

- Santoso, J.; Setiawan, E.I.; Purwanto, C.N.; Yuniarno, E.M.; Hariadi, M.; Purnomo, M.H. Named entity recognition for extracting concept in ontology building on Indonesian language using end-to-end bidirectional long short term memory. Expert Syst. Appl. 2021, 176, 114856. [Google Scholar] [CrossRef]

- Huang, Z.; Xu, W.; Yu, k. Bidirectional LSTM-CRF models for sequence tagging. arXiv 2015, arXiv:1508.01991. [Google Scholar] [CrossRef]

- Li, P.; Lin, W.; Wang, Y.; Xu, N.; Zhu, W.; Liu, W. Semi-supervised named entity recognition in low-resource domains: A case study of rare earth elements in coal. Ore Geol. Rev. 2025, 185, 106796. [Google Scholar] [CrossRef]

- Zhou, Z.; Wei, L.; Luan, H. Deep learning for named entity recognition in extracting critical information from struck-by accidents in construction. Autom. Constr. 2025, 173, 106106. [Google Scholar] [CrossRef]

- Jin, J. Fault diagnosis of coal mine equipment based on improved ga optimized BP neural network. Int. J. Smart Home 2016, 10, 275–284. [Google Scholar] [CrossRef]

- Pan, L.; Zhang, J.; Zhang, Y. Construction of knowledge graph in coal mine domain. Comput. Appl. Softw. 2019, 36, 47–64. [Google Scholar]

- Liu, Y.; Wang, H. Fire and coupling disaster emergency management based on mapping knowledge domain. Saf. Coal Mines 2022, 53, 144–150. [Google Scholar]

- Xu, N.; Liang, Y.; Guo, C.; Meng, B.; Zhou, X.; Hu, Y.; Zhang, B. Entity recognition in the field of coal mine construction safety based on a pre-training language model. Eng. Constr. Archit. Manag. 2025, 32, 2590–2613. [Google Scholar] [CrossRef]

- Zhai, S.; Guo, L.; Gao, S.; Meng, B.; Zhou, X.; Hu, Y.; Zhang, B. Method for Knowledge Graph Completion Based on Bayesian Reasoning. J. Chin. Comput. Syst. 2018, 39, 133–137. [Google Scholar]

- Bordes, A.; Usunier, N.; Garcia-Duran, A.; Weston, J.; Yakhnenko, O. Translating embeddings for modeling multi-relational data. In Proceedings of the 27th International Conference on Neural Information Processing Systems, Lake Tahoe, NV, USA, 5–10 December 2013; pp. 2787–2795. [Google Scholar]

- Nickel, M.; Tresp, V.; Kriegel, H.P. A Three-Way Model for Collective Learning on Multi-Relational Data. In Proceedings of the 28th International Conference on International Conference on Machine Learning, Bellevue, WA, USA, 28 June–2 July 2011; Volume 11, pp. 809–816. [Google Scholar]

- Ji, G.; He, S.; Xu, L.; Liu, K.; Zhao, J. Knowledge graph embedding via dynamic mapping matrix. In Proceedings of the 53rd Annual Meeting of the Association for Computational Linguistics and the 7th International Joint Conference on Natural Language Processing, Beijing, China, 26–31 July 2015; pp. 687–696. [Google Scholar]

- Wang, Z.; Zhang, J.; Feng, J.; Chen, Z. Knowledge graph and text jointly embedding. In Proceedings of the 2014 Conference on Empirical Methods in Natural Language Processing (EMNLP), Doha, Qatar, 25–29 October 2014; pp. 1591–1601. [Google Scholar]

- Xing, L. Book intelligent recommendation algorithm based on collaborative filtering and TransH improvement. J. Shenzhen Inst. Inf. Technol. 2024, 22, 1–6. [Google Scholar]

- Cao, L. Design and Implementation of Intelligent Legal Consulting Platform Based on Knowledge Graph. Master’s Thesis, Beijing University of Posts and Telecommunications, Beijing, China, 2024. [Google Scholar]

- Hristos, D. A regiona analysis of technica change in Australian manufacturing. Tech. Changes Aust. Manuf. 2000, 6, 184–199. [Google Scholar]

- McNown, R. Cointegration modeling of fertility in the United States. Math. Popul. Stud. 2003, 10, 99–126. [Google Scholar] [CrossRef]

- Teixeira, A.A.C.; Foruna, N. Human capital, innovation capability and economic growth in Portuga. Port. Econ. J. 2004, 3, 205–225. [Google Scholar] [CrossRef]

- Zhang, J.; Li, H.; Yue, W. Improvement and refinement of comparative and ratio analysis methods. Friends Account. 2012, 20–23. [Google Scholar] [CrossRef]

- Hu, Y. The prediction and control model of blasting mining cost that based on BP neural network in sedimentary type of mine. China Min. Mag. 2013, 22, 75–79. [Google Scholar]

- Peng, Y. Research on feedforward Neural Network based on time series. Electron. Des. Eng. 2021, 29, 102–106+111. [Google Scholar] [CrossRef]

- Zhang, N. Research on Production Cost Prediction and Control of Large Metal Open Pit Mine. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2023. [Google Scholar]

- Meng, F.; Yang, S.; Wang, J.; Xia, L.; Liu, H. Creating knowledge graph of electric power equipment faults based on BERT-BiLSTM-CRF model. J. Electr. Eng. Technol. 2022, 17, 2507–2516. [Google Scholar] [CrossRef]

- Wang, X. Comparing TransE and TransH Algorithms in Spatial Address Representation Learning: A Case Study of Tianhe District, Guangzhou City. J. Nanjing Univ. Posts Telecommun. (Nat. Sci. Ed.) 2020, 52, 86–94. [Google Scholar]

- Ning, Y. A Representation Learning Method of Knowledge Graph Integrating Relation Path and Entity Description Information. J. Comput. Res. Dev. 2022, 59, 1966–1979. [Google Scholar]

- Jiao, K.; Li, X. Survey of Chinese Named Entity Recognition Research. Comput. Eng. Appl. 2021, 57, 1–15. [Google Scholar]

- GB6722-2014; Safety Regulations for Blasting. Standards Press of China: Beijing, China, 2014.

- GB50197-2015; Code for Design of Open Pit Mine of Coal Industry. Standards Press of China: Beijing, China, 2015.

- GB51289-2018; Standard for Design of Slope Engineering of Open Pit Mine of Coal Industry. Standards Press of China: Beijing, China, 2018.

- MT/T1183-2020; The Slope Stability Analysis and Displacement Monit Oring Method of Open-Pit Mine. Standards Press of China: Beijing, China, 2020.

- MT/T1184-2020; Open-Pit Coal Mine Stripping and mining safety Technology Standard. Standards Press of China: Beijing, China, 2020.

- MT/T1185-2020; Technology Standard of Open-Pit Coal Mine Dump. Standards Press of China: Beijing, China, 2020.

- MT/T1186-2020; Open-Pit Coal Mine Transportation Safety Technology Standard. Standards Press of China: Beijing, China, 2020.

- MT 872-2000; General Technical Condition of Protective Devices of Belt Conveyor For Coal Mining. Standards Press of China: Beijing, China, 2000.

- AQ1055-2018; Specifications of Design Inspection and Completion Acceptance for Safety Devices in Coal Mine Construction Project. Standards Press of China: Beijing, China, 2018.

- AQ1083-2011; Safety Code for Coal Mine Construction. Standards Press of China: Beijing, China, 2011.

- GB/T 15663; Terms Relating to Coal Mining. Standards Press of China: Beijing, China, 2008.

- Rossi, A.; Barbosa, D.; Firmani, D.; Matinata, A.; Merialdo, P. Knowledge graph embedding for link prediction: A comparative analysis. ACM Trans. Knowl. Discov. Data (TKDD) 2021, 15, 1–49. [Google Scholar] [CrossRef]

- Gao, B. BioTrHMM: Named entity recognition algorithm based on transfer learning in biomedical texts. Appl. Res. Comput. 2019, 36, 45–48. [Google Scholar]

| Standard Specification Examples | Categorized by Issuing Agency and Action Scope | Divided According to Its Content |

|---|---|---|

| Coal Law of the People’s Republic of China | Law | Safety behavior standards |

| Mine Safety Law of the People’s Republic of China | Law | Safety management standards for coal mines |

| Coal Mine Construction Safety Regulations | Administrative regulations | Safety behavior standards |

| Safety regulations for blasting | Administrative regulations | Safety behavior standards |

| Safety regulations for blasting GB6722-2014 [37] | National standard (GB) | Safety behavior standards |

| Code for design of open pit mine of coal industry GB50197-2015 [38] | National standard (GB) | Coal mine production technical code standards |

| Standard for design of slope engineering of open pit mine of coal industry GB51289-2018 [39] | National standard (GB) | Coal mine production technical code standards |

| The slope stability analysis and displacement monit oring method of open-pit mine MT/T1183-2020 [40] | Industry standard (MT) | Coal mine production technical code standards |

| Open-pit coal mine stripping and mining safety technology standard MT/T1184-2020 [41] | Industry standard (MT) | Coal mine production technical code standards |

| Technology standard of open-pit coal mine dump MT/T1185-2020 [42] | Industry standard (MT) | Coal mine production technical code standards |

| Open-pit coal mine transportation safety technology standard MT/T1186-2020 [43] | Industry standard (MT) | Coal mine production technical code standards |

| General technical condition of protective devices of belt conveyor for coal mining MT 872-2000 [44] | Industry standard (MT) | Coal mine production technical code standards |

| Specifications of design inspection and completion acceptance for safety devices in coal mine construction project AQ1055-2018 [45] | Safety Standard for Coal Mines (AQ) | Coal mine safety management standards |

| Enterprise Product Cost Accounting System—Coal Industry | Significant cost specification | Coal mine costing standards |

| Guidelines for Mining Right Evaluation | Significant cost specifications | Coal mine costing standards |

| Data Source | Explanation | Detailed Requirements |

|---|---|---|

| Correlation Degree | Describe the strength of the relationship between different factors and costs. | Quantify the correlation between different factors and costs through statistical analysis or regression models, helping to understand which factors have a greater impact on costs. |

| Sensitivity | Reflect the sensitivity of cost changes to different factors. | Identify the factors most sensitive to cost changes through sensitivity analysis, providing important decision-making insights. |

| Hierarchy | Structurally display the hierarchical relationship between various factors and costs. | Establish a hierarchy based on production processes under different operating conditions, in compliance with the requirements of standard specification documents, to serve as the hierarchical basis for cost influencing factors. |

| Process Parameters | Reflect the impact of key process parameters on costs during production. | In compliance with standard specification documents, including process parameters such as drilling depth and blasting effects, quantify the impact of each parameter on the overall cost. |

| Historical Data | Provide the relationship between costs and factors in actual operations through historical data analysis. | Based on historical operational data, verify the relationships between factors and costs, supporting the construction and inference analysis of the knowledge graph. |

| Relation Name | Relation Concept |

|---|---|

| Establish | Factor A facilitates the existence or formation of Factor B through specific processes or conditions. |

| Devise | Factor A generates the logical relationship of Factor B through systematic planning or design. |

| Equip | Factor A forms the compositional structure of the more complex Factor B through combination or integration. |

| Distance | The spatial or logical separation between Factor A and Factor B has a quantifiable impact on cost. |

| Use | Factor A utilizes or consumes Factor B in the process of achieving a specific objective. |

| Measure | Factor A acquires quantitative information about Factor B through technical methods or approaches. |

| Include | Factor B is a component or an attribute subset within the hierarchical structure of Factor A. |

| Affect | Factor A exerts a direct or indirect causal effect on Factor B. |

| Value | Factor A assigns a specific numerical value or attribute-based quantitative definition to Factor B. |

| Implement | Factor A achieves the objectives or outcomes of Factor B through actions or operations. |

| Positive | Factor A and Factor B exhibit a statistically significant positive correlation, changing in the same direction. |

| Negative | Factor A and Factor B exhibit a statistically significant negative correlation, changing in opposite directions. |

| Entity Type | Specific Entity | Source of Entity Content |

|---|---|---|

| Facility | Excavator, Drilling machine, Loader, Explosive material transport vehicle, On-site mixed explosive vehicle, Dozer, Conveyor, Automobile, Truck, Water truck, Bulldozer | Safety regulations for blasting AQ1083-2011 [46] |

| Parameters | Mining height, Mining depth, Bench height, Borehole depth, Hole depth, Ramp bench borehole, Borehole diameter Sub-drilling depth, Minimum burden, Minimum resistance line, Basal burden, Bench face angle, Borehole spacing, Burden spacing, Stemming length, Borehole density coefficient, Specific charge, Total charge amount, Maximum charge per delay | Code for design of open pit mine of coal industry GB50197-2015 [38] |

| Method | Railway transportation, Road transportation, Inverted pile mining technique, Non-inverted pile mining technique, Pre-splitting blasting, Throw blasting, Deep hole blasting, Shallow hole blasting, Secondary blasting, Intermittent process, Continuous process, Semi-continuous process, Internal spoil disposal | Specifications of design inspection and completion acceptance for safety devices in coal mine construction project AQ1055-2018 [45] |

| Geologic | Degree of rock weathering, Rock mass structure, Rock mass fabric, Weak interlayer, Occurrence conditions, Lithology, Engineering geological conditions, Hydrogeological conditions | Classification of environmental geology of mine |

| Materials | Detonator, Blasting cap, Emulsion explosive, Ammonium nitrate-fuel oil explosive (ANFO), Porous granular explosive, Nitroglycerin-based explosive, | Regulations of safety managment for the manufacturing and marketing enterprise of civil explosive materials |

| Index | Vibration velocity, Bottom, Perforation, Flyrock distance, Back pull, Boulder yield, Lumpiness, Bucket rate, Measured value, Slope stability factor | Specifications of design inspection and completion acceptance for safety devices in coal mine construction project AQ1083-2011 [46] |

| Place | External waste dump, Internal waste dump, Mining-stripping face, Road transportation planning, Road classification, Railway alignment, General layout plan, Pit boundary, Working face | Code for design of open pit mine of coal industry GB50197-2015 [38] |

| Cost | Raw material and primary material cost, Auxiliary material cost, Fuel and power cost, Labor cost, Depreciation cost, Amortization and depletion cost, Safety production cost, Maintenance and repair cost, Transportation cost, Property insurance cost, Outsourced service cost, Amortization of low-value consumables | Enterprise Product Cost Accounting System—Coal Industry |

| Production | Drilling engineering, Blasting engineering, Stripping engineering, Transportation operations, Waste dumping engineering | Code for design of open pit mine of coal industry GB50197-2015 [38] |

| Term Name | Part of Speech |

|---|---|

| Single bucket-truck operation | vn |

| Hole spacing | vn |

| Blasting vibration | vn |

| Labor cost | nw |

| Stripping engineering | nw |

| Working face | s |

| Rock structure | s |

| Excavator | nz |

| Blasting worker | nz |

| Fuze | nz |

| Diesel | nz |

| Label Category | Label Name | Label Category | Label Name |

|---|---|---|---|

| B-Par | Design parameters category initials | B-Geo | Geological environment category initials |

| I-Par | Inside and end of design parameters category | I-Geo | Inside and end of geological environment category |

| B-Met | Mining method category initials | B-Pla | Spatial location category initials |

| I-Met | Inside and end of mining method category | I-Pla | Inside and end of Spatial location category |

| B-Ind | Excavation efficiency category initials | B-Mat | Material category initials |

| I-Ind | Inside and end of Excavation efficiency category | I-Mat | Inside and end of material category |

| B-Per | Personnel organization category initials | B-Fue | Fuel consumption category initials |

| I-Per | Inside and end of personnel organization category | I-Fue | Inside and end of fuel consumption category |

| B-Fac | Machine equipment category initials | B-Pro | Production category initials |

| I-Fac | Inside and end of machine equipment category | I-Pro | Inside and end of production category |

| B-Cost | Cost category initials | O | Non-entity symbol |

| I-Cost | Inside and end of cost category |

| Project Name | Environment Name |

|---|---|

| Operating System | Windows10 |

| CPU | Intel Core i9-14900Hx 5.80GHz |

| GPU | NVIDIA GeForce RTX 3090Ti |

| python | 3.7.12 |

| Pytorch | 1.12.0 |

| Tensorflow | 1.15 |

| Parameter Name | Parameter Value |

|---|---|

| Max_seq_length | 512 |

| Train_epochs | 33 |

| Train_batch_size | 32 |

| Learning rate | 3 × 10−5 |

| Dropout_rate | 0.3 |

| Clip | 5 |

| Entity Type | BERT-BiLSTM-CRF | BERT-BiLSTM | BiLSTM-CRF | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Precision | F1 | Recall | Precision | F1 | Recall | Precision | F1 | Recall | |

| Facility | 0.595 ± 0.013 | 0.600 ± 0.015 | 0.627 ± 0.010 | 0.563 ± 0.013 | 0.558 ± 0.009 | 0.548 ± 0.018 | 0.530 ± 0.022 | 0.525 ± 0.013 | 0.516 ± 0.018 |

| Parameters | 0.577 ± 0.018 | 0.618 ± 0.013 | 0.671 ± 0.021 | 0.529 ± 0.010 | 0.595 ± 0.008 | 0.665 ± 0.008 | 0.483 ± 0.008 | 0.529 ± 0.010 | 0.621 ± 0.014 |

| Method | 0.680 ± 0.014 | 0.701 ± 0.011 | 0.720 ± 0.016 | 0.629 ± 0.009 | 0.624 ± 0.011 | 0.636 ± 0.020 | 0.583 ± 0.008 | 0.608 ± 0.015 | 0.628 ± 0.008 |

| Geologic | 0.615 ± 0.011 | 0.616 ± 0.008 | 0.619 ± 0.010 | 0.482 ± 0.014 | 0.521 ± 0.022 | 0.581 ± 0.010 | 0.465 ± 0.011 | 0.480 ± 0.014 | 0.490 ± 0.014 |

| Materials | 0.417 ± 0.021 | 0.566 ± 0.030 | 0.836 ± 0.014 | 0.398 ± 0.035 | 0.533 ± 0.018 | 0.768 ± 0.031 | 0.374 ± 0.046 | 0.464 ± 0.025 | 0.646 ± 0.030 |

| Fuel | 0.418 ± 0.041 | 0.480 ± 0.037 | 0.534 ± 0.027 | 0.344 ± 0.048 | 0.387 ± 0.049 | 0.448 ± 0.030 | 0.348 ± 0.037 | 0.383 ± 0.045 | 0.447 ± 0.030 |

| Index | 0.637 ± 0.013 | 0.650 ± 0.020 | 0.656 ± 0.008 | 0.589 ± 0.008 | 0.599 ± 0.008 | 0.600 ± 0.015 | 0.500 ± 0.008 | 0.547 ± 0.008 | 0.511 ± 0.018 |

| Person | 0.625 ± 0.013 | 0.715 ± 0.012 | 0.812 ± 0.012 | 0.601 ± 0.017 | 0.636 ± 0.013 | 0.676 ± 0.010 | 0.535 ± 0.008 | 0.585 ± 0.018 | 0.621 ± 0.008 |

| Place | 0.647 ± 0.014 | 0.642 ± 0.012 | 0.646 ± 0.016 | 0.612 ± 0.014 | 0.606 ± 0.013 | 0.597 ± 0.019 | 0.574 ± 0.010 | 0.568 ± 0.014 | 0.574 ± 0.012 |

| Cost | 0.704 ± 0.016 | 0.748 ± 0.013 | 0.818 ± 0.013 | 0.650 ± 0.013 | 0.722 ± 0.010 | 0.800 ± 0.008 | 0.627 ± 0.014 | 0.687 ± 0.013 | 0.781 ± 0.009 |

| Production | 0.804 ± 0.008 | 0.812 ± 0.008 | 0.778 ± 0.014 | 0.718 ± 0.017 | 0.734 ± 0.014 | 0.727 ± 0.015 | 0.794 ± 0.013 | 0.702 ± 0.013 | 0.705 ± 0.016 |

| Model Name | hits@3 | hits@5 | hits@10 | mrr |

|---|---|---|---|---|

| TransE | 0.299 | 0.425 | 0.598 | 0.200 |

| TransH | 0.340 | 0.460 | 0.636 | 0.266 |

| TransR | 0.315 | 0.440 | 0.605 | 0.235 |

| TransD | 0.341 | 0.458 | 0.635 | 0.267 |

| DistMult | 0.293 | 0.407 | 0.593 | 0.205 |

| Expert ID | Influencing Factors | |||||||

|---|---|---|---|---|---|---|---|---|

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | |

| 1 | 4 | 1 | 4 | 4 | 4 | 4 | 2 | 3 |

| 2 | 5 | 3 | 4 | 5 | 4 | 5 | 4 | 3 |

| 3 | 2 | 3 | 4 | 5 | 3 | 4 | 2 | 4 |

| 4 | 3 | 4 | 4 | 5 | 5 | 5 | 3 | 4 |

| 5 | 5 | 4 | 4 | 5 | 4 | 3 | 4 | 3 |

| 6 | 3 | 5 | 5 | 3 | 5 | 5 | 3 | 4 |

| 7 | 4 | 4 | 2 | 3 | 3 | 3 | 3 | 3 |

| 8 | 3 | 5 | 4 | 5 | 3 | 5 | 4 | 2 |

| 9 | 5 | 5 | 2 | 4 | 4 | 4 | 4 | 2 |

| 10 | 2 | 4 | 2 | 4 | 3 | 5 | 5 | 3 |

| 11 | 3 | 4 | 3 | 5 | 3 | 4 | 4 | 4 |

| 12 | 3 | 3 | 4 | 4 | 3 | 3 | 4 | 3 |

| 13 | 5 | 4 | 5 | 4 | 4 | 4 | 3 | 3 |

| 14 | 3 | 3 | 2 | 5 | 5 | 5 | 4 | 4 |

| 15 | 4 | 5 | 3 | 4 | 2 | 3 | 4 | 2 |

| NO. | Influencing Factor | Entropy Weight | Sequential Ranking | Node Attribute Value | Sequential Ranking | Indicator Ranking |

|---|---|---|---|---|---|---|

| F1 | Hole depth | 0.089 | 5 | 0.056 | 5 | 0 |

| F2 | Burden | 0.133 | 3 | 0.088 | 3 | 0 |

| F3 | Lumpiness | 0.178 | 2 | 0.177 | 2 | 0 |

| F4 | Specific charge | 0.200 | 1 | 0.354 | 1 | 0 |

| F5 | Hole diameter | 0.067 | 6 | 0.051 | 6 | 0 |

| F6 | Blasting vibration | 0.111 | 4 | 0.071 | 4 | 0 |

| F7 | Bulk density | 0.022 | 8 | 0.038 | 8 | 0 |

| F8 | Step height | 0.044 | 7 | 0.044 | 7 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Li, P.; Guan, W.; Cui, X.; Wang, H.; Xie, S. Cost-Factor Recognition and Recommendation in Open-Pit Coal Mining via BERT-BiLSTM-CRF and Knowledge Graphs. Symmetry 2025, 17, 1834. https://doi.org/10.3390/sym17111834

Sun J, Li P, Guan W, Cui X, Wang H, Xie S. Cost-Factor Recognition and Recommendation in Open-Pit Coal Mining via BERT-BiLSTM-CRF and Knowledge Graphs. Symmetry. 2025; 17(11):1834. https://doi.org/10.3390/sym17111834

Chicago/Turabian StyleSun, Jiayi, Pingfeng Li, Weiming Guan, Xuejiao Cui, Haosen Wang, and Shoudong Xie. 2025. "Cost-Factor Recognition and Recommendation in Open-Pit Coal Mining via BERT-BiLSTM-CRF and Knowledge Graphs" Symmetry 17, no. 11: 1834. https://doi.org/10.3390/sym17111834

APA StyleSun, J., Li, P., Guan, W., Cui, X., Wang, H., & Xie, S. (2025). Cost-Factor Recognition and Recommendation in Open-Pit Coal Mining via BERT-BiLSTM-CRF and Knowledge Graphs. Symmetry, 17(11), 1834. https://doi.org/10.3390/sym17111834