Investigating the Pressure Fluctuations of Hydraulic Jump in an Abrupt Expanding Stilling Basin with Roughened Bed

Abstract

:1. Introduction

2. Materials and Methods

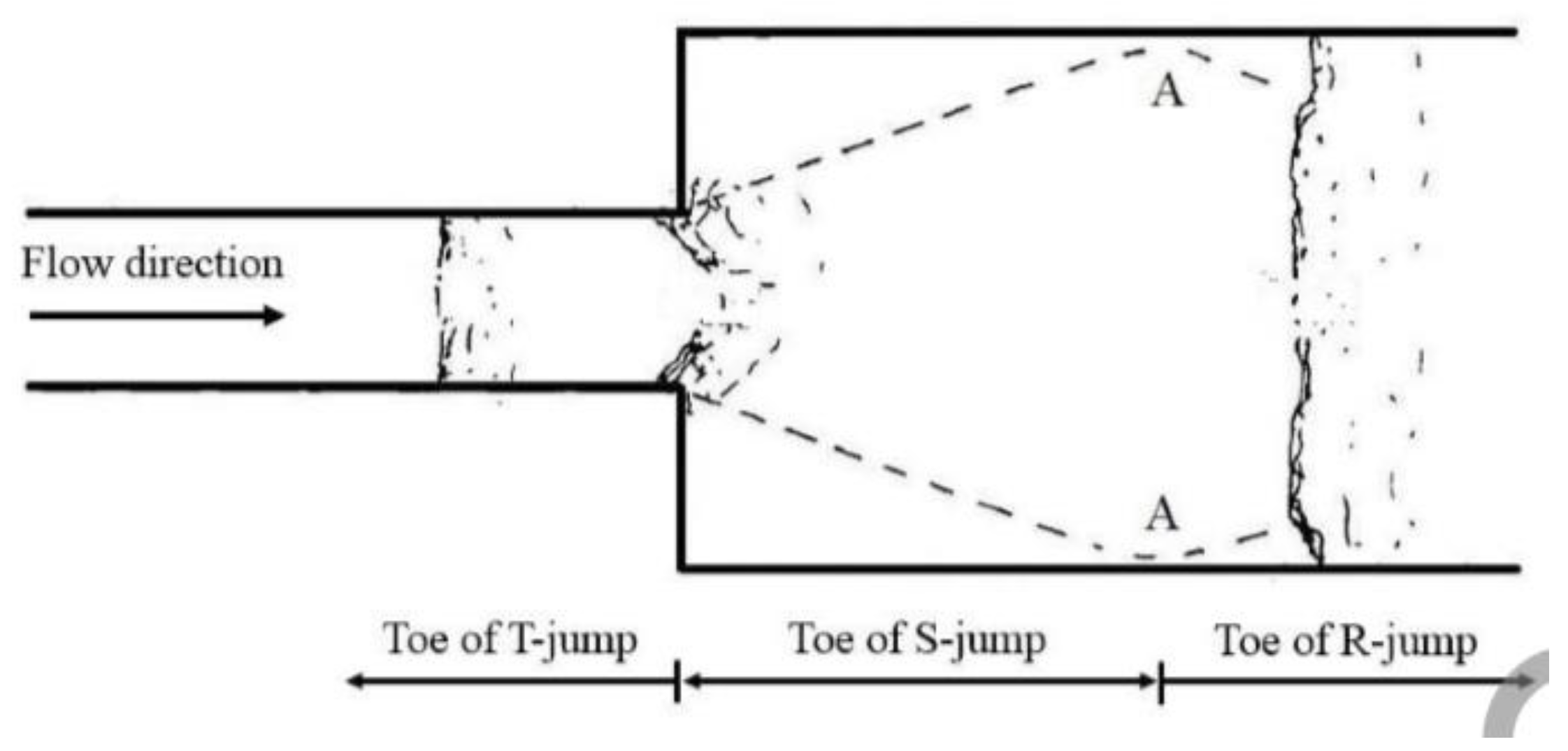

2.1. Experimental Setup

2.2. Theoretical Expression

2.3. Dimensional Analysis

3. Results and Discussions

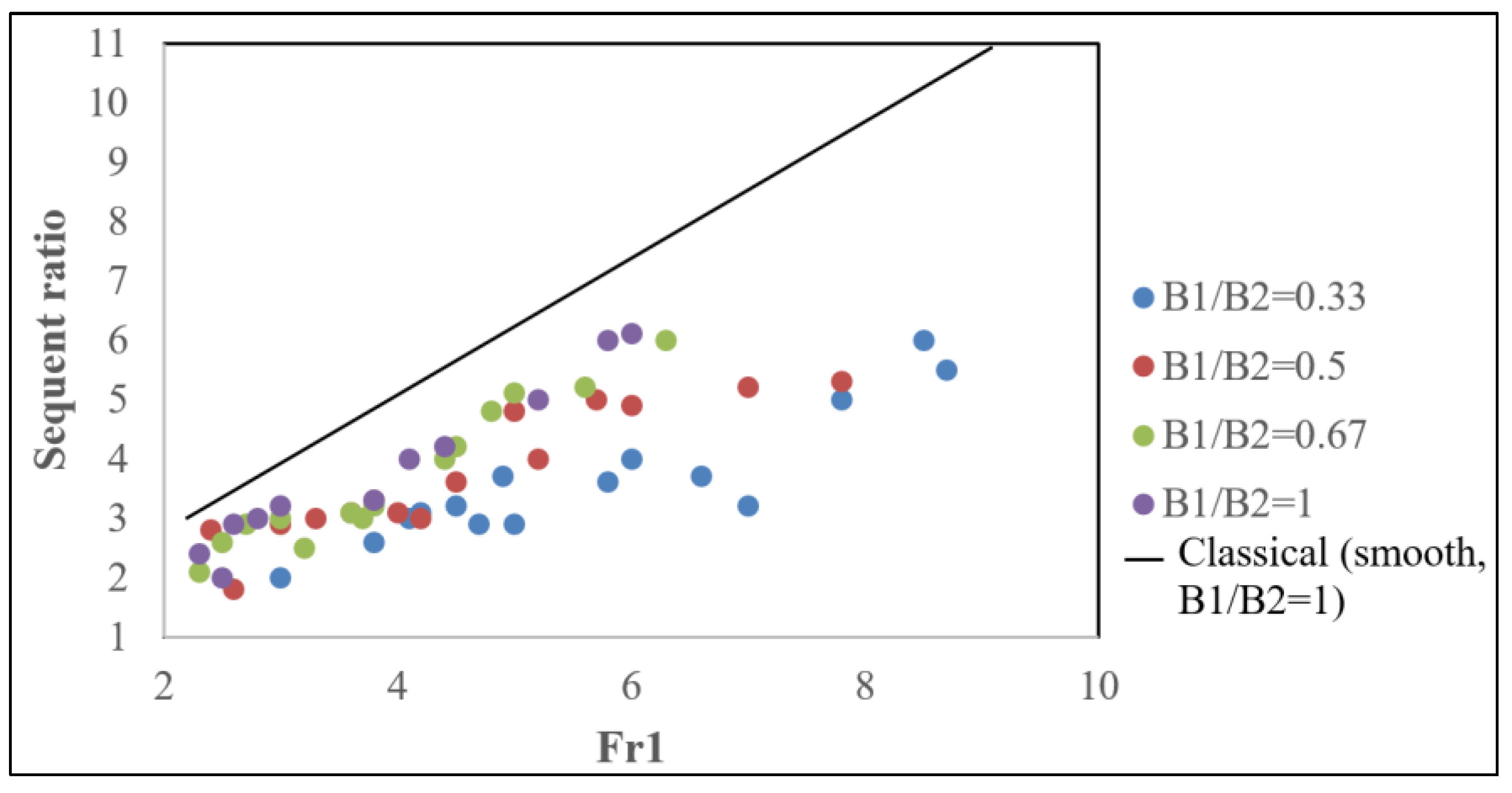

3.1. Sequent Depth Ratio

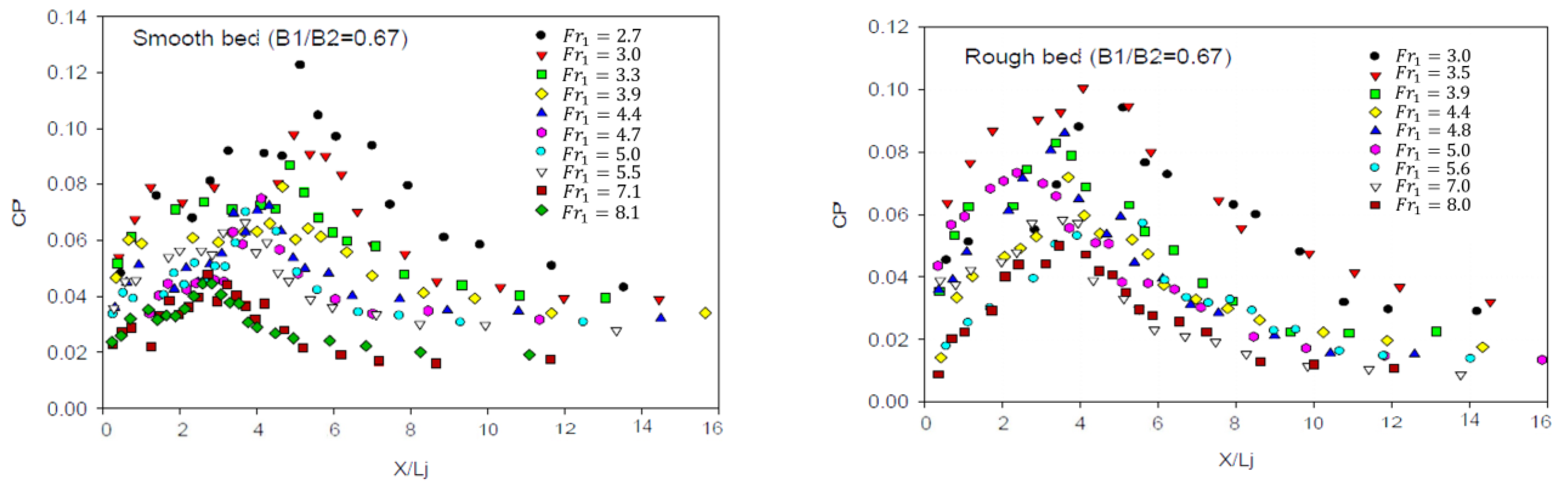

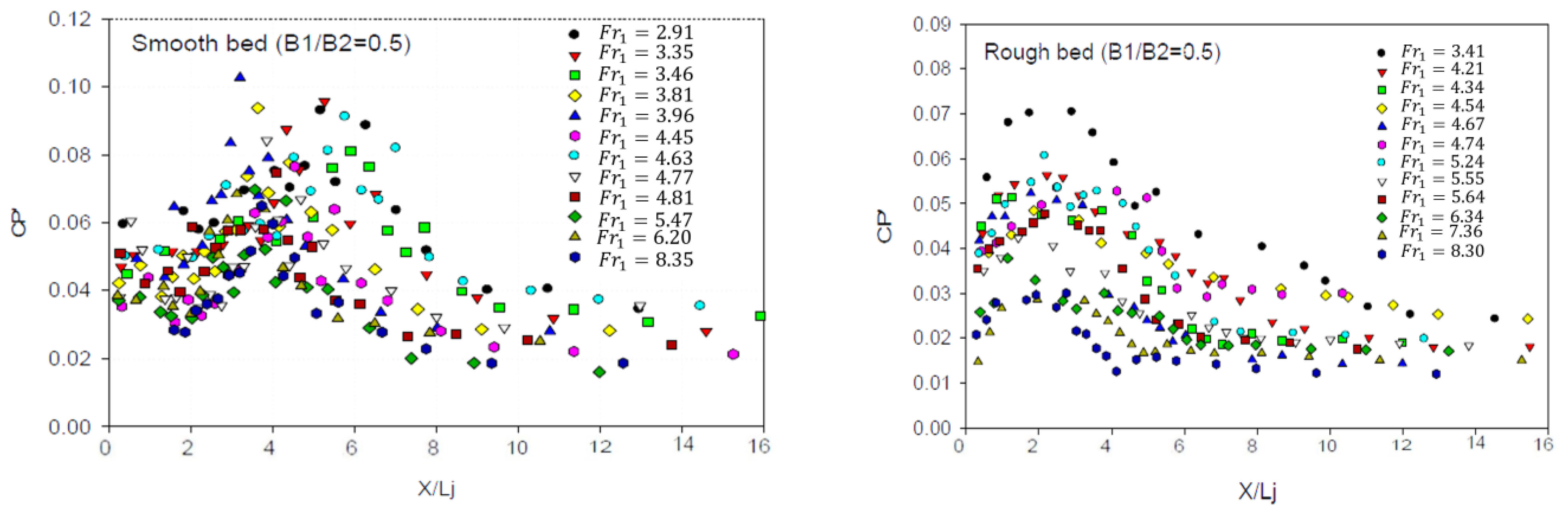

3.2. Parameter

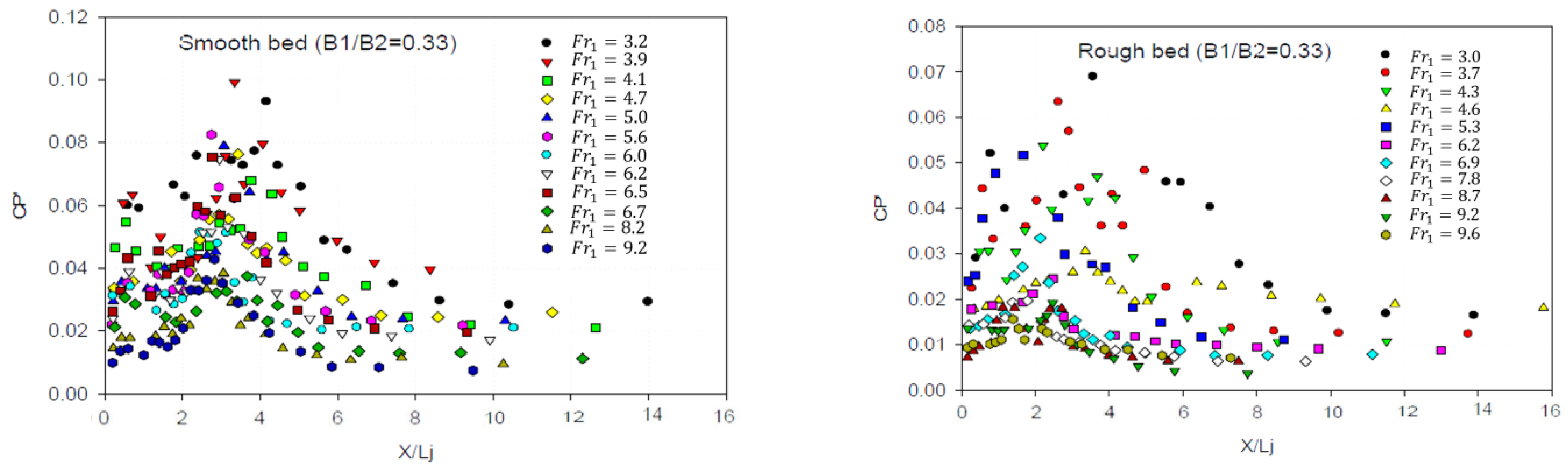

- Without expansion ()

- With abrupt expansion jump

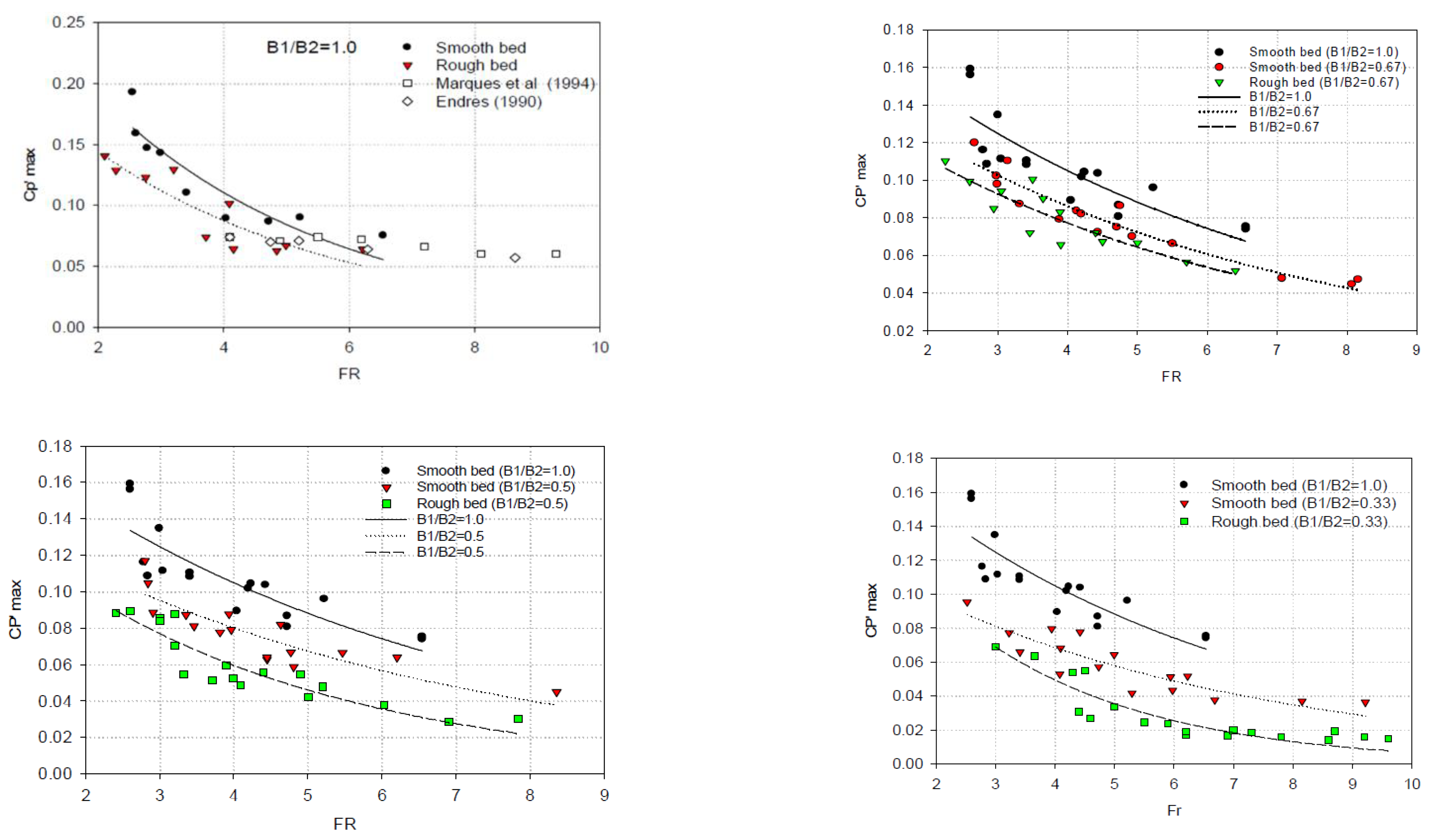

3.3. Maximum Non-Dimensional Pressure Fluctuations Parameter ()

3.4. Positive and Negative Pressure Coefficients ( ,)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hager, W.H.; Bremen, R.; Kawagoshi, N. Classical hydraulic jump: Length of roller. J. Hydraul. Res. 1990, 28, 591–608. [Google Scholar] [CrossRef]

- Chanson, H. Hydraulic jumps: Turbulence and air bubble entrainment. J. Houille Blanche 2011, 3, 5–16. [Google Scholar] [CrossRef] [Green Version]

- Daneshfaraz, R.; Sadeghi, H.; Rezazadeh Joudi, A.; Abraham, L. Experimental Investigation of Hydraulic Jump Characteristics in Contraction and Expansions. Sigma J. Eng. Nat. Sci. 2017, 35, 87–98. [Google Scholar]

- Sadeghfam, S.; Akhtari, A.; Daneshfaraz, R.; Tayfur, G. Experimental investigation of screens as energy dissipaters in submerged hydraulic jump. Turk. J. Eng. Environ. Sci. 2015, 38, 126–138. [Google Scholar] [CrossRef] [Green Version]

- Chanson, H. Development of the Bélanger equation and backwater equation by Jean-Baptiste Bélanger (1828). J. Hydraul. Eng. 2009, 135, 159–163. [Google Scholar] [CrossRef] [Green Version]

- Bremen, R.; Hager, W.H. T-jump in abruptly expanding channel. J. Hydraul. Res. 1990, 31, 61–78. [Google Scholar] [CrossRef]

- Rajaratnam, N.; Subramanya, K. Profile of Hydraulic Jump. J. Hydraul. Div. ASCE 1968, 94, 663–673. [Google Scholar] [CrossRef]

- Alhamid, A.A. S-jump characteristics on sloping basins. J. Hydraul. Res. 2004, 42, 657–662. [Google Scholar] [CrossRef]

- Bremen, R. Expanding Stilling Basin. Ph.D Thesis, Ecole Polytechnique Federale de Lausanne (EPFL), Lausanne, Switzerland, 1990. [Google Scholar]

- Herbrand, K. The Spatial Hydraulic Jump. J. Hydraul. Res. 1973, 11, 205–218. [Google Scholar] [CrossRef]

- Zare, H.K.; Doering, J.C. Forced hydraulic jumps below abrupt expansions. J. Hydraul. Eng. 2010, 137, 825–835. [Google Scholar] [CrossRef]

- Zahabi, H.; Torabi, M.; Alamatian, E.; Bahiraei, M.; Goodarzi, M. Effects of Geometry and Hydraulic Characteristics of Shallow Reservoirs on Sediment Entrapment. Water 2018, 10, 1725. [Google Scholar] [CrossRef]

- Hosseini, D.; Torabi, M.; Moghadam, M.A. Preference assessment of energy and momentum equations over 2D-SKM method in compound channels. J. Water Resour. Eng. Manag. 2019, 6, 24–34. [Google Scholar]

- Torabi, M.; Hamedi, A.; Alamatian, A.; Zahabi, H. The effect of geometry parameters and flow characteristics on erosion and sedimentation in channels junction using finite volume method. arXiv 2019, arXiv:1906.10102. [Google Scholar]

- Rajaratnam, N. Hydraulic jump on rough bed. Trans. Eng. Inst. Can. 1968, 11, 1–8. [Google Scholar]

- Parsamehr, P.; Farsadizadeh, D.; Hosseinzadeh Dalir, A.; Abbaspour, A.; Nasr Esfahani, M.J. Characteristics of hydraulic jump on rough bed with adverse slope. ISH J. Hydraul. Eng. 2017, 23, 301–307. [Google Scholar] [CrossRef]

- Matin, M.A.; Hasan, M.R.; Islam, M.A. Experiment on Hydraulic Jump in Sudden Expansion in a Sloping Rectangular Channel; Department of Water Resources Engineering, Bangladesh University of Engineering and Technology: Dhaka, Bangladesh, 2008; Volume 1000, pp. 65–77. [Google Scholar]

- Neisi, K.; Shafai Bajestan, M. Characteristics of S-jump on Roughened Bed Stilling Basin. J. Water Sci. Res. 2013, 5, 25–34. [Google Scholar]

- Daneshfaraz, R.; Majediasl, M.; Mirzaee, R.; Parsamehr, P. Experimental study of the roughness bed with non-continuous trapezoidal elements on S-jump characteristics in the non-prismatic rectangular channel. Sharif J. Civ. Eng. 2019, 2, 119–128. [Google Scholar]

- Torkamanzad, N.; Hosseinzadeh Dalir, A.; Salmasi, F.; Abbaspour, A. Hydraulic jump below abrupt asymmetric expanding stilling basin on rough bed. Water 2019, 11, 1756. [Google Scholar] [CrossRef] [Green Version]

- Torabi, M.; Shafieefar, M. An experimental investigation on the stability of foundation of composite vertical breakwaters. J. Mar. Sci. Appl. 2015, 14, 175–182. [Google Scholar] [CrossRef]

- Bejestan, M.S.; Neisi, K. A new roughened bed hydraulic jump stilling basin. Asian J. Appl. Sci. 2009, 2, 436–445. [Google Scholar] [CrossRef] [Green Version]

- Ead, S.; Rajaratnam, N. Hydraulic jumps on corrugated beds. J. Hydraul. Eng 2002, 128, 656–663. [Google Scholar] [CrossRef]

- Lopardo, R.A.; Solari, H.G. Pressure fluctuations beneath free hydraulic jump. Proc. 9th Congress of the Latin American Hydraulica. Int. Assoc. Hydraul. Res. 1980, 1, 77–89. [Google Scholar]

- Yan, Z.; Zhou, C.; Lu, S. Pressure fluctuations beneath spatial hydraulic jumps. J. Hydrodyn. 2006, 18, 723–726. [Google Scholar] [CrossRef]

- Hassanpour, N.; Hosseinzadeh Dalir, A.; Bayon, A.; Abdollahpour, M. Pressure fluctuations in the spatial hydraulic jump in stilling basins with different expansion ratio. Water 2020, 13, 60. [Google Scholar] [CrossRef]

- Lopardo, R.A.; Romagnoli, M. Pressure and Velocity Fluctuations in Stilling Basins. In Advances in Water Resources and Hydraulic Engineering; Springer: Berlin/Heidelberg, Germany, 2009; pp. 2093–2098. [Google Scholar]

- Marques, M.G.; Drapeau, J.; Verrette, J.L. Flutuaç de Presso em Umressalto Hidrulico, XVII; Congreso Latinoamericano de Hidrulica: Guayaquil, Ecuador, 1997. [Google Scholar]

- Onitsuka, K.; Akiyama, J.; Shige-Eda, M.; Ozeki, H.; Gotoh, S.; Shiraishi, T. Relationship between Pressure Fluctuations on the Bed Wall and Free Surface Fluctuations in Weak Hydraulic Jump. In New Trends in Fluid Mechanics Research; Springer: Berlin/Heidelberg, Germany, 2007; pp. 300–303. [Google Scholar]

- Hassanpour, N.; Hosseinzadeh Dalir, A.; Farsadizadeh, D.; Gualtieri, C. An experimental study of hydraulic jump in a gradually expanding rectangular stilling basin with roughened bed. Water 2017, 9, 945. [Google Scholar] [CrossRef]

| (cm) | (cm) | Expansion Ratio (β) | bed | (cm) | |||

|---|---|---|---|---|---|---|---|

| 80 | 80 | 1 | 60,000–132,000 | 2–6.9 | 40–90 | ||

| 53 | 80 | 0.67 | smooth | 3–6 | 82,000–161,000 | 2.2–8.5 | 45–102 |

| 40 | 80 | 0.5 | 53,000–172,000 | 2.3–9.5 | 22–73 | ||

| 27 | 80 | 0.33 | 91,000–192,000 | 2.5–10.5 | 25–60 | ||

| 80 | 80 | 1 | 52,000–141,000 | 2–6.5 | 31–96 | ||

| 53 | 80 | 0.67 | rough | 3–6 | 65,000–156,000 | 2.3–8 | 32–90 |

| 40 | 80 | 0.5 | 62,000–153,000 | 2.4–9.1 | 26–70 | ||

| 27 | 80 | 0.33 | 74,000–242,000 | 3–9.5 | 20-70 |

| Type of Jump | Reduction (%) of |

|---|---|

| smooth bed and sudden expansion; β = 0.67 | 18 |

| smooth bed and sudden expansion; β = 0.5 | 23 |

| smooth bed and sudden expansion; β = 0.33 | 30 |

| rough bed and prismatic jump; β = 1 | 20 |

| rough bed and sudden expansion; β = 0.67 | 27 |

| rough bed and sudden expansion; β = 0.5 | 46 |

| rough bed and sudden expansion; β = 0.33 | 58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasani, M.N.; Nekoufar, K.; Biklarian, M.; Jamshidi, M.; Pham, Q.B.; Anh, D.T. Investigating the Pressure Fluctuations of Hydraulic Jump in an Abrupt Expanding Stilling Basin with Roughened Bed. Water 2023, 15, 80. https://doi.org/10.3390/w15010080

Hasani MN, Nekoufar K, Biklarian M, Jamshidi M, Pham QB, Anh DT. Investigating the Pressure Fluctuations of Hydraulic Jump in an Abrupt Expanding Stilling Basin with Roughened Bed. Water. 2023; 15(1):80. https://doi.org/10.3390/w15010080

Chicago/Turabian StyleHasani, Marzieh Naem, Kouros Nekoufar, Morteza Biklarian, Morteza Jamshidi, Quoc Bao Pham, and Duong Tran Anh. 2023. "Investigating the Pressure Fluctuations of Hydraulic Jump in an Abrupt Expanding Stilling Basin with Roughened Bed" Water 15, no. 1: 80. https://doi.org/10.3390/w15010080