1. Introduction

Transient events are common in water distribution networks, usually leading to negative consequences such as water hammers [

1]. Accordingly, problems such as pipe bursts and leakage frequently occur in water distribution networks [

2,

3]. In water distribution systems, the source of transient events may be related to valve maneuvers, pump trips, load acceptance, or rejection of turbines [

4]. Therefore, researchers, water utilities, and engineers are interested in understanding the nature, generation, and propagation of water hammer waves [

5,

6,

7].

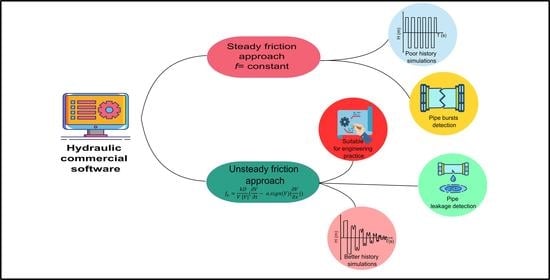

Several commercial software tools are available for the simulation of hydraulic transients and the design of hydraulic systems [

8]. It was noticed that there are currently 21 available water hammer commercial software, as illustrated in

Table 1. The majority of software (13 out of 21) use the methods of characteristics (MoC) to solve the hydraulic equation. Moreover, 18 out of the 21 software depends on steady/quasisteady friction models while computing water hammer equations. Out of the 21 software, three were only able to perform water hammer calculations based on the unsteady friction model. The Bentley Hammer, Hytran and TSNet Python package software used the Vítkovský friction model to analyze unsteady friction [

8,

9,

10]. In contrast, WANDA, which is a software developed by Deltares Consultancy in the Netherlands, still uses quasisteady friction for hydraulic transient simulations and hydraulic system designs.

As mentioned in

Table 1, currently available hydraulic commercial software can execute basic transient simulations. However, commercial software usually use a (quasi)steady friction assumption that notably affects the simulations’ quality [

11]. Unsteady friction is among other dynamic phenomena that significantly affect transient behavior [

12]. In contrast with steady friction, unsteady friction is dominant in the transient event’s later history [

13]. Even though unsteady friction has remarkable effects on the hydraulic transients, it is rarely introduced in commercial hydraulic software. Hence, current commercial software cannot be adequately used for applications requiring a long and accurate estimation of the pressure waves, e.g., leakage detection.

Recently, many researchers have been encouraged to focus their research on the unsteadiness of friction in water hammers [

13,

14,

15]. The underestimation of the dissipation, dispersion, and alteration of water hammer pressure waves in 1D models has been linked to unsteady friction [

16]. Different experiments illustrated the importance of unsteady friction over steady friction, especially in fast transients [

17,

18]. Different approaches have been adopted to incorporate unsteady friction in transient flow simulation [

19]. These methods can be classified into four categories [

19]: (i) instantaneous mean flow velocity; (ii) instantaneous mean flow velocity and local acceleration; (iii) instantaneous mean flow velocity, local acceleration, and convective acceleration; and (iv) instantaneous mean flow velocity and past velocity changes weights.

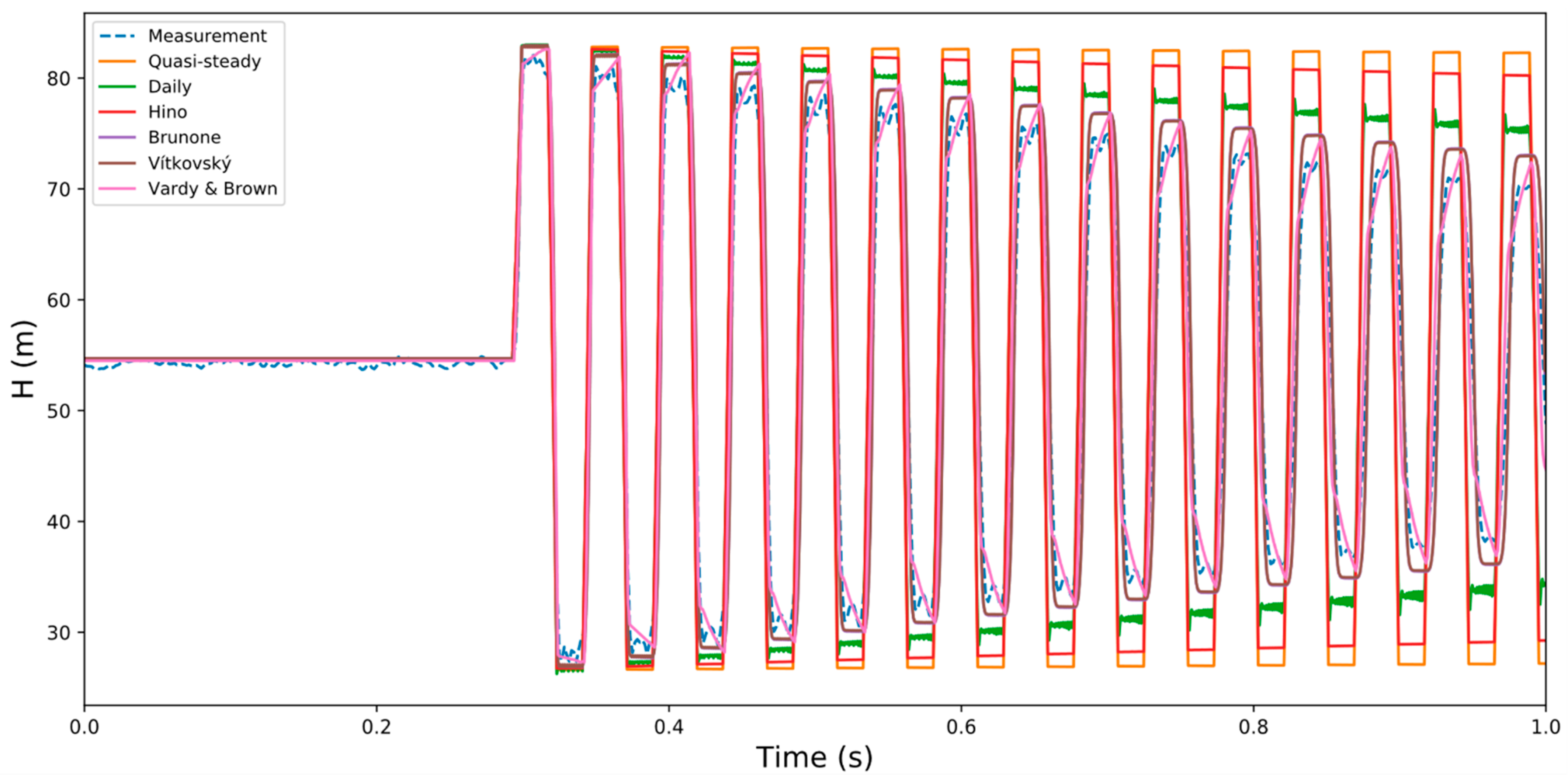

Shamloo et al. [

20] compared the numerical studies and experimental results done by Bergant and Simpson [

21]. The models used were Brunone, Zielke, Vardy and Brown, and Trikha. They concluded that the results obtained from Brunone’s model seem to be overestimated for laminar flow than the other unsteady models. The models of Zielke, Vardy and Brown, and Trikha have similar results, where the maximum heads and wave shape are accurately predicted. Another comparison was performed by Jensen et al. [

22], who compared different models (steady, quasisteady, Brunone, Vardy and Brown, Zielke) with experimental data performed by Soares et al. [

23]. This study showed that Brunone’s model provided better results over steady and quasisteady friction models. In contrast, convolution-based models (Zielke and Vardy and Brown) provided the most accurate results. The results illustrated that there is no need to enhance the model from steady friction to quasisteady friction as the improvement of accuracy is almost negligible, and the focus for improvement falls into the unsteady friction approach.

This study aims to fill the gap between academia and the hydraulic software industry in terms of implementing the most-suited unsteady friction model for engineering practice in hydraulic commercial software. Different unsteady friction models were compared, and the most suitable model was chosen to be implemented in WANDA based on well-developed criteria. The upgraded WANDA software with the unsteady friction model was tested on different hydraulic networks to illustrate the newly acquired attributes. Moreover, the recently implemented WANDA software was compared to other commercial software, including the Bentley Hammer and TSNet Python package, which also assumes unsteady friction computation. The main outcome of this study is to provide commercial software with more accurate transient solvers by means of adding unsteady friction, providing a framework to carry out analysis such as inverse transient analysis, which aims to solve standard engineering problems such as leakage detection.

2. Methodology

2.1. Implementation of the Hydraulic Solver

The method of characteristics was used to solve the water hammer hyperbolic differential equation due to its computational efficiency, accuracy, and ease of programming [

4]. The classic water hammer model has been implemented in Python based on the MoC, solving Equations (1)–(3),

where (

R) is the convenient coefficient, (

Q) is the flow, (

g) is acceleration due to gravity, (

t) is time, (

a) is the wave celerity, (

D) is the diameter, and (

A) is the Area. The friction (

f) is the summation of the quasisteady friction (

fq) and unsteady friction (

fu)

In this section, several friction models were implemented using the equations illustrated in

Table 2. The implemented models were quasisteady friction and unsteady friction models. Generally, steady friction assumes that the friction factor

f is constant along with the simulation. However, the quasisteady friction assumption assumes that the Reynolds number is calculated and updated at each new computation as shown in Equation (5).

Four different categories of unsteady friction models were implemented, including (i) instantaneous mean flow velocity; (ii) instantaneous mean flow velocity and local acceleration; (iii) instantaneous mean flow velocity, local acceleration, and convective acceleration; (iv) and instantaneous mean flow velocity and past velocity changes weights.

Hino is the most common instantaneous mean flow velocity unsteady friction model. The model is only function of instantaneous mean flow velocity. This model was implemented using Equation (6). The unsteady friction term was added to the quasisteady friction forming the overall friction at each new computation. Daily’s model was implemented using Equation (7). To compute Daily’s model, prior knowledge of the steady friction component is needed. Furthermore, the finite difference was used to calculate the local acceleration (). Brunone’s model is dependent on instantaneous acceleration, instantaneous convective acceleration and a damping coefficient as illustrated in Equation (8). Vítkovský’s model is similar to Brunone’s model. However, it has an additional sign term, which provides the right sign for the convection term for all potential flows, acceleration, or deceleration phases, as illustrated in Equation (9). Explicit first-order finite differences were used to calculate local acceleration () and convective acceleration (). Instantaneous mean flow velocity and past velocity changes weights unsteady friction models are usually solved using convolution equations as illustrated in Equation (10). The convolution was solved with a regular rectangular grid with first-order finite-difference approximation. In this paper, the Vardy and Brown weighting function was used as demonstrated by Equation (11). In terms of model analysis, it is expected that Hino’s model would require the least computational requirements due to the simpler modeling assumptions (instantaneous mean flow velocity); however, accuracy is expected to be lower. On the other hand, Vardy and Brown would provide the highest accuracy but the highest computational efforts due to more complex assumptions, involving convolution of past velocity changes. For Brunone, and Vítkovský, the models are expected to have moderate computational requirements as they are dependent on instantaneous mean flow velocity, local and convective accelerations.”

2.2. Validation with Experimental Data

The implemented water hammer models were validated by means of experimental data, which were collected as part of the water hammer test series in the copper straight pipe facility, assembled at the Laboratory of Hydraulics and Environment of Instituto Superior Técnico (LHE/IST) and presented in Ferràs et al. [

19]. The pipe rig consisted of a reservoir–pipe–valve system, and pressure histories were recorded at different pipe sections. The system comprises a 15.49 m long pipe, inner diameter

D = 0.020 m, pipe wall thickness

e = 0.0010 m, and a Young modulus of elasticity of

E = 105 GPa. High-quality pressure transducers (WIKA S-10) were used for the pressure data acquisition at a frequency of 600 Hz.

Regarding the experiment conditions, the flow used was Qin = 4.2 L/min, with a wave celerity (c) of 1239 m/s, while the effective valve closure time (tv) was 0.003 s. The initial head at the reservoir (Hres) was 54.2 m.

2.3. Comparison of Friction Models

The following criteria were followed to assess the unsteady friction models in the Python environment that can fit in commercial software:

- i.

User input requirements

- ii.

Stability of the model

- iii.

Computational efficiency

- iv.

Model accuracy

2.3.1. Input Requirements and Stability

Each model’s input requirements were analyzed to ensure that users do not need to have prior information to use any of the friction models. Hence, models that are dependent on user’s inputs were not favored to be implemented in commercial software, while robust models that do not require user’s inputs were favored.

The stability was checked qualitatively over short and long simulation periods to ensure that the models were running as expected without numerical instabilities.

2.3.2. Computational Efficiency

Execution time is a matter of interest for any software developer. To analyze such an aspect efficiently, the trends concerning a particular factor are the matter of interest rather than absolute values. Hence, the growth of execution time relative to the input is the concern.

Big O notation is one of the most common notations related to task size and the computational resources requirements. The Big O notation represents the trend of execution time in order (O) of a function (g(n)).

The computational efforts analysis was performed using a set of input time simulation period arrays for different friction model simulations. The execution time was tracked for each simulation period. The retrieved simulation period and execution time data were fitted, and the dominant term was determined for each friction model using Equation (12).

2.3.3. Accuracy Comparison

The accuracy comparison was performed by comparing the simulated friction models’ peaks and comparing it with the real measurement data. This means of comparison has been commonly applied in literature for comparing the accuracy of the friction models [

21,

22,

30]. The summation of square error (SSE) demonstrated in Equation (13) has also been used to assist the error calculation.

where

Hm is the measured head, and

Hsim is the simulated head.

2.3.4. Weighted Average Comparison

To assess the final chosen model, a weighted average matrix was used to compare between the models based on different criteria. A score out of 10 was given to each criterion. However, each criterion was given a different weight. For example, user input requirements and stability were given a weight of 1 each as most of the models were stable and did not need an input. However, accuracy and time computation were given a weight of 3 due to their significant importance.

2.4. Application

The most-suited unsteady friction was incorporated in WANDA’s environment. The unsteady friction was calculated and added to the quasisteady friction component at each computation time step, as illustrated in Equation (3).

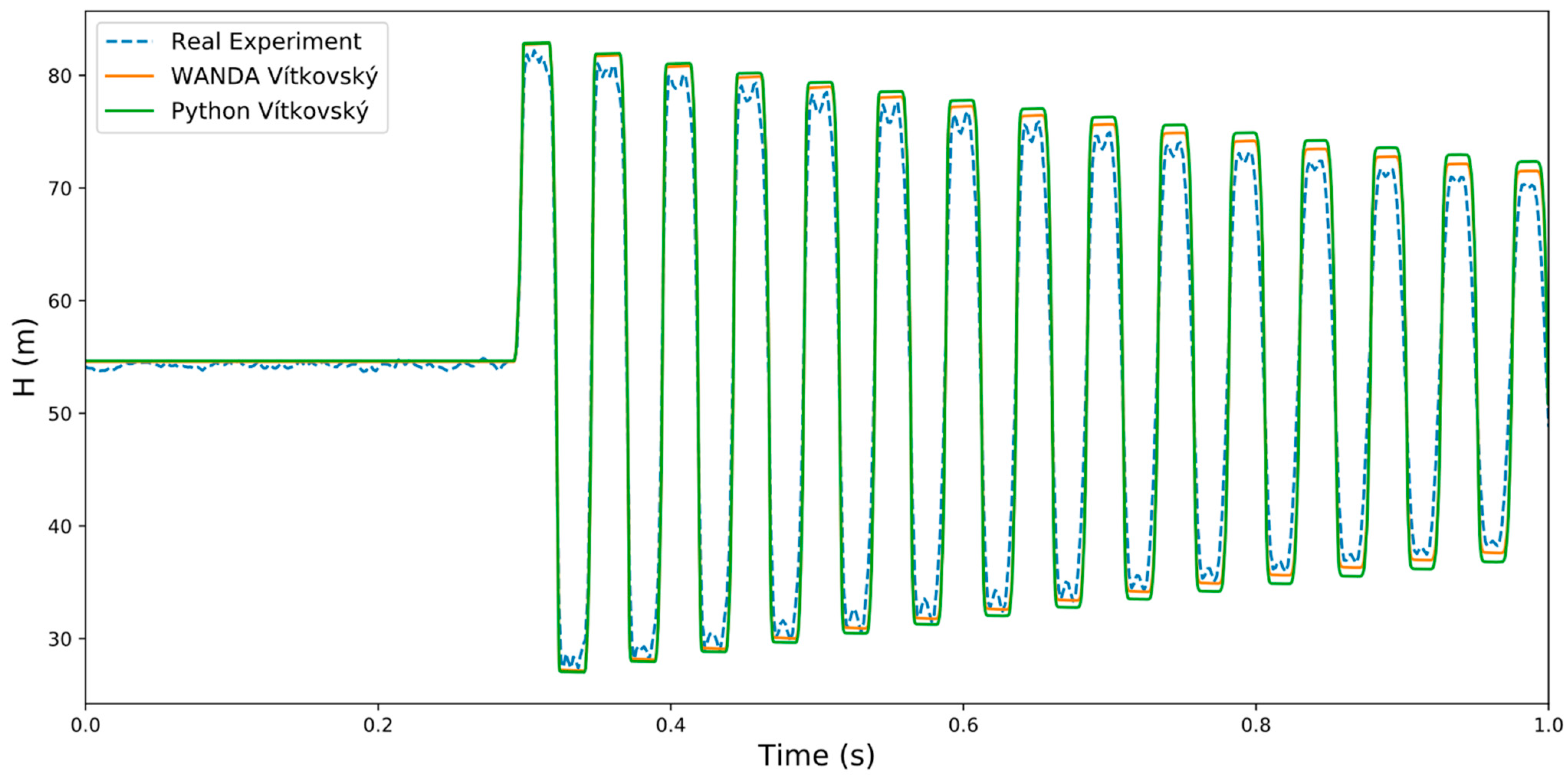

The WANDA software with the implemented new model was verified using the same experimental data stated in

Section 2.1. Additionally, WANDA was compared with the most-suited unsteady friction in the Python model. Hence, a comparison of WANDA’s and the developed Python’s code would be enough for the verification.

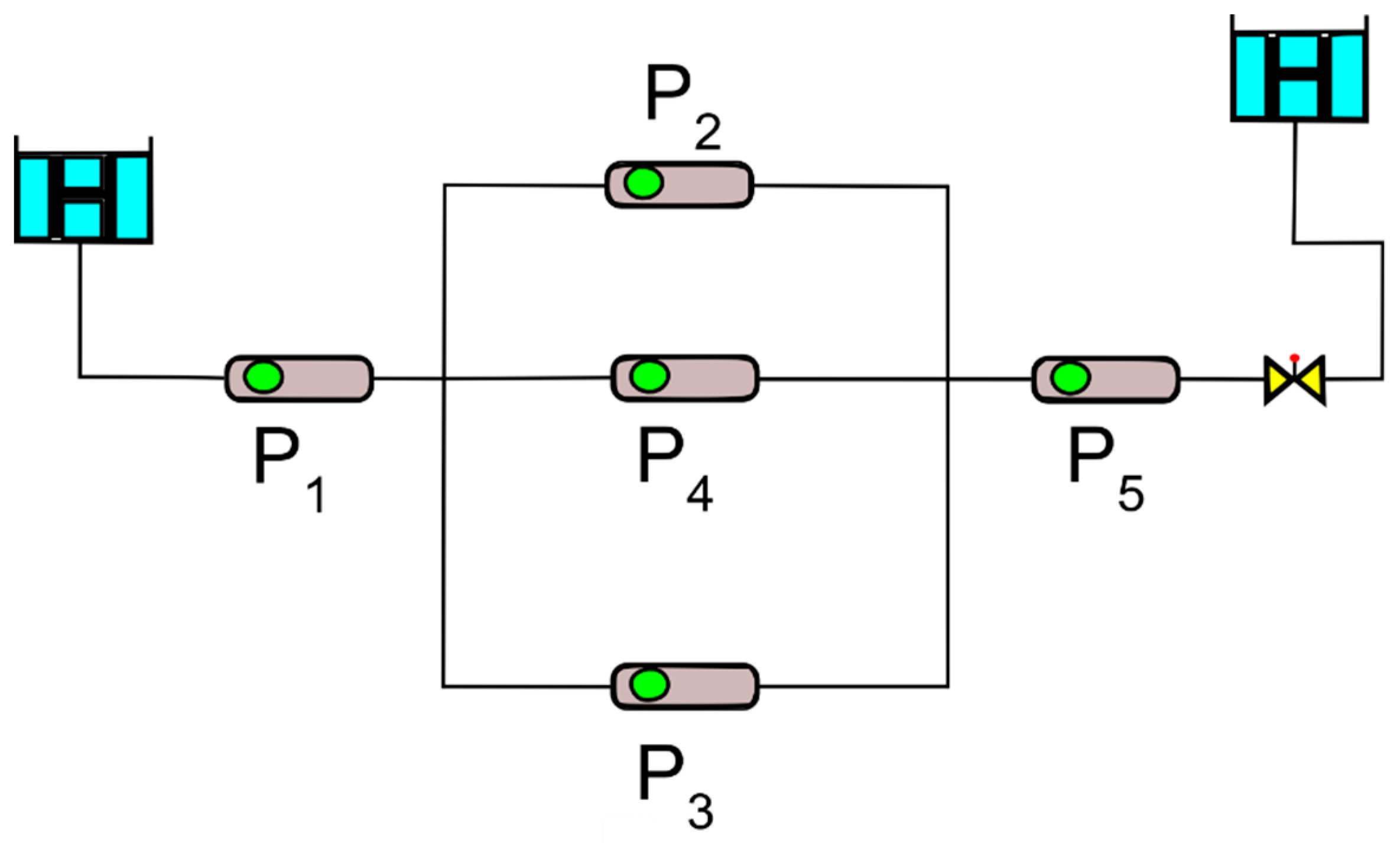

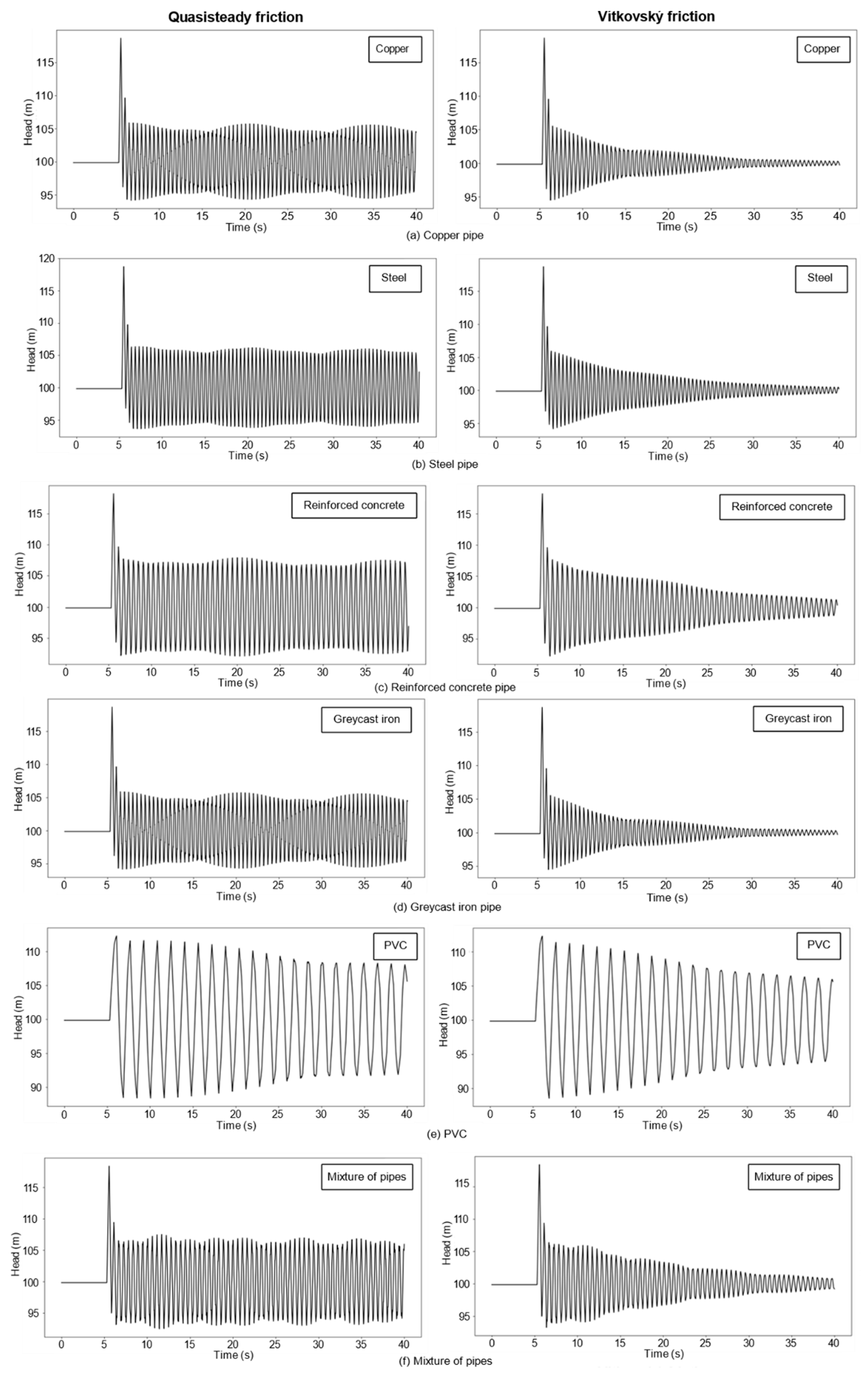

A simple synthetic network was constructed to easily compare the effects of transient event simulation at the valve using unsteady friction with the previously installed quasisteady friction model. The network is composed of an elevated tank, 5 pipes, 2 nodes, a butterfly valve, and the final reservoir. The network is illustrated in

Figure 1. Specifications of the network can be found in

Table 3.

At the same experiment, the effects of different pipe materials on the transient event simulated at the valve were studied. The pipes had different Young modulus values, as illustrated in

Table 4.

In these experiments, the valve closure was adjusted to be totally closed within 1 s, starting from 5.29 to 6.29.

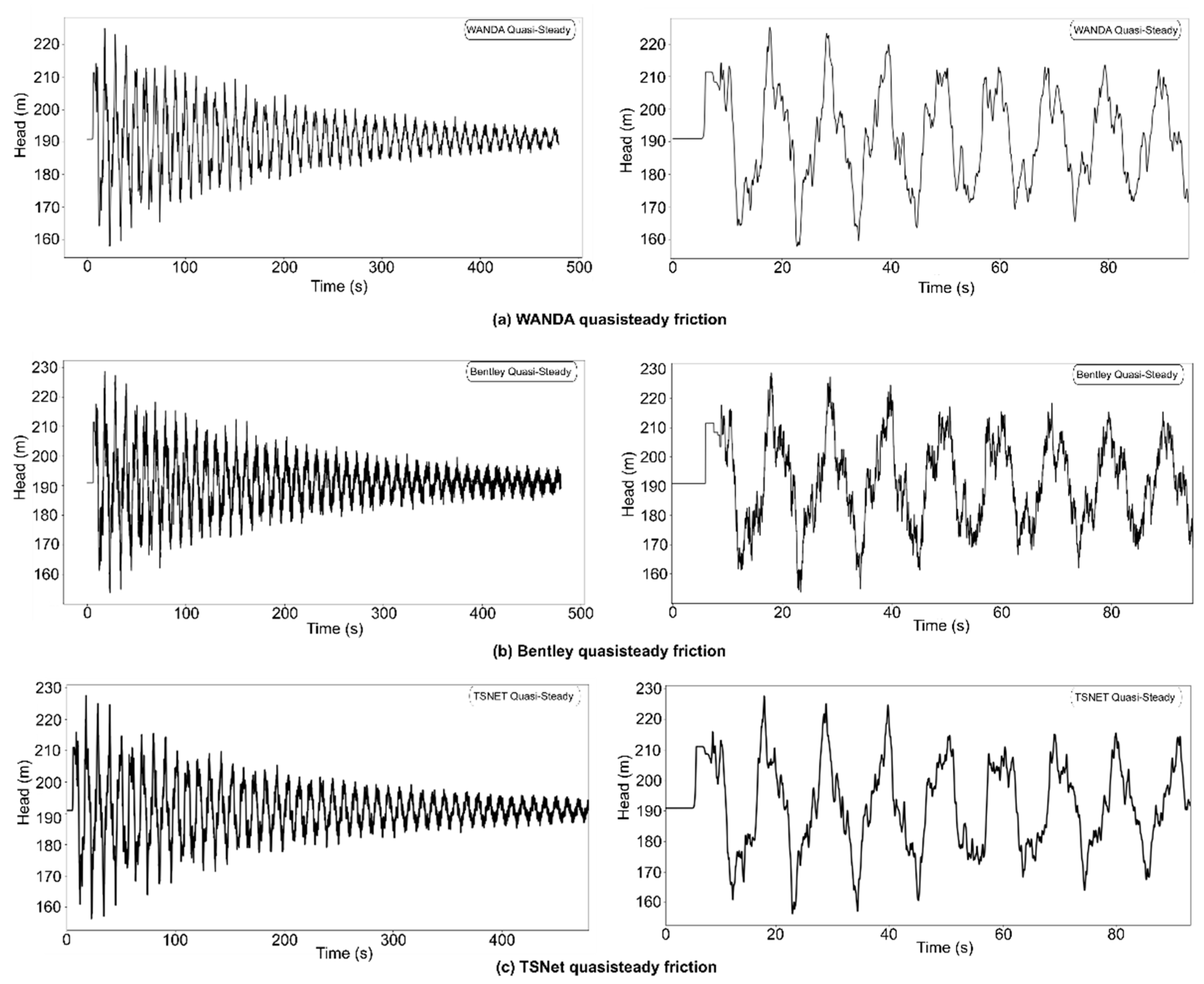

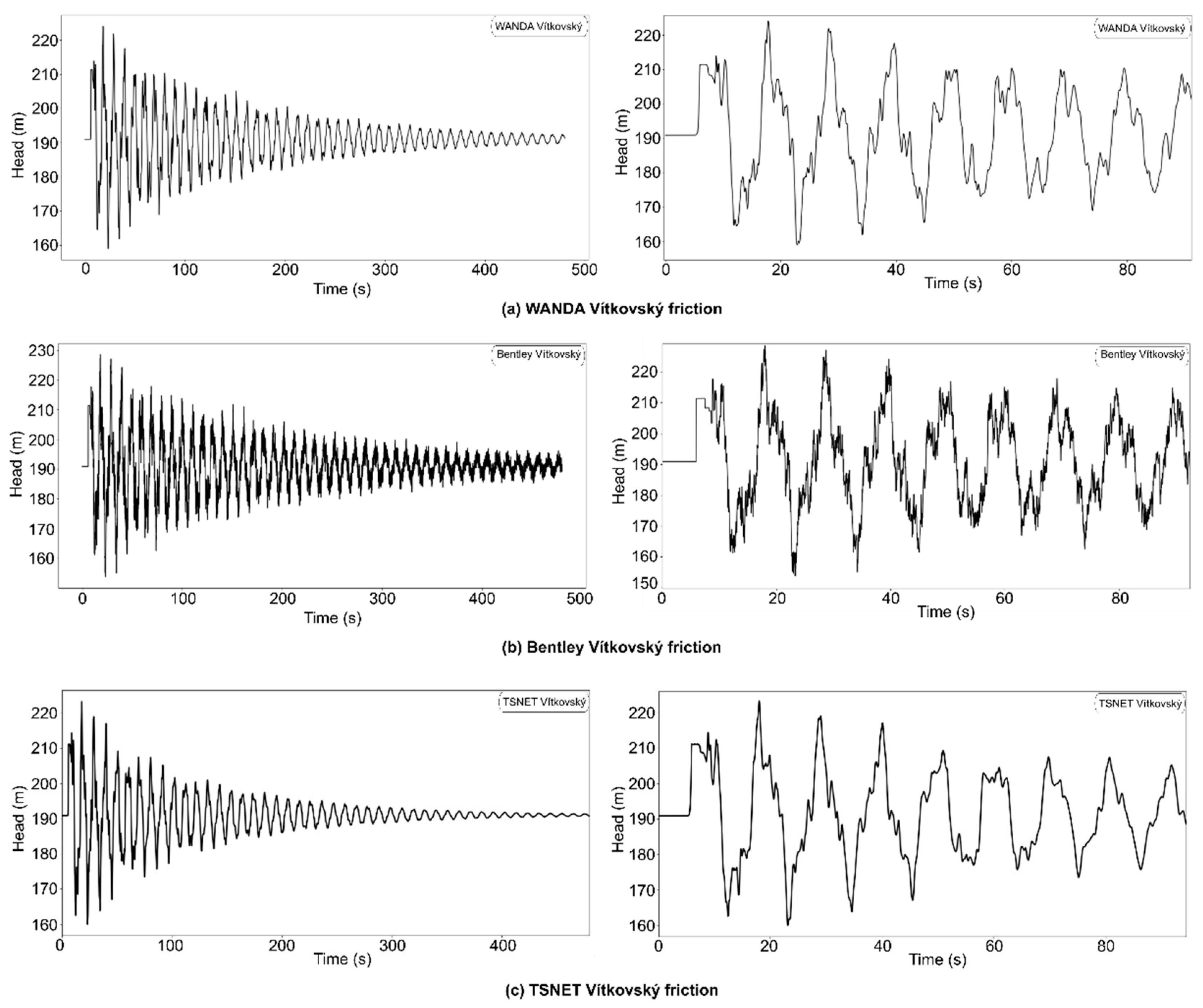

2.5. Comparison of WANDA with Available Commercial Software

Upon checking the scientific literature, it was found that there are currently three commercial software capable of doing the hydraulic simulation using an unsteady friction model. The three software are the Bentley Hammer (Bentley Systems, Exton, PA, USA), Hytran (University of Auckland, Auckland, New Zealand) and TSNet (University of Texas at Austin, Austin, TX, USA) package. All software are using Vítkovský’s friction. Hence, comparing the upgraded WANDA with those software would give precious insights into its current capabilities and performance.

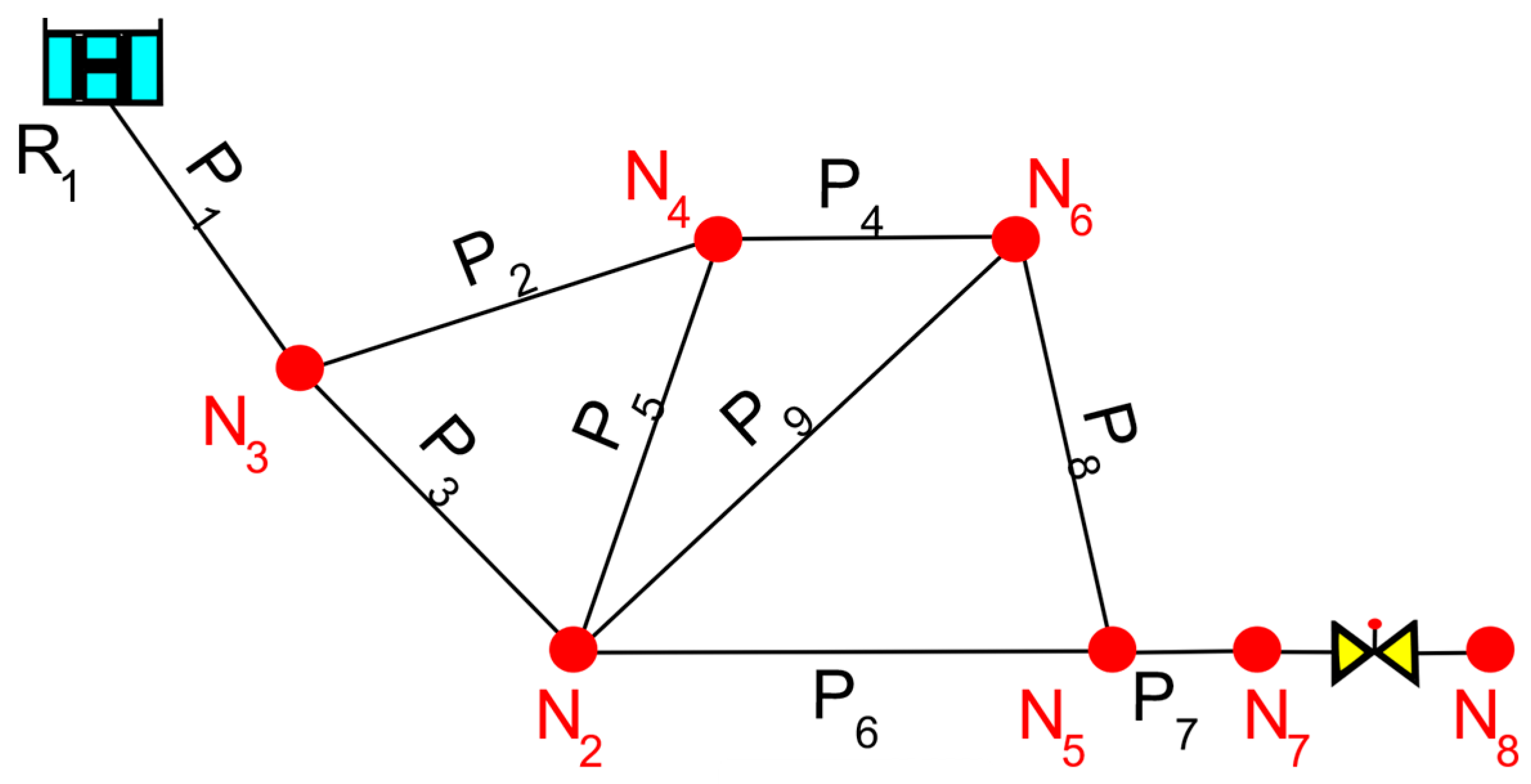

A benchmark network was used to compare between the different software WANDA, Bentley Hammer, and TSNet. The network structure is illustrated in

Figure 2, while the essential network properties are in

Table 5. The demands at N

2, N

4, and N

8 are 90, 90, and 360 m

3/h.

4. Conclusions and Future Perspectives

The conventional (quasi) steady friction assumption used in standard engineering practice for water hammer analyses limits transient simulations as wave damping becomes quickly underestimated due to the effect of unsteady friction. The computation of unsteady friction in commercial software is therefore mandatory for the accurate simulation of hydraulic transients, especially for those engineering applications requiring more in-depth insight into the pressure history (e.g., pipe flaw detection). Different unsteady friction models have been studied and compared based on developed criteria that focus on required user inputs, stability, accuracy, and computational efforts. The most-suited unsteady friction model that fits the engineering practices in the tested commercial software (i.e., WANDA) was Vítkovský’s model. The model has been implemented in WANDA and verified with other commercial software and experimental data. The model has also been tested on different hydraulic urban networks, with varying materials of pipe. It was found that incorporating the unsteady friction improves the description of the wave damping compared to the conventionally used quasisteady friction model.

Hydraulic transient software such as WANDA are becoming usual tools for water distribution analyses; however, their performance requires further improvement. For instance, implementation of the pipe-wall rheological behavior in WANDA for pipe networks simulation is crucial, since PVC and HDPE pipes are introduced more often to water distribution networks. The WANDA upgraded version presented should be tested for a set of engineering applications, e.g., leakage detection by means of inverse transient analysis.