A Highly Packed Biofilm Reactor with Cycle Cleaning for the Efficient Treatment of Rural Wastewater

Abstract

:1. Introduction

2. Materials and Methods

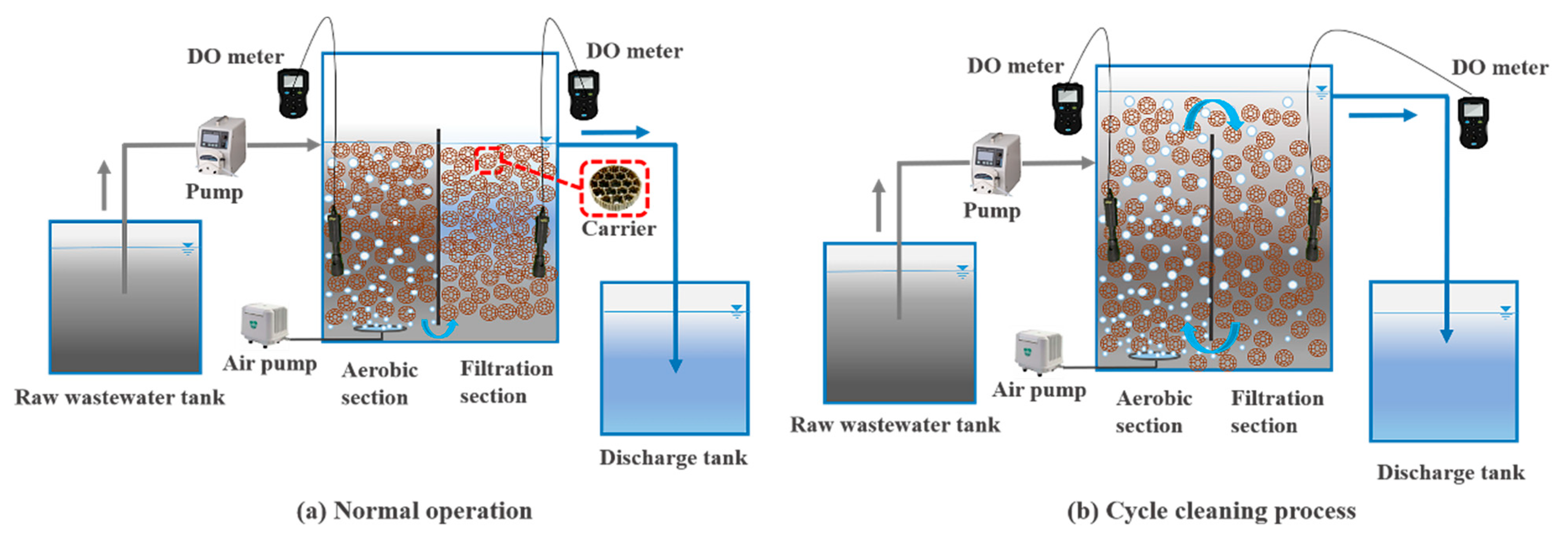

2.1. Experimental Setup

2.2. Bioreactor Operation

2.3. Wastewater Characteristics

2.4. Analytical Methods

3. Results and Discussion

3.1. Nutrients Removal Performance

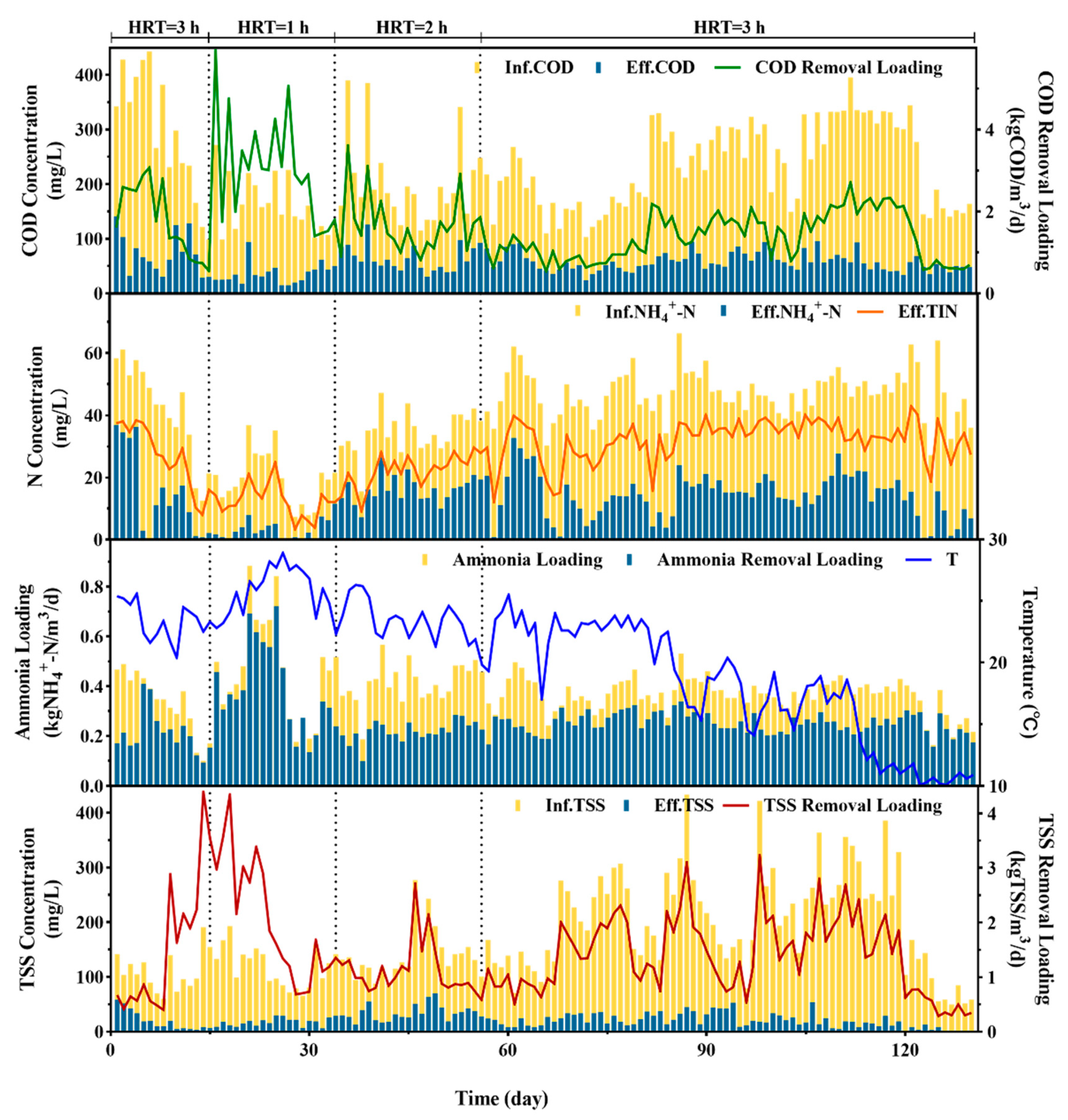

3.1.1. Overall Performance of HPBR

3.1.2. Role of Different Treatment Sections

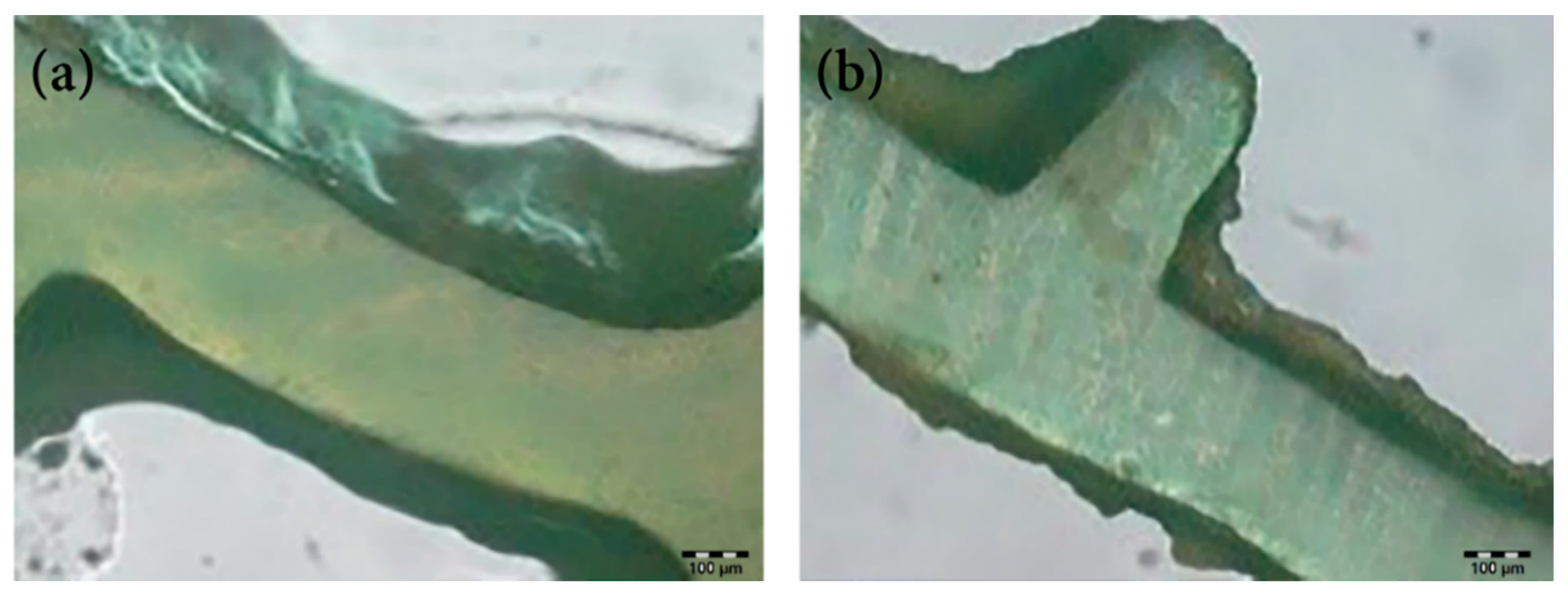

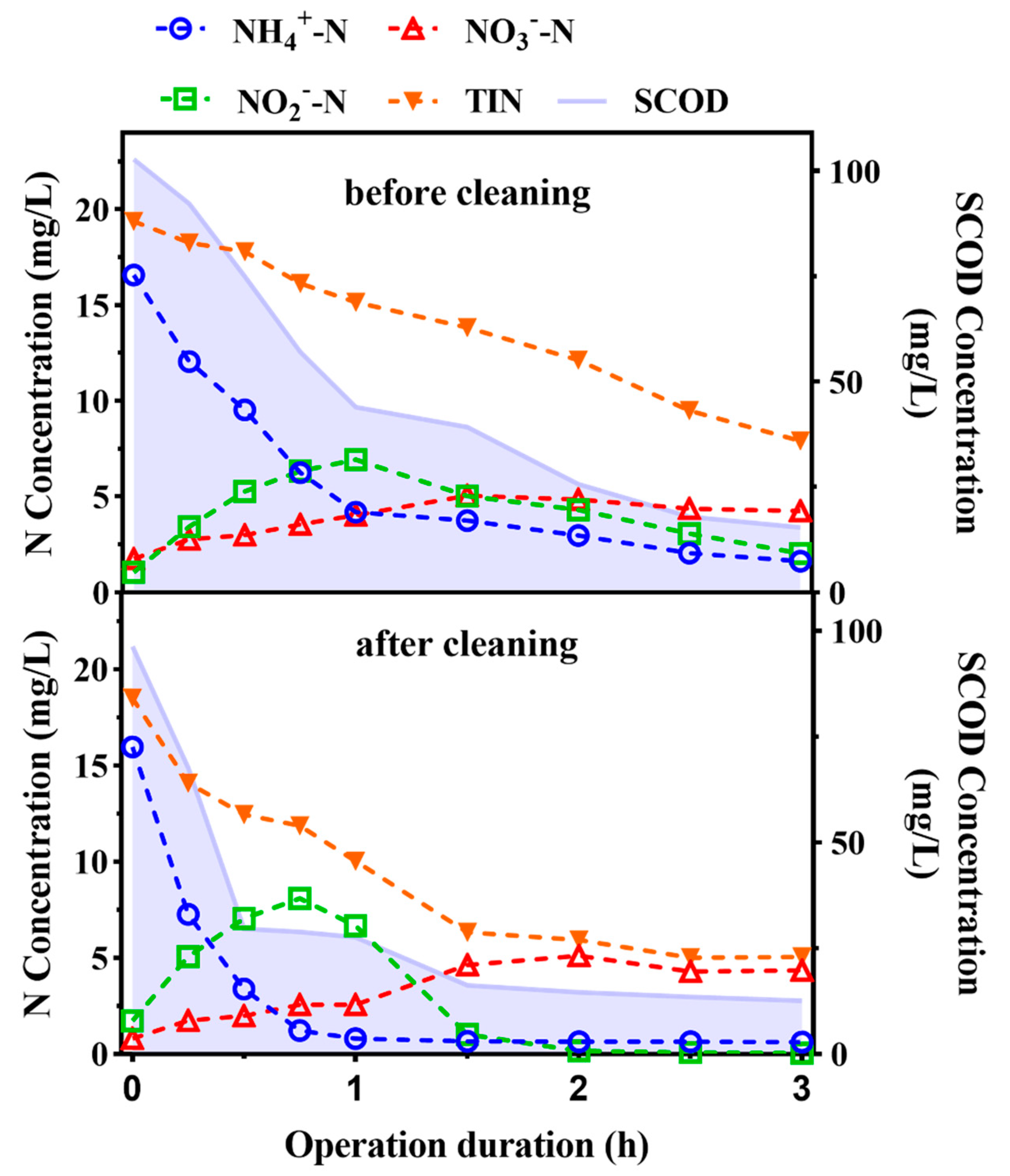

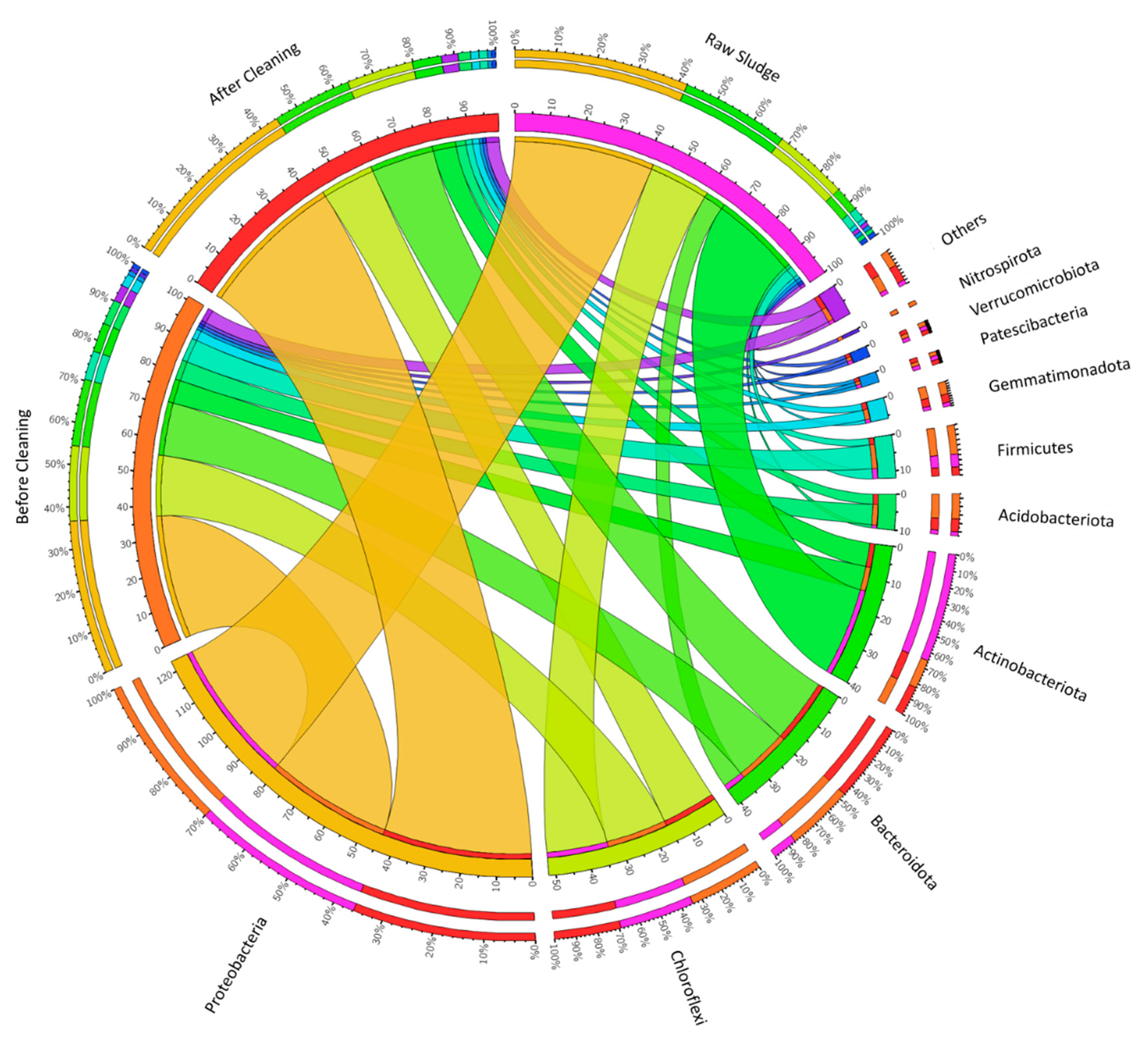

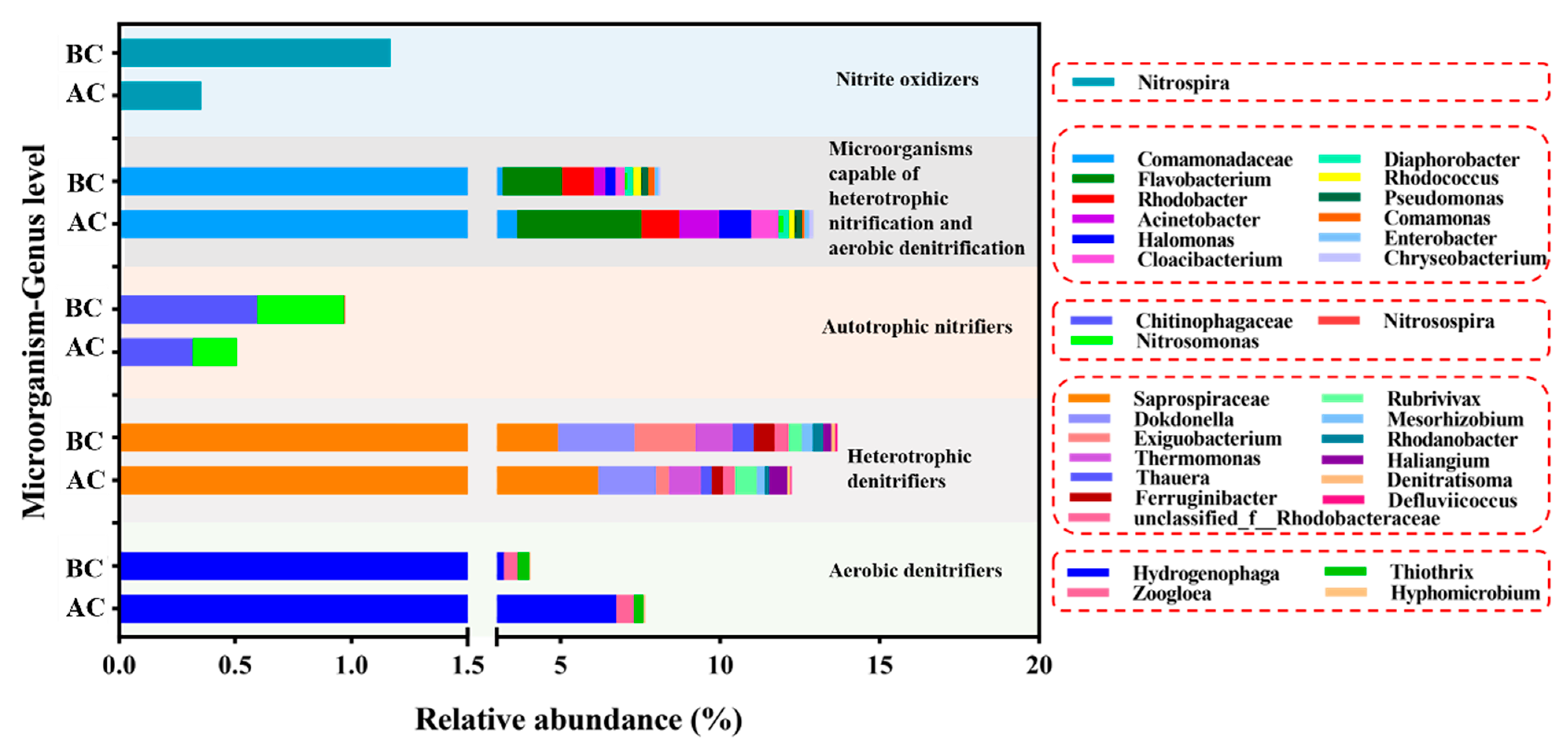

3.2. Mechanism of Sufficient Nutrients Removal Efficiency

3.3. Implications for Rural Wastewater Treatment Systems

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Guo, J.; Li, H.; Song, Y.; Chen, Z.; Lu, C.; Han, Y.; Hou, Y. Effect of dissolved oxygen on simultaneous removal of ammonia, nitrate and phosphorus via biological aerated filter with sulfur and pyrite as composite fillers. Bioresour. Technol. 2020, 296, 122340. [Google Scholar] [CrossRef]

- Rott, E.; Steinmetz, H.; Metzger, J.W. Organophosphonates: A review on environmental relevance, biodegradability and removal in wastewater treatment plants. Sci. Total Environ. 2018, 615, 1176–1191. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Xu, G.; Li, L.; Xu, Y.; Zhang, Y.; Liu, C.; Zhang, Z. Fabrication of Ceramsite Adsorbent from Industrial Wastes for the Removal of Phosphorus from Aqueous Solutions. J. Chem. 2020, 2020, 1–13. [Google Scholar] [CrossRef]

- Nie, E.; Wang, D.; Yang, M.; Luo, X.; Fang, C.; Yang, X.; Su, D.; Zhou, L.; Zheng, Z. Tower bio-vermifilter system for rural wastewater treatment: Bench-scale, pilot-scale, and engineering applications. Int. J. Environ. Sci. Technol. 2015, 12, 1053–1064. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; He, J. Complete nitrogen removal via simultaneous nitrification and denitrification by a novel phosphate accumulating Thauera sp. strain. Water Res. 2020, 185, 116300. [Google Scholar] [CrossRef]

- Loupasaki, E.; Diamadopoulos, E. Attached growth systems for wastewater treatment in small and rural communities: A review. J. Chem. Technol. Biotechnol. 2013, 88, 190–204. [Google Scholar] [CrossRef]

- Chen, F.; Yao, Q. The Development of Rural Domestic Wastewater Treatment in China. Adv. Mater. Res. 2014, 1073–1076, 829–832. [Google Scholar] [CrossRef]

- Singh, N.K.; Kazmi, A.A.; Starkl, M. A review on full-scale decentralized wastewater treatment systems: Techno-economical approach. Water Sci. Technol. 2015, 71, 468–478. [Google Scholar] [CrossRef]

- Chen, G.; Huang, J.; Fang, Y.; Zhao, Y.; Tian, X.; Jin, Y.; Zhao, H. Microbial community succession and pollutants removal of a novel carriers enhanced duckweed treatment system for rural wastewater in Dianchi Lake basin. Bioresour. Technol. 2019, 276, 8–17. [Google Scholar] [CrossRef]

- Zou, J.; Guo, X.; Han, Y.; Liu, J.; Liang, H. Study of a novel vertical flow constructed wetland system with drop aeration for rural wastewater treatment. Water. Air. Soil Pollut. 2012, 223, 889–900. [Google Scholar] [CrossRef]

- Guo, X.; Liu, Z.; Chen, M.; Liu, J.; Yang, M. Decentralized wastewater treatment technologies and management in Chinese villages. Front. Environ. Sci. Eng. 2014, 8, 929–936. [Google Scholar] [CrossRef]

- Zha, X.; Ma, J.; Lu, X. Performance of a coupling device combined energy-efficient rotating biological contactors with anoxic filter for low-strength rural wastewater treatment. J. Clean. Prod. 2018, 196, 1106–1115. [Google Scholar] [CrossRef]

- Ashkanani, A.; Almomani, F.; Khraisheh, M.; Bhosale, R.; Tawalbeh, M.; AlJaml, K. Bio-carrier and operating temperature effect on ammonia removal from secondary wastewater effluents using moving bed biofilm reactor (MBBR). Sci. Total Environ. 2019, 693, 133425. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Cheng, Y.; Yang, C.; Luo, W.; Zeng, G.; Lu, L. Performance of system consisting of vertical flow trickling filter and horizontal flow multi-soil-layering reactor for treatment of rural wastewater. Bioresour. Technol. 2015, 193, 424–432. [Google Scholar] [CrossRef]

- Rathnaweera, S.S.; Rusten, B.; Korczyk, K.; Helland, B.; Rismyhr, E. Novel biofilm reactor for denitrification of municipal wastewater. Water Sci. Technol. 2018, 78, 1566–1575. [Google Scholar] [CrossRef]

- Rathnaweera, S.S.; Rusten, B.; Manamperuma, L.D.; Wang, S.; Helland, B. Innovative, compact and energy-efficient biofilm process for nutrient removal from wastewater. Water Sci. Technol. 2020, 81, 1941–1950. [Google Scholar] [CrossRef] [PubMed]

- Association, A.P.H.; Association, A.W.W.; Federation, W.P.C.; Federation, W.E. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 1915; Volume 2, ISBN 8755-3546. [Google Scholar]

- Kowalski, M.S.; Devlin, T.R.; di Biase, A.; Oleszkiewicz, J.A. Effective nitrogen removal in a two-stage partial nitritation-anammox reactor treating municipal wastewater—Piloting PN-MBBR/AMX-IFAS configuration. Bioresour. Technol. 2019, 289, 121742. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, G. Integrated effects of temperature and COD/N on an up-flow anaerobic filter-biological aerated filter: Performance, biofilm characteristics and microbial community. Bioresour. Technol. 2019, 293, 122004. [Google Scholar] [CrossRef] [PubMed]

- Cui, B.; Yang, Q.; Zhang, Y.; Liu, X.; Wu, W.; Li, J. Improving nitrogen removal in biological aeration filter for domestic sewage treatment via adjusting microbial community structure. Bioresour. Technol. 2019, 293, 122006. [Google Scholar] [CrossRef]

- Wang, L.; Li, B.; Li, Y.; Wang, J. Enhanced biological nitrogen removal under low dissolved oxygen in an anaerobic-anoxic-oxic system: Kinetics, stoichiometry and microbial community. Chemosphere 2021, 263, 128184. [Google Scholar] [CrossRef]

- Wu, L.; Yang, Y.; Guo, W.; Huang, W.; Peng, Z.; Zhang, Z.; Zou, M.; Luo, J. Deterioration of biological pollutants removal induced by linear alkylbenzene sulphonates in sequencing batch reactors: Insight of sludge characteristics, microbial community and metabolic activity. Bioresour. Technol. 2020, 315, 123843. [Google Scholar] [CrossRef]

- Young, B.; Delatolla, R.; Kennedy, K.; Laflamme, E.; Stintzi, A. Low temperature MBBR nitrification: Microbiome analysis. Water Res. 2017, 111, 224–233. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, Q.; Miao, Y.; Sun, Y.; Chen, J.; Peng, Y. Stable and efficient partial nitritation granular sludge reactor treating domestic sewage at low temperature. Bioresour. Technol. 2018, 270, 746–750. [Google Scholar] [CrossRef] [PubMed]

- De Celis, M.; Belda, I.; Ortiz-Álvarez, R.; Arregui, L.; Marquina, D.; Serrano, S.; Santos, A. Tuning up microbiome analysis to monitor WWTPs’ biological reactors functioning. Sci. Rep. 2020, 10, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Deng, S.; Li, D.; Yang, X.; Zhu, S.; Li, J. Process of nitrogen transformation and microbial community structure in the Fe(0)–carbon-based bio-carrier filled in biological aerated filter. Environ. Sci. Pollut. Res. 2016, 23, 6621–6630. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhu, H. Treatment of Low C/N Ratio Wastewater by a Carbon Cloth Bipolar Plate Multicompartment Electroenhanced Bioreactor (CBM-EEB). ACS Omega 2020, 5, 27823–27832. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Miao, Y.; Zhang, Q.; Sun, Y.; Wu, L.; Peng, Y. Mechanism of stable sewage nitrogen removal in a partial nitrification-anammox biofilm system at low temperatures: Microbial community and EPS analysis. Bioresour. Technol. 2020, 297, 122459. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, J.; Liu, C.; Zhang, J.; Yang, J. Performance of a fixed-bed biofilm reactor with Microbubble aeration in aerobic wastewater treatment. Water Sci. Technol. 2016, 74, 138–146. [Google Scholar] [CrossRef]

- Yang, S.; Yang, F. Nitrogen removal via short-cut simultaneous nitrification and denitrification in an intermittently aerated moving bed membrane bioreactor. J. Hazard. Mater. 2011, 195, 318–323. [Google Scholar] [CrossRef]

- Kouba, V.; Widiayuningrum, P.; Chovancova, L.; Jenicek, P.; Bartacek, J. Applicability of one-stage partial nitritation and anammox in MBBR for anaerobically pre-treated municipal wastewater. J. Ind. Microbiol. Biotechnol. 2016, 43, 965–975. [Google Scholar] [CrossRef]

| Parameter | Value | |

|---|---|---|

| Average | Range | |

| Temperature (°C) | 20.6 ± 4.9 | 10.1–28.9 |

| DOAS (mg/L) | 6.7 ± 1.2 | 3.0–8.9 |

| DOFS (mg/L) | 2.3 ± 1.0 | 0.5–4.2 |

| pH | 7.9 ± 0.2 | 7.5–8.2 |

| COD (mg/L) | 231.5 ± 94.8 | 98.6–603.0 |

| SCOD (mg/L) | 151.7 ± 60.1 | 29.1–335.5 |

| Ammonia (mg/L) | 40.3 ± 13.1 | 7.3–66.4 |

| Nitrite (mg/L) | 0.1 ± 0.2 | 0–1.2 |

| Nitrate (mg/L) | 1.2 ± 1.2 | 0–7.4 |

| TIN (mg/L) | 41.7 ± 13.0 | 8.9–68.4 |

| TSS (mg/L) | 167.8 ± 83.5 | 50–433 |

| Nutrient | Influent (mg/L) | AS | FS | ||||

|---|---|---|---|---|---|---|---|

| Effluent (mg/L) | RE (%) | RL (g/m2/d) | Effluent (mg/L) | RE (%) | RL (g/m2/d) | ||

| COD | 226.0 ± 84.9 | 78.0 ± 31.7 | 65.49% | 6.03 ± 3.59 | 57.6 ± 23.5 | 26.15% | 0.78 ± 0.71 |

| Ammonia | 40.3 ± 13.1 | 14.8 ± 8.7 | 63.28% | 0.97 ± 0.35 | 13.1 ± 8.4 | 11.49% | 0.07 ± 0.11 |

| TIN | 41.6 ± 13.0 | 31.2 ± 10.5 | 25.00% | 0.39 ± 0.20 | 26.9 ± 9.7 | 13.78% | 0.19 ± 0.17 |

| TSS | 167.8 ± 83.5 | 44.6 ± 25.4 | 73.42% | 5.08 ± 3.25 | 22.9 ± 14.6 | 48.65% | 0.80 ± 0.66 |

| Reactor | Feed | DO (mg/L) | T (°C) | COD Influent Concentration (mg/L) | Ammonia Influent Concentration (mg/L) | TSS Influent Concentration (mg/L) | COD Removal Loading b (kg/m3/d) | Ammonia Removal Loading b (kg/m3/d) | TSS Removal Loading b (kg/m3/d) | Cycle Cleaning Process | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HPBR | Domestic wastewater | 6.7 ± 1.2 | 20.6 ± 4.9 | 231.5 ± 94.8 | 40.3 ± 13.1 | 167.8 ± 83.5 | 3.04 ± 1.81 | 0.49 ± 0.18 | 2.56 ± 1.64 | Yes | This study |

| MBBR | Domestic wastewater | 7.4–8.8 | 20 | 63.27–71.04 | 58–65.78 | - | 0.32 a | 0.09 a | - | No | [13] |

| MBBR | Diluted water | - | - | 99.8 ± 61.3 | 47.4 ± 8.6 | - | - | 0.04 a | - | No | [31] |

| ANF/ms-wdRBCs coupling device | Synthetic wastewater | - | 15–32 | 110.26 ± 5.96 | 24.98 ± 0.95 | - | 0.29 a | 0.07 a | - | No | [12] |

| vertical flow trickling filter (VFTF) | Synthetic wastewater | - | - | 255.20 ± 65.12 | 48.91 ± 7.93 | - | 0.81 a | 0.03 a | - | No | [14] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, Y.; Qiu, C.; Li, Y.; Kang, W.; Zhang, J.; Liao, Z.; Bi, X. A Highly Packed Biofilm Reactor with Cycle Cleaning for the Efficient Treatment of Rural Wastewater. Water 2021, 13, 369. https://doi.org/10.3390/w13030369

Luan Y, Qiu C, Li Y, Kang W, Zhang J, Liao Z, Bi X. A Highly Packed Biofilm Reactor with Cycle Cleaning for the Efficient Treatment of Rural Wastewater. Water. 2021; 13(3):369. https://doi.org/10.3390/w13030369

Chicago/Turabian StyleLuan, Yanan, Chen Qiu, Yaoxian Li, Weichang Kang, Jianhua Zhang, Zuliang Liao, and Xuejun Bi. 2021. "A Highly Packed Biofilm Reactor with Cycle Cleaning for the Efficient Treatment of Rural Wastewater" Water 13, no. 3: 369. https://doi.org/10.3390/w13030369