Water Hammer Simulation Method in Pressurized Pipeline with a Moving Isolation Device

Abstract

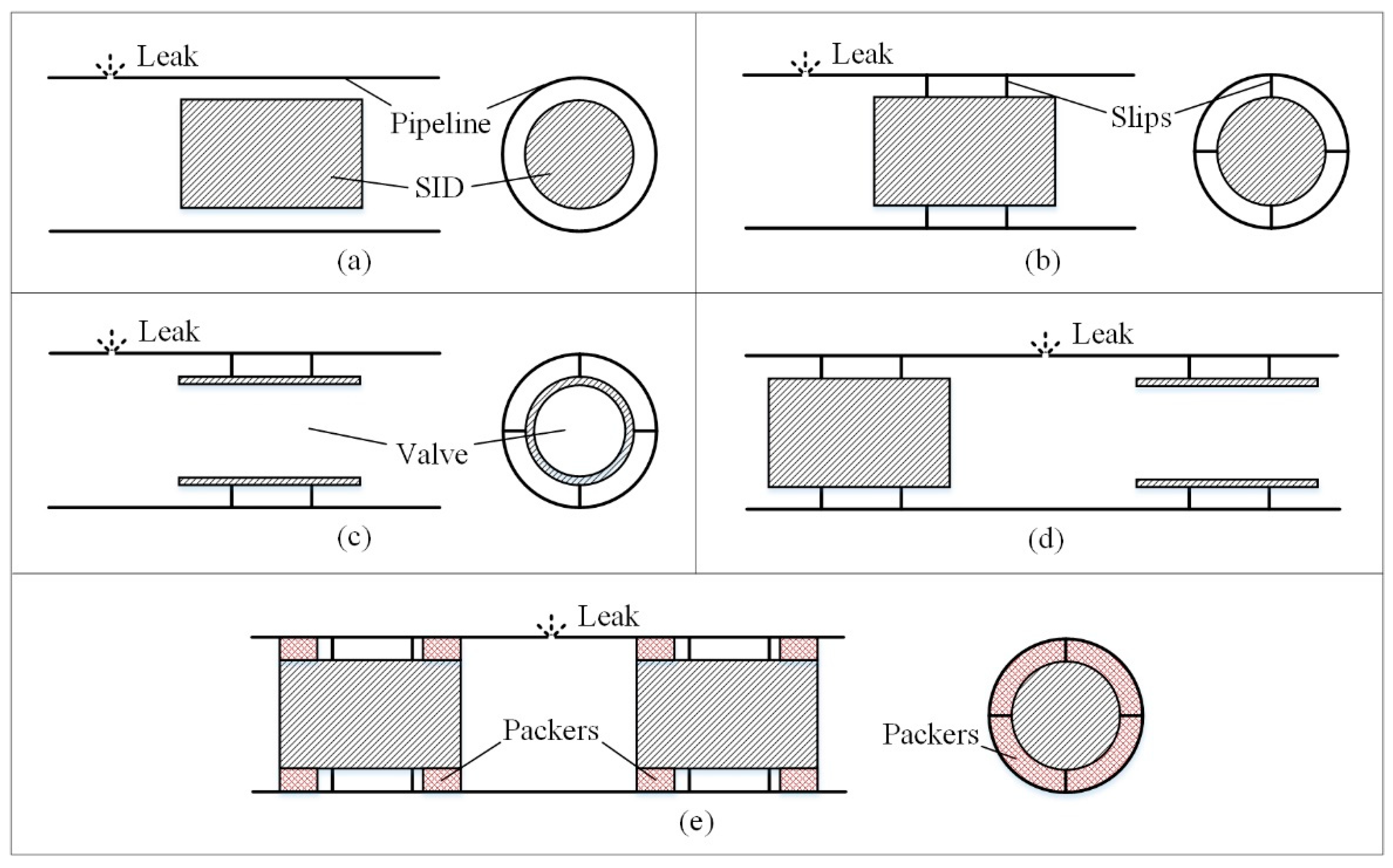

:1. Introduction

2. Methods to Model the SID Movement in Pipelines

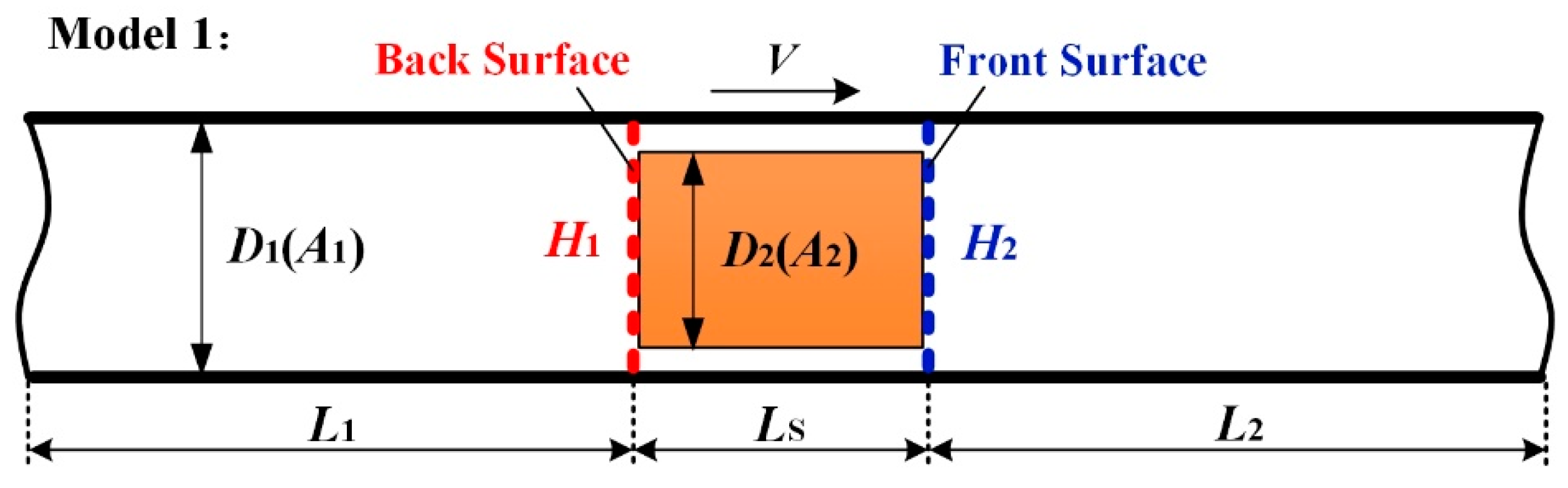

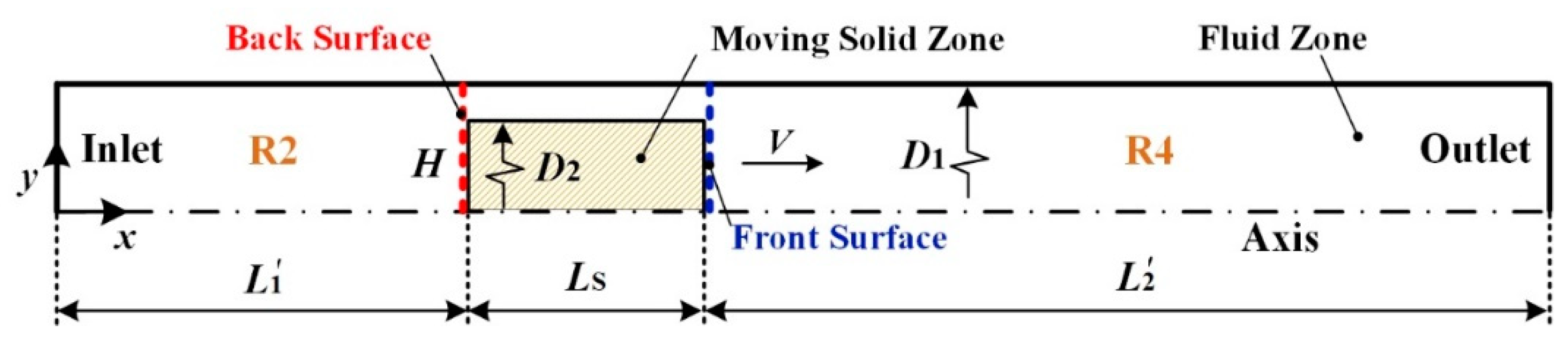

2.1. The Method to Simplify the Moving SID in the Pipeline

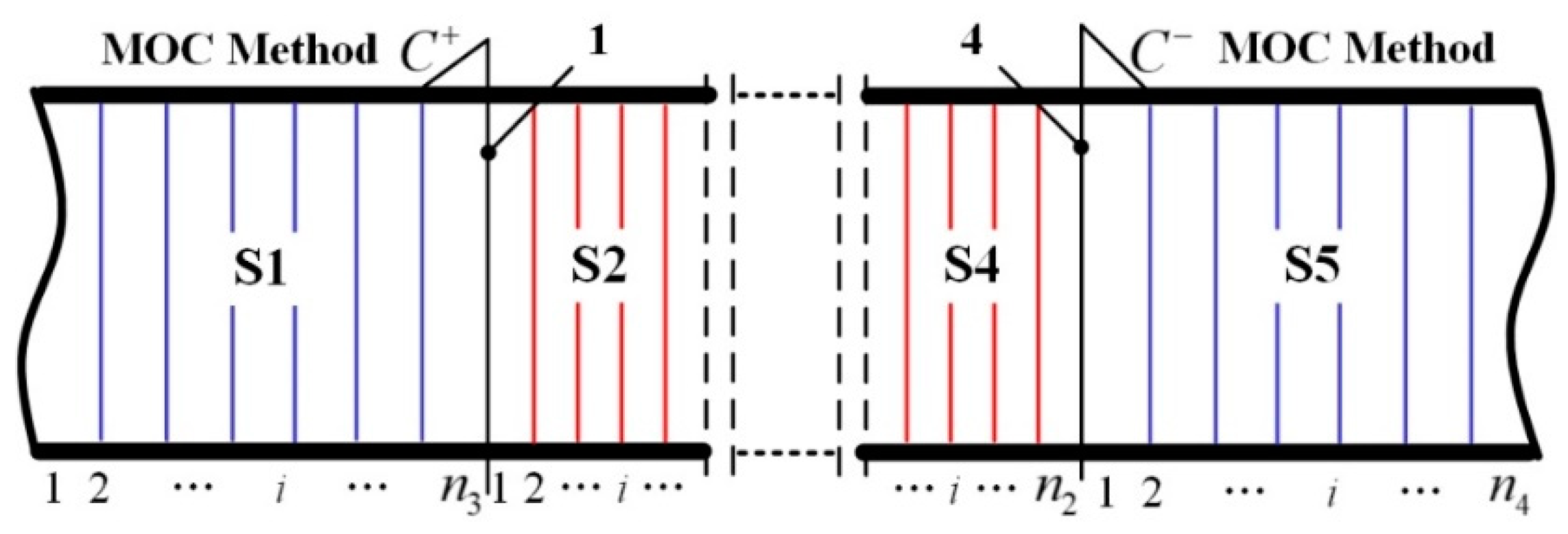

2.2. The Division of the Pipeline with Corresponding Methods

3. Discretization of the Governing Equations

3.1. Explicit Method of Characteristics

3.2. Discrete Implicit Method

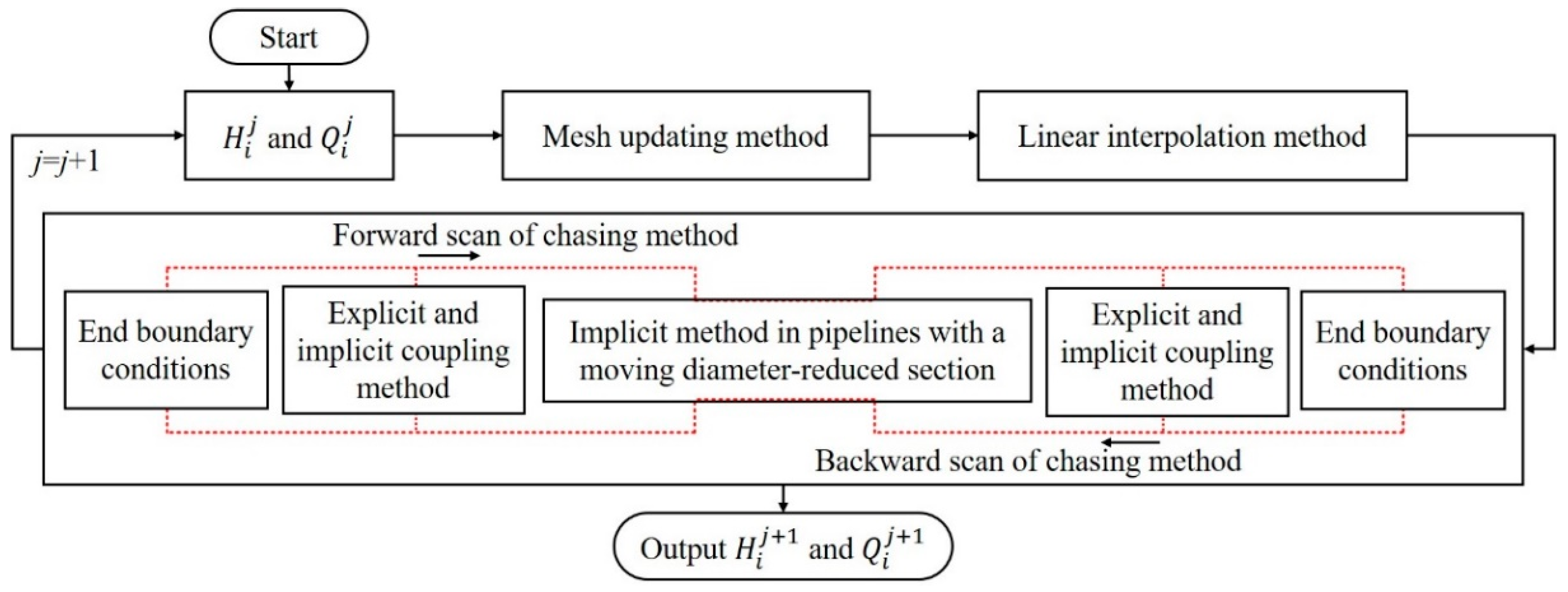

4. Coupling Method with Dynamic Meshes

4.1. Dynamic Meshes in the Implicit Method

4.2. Implicit Method in Pipelines with a Moving Diameter-Reduced Section

4.3. Explicit–Implicit Coupling Method

5. CFD Validation of the New Moving Mesh Method

5.1. System Configuration

5.2. Basic Information of the CFD Model

5.3. Steady State Flow

5.4. Scenario 1: The SID Moves in the Pipeline and Stops Immediately

5.5. Scenario 2: The SID Stops with a Deceleration Process

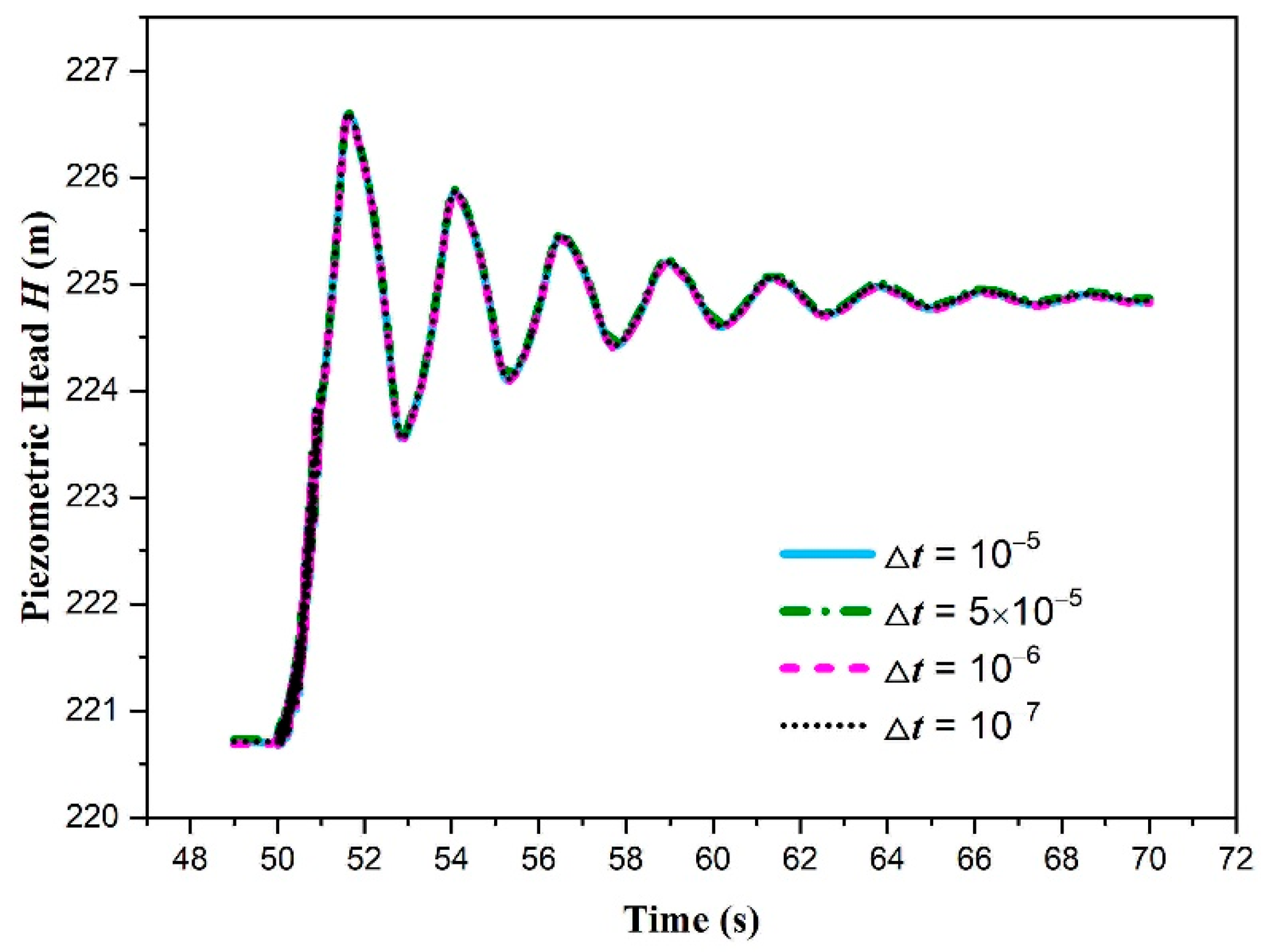

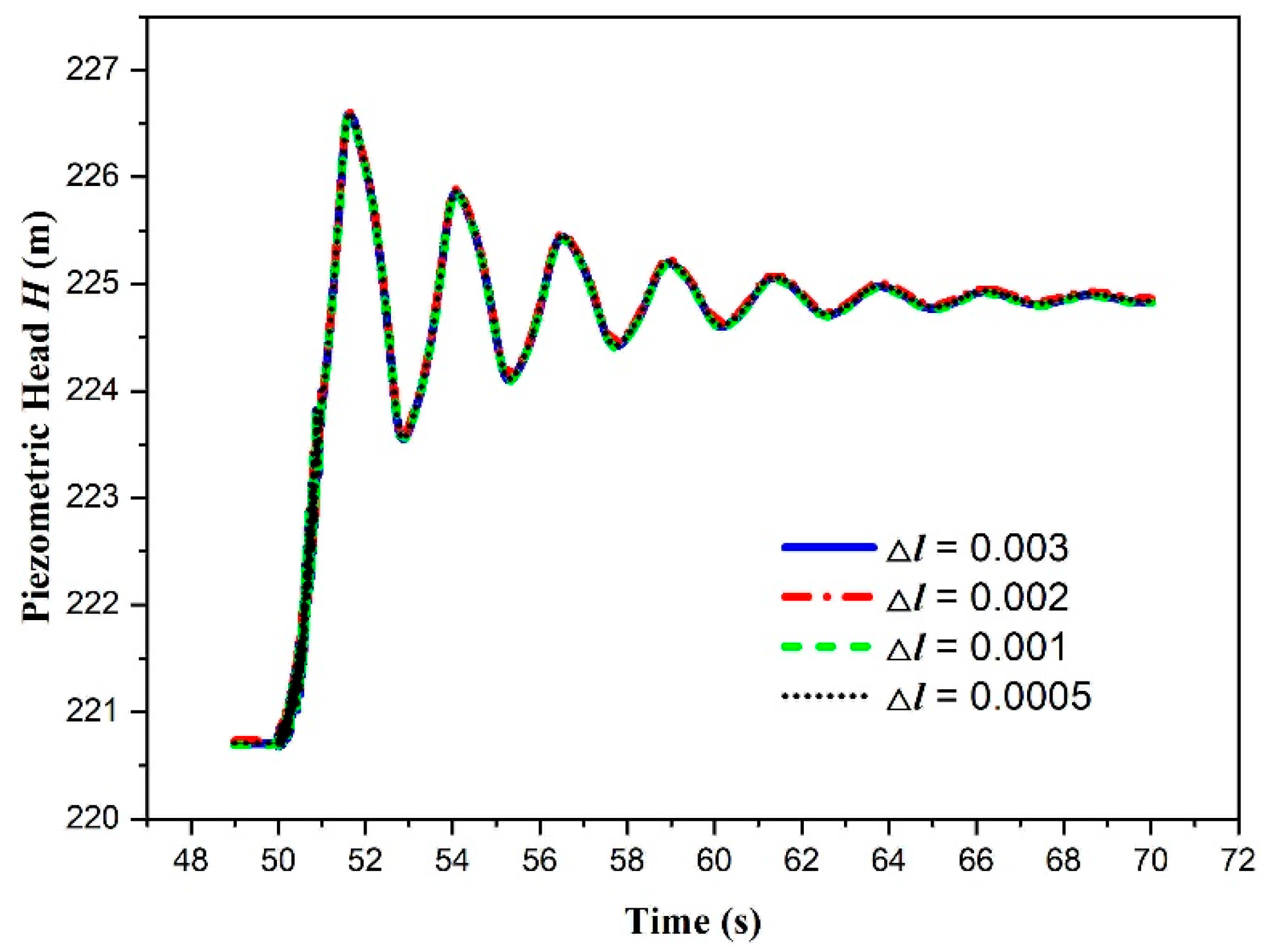

5.5.1. Validation of the Dynamic Mesh Technique in the Implicit Method

5.5.2. Validation of the Explicit–Implicit Coupling Method with Dynamic Meshes

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aleksandersen, J.; Tveit, E. The Smart Plug: A Remotely Controlled Pipeline Isolation System. In Proceedings of the Eleventh International Offshore and Polar Engineering Conference, Stavanger, Norway, 17–22 June 2001. [Google Scholar]

- Lie, M.R.G.; Muangsuankwan, M.N. Remote-Controlled Plugging Technology Minimizes Platform Downtime: Valve Replacement Through SmartPlug® Isolation. In Proceedings of the ASME 2015 India International Oil and Gas Pipeline Conference, New Delhi, India, 17–18 April 2015. [Google Scholar]

- Zhao, B.; Li, C.; Zhang, J.; Hu, Y. The Isolation Technology of Oil and Gas Pipeline in China. In Proceedings of the Twentieth International Offshore and Polar Engineering Conference, Beijing, China, 20–25 June 2010. [Google Scholar]

- Ghidaoui, M.S.; Zhao, M.; McInnis, D.A.; Axworthy, D.H. A Review of Water Hammer Theory and Practice. Appl. Mech. Rev. 2005, 58, 49–76. [Google Scholar] [CrossRef]

- Chaudhry, M.H. Applied Hydraulic Transients, 3th ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Wylie, E.B.; Streeter, V.L.; Suo, L. Fluid Transients in Systems; Prentice Hall: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

- Chaudhry, M.H.; Hussaini, M.Y. Second-Order Accurate Explicit Finite-Difference Schemes for Waterhammer Analysis. J. Fluids Eng. 1985, 107, 523–529. [Google Scholar] [CrossRef]

- Hwang, Y.-H.; Chung, N.-M. A Fast Godunov Method for the Water-Hammer Problem. Int. J. Numer. Methods Fluids 2002, 40, 799–819. [Google Scholar] [CrossRef]

- Zhao, M.; Ghidaoui, M.S. Godunov-Type Solutions for Water Hammer Flows. J. Hydraul. Eng. 2004, 130, 341–348. [Google Scholar] [CrossRef]

- Jin, M.; Coran, S.; Cook, J. New One-Dimensional Implicit Numerical Dynamic Sewer and Storm Model. In Global Solutions for Urban Drainage; American Society of Civil Engineers: Reston, VA, USA, 2002; pp. 1–9. [Google Scholar] [CrossRef]

- Afshar, M.H.; Rohani, M. Water Hammer Simulation by Implicit Method of Characteristic. Int. J. Press. Vessel. Pip. 2008, 85, 851–859. [Google Scholar] [CrossRef]

- Wang, C.; Yang, J.-D. Water Hammer Simulation Using Explicit–Implicit Coupling Methods. J. Hydraul. Eng. 2015, 141, 04014086. [Google Scholar] [CrossRef]

- Preissmann, A. Propagation Des Intumescences Dans Les Canaux et Les Riviers. In Proceedings of the First Congress of the French Association for Computation, Grenoble, France, 15 June 1961. [Google Scholar]

- Bergant, A.; Ross Simpson, A.; Vìtkovsk, J. Developments in Unsteady Pipe Flow Friction Modelling. J. Hydraul. Res. 2001, 39, 249–257. [Google Scholar] [CrossRef] [Green Version]

- Covas, D.; Stoianov, I.; Mano, J.F.; Ramos, H.; Graham, N.; Maksimovic, C. The Dynamic Effect of Pipe-Wall Viscoelasticity in Hydraulic Transients. Part II—Model Development, Calibration and Verification. J. Hydraul. Res. 2005, 43, 56–70. [Google Scholar] [CrossRef]

- Covas, D.; Stoianov, I.; Ramos, H.; Graham, N.; Maksimovic, C. The Dynamic Effect of Pipe-Wall Viscoelasticity in Hydraulic Transients. Part I—Experimental Analysis and Creep Characterization. J. Hydraul. Res. 2004, 42, 517–532. [Google Scholar] [CrossRef]

- Tijsseling, A.A. FLUID-STRUCTURE INTERACTION IN LIQUID-FILLED PIPE SYSTEMS: A REVIEW. J. Fluids Struct. 1996, 10, 109–146. [Google Scholar] [CrossRef] [Green Version]

- Bergant, A.; Simpson, A.; Tijsseling, A. Water Hammer with Column Separation: A Historical Review. J. Fluids Struct. 2006, 22, 135–171. [Google Scholar] [CrossRef] [Green Version]

- Tang, H.; Zhong, S. 2D Numerical Study of Circular Synthetic Jets in Quiescent Flows. Aeronaut. J. 2005, 109, 89–97. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Wang, S.; You, W. 1D and CFD Co-Simulation Approach Basing on General Purpose Simulation Software. In Proceedings of the 2009 International Conference on Computational Intelligence and Software Engineering, Wuhan, China, 11–13 December 2009; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, S.; Yu, D. 2D Axisymmetric CFD Simulation of Underwater Torpedo Launch Tube Flow. In Proceedings of the 2009 International Conference on Information Engineering and Computer Science, Wuhan, China, 19–20 December 2009; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Ben-Mansour, R.; Habib, M.; Shaik, A.Q. Modeling of Fluid Flow in a Tube with a Moving Indentation. Comput. Fluids 2009, 38, 818–829. [Google Scholar] [CrossRef]

- González, M.L.; Vega, M.G.; Oro, J.M.F.; Marigorta, E.B. Numerical Modeling of the Piston Effect in Longitudinal Ventilation Systems for Subway Tunnels. Tunn. Undergr. Space Technol. 2014, 40, 22–37. [Google Scholar] [CrossRef]

- Tijsseling, A.S.; Anderson, A. The Joukowsky Equation for Fluids and Solids; Eindhoven University of Technology: Eindhoven, The Netherlands, 2006. [Google Scholar]

| Properties | Values |

|---|---|

| Pressure head at Inlet (m) | 240 |

| Pressure head at Outlet (m) | 201.4 |

| Initial discharge (m3/s) | 0.024 |

| Initial wave speed a (m/s) | 1000 |

| Density of fluid (kg/m3) | 998.2 |

| Viscosity of fluid (Pa·s) | 1.003 × 10−3 |

| Darcy–Weisbach friction factor f | 0.014 |

| Gravitational acceleration (m/s2) | 9.81 |

| Initial velocity of the SID V (m/s) | 3 |

| Length of Section S1 and S2 (m) | 300 |

| Length of the SID (m) | 0.6 |

| Length of Section S4 and S5 (m) | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Zeng, W.; Simpson, A.R.; Zhang, S.; Wang, C. Water Hammer Simulation Method in Pressurized Pipeline with a Moving Isolation Device. Water 2021, 13, 1794. https://doi.org/10.3390/w13131794

Zhang K, Zeng W, Simpson AR, Zhang S, Wang C. Water Hammer Simulation Method in Pressurized Pipeline with a Moving Isolation Device. Water. 2021; 13(13):1794. https://doi.org/10.3390/w13131794

Chicago/Turabian StyleZhang, Kang, Wei Zeng, Angus R. Simpson, Shimin Zhang, and Chao Wang. 2021. "Water Hammer Simulation Method in Pressurized Pipeline with a Moving Isolation Device" Water 13, no. 13: 1794. https://doi.org/10.3390/w13131794