Analysis of Water Droplet Distribution in Wind for the Fluidic Sprinkler

Abstract

:1. Introduction

2. Materials and Methods

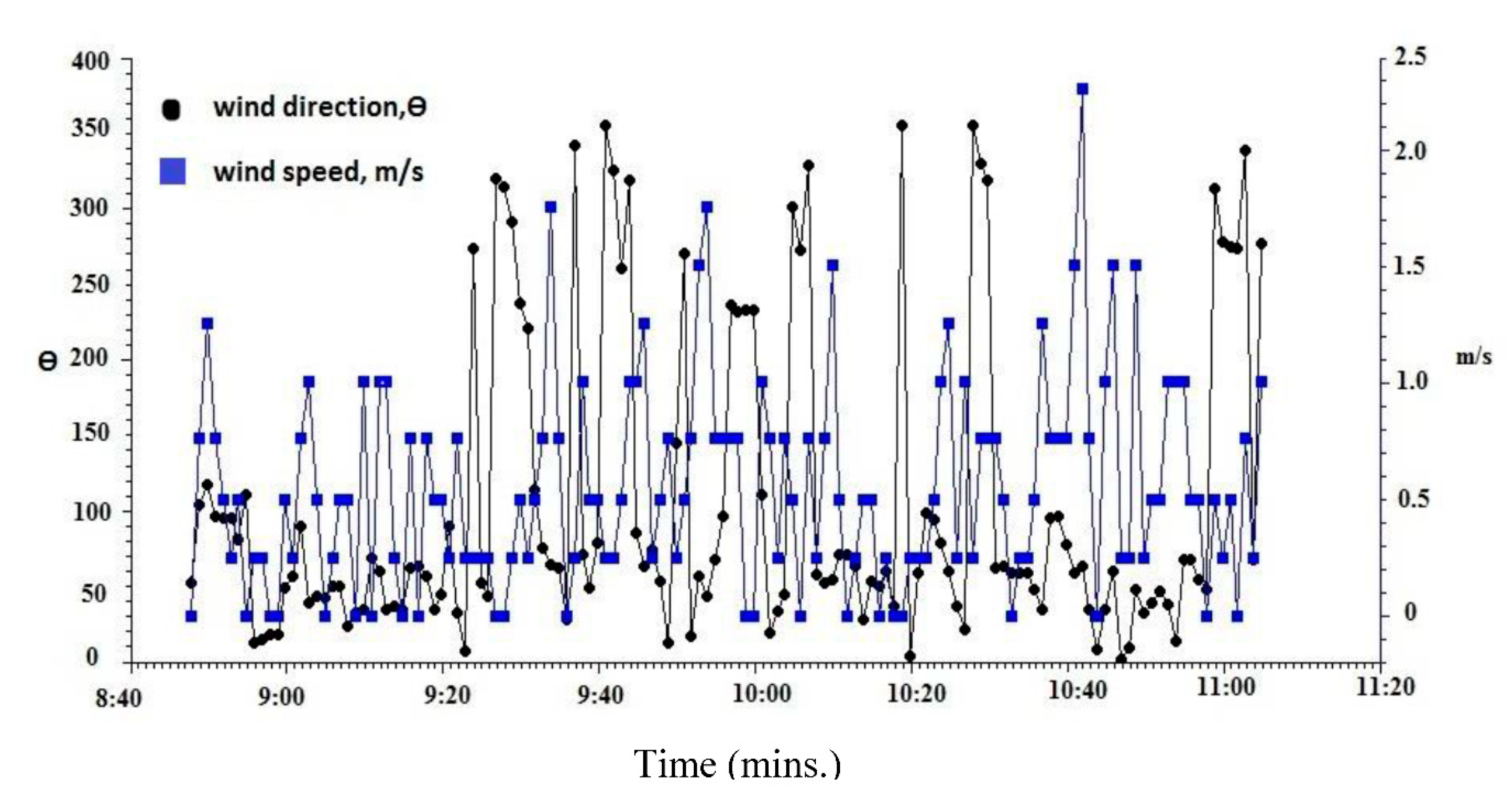

2.1. Experimental Set-Up

2.2. Modeling Cumulative Numeric Frequency and Cumulative Volumetric Frequency Curves

3. Results and Discussion

3.1. Velocity, Number of Drops and Drop Diameter Relationship

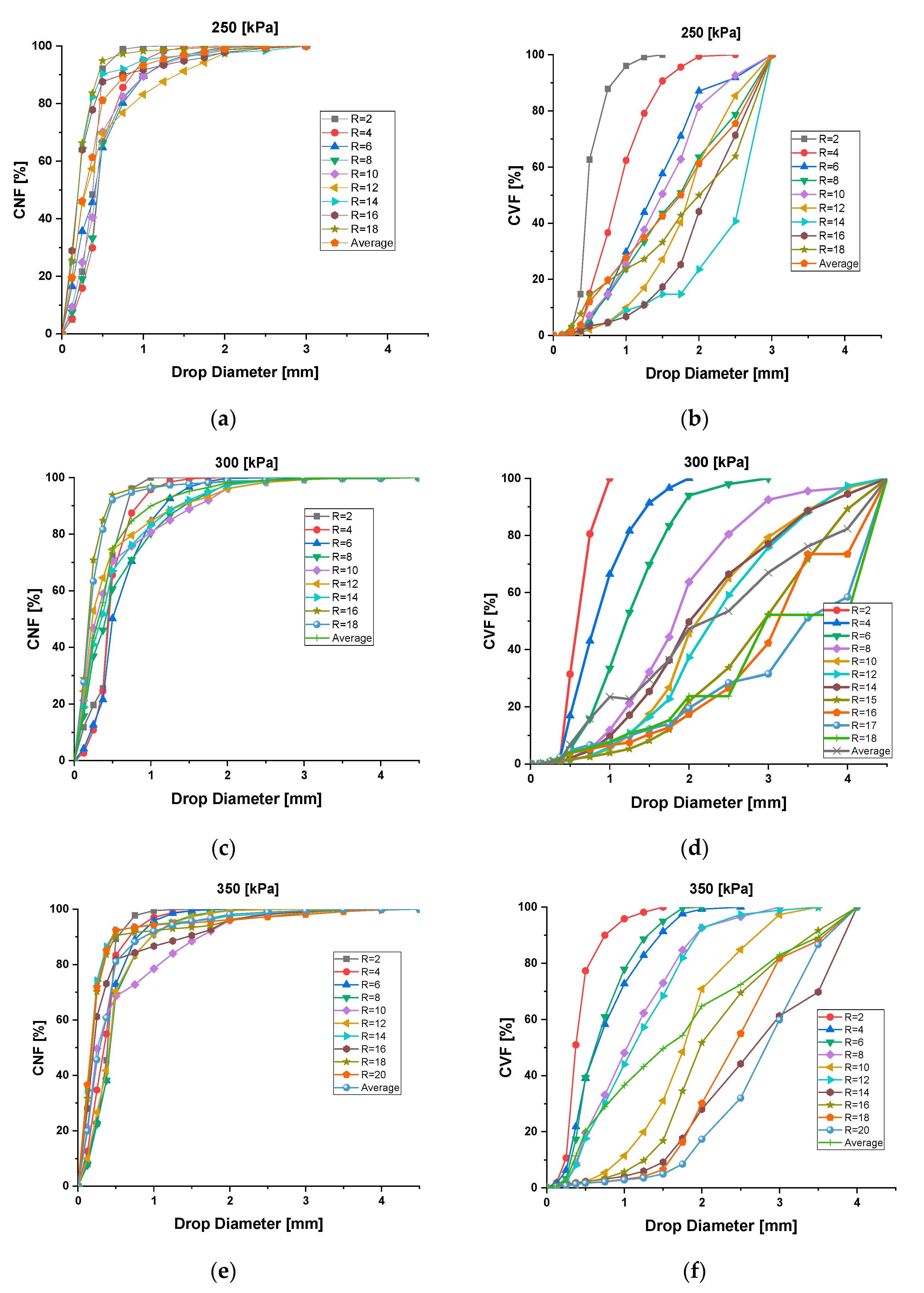

3.2. Analysis of the Cumulative Distribution Curves

3.3. Drop Diameter Distribution

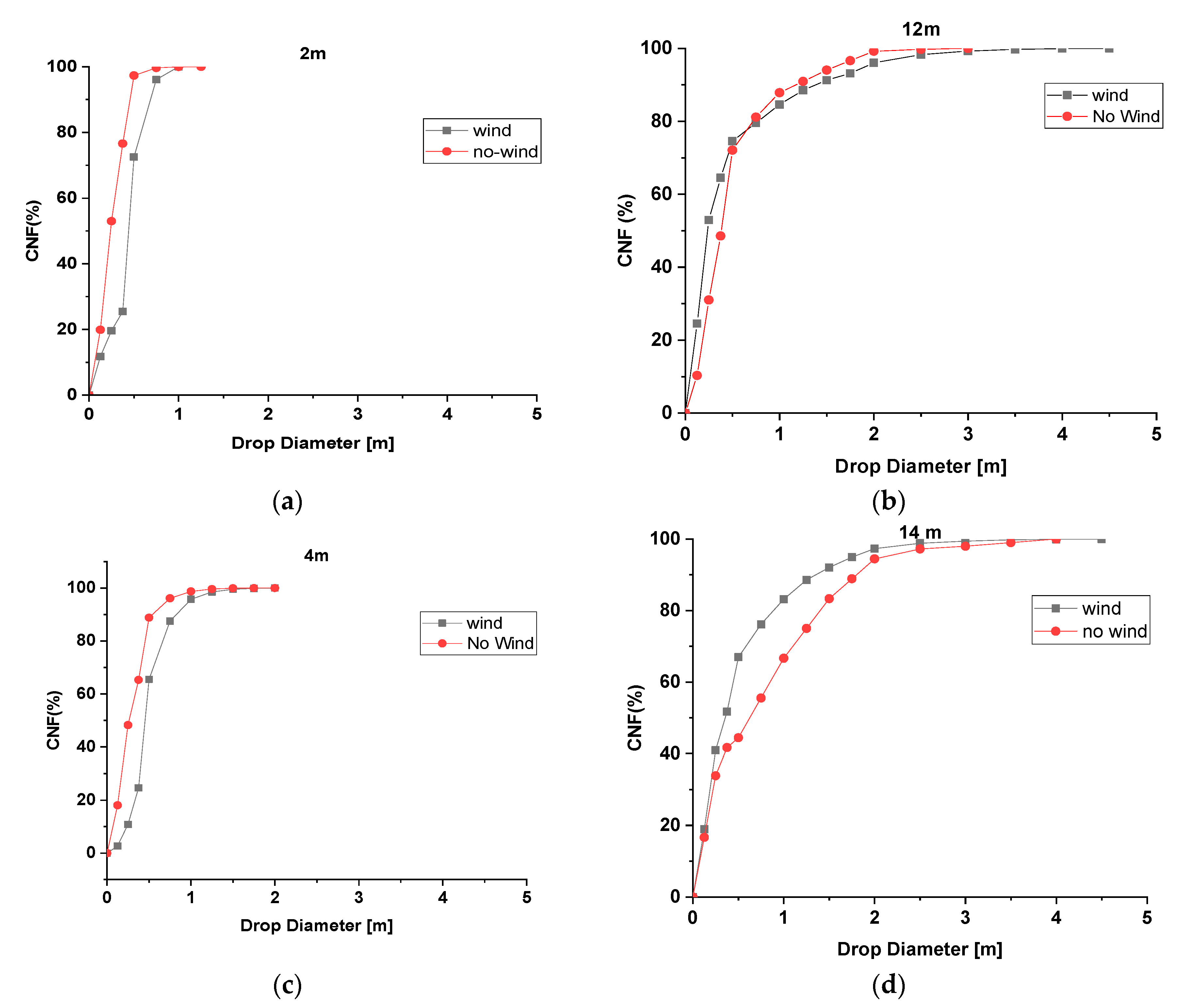

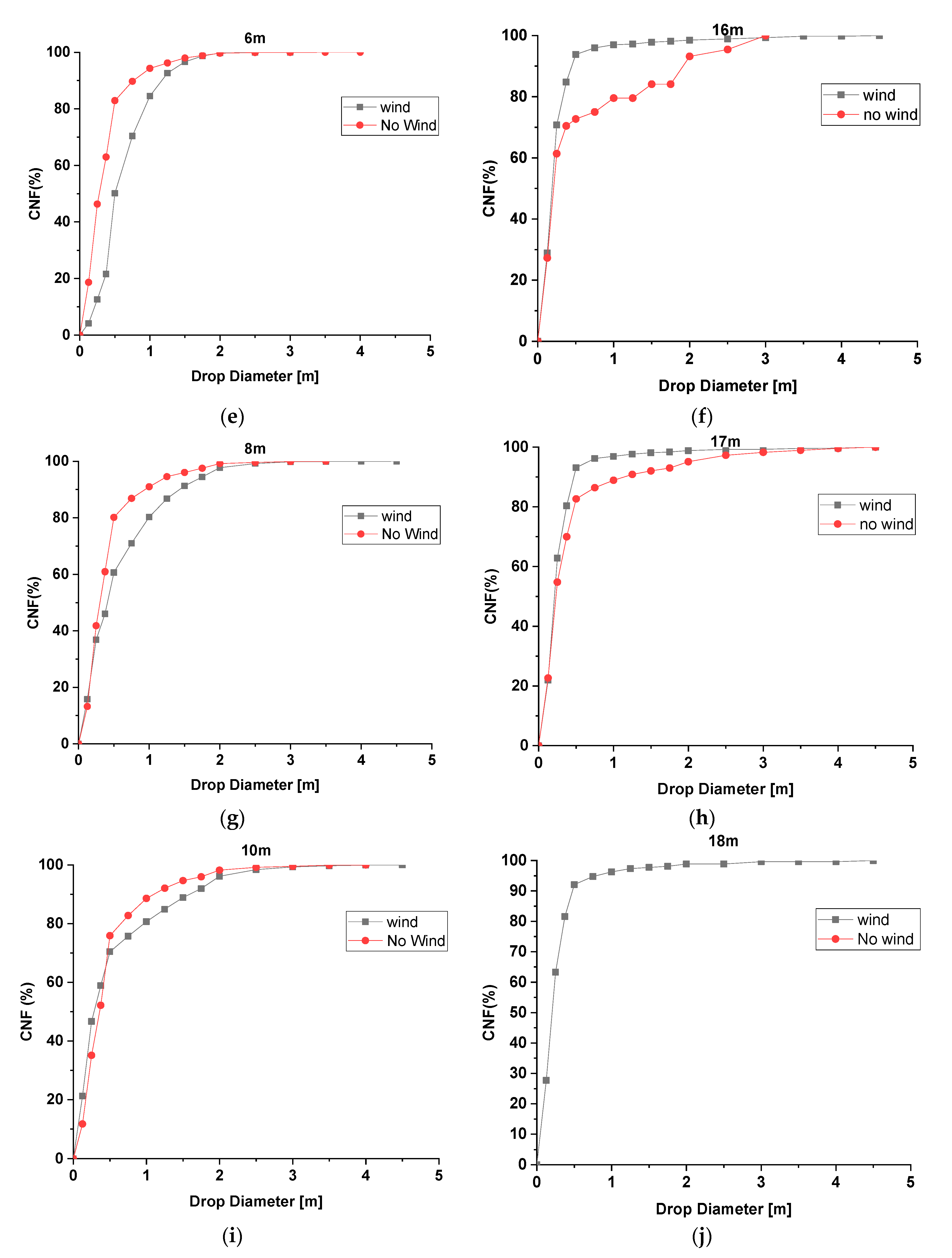

3.4. Comparison Between Droplet Distribution in Wind and No Wind Conditions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhu, X.; Yuan, S.; Li, H.; Liu, J. Orthogonal Tests and Precipitation Estimates for the Outside Signal Fluidic Sprinkler. Irrig. Drain. Syst. 2009, 23, 163–172. [Google Scholar] [CrossRef]

- Li, H.; Yuan, S.-Q.; Xiang, Q.-J.; Wang, C. Theoretical and Experimental Study on Water Offset Flow in Fluidic Component of Fluidic Sprinklers. J. Irrig. Drain. Eng. 2011, 137, 234–243. [Google Scholar] [CrossRef]

- Zhu, X.; Yuan, S.; Jiang, J.; Liu, J.; Liu, X. Comparison of Fluidic and Impact Sprinklers Based on Hydraulic Performance. Irrig. Sci. 2015, 33, 367–374. [Google Scholar] [CrossRef]

- Dwomoh, F.A.; Shouqi, Y.; Hong, L. Field Performance Characteristics of Fluidic sprinkler. Appl. Eng. Agric. 2013, 29, 529–536. [Google Scholar]

- Molle, B. Characterizing Droplet Distribution of an Irrigation Sprinkler Using Optical method. Ingénieries 2002, 31, 57–68. [Google Scholar]

- Burke, M.; Thompson, S.; Elcombe, C.R.; Halpert, J.; Haaparanta, T.; Mayer, R.T. Ethoxy-, Pentoxy- and Benzyloxyphenoxazones and Homologues: A Series of Substrates to Distinguish Between Different Induced Cytochromes P-450. Biochem. Pharmacol. 1985, 34, 3337–3345. [Google Scholar] [CrossRef]

- Thompson, A.L.; Gilley, J.R.; Norman, J.M. A Sprinkler Water Droplet Evaporation and Plant Canopy Model: II. Model Application. Trans. ASAE 1993, 36, 743–750. [Google Scholar] [CrossRef]

- King, B.A.; Bjorneberg, D.L. Characterizing Droplet Kinetic Energy Applied by Moving Spray-Plate Center-Pivot Irrigation Sprinklers. Trans. ASABE 2010, 53, 137–145. [Google Scholar] [CrossRef]

- Hills, D.J.; Gu, Y. Sprinkler Volume Mean Droplet Diameter as a Function of Pressure. Trans. ASAE 1989, 32, 0471–0476. [Google Scholar] [CrossRef]

- Von Bernuth, R.D. Effect of Trajectory Angle on Performance of Sprinklers in Wind. J. Irrig. Drain. Eng. 1988, 114, 579–587. [Google Scholar] [CrossRef]

- Kincaid, D.C. Spraydrop Kinetic Energy from Irrigation Sprinklers. Trans. ASAE 1996, 39, 847–853. [Google Scholar] [CrossRef] [Green Version]

- Laws, J.; Parson, D. The Relationship of Raindrop Siza to Intensity. Trans. Am. Geophys. 1943, 24, 452–460. [Google Scholar] [CrossRef]

- Kohl, R.A.; DeBoer, D.W.; Evenson, P.D. Kinetic Energy of Low Pressure Spray Sprinklers. Trans. ASAE 1985, 28, 1526–1529. [Google Scholar] [CrossRef]

- Li, J.; Kawano, H.; Yu, K. Droplet Size Distributions from Different Shaped Sprinkler Nozzles. Trans. ASAE 1994, 37, 1871–1878. [Google Scholar] [CrossRef]

- Kincaid, D.C.; Solomon, K.H.; Oliphant, J.C. Drop Size Distributions for Irrigation Sprinklers. Trans. ASAE 1996, 39, 839–845. [Google Scholar] [CrossRef]

- Molle, B. Characterising Droplet Distribution of an Irrigation Sprinkler Water application. In Proceedings of the Congrès ICID, Montréal, QC, Canada, 22–27 July 2002; p. 13. [Google Scholar]

- Kohl, R.A.; Von Bernuth, R.D.; Huebner, G. Drop Size Distribution Measurement Problems Using a Laser Unit. Trans. ASAE 1985, 28, 190–192. [Google Scholar] [CrossRef]

- King, B.A.; Winward, T.W.; Bjorneberg, D.L. Laser Precipitation Monitor for Measurement of Drop Size and Velocity of Moving Spray-Plate Sprinklers. Appl. Eng. Agric. 2010, 26, 263–271. [Google Scholar] [CrossRef]

- Evans, R.G.; A King, B. Site-Specific Sprinkler Irrigation in a Water Limited Future. In Proceedings of the 5th National Decennial Irrigation Conference, Phoenix Convention Center, Phoenix, AZ, USA, 5–8 December 2010; p. 1. [Google Scholar]

- Liu, J.; Yuan, S.; Li, H.; Zhu, X.Y. Numerical Simulation and Experimental Study on a New Type of Variable-Rate Fluidic Sprinkler. J. Agric. Sci. Technol. 2013, 15, 569–581. [Google Scholar]

- Zhu, X.; Fordjour, A.; Yuan, S.; Dwomoh, F.; Ye, D. Evaluation of Hydraulic Performance Characteristics of a Newly Designed Dynamic Fluidic Sprinkler. Water 2018, 10, 1301. [Google Scholar] [CrossRef] [Green Version]

- Dwomoh, F.A.; Shouqi, Y.; Hong, L. Sprinkler Rotation and Water Application Rate for the New Type Complete Fluidic Sprinkler and Impact sprinkler. Int. J. Agric. Biol. Eng. 2014, 7, 38–46. [Google Scholar]

- Solomon, K.; Zoldoske, D.; Oliphant, J. Laser Optical Measurement of Sprinkler Drop Sizes; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1991. [Google Scholar]

- Dwomoh, F.A. Droplet Size Characterization of the New Type Complete Fluidic Sprinkler. IOSR J. Mech. Civ. Eng. 2014, 11, 70–73. [Google Scholar] [CrossRef]

- Hong, H.; Jiang, Y.; Tang, P.; Chao, C.; Fordjour, A. Comparative Evaluation on Performance Characteristics of an Impact Sprinkler with Nozzle-Dispersion Devicesand Rotary Plate Sprinkler. Appl. Eng. Agric. 2020, 36, 321–329. [Google Scholar] [CrossRef]

- Li, H.; Issaka, Z.; Jiang, Y.; Tang, P.; Chen, C. Influence of a fixed water dispersion device on jet dispersion and range from an impact sprinkler. Irrig. Drain. 2019, 68, 669–678. [Google Scholar] [CrossRef]

- Nuyttens, D.; De Schampheleire, M.; Verboven, P.; Brusselman, E.; DeKeyser, D. Droplet Size and Velocity Characteristics of Agricultural Sprays. Trans. ASABE 2009, 52, 1471–1480. [Google Scholar] [CrossRef]

- Sidahmed, M.M. A Theory for Predicting the Size and Velocity of Droplets from Pressure Nozzles. Trans. ASAE 1996, 39, 385–391. [Google Scholar] [CrossRef]

- Holterman, H.J. Kinetics and Evaporation of Water Drops in Air; IMAG: Wageningen, The Netherlands, 2003. [Google Scholar]

- Ge, M.; Wu, P.; Zhu, D.; Zhang, L. Application of Different Curve Interpolation and Fitting Methods in Water Distribution Calculation of Mobile Sprinkler Machine. Biosyst. Eng. 2018, 174, 316–328. [Google Scholar] [CrossRef]

- Li, J. Effect of Pressure and Nozzle Shape on the Characteristics of Sprinkler Droplet Spectra. J. Agric. Eng. Res. 1997, 66, 15–21. [Google Scholar] [CrossRef]

- Martín-Benito, J.T.; Gómez, M.V.; Pardo, J.L. Working Conditions of Sprinkler to Optimize Application of Water. J. Irrig. Drain. Eng. 1992, 118, 895–913. [Google Scholar] [CrossRef]

- Li, H.; Issaka, Z.; Jiang, Y.; Tang, P.; Chen, C. Overview of Emerging Technologies in Sprinkler Irrigation to Optimize Crop Production. Int. J. Agric. Biol. Eng. 2019, 12, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Fritz, B.K.; Hoffmann, W.C.; Czaczyk, Z.; Bagley, W.; Kruger, G.R.; Henry, R.S. Measurement and Classification Methods Using the ASAE S572.1 Reference Nozzles. J. Plant Prot. Res. 2012, 52, 447–457. [Google Scholar] [CrossRef]

- Butts, T.R.; Samples, C.A.; Franca, L.X.; Dodds, D.M.; Reynolds, D.B.; Adams, J.W.; Zollinger, R.K.; Howatt, K.A.; Fritz, B.K.; Hoffmann, W.C.; et al. Spray Droplet Size and Carrier Volume Effect on Dicamba and Glufosinate Efficacy. Pest Manag. Sci. 2018, 74, 2020–2029. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Q.; Qureshi, W.A.; Tunio, M.H.; Solangi, K.A.; Xu, Z.; Lakhiar, I.A. Low-Pressure Drop Size Distribution Characterization of Impact Sprinkler Jet Nozzles with and Without Aeration. Agric. Water Manag. 2021, 243, 106458. [Google Scholar] [CrossRef]

- Zhu, X.; Yuan, S.-Q.; Liu, J.; Liu, X. Comparison of Droplet Distributions from Fluidic and Impact Sprinklers. Front. Agric. Sci. Eng. 2015, 2, 53–59. [Google Scholar] [CrossRef]

- Salvador, R.; Bautista-Capetillo, C.F.; Burguete, J.; Zapata, N.; Serreta, A.; Playán, E. A Photographic Method for Drop Characterization in Agricultural Sprinklers. Irrig. Sci. 2009, 27, 307–317. [Google Scholar] [CrossRef]

- Friso, D.; Bortolini, L. Numerical and Volumetric Frequency of Sprinkler Drop-Size from Water Distribution Radial Curve Part II: Experimental Validation. J. Eng. Appl. Sci. 2006, 12, 2672–2677. [Google Scholar]

- Bautista-Capetillo, C.F.; Salvador, R.; Burguete, J.; Montero, J.; Tarjuelo, J.M.; Zapata, N.; González, J.; Playán, E. Comparing Methodologies for the Characterization of Water Drops Emitted by an Irrigation Sprinkler. Trans. ASABE 2009, 52, 1493–1504. [Google Scholar] [CrossRef]

| S/N | Characteristic Features | Symbols | PXH20 |

|---|---|---|---|

| 1 | Inner Contraction angle | Θ ([0) | 20 |

| 2 | Offset lengths | S (mm) | 2.8 |

| 3 | Working area Length | L (mm) | 28 |

| 4 | Basic Hole diameter | D (mm) | 8 |

| 5 | Wetted Radius | R (m) | 17–20 |

| P (kPa) | R (m) | A1 | A2 | λ | D50 | R2 |

|---|---|---|---|---|---|---|

| 2 | 4.35074 | 101.13699 | 5.36928 | 0.36946 | 0.98428 | |

| 4 | 2.88752 | 99.94652 | 3.85044 | 0.44777 | 0.99335 | |

| 6 | 1.69551 | 104.99942 | 1.7467 | 0.39513 | 0.99516 | |

| 8 | 2.5024 | 99.02599 | 2.98966 | 0.44008 | 0.99227 | |

| 250 | 10 | 1.86698 | 100.20939 | 2.52046 | 0.40547 | 0.99278 |

| 12 | −0.85133 | 104.69056 | 1.31335 | 0.32243 | 0.99564 | |

| 14 | −0.1407 | 97.6805 | 2.45775 | 0.1912 | 0.99825 | |

| 16 | −0.32141 | 97.52474 | 2.01172 | 0.18659 | 0.99563 | |

| 2 | −0.8763 | 104.28791 | 5.59177 | 0.59115 | 0.99379 | |

| 4 | 2.0104 | 99.55765 | 4.76936 | 0.4573 | 0.99593 | |

| 6 | 1.30004 | 100.96095 | 2.85829 | 0.54546 | 0.99614 | |

| 8 | 0.23674 | 105.59931 | 1.4126 | 0.42248 | 0.99686 | |

| 300 | 10 | −0.98784 | 104.27079 | 1.21641 | 0.31175 | 0.99338 |

| 12 | −0.88509 | 101.98693 | 1.30446 | 0.25463 | 0.99452 | |

| 14 | −0.03001 | 103.90991 | 1.41498 | 0.35347 | 0.99797 | |

| 16 | −0.1027 | 98.99158 | 2.52459 | 0.17618 | 0.99898 | |

| 18 | 0.1686 | 99.3514 | 2.29874 | 0.19175 | 0.99883 | |

| 2 | 6.05989 | 100.59838 | 5.34356 | 0.37972 | 0.98388 | |

| 4 | 2.95144 | 100.89556 | 2.81991 | 0.32918 | 0.99261 | |

| 6 | 4.3256 | 100.52678 | 3.41895 | 0.41152 | 0.99063 | |

| 8 | 2.05796 | 100.21004 | 2.81285 | 0.41711 | 0.99433 | |

| 350 | 10 | −1.1916 | 106.69928 | 1.09705 | 0.32141 | 0.98744 |

| 12 | 2.21099 | 100.60703 | 2.52162 | 0.39871 | 0.99447 | |

| 14 | −0.19118 | 97.81052 | 2.3766 | 0.15883 | 0.99656 | |

| 16 | −0.99357 | 98.59122 | 1.51007 | 0.19818 | 0.98673 | |

| 18 | −0.31208 | 96.87356 | 2.2641 | 0.16788 | 0.99237 |

| P (kPa) | R (m) | A1 | A2 | λ | D50 | R2 |

|---|---|---|---|---|---|---|

| 250 | 2 | 0.08856 | 96.848411 | 7.26594 | 0.46555 | 0.99421 |

| 4 | −0.42105 | 104.41339 | 3.44243 | 0.88705 | 0.99881 | |

| 6 | 0.05231 | 111.11761 | 2.99371 | 1.42368 | 0.99676 | |

| 8 | −1.59095 | 238.02521 | 1.67524 | 1.65432 | 0.99741 | |

| 10 | 0.45277 | 122.62697 | 2.70279 | 1.67021 | 0.99554 | |

| 12 | 1.06059 | 122.93157 | 3.95813 | 2.05172 | 0.99721 | |

| 14 | 3.95472 | 6.72054E5 | 4.18789 | 2.09845 | 0.97431 | |

| 16 | 1.51554 | 172.42044 | 3.68582 | 2.35884 | 0.99669 | |

| 18 | 3.11196 | 2.32762E6 | 1.51411 | 2.45469 | 0.97306 | |

| 300 | 2 | −0.01509 | 97.40207 | 4.66525 | 0.37324 | 0.99804 |

| 4 | −1.27027 | 107.78744 | 2.16983 | 0.68425 | 0.99804 | |

| 6 | −1.54117 | 105.75077 | 2.59613 | 0.64925 | 0.99884 | |

| 8 | −0.28941 | 113.47855 | 2.20843 | 1.11596 | 0.99681 | |

| 10 | 1.41597 | 105.89393 | 4.44662 | 1.79166 | 0.99804 | |

| 12 | 0.59313 | 110.80845 | 2.36416 | 1.16741 | 0.99731 | |

| 14 | 0.38831 | 232.47864 | 2.57067 | 1.58233 | 0.98813 | |

| 16 | 0.80295 | 103.08389 | 4.25144 | 2.09048 | 0.99804 | |

| 18 | 1.06507 | 105.26508 | 5.26081 | 2.43845 | 0.99407 | |

| 350 | 2 | −0.01509 | 97.40207 | 4.66525 | 0.37324 | 0.99651 |

| 4 | −1.27027 | 107.78744 | 2.16983 | 0.68425 | 0.99661 | |

| 6 | −1.54117 | 105.75077 | 2.59613 | 0.64925 | 0.99621 | |

| 8 | −0.28941 | 113.47855 | 2.20843 | 1.11596 | 0.99681 | |

| 10 | 1.41597 | 105.89393 | 4.44662 | 1.79166 | 0.99611 | |

| 12 | 0.59313 | 110.80845 | 2.36416 | 1.16741 | 0.99407 | |

| 14 | 0.38831 | 232.47864 | 2.57067 | 1.58233 | 0.98813 | |

| 16 | 0.80295 | 103.08389 | 4.25144 | 2.09048 | 0.99572 | |

| 18 | 1.06507 | 105.26508 | 5.26082 | 2.43845 | 0.99731 | |

| 20 | 1.43634 | 129.69815 | 4.93339 | 3.10043 | 0.99791 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dwomoh, F.A.; Yuan, S.; Li, H.; Zhu, X.; Liu, J.; Mensah, R.; Fordjour, A. Analysis of Water Droplet Distribution in Wind for the Fluidic Sprinkler. Water 2020, 12, 3320. https://doi.org/10.3390/w12123320

Dwomoh FA, Yuan S, Li H, Zhu X, Liu J, Mensah R, Fordjour A. Analysis of Water Droplet Distribution in Wind for the Fluidic Sprinkler. Water. 2020; 12(12):3320. https://doi.org/10.3390/w12123320

Chicago/Turabian StyleDwomoh, Frank Agyen, Shouqi Yuan, Hong Li, Xingye Zhu, Junping Liu, Richard Mensah, and Alexander Fordjour. 2020. "Analysis of Water Droplet Distribution in Wind for the Fluidic Sprinkler" Water 12, no. 12: 3320. https://doi.org/10.3390/w12123320