1. Introduction

Dramatic changes and increasing public interest in solar photovoltaic (PV) landscapes show that the dual beneficial use of land may have better impacts on energy production and future agriculture transdisciplinary design. Some highlights and recent research in solar PV projects by higher education institutions show that the solar industry has broadened its stakeholders and interest in the future, reflecting a significant shift in the dynamics of the market [

1,

2]. The PV industry for large scale solar projects is dominated by energy companies but, based on the effort above, it is shown that experts in higher education within the research environment have the capabilities to compete with energy companies in the solar PV industry. This trend has been transferred to ecological efficiency and positive effects, consequently upscaling the number and size of PV systems installed on the land. Rapidly decreasing price of PV modules in the world market in line with the increasing demand of fresh produce promotes the idea of agro-PV integration, commonly known as an agrivoltaic system.

This type of solar power system is a power generation system that incorporates several parts, namely PV modules, solar inverters, mounting, cabling and other electrical components, which are integrated in the balance of systems (BOS) [

3,

4]. This PV device absorbs rays from sunlight and translates them into a direct current (DC) via semiconductor materials. Malaysia, a tropical country in Southeast Asia, has given years of commitment to culturing green initiatives, especially PV systems and applications. This statement is evidenced by the increasing quota specifically for large scale solar (LSS) PV systems and the commitment by the Ministry of Energy, Science, Technology, Environment and Climate Change (MESTECC) [

5] to persistently aim for a 20% energy mix by the year 2025 with multiple initiatives [

6].

Generally, based on PV projects in University Putra Malaysia, where the size and ground conditions are put into a factor that generates empty areas under the panels, 1 kWp solar PV arrays may occupy roughly 8 to 12 square meters of land [

7,

8]. Based on their high demand, solar PV models in the market nowadays are ground-mounted arrays and require a fixed PV panel arrangement. There is a call for futuristic features from the market, with application in large-scale areas by enhancing their design while maintaining cost-effective deployment [

9]. Temperature plays an important role in DC generation via PV modules. Park et al. [

10], in their research on building-integrated PV (BIPV), defined such significant effects of the PV module’s thermal characteristics, where approximately a 0.5% reduction in energy is generated based on a 1 °C increase of the module temperature. This statement is supported by Kim et al. [

11], with additional information on the energy efficiency from a common PV module that can be increased due to a drop in surface temperature, especially on the highest heated portions of PV cells and ribbons.

The concept of agrivoltaics, or solar farming, aspired to creatively convert agriculture to photovoltaics, applied on the same land to maximize the yield [

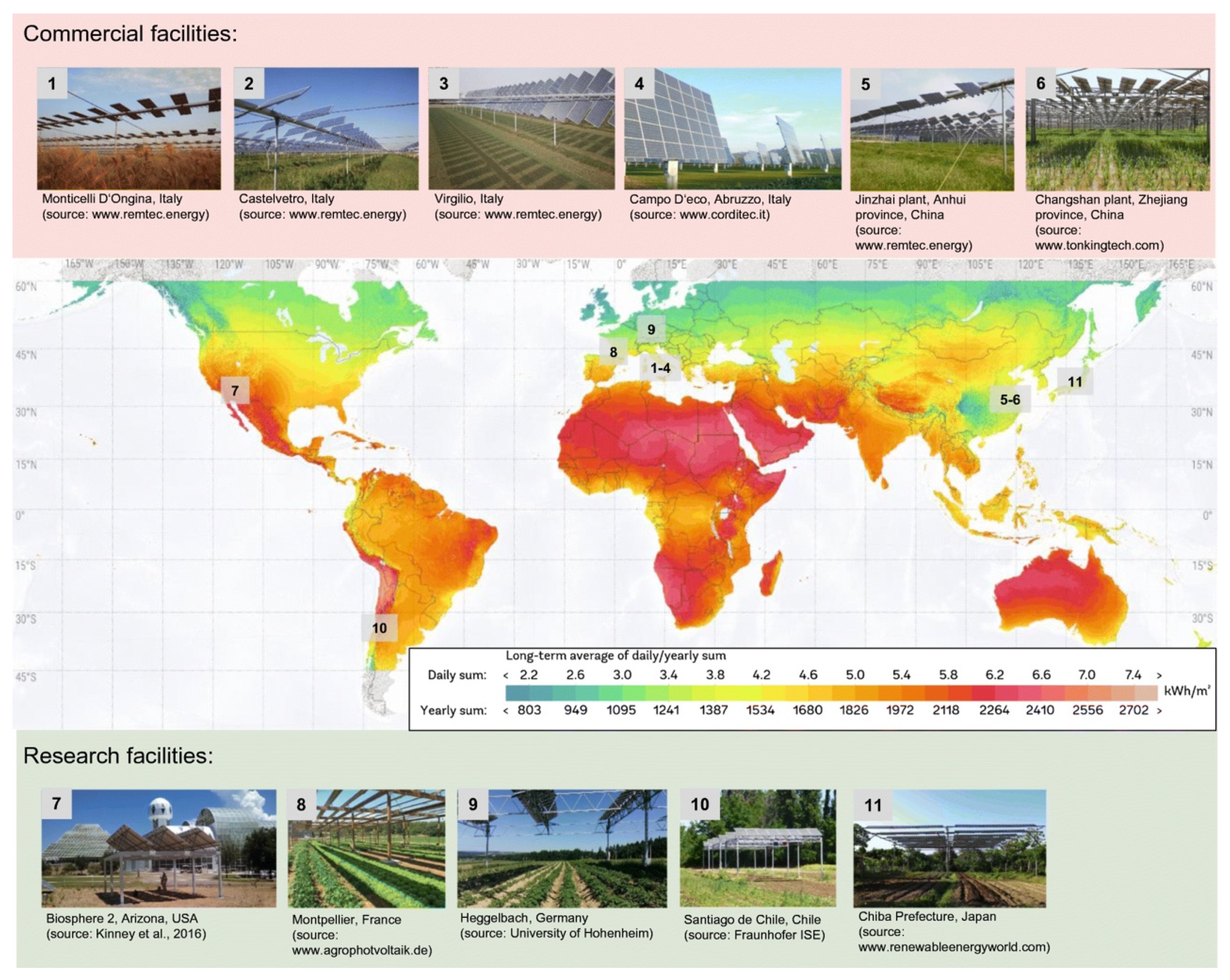

12]. The agrivoltaic system, as shown in

Figure 1, contemplates specific plant attributes: height, productivity, water consumption and shading resistance. The figure demonstrates the idea of the agrivoltaic method employed in several countries by plotting vacant land with various types of crops. This method of farming under the solar panel is an innovation of incorporating green energy into agriculture and it is a part of introducing modern aspects to the agricultural community [

13]. Some of the published results in [

9,

12,

13,

14] relating to agrivoltaic projects summarized the importance and successful integration of the systems by assessing whether:

The AV system improved environmental efficiency.

The AV system promoted effective usage of light and space for concurrent energy and food output.

The AV system boosted the technological capacity for PV and agricultural production conjointly by implementing a hybrid simulation model.

The AV system yielded more crop as compared to the period before the deployment.

This integrated system will maximize crop production, enhancing the system’s performance while addressing land management and sustainability issues. The integration of these two resources would optimize the yield, improve clean system efficiency and solve the issue of land resource sustainability. The issue of the agrivoltaic concept implemented in ground-mounted PV systems and the shading effect of the PV arrays on crop canopy have been discussed by [

15] recently.

The group suggested that the density of the PV arrays should be reduced adequately to enable ample amounts of light penetration while also maintaining a respectable production of DC electricity. The concept of agrivoltaics is in line with the Kyoto Protocol [

16] and the United Nations Sustainable Development Goals (UN-SDG) [

17,

18], which promote the usage of clean and affordable energy towards sustainable urban infrastructure and further reducing the usage of fossil fuels.

In Malaysia, most planned and retrofitted agrivoltaic facilities are based on existing ground-mounted solar PV farm infrastructures where the primary activity is to sell the electricity generated to the National Grid. The issue of ground-mounted photovoltaic systems can be explained based on several factors, namely:

The fact that existing solar PV farms do not allow any intervention or disturbance to any wiring, operation, structure or subsurface of the PV systems.

The difficulties and hazards for farmers working under PV arrays result in lower production yield.

Semi-confined working spaces, as workers have to bend down and inspect plants under PV array structures for growth monitoring and harvesting activities.

The need for some tools to ease the process of planting, harvesting and post-harvest under agrivoltaic farming (most crop yields four cycle harvest per annum).

Heat stress normally occurs when temperatures rise above a certain level for a certain period and bear deleterious and permanent effects on a crop cycle, thus affecting yield [

19,

20]. Generally, heat stress is set to occur when a transient temperature rises over the average temperature of 10–15 °C [

20,

21,

22,

23,

24,

25]. The degree to which it happens in a particular climate zone relies on the frequency and amount of extreme temperatures happening during the day and/or the night. Some general definitions by [

20] have also discussed the tendency of plants to grow with good economic yield under high temperature conditions. The extent to which this occurs in specific climatic zones depends on the probability and period of high temperatures occurring during the day and/or the night.

The transpiration process plays an important role in the cooling of green plants where, on average, it could dissipate around 32.9% of the total solar energy absorbed by the leaves, making it a good natural cooling mechanism [

26,

27,

28]. However, the magnitude of its impact varies from species to species. Increased transpiration levels do have an impact on water stress because the increase in ambient temperature increases the water evaporation from ground soil, thus, some plants have a tendency to grow slowly or even die at an early stage.

Orthosiphon stamineus was chosen as the herbal plant for a project where, based on field evaluation (40 days under tropical climate), remarkably, the crop proved growth sustainability [

29]. Compared to the four other types of herbal plants in the assessment,

Orthosiphon stamineus showed healthy growth and its morphological aspects were enhanced compared to the normal conditions. The roots and fresh branches showed aggressive growth, mostly due to the soil’s moisture content, thus, it could be harvested on time. The method of cultivation underneath solar PV arrays used a drip fertigation system (DFS) directly to polybags, to maintain the soil’s moisture level and to prevent any disturbances to the electrical cablings and trenches. This method also eased the process of harvesting and replanting under such restricted conditions.

Herbal plants tend to possess valuable bioactive chemical compound reserves with an abundance of possible applications in pharmaceutical and agrochemical industries. [

30] explained the basic concept of microclimate conditions as a set of climate parameters assessed in a specified area near the surface of the planet, including a variation of temperature, light, wind intensity and relative humidity (RH), which are significant measures for habitat selection and other ecological practices. One of the critical elements calculated based on these parameters was the vapor pressure deficit (VPD), which is defined as the discrepancy between the volume of moisture in normal settings with saturated condition (VPD in a greenhouse range of 0.45 kPa to 1.25 kPa with an idle of 0.84 kPa) [

30]. Leonardi, Guichard and Berlin, in [

31], explained that during daylight hours, where the high VPD condition was enhanced, the transpiration rates were better for plants to grow because the VPD exerted a substantial rise of soluble solids but lowered the fruits’ fresh weight and internal fluid levels. A plant’s transpiration, and the correct VPD under a controlled environment, can effectively help to optimize the plant’s ideal growth and plant health [

32,

33]. Hot and dry surrounding air under shade can produce high VPD and causes stress to the plant.

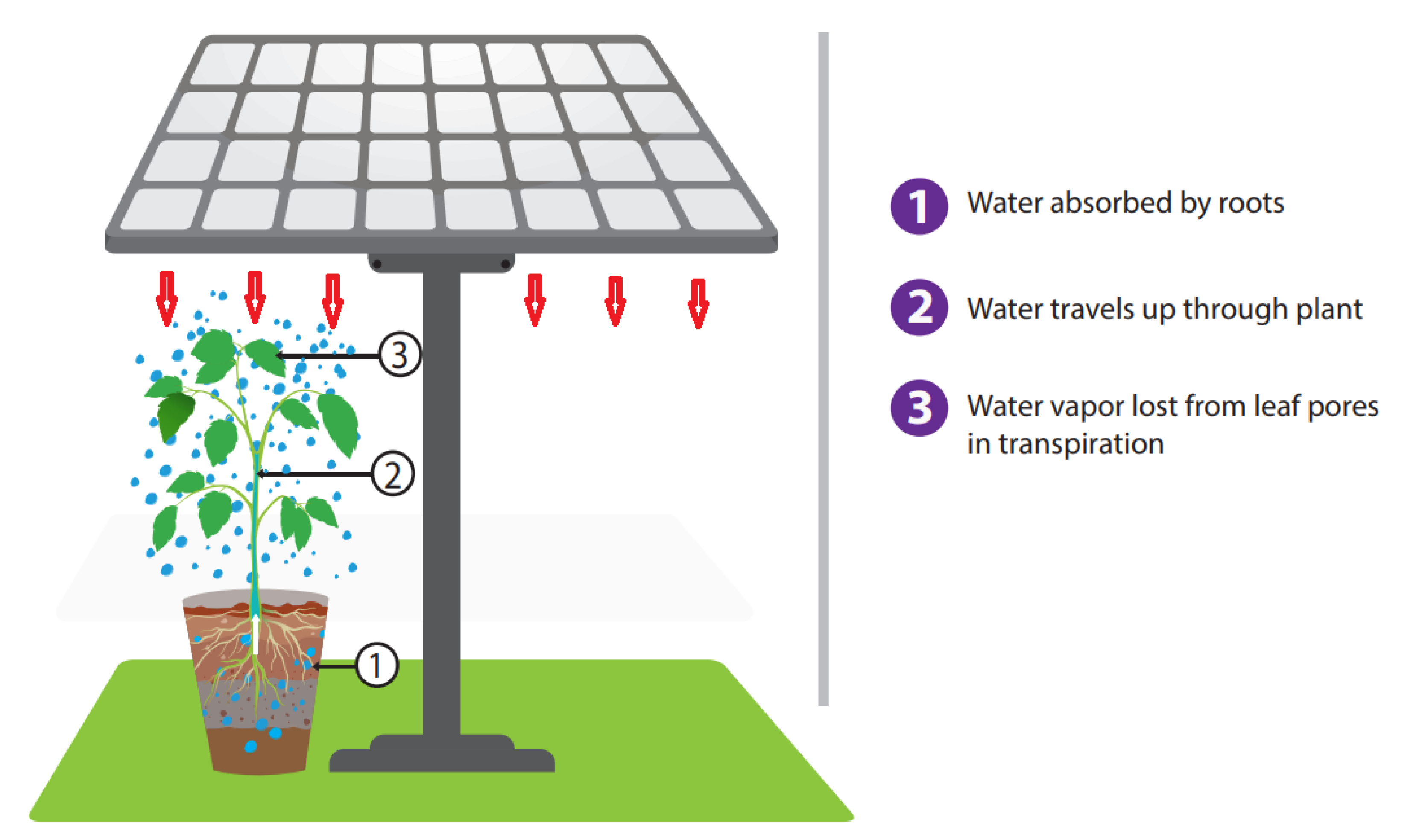

In agrivoltaic systems, plants, or crops, are one of the crucial elements that need to be considered. The transpiration process in plant growth takes place when water is biologically released from the aerial parts of the plants in the form of water vapor. During the process of transpiration, as illustrated in

Figure 2, water molecules are transmitted from roots to stomata, the small pores underneath the leaves, where vaporization takes place, and the molecules are transpired through the surrounding air. The effect of vaporization increases with the number of plants being deposited under the PV panels, which results in an increased RH value.

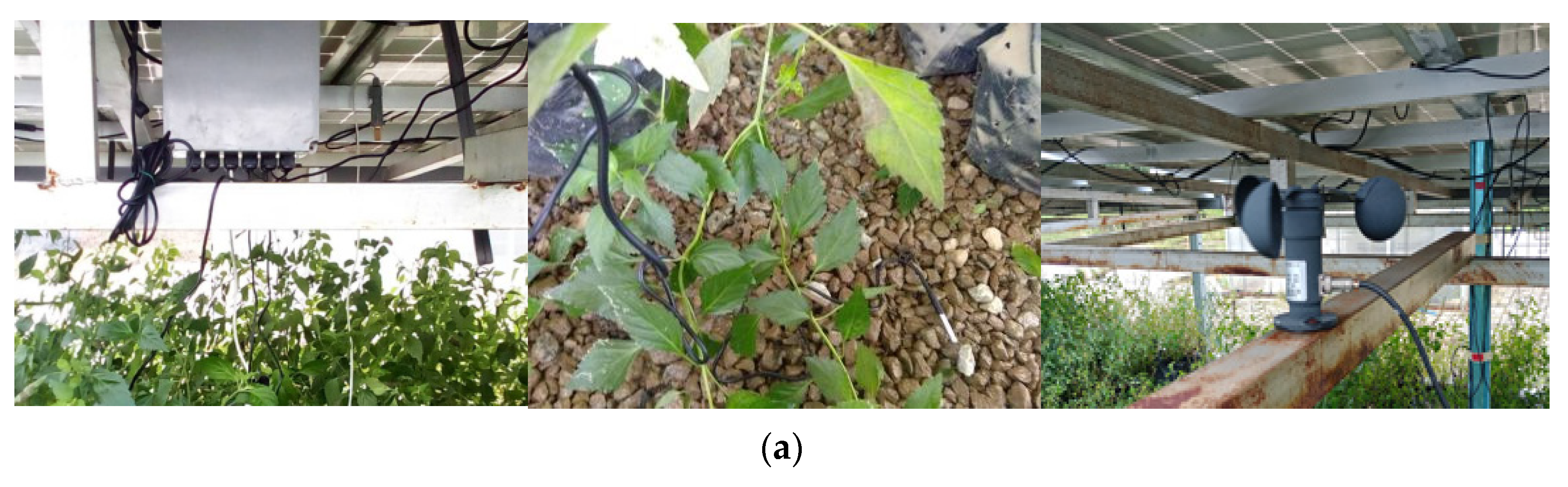

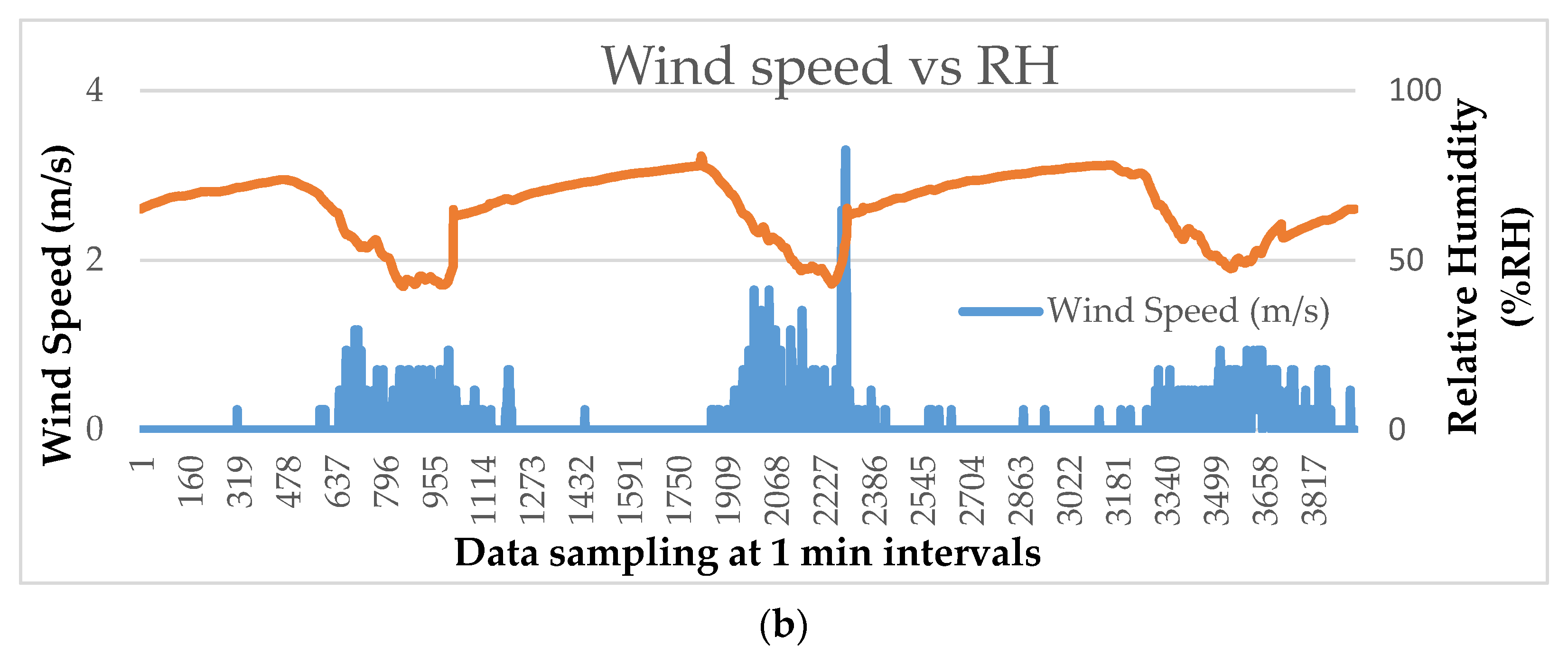

Crawford et al., in [

28], explained that extreme temperatures multiply the risk of plant damage due to the heat and, simultaneously, water shortage, which enhances the plant cooling capability, as shown in

Figure 3. The increase in transpiration rate is directly correlated with the increased in stomata opening thus, this increases photosynthesis activities.

The transpiration characteristics of plants in different surrounding temperatures and relative humidities portray a significant heat dissipation value (transpirative heat transfer through leaves). In relation to this, a study by [

27] in Wuxi, China, during the summer and winter seasons reflected a 55.8% and 24.3% transpiratory heat flux for each season, respectively, accounting for the total heat dissipation of the cinnamon. Temperature difference, ∆T, is a crucial factor to be analyzed in agrivoltaic conditions, especially the effect of plant height for each growth cycle. Mittler, in [

35], explained that heat is one of the prominent elements in the abiotic stress effect on plant growth where, during heat stress, plants open their stomata to cool their leaves by transpiration. If the condition is prolonged or under an increasing rate, this will eventually create a greater detrimental effect on the plant’s growth and productivity. Therefore, this study aims to measure the ambient temperature profile and the impacts of heat stress occurrences directly underneath ground-mounted solar PV arrays, focusing on different temperature levels.

3. Results and Discussion

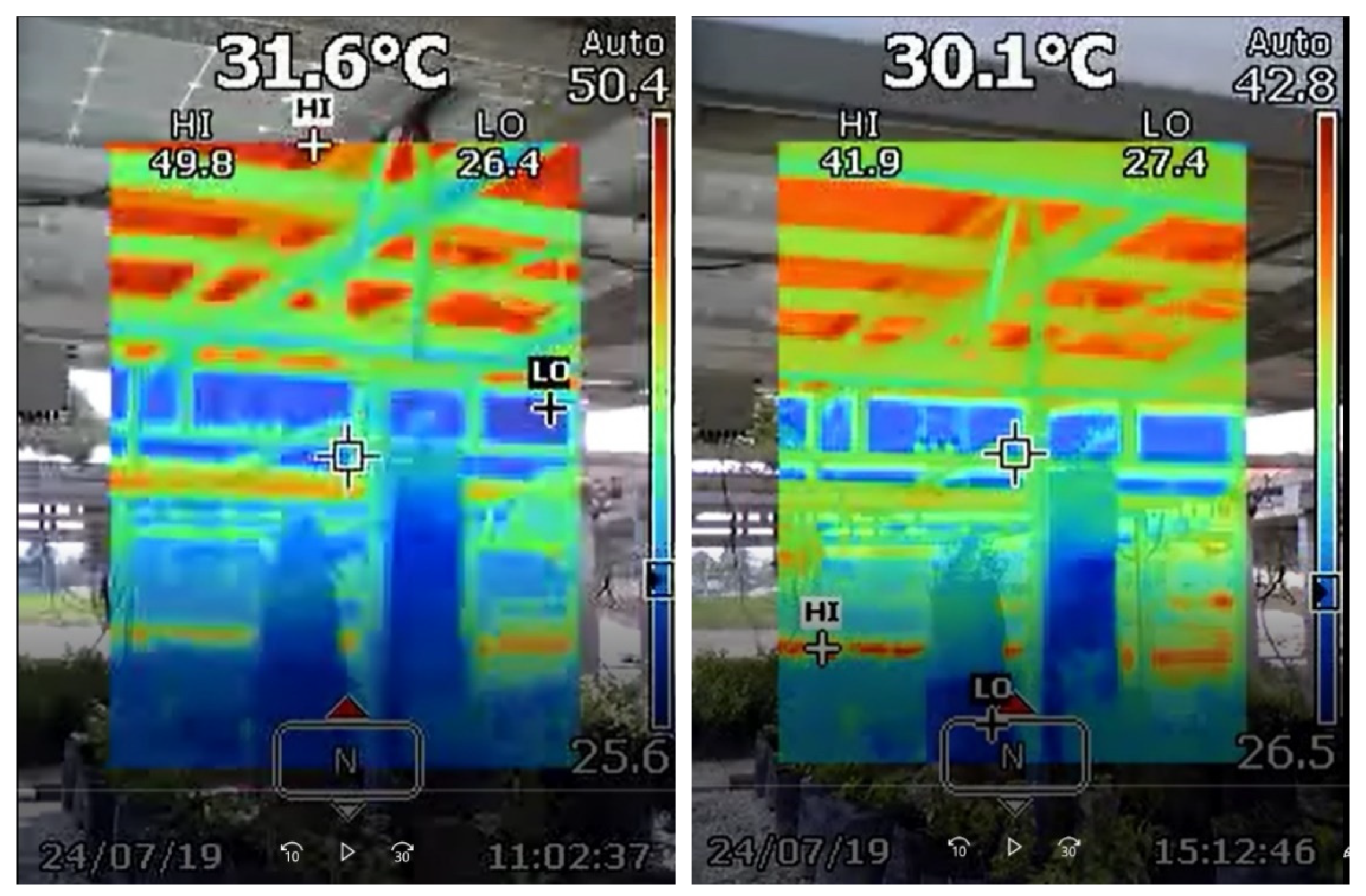

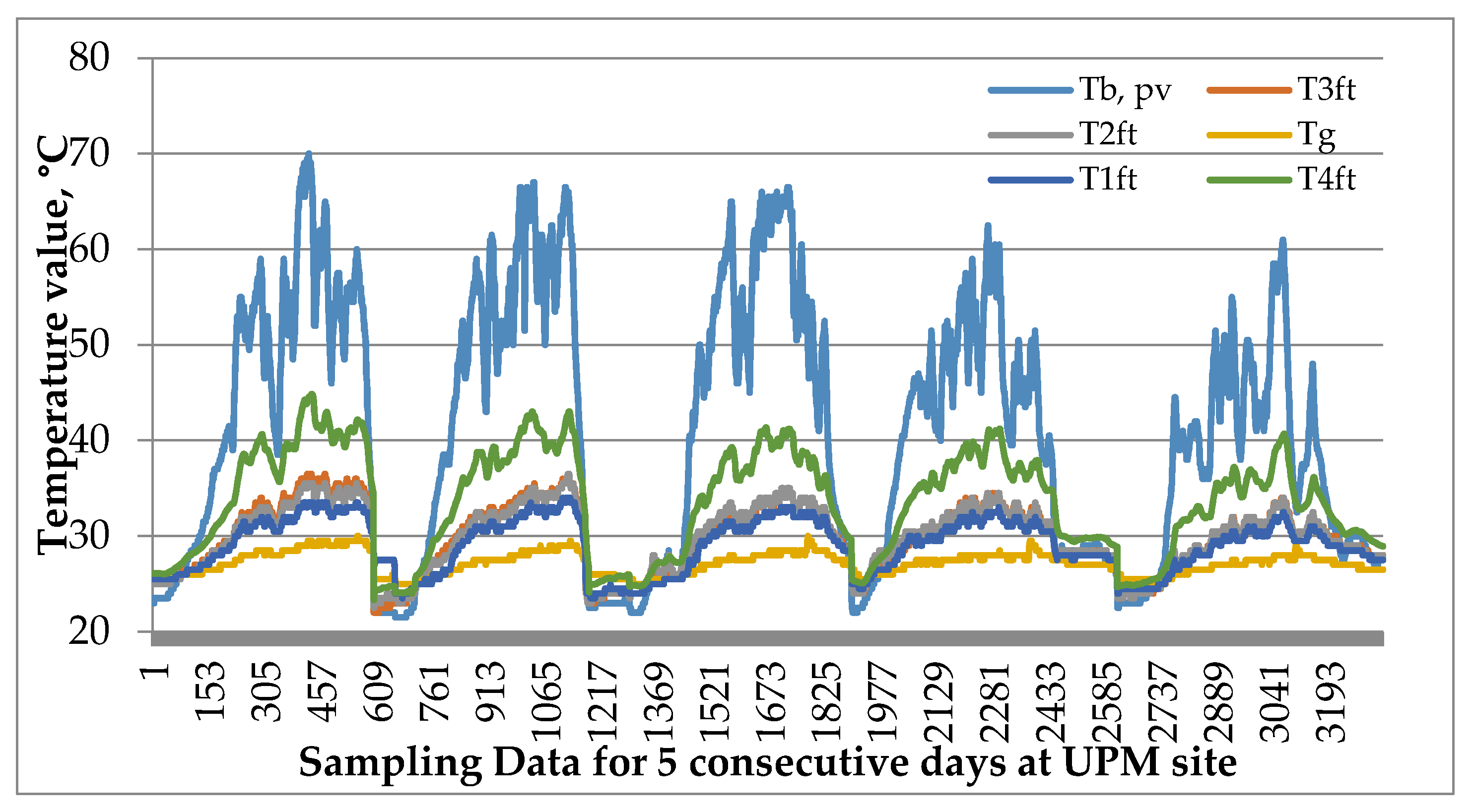

The contribution from this work can be shown in the temperature elements plotted in

Figure 7, where the actual temperature pattern for six different heights under agrivoltaic conditions is portrayed, using 3600 data samples for five consecutive days from 7 a.m. to 7 p.m., daily. Each temperature value came from a thermal sensor (Type K: DS18B20, Maxim Integrated, San Jose, CA, US), starting from T

g, which was the ground surface temperature, up to the bottom of the PV array, (T

b, pv) which was directly glued to the PV array’s bottom surface. The other four temperature locations (T

1ft,2ft,3ft,4ft) were based on readings from a hanging sensor to measure the surrounding air temperature.

Based on the temperature values in

Table 1, the maximum recorded temperature for T

1ft, T

2ft and T

3ft was 34 °C, 36.5 °C and 36.5 °C, respectively, where, at this height, the plant started growing under agrivoltaic conditions. The value for ∆T

max was increasing with the plant height–temperature difference (1–2 feet) ranging below 3 °C. The ground temperature (T

g) was considered as the reference value based on its effect on plant seedlings, and T

b (the bottom surface of PV module) as the maximum plant height. Hatfield and Prueger [

39] explained that the rate of plant growth and development is heavily dependent on the surrounding temperature (min, max and optimum temperature values) and the annual temperature increment due to global warming over the next 50 years is likely to reach 1.5 °C between 2030 and 2052 [

40].

Based on Equation (1) and an online calculator software, the values for VPD are summarized in

Table 2. The value for T

1ft was used to represent the designated surrounding air temperature (T

a) because the location was at par with the plant at a 1 foot height and touching the polybags and soil.

The optimum value for VPD under a greenhouse condition ranges from 0.45 kPa to 1.25 kPa, ideally sitting at around 0.85 kPa [

31]. For agrivoltaic conditions, the VPD value ranged between 2.005 kPa (max) to 0.548 kPa (min), with an average value of 1.072 kPa.

For the temperature analysis, the field data measured were segregated into five sampling hours (daily) with different temperature levels, as shown in

Table 3.

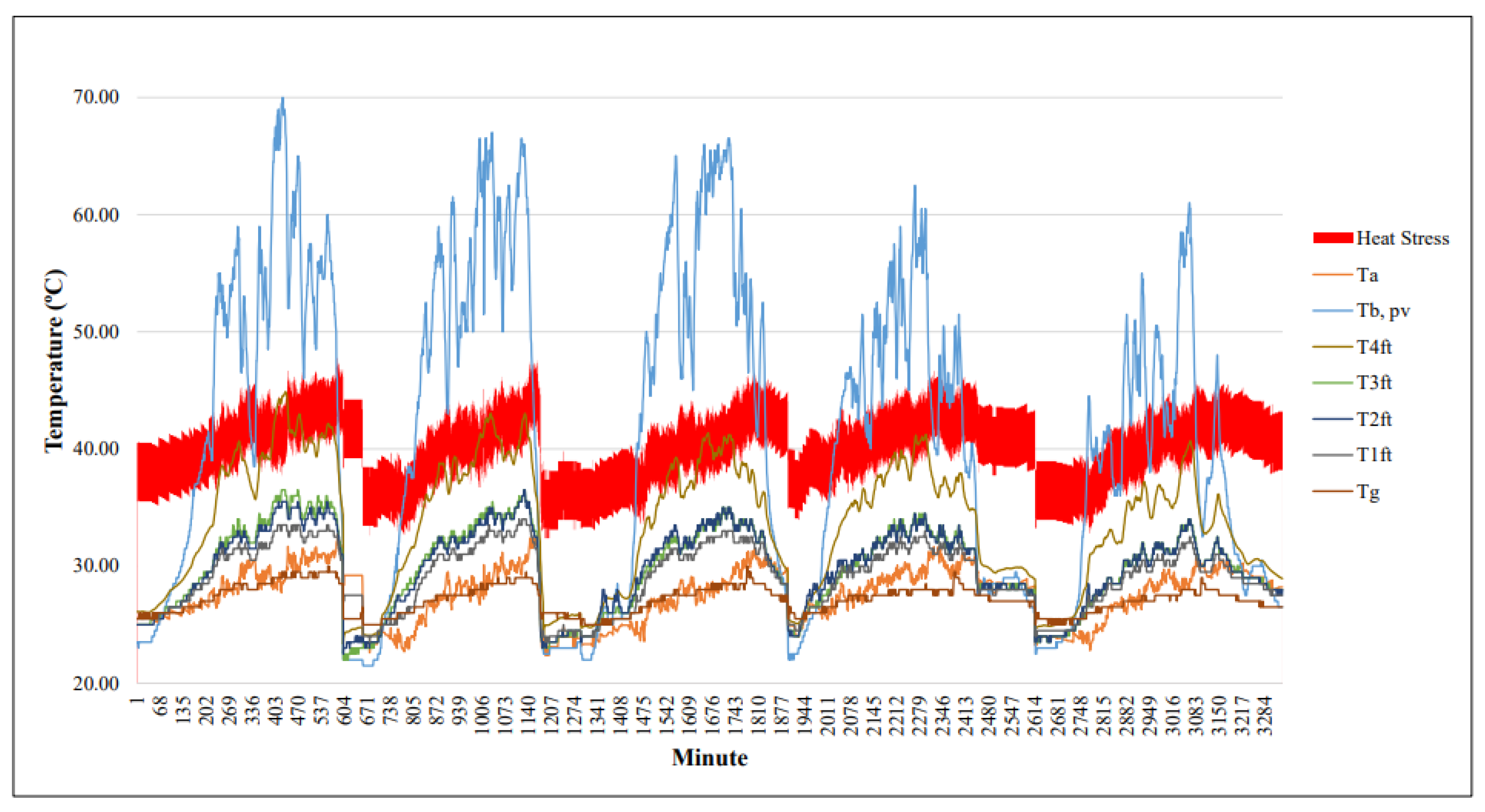

Based on

Table 3 and R programming, the heat stress contour throughout the five sampling hours was plotted as shown in

Figure 8.

An illustration of heat stress occurrences in % value with respect to the 1 foot height–temperature level under agrivoltaic conditions is shown in

Figure 8. These field data were further analyzed as shown in

Figure 9, where dependencies on the bottom of the PV panel and at a 4 foot height can be observed.

Based on

Figure 8, the percentage of heat stress occurrences shows at what specific time in the day the plant will possibly experience a high surrounding temperature, above the normal ambient temperature. Based on the data sample, the highest heat stress occurred at a 4 foot height during peak sun and moderate sun (afternoon), with more than 23% heat stress points, as shown in

Table 4. This is due to the bottom of the PV panel producing a much higher temperature after the photonic conversion and heat dissipation process. The ground heat’s effect in this agrivoltaic condition was relatively low due to the PV array shading, as per temperature values for T

g until T

2ft, thus, it can be assumed that no heat stress was caused by this.

A two-sample proportion test and a Chi-square test were used as the statistical approaches as shown in

Table 5 and

Table 6, respectively.

Based on the Chi-square test, T4ft had a higher percentage of heat stress occurrence than Tb,pv during peak sun at 99% confidence level (p < 0.00001). The same test was conducted for height level during moderate sun (afternoon) and these results also proved that T4ft had a higher percentage of heat stress occurrence than Tb,pv during moderate sun (afternoon) at 99% confidence level (p < 0.00001).

Based on the correlations of T

b,pv and T

4ft towards heat stress (T

h) under agrivoltaic conditions, a summary of the findings of both the minimum and maximum values of heat stress, T

h,min and T

h,max, is modelled as shown in

Table 7. Some preliminary assessments were conducted to assess the fitness of data for regression modelling and the findings are displayed in

Figures S1a–d, S2a–d, S3a–b, S4a–b and Table S7. Since all assumptions were fulfilled, regression models were developed and detailed findings are presented in

Table S1–S6 which were simplified into

Table 7 and

Table 8. The coefficient of determination (R squared) was 0.739, which indicates that 73.9% of the variation in T

h,min and T

h,max could be explained by the variation in both T

b, pv and T

4ft, and both the T

h,min and T

h,max models were significantly fit at a 99% confidence level (

F = 4724.462,

p-value < 0.001).

A t-test on independent variables, as shown in

Table 8, confirmed that both T

b,pv and T

4ft significantly affected the T

h,min and T

h,max at 99% confidence level (

tTb, pv = −57.141,

tT4ft = 78.155;

p-value < 0.001). Hence, both were significant predictors of T

h,min and T

h,max. Meanwhile, a unit increase of T

b, pv, T

h,min and T

h,max would decrease by 0.293 °C, and a unit increase in T

4ft would increase T

h,min and T

h,max by 0.987 °C.

T

h,min and T

h,max could be expressed by the following new equations:

Or both equations could be simplified into a heat stress temperature model: